How to Source Pneumatic Cylinder Mounting Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for pneumatic cylinder mounting

In the fast-evolving landscape of manufacturing and automation, sourcing effective pneumatic cylinder mounting solutions can present a significant challenge for international B2B buyers. The mounting of pneumatic cylinders is not just a technical decision; it is a pivotal factor that influences operational efficiency, product longevity, and overall system reliability. This comprehensive guide delves into the various types of pneumatic cylinder mounting styles—including fixed centerline, fixed offset, and fixed pivot—while exploring their specific applications across diverse industries.

By providing an in-depth analysis of each mounting style, along with practical insights into supplier vetting, cost considerations, and best practices for installation, this guide empowers B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—to make informed purchasing decisions. Understanding these nuances not only aids in optimizing performance but also enhances the strategic alignment of pneumatic solutions with business objectives. As you navigate this global market, leverage the insights presented here to ensure that your pneumatic cylinder mounting choices drive productivity and meet your operational needs.

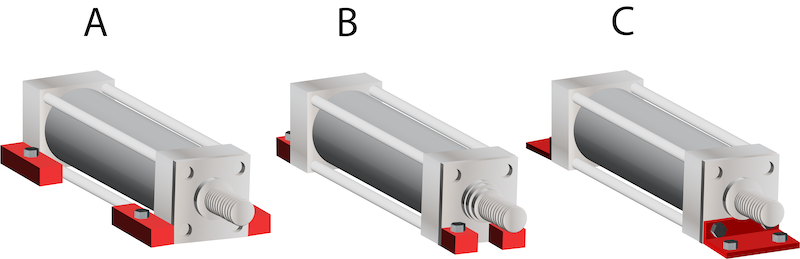

Understanding pneumatic cylinder mounting Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Centerline Mount | Mounts along the centerline, distributing force evenly | Material handling, assembly automation | Pros: Reduces misalignment; enhances reliability. Cons: Requires precise installation; may need dowel pins for shock loads. |

| Fixed Offset Mount | Mounts at the sides or feet, allowing for easy installation | Robotics, packaging machinery | Pros: Flexible for various applications; easy access for maintenance. Cons: Susceptible to side loads; requires careful torque management. |

| Fixed Pivot Mount | Allows for slight rotational movement; absorbs misalignment | Conveyors, lifting systems | Pros: Protects against bending stresses; accommodates alignment changes. Cons: Limited to specific applications; requires precise alignment for optimal performance. |

| Nose Mount | Mounting from the top only; limited pivot capabilities | Compact spaces, specialized machinery | Pros: Space-efficient; straightforward installation. Cons: Limited mounting flexibility; not suitable for all applications. |

| Universal Mount | Can be mounted from multiple points; versatile in applications | Diverse industrial applications | Pros: Highly adaptable; can pivot from the rear. Cons: May require additional accessories; installation can be complex. |

What are the Characteristics of Fixed Centerline Mounts?

Fixed centerline mounts are designed to secure pneumatic cylinders along their centerline, effectively distributing forces evenly across the mounting bolts. This configuration is particularly beneficial in applications requiring linear movement, such as material handling and assembly automation. When purchasing, businesses should consider the installation precision required, as dowel pins may be necessary for high-shock applications to maintain alignment and prevent wear on components.

How Do Fixed Offset Mounts Function in Various Applications?

Fixed offset mounts attach cylinders at their sides or feet, making them a versatile choice for applications like robotics and packaging machinery. Their design allows for easy installation and accessibility for maintenance. However, buyers should be aware that offset mounting can introduce side loads, which necessitate careful management of torque and mounting surfaces to prevent premature failure. It’s crucial to assess the mounting structure’s capacity to handle these additional stresses.

What Advantages Do Fixed Pivot Mounts Offer?

Fixed pivot mounts provide the ability to absorb slight misalignments, making them ideal for use in conveyors and lifting systems. This mounting style allows for rotational movement, which can protect the cylinder rod from bending stresses during operation. When selecting a pivot mount, businesses should ensure that the alignment is precise to avoid performance issues. Additionally, the use of accessories like rod-end attachments can enhance functionality but may require further investment.

In What Scenarios are Nose Mount Cylinders Preferred?

Nose mount cylinders are characterized by their ability to be mounted from the top only, making them suitable for applications where space is limited. Their straightforward installation process is a significant advantage, especially in compact machinery setups. However, buyers should note the reduced flexibility in mounting options, which may limit their applicability in certain scenarios. Proper assessment of the specific application requirements is essential to ensure compatibility.

How Does the Universal Mount Stand Out?

Universal mounts are designed for versatility, allowing for mounting from various points and accommodating a wide range of industrial applications. This adaptability makes them a popular choice for businesses looking for flexibility in their pneumatic systems. However, the installation process may be more complex, and additional accessories might be necessary to optimize functionality. Buyers should evaluate the specific needs of their operations to determine if the benefits of a universal mount outweigh the potential complexities involved.

