How to Source Plati Dip Colors Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for plati dip colors

In today’s competitive landscape, sourcing Plasti Dip colors can be a daunting task for international B2B buyers. With a plethora of options available across various suppliers, businesses must navigate complex decisions to ensure they select the right products that meet their specific needs. This guide offers a comprehensive overview of Plasti Dip colors, covering types, applications, and critical factors for supplier vetting. By delving into pricing structures and regional market insights, we aim to equip buyers from Africa, South America, the Middle East, and Europe—specifically in countries like Nigeria and Germany—with the knowledge necessary to make informed purchasing decisions.

Understanding the diverse applications of Plasti Dip, from automotive customization to industrial uses, is crucial for identifying the best products for your business. Furthermore, this guide emphasizes the importance of evaluating supplier reliability and product quality, ensuring that your investments yield the desired results. As you explore the various facets of the Plasti Dip market, you will find actionable insights that not only streamline the procurement process but also enhance your overall business strategy. With this knowledge, B2B buyers can confidently navigate the global market, choosing Plasti Dip colors that align with their operational goals and customer expectations.

Understanding plati dip colors Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Colors | Bright, solid finishes available in a wide color range | Automotive customization, DIY projects | Pros: Easy to apply, affordable; Cons: Limited durability compared to other types. |

| Metallic Colors | Shimmering effects with a metallic finish | Automotive refinishing, industrial uses | Pros: Eye-catching appearance; Cons: Requires careful application for optimal results. |

| Pearlescent Colors | Color-shifting properties that create depth | High-end automotive, luxury branding | Pros: Unique visual appeal; Cons: Higher cost and complexity in application. |

| Camo Colors | Camouflage patterns ideal for tactical applications | Military, outdoor vehicles | Pros: Specialized design for specific uses; Cons: Limited color options. |

| Glow-in-the-Dark | Luminous properties for visibility in low light | Safety applications, promotional items | Pros: Enhances safety and visibility; Cons: Limited application in everyday settings. |

What are the characteristics and suitability of Standard Colors in Plasti Dip?

Standard colors are the most widely utilized variation of Plasti Dip, characterized by their vibrant, solid finishes. They are available in an extensive range of hues, making them suitable for a variety of applications, including automotive customization and DIY projects. For B2B buyers, standard colors offer an accessible entry point into the world of Plasti Dip, thanks to their affordability and ease of application. However, it is important to note that while they provide an attractive finish, they may lack the durability of more specialized options.

How do Metallic Colors enhance automotive refinishing and industrial uses?

Metallic colors are distinguished by their shimmering effects, giving surfaces a reflective quality that enhances visual appeal. This type of Plasti Dip is particularly popular in automotive refinishing and industrial applications where aesthetics are crucial. B2B buyers should consider metallic colors for projects that require a striking appearance, such as custom vehicle wraps or industrial equipment. While they offer an eye-catching finish, successful application demands a certain level of expertise to achieve the desired look, making it essential to evaluate the skill set of the application team.

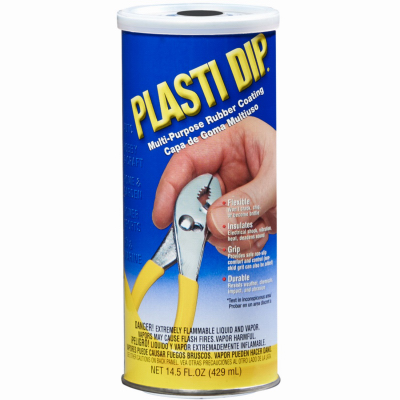

Illustrative image related to plati dip colors

What makes Pearlescent Colors a unique choice for high-end applications?

Pearlescent colors are known for their color-shifting properties, which create depth and complexity in the finish. They are often used in high-end automotive applications and luxury branding, where a distinctive look can significantly enhance a product’s marketability. For B2B buyers, investing in pearlescent colors can elevate brand perception, but it comes at a higher cost. Additionally, the application process can be more complex than standard options, requiring skilled professionals to ensure an optimal outcome.

Why are Camo Colors preferred for tactical and outdoor applications?

Camo colors are designed specifically for tactical applications, featuring camouflage patterns that blend seamlessly into natural environments. They are ideal for military vehicles and outdoor equipment, providing both functionality and aesthetic appeal. B2B buyers in sectors such as defense and outdoor recreation should consider camo colors for products that require stealth and tactical advantages. However, the range of color options is typically more limited compared to other variations, which may restrict choices for branding purposes.

In what scenarios are Glow-in-the-Dark Plasti Dip colors most effective?

Glow-in-the-dark Plasti Dip colors possess luminous properties that enhance visibility in low-light conditions. They are particularly effective for safety applications, such as marking emergency exits or creating promotional items that stand out in the dark. B2B buyers focused on safety and visibility should consider this type for specific projects that require enhanced light reflection. However, the application of glow-in-the-dark colors may be limited in everyday scenarios, making it essential to assess the context in which they will be used.

Key Industrial Applications of plati dip colors

| Industry/Sector | Specific Application of plati dip colors | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Custom vehicle wraps and color changes | Enhances brand visibility and vehicle aesthetics, increasing resale value. | Ensure availability of a wide color range and compatibility with different vehicle materials. |

| Construction | Protective coatings for tools and machinery | Provides weather resistance and durability, extending tool life. | Look for bulk purchasing options and easy application methods for large equipment. |

| Electronics | Coatings for consumer electronics | Improves grip and aesthetic appeal while offering protection from scratches. | Assess the drying time and finish quality for consumer satisfaction. |

| Sports Equipment | Customization of sporting goods | Enhances team branding and personal expression, boosting sales. | Verify colorfastness and adhesion for high-use items like helmets and bats. |

| Industrial Equipment | Protective coatings for machinery and equipment | Reduces maintenance costs and downtime through enhanced durability. | Consider the chemical resistance and application methods suitable for industrial environments. |

How is Plasti Dip Used in the Automotive Sector?

