How to Source Nylon Bristle Brush For Cleaning Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for nylon bristle brush for cleaning

In today’s rapidly evolving global marketplace, sourcing high-quality nylon bristle brushes for cleaning presents a significant challenge for international B2B buyers. As businesses strive to maintain cleanliness and hygiene across various industries, understanding the nuances of this product category becomes essential. This comprehensive guide delves into the diverse types of nylon bristle brushes available, their specific applications in sectors ranging from janitorial services to manufacturing, and critical insights into supplier vetting processes.

Buyers from regions such as Africa, South America, the Middle East, and Europe will benefit from our exploration of cost-effective options and the latest trends shaping the nylon brush market. By addressing key considerations like durability, bristle stiffness, and compatibility with different cleaning agents, this guide equips decision-makers with the knowledge to make informed purchasing choices.

Furthermore, we will provide actionable tips for evaluating suppliers, ensuring compliance with international standards, and leveraging bulk purchasing strategies. By arming B2B buyers with this essential information, we aim to simplify the sourcing process, enhance procurement efficiency, and ultimately support the operational needs of businesses across the globe. Whether you’re in Vietnam, Brazil, or beyond, navigating the complexities of the nylon bristle brush market has never been easier.

Understanding nylon bristle brush for cleaning Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Hard Bristle Brush | Stiff nylon bristles for tough scrubbing | Industrial cleaning, heavy machinery maintenance | Pros: Effective on tough grime; durable. Cons: May scratch delicate surfaces. |

| Soft Bristle Brush | Flexible bristles for gentle cleaning | Janitorial services, home cleaning supplies | Pros: Safe for delicate surfaces; versatile. Cons: Less effective on heavy stains. |

| Tapered Tube Brush | Tapered design for cleaning narrow or hard-to-reach spaces | Automotive, plumbing, and equipment maintenance | Pros: Excellent for precision cleaning; specialized use. Cons: Limited general cleaning applications. |

| Specialty Brush | Designed for specific tasks (e.g., tile and grout cleaning) | Construction, renovation, and specialty cleaning | Pros: Targeted cleaning capabilities; efficient. Cons: May require multiple brushes for various tasks. |

| Spotting Brush | Small size with short bristles for detailed work | Textile cleaning, upholstery maintenance | Pros: Precise cleaning; ideal for stains. Cons: Not suitable for large surface areas. |

What Are the Key Characteristics of a Hard Bristle Brush?

Hard bristle brushes are characterized by their stiff nylon bristles, which provide the necessary rigidity for scrubbing tough surfaces. They are predominantly used in industrial cleaning and heavy machinery maintenance, where grime and dirt build-up can be significant. When considering a hard bristle brush, buyers should evaluate the brush’s durability and ability to withstand harsh cleaning agents, as these brushes are often exposed to rigorous cleaning tasks. However, caution is advised when using them on delicate surfaces, as they may cause scratches.

How Does a Soft Bristle Brush Differ in Use?

Soft bristle brushes feature flexible nylon bristles, making them ideal for gentle cleaning tasks. They are commonly utilized in janitorial services and for home cleaning applications, where protecting surfaces is a priority. Buyers looking to purchase soft bristle brushes should focus on their versatility and effectiveness in cleaning sensitive areas. While they excel in delicate cleaning, they may not perform as well on heavy stains, which is a consideration for B2B buyers in the cleaning sector.

Why Choose a Tapered Tube Brush?

Tapered tube brushes are designed with a unique shape to clean narrow or hard-to-reach spaces effectively. They find their primary applications in automotive, plumbing, and equipment maintenance, where precision cleaning is essential. When purchasing tapered tube brushes, B2B buyers should consider the size and diameter options available to ensure compatibility with specific applications. While they offer excellent cleaning capabilities in tight spots, their specialized nature may limit their use for broader cleaning tasks.

What Makes Specialty Brushes Essential for Specific Tasks?

Specialty brushes are tailored for particular cleaning tasks, such as tile and grout cleaning or other niche applications. They are widely used in construction, renovation, and specialty cleaning industries. B2B buyers should assess the specific needs of their cleaning operations when selecting specialty brushes, as they can significantly improve efficiency in targeted cleaning tasks. However, investing in multiple specialty brushes may be necessary to cover various cleaning requirements, which can increase initial costs.

How Does a Spotting Brush Serve in Detailed Cleaning?