Key Industrial Applications of pneumatic cylinder mounting

| Industry/Sector | Specific Application of pneumatic cylinder mounting | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Automated assembly lines using fixed centerline mounts | Increases efficiency and reduces downtime through precise alignment and operation. | Ensure compatibility with existing machinery and ISO standards. |

| Food and Beverage | Packaging and bottling processes with fixed offset mounts | Enhances reliability and minimizes product contamination risks. | Consider hygiene standards and materials suited for food safety. |

| Automotive | Robotics in assembly lines with pivot mounting options | Provides flexibility and adaptability in operations, improving throughput. | Evaluate the load capacity and ensure compliance with industry regulations. |

| Construction | Heavy machinery operation using foot-mounted cylinders | Improves stability and safety during operation, reducing risk of accidents. | Assess the environmental conditions and durability of components. |

| Mining | Material handling systems with side-mounted cylinders | Streamlines operations and increases safety by automating heavy lifting tasks. | Focus on sourcing robust materials that can withstand harsh environments. |

In the manufacturing industry, pneumatic cylinder mounting is crucial for automated assembly lines, particularly with fixed centerline mounts. These mounts ensure that cylinders operate in a straight line, reducing misalignment and enhancing the efficiency of production processes. For international buyers, particularly in regions like Germany and Nigeria, ensuring compatibility with existing machinery and adherence to ISO standards is vital for seamless integration.

In the food and beverage sector, fixed offset mounts are commonly used in packaging and bottling processes. These mounts allow for easy installation and flexibility in handling various products while minimizing contamination risks. Buyers must prioritize hygiene standards and select materials that comply with food safety regulations to maintain product integrity.

The automotive industry utilizes pneumatic cylinder mounting extensively in robotics for assembly lines. Pivot mounting options provide the necessary flexibility to adapt to various tasks, improving overall throughput. Key considerations for sourcing include evaluating the load capacity and ensuring compliance with industry regulations to maintain operational efficiency.

In construction, foot-mounted pneumatic cylinders are essential for the operation of heavy machinery. This mounting style enhances stability and safety, significantly reducing the risk of accidents on job sites. International buyers should assess environmental conditions and the durability of components to ensure they can withstand the rigors of construction environments.

Lastly, the mining industry employs side-mounted cylinders in material handling systems. These cylinders automate heavy lifting tasks, streamlining operations and enhancing safety for workers. When sourcing for this application, it is crucial to focus on robust materials that can endure harsh mining conditions, ensuring long-term reliability and performance.

3 Common User Pain Points for ‘pneumatic cylinder mounting’ & Their Solutions

Scenario 1: Misalignment Issues Leading to Cylinder Wear

The Problem: A common challenge faced by B2B buyers is the misalignment of pneumatic cylinders during installation. When cylinders are mounted off-center, they can experience excessive side loads, leading to premature wear on the piston and rod bearings. This not only shortens the lifespan of the equipment but also increases downtime and maintenance costs, especially in high-demand environments such as manufacturing or packaging. Buyers often struggle to identify the root cause of these alignment issues, which can stem from poor mounting surfaces or inadequate mounting hardware.

The Solution: To mitigate misalignment issues, buyers should first conduct a thorough assessment of their mounting surfaces and ensure they are suitable for the specific mounting style of the pneumatic cylinder. Opt for fixed centerline mounts when possible, as they distribute forces evenly and minimize side loading. Additionally, it’s essential to utilize precision mounting hardware, such as dowel pins or alignment jigs, to secure the cylinder in the correct position. Regular maintenance checks should be scheduled to monitor the alignment and condition of the mounting components, allowing for timely adjustments before significant wear occurs.

Scenario 2: Inadequate Load Capacity and Cylinder Failure

The Problem: Another pain point for B2B buyers is selecting pneumatic cylinders that do not meet the load requirements of their applications. This can lead to cylinder failure and operational inefficiencies. Buyers may choose a cylinder based on its size or cost without adequately considering the force it needs to exert. For instance, in industries where heavy loads are moved, a cylinder that cannot handle the expected load can lead to catastrophic failures, jeopardizing safety and productivity.

The Solution: To address this issue, buyers should perform a detailed analysis of the required cylinder force based on the specific application. This includes calculating the load weight, the distance it must be moved, and the speed of actuation. Selecting cylinders that adhere to industry standards, such as ISO specifications, can also ensure that they are built to handle the necessary forces. Consulting with manufacturers or suppliers for recommendations on cylinder specifications and mounting styles will further enhance decision-making. Additionally, implementing a monitoring system to track the performance of pneumatic cylinders can help identify potential overload conditions before they result in failure.

Scenario 3: Difficulty in Selecting the Appropriate Mounting Style

The Problem: Many B2B buyers encounter confusion when it comes to selecting the right mounting style for their pneumatic cylinders. With various options available—fixed centerline, fixed offset, and fixed pivot—determining the best fit for specific applications can be daunting. This indecision can lead to improper installations, resulting in performance issues and increased costs due to trial and error.

