How to Source Perf Mesh Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for perf mesh

In today’s competitive landscape, sourcing high-quality perforated mesh that meets specific industrial and architectural needs poses a significant challenge for B2B buyers across the globe. With diverse applications ranging from filtration systems and sound barriers to aesthetic architectural features, understanding the nuances of perforated mesh is essential for making informed purchasing decisions. This comprehensive guide aims to demystify the global market for perf mesh by exploring various types, including round, square, slotted, and decorative options, as well as their applications across different sectors.

Buyers will benefit from insights into supplier vetting processes, ensuring they partner with reputable manufacturers and distributors that align with their quality standards and project requirements. Additionally, this guide addresses cost considerations, helping businesses navigate pricing structures and optimize their budgets effectively.

Whether you are a buyer in Germany seeking innovative architectural solutions, a company in Nigeria looking to enhance your industrial processes, or a business in South America exploring versatile materials, this guide equips you with the essential knowledge to make strategic decisions. By leveraging the insights provided, international B2B buyers can confidently navigate the perf mesh market, ensuring they select the right products that deliver both performance and value.

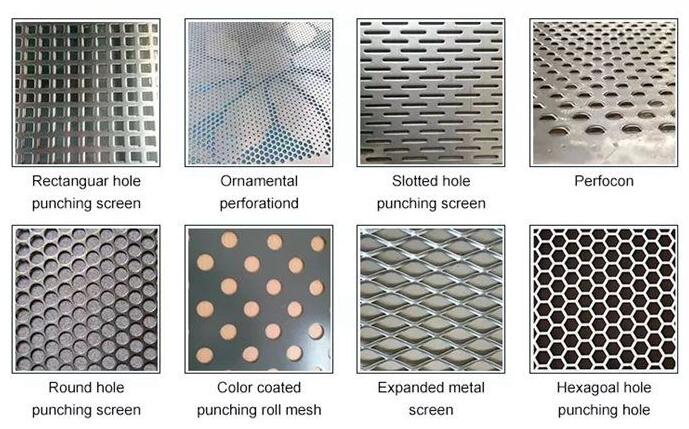

Understanding perf mesh Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Round Hole Perforated Metal | Most common, offers varied hole sizes and gauges | Architectural panels, metal screens, ventilation | Pros: Versatile, wide selection; Cons: Limited airflow compared to slotted types. |

| Square Hole Perforated Metal | Greater open area, lightweight, staggered or straight rows | Filtration, safety barriers, decorative applications | Pros: High open area; Cons: Less aesthetic appeal than decorative types. |

| Slotted Hole Perforated Metal | Elongated openings for enhanced airflow and material passage | Ventilation systems, noise barriers | Pros: Improved airflow; Cons: May require more structural support. |

| Hexagonal Perforated Metal | Highest open area, unique hole shape | High airflow applications, architectural features | Pros: Excellent ventilation; Cons: Limited decorative options. |

| Decorative Perforated Metal | Custom designs, varied hole shapes for aesthetic appeal | Facades, interior design, signage | Pros: Aesthetic versatility; Cons: Often higher cost and lead times. |

What Are the Characteristics of Round Hole Perforated Metal?

Round hole perforated metal is the most widely used type due to its versatility and broad selection of hole sizes and gauges. It is suitable for a variety of applications, including architectural panels, metal screens, and ventilation systems. Buyers should consider the specific needs of their projects, such as required airflow and aesthetic preferences, while also noting that while this type offers excellent strength-to-weight ratios, it may not provide as much airflow as slotted options.

How Does Square Hole Perforated Metal Stand Out?

Square hole perforated metal is recognized for its ability to provide a greater open area compared to round holes, making it ideal for applications like filtration and safety barriers. The lightweight nature of square holes allows for easy handling and installation. However, buyers should be aware that while this type is highly functional, it may lack the aesthetic appeal of decorative perforated options, which could be a consideration for projects requiring visual impact.

What Are the Benefits of Slotted Hole Perforated Metal?

Slotted hole perforated metal features elongated openings that facilitate enhanced airflow and material passage, making it particularly effective in ventilation systems and noise barriers. This type is advantageous for applications where airflow is critical. However, buyers should consider the potential need for additional structural support due to the larger openings, which may affect the overall design and installation process.

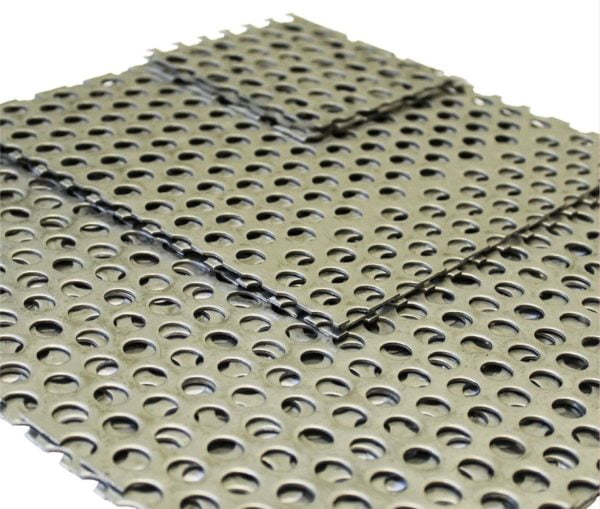

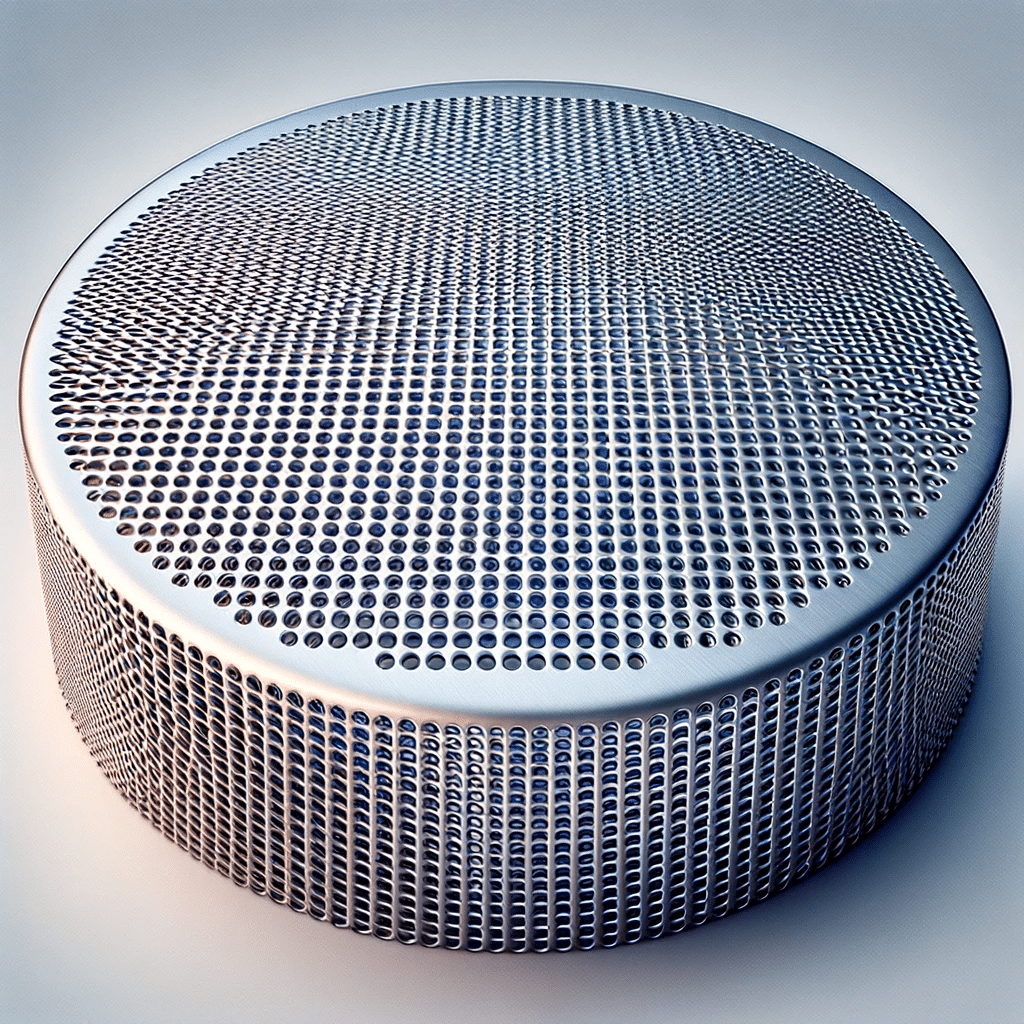

Illustrative image related to perf mesh

Why Choose Hexagonal Perforated Metal?

