How to Source Parini Cookware Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for parini cookware

In the ever-evolving landscape of global commerce, sourcing high-quality Parini cookware can be a significant challenge for B2B buyers. With a diverse range of products that promise affordability without compromising on performance, understanding the nuances of Parini cookware is essential for making informed purchasing decisions. This guide delves into the myriad types of cookware available, their specific applications, and critical considerations for supplier vetting.

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe—including key markets such as Germany and Nigeria—will find invaluable insights into cost structures, shipping logistics, and market trends. By addressing these key areas, we aim to empower you with the knowledge necessary to select the right cookware that meets your business needs while maximizing value.

Whether you are equipping a new restaurant, expanding retail offerings, or seeking reliable kitchen solutions, this comprehensive guide serves as your roadmap to successfully navigate the global market for Parini cookware. With actionable insights and strategic recommendations, you can confidently approach your sourcing efforts, ensuring that your investments yield both quality and satisfaction for your customers.

Understanding parini cookware Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Dutch Oven | Thick cast iron construction, enameled surface, moisture retention | Stews, braises, baking bread | Pros: Excellent heat retention; Cons: Heavy and requires maintenance. |

| Non-Stick Frying Pan | Non-stick surface for easy cooking and cleaning | Everyday frying, sautéing, and omelets | Pros: Easy to clean; Cons: Can scratch easily if not maintained. |

| Stainless Steel Cookware | Encapsulated aluminum core for even heating, durable exterior | Sauces, simmering, and professional kitchens | Pros: Durable and versatile; Cons: Can be expensive compared to alternatives. |

| Cast Iron Skillet | Seasoned for natural non-stick, retains heat for high-temperature cooking | Searing, frying, baking | Pros: Versatile and long-lasting; Cons: Requires seasoning and care. |

| Slow Cooker | Programmable timer, triple-glazed stoneware crock | Preparing soups, stews, and tenderizing meats | Pros: Convenient for meal prep; Cons: Takes longer to cook. |

What Are the Characteristics of Dutch Ovens and Their Suitability for B2B Buyers?

The Parini Dutch Oven is characterized by its thick cast iron construction and enameled surface, which provides excellent heat distribution and moisture retention. This makes it ideal for stews, braises, and baking bread, appealing to restaurants and catering businesses that require reliable cooking equipment. B2B buyers should consider the Dutch Oven’s durability and its ability to perform well under high temperatures, but they should also be aware of its weight and the maintenance involved to preserve its quality.

Why Choose Non-Stick Frying Pans for Everyday Use?

Non-stick frying pans from Parini feature a specially designed surface that allows for easy cooking and cleanup, making them a staple for both home kitchens and commercial settings. They are suitable for a variety of cooking methods, including frying, sautéing, and preparing delicate foods like eggs. B2B buyers should evaluate the non-stick technology used, as it can affect the longevity of the cookware. While these pans are convenient, they require careful handling to avoid scratches, which can compromise their non-stick properties.

How Does Stainless Steel Cookware Benefit Professional Kitchens?

Parini’s stainless steel cookware is known for its encapsulated aluminum core, which ensures even heating and precise temperature control. This type of cookware is particularly advantageous in professional kitchens where consistent cooking results are crucial. B2B buyers should consider the versatility of stainless steel, as it can be used for a wide range of cooking applications, from simmering sauces to frying. While generally more expensive than other materials, the long-term durability and performance justify the investment.