In the automotive industry, Plasti Dip colors are primarily utilized for custom vehicle wraps and color changes. Businesses can enhance brand visibility through unique color schemes while offering customers the flexibility of temporary changes. This application not only allows for aesthetic enhancements but also increases the vehicle’s resale value. For international buyers, especially in regions like Nigeria or Germany, it’s essential to ensure that a wide range of colors is available and that the product is compatible with various vehicle materials to meet diverse customer preferences.

What Role Does Plasti Dip Play in Construction?

In construction, Plasti Dip colors serve as protective coatings for tools and machinery. This application significantly enhances the durability and weather resistance of equipment, extending its lifespan and reducing maintenance costs. For B2B buyers in South America and the Middle East, sourcing considerations should include bulk purchasing options and user-friendly application methods, as these factors can streamline operations on large job sites.

Illustrative image related to plati dip colors

How Does Plasti Dip Enhance Electronics?

Plasti Dip colors find applications in the electronics sector, where they are used as coatings for consumer electronics. This not only improves the aesthetic appeal but also provides a better grip and protection against scratches. For international buyers, particularly in Europe, assessing the drying time and finish quality is crucial, as these factors can directly impact customer satisfaction and product performance.

In What Ways Does Plasti Dip Benefit Sports Equipment?

In the sports equipment industry, Plasti Dip colors are used for the customization of sporting goods, allowing teams to enhance their branding and individuals to express personal style. This application can lead to increased sales, as customers are often drawn to uniquely colored and branded items. Buyers should verify the colorfastness and adhesion properties of the coatings, especially for high-use items like helmets and bats, to ensure they withstand rigorous activity.

How is Plasti Dip Applied in Industrial Equipment?

Plasti Dip colors are also vital in the industrial sector, where they provide protective coatings for machinery and equipment. By reducing maintenance costs and downtime, these coatings enhance operational efficiency. For B2B buyers, particularly in Africa, it is important to consider the chemical resistance of the coatings and the application methods suitable for various industrial environments, ensuring that the products meet rigorous operational demands.

3 Common User Pain Points for ‘plati dip colors’ & Their Solutions

Scenario 1: Inconsistent Color Quality Across Different Batches

The Problem: B2B buyers often face the challenge of receiving inconsistent color quality when ordering plasti dip colors in bulk. This inconsistency can stem from variations in manufacturing processes or raw material sourcing, leading to mismatches in shades that can affect branding and product aesthetics. For businesses that rely on specific color codes for branding or customer satisfaction, such discrepancies can result in significant operational disruptions and potential loss of client trust.

The Solution: To mitigate this issue, it’s essential for buyers to establish a strong partnership with suppliers who provide consistent quality assurance processes. Buyers should request color samples from suppliers before placing bulk orders. Additionally, implementing a robust quality control protocol upon receipt of goods can help identify any discrepancies early on. Using a standardized color matching system, such as Pantone or RAL, can also aid in ensuring that colors meet the required specifications. Regular communication with suppliers about quality standards and batch production can further minimize the risk of color inconsistencies.

Illustrative image related to plati dip colors

Scenario 2: Limited Availability of Desired Colors

The Problem: Another significant pain point for B2B buyers is the limited availability of specific plasti dip colors that meet their project needs or client demands. Different regions may have varying stock levels, and some unique or custom colors may not be readily accessible. This scarcity can lead to project delays, increased costs due to expedited shipping from alternate suppliers, or even the need to compromise on color choices, which can affect overall project integrity.

The Solution: To address this challenge, buyers should conduct thorough market research to identify multiple suppliers who carry a wide range of plasti dip colors. Establishing relationships with manufacturers that can produce custom colors on demand can also be beneficial. Creating a well-structured inventory management system will enable buyers to track color availability and anticipate future needs based on project timelines. Additionally, buyers can negotiate long-term contracts with suppliers to secure preferred colors, ensuring consistent availability and potentially better pricing.

Scenario 3: Difficulty in Application and Finish Consistency

The Problem: Many B2B buyers encounter challenges related to the application process of plasti dip colors, particularly in achieving a smooth and even finish. Factors such as environmental conditions, surface preparation, and application techniques can significantly impact the final outcome. Inconsistent application can lead to dissatisfaction from end-users and may necessitate rework or adjustments, which can be costly in terms of both time and resources.

The Solution: To overcome application difficulties, buyers should invest in proper training for their application teams. This includes understanding the importance of surface preparation, the right tools, and optimal environmental conditions for application. Providing detailed application guides and conducting hands-on workshops can enhance the skill set of the workforce. Additionally, suppliers often have technical support teams that can assist with troubleshooting application issues. Utilizing high-quality application equipment, such as spray guns specifically designed for plasti dip, can also help achieve a more consistent finish. Regular evaluations of the application process and feedback loops with the application teams will ensure continuous improvement and better results.

Illustrative image related to plati dip colors

Strategic Material Selection Guide for plati dip colors

What Are the Key Materials Used in Plasti Dip Colors?

When selecting materials for Plasti Dip colors, it is crucial to understand their properties, advantages, and limitations. This knowledge enables B2B buyers to make informed decisions that align with their specific application needs and regional compliance requirements. Below, we analyze several common materials utilized in the formulation of Plasti Dip colors.