The Solution: To simplify the selection process, buyers should start by clearly defining the operational requirements of their application, including load travel displacement, required cylinder force, and available mounting space. Creating a checklist that outlines these factors can help streamline decision-making. Furthermore, engaging with knowledgeable suppliers who can provide insights into the pros and cons of each mounting style is invaluable. Buyers should also consider investing in mounting accessories that allow for flexibility, such as adjustable brackets or pivot mounts, which can accommodate slight variations in alignment. By taking a systematic approach to selecting mounting styles, buyers can enhance the reliability and efficiency of their pneumatic systems.

Strategic Material Selection Guide for pneumatic cylinder mounting

When selecting materials for pneumatic cylinder mounting, it is crucial to consider factors such as the operating environment, load requirements, and compatibility with various media. Here, we analyze four common materials used in pneumatic cylinder mounting, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What are the Key Properties of Aluminum for Pneumatic Cylinder Mounting?

Aluminum is a popular choice for pneumatic cylinder mounting due to its lightweight nature and excellent corrosion resistance. With a temperature rating typically ranging from -50°C to 150°C, aluminum can perform well in various environments. Its low density makes it easy to handle and install, while its inherent resistance to oxidation helps maintain structural integrity over time.

Pros and Cons of Aluminum

The primary advantage of aluminum is its excellent strength-to-weight ratio, which allows for durable yet lightweight mounting solutions. Additionally, aluminum is relatively cost-effective compared to other metals. However, it may not withstand extremely high temperatures or pressures, which could limit its use in certain applications. Manufacturing complexity is moderate, as aluminum can be machined and formed easily.

Impact on Application

Aluminum is compatible with most pneumatic media, but care should be taken in environments with aggressive chemicals, as certain acids can corrode aluminum. International buyers should ensure compliance with standards such as ASTM and DIN, particularly in industries like automotive and manufacturing.

Why is Steel a Preferred Material for Heavy-Duty Applications?

Steel, particularly carbon steel, is often chosen for its high strength and durability, making it suitable for heavy-duty pneumatic cylinder mounting applications. With a temperature tolerance of up to 300°C and high pressure ratings, steel can handle demanding operational conditions.

Pros and Cons of Steel

The key advantage of steel is its exceptional load-bearing capacity, making it ideal for applications involving heavy loads. However, its susceptibility to corrosion requires protective coatings, which can increase manufacturing costs. The complexity of fabrication can also be higher compared to aluminum, particularly for intricate designs.

Illustrative image related to pneumatic cylinder mounting

Impact on Application

Steel is compatible with a wide range of pneumatic media but should be avoided in environments with high moisture unless adequately protected. For international buyers, understanding local compliance standards is essential, as steel grades vary by region (e.g., JIS in Japan, DIN in Germany).

How Does Plastic Compare for Lightweight and Cost-Effective Solutions?

Plastics, such as polycarbonate and nylon, are increasingly used for pneumatic cylinder mounting due to their lightweight nature and cost-effectiveness. They can typically withstand temperatures up to 100°C and offer good chemical resistance.

Pros and Cons of Plastic

The main advantage of plastics is their low weight and resistance to corrosion, making them ideal for applications where weight reduction is critical. However, they generally have lower load-bearing capacities compared to metals, which may limit their use in heavy-duty applications. Manufacturing processes for plastics can be simpler, but they may require specific conditions to ensure durability.

Impact on Application

Plastics are compatible with many pneumatic media, but their performance can degrade under high temperatures or pressures. Buyers from regions like Africa and South America should consider the availability of specific plastic grades and their compliance with local standards.

What are the Benefits of Using Stainless Steel for Corrosive Environments?

Stainless steel is known for its excellent corrosion resistance and is often used in environments where exposure to moisture or corrosive substances is a concern. With a temperature rating of up to 400°C, stainless steel can handle high-temperature applications effectively.

Pros and Cons of Stainless Steel

The key advantage of stainless steel is its durability and resistance to corrosion, making it suitable for harsh environments. However, it is generally more expensive than carbon steel and aluminum, which can impact budget considerations. Manufacturing complexity is high due to the material’s hardness, requiring specialized tools for machining.

Impact on Application

Stainless steel is compatible with various pneumatic media, including those found in food processing and chemical industries. International buyers should be aware of compliance with standards such as ASTM and ISO, especially in regulated industries.

Summary Table of Material Properties for Pneumatic Cylinder Mounting

| Material | Typical Use Case for pneumatic cylinder mounting | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | General-purpose mounting in moderate conditions | Lightweight and corrosion-resistant | Limited high-temperature performance | Medium |

| Steel | Heavy-duty applications | Exceptional load-bearing capacity | Susceptible to corrosion | Medium |

| Plastic | Lightweight and cost-effective solutions | Low weight and good chemical resistance | Lower load capacity | Low |

| Stainless Steel | Corrosive environments | Excellent corrosion resistance | Higher cost and machining complexity | High |

This analysis provides valuable insights for B2B buyers considering pneumatic cylinder mounting materials, emphasizing the importance of material properties, application suitability, and compliance with international standards.

In-depth Look: Manufacturing Processes and Quality Assurance for pneumatic cylinder mounting

What Are the Key Manufacturing Processes for Pneumatic Cylinder Mounting?