Spotting brushes are small, featuring short bristles that allow for detailed cleaning work, particularly in textile and upholstery maintenance. They are ideal for removing stains and dirt from fabrics without damaging the material. For B2B buyers, the precision offered by spotting brushes is a significant advantage, especially when dealing with delicate fabrics. However, their size limits their effectiveness on larger surfaces, making them unsuitable for broader cleaning applications.

Key Industrial Applications of nylon bristle brush for cleaning

| Industry/Sector | Specific Application of nylon bristle brush for cleaning | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Processing | Cleaning food equipment and surfaces | Ensures hygiene compliance and reduces contamination risks | FDA compliance, durability against chemicals, easy to sanitize |

| Automotive | Engine and component cleaning | Enhances maintenance efficiency and prolongs equipment lifespan | Resistance to solvents, bristle stiffness options, bulk purchasing discounts |

| Pharmaceutical | Cleaning laboratory instruments and equipment | Maintains sterile conditions and ensures accuracy in processes | Non-reactive materials, precision in bristle size, ESD compliance |

| Janitorial Services | General-purpose cleaning in commercial spaces | Improves cleanliness standards and customer satisfaction | Variety in brush sizes, ergonomic handles, and availability of custom designs |

| Electronics Manufacturing | Cleaning circuit boards and sensitive components | Prevents damage to components and ensures quality control | Anti-static properties, precision bristle size, compliance with industry standards |

How is Nylon Bristle Brush Used in Food Processing?

In the food processing industry, nylon bristle brushes are essential for cleaning equipment such as mixers, conveyor belts, and storage bins. Their durability and resistance to high temperatures and chemicals make them suitable for rigorous cleaning tasks, ensuring compliance with hygiene standards. These brushes effectively remove food residues and contaminants, significantly reducing the risk of cross-contamination. B2B buyers in this sector should prioritize brushes that meet FDA regulations and can withstand repeated sanitization processes, ensuring both efficiency and safety.

What Role Does Nylon Bristle Brush Play in Automotive Cleaning?

Automotive maintenance relies heavily on nylon bristle brushes for cleaning engines, wheels, and other components. These brushes can effectively dislodge dirt and grime without scratching surfaces, making them ideal for sensitive areas. Their ability to withstand solvents and harsh chemicals is crucial for automotive applications. Buyers should consider the bristle stiffness and length to tailor their choice to specific cleaning needs, ensuring optimal performance and longevity of equipment.

Why is Nylon Bristle Brush Important in Pharmaceutical Settings?

In pharmaceutical manufacturing, maintaining sterile environments is paramount. Nylon bristle brushes are utilized for cleaning laboratory instruments, ensuring that no contaminants interfere with sensitive processes. The non-reactive nature of nylon prevents any chemical interaction that could compromise drug safety. Buyers in this field must focus on sourcing brushes that meet stringent regulatory standards, including ESD compliance for sensitive electronic equipment, while also considering the precision of bristle sizes to accommodate various instrument designs.

How Do Janitorial Services Benefit from Nylon Bristle Brushes?

Janitorial services utilize nylon bristle brushes for a wide range of cleaning tasks in commercial spaces, from floors to restrooms. These brushes help maintain high cleanliness standards, which are critical for customer satisfaction and health regulations. The versatility of nylon bristle brushes allows for different sizes and stiffness levels, catering to various surfaces and cleaning needs. When sourcing these brushes, B2B buyers should look for ergonomic designs that enhance usability and reduce worker fatigue, as well as options for custom designs to meet specific client requirements.

What is the Significance of Nylon Bristle Brush in Electronics Manufacturing?

In electronics manufacturing, nylon bristle brushes are crucial for cleaning circuit boards and delicate components without causing damage. Their anti-static properties help prevent electrostatic discharge that could harm sensitive electronic parts. The precision of bristle sizes allows for thorough cleaning in tight spaces, ensuring quality control. Buyers in this sector should prioritize brushes that comply with industry standards and consider bulk purchasing options to reduce costs while ensuring a steady supply for ongoing production needs.

3 Common User Pain Points for ‘nylon bristle brush for cleaning’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Bristle Stiffness for Various Applications

The Problem: B2B buyers often struggle to select the appropriate nylon bristle stiffness for specific cleaning tasks. For instance, using a hard bristle brush on sensitive surfaces like upholstery can lead to damage, while soft bristles may not effectively remove stubborn dirt from industrial machinery. This mismatch can lead to increased costs due to product damage and inefficient cleaning processes, ultimately impacting customer satisfaction and retention.