How Do Synthetic Polymers Perform in Plasti Dip Applications?

Synthetic polymers are the backbone of Plasti Dip formulations. They provide flexibility, adhesion, and a wide range of color options. Key properties include excellent temperature resistance and a high degree of corrosion resistance, making them suitable for various environmental conditions.

Pros: Synthetic polymers are durable and can withstand harsh weather, making them ideal for outdoor applications. They also offer a variety of finishes, from matte to glossy, which can enhance aesthetic appeal.

Cons: The manufacturing process can be complex and costly, especially when producing custom colors. Additionally, some synthetic polymers may not be biodegradable, raising environmental concerns.

International Considerations: Buyers in regions like Europe may need to comply with stringent environmental regulations, such as REACH. Understanding local preferences for eco-friendly materials is essential.

What Role Do Additives Play in Enhancing Plasti Dip Colors?

Additives are crucial for enhancing the performance of Plasti Dip colors. These can include UV stabilizers, anti-foaming agents, and color pigments. They help improve durability, color retention, and application ease.

Pros: Additives can significantly enhance the longevity and performance of Plasti Dip products, ensuring that colors remain vibrant over time. They also improve application characteristics, making the product easier to work with.

Cons: The inclusion of additives can increase the overall cost of the product. Moreover, excessive additives may complicate the manufacturing process and affect the final product’s properties.

International Considerations: Buyers should be aware of common standards such as ASTM and DIN, which may dictate the types and quantities of additives permissible in their regions.

How Does the Choice of Solvents Impact Plasti Dip Color Formulations?

Solvents are integral to the application of Plasti Dip colors, affecting drying time, viscosity, and application method. Common solvents include acetone and xylene, which help dissolve the polymer and facilitate spray application.

Pros: The right solvent can enhance the ease of application, allowing for a smooth finish. They also help in achieving a quick drying time, which is beneficial for production efficiency.

Illustrative image related to plati dip colors

Cons: Some solvents can be hazardous and may require special handling and storage. Additionally, the choice of solvent can impact the environmental footprint of the product, making it a critical consideration for eco-conscious buyers.

International Considerations: Compliance with local VOC regulations is vital, especially in regions like Germany, where environmental standards are stringent. Buyers should ensure that the solvents used meet local compliance requirements.

What Are the Implications of Color Pigments in Plasti Dip Products?

Color pigments are essential for achieving the desired aesthetic in Plasti Dip colors. They can be organic or inorganic, each offering different properties in terms of opacity and lightfastness.

Pros: High-quality pigments can provide vibrant colors and excellent coverage, enhancing the visual appeal of the finished product. They also contribute to UV stability, preventing color fading over time.

Cons: The cost of high-quality pigments can be significant, impacting the overall pricing of Plasti Dip products. Additionally, some pigments may have limited compatibility with certain base materials, affecting application.

International Considerations: Buyers should be aware of color preferences in their markets, as well as any regulations regarding the use of specific pigments, particularly in the Middle East and Africa, where local standards may vary.

Summary Table of Material Selection for Plasti Dip Colors

| Material | Typical Use Case for plati dip colors | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Synthetic Polymers | Automotive coatings, outdoor furniture | Excellent durability and weather resistance | High manufacturing complexity | Medium |

| Additives | Enhancing color and performance | Improves longevity and application ease | Can increase overall product cost | Medium |

| Solvents | Spray application | Facilitates smooth application and quick drying | Hazardous handling requirements | Low |

| Color Pigments | Achieving desired aesthetics | Provides vibrant colors and UV stability | Costly and compatibility issues | Medium |

In conclusion, understanding the properties and implications of each material used in Plasti Dip colors is vital for B2B buyers. By considering the advantages, disadvantages, and regional compliance requirements, businesses can make strategic decisions that align with their operational needs and market demands.

In-depth Look: Manufacturing Processes and Quality Assurance for plati dip colors

What Are the Key Stages in the Manufacturing Process of Plasti Dip Colors?

The manufacturing of Plasti Dip colors involves a series of critical stages designed to ensure high-quality products that meet the diverse needs of B2B buyers. Understanding these processes can help buyers make informed decisions when selecting suppliers.

1. Material Preparation

The first stage in manufacturing Plasti Dip colors involves sourcing and preparing raw materials. High-quality polymers, pigments, and solvents are essential for producing vibrant and durable colors. Suppliers often rely on suppliers who provide materials that meet international standards, ensuring consistency and quality in the final product. This stage may also involve the blending of materials to achieve specific color formulations.

Illustrative image related to plati dip colors

2. Forming

Once the materials are prepared, the next step is the forming process. This typically includes mixing the raw materials in large-scale mixers to achieve a homogeneous mixture. The mixture is then subjected to processes such as extrusion or spraying, depending on the intended application of the Plasti Dip product. For example, aerosolized products require specialized equipment to ensure an even spray pattern, which is crucial for achieving the desired finish.

3. Assembly

After forming, the product moves to the assembly stage, where it is packaged into various formats such as spray cans, gallons, or bulk containers. This stage may involve automated processes to ensure efficiency and consistency. Packaging is designed not only for protection during shipping but also for user convenience, often featuring detailed labels with application instructions and safety warnings.

4. Finishing

The final stage in manufacturing involves quality checks and finishing touches. This can include labeling, coding for batch tracking, and ensuring that the product meets specific aesthetic criteria. The finishing stage is critical as it prepares the product for market readiness, ensuring it meets all specifications and customer expectations.

How Is Quality Assurance Implemented in Plasti Dip Color Production?