The manufacturing processes for pneumatic cylinder mounting are crucial for ensuring reliability and performance in various applications. Understanding these processes helps B2B buyers evaluate potential suppliers effectively. The main stages in the manufacturing process typically include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Pneumatic Cylinder Mounting?

Material preparation is the first step in the manufacturing process. High-quality materials such as aluminum, steel, and sometimes composite materials are chosen based on the application requirements. The selection of materials must consider factors like strength, weight, and resistance to environmental conditions.

Once the materials are selected, they undergo cutting and machining to achieve the required dimensions. This phase often involves precision CNC machining, which ensures that components like brackets and flanges meet exact specifications. Proper material preparation is essential to reduce defects and enhance the durability of the final product.

What Techniques Are Used in Forming Pneumatic Cylinder Mounting Components?

The forming stage involves shaping the prepared materials into components such as brackets, flanges, and mounting nuts. Techniques commonly used include:

- Casting: Useful for creating complex shapes that require high precision.

- Forging: Provides high strength and improved fatigue resistance, particularly for components subjected to heavy loads.

- Welding: Often used to assemble parts of the mounting system, ensuring structural integrity.

Advanced forming techniques not only enhance the performance of the mounting components but also allow for mass production, making it easier for manufacturers to meet the demands of international B2B buyers.

How Are Pneumatic Cylinder Mounting Components Assembled?

Assembly is a critical stage where individual components are brought together to create the final mounting system. This process can be manual or automated, depending on the scale of production. During assembly, it is vital to ensure that all components fit together seamlessly to prevent misalignment and operational failures.

Key aspects of the assembly process include:

- Use of Fasteners: Bolts, nuts, and screws are employed to securely attach components.

- Alignment Checks: Proper alignment is crucial to avoid side loads that can lead to premature wear.

- Integration of Accessories: Additional components such as clevis mounts or foot brackets may be included, depending on the application requirements.

An efficient assembly process is essential for reducing production time and ensuring that the mounting systems meet quality standards.

What Finishing Techniques Are Essential for Pneumatic Cylinder Mounting?

Finishing processes enhance the aesthetic appeal and functional performance of pneumatic cylinder mounting components. Common finishing techniques include:

- Coating: Protective coatings such as anodizing or powder coating are applied to prevent corrosion and wear, particularly important for applications in harsh environments.

- Polishing: Provides a smooth surface finish, reducing friction and improving operational efficiency.

- Quality Inspection: Visual and dimensional inspections are conducted to ensure that the finishing meets established standards.

Finishing is not just about appearance; it significantly impacts the longevity and reliability of the mounting systems.

What Are the Quality Assurance Standards for Pneumatic Cylinder Mounting?

Quality assurance is critical in the manufacturing of pneumatic cylinder mounting systems. International standards such as ISO 9001 set guidelines for quality management systems, ensuring that manufacturers consistently meet customer requirements and regulatory standards.

How Do Quality Control Checkpoints Function?

Quality control (QC) involves several checkpoints throughout the manufacturing process, including:

- Incoming Quality Control (IQC): Inspecting raw materials upon receipt to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing to catch defects early and reduce waste.

- Final Quality Control (FQC): Comprehensive testing of finished products to ensure they meet performance specifications before shipment.

These checkpoints are designed to catch and correct any issues before they escalate, thereby maintaining high quality and reliability.

What Testing Methods Are Commonly Used in Quality Assurance?

Various testing methods are employed to verify the quality and performance of pneumatic cylinder mounting systems, including:

- Dimensional Inspection: Ensuring that components meet specified measurements.

- Functional Testing: Verifying that the mounting systems perform as intended under operational conditions.

- Fatigue Testing: Assessing how components withstand repeated loads over time.

These testing methods provide B2B buyers with confidence in the durability and functionality of the products they purchase.

Illustrative image related to pneumatic cylinder mounting

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers must be proactive in verifying the quality control practices of potential suppliers. Here are several strategies to ensure supplier compliance with quality standards:

- Supplier Audits: Conducting regular audits of suppliers’ facilities and processes can provide insight into their quality management systems.

- Requesting Quality Reports: Buyers can request documentation of quality control processes and test results to assess the supplier’s commitment to quality.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality practices.

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding the nuances of supplier quality control is essential for mitigating risks and ensuring successful partnerships.

What Are the Quality Certification Nuances for International B2B Buyers?

Quality certification can vary widely across regions, impacting the procurement process for international buyers. Understanding regional standards, such as CE marking in Europe or API standards in oil and gas applications, is crucial for compliance and market acceptance.

Buyers should also be aware of potential discrepancies in quality standards between their home markets and suppliers’ locations. It is advisable to engage local experts or consultants familiar with both the buyer’s and supplier’s regulatory landscapes to navigate these complexities effectively.

In conclusion, a thorough understanding of manufacturing processes and quality assurance practices is essential for B2B buyers in the pneumatic cylinder mounting sector. By focusing on the right manufacturers and verifying their quality control measures, buyers can ensure they receive reliable and high-performance products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘pneumatic cylinder mounting’

In this guide, we provide a practical checklist to assist B2B buyers in the procurement of pneumatic cylinder mounting solutions. This checklist outlines essential steps that ensure the selection of appropriate mounting styles and suppliers, ultimately enhancing operational efficiency and product longevity.