Hexagonal perforated metal is distinct for its unique hole shape and high open area, making it especially suitable for applications demanding maximum airflow, such as architectural features and grilles. This type is advantageous for those looking to balance functionality with a modern aesthetic. However, buyers should note that hexagonal perforated metal may have limited decorative options compared to other types, which could restrict design versatility.

What Should Buyers Know About Decorative Perforated Metal?

Decorative perforated metal allows for a range of custom designs and varied hole shapes, catering to aesthetic applications like facades, interior design, and signage. This type is perfect for projects where visual appeal is paramount. However, buyers should be prepared for potentially higher costs and longer lead times associated with custom designs, which can impact project timelines and budgets.

Key Industrial Applications of perf mesh

| Industry/Sector | Specific Application of perf mesh | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Architecture | Facades and decorative elements | Enhances aesthetic appeal while providing ventilation | Material durability, design flexibility, compliance with local regulations |

| Automotive | Grilles and air intake systems | Improves airflow and engine cooling efficiency | Compatibility with existing designs, corrosion resistance, material weight |

| Filtration & Separation | Industrial filters for air and liquids | Efficient separation of particles and contaminants | Open area percentage, hole size specifications, material compatibility |

| HVAC Systems | Ventilation grilles and diffusers | Optimizes airflow and energy efficiency | Size and gauge options, noise reduction properties, ease of installation |

| Safety & Security | Barriers and guards in industrial settings | Provides safety and protection without obstructing visibility | Strength-to-weight ratio, corrosion resistance, compliance with safety standards |

How is perf mesh utilized in construction and architecture?

In the construction and architectural sectors, perforated mesh is often employed for facades and decorative elements. It serves a dual purpose by enhancing aesthetic appeal while allowing for necessary ventilation. For international buyers, particularly in regions like Africa and the Middle East, sourcing considerations include material durability, design flexibility, and adherence to local building regulations. The choice of materials—such as aluminum or stainless steel—can significantly impact both the longevity and visual appeal of the installation.

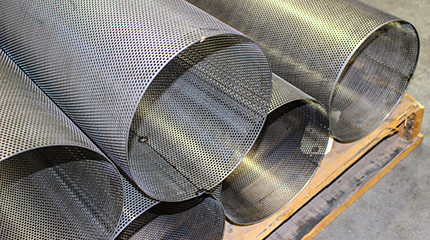

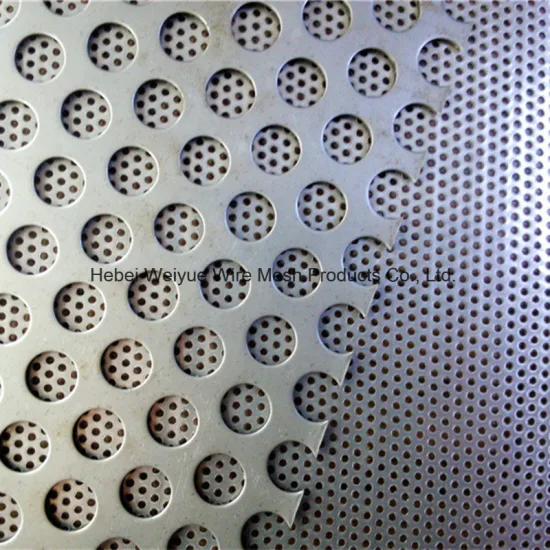

Illustrative image related to perf mesh

What role does perf mesh play in the automotive industry?

In the automotive industry, perforated mesh is integral to the design of grilles and air intake systems. It facilitates improved airflow, which is crucial for engine cooling and overall vehicle performance. Buyers in South America and Europe must consider compatibility with existing designs, the material’s corrosion resistance, and the overall weight of the mesh, as these factors can influence vehicle efficiency and safety.

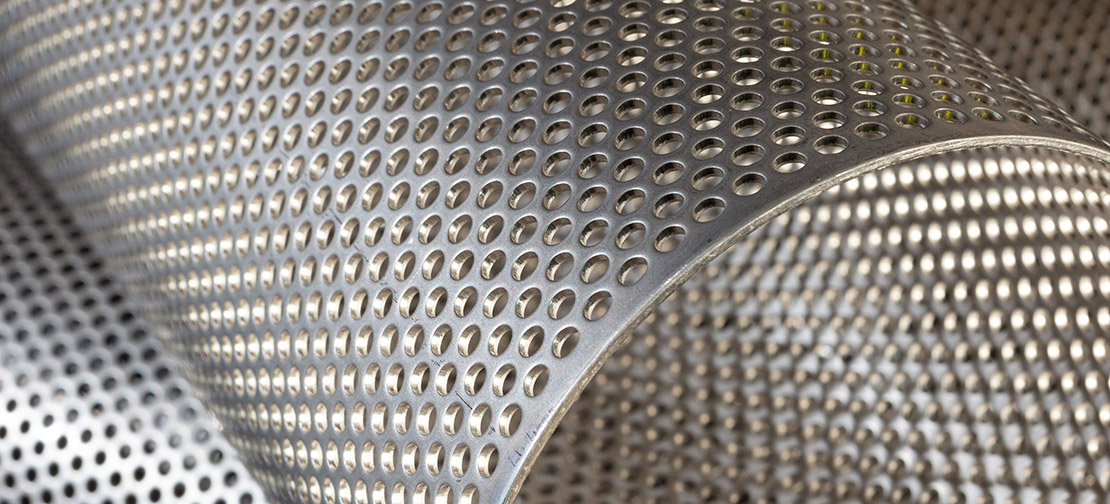

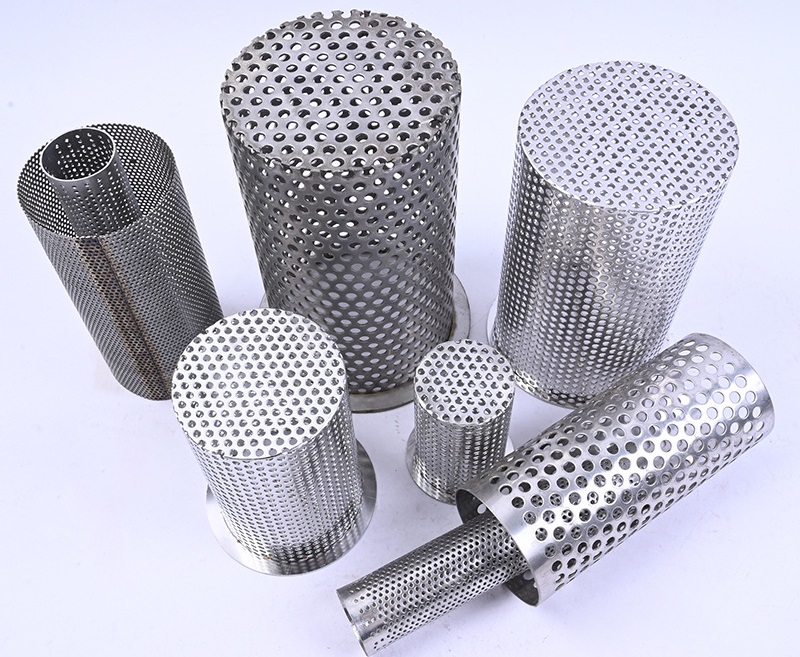

How does perf mesh function in filtration and separation applications?

