How to Source Paper Air Filter Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for paper air filter

Navigating the complexities of sourcing paper air filters can be a daunting challenge for B2B buyers across diverse global markets. The demand for high-performance filtration solutions is rising, driven by industries ranging from automotive to manufacturing, where air quality directly impacts operational efficiency and product quality. This comprehensive guide is designed to equip international buyers from regions such as Africa, South America, the Middle East, and Europe—specifically countries like Saudi Arabia and Germany—with the knowledge necessary to make informed purchasing decisions.

Within these pages, you will find an in-depth exploration of various types of paper air filters, their applications in different sectors, and essential criteria for supplier vetting. We will discuss factors influencing costs, performance metrics, and the significance of compliance with regional regulations. This guide empowers you to navigate supplier landscapes effectively, ensuring that you select filters that not only meet quality standards but also align with your operational needs and budget constraints.

By leveraging the insights and actionable strategies outlined here, B2B buyers can enhance their procurement processes, leading to improved air quality management and ultimately driving business success. Whether you’re looking to optimize your supply chain or enhance your product offerings, this guide serves as a vital resource in the journey toward sourcing superior paper air filters.

Understanding paper air filter Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Paper Filter | Basic filtration, typically dry, made from cellulose fibers | Automotive, industrial machinery | Pros: Cost-effective, easy to replace. Cons: Limited filtration efficiency compared to advanced options. |

| High-Performance Filter | Enhanced airflow and filtration efficiency, often pleated design | Racing, high-performance engines | Pros: Improved engine performance, better filtration. Cons: Higher cost, may require more frequent replacement. |

| Oiled Paper Filter | Pre-treated with oil to capture finer particles | Off-road vehicles, heavy machinery | Pros: Superior filtration, reusable with cleaning. Cons: Requires oil maintenance, more complex installation. |

| Washable Paper Filter | Designed for cleaning and reuse, often with a protective layer | Commercial vehicles, fleet operations | Pros: Long-term cost savings, eco-friendly. Cons: Higher upfront cost, requires maintenance and cleaning. |

| Specialty Air Filter | Tailored for specific applications (e.g., dust, moisture) | Agriculture, construction equipment | Pros: Customized performance, targeted filtration. Cons: May have limited availability, higher price point. |

What Are the Characteristics of Standard Paper Filters?

Standard paper filters are the most common type used across various industries. They are typically made from cellulose fibers, offering basic filtration capabilities. These filters are primarily utilized in automotive applications and industrial machinery where cost-effective solutions are needed. While they are easy to replace and affordable, their limited efficiency in capturing fine particles can be a drawback for businesses seeking higher performance.

How Do High-Performance Filters Enhance Engine Efficiency?

High-performance paper filters are designed with a pleated structure that maximizes airflow while improving filtration efficiency. These filters are ideal for racing and high-performance engines, where optimal air intake is crucial. While they provide significant advantages in engine performance and filtration, they come at a higher price point and may require more frequent replacements, making them suitable for businesses focused on performance over cost.

Why Choose Oiled Paper Filters for Heavy-Duty Applications?

Oiled paper filters are pre-treated to enhance their ability to capture fine particles, making them particularly effective in off-road vehicles and heavy machinery. They offer superior filtration and can be reused after cleaning, thus providing long-term value. However, these filters necessitate regular maintenance and oil application, which can complicate installation and management for some businesses.

What Are the Benefits of Washable Paper Filters?

Washable paper filters are designed for repeated use, making them an eco-friendly choice for commercial vehicles and fleet operations. Their initial higher cost is offset by the potential for long-term savings, as they can be cleaned and reused multiple times. However, they require diligent maintenance and cleaning processes, which may not suit all operational environments.

How Do Specialty Air Filters Address Specific Needs?

Specialty air filters are engineered for specific conditions such as dust, moisture, or chemical exposure, making them invaluable in agriculture and construction. Their tailored designs ensure optimal performance in challenging environments, but they can be more expensive and less readily available than standard options. Businesses should evaluate their specific needs and operational environments to determine if the investment in specialty filters is justified.

Key Industrial Applications of paper air filter

| Industry/Sector | Specific Application of Paper Air Filter | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Engine air intake systems | Enhances engine performance and fuel efficiency | Ensure compatibility with vehicle models, filter dimensions, and airflow rates. |

| Industrial Machinery | Dust collection systems | Protects machinery from contaminants, reducing maintenance costs | Evaluate filter efficiency ratings and material durability for specific environments. |

| HVAC Systems | Air purification in buildings | Improves indoor air quality and compliance with health standards | Consider MERV ratings and filter lifespan to optimize replacement schedules. |

| Agriculture | Equipment air filtration | Minimizes dust and pollen exposure in farming equipment | Assess filter size and resistance to agricultural dust types. |

| Marine Applications | Engine and cabin air filtration | Protects engines from salt and moisture damage | Focus on corrosion resistance and marine-grade certifications. |

How is Paper Air Filter Used in the Automotive Sector?

In the automotive industry, paper air filters are crucial for engine air intake systems. They enhance engine performance by ensuring clean air enters the combustion chamber, which is vital for fuel efficiency and power output. International buyers, particularly from regions like Africa and South America, should consider compatibility with specific vehicle models and dimensions. Additionally, understanding the airflow rates is essential to ensure optimal engine performance and longevity.

What Role Does Paper Air Filter Play in Industrial Machinery?

In industrial machinery, paper air filters are employed in dust collection systems to protect equipment from harmful contaminants. This application is especially critical in sectors like mining and manufacturing, where dust can cause significant wear and tear on machinery, leading to costly downtime. B2B buyers should evaluate filter efficiency ratings and the durability of materials used, as these factors directly impact maintenance costs and operational efficiency.

Why are Paper Air Filters Important for HVAC Systems?

Paper air filters are integral to HVAC systems, as they purify indoor air by trapping pollutants and allergens. This application is essential for maintaining health standards in commercial buildings and ensuring occupant comfort. Buyers from Europe and the Middle East should focus on MERV (Minimum Efficiency Reporting Value) ratings to determine filter effectiveness and consider the lifespan of filters to optimize replacement schedules and reduce operational costs.