Step 1: Define Your Technical Specifications

Before initiating your sourcing process, clearly outline the technical specifications required for your pneumatic cylinder mounting. Consider factors such as load capacity, stroke length, and operational environment. Documenting these specifications helps streamline discussions with suppliers and ensures you receive products that meet your operational needs.

Step 2: Identify Mounting Style Requirements

Evaluate the specific mounting style that aligns with your application. Common styles include fixed centerline, fixed offset, and fixed pivot mounts. Each style has unique benefits; for instance, centerline mounts are ideal for straight-line force applications, while pivot mounts allow for slight misalignments. Ensure you understand the load dynamics involved to select the most suitable option.

Step 3: Assess Material Compatibility

Check the material compatibility of the mounting accessories with your operational environment. Mounting components may be exposed to various conditions, including humidity, temperature fluctuations, and chemical exposure. Selecting materials such as aluminum or stainless steel that can withstand these conditions will enhance the durability and reliability of your pneumatic systems.

Step 4: Evaluate Supplier Certifications

Before finalizing your procurement, verify the certifications and standards compliance of potential suppliers. Look for suppliers who adhere to international standards such as ISO or NFPA, which indicate quality and reliability in manufacturing practices. This step is crucial in ensuring that the products meet safety and performance requirements in your region.

Step 5: Request Samples for Testing

Request samples of the pneumatic cylinder mounting components you are considering. Testing samples in your specific application allows you to evaluate their performance, ease of installation, and compatibility with existing systems. This hands-on approach minimizes the risk of purchasing unsuitable products and helps identify any potential issues early in the process.

Step 6: Review Supplier Lead Times and Logistics

Discuss lead times and shipping logistics with your selected suppliers. Understanding the timelines for production and delivery is essential for planning your operations effectively. Ensure that suppliers can meet your project deadlines and have a reliable logistics strategy to avoid disruptions in your supply chain.

Step 7: Establish a Quality Assurance Plan

Develop a quality assurance plan to monitor the performance of the pneumatic cylinder mounts post-purchase. Define criteria for evaluating the effectiveness of the mounting solutions and set a schedule for regular assessments. A proactive approach to quality assurance helps ensure that the components continue to perform optimally throughout their lifecycle, thus safeguarding your investment.

By following this comprehensive checklist, B2B buyers can confidently navigate the procurement process for pneumatic cylinder mounting solutions, ensuring optimal performance and reliability in their operations.

Comprehensive Cost and Pricing Analysis for pneumatic cylinder mounting Sourcing

What Are the Key Cost Components in Pneumatic Cylinder Mounting Sourcing?

When sourcing pneumatic cylinder mounting solutions, understanding the cost structure is critical for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly impacts pricing. Common materials for mounting accessories, such as steel and aluminum, vary in cost depending on market conditions. High-strength materials may incur additional expenses but offer greater durability and performance.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. Skilled labor might be necessary for custom mounting solutions, which can increase overall costs.

-

Manufacturing Overhead: This encompasses all indirect costs related to production, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize overhead, leading to more competitive pricing.

-

Tooling: The initial investment in tooling for specialized mounting configurations can be substantial. However, the cost can be amortized over large production runs, making it more economical for high-volume orders.

-

Quality Control: Ensuring that mounting solutions meet specific quality standards is vital. Rigorous QC processes add to the cost but are essential for preventing failures in pneumatic systems.

-

Logistics: Transportation and warehousing costs are significant factors, especially for international shipments. Incoterms should be clearly defined to avoid unexpected charges.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary widely. Buyers should assess the value provided against the margin to ensure they receive a fair deal.

How Do Price Influencers Affect Pneumatic Cylinder Mounting Costs?

Several factors can influence the pricing of pneumatic cylinder mounting solutions, including volume or minimum order quantity (MOQ), specifications, customization, materials, quality certifications, supplier factors, and the chosen Incoterms.

-

Volume/MOQ: Larger orders often result in lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, which can significantly reduce the total cost.

-

Specifications and Customization: Customized mounting solutions tailored to specific applications can increase costs. Buyers should clearly define their requirements to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO standards) can elevate costs but often justify the investment through improved performance and reliability.

-

Supplier Factors: Supplier reputation, production capacity, and location play crucial roles in pricing. Established suppliers may charge more for their expertise and reliability.

-

Incoterms: The chosen shipping terms (e.g., FOB, CIF) impact logistics costs. Understanding these terms can help buyers negotiate better deals and manage risks associated with international shipping.

What Are Effective Buyer Tips for Negotiating Pneumatic Cylinder Mounting Prices?

Negotiating effectively can lead to substantial cost savings for B2B buyers in the pneumatic cylinder mounting market. Here are some actionable tips:

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider the long-term costs associated with installation, maintenance, and potential downtime. A lower upfront cost may not always equate to better value.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and terms. Suppliers are more likely to offer competitive prices to long-term customers.