Quality assurance is paramount in ensuring that Plasti Dip colors meet industry standards and customer expectations. A robust QA process involves several key components.

Relevant International Standards and Certifications

B2B buyers should look for manufacturers that comply with international standards such as ISO 9001, which outlines requirements for a quality management system. Additionally, specific industry certifications like CE and API can indicate a manufacturer’s commitment to quality and safety. These certifications assure buyers that the products have been tested and meet stringent regulatory requirements.

Illustrative image related to plati dip colors

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are essential for maintaining high standards throughout the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified quality criteria before they enter the production line.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, periodic checks are conducted to monitor processes and identify any deviations from quality standards. This includes testing the viscosity and color consistency of the mixture.

-

Final Quality Control (FQC): Once the product is assembled, a final inspection is conducted to verify that the finished goods meet all quality specifications. This may include performance testing to assess the durability and finish of the Plasti Dip colors.

What Testing Methods Are Commonly Used in Plasti Dip Quality Assurance?

A variety of testing methods are employed to ensure that Plasti Dip colors perform as expected. Some of the common methods include:

-

Adhesion Testing: This assesses how well the Plasti Dip adheres to various surfaces, which is critical for user satisfaction.

-

Weather Resistance Testing: Products are exposed to simulated environmental conditions to evaluate their durability against UV light, moisture, and temperature fluctuations.

-

Color Consistency Testing: This ensures that color batches remain consistent across different production runs, which is particularly important for businesses requiring uniformity for branding purposes.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is crucial. Here are several strategies:

Conducting Audits

Buyers should consider conducting audits of potential suppliers to assess their manufacturing processes and quality assurance protocols. This can provide insights into the supplier’s commitment to quality and help identify any potential risks.

Requesting Quality Reports

Regular quality reports that detail the results of QC tests can give buyers confidence in the products they are purchasing. Suppliers should be willing to share this information to build trust and transparency.

Engaging Third-Party Inspectors

Utilizing third-party inspection services can provide an unbiased assessment of a supplier’s quality practices. These inspectors can conduct thorough evaluations of the manufacturing processes and product quality before shipment.

What Are the QC and Certification Nuances for International Buyers?

International buyers must navigate various QC and certification nuances when sourcing Plasti Dip colors. Different regions may have specific regulatory requirements, and understanding these can help in making compliant purchases. For example, European buyers may need to ensure that products conform to REACH regulations, which govern the use of chemicals.

Additionally, cultural differences in business practices and quality expectations can impact supplier relationships. Buyers from regions like Nigeria or Brazil may face unique challenges and should approach supplier evaluations with an understanding of local market conditions.

In conclusion, the manufacturing and quality assurance processes for Plasti Dip colors are complex and multifaceted. By understanding these stages, B2B buyers can make more informed decisions when selecting suppliers, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘plati dip colors’

Introduction

Navigating the procurement process for Plasti Dip colors can be complex, especially for international B2B buyers. This guide provides a practical checklist to streamline your sourcing efforts, ensuring you find high-quality products that meet your specific requirements. By following these steps, you can make informed decisions that align with your business goals and regional market needs.

Step 1: Define Your Technical Specifications

Establish clear technical specifications for the Plasti Dip colors you need. This includes understanding the color variants, finish types (matte, gloss, etc.), and application methods (sprayable, aerosol, etc.). Precise specifications will help you communicate effectively with suppliers and ensure the products align with your project requirements.

Illustrative image related to plati dip colors

Step 2: Research Market Trends and Demand

Investigate current market trends in your target regions, such as Africa, South America, the Middle East, and Europe. Understanding the demand for specific colors and finishes can guide your procurement strategy. Look for insights on popular applications in automotive, industrial, or DIY markets to ensure you stock products that resonate with your customer base.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Consider the following:

– Product Range: Ensure the supplier offers a comprehensive selection of Plasti Dip colors.

– Reputation: Research online reviews and testimonials to gauge the supplier’s reliability and service quality.

Step 4: Verify Compliance with Regional Standards

Ensure that the Plasti Dip products you intend to source comply with local regulations and standards in your target markets. This may include safety regulations, environmental guidelines, and quality certifications. Compliance not only protects your business but also builds trust with your customers.

Step 5: Request Samples for Evaluation

Before placing bulk orders, request samples of the Plasti Dip colors you are considering. Testing samples allows you to assess color accuracy, application ease, and finish quality. Pay attention to:

– Durability: Ensure the product meets your expectations for longevity and resistance to wear.

– Compatibility: Verify how well the Plasti Dip adheres to different surfaces relevant to your market.

Step 6: Negotiate Pricing and Terms

Engage in negotiations with your shortlisted suppliers to secure favorable pricing and terms. Consider factors such as minimum order quantities, payment terms, and shipping costs. A good negotiation can enhance your profit margins and improve your overall procurement strategy.

Step 7: Establish a Clear Supply Chain Plan

Create a comprehensive supply chain plan that outlines logistics, delivery schedules, and inventory management. A well-defined plan ensures timely availability of products and minimizes disruptions in your business operations. Collaborate with suppliers to streamline processes and enhance communication.

By following this checklist, international B2B buyers can effectively source Plasti Dip colors that meet their unique needs while ensuring compliance and quality.

Comprehensive Cost and Pricing Analysis for plati dip colors Sourcing

What Are the Key Cost Components in Plasti Dip Color Sourcing?

When sourcing Plasti Dip colors, it’s crucial to understand the multifaceted cost structure involved in the manufacturing and supply chain processes. The primary cost components include:

-

Materials: The base materials for Plasti Dip colors, including polymers, pigments, and solvents, represent a significant portion of the total cost. The quality and type of materials can influence both the price and the final product’s performance.