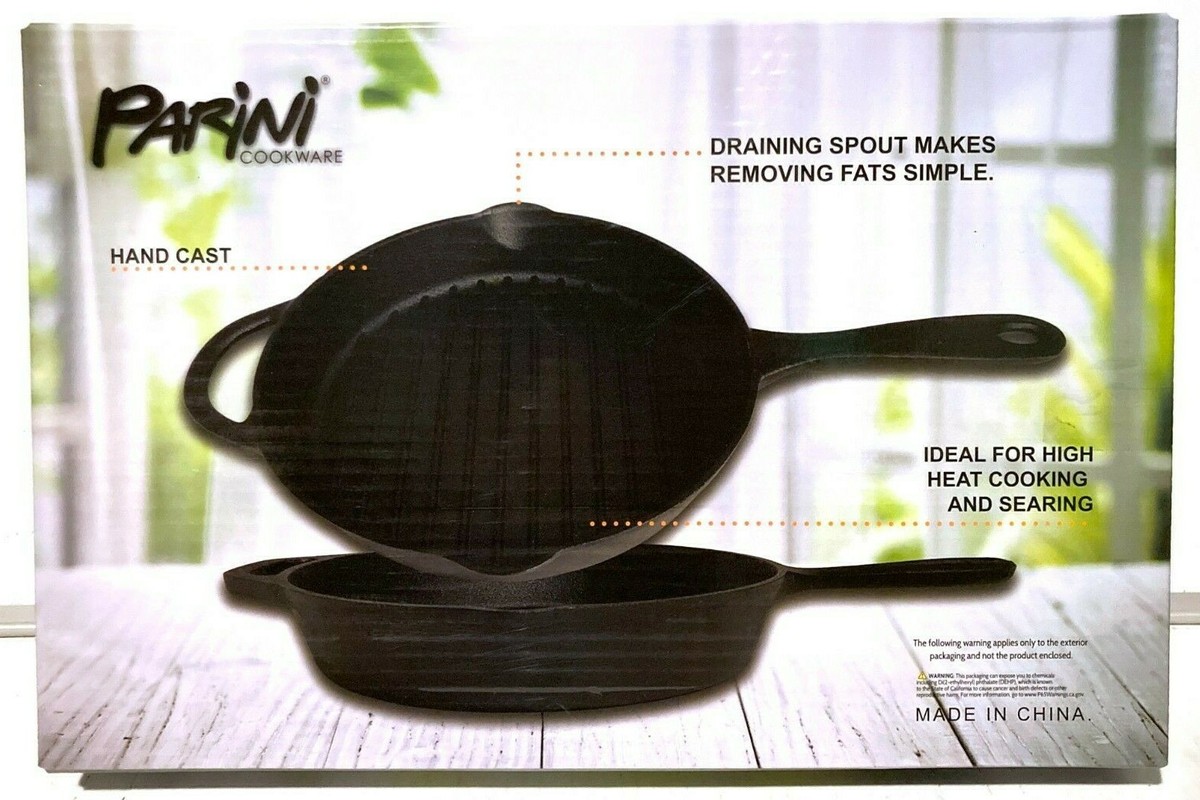

What Makes Cast Iron Skillets a Versatile Choice?

The Parini cast iron skillet is seasoned for natural non-stick release and is thick enough to retain high heat, making it perfect for searing, frying, and baking. Its versatility is a significant draw for restaurants and catering services looking to expand their cooking capabilities. B2B buyers should note that while cast iron skillets are long-lasting and capable of excellent heat retention, they require regular seasoning and proper care to maintain their performance.

How Can Slow Cookers Enhance Meal Preparation Efficiency?

Parini’s slow cooker features a programmable timer and a triple-glazed stoneware crock, making it an excellent choice for preparing soups, stews, and tenderizing tougher cuts of meat. This type of cookware is particularly beneficial for food service operations that prioritize meal prep efficiency. B2B buyers should consider the slow cooker’s ability to enhance flavors over longer cooking times, but they should also be aware that it may not suit all cooking styles due to its longer cooking duration.

Key Industrial Applications of parini cookware

| Industry/Sector | Specific Application of parini cookware | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Restaurant Cookware Sets | High-quality, durable cookware ensures consistent meal preparation. | Bulk purchasing options and warranty for longevity and reliability. |

| Catering | Portable Cookware for Events | Versatile cookware enhances menu offerings and cooking efficiency. | Lightweight materials for easy transport and quick setup. |

| Hospitality | In-Room Dining Cookware | Quality cookware elevates guest dining experience and satisfaction. | Aesthetic appeal and easy maintenance to meet hotel standards. |

| Retail | Consumer Cookware Sales | Affordable, functional cookware attracts budget-conscious shoppers. | Competitive pricing and availability of diverse product ranges. |

| Educational Institutions | Culinary Training Programs | Reliable cookware aids in teaching cooking techniques effectively. | Safety certifications and ease of use for students. |

How is Parini Cookware Beneficial for the Food Service Industry?

In the food service industry, Parini cookware is essential for restaurants and cafes aiming to deliver consistent quality in their meals. The durable construction of Parini products, such as non-stick pans and Dutch ovens, ensures that they can withstand the rigors of daily use. By sourcing Parini cookware, businesses can benefit from reliable performance and cost-effectiveness, which is vital for maintaining profit margins. Bulk purchasing options are crucial, as they allow food service providers to stock up on necessary items while ensuring warranties and service agreements are in place for long-term reliability.

Why is Parini Cookware Ideal for Catering Applications?

Catering companies benefit significantly from the versatility of Parini cookware, which allows for a wide range of cooking methods. Portable cookware solutions enable caterers to prepare and serve meals efficiently at various events. The lightweight materials used in Parini products facilitate easy transport, making it convenient for caterers to set up quickly. Additionally, the ability to create appealing dishes enhances the overall dining experience, which is critical in a competitive catering market. Buyers in this sector should consider the durability and ease of cleaning of the cookware to maintain high hygiene standards.

How Can Hospitality Businesses Enhance Guest Experience with Parini Cookware?

In the hospitality sector, Parini cookware can significantly enhance in-room dining services. Hotels can offer guests the option to prepare meals themselves with high-quality cookware, elevating their overall experience. The aesthetic appeal of Parini products, combined with their functional design, allows hotels to maintain a high standard of service. For international buyers in regions such as Europe and the Middle East, sourcing cookware that meets local culinary expectations is vital. Considerations should include the ease of maintenance and the cookware’s ability to withstand frequent use without compromising on performance.

What Advantages Does Parini Cookware Provide to Retailers?

Retailers focusing on consumer cookware can leverage the affordability and functionality of Parini products to attract budget-conscious shoppers. The diverse range of cookware, from frying pans to casserole dishes, ensures that retailers can cater to various customer needs. Competitive pricing is a key factor for retailers, especially in markets across Africa and South America, where price sensitivity is prevalent. Additionally, having a reliable supply chain and stock availability is crucial to meet consumer demand and capitalize on seasonal sales.

How Does Parini Cookware Support Culinary Education?

Educational institutions offering culinary programs can greatly benefit from Parini cookware. The reliable performance of these products aids instructors in teaching essential cooking techniques to students. Parini cookware’s safety certifications and ease of use make it suitable for a learning environment, ensuring that students can focus on developing their skills without the distraction of complicated equipment. Institutions should prioritize sourcing cookware that is durable and easy to maintain, allowing for consistent use throughout the academic year.