Illustrative image related to nylon bristle brush for cleaning

The Solution: To mitigate this issue, buyers should conduct a comprehensive analysis of the surfaces and materials they will be cleaning. It’s advisable to categorize cleaning tasks based on surface type—soft, hard, or delicate—and specify the bristle stiffness accordingly. When sourcing nylon bristle brushes, ensure the supplier provides detailed specifications on bristle stiffness options. Additionally, consider investing in a variety of brushes to accommodate different cleaning needs. This proactive approach not only enhances cleaning efficiency but also minimizes the risk of damage to surfaces.

Scenario 2: Ineffective Cleaning Due to Brush Size Mismatch

The Problem: Another common issue faced by B2B buyers is the challenge of selecting the right brush size for the cleaning task at hand. For instance, using a large brush to clean tight spaces, such as intricate machinery components or small kitchen appliances, can result in ineffective cleaning and wasted effort. This oversight can lead to increased labor costs and lower productivity, as employees may need to spend additional time re-cleaning areas that were not adequately addressed.

The Solution: To address this challenge, buyers should evaluate the specific dimensions and accessibility of the areas they intend to clean. When sourcing nylon bristle brushes, look for options that offer a range of sizes, including specialty brushes designed for narrow or hard-to-reach spaces. Additionally, investing in multi-functional brushes that can adapt to different cleaning scenarios can prove beneficial. Providing training for cleaning staff on the importance of using the correct brush size can also enhance overall cleaning effectiveness and efficiency.

Scenario 3: Concerns About Durability and Resistance to Chemicals

The Problem: B2B buyers often express concerns regarding the durability of nylon bristle brushes, particularly in environments that require exposure to harsh chemicals or extreme conditions. For example, brushes used in industrial cleaning or food processing environments must withstand regular exposure to solvents and high temperatures. If the brushes degrade quickly, it can lead to increased replacement costs and disruptions in workflow, ultimately affecting the bottom line.

The Solution: Buyers should prioritize sourcing nylon bristle brushes that are specifically designed for high-durability applications. When selecting brushes, inquire about the material specifications, including resistance to chemicals and temperature extremes. Look for products that have been tested for longevity in challenging environments. Establishing relationships with reputable suppliers who offer warranties and guarantees can provide peace of mind. Additionally, implementing a regular maintenance schedule for cleaning tools can prolong their lifespan and ensure that they remain effective over time. This proactive maintenance strategy not only enhances the reliability of cleaning operations but also contributes to overall cost savings.

Strategic Material Selection Guide for nylon bristle brush for cleaning

What Are the Key Materials Used in Nylon Bristle Brushes for Cleaning?

When selecting nylon bristle brushes for cleaning applications, understanding the properties and implications of various materials is crucial for B2B buyers. This guide analyzes four common materials used in the construction of nylon bristle brushes, focusing on their performance, advantages, and considerations for international markets.

Illustrative image related to nylon bristle brush for cleaning

1. Nylon

Key Properties: Nylon is a synthetic polymer known for its excellent tensile strength and abrasion resistance. It can withstand temperatures up to 120°C (248°F) and is resistant to a variety of chemicals, making it suitable for diverse cleaning environments.

Pros & Cons: Nylon brushes are durable and maintain their shape over time, which enhances cleaning efficiency. However, they can be more expensive than natural bristle alternatives, and their manufacturing process can be complex, impacting overall costs.

Impact on Application: Nylon brushes are ideal for cleaning hard surfaces, such as tiles and metal, due to their stiffness. They are compatible with various cleaning agents, including solvents and detergents, making them versatile for industrial applications.

International Considerations: Buyers from regions like Africa and South America should ensure compliance with local regulations regarding synthetic materials. Standards such as ASTM and ISO may apply, influencing material selection.

2. Polypropylene

Key Properties: Polypropylene is another synthetic material known for its lightweight nature and resistance to moisture and chemicals. It has a lower temperature tolerance than nylon, typically around 100°C (212°F).

Pros & Cons: Polypropylene brushes are generally less expensive and lighter than nylon brushes, making them cost-effective for large-scale cleaning operations. However, they may not be as durable or effective in high-temperature applications.