-

Labor: Labor costs encompass both direct and indirect labor associated with production. Skilled labor may be required for quality assurance and specialized tasks, which can increase costs.

-

Manufacturing Overhead: This includes costs related to the facility, utilities, equipment maintenance, and other operational expenses. Efficient manufacturing processes can help in minimizing overhead costs.

-

Tooling: Specific tooling requirements for different color formulations or container sizes can add to the initial setup costs. These costs can vary significantly based on the complexity of the required tools.

-

Quality Control (QC): Ensuring that products meet specified standards incurs additional costs. QC processes may involve testing and inspection, which are essential for maintaining product integrity, especially for international markets.

-

Logistics: Transportation and warehousing costs play a crucial role, especially for international shipments. Factors like distance, mode of transport, and customs duties can affect overall logistics costs.

-

Margin: Suppliers typically apply a markup on their costs to ensure profitability. Understanding the margin expectations can help in negotiating better pricing.

How Do Price Influencers Affect Plasti Dip Color Costs?

Several factors can influence the pricing of Plasti Dip colors, particularly for international buyers:

Illustrative image related to plati dip colors

-

Volume/MOQ (Minimum Order Quantity): Purchasing in larger quantities often leads to lower per-unit costs. Suppliers may offer discounts for bulk orders, which can be a significant cost-saving opportunity.

-

Specifications and Customization: Customized colors or formulations can lead to higher costs due to the additional resources required for development and production. Clear communication of specifications can help avoid unexpected expenses.

-

Material Quality and Certifications: Higher-quality materials or those with certifications (e.g., environmental compliance) may come at a premium. Buyers should weigh the benefits against the added costs.

-

Supplier Factors: The reputation and reliability of suppliers can influence pricing. Established suppliers may charge more, but they often provide greater assurance in terms of quality and service.

-

Incoterms: Understanding the International Commercial Terms (Incoterms) used in a transaction is vital for determining responsibility for shipping costs, insurance, and customs duties. This knowledge can significantly impact the total landed cost.

What Are the Best Negotiation Tips for B2B Buyers of Plasti Dip Colors?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can help achieve cost efficiencies:

-

Research and Benchmarking: Familiarize yourself with market prices and suppliers’ offerings. This knowledge will empower you during negotiations.

-

Focus on Total Cost of Ownership (TCO): Instead of solely considering the initial purchase price, evaluate the long-term costs, including maintenance, logistics, and potential wastage. This broader perspective can guide more informed purchasing decisions.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Trust and reliability can often yield better negotiation outcomes.

-

Be Clear About Expectations: Clearly communicate your requirements regarding quality, delivery times, and quantities. This transparency can prevent misunderstandings and additional costs later on.

-

Explore Multiple Suppliers: Don’t limit yourself to one supplier. Soliciting quotes from multiple sources not only provides options but also strengthens your bargaining position.

Important Note on Pricing

Prices for Plasti Dip colors can vary widely based on the factors discussed above. The prices referenced in various sources may serve as a guide but should not be viewed as definitive. Always seek customized quotes that reflect your specific needs and circumstances.

Alternatives Analysis: Comparing plati dip colors With Other Solutions

Understanding Alternatives to Plasti Dip Colors

In the competitive landscape of automotive coatings and finishes, B2B buyers often seek various solutions to meet their specific needs. While Plasti Dip colors are a popular choice for their versatility and ease of application, several alternative solutions also offer unique benefits. This section compares Plasti Dip colors with two alternative products: traditional automotive paint and vinyl wraps.

Comparison Table

| Comparison Aspect | Plasti Dip Colors | Traditional Automotive Paint | Vinyl Wraps |

|---|---|---|---|

| Performance | Flexible and peelable, good for temporary applications | Durable, high-gloss finish, excellent for permanent applications | Offers a wide range of finishes and designs, but less durable than paint |

| Cost | Generally cost-effective, around $14.85 – $24.85 per gallon | Higher initial cost, typically $50 – $150 per gallon | Mid-range pricing, around $30 – $100 per linear foot |

| Ease of Implementation | Simple spray application, minimal prep required | Requires professional application, more complex | Requires professional installation for best results |

| Maintenance | Easy to maintain and reapply | Requires regular maintenance and touch-ups | Low maintenance, but can be damaged by harsh elements |

| Best Use Case | Ideal for temporary customization and DIY projects | Best for permanent finishes and high-value vehicles | Great for branding and unique aesthetics |

Detailed Breakdown of Alternatives

Traditional Automotive Paint

Traditional automotive paint is known for its durability and high-quality finish. It provides a permanent solution ideal for high-value vehicles where appearance is crucial. However, the application process is more complex, often requiring professional services and extensive preparation. The higher cost can be a deterrent for some businesses, but the longevity and robustness of the finish may justify the investment.

Vinyl Wraps

Vinyl wraps have gained popularity due to their versatility in design and ease of application. They allow businesses to customize their vehicles with unique graphics and colors without the permanence of paint. However, while vinyl wraps can be less durable than paint, they are generally more resistant to scratches and UV damage compared to Plasti Dip. Installation often requires professional help, which can add to overall costs, but they offer a compelling option for branding and aesthetic appeal.

Conclusion: How to Choose the Right Solution

When selecting the best coating solution, B2B buyers should consider their specific use case, budget, and desired longevity. Plasti Dip colors are ideal for temporary applications and DIY projects, making them a cost-effective choice for businesses seeking flexibility. Traditional automotive paint is better suited for those requiring a permanent, high-quality finish, while vinyl wraps provide a unique branding opportunity with a balance of aesthetics and durability. By weighing these factors, businesses can make informed decisions that align with their operational needs and branding strategies.