3 Common User Pain Points for ‘parini cookware’ & Their Solutions

Scenario 1: Sourcing Quality Cookware for Diverse Markets

The Problem: B2B buyers often struggle with sourcing cookware that meets varied market demands, especially in regions like Africa and South America where cooking styles and materials differ significantly. Buyers may face challenges in ensuring that the cookware is not only affordable but also of high quality, durable, and suitable for local culinary practices. For instance, a distributor in Nigeria may find it hard to identify cookware that withstands high heat and humidity, while also being budget-friendly for local consumers.

The Solution: To effectively source Parini cookware that aligns with these diverse requirements, buyers should conduct thorough market research to understand local cooking habits and preferences. It is essential to focus on Parini’s range of products that use durable materials like stainless steel and cast iron, which offer excellent heat retention and are resilient in various cooking environments. Additionally, buyers should consider establishing relationships with local retailers who understand the nuances of the market. By choosing versatile items such as the Parini Dutch oven or non-stick pans that are easy to clean and maintain, buyers can cater to a wide array of culinary practices while ensuring customer satisfaction.

Scenario 2: Addressing Concerns About Product Durability and Quality

The Problem: A common concern among B2B buyers is the perceived durability and quality of cookware, especially when importing products from overseas. Retailers in Europe, for instance, might worry that the cookware will not withstand the rigors of daily use, leading to negative customer reviews and returns. This is particularly critical for budget-conscious consumers who expect both affordability and longevity.

The Solution: To alleviate these concerns, B2B buyers should emphasize the quality craftsmanship and materials used in Parini cookware. Highlighting features such as the encapsulated aluminum cores in the stainless steel pots, which ensure even heating and prevent warping, can reassure retailers about the product’s reliability. Buyers should also encourage retailers to offer warranties or guarantees to build consumer trust. Providing detailed product specifications and performance comparisons with competitors can further enhance confidence in the product’s durability. Regular training sessions or workshops for retail staff on the benefits and care of Parini cookware can also help them communicate the quality effectively to end customers.

Scenario 3: Managing Customer Expectations on Non-Stick Performance

The Problem: B2B buyers often encounter challenges in managing customer expectations regarding the performance of non-stick cookware. In regions with a high demand for easy-to-clean options, such as in Middle Eastern countries where oil-based cooking is prevalent, customers may expect non-stick surfaces to perform at a level that is sometimes unattainable if the products are not used correctly.

The Solution: To address this pain point, B2B buyers should proactively educate their customers on the proper use and maintenance of Parini’s non-stick cookware. Creating informative materials that outline best practices, such as using non-metal utensils, avoiding high heat, and hand washing, can significantly extend the life of the cookware and ensure optimal performance. Additionally, providing demonstrations or cooking classes can help customers understand the capabilities of Parini’s non-stick surfaces, thereby setting realistic expectations. By offering a comprehensive customer service approach that includes follow-up support and tips, buyers can enhance customer satisfaction and loyalty while reducing the risk of complaints or returns.

Strategic Material Selection Guide for parini cookware

What Are the Key Properties of Aluminum in Parini Cookware?

Aluminum is a widely used material in Parini cookware due to its excellent thermal conductivity, lightweight nature, and affordability. It can withstand temperatures up to 500°F (260°C), making it suitable for various cooking methods, including frying and sautéing. Additionally, aluminum cookware is often anodized to enhance its corrosion resistance, providing a longer lifespan.

Pros and Cons of Aluminum Cookware

The primary advantage of aluminum cookware is its lightweight design, which makes it easy to handle, especially for commercial kitchens where efficiency is key. It heats up quickly and evenly, reducing cooking times and energy consumption. However, aluminum is prone to warping under high heat and can react with acidic foods, potentially affecting flavor. The manufacturing process is relatively straightforward, but care must be taken to ensure quality control to prevent defects.

Impact on Application and Considerations for International Buyers

For international B2B buyers, especially from regions like Africa and South America, it is essential to consider local cooking preferences and food safety standards. Aluminum cookware must comply with regulations such as the EU’s REACH or FDA guidelines in the U.S. Buyers should also ensure that the cookware is anodized to prevent leaching and maintain food safety.

How Does Stainless Steel Perform in Parini Cookware?

Stainless steel is another key material used in Parini cookware, known for its durability and resistance to corrosion and staining. It can withstand high temperatures and is compatible with all cooking surfaces, including induction. Stainless steel cookware typically has a temperature rating of up to 600°F (315°C), making it versatile for various cooking techniques.

Pros and Cons of Stainless Steel Cookware

The advantages of stainless steel cookware include its longevity, ease of maintenance, and non-reactive nature, making it ideal for cooking acidic dishes. However, stainless steel can be more expensive than aluminum and may require a thicker base to ensure even heat distribution. The manufacturing process can be more complex, involving multiple layers for optimal performance.

Impact on Application and Considerations for International Buyers

B2B buyers from Europe, particularly Germany, will appreciate the high-quality standards associated with stainless steel cookware. Compliance with DIN standards ensures that the products meet rigorous safety and performance criteria. Buyers in the Middle East should also consider the cookware’s compatibility with local cooking methods and preferences.

What Role Does Cast Iron Play in Parini Cookware?

Cast iron is celebrated for its exceptional heat retention and even heat distribution, making it perfect for slow cooking and baking. Parini’s cast iron cookware is typically enameled, allowing for easy cleaning and preventing rust. It can withstand temperatures of up to 500°F (260°C) and is ideal for both stovetop and oven use.