Perf mesh is widely used in filtration and separation processes across various industries, including water treatment and air purification. It efficiently separates particles and contaminants, ensuring clean output. For businesses sourcing these products, critical considerations include the open area percentage, hole size specifications, and material compatibility, especially for applications requiring chemical resistance. This is particularly relevant for buyers in diverse markets like Nigeria and Germany, where environmental regulations may dictate specific performance standards.

Why is perf mesh important for HVAC systems?

In HVAC systems, perforated mesh is essential for ventilation grilles and diffusers, optimizing airflow and enhancing energy efficiency. By allowing controlled air distribution, it helps maintain comfortable indoor environments. International buyers should focus on size and gauge options, noise reduction properties, and ease of installation when sourcing perforated mesh for HVAC applications. These factors are vital for ensuring effective system performance and compliance with local standards.

How is perf mesh utilized for safety and security?

Perforated mesh is also utilized in safety and security applications, such as barriers and guards in industrial settings. It provides essential protection while maintaining visibility, which is crucial in high-traffic areas. When sourcing for these applications, businesses must consider the strength-to-weight ratio, corrosion resistance, and compliance with safety standards. This is especially important for companies operating in regions with stringent safety regulations, ensuring that their installations meet both functional and legal requirements.

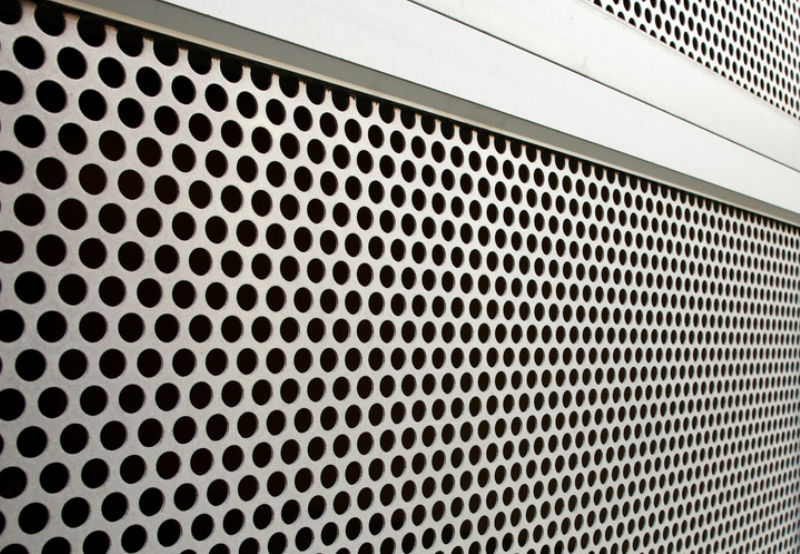

Illustrative image related to perf mesh

3 Common User Pain Points for ‘perf mesh’ & Their Solutions

Scenario 1: Navigating Supply Chain Disruptions in Perforated Metal Orders

The Problem: B2B buyers often encounter significant delays in obtaining perforated metal products due to supply chain disruptions. Factors such as geopolitical tensions, raw material shortages, or unexpected demand surges can lead to extended lead times. This unpredictability not only hampers project timelines but can also escalate costs as companies scramble for alternatives or expedite shipping.

The Solution: To mitigate these challenges, buyers should establish relationships with multiple suppliers across different regions. This diversification strategy enables companies to source perforated metal from various manufacturers, thus reducing dependency on a single supply chain. Additionally, buyers should consider placing larger, periodic orders rather than smaller, frequent ones. By predicting their needs more accurately, they can take advantage of bulk pricing and ensure they have stock on hand during potential shortages. Lastly, implementing a just-in-time inventory system could help manage stock levels effectively while minimizing excess inventory costs.

Scenario 2: Achieving the Right Specifications for Performance Needs

The Problem: Another common issue is the difficulty in specifying the correct perforated metal characteristics for specific applications. Buyers often struggle with determining the appropriate hole size, pattern, gauge, and material type necessary for their unique requirements, which can lead to suboptimal performance and wasted resources. This can be particularly critical in industries where filtration, ventilation, or aesthetic considerations are paramount.

The Solution: To address this, B2B buyers should engage in thorough consultations with their suppliers before making a purchase. Providing detailed information about the intended application, including environmental conditions, required airflow rates, and any regulatory compliance needs, can help suppliers recommend the most suitable perforated metal options. Additionally, utilizing tools such as CAD software can allow buyers to visualize how different perforation designs will function within their specific setups. This proactive approach ensures that the selected perforated mesh meets all performance criteria, thus enhancing overall operational efficiency.

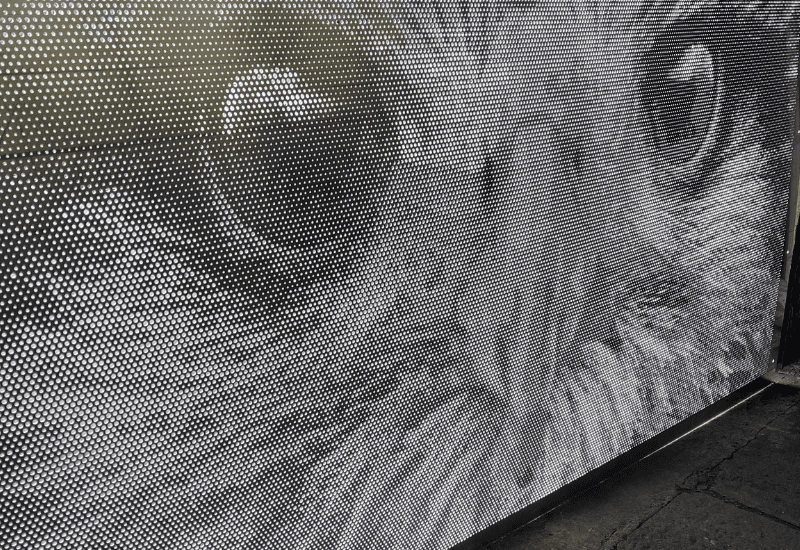

Scenario 3: Balancing Aesthetics and Functionality in Design Projects

The Problem: In architectural and design projects, buyers frequently face the challenge of balancing aesthetic appeal with functional requirements. They need perforated metal that not only fulfills practical roles—such as ventilation or safety—but also contributes to the overall design vision. This dual requirement can complicate the selection process and lead to compromises that detract from the final product.

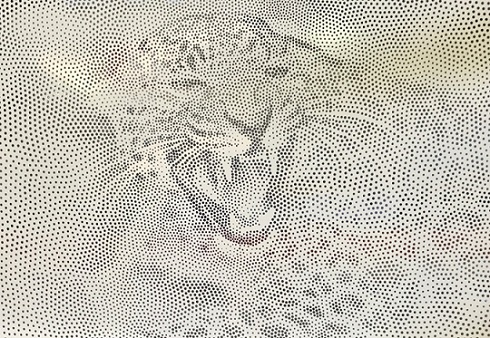

Illustrative image related to perf mesh

The Solution: To navigate this complexity, buyers should prioritize collaboration with design professionals early in the project lifecycle. Engaging architects or designers who specialize in metal applications can yield insights into how different perforation patterns and materials can be utilized effectively. Additionally, buyers can explore custom perforation options that cater specifically to their design needs without sacrificing functionality. Many suppliers offer design services that can help visualize the end product, ensuring that both aesthetic and functional requirements are met harmoniously. By focusing on this integrative approach, B2B buyers can achieve their desired outcomes without compromising on either front.

Strategic Material Selection Guide for perf mesh

When selecting materials for perforated mesh (perf mesh), it’s crucial to consider properties such as strength, weight, corrosion resistance, and suitability for specific applications. Below, we analyze four common materials used in perf mesh, focusing on their key properties, advantages and disadvantages, and considerations for international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe.

What are the Key Properties of Aluminum in Perf Mesh Applications?