How Do Paper Air Filters Benefit Agriculture?

In agriculture, paper air filters are used in equipment air filtration systems to minimize dust and pollen exposure, which can impede the performance of farming machinery. This application is vital for ensuring the longevity of equipment and reducing maintenance needs. Buyers should assess the specific filter sizes required and the resistance of filters to various agricultural dust types, ensuring they meet the demands of the farming environment.

What is the Significance of Paper Air Filters in Marine Applications?

Marine applications utilize paper air filters to protect both engine and cabin air systems from the corrosive effects of saltwater and moisture. This is particularly important for maintaining engine performance and ensuring a healthy cabin environment. Buyers in this sector should prioritize filters that offer corrosion resistance and check for marine-grade certifications to ensure they meet the unique challenges posed by marine environments.

3 Common User Pain Points for ‘paper air filter’ & Their Solutions

Scenario 1: Difficulty Maintaining Optimal Airflow in Harsh Environments

The Problem: B2B buyers often struggle with ensuring optimal airflow through paper air filters in environments filled with dust, sand, or industrial pollutants. This challenge is particularly pronounced in regions like the Middle East or parts of Africa, where harsh climatic conditions can lead to rapid clogging of filters. When filters become clogged, the performance of machinery can decline, leading to increased operational costs and potential equipment damage. Buyers may also face uncertainty about the best filter specifications to withstand such conditions.

The Solution: To combat this issue, it’s essential to source high-performance paper air filters specifically designed for harsh environments. Buyers should consider filters with advanced media that enhance dust holding capacity and airflow. Additionally, implementing a regular maintenance schedule that includes frequent inspection and replacement of filters can prolong the life of equipment. Working with suppliers who offer detailed product specifications and performance data can further assist buyers in making informed decisions. Finally, training maintenance personnel on how to properly assess filter condition and airflow can ensure timely replacements, ultimately reducing downtime and operational costs.

Scenario 2: Inconsistent Quality Leading to Downtime

The Problem: Many B2B buyers face the issue of inconsistent quality in paper air filters, which can lead to equipment failure and unexpected downtime. This is particularly critical for businesses in manufacturing or logistics, where any interruption can cause significant financial losses. Inconsistent filters may not provide adequate filtration or airflow, leading to engine strain and premature wear. Buyers often find it challenging to identify reliable suppliers who consistently deliver high-quality products.

The Solution: To mitigate the risk of quality inconsistency, buyers should prioritize sourcing filters from established manufacturers with a proven track record. Requesting certifications, such as ISO or SAE, can help verify the quality of the products. Additionally, implementing a quality assurance process that includes receiving inspections and performance testing can catch potential issues before filters are used. Establishing long-term relationships with suppliers who provide reliable support and transparent product information can also enhance trust and ensure consistent quality over time.

Scenario 3: Challenges with Sizing and Compatibility

The Problem: Sizing and compatibility issues are common pain points for B2B buyers when it comes to paper air filters. Many organizations may struggle to find filters that fit their specific equipment or applications, leading to delays and increased costs. Incorrectly sized filters can lead to improper sealing, reduced efficiency, and increased risk of contamination. This problem is exacerbated by the variety of equipment types across different industries.