Pros and Cons of Cast Iron Cookware

The key advantage of cast iron cookware is its durability; with proper care, it can last a lifetime. It also enhances the flavor of dishes over time, as it develops a natural non-stick surface. However, cast iron is heavy and requires more maintenance than other materials, such as seasoning to prevent rust. The manufacturing process is more labor-intensive, which can increase costs.

Impact on Application and Considerations for International Buyers

For buyers in regions like Africa, where traditional cooking methods are prevalent, cast iron cookware aligns with cultural practices. However, buyers should be aware of the need for proper seasoning and maintenance. Compliance with local regulations regarding food safety and material quality is also crucial.

What Are the Benefits of Non-Stick Coatings in Parini Cookware?

Non-stick coatings, often made from materials like Teflon or ceramic, are designed to provide a smooth cooking surface that minimizes the need for oil. This type of cookware is particularly popular for frying and sautéing, as it allows for easy food release and cleanup. Non-stick cookware typically has a temperature rating of around 500°F (260°C).

Pros and Cons of Non-Stick Cookware

The main advantage of non-stick cookware is its ease of use and cleaning, making it ideal for busy kitchens. However, the coatings can wear off over time, especially if not cared for properly. Non-stick cookware is generally less durable than stainless steel or cast iron and may not be suitable for high-heat cooking methods.

Impact on Application and Considerations for International Buyers

International buyers should consider the safety of non-stick coatings, ensuring that they meet global standards such as those set by the FDA or the EU. Additionally, cultural preferences for cooking methods may influence the demand for non-stick cookware in various regions.

Summary Table of Material Selection for Parini Cookware

| Material | Typical Use Case for parini cookware | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Frying pans, sauté pans | Lightweight and quick heating | Prone to warping and reactivity | Low |

| Stainless Steel | Sauce pans, stock pots | Durable and non-reactive | Higher cost and complex mfg | Med |

| Cast Iron | Dutch ovens, skillets | Excellent heat retention | Heavy and requires maintenance | High |

| Non-Stick | Frying pans, omelet pans | Easy to clean and use | Limited durability of coating | Med |

In-depth Look: Manufacturing Processes and Quality Assurance for parini cookware

What Are the Main Stages of Manufacturing Parini Cookware?

The manufacturing process of Parini cookware is a well-structured operation that ensures the production of high-quality kitchen essentials. This process can be divided into four main stages: material preparation, forming, assembly, and finishing.

Material Preparation: How Are Raw Materials Selected and Processed?

The first stage involves the selection of high-quality raw materials, primarily aluminum, stainless steel, and cast iron. These materials are sourced from reliable suppliers who adhere to international quality standards. Once sourced, the materials undergo rigorous inspections to confirm their integrity and suitability for cookware manufacturing.

After inspection, the materials are processed. For instance, aluminum sheets are cut into specific sizes for various cookware products, while stainless steel is rolled and tempered to enhance its durability. This meticulous preparation is crucial as it lays the foundation for the performance and longevity of the cookware.

Forming: What Techniques Are Used to Shape Cookware?

In the forming stage, advanced techniques such as stamping, die-casting, and forging are employed to shape the cookware. For example, the aluminum is stamped into flat shapes that will later be molded into pans or pots. Cast iron products are typically made using a die-casting process, where molten metal is poured into molds to create specific shapes.

The forming process is designed to ensure uniformity in the thickness and shape of each product, which is essential for even cooking. This stage is also where features such as riveted handles and encapsulated aluminum cores are integrated into the cookware, enhancing usability and performance.

Assembly: How Is Cookware Brought Together?

Once the individual components are formed, they move to the assembly stage. This involves joining various parts, such as attaching handles to pots or lids to Dutch ovens. The assembly process is carried out using high-precision machinery as well as skilled labor to ensure that each piece fits perfectly and functions as intended.

Quality checks are integrated into the assembly line, where every unit is inspected for any defects or inconsistencies. This proactive approach helps to minimize errors before the products move to the next stage.

Finishing: What Are the Final Steps in Producing Parini Cookware?

The finishing stage involves several processes, including polishing, coating, and packaging. For non-stick cookware, a specialized coating is applied to ensure ease of use and cleaning. Stainless steel products may undergo a brushing process to create a fingerprint-resistant surface.

Each piece is then subjected to final inspections to ensure it meets Parini’s quality standards. Products that pass these checks are packaged for distribution, while any that do not meet the standards are reworked or discarded.

How Is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance is a critical aspect of Parini cookware’s manufacturing process. The company adheres to international standards such as ISO 9001, which establishes a framework for quality management systems. This commitment to quality is reflected at every stage of production.

What Are the Key Quality Control Checkpoints?

Several quality control checkpoints are strategically placed throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet predetermined quality criteria.

-

In-Process Quality Control (IPQC): During the forming and assembly stages, IPQC checks monitor the production process to detect any deviations from quality standards in real-time.

-

Final Quality Control (FQC): After finishing, FQC involves comprehensive inspections of the final products, ensuring they are free from defects and meet all functional requirements.

Which Testing Methods Are Commonly Used for Parini Cookware?

Parini employs a range of testing methods to ensure the safety and performance of its cookware. These include:

- Heat Distribution Tests: Ensuring even heating across the surface.

- Non-Stick Performance Tests: Evaluating the durability of non-stick coatings.

- Durability Testing: Subjecting products to extreme conditions to assess their longevity.

- Food Safety Testing: Ensuring that materials used are safe for food contact and free from harmful substances.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to source Parini cookware should consider several methods to verify the quality control processes of their suppliers:

-

Supplier Audits: Conducting regular audits of suppliers can provide insights into their manufacturing practices and adherence to quality standards.