-

Request Multiple Quotes: Obtain quotes from several suppliers to compare prices and services. This will provide leverage in negotiations and help identify the best deal.

-

Consider Local Suppliers: For buyers in regions like Africa and South America, sourcing from local suppliers may reduce logistics costs and lead times, despite potentially higher per-unit prices.

-

Be Open to Alternatives: If a specific mounting style or material is too costly, explore alternative solutions that can meet your operational needs without compromising quality.

Disclaimer on Indicative Prices

Prices for pneumatic cylinder mounting solutions can fluctuate based on market conditions, material availability, and supplier pricing strategies. It is essential for buyers to conduct thorough research and obtain current quotes to ensure accurate budgeting.

Alternatives Analysis: Comparing pneumatic cylinder mounting With Other Solutions

Exploring Alternatives to Pneumatic Cylinder Mounting

When selecting a pneumatic cylinder mounting solution, it’s essential to consider various alternatives that may offer distinct advantages depending on specific operational needs. This analysis will compare pneumatic cylinder mounting against two viable alternatives: electric actuators and hydraulic cylinders. Each option has unique characteristics that may be more suitable based on application requirements, space constraints, and cost considerations.

| Comparison Aspect | Pneumatic Cylinder Mounting | Electric Actuators | Hydraulic Cylinders |

|---|---|---|---|

| Performance | Quick response time, moderate force | High precision and control | High force output and stability |

| Cost | Generally affordable, low operating costs | Higher initial investment, but lower maintenance | Moderate to high cost, depending on size and complexity |

| Ease of Implementation | Simple installation, various mounting styles | Requires electrical setup and integration | More complex installation and plumbing |

| Maintenance | Low maintenance, but may require regular checks | Low maintenance, less frequent servicing | Higher maintenance due to fluid management |

| Best Use Case | Assembly lines, packaging, light material handling | Robotics, positioning systems, precision tasks | Heavy machinery, construction, and metal forming |

Analyzing Electric Actuators

Electric actuators utilize electric motors to produce linear or rotational motion, offering high precision and control. Their ability to provide consistent torque and position feedback makes them ideal for applications requiring exact movements, such as robotics or automated assembly lines. However, the initial costs of electric actuators can be higher than pneumatic systems, and they require a robust electrical infrastructure. Maintenance is generally low, but users must be cautious of potential electronic failures, which can disrupt operations.

Evaluating Hydraulic Cylinders

Hydraulic cylinders operate by using pressurized hydraulic fluid to generate motion, delivering substantial force and stability. They are particularly effective in heavy-duty applications, such as construction and manufacturing, where high power is necessary. While hydraulic systems can be more expensive to install and maintain due to the complexity of fluid management and potential leaks, they offer unmatched force output compared to pneumatic options. Additionally, the maintenance requirements can be significant, as regular checks on fluid levels and seals are crucial for optimal performance.

Illustrative image related to pneumatic cylinder mounting

Conclusion: How to Choose the Right Solution for Your Needs

When determining the most suitable mounting solution, B2B buyers should carefully assess their specific application requirements, including the required force, precision, and available space. Pneumatic cylinder mounting is an excellent choice for applications where speed and simplicity are priorities, while electric actuators provide precision for tasks requiring exact movements. Conversely, hydraulic cylinders are best for scenarios demanding high force and stability. By understanding the strengths and weaknesses of each alternative, buyers can make informed decisions that align with their operational objectives and budget constraints.

Essential Technical Properties and Trade Terminology for pneumatic cylinder mounting

What Are the Key Technical Properties of Pneumatic Cylinder Mounting?

When selecting pneumatic cylinder mounting solutions, understanding critical technical properties is essential for ensuring optimal performance and longevity. Here are some of the most important specifications to consider:

1. Material Grade

The material grade of mounting components, such as brackets and nuts, significantly influences durability and strength. Common materials include aluminum for lightweight applications and steel for heavy-duty environments. In B2B contexts, material choice affects both the initial cost and long-term maintenance, impacting overall operational efficiency.

2. Tolerance

Tolerance refers to the allowable deviation in dimensions during manufacturing. High precision is crucial for components that must fit together seamlessly, ensuring smooth operation and reducing wear over time. In industries where pneumatic systems must operate under strict guidelines, such as automotive or manufacturing, maintaining tight tolerances can prevent costly downtime.

3. Load Capacity

Load capacity defines the maximum weight or force that the mounting system can support. Understanding this specification is vital for selecting the appropriate mounting style based on application needs. Businesses must ensure that the chosen mount can handle the expected loads to avoid premature failures and safety hazards.

4. Environmental Resistance

This property describes a component’s ability to withstand various environmental factors, such as temperature fluctuations, moisture, and corrosive substances. Selecting mounts with the right resistance properties is critical in industries like food processing or chemical manufacturing, where exposure to harsh conditions is common. This decision can significantly affect the lifespan and reliability of the pneumatic system.

5. Mounting Style Compatibility

Different mounting styles—such as fixed centerline, fixed offset, and fixed pivot—offer unique advantages depending on application requirements. Understanding compatibility with specific pneumatic cylinder designs is essential for ensuring optimal performance. Choosing the right style can lead to improved system efficiency and reduced installation complexities.