Impact on Application: These brushes are suitable for general cleaning tasks, particularly in wet environments. Their resistance to moisture makes them ideal for use in food processing and janitorial applications.

International Considerations: Compliance with food safety standards is crucial for buyers in the food industry. Various countries may have specific regulations regarding the use of polypropylene in food-related applications.

3. Polyester

Key Properties: Polyester bristles offer good chemical resistance and can tolerate moderate temperatures (up to 80°C or 176°F). They are less abrasive than nylon, making them suitable for delicate surfaces.

Pros & Cons: Polyester brushes are cost-effective and provide a softer cleaning action, reducing the risk of scratching surfaces. However, they may wear out faster than nylon and are less effective in heavy-duty applications.

Impact on Application: Ideal for cleaning sensitive surfaces, such as glass and painted finishes, polyester brushes excel in applications where gentleness is required. They are often used in automotive and electronics cleaning.

International Considerations: Buyers should consider the environmental impact of polyester, as it is derived from petroleum. Compliance with eco-friendly standards may be a consideration in regions with strict environmental regulations.

Illustrative image related to nylon bristle brush for cleaning

4. Natural Bristles (e.g., Horsehair)

Key Properties: Natural bristles provide a softer touch and are biodegradable. They typically have a lower resistance to chemicals and heat compared to synthetic options.

Pros & Cons: Natural bristles are excellent for delicate cleaning tasks and provide a natural sheen to surfaces. However, they can be less durable and more expensive, and their performance can degrade when exposed to moisture.

Impact on Application: Best for cleaning delicate items like furniture and fine art, natural bristle brushes are often used in specialty applications. They may not be suitable for industrial cleaning tasks due to their lower durability.

International Considerations: Buyers should be aware of ethical sourcing practices and regulations regarding animal products, especially in regions with strict animal welfare laws.

Summary Table of Material Selection for Nylon Bristle Brushes

| Material | Typical Use Case for nylon bristle brush for cleaning | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Heavy-duty cleaning of hard surfaces | Excellent durability and chemical resistance | Higher cost and complex manufacturing | High |

| Polypropylene | General cleaning in wet environments | Lightweight and cost-effective | Lower durability at high temperatures | Medium |

| Polyester | Cleaning sensitive surfaces like glass | Gentle cleaning action | Wears out faster than nylon | Medium |

| Natural Bristles | Specialty cleaning for delicate items | Biodegradable and soft | Less durable and higher cost | High |

This strategic material selection guide provides B2B buyers with essential insights into nylon bristle brushes, enabling informed decisions based on application needs and regional compliance considerations.

Illustrative image related to nylon bristle brush for cleaning

In-depth Look: Manufacturing Processes and Quality Assurance for nylon bristle brush for cleaning

What Are the Key Stages in the Manufacturing Process of Nylon Bristle Brushes for Cleaning?

The manufacturing of nylon bristle brushes for cleaning involves several critical stages, each designed to ensure the final product meets quality and performance standards required by international markets.

-

Material Preparation

The first stage involves sourcing high-quality nylon filaments. Nylon is chosen for its durability, flexibility, and resistance to chemicals and moisture. Suppliers typically provide nylon in various grades, and manufacturers must select the appropriate type based on the intended use of the brush. The nylon is then cut into specific lengths, depending on the brush design. -

Forming

The next step is the forming process, where the bristles are inserted into a brush head. This can be done using several techniques, including tufting, where bristles are arranged in tufts and secured into pre-drilled holes in the brush body. For more complex designs, advanced techniques such as injection molding may be employed to form the brush head and embed the bristles in one step, ensuring a strong bond. -

Assembly

After forming, the brushes are assembled. This includes attaching the handle to the brush head. Handles can be made from various materials, such as plastic, wood, or metal, depending on the desired ergonomics and aesthetics. Quality assurance checks at this stage ensure that all components fit correctly and securely. -

Finishing

The finishing process includes any additional treatments that enhance the brush’s performance. This could involve coating the handle for better grip, sterilizing the brush for medical applications, or packaging for retail. Quality checks are performed to ensure that the brushes meet the required specifications for appearance and functionality.

How is Quality Assurance Implemented in the Production of Nylon Bristle Brushes?