-

Quality Assurance Reports: Requesting detailed reports on quality control measures, testing results, and certifications can help buyers assess supplier reliability.

-

Third-Party Inspections: Engaging third-party inspection services can offer an impartial evaluation of the cookware’s quality, ensuring it meets the buyer’s requirements.

What Quality Control and Certification Nuances Should International Buyers Be Aware Of?

For international B2B buyers, especially from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial. Different markets may have varying regulations regarding cookware safety and materials.

-

CE Certification: In Europe, CE marking signifies compliance with health, safety, and environmental protection standards. Buyers should ensure that the cookware meets these standards.

-

Food Safety Standards: Buyers in regions like Africa and South America should verify that cookware complies with local food safety regulations, which may differ from international standards.

By understanding these factors, B2B buyers can ensure they are sourcing high-quality cookware that meets their regional standards and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘parini cookware’

To assist B2B buyers in successfully procuring Parini cookware, this practical sourcing guide outlines essential steps to ensure a strategic and informed purchasing decision. The following checklist is designed to help you navigate the procurement process effectively, ensuring that you select the right products and suppliers for your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial in aligning your purchase with your operational needs. Consider the types of cookware you require, such as non-stick pans, Dutch ovens, or casserole dishes, and determine the materials (e.g., stainless steel, cast iron) that best suit your cooking methods. This clarity will streamline the sourcing process and help avoid mismatched products.

Step 2: Conduct Market Research

Thorough market research allows you to understand the competitive landscape and identify potential suppliers of Parini cookware. Review industry reports, customer reviews, and product comparisons to gauge the quality and pricing of available options. This step is vital for identifying reputable suppliers who can meet your quality and budget requirements.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to vet them thoroughly. Request company profiles, product catalogs, and references from other buyers in your region or industry. Pay attention to their track record in terms of product quality, delivery times, and customer service, as these factors will impact your overall satisfaction and operational efficiency.

- Check Supplier Certifications: Ensure that the supplier complies with international quality standards and has relevant certifications (e.g., ISO, CE) to guarantee product safety and reliability.

Step 4: Request Samples for Testing

Obtaining samples of Parini cookware is a critical step in the evaluation process. Testing the cookware in your kitchen will help you assess its performance, durability, and ease of use. Look for aspects such as heat distribution, non-stick capabilities, and overall design to ensure that the products meet your operational needs.

Step 5: Negotiate Terms and Conditions

Once you’ve selected a supplier, engaging in negotiations is essential to secure favorable terms. Discuss pricing, payment options, lead times, and return policies to ensure that both parties are aligned. A transparent negotiation process will help establish a strong working relationship and prevent future misunderstandings.

Step 6: Place Your Order Wisely

When placing your order, ensure that it aligns with your inventory management strategy. Consider factors such as lead time, demand forecasting, and storage capabilities. It’s advisable to order in bulk if feasible, as this can lead to cost savings and ensure you have sufficient stock to meet customer demand.

Step 7: Monitor Delivery and Quality Control

After placing your order, closely monitor the delivery process to ensure that the products arrive on time and in good condition. Upon receipt, conduct a thorough quality inspection to verify that the cookware meets the specified standards. Document any discrepancies or issues to address with the supplier promptly.

By following this structured checklist, B2B buyers can navigate the sourcing process for Parini cookware more effectively, ensuring they procure high-quality products that meet their culinary needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for parini cookware Sourcing

What Are the Key Cost Components for Sourcing Parini Cookware?

When sourcing Parini cookware, understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and margin.

-

Materials: Parini cookware is crafted from high-quality materials such as stainless steel, aluminum, and cast iron. The choice of material significantly impacts the cost, as premium materials enhance durability and cooking performance. Buyers should assess the material specifications to align with their market expectations.

-

Labor: Labor costs can vary significantly based on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but it’s essential to consider the skill level and craftsmanship associated with the production of cookware.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and facility management. Efficient manufacturing processes can reduce overhead, which may be reflected in the pricing offered to B2B buyers.

-

Tooling: Initial setup costs for molds and production lines can be substantial. Customization or specific design requests may require additional tooling expenses, which should be factored into the total cost.

-

Quality Control (QC): Ensuring that each piece of cookware meets quality standards is crucial for maintaining brand reputation. Investment in QC processes can add to the overall cost but is vital for long-term customer satisfaction.

-

Logistics: Shipping and handling costs can vary based on the destination and Incoterms used. Understanding these logistics will help buyers calculate the total landed cost of the products.

-

Margin: Suppliers typically include a margin that reflects their business model, market conditions, and competition. Understanding the expected margins can help buyers negotiate better pricing.

How Do Pricing Influencers Affect Parini Cookware Costs?

Several factors can influence the pricing of Parini cookware, making it essential for B2B buyers to evaluate these aspects when sourcing.

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs. Buyers should negotiate MOQs that align with their sales forecasts to maximize cost efficiency.

-

Specifications and Customization: Custom designs or specific features may lead to increased costs. Buyers should carefully consider whether these enhancements are necessary for their target market.

-

Quality and Certifications: Products that meet specific quality certifications (e.g., FDA, NSF) may command higher prices due to the costs associated with compliance. Buyers should weigh the benefits of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of suppliers can also affect pricing. Established suppliers with a track record of quality may charge more, but this can lead to fewer returns and higher customer satisfaction.

-

Incoterms: The choice of Incoterms affects shipping costs and responsibilities. Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers manage logistics costs effectively.