Illustrative image related to pneumatic cylinder mounting

Which Trade Terms Are Essential for Understanding Pneumatic Cylinder Mounting?

Familiarity with industry-specific terminology helps facilitate smoother communication and negotiations in B2B transactions. Here are some key terms to know:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of pneumatic cylinders, understanding the OEM can help buyers ascertain quality and compatibility with existing systems.

2. MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it affects inventory management and purchasing strategies. Knowing the MOQ can help companies avoid overstocking or frequent reordering, which can lead to increased costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotes on specific products or services. For pneumatic cylinder mounts, submitting an RFQ allows buyers to compare prices and terms from multiple suppliers, facilitating better decision-making.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade, covering aspects like shipping, insurance, and tariffs. Understanding these terms is essential for B2B buyers, especially those importing pneumatic components from different regions, as they clarify obligations and costs.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the goods. In the context of pneumatic cylinder mounting, shorter lead times can enhance production schedules and reduce downtime. Buyers must consider lead times when planning procurement to ensure timely availability of components.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions regarding pneumatic cylinder mounting solutions that align with their operational needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the pneumatic cylinder mounting Sector

What Are the Key Trends Shaping the Pneumatic Cylinder Mounting Market?

The pneumatic cylinder mounting sector is witnessing significant evolution driven by technological advancements and changing market demands. Key global drivers include the increasing automation across industries, particularly in manufacturing, automotive, and material handling sectors. This surge in automation necessitates reliable and efficient pneumatic systems, fostering demand for various mounting styles that optimize performance and space utilization. Emerging B2B technologies, such as IoT-enabled pneumatic systems, are enhancing monitoring and predictive maintenance capabilities, allowing businesses to minimize downtime and improve operational efficiency.

Furthermore, international B2B buyers are increasingly prioritizing modular designs that allow for flexibility in assembly and integration. This trend is particularly relevant for buyers in diverse markets like Africa and South America, where adaptability to varying operational environments is crucial. In Europe, especially in countries like Germany, there is a growing emphasis on compliance with industry standards such as ISO for enhanced compatibility and safety. The market dynamics also reflect a heightened focus on supply chain resilience, prompting buyers to seek suppliers who can offer reliable logistics and just-in-time delivery solutions.

How Are Sustainability and Ethical Sourcing Influencing Pneumatic Cylinder Mounting?

Sustainability has emerged as a critical concern in the pneumatic cylinder mounting sector, influencing both sourcing decisions and product development. The environmental impact of manufacturing processes and materials is under scrutiny, prompting B2B buyers to consider suppliers who demonstrate a commitment to sustainable practices. This includes the use of recycled materials, energy-efficient production methods, and responsible waste management.

Ethical sourcing is equally important, with buyers increasingly favoring suppliers who maintain transparency in their supply chains. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications provide assurance that suppliers adhere to stringent environmental standards. Additionally, utilizing materials that have a lower ecological footprint, such as aluminum and high-strength composites, can significantly contribute to the sustainability goals of organizations. For international buyers, particularly in emerging markets, aligning with ethical suppliers not only enhances brand reputation but also opens doors to new business opportunities in markets where sustainability is becoming a key differentiator.

What Is the Historical Context of Pneumatic Cylinder Mounting?

The evolution of pneumatic cylinder mounting has been shaped by advancements in engineering and manufacturing practices. Initially, the focus was primarily on basic mounting solutions that provided adequate functionality. However, as industries evolved, the demand for more sophisticated mounting options grew. The introduction of standardized mounting styles, such as fixed centerline and fixed offset mounts, allowed for greater flexibility and efficiency in design and application.

Over the years, technological advancements have further refined these solutions, leading to the development of modular and customizable mounting options that cater to specific operational needs. The integration of automation and digital technologies has also transformed the landscape, making it essential for suppliers to innovate continually. This historical context underscores the importance of adaptability and forward-thinking in the pneumatic cylinder mounting sector, providing valuable insights for B2B buyers looking to make informed sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of pneumatic cylinder mounting

-

How do I solve alignment issues when mounting pneumatic cylinders?

Alignment issues can lead to premature wear and cylinder failure. To solve this, first ensure that the mounting surface is flat and level. Use adjustable brackets or pivot mounts to accommodate slight misalignments. Additionally, consider using centerline mounting styles, as they distribute forces evenly and reduce the risk of side loading. Regular maintenance checks can help identify and rectify misalignments before they escalate into significant problems. -

What is the best mounting style for limited space applications?

For applications with limited space, fixed offset mounts, such as side mounts or foot mounts, are often the best choice. These mounting styles allow for versatile installation options without requiring extensive space around the cylinder. However, be cautious of potential side loads, which can increase wear. Assess the specific requirements of your application, including load direction and environmental conditions, to ensure optimal performance. -

What factors should I consider when selecting a supplier for pneumatic cylinder mounting components?