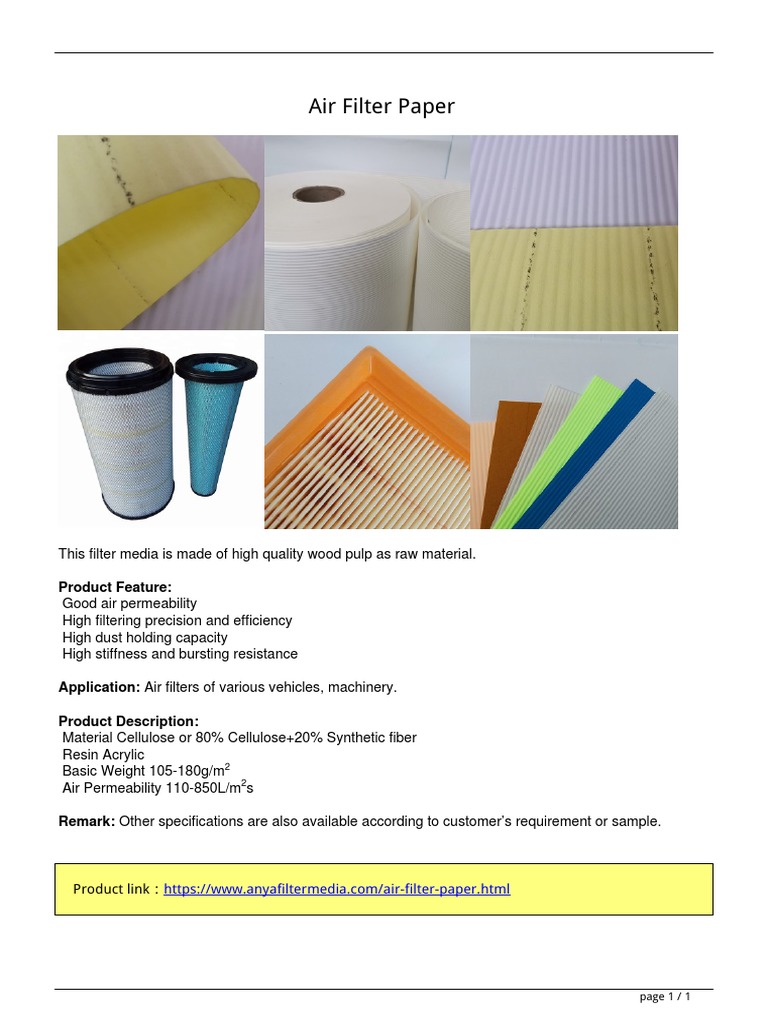

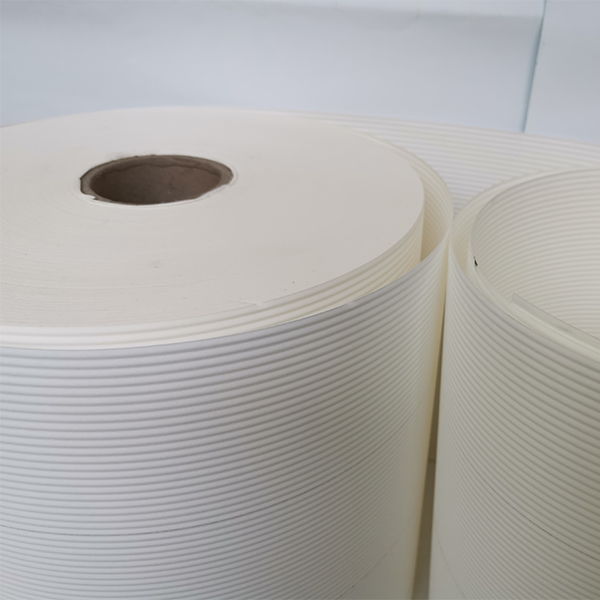

Illustrative image related to paper air filter

The Solution: To address sizing and compatibility concerns, buyers should conduct thorough research on the specifications of their equipment and the corresponding filter requirements. Creating a detailed inventory of all machinery and their filter specifications can serve as a reference for future purchases. Additionally, collaborating with suppliers who offer customizable filter solutions can provide the flexibility needed to meet unique specifications. Utilizing online filter selection tools or consulting with technical representatives can also streamline the sourcing process, ensuring that the right filters are selected for each application. By taking these proactive steps, buyers can enhance operational efficiency and reduce the risk of errors in filter selection.

Strategic Material Selection Guide for paper air filter

What Are the Key Materials Used in Paper Air Filters?

When selecting materials for paper air filters, it’s essential to consider various factors that affect performance, durability, and cost. The most common materials include cellulose, synthetic fibers, fiberglass, and pleated paper. Each has unique properties that influence their suitability for specific applications.

How Does Cellulose Impact Paper Air Filter Performance?

Cellulose is a natural fiber derived from wood pulp and is widely used in paper air filters. It offers excellent filtration efficiency, particularly for larger particles. Key properties include a temperature rating of up to 100°C and good moisture resistance. However, cellulose filters can be less durable than synthetic options, making them prone to degradation over time, especially in humid environments.

Pros:

– Cost-effective and easily available.

– Good filtration efficiency for larger particles.

Cons:

– Lower durability compared to synthetic materials.

– Limited performance in extreme temperature or moisture conditions.

For international buyers, particularly in regions like Africa and South America, cellulose filters may align with local manufacturing capabilities and cost structures. However, compliance with local environmental regulations regarding biodegradability should be considered.

What Advantages Do Synthetic Fibers Offer?

Synthetic fibers, such as polyester and polypropylene, are engineered for enhanced performance. They can withstand higher temperatures (up to 120°C) and offer superior chemical resistance. Synthetic filters are also more durable and can maintain their structural integrity in challenging conditions.

Pros:

– High durability and resistance to moisture and chemicals.

– Better filtration efficiency for smaller particles.

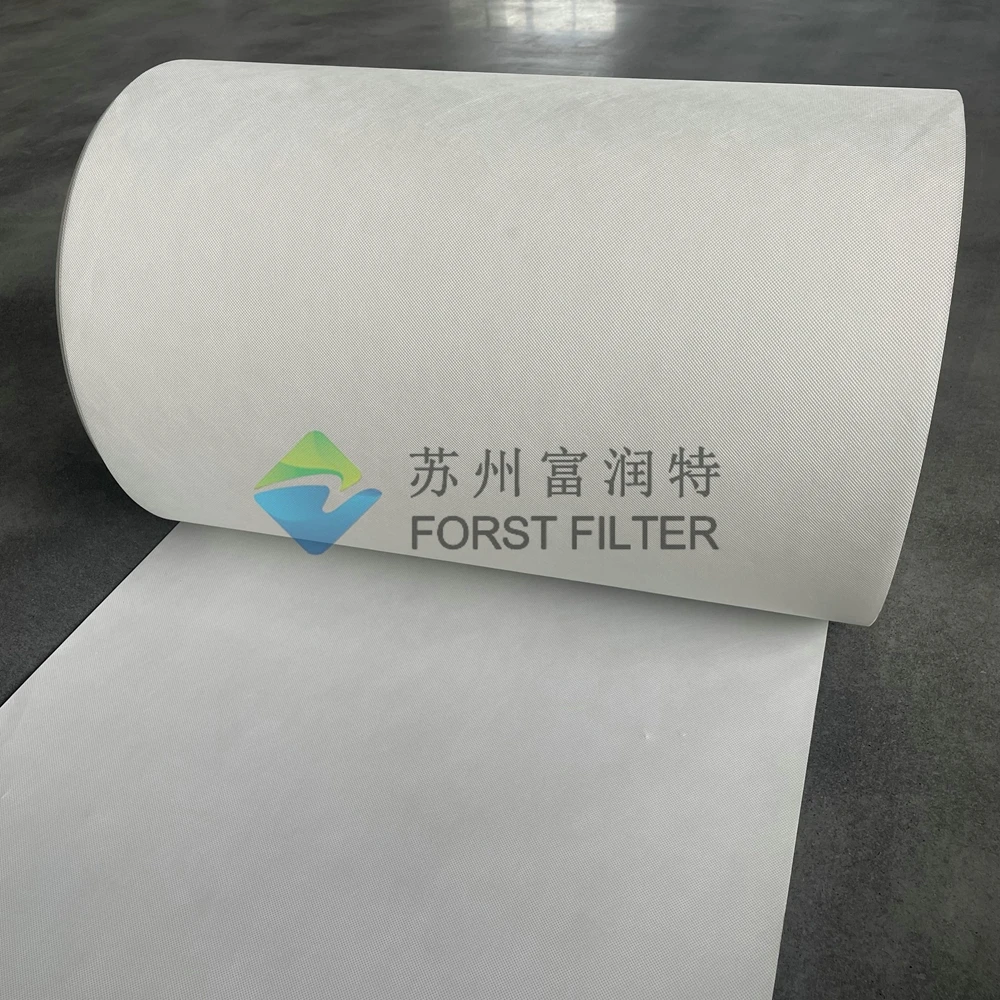

Illustrative image related to paper air filter

Cons:

– Generally more expensive than cellulose filters.