Quality assurance (QA) is vital to ensure that nylon bristle brushes meet international standards and customer expectations. Here are the key components of a robust QA process:

-

International Standards and Certifications

Manufacturers often adhere to ISO 9001 standards, which dictate quality management systems and practices. This certification ensures that the production process is consistently monitored and improved. Additionally, for specific markets, certifications like CE (Conformité Européenne) for products sold in Europe or API (American Petroleum Institute) for industrial brushes may be required. -

Quality Control Checkpoints

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials, such as nylon and other components, undergo inspection upon arrival to verify their compliance with specifications.

– In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to ensure that production processes are followed correctly and that any defects are caught early.

– Final Quality Control (FQC): Once brushes are completed, they undergo a final inspection to check for defects in functionality, appearance, and packaging. -

Common Testing Methods

Various testing methods are employed to ensure the brushes meet industry standards. These can include:

– Durability Testing: Brushes are subjected to wear-and-tear simulations to assess longevity.

– Chemical Resistance Testing: Brushes are exposed to various cleaning agents to ensure they maintain their integrity.

– Performance Testing: Brushes are tested for effectiveness in cleaning different surfaces.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is crucial. Here are some actionable steps:

Illustrative image related to nylon bristle brush for cleaning

-

Conduct Audits

Buyers should consider conducting on-site audits of potential suppliers. This allows them to assess the manufacturing environment, quality control processes, and adherence to international standards firsthand. -

Request Documentation and Reports

Suppliers should provide documentation of their quality control processes, including certificates of compliance with international standards like ISO 9001, CE, or API. Buyers can also request reports from previous quality inspections or test results to ensure reliability. -

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased evaluation of a supplier’s quality control practices. These services can conduct random checks and provide detailed reports on product quality before shipment. -

Understand Regional Quality Nuances

Buyers should be aware of regional variations in quality expectations. For instance, European markets may have stricter regulations compared to those in South America. Understanding these nuances can help buyers navigate compliance effectively.

What Are the Challenges and Solutions in Ensuring Quality for International Buyers?

International buyers face unique challenges when sourcing nylon bristle brushes, including differing standards and potential communication barriers with suppliers.

-

Navigating Diverse Regulations

Each region may have its own compliance requirements, making it essential for buyers to conduct thorough research. Collaborating with local experts or using trade associations can help clarify these regulations. -

Ensuring Consistency Across Orders

Variability in production quality can occur, particularly when suppliers operate multiple facilities. Establishing clear specifications and maintaining consistent communication can mitigate this risk. -

Cultural and Language Barriers

Communication challenges can lead to misunderstandings about quality requirements. Utilizing bilingual staff or professional translation services can enhance clarity and reduce errors.

By understanding the manufacturing processes and quality assurance measures for nylon bristle brushes, B2B buyers can make informed decisions, ensuring they source products that meet their quality standards and specifications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘nylon bristle brush for cleaning’

To successfully procure nylon bristle brushes for cleaning, it is essential to follow a structured approach that ensures quality and suitability for your specific needs. This guide outlines critical steps to help B2B buyers navigate the sourcing process effectively.

Step 1: Define Your Technical Specifications

Begin by outlining the technical requirements of the nylon bristle brushes you need. Consider factors such as bristle stiffness, size, and intended application (e.g., general cleaning, specialized tasks like tube or spout cleaning).

– Bristle Material: Ensure the nylon is durable and resistant to solvents if applicable.

– Brush Dimensions: Specify lengths and diameters suitable for your cleaning tasks.

Illustrative image related to nylon bristle brush for cleaning

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in nylon bristle brushes. Utilize online marketplaces, industry directories, and trade shows to gather a list of candidates.

– Supplier Reputation: Look for suppliers with positive reviews and a strong presence in your region, especially if you’re sourcing from Africa, South America, or Europe.

– Product Range: Ensure the suppliers offer a variety of brushes to meet your specific requirements.

Step 3: Evaluate Supplier Certifications

Before making a decision, verify the certifications and compliance of the suppliers. This is crucial for ensuring product quality and adherence to international standards.

– ISO Certification: Check if the supplier has relevant ISO certifications, which indicate a commitment to quality management.

– Safety Standards: Confirm that products meet safety regulations, especially if they will be used in sensitive environments.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, request samples of the nylon bristle brushes. Testing samples allows you to assess the quality and performance of the brushes in real-world applications.