Essential Technical Properties and Trade Terminology for plati dip colors

What Are the Essential Technical Properties of Plasti Dip Colors for B2B Buyers?

When sourcing Plasti Dip colors for commercial applications, understanding the critical technical properties is crucial for making informed purchasing decisions. Here are some key specifications that you should consider:

1. Material Composition

Plasti Dip is primarily made of a synthetic rubber compound that is flexible and durable. This composition allows for easy application and removal, making it ideal for temporary finishes on vehicles and other surfaces. For B2B buyers, knowing the material ensures compatibility with various substrates and helps assess the product’s longevity and performance in different environments.

2. Color Consistency and Accuracy

Color consistency refers to the uniformity of color across different batches of Plasti Dip. This is particularly important for businesses that require a consistent brand identity or aesthetic. B2B buyers should verify that suppliers can provide color matching services and documentation to ensure that colors remain consistent across orders, which is vital for large-scale applications.

Illustrative image related to plati dip colors

3. Drying Time and Curing

Understanding the drying and curing times of Plasti Dip colors is critical for planning application processes. Generally, Plasti Dip dries to the touch within 30 minutes, but full curing may take up to 24 hours. This information helps businesses schedule their projects effectively, ensuring that surfaces are ready for use or further processing in a timely manner.

4. Adhesion Properties

The adhesion of Plasti Dip to various surfaces (such as metal, plastic, and wood) is a key property that affects its performance. High adhesion means a more durable finish that can withstand environmental factors like UV exposure and moisture. For B2B buyers, evaluating adhesion properties can help in selecting the right product for specific applications, reducing the risk of peeling or flaking.

5. Thickness and Coverage

Plasti Dip products vary in thickness, which can impact the coverage area per gallon. Generally, a gallon can cover approximately 50 to 75 square feet, depending on the application method and surface texture. Understanding these metrics allows B2B buyers to estimate material requirements accurately, ensuring cost-efficiency in large projects.

What Are Common Trade Terms in the Plasti Dip Industry?

Familiarity with industry jargon is crucial for effective communication and negotiation. Here are some common terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. In the context of Plasti Dip, OEM colors are specific shades that match factory colors for vehicles. B2B buyers should inquire about OEM offerings to ensure that they meet industry standards for quality and compatibility.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of product that a supplier is willing to sell. For Plasti Dip colors, MOQs can vary widely depending on the supplier and specific product line. Understanding MOQs helps B2B buyers plan their inventory and budget accordingly, ensuring they do not overcommit financially.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing for a specific quantity of products. B2B buyers should prepare detailed RFQs that specify the required Plasti Dip colors, quantities, and delivery timelines to receive accurate and competitive pricing.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, covering aspects such as shipping, insurance, and risk transfer. Familiarity with these terms is essential for B2B buyers involved in cross-border procurement of Plasti Dip products, ensuring clarity in shipping arrangements and cost implications.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. In the context of Plasti Dip, understanding lead times helps businesses manage project schedules effectively and avoid delays.

By grasping these essential technical properties and trade terms, B2B buyers can make more informed decisions when sourcing Plasti Dip colors, ultimately leading to greater operational efficiency and cost savings.

Illustrative image related to plati dip colors

Navigating Market Dynamics and Sourcing Trends in the plati dip colors Sector

What Are the Key Market Dynamics and Trends Influencing Plasti Dip Colors?

The plasti dip colors market is witnessing significant growth driven by various global factors. The increasing demand for customizable automotive finishes, particularly in emerging markets like Nigeria and Brazil, is a key driver. The rise of DIY culture and consumer interest in personalizing vehicles has led to a surge in the popularity of peelable coatings. Additionally, technological advancements in sprayable formulations and application methods are enhancing product offerings, allowing for a wider range of colors and finishes that cater to diverse consumer preferences.

B2B buyers must also consider the impact of e-commerce as a sourcing trend. Online platforms are becoming primary channels for sourcing plasti dip products, allowing buyers from regions like the Middle East and Europe to access a broader selection of products easily. Furthermore, the adoption of digital tools for inventory management and order processing is streamlining operations, making it easier for businesses to meet customer demands efficiently.

Another essential market dynamic is the growing emphasis on quality and performance. Buyers are increasingly looking for high-quality products that offer durability and ease of application. This trend is particularly relevant in regions with diverse climates, where coatings must withstand harsh weather conditions. Suppliers that can demonstrate superior product performance through certifications or customer testimonials will have a competitive edge.

How Is Sustainability and Ethical Sourcing Shaping the Plasti Dip Colors Market?

Sustainability has become a pivotal concern in the plasti dip colors sector. The environmental impact of chemical coatings and the push for greener alternatives are influencing sourcing decisions among B2B buyers. Companies are increasingly seeking suppliers that prioritize eco-friendly practices, including the use of low-VOC (volatile organic compounds) formulations and sustainable manufacturing processes.

Ethical sourcing is equally important. Buyers are encouraged to evaluate their supply chains for transparency, ensuring that raw materials are sourced responsibly. This includes verifying that suppliers adhere to labor standards and environmental regulations. Certifications like ISO 14001 for environmental management and Green Seal for sustainable products are becoming essential benchmarks for buyers aiming to align with corporate social responsibility (CSR) goals.