– May require more complex manufacturing processes.

For buyers in the Middle East and Europe, synthetic filters often meet stringent compliance standards, such as DIN and ASTM, making them suitable for high-performance applications in automotive and industrial sectors.

How Does Fiberglass Compare in Paper Air Filter Applications?

Fiberglass is another material used in air filters, particularly in industrial applications. It is known for its high-temperature resistance (up to 200°C) and excellent filtration capabilities. Fiberglass filters can trap very fine particles, making them ideal for environments with high dust levels.

Pros:

– Exceptional filtration efficiency for fine particles.

– High-temperature resistance enhances longevity.

Cons:

– Higher manufacturing costs and complexity.

– Less environmentally friendly due to non-biodegradable nature.

International buyers should be aware of the specific regulations regarding fiberglass waste disposal, especially in regions with strict environmental laws, such as Germany.

What Role Does Pleated Paper Play in Filter Design?

Pleated paper filters are designed to increase surface area, enhancing filtration efficiency without significantly increasing size. They are often made from a combination of cellulose and synthetic fibers, providing a balance between cost and performance.

Pros:

– Increased surface area allows for better airflow and filtration.

– Versatile and can be tailored for specific applications.

Cons:

– May be more expensive than standard flat paper filters.

– Requires careful handling to avoid damage during installation.

For B2B buyers in diverse regions, the adaptability of pleated paper filters can meet various industry needs while complying with local standards.

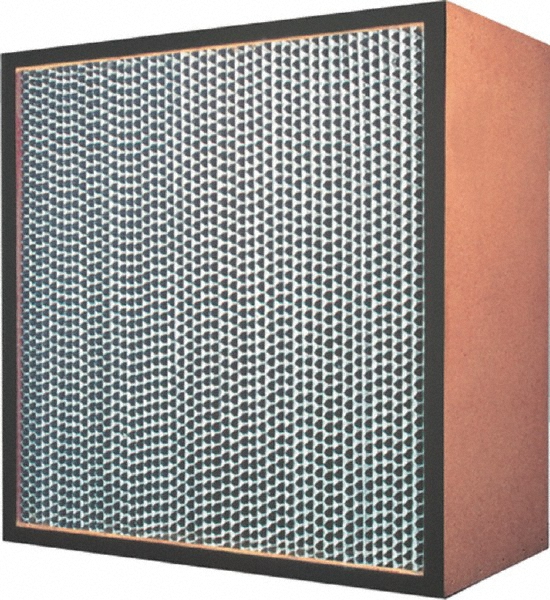

Illustrative image related to paper air filter

Summary of Material Selection for Paper Air Filters

| Material | Typical Use Case for paper air filter | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cellulose | General automotive and light-duty use | Cost-effective and readily available | Lower durability in humid conditions | Low |

| Synthetic Fibers | High-performance automotive and industrial applications | High durability and chemical resistance | Higher cost and manufacturing complexity | High |

| Fiberglass | Industrial and high-temperature applications | Exceptional filtration for fine particles | Non-biodegradable and higher costs | Med |

| Pleated Paper | Versatile applications across industries | Increased surface area for better airflow | More expensive than flat filters | Med |

This table provides a concise overview of the materials used in paper air filters, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for paper air filter

What Are the Key Stages in the Manufacturing Process of Paper Air Filters?

The manufacturing of paper air filters involves several critical stages that ensure high performance and reliability. Understanding these stages helps B2B buyers evaluate potential suppliers effectively.

Material Preparation: What Raw Materials Are Used?

The first step in manufacturing paper air filters is material preparation. Typically, high-quality cellulose or synthetic fibers are used as the primary filtering medium. These materials are chosen for their ability to trap airborne particles effectively while maintaining airflow. Additionally, additives may be incorporated to enhance the filter’s performance characteristics, such as moisture resistance or mechanical strength.

To prepare these materials, they are often treated with chemical agents that improve their filtering efficiency and durability. This treatment process is crucial, as it directly impacts the filter’s lifespan and performance metrics.

How Is the Forming Process Executed?

After material preparation, the next stage is forming. This involves shaping the filter media into the desired configuration, which can vary significantly depending on the application. Techniques used include:

Illustrative image related to paper air filter

- Die Cutting: This method shapes the filter media into specific dimensions, ensuring a perfect fit for various filter housings.

- Pleating: Many paper air filters are pleated to increase the surface area. This is critical for improving airflow and filtering efficiency. Pleating machines automate this process, ensuring uniformity in the pleat depth and spacing.

- Adhesive Application: Once pleated, adhesive is applied to secure the pleats. This step is essential for maintaining the structural integrity of the filter during operation.

What Does the Assembly Stage Involve?

The assembly stage integrates the formed filter media with other components, such as frames or end caps. Typically, the assembly process includes:

- Joining Components: The filter media is attached to the frame using adhesives or mechanical fasteners. This ensures that the filter can withstand operational stresses.

- Sealing Edges: Sealing the edges prevents unfiltered air from bypassing the filter, which is crucial for maintaining performance.

- Quality Checks: During assembly, initial quality checks are performed to ensure that all components meet the required specifications.

How Is Finishing Conducted to Ensure Quality?

Finishing processes enhance the filter’s aesthetic and functional properties. This may include:

- Coating: A protective coating may be applied to enhance durability and resistance to environmental factors.

- Labeling: Proper labeling is essential for identification and compliance with regulatory standards.

- Final Inspection: Before packaging, each filter undergoes a final inspection to ensure it meets all specifications and performance standards.

What Quality Assurance Measures Are Typically Implemented?

Quality assurance (QA) is paramount in the manufacturing of paper air filters, ensuring that they meet international standards and customer expectations. B2B buyers should pay attention to the following aspects of QA:

Which International Standards Should Buyers Be Aware Of?