What Are the Best Buyer Tips for Negotiating Prices on Parini Cookware?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant cost savings.

-

Negotiate Bulk Discounts: Leverage larger order volumes to negotiate better pricing. Suppliers are often willing to offer discounts for bulk purchases, which can significantly reduce the overall cost per unit.

-

Evaluate Total Cost of Ownership (TCO): Beyond the initial purchase price, consider factors like durability, maintenance, and potential replacement costs. Investing in higher-quality cookware may yield savings in the long run.

-

Understand Pricing Nuances: Be aware of regional pricing variations. For instance, European markets may have different pricing structures compared to African or South American markets due to economic conditions and demand.

-

Build Long-Term Relationships: Establishing a good rapport with suppliers can lead to better pricing and terms over time. Consistent communication and collaboration can result in more favorable negotiations.

-

Request Samples: Before committing to large orders, request samples to assess quality firsthand. This can help mitigate risks and ensure that the products meet your standards.

Disclaimer on Indicative Prices

Pricing for Parini cookware can vary widely based on the factors discussed above. It is advisable for buyers to conduct thorough market research and request quotes from multiple suppliers to obtain the most accurate pricing information tailored to their specific needs and locations.

Alternatives Analysis: Comparing parini cookware With Other Solutions

Introduction to Alternative Cookware Solutions

When considering cookware options for a commercial kitchen or a food service operation, B2B buyers are often faced with a variety of choices. Selecting the right cookware can significantly impact cooking efficiency, food quality, and overall operational costs. This analysis compares Parini cookware with two viable alternatives: Teflon-coated cookware and cast iron cookware. Each option presents unique advantages and disadvantages that can influence purchasing decisions.

| Comparison Aspect | Parini Cookware | Teflon-Coated Cookware | Cast Iron Cookware |

|---|---|---|---|

| Performance | Excellent heat distribution and durability; good for everyday use. | Superior non-stick properties; ideal for low-fat cooking. | Exceptional heat retention; perfect for slow cooking and searing. |

| Cost | Affordable, budget-friendly options suitable for various buyers. | Mid-range pricing; can vary based on brand and quality. | Generally higher initial investment; long-lasting. |

| Ease of Implementation | User-friendly and versatile for different cooking methods. | Lightweight and easy to handle; quick to heat up. | Requires more skill and knowledge to maintain properly. |

| Maintenance | Dishwasher safe; requires hand washing for longevity. | Simple to clean but can scratch easily; non-metal utensils recommended. | Requires seasoning and careful cleaning to prevent rust. |

| Best Use Case | Ideal for budget-conscious kitchens needing reliable cookware. | Best for quick, low-fat cooking with minimal cleanup. | Excellent for traditional cooking methods, especially in high-heat applications. |

Detailed Breakdown of Alternatives

Teflon-Coated Cookware

Teflon-coated cookware is celebrated for its non-stick properties, making it easy to prepare meals with minimal oil, which is a significant advantage for health-conscious kitchens. It heats quickly, allowing for efficient cooking. However, Teflon pans can be prone to scratching if metal utensils are used, which may affect their longevity. Additionally, they can be less durable than Parini cookware, especially under high heat. For operations focused on quick, simple meal preparations, Teflon is a strong contender.

Cast Iron Cookware

Cast iron cookware is renowned for its durability and heat retention, making it an excellent choice for slow cooking, braising, and baking. It offers a unique ability to retain and evenly distribute heat, resulting in superior cooking outcomes. The initial cost is generally higher than Parini cookware, and it requires specific maintenance practices, such as seasoning to prevent rust. This cookware is ideal for kitchens that prioritize traditional cooking methods and are willing to invest in long-lasting tools.

Conclusion: How to Choose the Right Cookware Solution

When selecting cookware for a B2B environment, it is crucial to consider the specific needs of the kitchen and the types of dishes being prepared. Parini cookware offers a balanced approach, providing affordability and functionality, making it suitable for budget-conscious operations. Teflon-coated cookware excels in ease of use and cleanup, while cast iron cookware is unmatched in heat retention and cooking versatility. By evaluating performance, cost, ease of implementation, and maintenance requirements, buyers can make informed decisions that align with their culinary goals and operational budgets.

Essential Technical Properties and Trade Terminology for parini cookware

What Are the Key Technical Properties of Parini Cookware?

Understanding the technical properties of Parini cookware is essential for international B2B buyers to make informed purchasing decisions. Here are some critical specifications:

1. Material Composition

Parini cookware is primarily made from high-quality materials such as stainless steel, aluminum, and cast iron. Stainless steel provides durability and resistance to rust and corrosion, while aluminum ensures even heat distribution. Cast iron is renowned for its heat retention and versatility, making it ideal for a variety of cooking methods. This material diversity allows buyers to choose products that best fit their market demands and customer preferences.

2. Non-Stick Surface Quality

Many Parini products feature a non-stick coating that enhances cooking performance and simplifies cleanup. The quality of this coating can significantly impact the longevity of the cookware and customer satisfaction. Understanding the type of non-stick technology used (e.g., PFOA-free) is crucial for buyers, particularly those catering to health-conscious consumers.

3. Thermal Conductivity

The thermal conductivity of cookware is vital for efficient cooking. Parini’s products often incorporate encapsulated aluminum cores within stainless steel exteriors, providing rapid and even heating. This property not only improves cooking efficiency but also helps in energy conservation—a key selling point in many international markets.

4. Weight and Handle Design

The weight of cookware affects usability and control during cooking. Parini cookware is designed to balance durability with user comfort, featuring riveted handles that provide a secure grip. Buyers should consider ergonomic design as a selling point, especially for markets where ease of use is a significant factor.