Aluminum is a popular choice for perf mesh due to its lightweight nature and excellent corrosion resistance. It typically has a temperature rating up to 150°C and can withstand moderate pressure. Aluminum is also non-magnetic, making it suitable for applications in environments where magnetism must be avoided.

Pros: Aluminum is highly durable, lightweight, and easy to fabricate, which reduces manufacturing complexity. It is also cost-effective for large-scale applications.

Cons: While it has good corrosion resistance, aluminum can be susceptible to certain chemicals, which may limit its use in specific environments.

Illustrative image related to perf mesh

Impact on Application: Aluminum perf mesh is ideal for applications requiring ventilation, such as air filters and decorative panels. However, it may not be suitable for high-stress environments.

Considerations for International Buyers: Compliance with standards such as ASTM and EN is essential. Buyers should also consider local market preferences for aluminum grades and finishes.

How Does Stainless Steel Perform in Perf Mesh Applications?

Stainless steel is renowned for its exceptional strength and corrosion resistance, making it a top choice for demanding applications. It can withstand high temperatures (up to 800°C) and is highly resistant to oxidation and rust.

Pros: Stainless steel offers excellent durability and longevity, making it suitable for both industrial and architectural applications. Its aesthetic appeal is also a significant advantage in decorative applications.

Cons: The material is heavier and more expensive than aluminum, which can increase shipping costs and affect overall project budgets.

Impact on Application: Stainless steel perf mesh is ideal for filtration systems, safety barriers, and architectural features in environments with high humidity or exposure to corrosive substances.

Considerations for International Buyers: Buyers should ensure compliance with international standards like ASTM A240 for stainless steel. Additionally, understanding local regulations regarding stainless steel grades is crucial, especially in regions with varying environmental conditions.

What are the Benefits of Carbon Steel in Perf Mesh?

Carbon steel is a robust and economical option for perf mesh, offering high strength and a variety of finishes. It can handle high-pressure applications and is often used in industrial settings.

Pros: Carbon steel is cost-effective and widely available, making it an attractive choice for large-scale projects. It can be easily welded and fabricated.

Cons: It is prone to rust and corrosion if not properly treated, which can limit its lifespan in certain environments.

Illustrative image related to perf mesh

Impact on Application: Carbon steel perf mesh is commonly used in construction, fencing, and industrial applications where strength is prioritized over aesthetic appeal.

Considerations for International Buyers: Buyers should be aware of the need for protective coatings to prevent corrosion, especially in humid or coastal regions. Compliance with local standards for carbon steel, such as JIS G3101 in Japan or DIN 17100 in Germany, is also necessary.

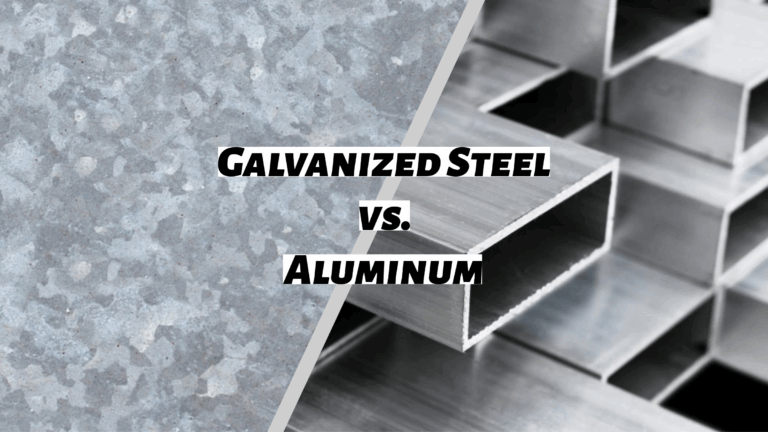

How Does Galvanized Steel Compare for Perf Mesh Use?

Galvanized steel combines the strength of carbon steel with a protective zinc coating, enhancing its corrosion resistance. It is suitable for outdoor applications and can withstand moderate temperatures.

Illustrative image related to perf mesh

Pros: The galvanization process provides a longer lifespan than untreated carbon steel, making it a durable choice for outdoor and industrial applications.

Cons: While galvanized steel is more resistant to corrosion than carbon steel, it may still be susceptible to damage from harsh chemicals.

Impact on Application: Galvanized steel perf mesh is ideal for outdoor fencing, ventilation systems, and other applications exposed to the elements.

Considerations for International Buyers: Buyers should verify that the galvanization process meets local standards, such as ASTM A123 in the U.S. or EN ISO 1461 in Europe. Understanding the local climate and its impact on galvanized steel performance is also essential.

Summary Table of Material Selection for Perf Mesh

| Material | Typical Use Case for perf mesh | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Air filters, decorative panels | Lightweight and corrosion-resistant | Susceptible to certain chemicals | Low |

| Stainless Steel | Filtration systems, safety barriers | Exceptional strength and aesthetic appeal | Heavier and more expensive | High |

| Carbon Steel | Construction, industrial applications | Cost-effective and widely available | Prone to rust without treatment | Low |

| Galvanized Steel | Outdoor fencing, ventilation systems | Enhanced corrosion resistance | Vulnerable to harsh chemicals | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of different materials used in perf mesh applications, enabling informed decision-making tailored to specific project needs.

Illustrative image related to perf mesh

In-depth Look: Manufacturing Processes and Quality Assurance for perf mesh

What Are the Key Stages in the Manufacturing Process of Perforated Mesh?

The manufacturing process for perforated mesh involves several critical stages, each designed to ensure that the final product meets both performance and aesthetic standards required by various industries. Understanding these stages can help B2B buyers assess potential suppliers effectively.

1. Material Preparation: What Materials Are Commonly Used?

The first step in manufacturing perforated mesh is material selection. Common materials include aluminum, carbon steel, stainless steel, and galvanized steel, each offering unique properties suitable for different applications. For instance, aluminum is lightweight and resistant to corrosion, making it ideal for architectural applications, while stainless steel provides durability and strength for industrial uses.

Once the material is selected, it is cut into sheets of specified sizes. This is typically done using precision cutting machines that ensure uniformity. The sheets are then inspected for defects, such as dents or scratches, which could compromise the quality of the final product.

2. Forming: How Is Perforation Achieved?

The forming stage involves creating holes in the metal sheets. This is primarily done through methods such as punching, laser cutting, or water jet cutting, depending on the complexity and volume of production.

- Punching is a common method where a die is used to create holes in the sheets. This process is efficient for high-volume production and can produce various hole shapes, including round, square, and slotted designs.

- Laser Cutting offers high precision and flexibility, allowing for intricate designs and smaller hole sizes that may not be achievable through traditional punching.

- Water Jet Cutting is particularly useful for thicker materials and offers a clean edge without thermal distortion.

After perforation, the sheets may undergo further shaping or forming processes, including bending or curving, to meet specific design requirements.

Illustrative image related to perf mesh

3. Assembly: Are Additional Components Used?

In some cases, perforated sheets may require additional components or finishing processes. This can involve welding or fastening perforated panels to frames or other structural elements, particularly for architectural applications.

The assembly stage is crucial for ensuring the product’s structural integrity, especially in applications where the perforated mesh will bear weight or be subjected to stress.

4. Finishing: What Treatments Enhance Durability?

The finishing stage applies protective coatings or treatments to enhance the performance and longevity of the perforated mesh. Common treatments include:

Illustrative image related to perf mesh

- Powder Coating: This provides a durable, weather-resistant finish that can also add color and aesthetic appeal.

- Galvanizing: For steel products, galvanization offers corrosion resistance, extending the lifespan of the material in harsh environments.

- Anodizing: Specifically for aluminum, anodizing increases corrosion resistance and surface hardness while allowing for various color finishes.

Finishing processes are tailored to the end-use environment, ensuring that the product meets the necessary durability and aesthetic standards.

What Quality Assurance Measures Are Essential for Perforated Mesh?

Quality assurance (QA) is a vital aspect of the manufacturing process for perforated mesh, particularly for B2B transactions where product reliability is paramount.

International Standards: Which Certifications Should Buyers Look For?