Manufacturers of paper air filters should adhere to several international standards to ensure product quality and safety. Key standards include:

- ISO 9001: This standard outlines the requirements for a quality management system. Compliance indicates that the manufacturer maintains high-quality processes and continual improvement.

- CE Marking: Essential for products sold in Europe, CE marking indicates conformity with health, safety, and environmental protection standards.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early. Common checkpoints include:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): Inspections are conducted at various stages of production to identify defects during the manufacturing process.

- Final Quality Control (FQC): The finished product undergoes a comprehensive inspection to verify performance, dimensions, and compliance with specifications.

What Testing Methods Are Commonly Used to Validate Filter Performance?

Various testing methods are employed to ensure that paper air filters meet performance standards. Common tests include:

Illustrative image related to paper air filter

- Flow Rate Testing: Measures the amount of air that can pass through the filter without exceeding specified pressure drop limits.

- Efficiency Testing: Assesses how effectively the filter captures particles of varying sizes, often measured using a particle counter.

- Durability Testing: Simulates long-term use to evaluate how well the filter maintains its performance over time.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial. Here are actionable steps:

What Are Effective Methods for Supplier Audits?

Conducting supplier audits is an effective way to evaluate a manufacturer’s quality control processes. During an audit, buyers should focus on:

- Facility Inspection: Assess the manufacturing environment, equipment, and overall cleanliness.

- Process Evaluation: Review the manufacturing processes and QC checkpoints to ensure compliance with established standards.

- Documentation Review: Examine quality control records, testing results, and certifications to verify adherence to international standards.

How Can Buyers Utilize Reports and Third-Party Inspections?

Buyers should request quality assurance reports that detail the supplier’s compliance with relevant standards. Additionally, engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality systems and product performance. This is particularly important for buyers in regions with stringent import regulations.

What Nuances Should International Buyers Consider?

When sourcing paper air filters, international buyers must consider the nuances of quality control and certification requirements specific to their regions. For instance:

- Local Regulations: Different countries may have specific regulations regarding air quality and filter performance. Understanding these regulations is essential for compliance.

- Cultural Differences: Communication and expectations around quality may vary. Establishing clear quality standards and expectations upfront can help mitigate misunderstandings.

By understanding the manufacturing processes and quality assurance measures of paper air filters, B2B buyers can make informed decisions that align with their operational needs and compliance requirements.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘paper air filter’

Introduction

Sourcing paper air filters for industrial or commercial applications requires careful consideration to ensure optimal performance and value. This guide offers a step-by-step checklist to help B2B buyers navigate the procurement process effectively, ensuring that you select the right products from reliable suppliers.

Step 1: Define Your Technical Specifications

Before initiating your search, clearly outline the technical specifications required for your paper air filters. This includes dimensions, filtration efficiency, airflow rate, and material type. Defining these parameters upfront will help you target suppliers that meet your specific needs and streamline the evaluation process.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in paper air filters. Look for manufacturers and distributors with a proven track record in your industry. Utilize online directories, trade shows, and industry publications to compile a list of reputable suppliers.

Step 3: Verify Supplier Certifications

Ensuring that your suppliers hold relevant certifications is crucial for maintaining quality standards. Check for ISO certifications, compliance with environmental regulations, and other industry-specific certifications. This not only guarantees product quality but also helps mitigate risks associated with substandard products.

Illustrative image related to paper air filter

Step 4: Request Product Samples

Once you have shortlisted suppliers, request product samples to evaluate their quality firsthand. Analyzing the samples allows you to assess filter performance, durability, and overall construction. Pay attention to factors like filtration efficiency and the material’s ability to withstand environmental conditions.

Step 5: Assess Pricing and Terms

Evaluate the pricing structures and payment terms offered by each supplier. While cost is a significant factor, consider the total cost of ownership, which includes shipping, taxes, and potential tariffs, especially for international procurement. Ensure that you understand the terms regarding returns, warranties, and support.

Step 6: Inquire About Lead Times and Availability

Understanding lead times is essential for planning your inventory and production schedules. Inquire about the suppliers’ production capabilities and stock availability. Suppliers with reliable delivery timelines can help prevent production delays and maintain your operational efficiency.

Step 7: Establish Clear Communication Channels

Effective communication is vital for a successful partnership. Ensure that the supplier has a responsive customer service team and clear channels for addressing inquiries or issues. Establishing a strong line of communication will facilitate smoother transactions and foster a long-term business relationship.

By following this checklist, B2B buyers can enhance their sourcing strategy for paper air filters, ensuring that they procure high-quality products that meet their operational needs while building reliable partnerships with suppliers.

Illustrative image related to paper air filter

Comprehensive Cost and Pricing Analysis for paper air filter Sourcing

What Are the Key Cost Components for Paper Air Filter Production?

When sourcing paper air filters, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The core material for paper air filters is typically high-quality filter paper, which varies in price based on thickness, density, and type. Additional materials such as adhesives, frames, and end caps can also contribute significantly to overall costs.

-

Labor: Labor costs depend on the complexity of the manufacturing process and the region where production takes place. Skilled labor may be required for quality control and assembly, especially for filters that require precision.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and facility expenses. Overhead can vary significantly depending on the production scale and location.

-

Tooling: Custom molds and dies are often necessary for producing specific filter shapes and sizes. The initial investment in tooling can be substantial but is amortized over larger production runs.

-

Quality Control (QC): Ensuring that filters meet performance and regulatory standards is vital. Quality control processes can add to the costs, but they are essential for maintaining product reliability.

-

Logistics: Shipping and handling costs are influenced by the weight and volume of the filters, as well as the distance to the buyer. International logistics can introduce additional complexities and costs.

-

Margin: Suppliers typically add a margin to cover their costs and profit. This margin can fluctuate based on market demand, competition, and the supplier’s overall business strategy.

What Influences Pricing for Paper Air Filters?

Several factors can influence the pricing of paper air filters in the B2B market:

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide discounts for bulk orders. Understanding the MOQ can help buyers negotiate better pricing.