When selecting a supplier, evaluate their reputation, product quality, and adherence to international standards. Review their experience in your industry and check for certifications like ISO. Additionally, consider their customer service and support capabilities, especially regarding technical assistance. It’s beneficial to request samples or references to gauge their reliability before making a bulk purchase. -

How can I customize pneumatic cylinder mounting solutions for my specific needs?

Customization can be achieved by collaborating with suppliers who offer tailored solutions. Discuss your application requirements, including load capacity, environmental conditions, and mounting space constraints. Suppliers may provide options for custom mounting brackets, specialized materials, or unique designs. Ensure that any modifications comply with industry standards to maintain performance and safety. -

What are the minimum order quantities (MOQs) for pneumatic cylinder mounting components?

Minimum order quantities can vary significantly by supplier and region. Typically, MOQs are determined by production costs and inventory management practices. It’s advisable to communicate your needs directly with potential suppliers to negotiate terms that suit your business model. Some suppliers may offer lower MOQs for first-time orders or trial runs, which can be advantageous for smaller businesses. -

What payment terms are commonly offered by suppliers of pneumatic cylinder mounting?

Payment terms can vary widely among suppliers but typically include options such as net 30, net 60, or upfront payment. Some suppliers may accept letters of credit or offer financing options. It’s crucial to clarify payment expectations during negotiations to avoid misunderstandings. Always ensure that the terms align with your cash flow and financial planning. -

How do I ensure quality assurance (QA) for pneumatic cylinder mounting products?

To ensure quality assurance, request documentation regarding the supplier’s QA processes and certifications. Look for suppliers who follow industry standards such as ISO 9001. Consider conducting periodic audits or inspections of the manufacturing process. Additionally, establishing a clear return policy for defective products can help safeguard your investment and maintain operational efficiency. -

What logistics considerations should I keep in mind when sourcing pneumatic cylinder mounting components internationally?

When sourcing internationally, consider shipping methods, lead times, and customs regulations that may affect delivery schedules. Collaborate with suppliers who have experience in your target regions to navigate potential logistical challenges. Additionally, evaluate the total landed cost, including shipping, duties, and taxes, to ensure your budget aligns with your procurement strategy. Developing a robust supply chain relationship can also enhance reliability and efficiency.

Top 4 Pneumatic Cylinder Mounting Manufacturers & Suppliers List

1. FrightProps – Pneumatic Cylinder Mounting Solutions

Domain: frightprops.com

Registered: 2003 (22 years)

Introduction: FrightProps offers various mounting options for pneumatic cylinders, including:

1. **Nose Mount Cylinder**: Can only be mounted from the threads on top.

2. **Universal Mount Cylinder**: Can be mounted from the top and bottom and pivoted from the rear.

3. **Mounting Nut**: Allows mounting from the top or bottom; must match thread size of the cylinder.

4. **Jam Nut**: Used to mount to the cylind…

2. Festo – Cylinder Mounting Parts

Domain: festo.com

Registered: 1997 (28 years)

Introduction: This company, Festo – Cylinder Mounting Parts, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Disumtec – Key Product

Domain: disumtec.com

Registered: 2013 (12 years)

Introduction: Key product details for fixings for pneumatic cylinders include:

1. **Ball Joint Stem ISO-15552**

– Price: €5.75 (tax excl.), €6.96 (tax included)

– Function: Connects the rod end of a pneumatic or hydraulic cylinder to a moving component or fixed structure.

– Applications: Industrial Automation, Processing Machinery.

2. **Ball Joint Stem ISO-6432**

– Price: €5.75 (tax excl.), €6.96 …

4. AutomationDirect – Pneumatic Cylinder Mounting Options

Domain: automationdirect.com

Registered: 1999 (26 years)

Introduction: Cylinder mounting options for pneumatic cylinders including various styles such as fixed, adjustable, and pivoting mounts. Features include compatibility with different cylinder sizes and types, ease of installation, and durability for industrial applications. Available materials include aluminum and steel, with options for corrosion resistance. Suitable for a range of applications in automation a…

Strategic Sourcing Conclusion and Outlook for pneumatic cylinder mounting

In the rapidly evolving landscape of industrial automation, selecting the right pneumatic cylinder mounting style is pivotal for optimizing performance and ensuring reliability. Understanding the nuances of fixed centerline, fixed offset, and fixed pivot mounts allows buyers to make informed decisions tailored to their specific applications. Strategic sourcing not only enhances operational efficiency but also mitigates risks associated with misalignment and improper load handling.

As international B2B buyers from diverse regions such as Africa, South America, the Middle East, and Europe seek competitive advantages, prioritizing quality and compatibility in pneumatic cylinder mounting options will be essential. Investing in superior mounting solutions ensures longevity and reduces maintenance costs, ultimately leading to enhanced productivity.

Looking ahead, it is crucial for businesses to stay abreast of advancements in pneumatic technology and sourcing strategies. By fostering partnerships with reputable suppliers and leveraging local expertise, companies can navigate the complexities of pneumatic cylinder mounting more effectively. Embrace the future of automation with confidence—invest in strategic sourcing today to ensure your operations are set for success tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to pneumatic cylinder mounting