To ensure quality, many manufacturers adhere to international standards such as ISO 9001, which outlines quality management principles. This certification demonstrates a commitment to maintaining high-quality processes and continuous improvement.

Additionally, industry-specific certifications such as CE marking for European markets and API specifications for oil and gas applications further assure buyers of the product’s compliance with stringent industry standards.

Quality Control Checkpoints: What Are the Key Inspection Stages?

Quality control (QC) is integrated into various stages of the manufacturing process, with specific checkpoints established to identify defects early.

- Incoming Quality Control (IQC): This initial inspection assesses the raw materials upon arrival, ensuring they meet specified standards before processing begins.

- In-Process Quality Control (IPQC): During manufacturing, ongoing inspections occur to monitor the perforation process, checking for dimensional accuracy and defect rates.

- Final Quality Control (FQC): After the product is completed, a thorough inspection is conducted to verify that the final output meets all specifications, including dimensional tolerances, surface finishes, and structural integrity.

Common Testing Methods: How Is Product Quality Verified?

Testing methods vary depending on the application but typically include:

- Visual Inspections: To identify surface defects or inconsistencies.

- Dimensional Testing: To ensure that the perforated mesh meets specified sizes and tolerances.

- Mechanical Testing: Such as tensile strength tests to verify that the material can withstand expected loads.

How Can B2B Buyers Verify Supplier Quality Assurance?

When sourcing perforated mesh, B2B buyers should take proactive steps to verify the quality assurance practices of potential suppliers. Here are effective strategies:

Audits: What Should Be Included in a Supplier Audit?

Conducting supplier audits is a critical step in assessing the manufacturing capabilities and quality control processes of potential partners. During the audit, buyers should evaluate:

- Production processes and technologies.

- Compliance with international and industry-specific standards.

- Documentation of quality control processes and records.

Reports: What Documentation Is Important?

Buyers should request detailed quality assurance reports, including:

- Certificates of compliance with relevant standards (e.g., ISO 9001).

- Inspection and test reports demonstrating adherence to specifications.

- Documentation of any past quality issues and corrective actions taken.

Third-Party Inspections: How Can They Enhance Assurance?

Engaging third-party inspection services can provide an additional layer of assurance. These independent organizations can conduct thorough assessments of the manufacturing processes and final products, ensuring that they meet all required standards and specifications.

What Are the Unique Considerations for International B2B Buyers?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, it is essential to consider local regulations and standards that may impact procurement.

- Regional Standards: Buyers should be familiar with regional compliance requirements, such as those mandated by the EU or specific countries, to ensure that the products are suitable for their markets.

- Cultural and Language Considerations: Effective communication with suppliers is vital. Buyers should ensure that any specifications and quality requirements are clearly understood and agreed upon, which may involve translators or local representatives.

- Logistics and Supply Chain Considerations: Understanding the logistics involved in shipping perforated mesh, including customs regulations and potential delays, is crucial for timely project completion.

By comprehensively evaluating the manufacturing processes and quality assurance measures in place, B2B buyers can make informed decisions, ensuring that they source high-quality perforated mesh that meets their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘perf mesh’

In this guide, we aim to provide a comprehensive checklist for B2B buyers looking to procure perforated mesh (perf mesh) products. This resource will help you navigate the complexities of sourcing perf mesh, ensuring that you make informed decisions that align with your project requirements and business needs.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, clearly outline the technical specifications for your perforated mesh needs. Consider factors such as material type (e.g., aluminum, stainless steel), gauge or thickness, and hole shape (round, square, or slotted). Defining these specifications upfront will streamline your procurement process and help suppliers provide accurate quotes.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers that specialize in perforated mesh. Look for companies with extensive inventories and a proven track record in your industry. Utilize online directories, trade shows, and industry publications to compile a list of potential suppliers that meet your criteria.

Step 3: Evaluate Supplier Certifications and Compliance

It’s vital to verify that your chosen suppliers adhere to industry standards and certifications. Look for ISO certifications, compliance with local regulations, and quality assurance processes. These certifications not only ensure product quality but also minimize the risk of regulatory issues in your procurement process.

Step 4: Request Samples for Quality Assessment

Before placing a bulk order, request samples of the perforated mesh from shortlisted suppliers. Evaluate the samples for quality, durability, and compliance with your specifications. This step is crucial in determining whether the supplier can meet your expectations in terms of product performance and aesthetics.

Step 5: Assess Lead Times and Delivery Options

Inquire about lead times and shipping options to avoid delays in your project timeline. Different suppliers may have varying capabilities regarding production schedules and shipping logistics. Understanding these factors can help you select a supplier that aligns with your delivery requirements.

Illustrative image related to perf mesh

Step 6: Negotiate Pricing and Payment Terms

Once you’ve narrowed down your options, engage in discussions regarding pricing and payment terms. Be prepared to negotiate bulk pricing or discounts based on your order size. Clear agreement on payment terms will help prevent misunderstandings and foster a better relationship with your supplier.

Step 7: Establish a Communication Plan

Effective communication is critical throughout the sourcing process. Establish a communication plan that outlines how often you will check in with your supplier and the preferred channels for updates. This ensures that both parties remain informed about order status, potential issues, or changes in specifications.

By following this checklist, you will enhance your sourcing strategy for perforated mesh and ensure that you choose suppliers that can meet your business needs effectively.

Comprehensive Cost and Pricing Analysis for perf mesh Sourcing

What Are the Key Cost Components in Sourcing Perf Mesh?

When considering the procurement of perforated mesh (perf mesh), understanding the cost structure is essential for effective budgeting and negotiation. The primary components include:

-

Materials: The cost of materials varies significantly based on type—aluminum, stainless steel, carbon steel, or plastic. Each material has its own pricing dynamics influenced by market demand and availability. For example, stainless steel is generally more expensive due to its corrosion resistance and strength.

-

Labor: This encompasses the costs associated with the workforce involved in the manufacturing process. Labor costs can fluctuate based on geographic location, with regions having higher wage standards impacting overall pricing.

-

Manufacturing Overhead: These are the indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient factories with automated processes may have lower overhead, which can translate to cost savings for buyers.

-

Tooling: Custom tooling for specific perforation patterns or sizes can incur significant upfront costs. However, these costs may be amortized over larger production runs, making bulk orders more economical.

-

Quality Control (QC): Implementing stringent QC processes ensures product reliability but can add to the overall cost. Certifications and compliance with international standards may also influence pricing.

-

Logistics: Shipping costs, particularly for international buyers, can vary widely based on distance, mode of transport, and freight terms. Understanding Incoterms is critical to ensure clarity on who bears these costs.

-

Margin: Suppliers will incorporate their profit margins into the final pricing, which can vary based on market competition and perceived value.

How Do Volume and Customization Affect Perf Mesh Pricing?

Volume and customization are significant influencers of pricing in the perf mesh market.

-

Volume/MOQ (Minimum Order Quantity): Suppliers often offer tiered pricing structures where larger orders reduce the per-unit cost. For international buyers, negotiating favorable MOQs can lead to substantial savings.

-

Specifications and Customization: Custom designs, hole sizes, and material specifications can lead to higher costs. The more complex the requirements, the higher the tooling and manufacturing costs. Buyers should weigh the benefits of customization against their budget constraints.

What Factors Influence Perf Mesh Pricing for International Buyers?

International buyers, particularly from diverse markets like Africa, South America, the Middle East, and Europe, must navigate several pricing nuances:

Illustrative image related to perf mesh

-

Quality and Certifications: Products that meet specific international standards may come at a premium. Buyers should ensure that the materials used align with local regulations to avoid costly compliance issues.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers with a track record of quality may charge higher prices, but they can also offer better service and product guarantees.

-

Incoterms: Understanding terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) is crucial. These terms dictate shipping responsibilities and costs, influencing the total landed cost of the product.

What Are Essential Buyer Tips for Cost-Efficiency in Perf Mesh Procurement?