-

Specifications and Customization: Custom filters tailored to specific applications may incur additional costs. Buyers should clearly outline their requirements to avoid unexpected expenses.

-

Material Quality and Certifications: Filters that meet industry standards or certifications (such as ISO or HEPA) may come at a premium. The quality of the filter paper and its performance characteristics can significantly affect the price.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers with proven track records may charge higher prices due to their perceived value.

-

Incoterms: Understanding the terms of shipping and delivery (Incoterms) is crucial. They dictate who bears the costs and risks during transport, which can impact overall pricing.

How Can Buyers Optimize Costs When Sourcing Paper Air Filters?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, optimizing costs involves strategic negotiation and consideration of the total cost of ownership (TCO):

-

Negotiation: Building a good relationship with suppliers can lead to better pricing and terms. Engage in open discussions about cost structures and potential discounts based on order volume.

-

Cost-Efficiency: Evaluate the total cost of ownership, which includes not just the purchase price but also shipping, handling, and potential downtime associated with lower-quality products. Investing in higher-quality filters may save money in the long run.

-

Pricing Nuances for International Buyers: Be aware of fluctuations in currency exchange rates and international tariffs. These factors can affect the final price significantly.

-

Supplier Diversity: Consider sourcing from multiple suppliers to avoid dependency on a single source. This can also foster competitive pricing.

Disclaimer on Pricing

The prices of paper air filters can vary widely based on market conditions, production costs, and specific buyer requirements. This analysis provides indicative pricing and cost components but may not reflect the actual prices in real-time. Always request quotes from multiple suppliers to ensure competitive pricing and the best value for your specific needs.

Alternatives Analysis: Comparing paper air filter With Other Solutions

Exploring Alternatives to Paper Air Filters: What B2B Buyers Need to Know

In the quest for optimal air filtration solutions, understanding the available alternatives to paper air filters is crucial for B2B buyers. Each option presents unique advantages and challenges, making it imperative to evaluate them based on performance, cost, ease of implementation, maintenance, and best use cases. Below, we compare paper air filters with two viable alternatives: cotton cleanable filters and synthetic filters.

| Comparison Aspect | Paper Air Filter | Cotton Cleanable Filter | Synthetic Filter |

|---|---|---|---|

| Performance | Good airflow, moderate filtration efficiency | High airflow and filtration efficiency | Excellent filtration, low airflow resistance |

| Cost | Generally lower initial cost | Higher initial cost, but reusable | Moderate to high initial cost |

| Ease of Implementation | Easy to install and replace | Slightly more complex due to cleaning | Easy installation, but may require specialized fittings |

| Maintenance | Regular replacement required | Requires periodic cleaning | Minimal maintenance needed |

| Best Use Case | General automotive applications | Performance vehicles, off-road | Industrial applications, high dust environments |

What Are the Pros and Cons of Cotton Cleanable Filters?

Cotton cleanable filters are designed for high performance and can be reused multiple times, making them a popular choice among automotive enthusiasts and businesses focused on sustainability. They generally offer superior airflow and filtration efficiency compared to paper air filters. However, they come with a higher upfront cost and require regular cleaning and re-oiling, which may not be feasible for all users. This maintenance can lead to downtime if not managed properly, making it less ideal for operations that prioritize minimal disruption.

How Do Synthetic Filters Compare?

Synthetic filters, crafted from synthetic materials, provide an excellent filtration capability while maintaining low airflow resistance. This makes them highly effective in environments with high levels of dust and particulates, such as industrial settings. While they have a moderate to high initial cost, their durability and minimal maintenance needs often justify the investment. They can be a great choice for businesses looking for a long-term solution that requires less frequent replacement. However, they may need specialized fittings or installation techniques, which could complicate the initial setup.

Conclusion: How to Choose the Right Air Filter Solution for Your Business

When selecting the appropriate air filter solution, B2B buyers should consider their specific operational requirements, budget constraints, and maintenance capabilities. Paper air filters may be the most cost-effective option for general applications, while cotton cleanable filters might be ideal for performance-focused environments. Synthetic filters, on the other hand, are well-suited for industrial applications where high efficiency and low maintenance are paramount. By carefully weighing these factors, businesses can make informed decisions that enhance their operations while ensuring optimal air quality.

Essential Technical Properties and Trade Terminology for paper air filter

What Are the Key Technical Properties of Paper Air Filters?

When assessing paper air filters, several technical properties are crucial for ensuring optimal performance, reliability, and compatibility with various applications. Understanding these properties can significantly influence procurement decisions for B2B buyers.

1. Material Grade

The material grade of a paper air filter primarily refers to the quality and type of paper used in its construction. High-quality cellulose or synthetic fiber blends are common, impacting filtration efficiency and durability. For B2B buyers, selecting the right material grade ensures that the filter meets specific air quality standards and operational requirements, particularly in industries like automotive, manufacturing, and HVAC.

2. Air Flow Rate

The air flow rate indicates the volume of air that can pass through the filter within a given time frame, typically measured in cubic feet per minute (CFM). A higher air flow rate often translates to better engine performance or air quality. For B2B buyers, understanding the required air flow rate for their applications is essential to ensure that the filters maintain efficiency without causing excessive strain on equipment.

3. Filtration Efficiency

Filtration efficiency measures the filter’s ability to capture airborne particles, often expressed as a percentage. Higher efficiency ratings indicate that the filter can trap more contaminants, such as dust, pollen, and other particulates. For businesses, this property is vital for maintaining air quality, reducing maintenance costs, and prolonging the lifespan of machinery and equipment.

4. Dust Holding Capacity

This property refers to the amount of dust a filter can retain before it needs to be replaced or cleaned. A higher dust holding capacity means less frequent replacements, which can lead to cost savings and reduced downtime. For B2B buyers, considering the dust holding capacity can optimize operational efficiency and maintenance schedules.

5. Temperature Resistance

Temperature resistance defines the filter’s ability to function effectively under varying thermal conditions. Filters designed for high-temperature applications, such as automotive engines, must withstand significant heat without degrading. Buyers must evaluate the temperature range in which their filters will operate to prevent premature failure.