5. Durability and Longevity

Durability is a critical factor in cookware selection. Parini products are engineered to withstand high temperatures and rigorous use, ensuring they maintain their performance over time. For B2B buyers, emphasizing longevity can differentiate their offerings in competitive markets.

6. Dishwasher and Oven Safety

Many Parini cookware items are dishwasher safe and oven-safe up to specific temperatures. Understanding these specifications is essential for buyers who need to communicate care instructions and usability to their customers.

What Are Common Trade Terms Used in the Cookware Industry?

Knowledge of industry jargon is vital for effective communication and negotiation in B2B transactions. Here are some common terms related to Parini cookware:

1. OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or products that are marketed by another company under its own brand name. For buyers, understanding OEM relationships can help them identify potential suppliers and negotiate better terms.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. This is crucial for buyers to understand, as it affects inventory management and cash flow. Knowing the MOQ for Parini products can help buyers plan their purchasing strategies effectively.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for specific products. For B2B buyers, utilizing RFQs can streamline the procurement process and ensure competitive pricing for Parini cookware.

4. Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, risk management, and costs associated with the delivery of Parini products.

5. Lead Time

Lead time refers to the period between placing an order and receiving it. This is a critical metric for B2B buyers as it affects inventory levels and supply chain efficiency. Understanding lead times for Parini cookware can help businesses manage their stock effectively.

6. Certification Standards

Various certification standards (e.g., FDA, LFGB) indicate the safety and quality of cookware. Buyers should be aware of these certifications when sourcing Parini products to ensure compliance with local regulations and consumer expectations.

By understanding these technical properties and trade terms, B2B buyers can enhance their purchasing strategies and effectively communicate the value of Parini cookware to their customers.

Navigating Market Dynamics and Sourcing Trends in the parini cookware Sector

What Are the Key Market Trends Affecting the Parini Cookware Sector?

The global cookware market is witnessing significant growth driven by several factors, particularly in regions such as Africa, South America, the Middle East, and Europe. One of the primary drivers is the increasing demand for affordable yet high-quality cookware among budget-conscious consumers. Parini Cookware, with its reputation for quality and functionality at competitive prices, is well-positioned to meet this demand.

Emerging trends include the rise of e-commerce, which is reshaping how B2B buyers source cookware. Online platforms enable international buyers to access a wide range of products, compare prices, and read customer reviews, facilitating informed purchasing decisions. Additionally, there’s a growing emphasis on innovative cookware solutions that enhance cooking efficiency, such as non-stick surfaces and durable materials like stainless steel and cast iron.

Market dynamics are also influenced by the shift towards healthier cooking options, which drives demand for non-toxic, easy-to-clean cookware. Buyers from diverse regions are increasingly looking for products that promote healthy eating habits while ensuring ease of use. This trend is particularly evident in markets like Nigeria and Germany, where culinary practices vary but the need for reliable kitchen tools remains consistent.

How Is Sustainability and Ethical Sourcing Impacting B2B Decisions in Cookware?

Sustainability has become a cornerstone of purchasing decisions in the cookware industry. B2B buyers are increasingly prioritizing products that minimize environmental impact, leading to a demand for cookware made from sustainable materials. Parini Cookware’s commitment to using high-quality aluminum, stainless steel, and cast iron aligns with this trend, as these materials are not only durable but also recyclable.

Ethical sourcing practices are gaining traction, with businesses seeking suppliers who adhere to fair labor practices and responsible manufacturing processes. This is especially important in regions like South America and Africa, where there is heightened awareness of social and environmental issues. Certifications such as ISO 14001 for environmental management and Fair Trade can enhance brand credibility and appeal to socially conscious buyers.

Furthermore, the incorporation of ‘green’ materials, such as non-toxic coatings and eco-friendly packaging, is becoming a key differentiator in the market. Parini’s focus on creating products that are safe for both consumers and the environment positions the brand favorably amidst rising consumer expectations for sustainability.

What Is the Brief Evolution of Parini Cookware in the B2B Context?

Parini Cookware has evolved significantly since its inception, adapting to the changing needs of consumers and the market. Initially focused on providing basic cookware options, the brand has expanded its product line to include a diverse range of items that cater to both novice and experienced cooks. The introduction of innovative designs, such as the dual-wall construction of pizza cookers and the heat-retaining properties of Dutch ovens, demonstrates Parini’s commitment to quality and functionality.

As the market has evolved, so too has Parini’s approach to sourcing and production. The brand has embraced sustainable practices and ethical sourcing, ensuring that its products not only meet the demands of modern consumers but also align with global sustainability goals. This evolution has positioned Parini as a reliable partner for international B2B buyers seeking quality cookware solutions that meet both performance and ethical standards.

In conclusion, the Parini Cookware sector is navigating a landscape marked by increasing demand for quality, sustainability, and ethical practices. B2B buyers can leverage these trends to make informed sourcing decisions that align with their business values and consumer expectations.

Frequently Asked Questions (FAQs) for B2B Buyers of parini cookware

-

How do I ensure the quality of Parini cookware before purchasing?

To verify the quality of Parini cookware, request product samples to assess material integrity and craftsmanship. Conduct thorough inspections for durability, heat distribution, and non-stick properties. Additionally, review certifications and compliance with international standards, such as FDA or CE marking, to ensure safety and reliability. Engaging with existing customers and reading reviews can provide further insights into the performance of the cookware in real-world settings. -

What are the minimum order quantities (MOQs) for Parini cookware?