To maximize cost-efficiency when sourcing perforated mesh, buyers should consider the following strategies:

-

Negotiation: Engage suppliers in discussions about pricing, especially for larger orders. Leverage competitive quotes to negotiate better terms.

-

Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors like installation, maintenance, and potential waste when evaluating costs.

-

Pricing Nuances: Stay informed about market trends and material costs, as these can fluctuate. Establishing long-term relationships with suppliers may yield better pricing over time.

Disclaimer on Indicative Prices

Please note that prices for perforated mesh can vary widely based on the aforementioned factors. It is advisable for buyers to request detailed quotes and conduct thorough market research to obtain accurate pricing tailored to their specific needs.

Alternatives Analysis: Comparing perf mesh With Other Solutions

Exploring Alternatives to Perf Mesh Solutions

When considering the best solution for industrial applications, it’s essential to evaluate various options available on the market. Perf mesh, a type of perforated metal often used for ventilation, filtration, and aesthetic purposes, competes with several alternatives. Understanding these alternatives can help B2B buyers make informed decisions tailored to their specific needs.

| Comparison Aspect | Perf Mesh | Expanded Metal | Wire Mesh |

|---|---|---|---|

| Performance | High airflow, customizable hole sizes | Excellent strength-to-weight ratio, good ventilation | Versatile, good for filtration and security |

| Cost | Moderate | Generally lower cost | Varies, can be economical |

| Ease of Implementation | Easy to install with standard tools | Requires cutting tools for custom sizes | Simple installation, but may require additional supports |

| Maintenance | Low maintenance, durable | Low maintenance, very durable | Moderate maintenance, may rust if untreated |

| Best Use Case | Architectural designs, sound barriers, filters | Safety barriers, grating, structural support | Security fencing, filtration systems, decorative applications |

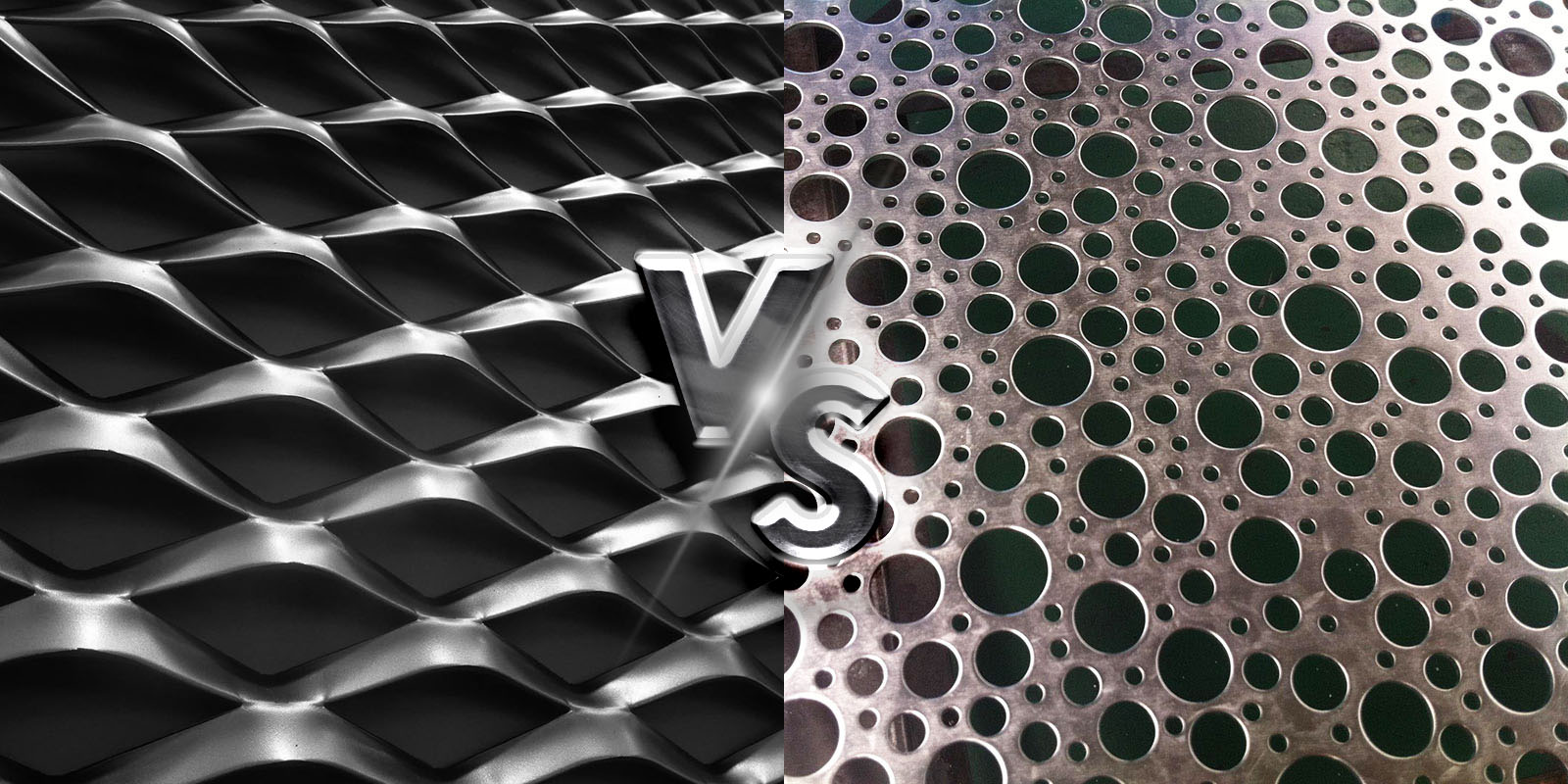

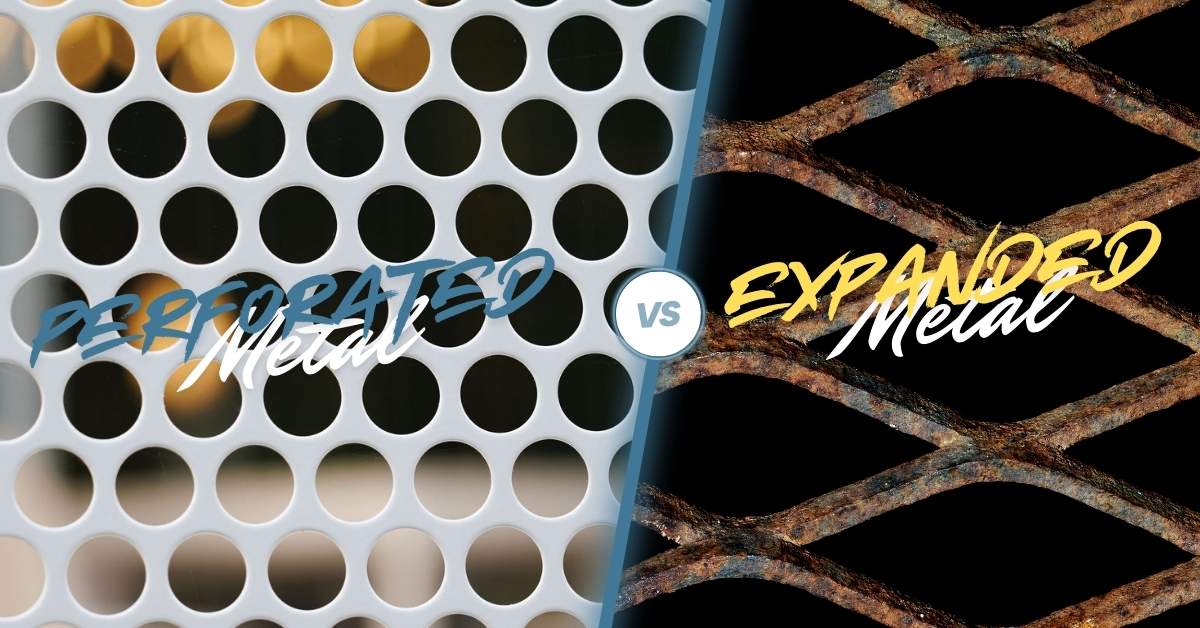

What Are the Advantages and Disadvantages of Expanded Metal?