6. Dimensions and Fit

The dimensions of a paper air filter (length, width, height) are critical for ensuring that it fits seamlessly into the intended application. Misalignment can lead to air leaks, reducing filtration efficiency. For B2B buyers, verifying compatibility with existing systems is crucial to avoid costly replacements or modifications.

Illustrative image related to paper air filter

What Are Common Trade Terms Used in the Paper Air Filter Industry?

Understanding industry jargon is essential for effective communication and negotiation in the procurement process. Here are some common terms relevant to paper air filters.

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of paper air filters, OEM filters are designed to meet the specifications of the original equipment, ensuring compatibility and performance. For B2B buyers, sourcing OEM filters can enhance reliability and performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. Understanding the MOQ is crucial for B2B buyers as it can impact inventory management and cash flow. Buyers should negotiate MOQs that align with their operational needs to avoid excess inventory costs.

Illustrative image related to paper air filter

3. RFQ (Request for Quotation)

An RFQ is a document used to solicit price bids from suppliers for specific products or services. B2B buyers typically issue RFQs when they require competitive pricing and detailed product specifications. A well-structured RFQ can streamline the procurement process and lead to better pricing and terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in the shipping process. Understanding Incoterms is essential for B2B transactions, as they define who is responsible for shipping costs, insurance, and risk during transport.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order until it is delivered. For B2B buyers, knowing the lead time is critical for planning and ensuring that production schedules are not disrupted.

Illustrative image related to paper air filter

6. Aftermarket

Aftermarket refers to the secondary market for products that are not sourced from the original manufacturer. In the paper air filter industry, aftermarket filters may offer competitive pricing or alternative options. B2B buyers should evaluate the quality and performance of aftermarket options compared to OEM products.

Understanding these technical properties and trade terms will empower B2B buyers to make informed decisions when sourcing paper air filters, ensuring they meet their operational requirements while optimizing costs.

Navigating Market Dynamics and Sourcing Trends in the paper air filter Sector

What Are the Current Market Dynamics and Key Trends Affecting the Paper Air Filter Sector?

The global paper air filter market is currently influenced by several key drivers, shaping the landscape for international B2B buyers. Increasing environmental regulations worldwide, particularly in Europe and the Middle East, are pushing manufacturers to adopt high-efficiency filtration technologies. This trend is further fueled by the growing awareness of air quality issues and the need for sustainable solutions. In Africa and South America, rapid urbanization and industrialization are leading to an uptick in demand for effective air filtration systems, as businesses strive to meet health standards and improve indoor air quality.

Emerging technologies such as smart filtration systems are also gaining traction, allowing for real-time monitoring of air quality and filter performance. B2B buyers are increasingly looking for suppliers who can provide advanced solutions that integrate with IoT devices, enhancing operational efficiency. Additionally, the rise of e-commerce platforms is changing sourcing dynamics, enabling international buyers to access a broader range of products and suppliers with ease.

From a sourcing perspective, buyers are advised to consider the total cost of ownership, including maintenance and replacement cycles, when evaluating paper air filters. The market is seeing a shift towards more durable and efficient products that promise longer lifespans and lower operational costs, making it essential for buyers to stay informed about the latest innovations.

How Are Sustainability and Ethical Sourcing Impacting the Paper Air Filter Industry?

Sustainability is becoming a cornerstone of the paper air filter sector, influencing sourcing decisions for B2B buyers. The environmental impact of traditional manufacturing processes is prompting companies to seek out suppliers who prioritize eco-friendly practices. This includes the use of recycled materials and sustainable production methods, which not only reduce waste but also enhance brand reputation among environmentally conscious consumers.

Ethical sourcing is equally vital, as businesses increasingly recognize the importance of transparent supply chains. Buyers are encouraged to partner with manufacturers that comply with international labor standards and engage in fair trade practices. Certifications such as FSC (Forest Stewardship Council) for paper products and ISO 14001 for environmental management systems are becoming essential criteria for evaluating suppliers. These certifications assure buyers that their sourcing decisions align with corporate social responsibility goals, creating a positive impact on local communities and the environment.

Moreover, the demand for “green” products is rising, with buyers looking for filters that are not only efficient but also biodegradable or recyclable. This trend is expected to accelerate, as regulatory bodies impose stricter environmental standards, pushing manufacturers to innovate in sustainable product offerings.

What Is the Historical Context of the Paper Air Filter Industry?

The evolution of the paper air filter industry can be traced back to the early 20th century, when the first commercial air filters were developed. Initially, filters were primarily used in industrial applications to protect machinery from dust and debris. As air quality concerns began to gain attention in the latter half of the century, the focus shifted towards improving indoor air quality for both residential and commercial spaces.

The introduction of synthetic materials in the 1970s marked a significant turning point, providing alternatives to traditional paper filters. However, paper air filters have maintained their relevance due to their cost-effectiveness and efficiency in capturing airborne particles. Today, advancements in technology and materials are driving innovation in the sector, allowing for the production of high-performance filters that meet stringent regulatory standards while catering to the diverse needs of global B2B buyers.

As the market continues to evolve, staying informed about historical trends and technological advancements will be crucial for businesses looking to navigate the complexities of sourcing and supply in the paper air filter sector.

Frequently Asked Questions (FAQs) for B2B Buyers of paper air filter

-

How do I choose the right paper air filter for my application?

Choosing the right paper air filter depends on several factors, including the specific requirements of your machinery or vehicle, the operating environment, and the filter’s airflow capacity. Assess the size and shape of the filter needed and verify compatibility with your equipment. Consider the filtration efficiency and the level of dust and particulate matter in your working environment. Always consult with suppliers to understand their product specifications, and request samples if possible to test performance before making bulk purchases. -

What is the best paper air filter for high-performance applications?

For high-performance applications, look for paper air filters that are designed specifically for increased airflow and filtration efficiency. Filters that feature high-flow, synthetic media or multi-layer designs can significantly improve engine performance by allowing more air to pass through while trapping contaminants effectively. Brands like Allstar Performance offer specialized filters that enhance airflow without compromising filtration. Always evaluate filters based on independent testing and performance data to ensure they meet your specific operational needs. -

What should I consider when vetting suppliers for paper air filters?