Illustrative image related to plati dip colors

Furthermore, the integration of recycled materials into product formulations is gaining traction. Suppliers that can offer plasti dip colors made with recycled content or those that participate in circular economy initiatives will appeal to environmentally conscious buyers. This trend not only fulfills the demand for sustainable products but also enhances brand reputation and customer loyalty.

What Is the Brief History of Plasti Dip Colors in the B2B Context?

Plasti dip colors have evolved significantly since their inception in the 1950s as a rubber coating primarily used for tool grips and insulation. Over the decades, the product found its way into the automotive industry, gaining popularity among enthusiasts for its versatility and ease of use. The introduction of sprayable formulations in the late 20th century revolutionized the market, allowing for more straightforward applications and broader consumer access.

In recent years, the plasti dip sector has expanded to include a diverse range of colors and finishes, catering to both personal and commercial applications. This evolution has been fueled by advances in technology and increasing consumer interest in customization. Today, plasti dip colors are not only a preferred choice for DIY enthusiasts but also for businesses looking to enhance their branding and vehicle aesthetics. As the market continues to grow, staying informed about these developments will be crucial for B2B buyers aiming to leverage the benefits of plasti dip products.

Frequently Asked Questions (FAQs) for B2B Buyers of plati dip colors

-

How do I choose the right Plasti Dip color for my business needs?

When selecting a Plasti Dip color, consider your target market and the applications of the product. Research popular colors in your region and industry; for example, vibrant colors may appeal more to younger demographics while muted tones might suit corporate clients. Additionally, consider the purpose of the coating—whether for aesthetic enhancement, protective coating, or branding. Request samples from suppliers to assess how colors appear in different lighting and on various surfaces before making a bulk purchase. -

What is the best Plasti Dip color for automotive applications?

For automotive applications, popular choices often include colors that offer both aesthetic appeal and durability. Colors like Arctic Black, Army Green, and Camo Tan are commonly favored for their versatility and ability to withstand the elements. Additionally, consider the trend of color-shifting or pearlescent options to attract a niche market. Always ensure the chosen color aligns with current automotive trends and meets your customer preferences to maximize sales potential. -

What are the minimum order quantities (MOQs) for Plasti Dip products?

Minimum order quantities can vary significantly between suppliers, often ranging from a few gallons to several hundred depending on the manufacturer and product line. It’s crucial to confirm MOQs during the negotiation process, as lower MOQs can be advantageous for smaller businesses or those testing the market. Additionally, inquire about bulk discounts or tiered pricing to optimize your purchasing strategy and reduce overall costs. -

How can I ensure quality when sourcing Plasti Dip colors internationally?

To ensure quality, conduct thorough due diligence on potential suppliers. Request product samples to evaluate color accuracy, consistency, and performance. Look for suppliers with established reputations and certifications that adhere to international quality standards. It’s also beneficial to review customer testimonials and seek references from other B2B buyers in your region. Establishing clear quality assurance protocols in your purchase agreements can further safeguard your interests. -

What payment terms should I negotiate when purchasing Plasti Dip colors?

When negotiating payment terms, consider options that minimize risk and enhance cash flow. Common terms include a deposit upfront with the balance due upon delivery, or net 30/60 days after receipt of goods. Ensure clarity on currency exchange rates and transaction fees, especially when dealing with international suppliers. Establishing a mutually agreeable payment schedule helps build trust and fosters long-term relationships with suppliers. -

What logistics considerations should I keep in mind when importing Plasti Dip colors?

Logistics is crucial when importing Plasti Dip colors. Assess shipping methods, costs, and delivery times to ensure they align with your business needs. Confirm whether your supplier handles logistics or if you need to coordinate shipping independently. Additionally, be aware of customs regulations and potential tariffs in your country, particularly in regions like Africa and South America, which can affect overall costs and timelines. -

Can I customize Plasti Dip colors for my brand?

Yes, many suppliers offer customization options for Plasti Dip colors to align with your brand identity. You can work with manufacturers to create unique colors or finishes that resonate with your market. Be prepared to discuss specifics such as color codes, finish types (matte, gloss, etc.), and quantities required for custom orders. Ensure you receive a sample for approval before proceeding with larger orders to guarantee satisfaction. -

What are the common applications for Plasti Dip colors in various industries?

Plasti Dip colors are widely used across multiple industries, including automotive, electronics, and construction. In the automotive sector, they serve for aesthetic enhancements and protective coatings. In electronics, they provide insulation and grip. In construction, Plasti Dip is utilized for tools and equipment to improve durability and visibility. Understanding the diverse applications can help you target your marketing efforts effectively and broaden your customer base.

Top 4 Plati Dip Colors Manufacturers & Suppliers List

1. Dip Your Car – Plasti Dip® Sprayable Gallon Colors

Domain: dipyourcar.com

Registered: 2011 (14 years)

Introduction: Plasti Dip® Sprayable Gallon Colors available in various colors and finishes. Key details include: 124 products in total, with color options such as Black (4), Blue (11), Colorshift (1), Gold (1), Green (11), Orange (2), Pink (2), Purple (6), Red (6), Silver/Grey (8), Tan/Brown (6), Teal (3), White (2), Yellow (2). Finishes include Colorshift (2), Matte (22), Metallic (38), Satin (2). Product type…

2. Plasti Dip – Standard Colors and Enhancers

Domain: plastidip.com

Registered: 1996 (29 years)

Introduction: Standard Colors include various Plasti Dip products such as Plasti Dip ®, Plasti Dip ® Glossy, Plasti Dip ® Blaze, Plasti Dip ® Camo, Plasti Dip ® Luxury Metal, Plasti Dip ® Classic Muscle, and Plasti Dip ® Craft Enhancers like Glossifier, Metalizer, and Pearlizer. Additional products listed are Liquid Tape, RERACK ®, Vinyl Leather Repair (VLP ®), Super-Grip ®, and Primer Smoke.