Expanded metal is made by cutting and stretching a metal sheet, creating a mesh-like structure. This alternative is known for its excellent strength-to-weight ratio, making it suitable for safety barriers and structural support. Its cost-effectiveness is a significant advantage, as it often comes at a lower price point than perf mesh. However, expanded metal typically offers less versatility in terms of hole size and shape, which may limit its use in specific applications requiring precise filtration or aesthetic appeal.

Illustrative image related to perf mesh

How Does Wire Mesh Compare to Perf Mesh?

Wire mesh, composed of interwoven metal wires, is another viable alternative. It is highly versatile and can be used for various applications, including security fencing and filtration systems. Wire mesh can be more economical depending on the gauge and material chosen. However, it may require additional supports for installation and can be less durable than perf mesh if not treated correctly to prevent rust. Wire mesh is often used in situations where visibility and airflow are essential, but it may not provide the same aesthetic quality as perf mesh.

Conclusion: How to Choose the Right Solution for Your Business Needs?

Selecting the right solution requires a careful assessment of your specific application needs, budget constraints, and long-term goals. If you prioritize aesthetic appeal and precise filtration, perf mesh may be your best bet. However, if cost is a significant factor and your application requires structural support, expanded metal could be the ideal choice. For those seeking a balance of versatility and affordability, wire mesh offers a compelling option. Ultimately, understanding the strengths and limitations of each alternative will empower B2B buyers to make informed decisions that align with their operational requirements and project specifications.

Essential Technical Properties and Trade Terminology for perf mesh

What Are the Key Technical Properties of Perf Mesh for B2B Buyers?

When sourcing perforated mesh, understanding its technical properties is crucial for making informed purchasing decisions. Here are several key specifications that should be considered:

1. Material Grade

Perf mesh can be made from various materials, including aluminum, stainless steel, carbon steel, and plastic. Each material has distinct properties, such as corrosion resistance and strength, making it suitable for different applications. For instance, stainless steel is ideal for environments exposed to moisture, while aluminum is favored for its lightweight nature. Selecting the right material is vital for ensuring durability and performance in specific applications.

Illustrative image related to perf mesh

2. Gauge/Thickness

The gauge or thickness of perforated mesh affects its strength and weight. Common gauges range from 8 to 22, with lower numbers indicating thicker sheets. A thicker gauge provides greater strength, making it suitable for heavy-duty applications such as safety barriers or structural components. Conversely, thinner gauges are often used for decorative purposes or lightweight installations. Understanding gauge specifications helps buyers choose the right balance between strength and weight for their projects.

3. Hole Size and Shape

The size and shape of the perforations significantly influence the mesh’s functionality. Common hole shapes include round, square, slotted, and hexagonal. Each shape has unique benefits; for example, slotted holes allow for better airflow, while round holes are often used for aesthetic applications. Buyers should consider the intended use when selecting hole dimensions, as this will impact the mesh’s performance in filtering, ventilation, or decorative roles.

4. Percent Open Area

This specification refers to the ratio of open space (the area of the holes) to the total surface area of the mesh. A higher percent open area (e.g., 70-80%) allows for greater airflow and light penetration, making it ideal for applications like ventilation and acoustics. Conversely, a lower percent open area can enhance privacy or structural integrity. Understanding this property helps buyers assess the mesh’s suitability for specific applications.

5. Tolerance

Tolerance refers to the permissible variation in dimensions from specified measurements. For perforated mesh, tight tolerances are essential for ensuring proper fit in assemblies and installations. This specification is particularly important in industries where precision is critical, such as aerospace or automotive manufacturing. Buyers should confirm the tolerance levels with suppliers to ensure compatibility with their design requirements.

What Common Trade Terms Should B2B Buyers of Perf Mesh Know?

Familiarity with industry jargon can streamline communication and facilitate smoother transactions. Here are several common terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

An OEM produces parts or equipment that may be marketed under another company’s brand. In the context of perf mesh, buyers often work with OEMs to source customized mesh products that meet specific design or functional requirements.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units a supplier is willing to sell. Understanding the MOQ is essential for buyers to gauge their purchasing power and manage inventory effectively. Some suppliers may offer lower MOQs for standard products but require higher quantities for custom orders.

Illustrative image related to perf mesh

3. RFQ (Request for Quotation)

An RFQ is a formal request sent to suppliers for pricing and availability of specific products. For B2B buyers, submitting an RFQ for perf mesh allows them to compare prices, lead times, and specifications from different suppliers, facilitating informed purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international trade. They specify who bears the costs and risks during shipping. Understanding Incoterms is vital for B2B buyers to clarify delivery responsibilities and avoid potential disputes.

5. Lead Time

Lead time is the period between placing an order and receiving the goods. For buyers, understanding lead times is crucial for planning projects and managing supply chain logistics. Longer lead times may require advance ordering to avoid delays in production schedules.

Illustrative image related to perf mesh

By grasping these technical properties and trade terms, B2B buyers can make well-informed decisions when procuring perforated mesh, ensuring they select the right products for their applications and streamline their purchasing process.

Navigating Market Dynamics and Sourcing Trends in the perf mesh Sector

What Are the Current Market Dynamics and Key Trends in the Perf Mesh Sector?

The global market for perforated mesh, particularly in the B2B sector, is witnessing significant growth driven by urbanization, infrastructural developments, and an increasing emphasis on aesthetic appeal in architecture. Industries such as construction, automotive, and manufacturing are leveraging perforated metal for its versatile applications, including filtration, ventilation, and decorative purposes. In regions like Africa and South America, rapid urban expansion is propelling demand for cost-effective and durable materials, creating opportunities for suppliers to cater to local construction needs.

Emerging technologies are reshaping sourcing trends in the perf mesh sector. Digital platforms are increasingly being used for procurement, enabling buyers to access a wider range of products and suppliers. This shift towards e-commerce is particularly beneficial for international buyers, as it facilitates easier comparison of products and pricing. Additionally, advancements in manufacturing processes, such as laser cutting and automated perforation, are enhancing the precision and customization of perforated products, allowing for tailored solutions that meet specific project requirements.

International buyers must navigate various market dynamics, including fluctuating raw material prices and supply chain disruptions, which have become more pronounced due to geopolitical tensions and the ongoing effects of the COVID-19 pandemic. Understanding these dynamics is critical for making informed purchasing decisions and establishing resilient supply chains.

How Does Sustainability and Ethical Sourcing Impact the Perf Mesh Industry?

Sustainability has become a pivotal consideration in the perf mesh sector, with both buyers and manufacturers increasingly prioritizing environmentally friendly practices. The production of perforated metal can have a significant environmental impact, from resource extraction to energy-intensive manufacturing processes. Therefore, international buyers are encouraged to seek suppliers who adhere to sustainable practices, such as using recycled materials and reducing waste in production.

Ethical sourcing is also paramount. Buyers should prioritize suppliers that maintain transparent supply chains and adhere to fair labor practices. Certifications such as ISO 14001 for environmental management and other ‘green’ certifications can provide assurance that suppliers are committed to sustainability. Additionally, opting for materials like stainless steel and aluminum, which are recyclable and have a lower environmental footprint, can enhance the sustainability profile of projects utilizing perf mesh.

By aligning procurement strategies with sustainability goals, B2B buyers not only contribute to environmental conservation but also enhance their brand reputation in an increasingly eco-conscious marketplace.

How Has the Perf Mesh Sector Evolved Over Time?

The evolution of the perf mesh sector can be traced back to its initial applications in industrial settings, where functionality was the primary concern. Over the years, the versatility of perforated metal has led to its integration into various sectors, including architecture and design. The introduction of advanced manufacturing technologies has allowed for greater customization, enabling designers to explore innovative uses of perforated materials in aesthetic and functional applications.