When vetting suppliers for paper air filters, consider their reputation in the industry, years of experience, and customer reviews. Request certifications and compliance with international standards, such as ISO or CE, to ensure quality. It’s also essential to assess their production capabilities, lead times, and flexibility in meeting custom orders. Engaging in direct communication to gauge their responsiveness and customer service can provide insights into their reliability as a partner. -

What are the typical minimum order quantities (MOQs) for paper air filters?

Minimum order quantities (MOQs) for paper air filters can vary significantly depending on the supplier and the specific product. Generally, MOQs can range from 100 to 1,000 units. Larger suppliers may offer lower MOQs for standard products, while custom filters may require higher orders. Always confirm MOQs upfront and inquire about pricing breaks for larger orders, which can help optimize your procurement costs. -

What payment terms should I expect when purchasing paper air filters internationally?

Payment terms for international purchases of paper air filters typically include options like letter of credit, advance payment, or net 30/60 terms. Suppliers may request a deposit before production, especially for large orders or custom designs. It’s crucial to clarify payment methods accepted, currency preferences, and any additional fees that may apply. Establishing clear payment terms can help mitigate risks and ensure a smooth transaction process. -

How can I ensure the quality of paper air filters before shipment?

To ensure quality before shipment, request a detailed quality assurance (QA) process from your supplier. This should include pre-shipment inspections, compliance with specified filtration standards, and documentation of testing results. If possible, arrange for third-party inspections to validate the filter performance and integrity. Engaging in quality checks will help you avoid receiving defective products and maintain operational efficiency in your applications. -

What logistics considerations should I keep in mind when sourcing paper air filters?

When sourcing paper air filters, consider logistics aspects such as shipping methods, lead times, and customs regulations. Evaluate the supplier’s ability to handle international shipping efficiently and inquire about available shipping options, such as air or sea freight, based on your urgency and budget. Additionally, be aware of import duties, taxes, and documentation required for customs clearance in your country to avoid delays. -

What are the benefits of customizing paper air filters for my specific needs?

Customizing paper air filters allows you to tailor the product to your unique operational requirements, enhancing performance and efficiency. Custom filters can be designed for specific dimensions, filtration levels, and airflow capacities, ensuring optimal compatibility with your equipment. This can lead to improved machinery performance, reduced maintenance costs, and enhanced air quality. Collaborating with suppliers on custom designs can also provide you with a competitive edge in your market.

Top 4 Paper Air Filter Manufacturers & Suppliers List

1. Reddit – Stock Paper Air Filter vs K&N Oiled Filter

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Stock paper air filter vs K&N oiled filter; K&N filters are reusable but require proper maintenance; K&N filters may not provide significant power gains; concerns about K&N filters include potential clogging and less effective filtration; stock paper filters are recommended for RX-8 due to better filtration and engine protection; K&N filters can lead to oil on MAF sensor and potential engine issue…

2. Allstar Performance – Paper Air Filter Element 14 x 5

Domain: allstarperformance.com

Registered: 2000 (25 years)

Introduction: {“Product Name”: “Paper Air Filter Element 14″ x 5″”,”SKU”: “ALL26023″,”UPC”: “848238016475”,”MPN”: “ALL26023″,”Price”: “$16.99″,”Package Weight”: “2.23 lbs (1.01 kg)”,”Package Dimensions”: {“Length”: “14.75 in (37.47 cm)”,”Width”: “14 in (35.56 cm)”,”Height”: “5.5 in (13.97 cm)”},”Shape”: “Round”,”Universal”: “Yes”,”Diameter”: “14 in”,”Height”: “5 in”,”Oiled/Dry”: “Dry”,”Style”: “Paper”,”Color”: …

3. PG Filters – Air Filter Element Materials

Domain: pgfilters.com

Registered: 2006 (19 years)

Introduction: The article discusses three main types of air filter element materials: 1. Paper Filters: Affordable and reliable, typically used as OEM filters, designed to be replaced every 12,000 to 30,000 miles. They provide good airflow while reducing dust and debris. 2. Cotton Filters: Reusable and designed to be cleaned and oiled every 5,000 miles. They are more expensive (about twice the price of paper fi…

4. Outdoor Parts – Paper Panel Air Filters

Domain: tksoutdoorparts.com

Registered: 2021 (4 years)

Introduction: Paper Panel Air Filters available from various brands including Ariens, Briggs & Stratton, Craftsman, Generac, Honda, Husqvarna, John Deere, Kawasaki, Kohler, Lawnboy, MTD, Onan, Partner, Shindaiwa, Stihl, Tecumseh, and Toro. Prices range from $6.26 to $24.37. Filter sizes include dimensions such as 5-1/4″x2-1/4″, 3″x3″, 6-1/4″x4-1/2″, 8-5/8″x4-3/4″, and more. Free shipping on orders over $59.

Strategic Sourcing Conclusion and Outlook for paper air filter

In conclusion, the strategic sourcing of paper air filters presents a unique opportunity for B2B buyers across diverse markets, including Africa, South America, the Middle East, and Europe. By prioritizing quality and performance, businesses can enhance operational efficiency and customer satisfaction. Key takeaways include the importance of selecting suppliers who offer not only high-performance products but also scalable solutions tailored to regional needs. Leveraging local suppliers can significantly reduce logistics costs and delivery times, making it a strategic advantage in today’s competitive landscape.

As the demand for sustainable and efficient filtration solutions continues to grow, international buyers should remain proactive in exploring innovative technologies and materials. Investing in advanced paper air filters can lead to long-term savings and improved air quality, which is increasingly critical in industrial and commercial environments.

Looking ahead, the shift towards eco-friendly products will redefine market dynamics. B2B buyers are encouraged to engage with manufacturers and distributors who align with these sustainability goals. By forging strategic partnerships now, businesses can secure a competitive edge and contribute to a healthier environment for future generations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.