Minimum order quantities for Parini cookware can vary based on product type and supplier agreements. Generally, MOQs range from 50 to 200 units per item, depending on the specific cookware line. It’s advisable to communicate directly with your supplier to negotiate MOQs that align with your purchasing capabilities and inventory strategy, especially if you aim to stock a diverse range of products. -

What payment terms are typically offered for international orders of Parini cookware?

Payment terms for international orders of Parini cookware often include options such as advance payment, letter of credit, or net 30/60 days after delivery. These terms can vary based on the supplier’s policies and your business relationship. Ensure to discuss payment options upfront and confirm any additional costs related to shipping, tariffs, or currency exchange to avoid unexpected expenses. -

How can I customize Parini cookware for my market?

Customization options for Parini cookware may include branding, color variations, and packaging designs tailored to your market’s preferences. To initiate the customization process, discuss your requirements with the supplier during negotiations. Keep in mind that customization might impact MOQs and lead times, so plan accordingly to ensure your needs are met without compromising delivery schedules. -

What logistics considerations should I be aware of when importing Parini cookware?

When importing Parini cookware, consider logistics factors such as shipping methods, customs clearance, and potential duties or tariffs. It’s crucial to collaborate with a reliable freight forwarder familiar with international trade regulations to facilitate smooth transportation. Additionally, ensure that the supplier provides accurate shipping documentation to prevent delays at customs and ensure compliance with local import laws. -

What quality assurance processes are in place for Parini cookware?

Parini cookware undergoes rigorous quality assurance processes that include material inspections, performance testing, and compliance checks with industry standards. Suppliers should provide documentation of these QA processes, including any certifications obtained. Regular audits and inspections throughout the manufacturing process help maintain consistent quality and address any potential issues before products reach the market. -

What types of Parini cookware products are available for wholesale purchase?

Parini offers a wide range of cookware products suitable for wholesale purchase, including non-stick pans, casserole dishes, Dutch ovens, and specialty items like pizza cookers. Each product line is designed with durability and functionality in mind, making them appealing for both retail and commercial kitchens. Review the supplier’s catalog to identify the specific products that align with your target market and customer preferences. -

How can I assess the reliability of a Parini cookware supplier?

To assess the reliability of a Parini cookware supplier, conduct thorough research into their business history, customer reviews, and industry reputation. Request references from other B2B buyers who have previously worked with them. Additionally, evaluate their responsiveness, willingness to share information, and transparency in pricing and terms. Engaging in a trial order can also help gauge their reliability and product quality before committing to larger purchases.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 4 Parini Cookware Manufacturers & Suppliers List

1. Parini – Dutch Oven & Pizza Cooker

Domain: theparini.com

Registered: 2024 (1 years)

Introduction: Parini Cookware Products: 1. Parini Dutch Oven: Thick cast iron construction, enameled surface, evenly distributes heat, retains moisture for tender stews, braises, and bread. 2. Parini Pizza Cooker: Double-walled stainless steel interior, nonstick surface, mimics professional pizza oven heat for charred and crisp crusts. 3. Parini Cast Iron Skillet: Seasoned for natural nonstick, thick for heat r…

2. PARINI – 4 Quart Stainless Dutch Oven

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: PARINI Other Cookware includes various items such as a 4 Quart Stainless Dutch Oven with Tempered Glass Lid priced at $15.00, Non-Stick Ceramic for Grill Black Casserole Pan, and a Bundt Cake Pan. Related searches include Parini Stainless Cookware, Parini Cookware Set, Parini Cookware Cast Iron, and Parini Bakeware. Categories include Casserole Pans, Frying & Grill Pans, Pan Sets, Saucepans & Stoc…

3. Parini – Cookware

Domain: macys.com

Registered: 1994 (31 years)

Introduction: This company, Parini – Cookware, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Parini Cookware – Ceramic Non Stick Coated Cookware

Domain: replacements.com

Registered: 1996 (29 years)

Introduction: Parini Cookware, Ceramic Cookware | Replacements, Ltd. Item#: 575888 Pattern Code: PA2CEC Description: Ceramic Non Stick Coated Cookware Pattern: Ceramic Cookware by Parini Cookware Status: Discontinued. Available items include: 1 Qt Round Covered Casserole (8 3/4 in, GREEN FADE) – $69.95, 2 Qt Round Covered Casserole (9 3/4 in) – $79.95, 1.5 Quart Round Covered Baker (10 in, GREEN FADE) – $59.99….

Strategic Sourcing Conclusion and Outlook for parini cookware

In closing, the strategic sourcing of Parini cookware offers international B2B buyers an exceptional opportunity to enhance their culinary product offerings. Parini’s commitment to quality craftsmanship, combined with their affordable pricing, ensures that businesses can meet diverse customer needs without compromising on performance. The range of cookware designed for everyday use—crafted from durable materials like stainless steel and cast iron—enables buyers to cater to both budget-conscious consumers and culinary enthusiasts alike.

As markets in Africa, South America, the Middle East, and Europe continue to evolve, the demand for reliable and versatile kitchen solutions will grow. Leveraging strategic sourcing partnerships with Parini can provide businesses with a competitive edge, allowing them to offer high-quality products that resonate with their target markets.

Now is the time to explore the potential of Parini cookware in your portfolio. By investing in quality, you position your business for success in a dynamic market landscape. Connect with Parini today to discover how their innovative cookware can enrich your product offerings and satisfy your customers’ culinary aspirations.