Illustrative image related to perf mesh

Today, perf mesh is not merely a utilitarian product but a vital component in modern design, reflecting a trend towards combining practicality with style. This evolution underscores the importance of understanding both historical context and contemporary applications for B2B buyers, as it informs their purchasing decisions and helps them anticipate future trends in the market.

Frequently Asked Questions (FAQs) for B2B Buyers of perf mesh

-

1. How do I choose the right perforated mesh for my application?

Selecting the appropriate perforated mesh involves considering several factors, including the intended use, material requirements, hole shape and size, and gauge. Identify the specific properties needed for your application—such as strength, corrosion resistance, or aesthetic appeal. For example, if you require high airflow, hexagonal perforated metal may be best. Consult with suppliers to evaluate the options available and ensure the product meets your technical specifications. -

2. What types of materials are available for perforated mesh, and which is best for my needs?

Perforated mesh is available in various materials, including aluminum, carbon steel, stainless steel, and plastic. Aluminum offers lightweight and corrosion resistance, making it ideal for architectural applications. Stainless steel provides superior durability and is suitable for harsh environments. Carbon steel is cost-effective for industrial uses but may require coatings to prevent rust. Determine the environmental conditions and functional requirements of your project to select the most appropriate material. -

3. What customization options are available for perforated mesh?

Most suppliers offer customization options such as varying hole sizes, shapes, and patterns, as well as specific gauge thicknesses and dimensions. You can also request special coatings or finishes to enhance durability or aesthetic appeal. When ordering, provide detailed specifications, including material type, hole configuration, and any additional treatments needed. Engaging in a conversation with your supplier can help clarify your requirements and ensure a tailored solution. -

4. What is the minimum order quantity (MOQ) for perforated mesh products?

Minimum order quantities can vary significantly between suppliers and depend on the type of perforated mesh being ordered. While some manufacturers may have a low MOQ for standard sheets, custom orders typically require larger quantities. It’s advisable to inquire directly with potential suppliers about their MOQ policies and negotiate terms that align with your project needs. -

5. How can I ensure the quality of perforated mesh products before purchasing?

To ensure quality, request product samples or certifications that verify the material’s specifications and performance standards. Engage with suppliers who have established quality assurance processes, such as ISO certifications. Additionally, seek feedback from other customers or review case studies that demonstrate the supplier’s reliability and product efficacy in similar applications. -

6. What payment terms should I expect when sourcing perforated mesh internationally?

Payment terms vary by supplier and may include options like advance payment, net 30/60/90 days, or letter of credit for larger orders. It’s essential to clarify payment conditions before finalizing an order to avoid misunderstandings. Be aware of additional costs such as shipping and customs duties, which may affect your overall budget. Discussing terms early in the negotiation process can facilitate smoother transactions. -

7. What logistics considerations should I keep in mind when importing perforated mesh?

When importing perforated mesh, consider shipping methods, lead times, and customs regulations specific to your country. Air freight is faster but more expensive, while sea freight is cost-effective for larger orders but may take longer. Ensure that your supplier provides necessary shipping documents, such as bills of lading and customs declarations, to facilitate clearance. Partnering with a reliable freight forwarder can help streamline the logistics process. -

8. How can I vet potential suppliers for perforated mesh products?

To vet suppliers, check their industry reputation through online reviews, testimonials, and case studies. Evaluate their production capabilities and quality control measures by requesting certifications or visiting their facilities if possible. Establishing clear communication and responsiveness is crucial. Additionally, consider engaging in a pilot order to assess their service and product quality before committing to larger transactions.

Top 6 Perf Mesh Manufacturers & Suppliers List

1. McNICHOLS – Perforated Metal Sheets & Panels

Domain: mcnichols.com

Registered: 1996 (29 years)

Introduction: McNICHOLS offers a wide range of Perforated Metal Sheets & Panels in various materials including Aluminum, Carbon Steel, Galvanized Steel, Stainless Steel, and Plastic. The product line features multiple hole types such as Round (223), Square (22), Slotted (8), Hexagonal (4), and Designer Perforated (31). Key series include AIRLINE, CLASSIC, GRECIAN, MAJESTIC, and more. Available gauges/thickness …

2. McMaster – Wire Cloth & Mesh Solutions

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Wire Cloth & Mesh Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Direct Metals – Perforated Metal Solutions

Domain: directmetals.com

Registered: 1998 (27 years)

Introduction: Perforated metal is versatile and popular, available in light to heavy gauge thickness. It can be made from various materials including carbon steel, aluminum, stainless steel, galvanized steel, and PVC plastic. The product features different hole shapes such as round, square, slotted, hexagonal, and decorative, making it suitable for architectural and decorative applications. Common uses include …

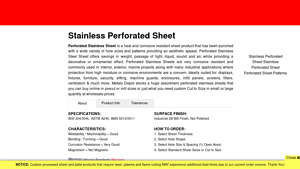

4. Metals Depot – Perforated Stainless Sheet

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: Product: Perforated Stainless Sheet

Material: AISI 304/304L, ASTM A240, AMS 5513/5511

Surface Finish: Industrial 2B Mill Finish, Not Polished

Characteristics:

– Weldability / Machinability: Good

– Bending / Forming: Good

– Corrosion Resistance: Very Good

– Magnetism: Not Magnetic

Applications: Displays, fixtures, furniture, security, sifting, machine guards, enclosures, infill panels, screens, fi…

5. Custom Car Grills – Heavy Duty Perforated Hex Aluminum Grill Mesh Sheets

Domain: customcargrills.com

Registered: 2001 (24 years)

Introduction: {“product_name”: “Heavy Duty Perforated Hex Aluminum Grill Mesh Sheets”, “SKU”: “HD_Perf_Hex”, “UPC”: “682604772783”, “sheet_sizes”: [{“size”: “16in. x 48in.”, “color_options”: [{“color”: “Silver”, “price”: “$99.99”}, {“color”: “Black Gloss Powder Coat”, “price”: “$119.99”}]}, {“size”: “24in. x 60in.”, “color_options”: [{“color”: “Silver”, “price”: “$149.99”}, {“color”: “Black Gloss Powder Coat”, …

6. The Mesh Company – Mild Steel Mesh

Domain: themeshcompany.com

Registered: 2007 (18 years)

Introduction: [{‘type’: ‘Mild Steel’, ‘hole_size’: ‘0.5mm’, ‘pitch’: ‘1mm’, ‘thickness’: ‘0.5mm’, ‘price_range’: ‘£13.99 – £52.99’}, {‘type’: ‘Stainless Steel’, ‘hole_size’: ‘0.75mm’, ‘pitch’: ‘1.5mm’, ‘thickness’: ‘0.6mm’, ‘price_range’: ‘£15.99 – £89.99’}, {‘type’: ‘Mild Steel’, ‘hole_size’: ‘1mm’, ‘pitch’: ‘2mm’, ‘thickness’: ‘1mm’, ‘price_range’: ‘£15.99 – £49.99’}, {‘type’: ‘Stainless Steel’, ‘hole_size’: …

Strategic Sourcing Conclusion and Outlook for perf mesh

In the dynamic landscape of perforated metal sourcing, strategic procurement plays a pivotal role in maximizing value and ensuring quality. Key takeaways for international B2B buyers include the versatility of perforated mesh, which can serve multiple applications across industries—from architectural designs to filtration systems. Understanding the variety of materials available, such as aluminum, stainless steel, and carbon steel, allows businesses to tailor their sourcing decisions to specific project requirements, enhancing both functionality and aesthetic appeal.

Moreover, leveraging suppliers with extensive inventories and customization options can significantly reduce lead times and improve project efficiency. As global markets become increasingly interconnected, buyers from regions like Africa, South America, the Middle East, and Europe (notably Germany and Nigeria) are encouraged to explore partnerships with reputable suppliers who can meet their diverse needs.

Looking ahead, the demand for innovative and sustainable solutions in perforated metal applications is expected to rise. By embracing a strategic sourcing approach, businesses can not only secure competitive pricing but also foster long-term relationships that drive growth and innovation. Engage with suppliers today to unlock the full potential of perforated mesh for your upcoming projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.