3. Plasti Dip – Color Samples

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Plasti Dip color examples, including various shades such as Chameleon purple, Matte Gray, Shadow Grey Metallic, Blue, Baby Blue, Light Blue, Teal, Hot Pink, and Navy. Related interests include automotive paint, car wraps, and custom vehicle modifications.

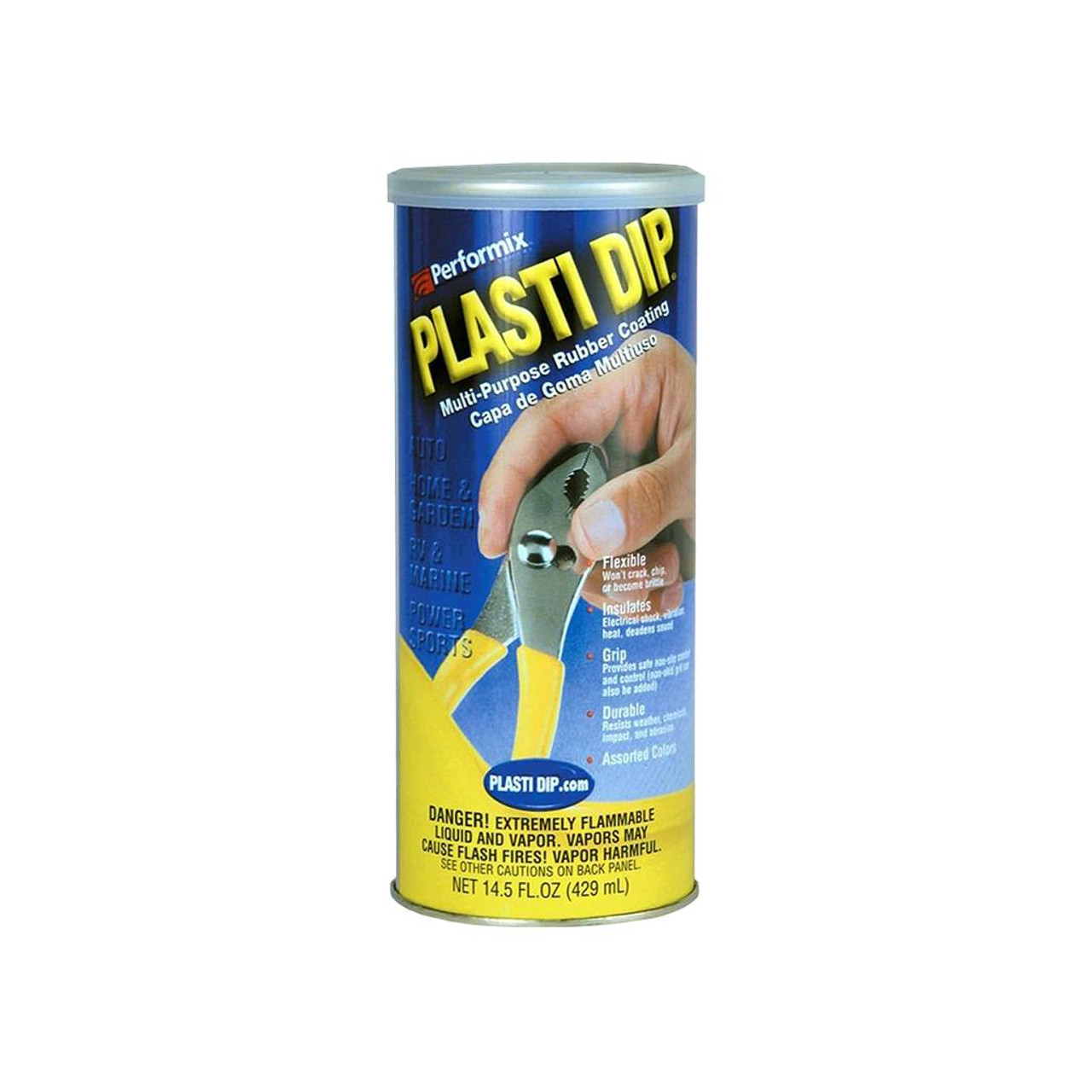

4. Plasti Dip – Regular Colors

Domain: plastidip.co.uk

Registered: 2000 (25 years)

Introduction: This company, Plasti Dip – Regular Colors, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for plati dip colors

As the market for Plasti Dip colors continues to expand globally, strategic sourcing emerges as a critical factor for B2B buyers aiming to optimize their procurement processes. By carefully selecting suppliers that offer a wide range of colors and formulations, businesses can enhance their product offerings and meet diverse customer demands. The availability of various options, from standard colors to unique custom shades, enables companies to differentiate themselves in competitive markets across Africa, South America, the Middle East, and Europe.

For buyers in regions like Nigeria and Germany, understanding local preferences and trends in automotive customization can drive successful sourcing strategies. Leveraging partnerships with reputable suppliers not only ensures quality but also facilitates access to innovative products that can attract a broader customer base.

Illustrative image related to plati dip colors

Looking ahead, the growth potential for Plasti Dip colors is significant, driven by increasing demand for customizable solutions in various industries. Now is the time for international buyers to engage with suppliers, explore new color offerings, and implement strategic sourcing practices that position their businesses for success in the evolving marketplace. Embrace this opportunity to enhance your product line and meet the dynamic needs of your customers.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.