– Performance Evaluation: Examine the brushes for durability, effectiveness, and ease of use during cleaning tasks.

– Feedback from Users: Gather input from your cleaning staff to understand their preferences and any potential issues.

Step 5: Negotiate Terms and Pricing

Engage in discussions with your chosen suppliers to negotiate pricing, terms, and conditions. This step is vital for ensuring that you receive the best value for your investment.

– Bulk Discounts: Inquire about pricing structures for bulk purchases, as many suppliers offer significant discounts for larger orders.

– Payment Terms: Clarify payment methods and terms to avoid any misunderstandings.

Step 6: Establish a Long-Term Relationship

After selecting a supplier, focus on building a long-term relationship. Strong partnerships can lead to better pricing, priority support, and access to new products.

– Regular Communication: Maintain open lines of communication to discuss needs, updates, and feedback on product performance.

– Evaluate Performance: Periodically assess the supplier’s performance and reliability to ensure they continue to meet your standards.

Illustrative image related to nylon bristle brush for cleaning

Step 7: Plan for Ongoing Supply Needs

Finally, develop a strategy for ongoing procurement to avoid stock shortages. This is particularly important for businesses with high cleaning demands.

– Inventory Management: Implement an inventory management system to track usage and reorder levels.

– Supplier Evaluation: Regularly review supplier performance to ensure they consistently meet your quality and delivery expectations.

By following these steps, B2B buyers can effectively source nylon bristle brushes for cleaning, ensuring they meet their operational needs while maintaining quality and cost-effectiveness.

Comprehensive Cost and Pricing Analysis for nylon bristle brush for cleaning Sourcing

What Are the Key Cost Components for Sourcing Nylon Bristle Brushes?

When sourcing nylon bristle brushes for cleaning, understanding the cost structure is crucial for effective budgeting and procurement strategies. The primary cost components include:

Illustrative image related to nylon bristle brush for cleaning

-

Materials: The cost of nylon bristles varies based on quality and type. High-quality nylon that is durable and resistant to chemicals will generally incur a higher cost. Additionally, handle materials (plastic, metal, or wood) can also influence total material costs.

-

Labor: Labor costs encompass wages for workers involved in the manufacturing process, including assembly and quality control. Regions with lower labor costs may offer more competitive pricing, but this can also impact the quality of the final product.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and equipment maintenance. Efficient production methods and technology can help reduce overhead, making the final product more cost-effective.

-

Tooling: Custom tooling for specific brush designs can require significant investment. Buyers should consider whether standard products meet their needs or if custom tools are necessary, as this can substantially affect costs.

-

Quality Control (QC): Ensuring the brushes meet industry standards and buyer specifications incurs additional costs. Investing in robust QC processes can prevent costly returns and dissatisfaction later.

-

Logistics: Shipping costs can vary significantly based on the distance, mode of transport, and the volume of goods. International buyers must account for customs duties and potential tariffs when calculating total logistics costs.

-

Margin: Suppliers typically add a markup to cover their costs and profit. Understanding the supplier’s pricing strategy can help in negotiations.

How Do Price Influencers Affect Sourcing Decisions?

Several factors influence the pricing of nylon bristle brushes, which can help buyers make informed decisions:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQ) that can affect pricing. Larger orders usually result in lower per-unit costs due to economies of scale.

-

Specifications and Customization: Customized brushes designed for specific applications can significantly increase costs. Buyers should assess whether they need specialized features or if standard options suffice.

-

Material Quality and Certifications: Brushes made from higher-grade materials or those that meet specific industry certifications (e.g., FDA approval for food-related applications) may command higher prices.

-

Supplier Factors: The reputation, reliability, and geographical location of suppliers can impact pricing. Established suppliers may offer better service and quality assurance but at a premium.

-

Incoterms: The shipping terms agreed upon (e.g., FOB, CIF) can influence overall costs, affecting who bears shipping risks and expenses.

What Are Effective Buyer Tips for Negotiating Prices?

To ensure cost-efficiency and secure favorable pricing, buyers should consider the following strategies:

-

Negotiate Terms: Don’t hesitate to negotiate price, payment terms, and delivery schedules. Suppliers may be willing to offer discounts for upfront payments or larger orders.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors like durability, maintenance, and replacement frequency. A slightly higher initial cost may result in lower long-term expenses.

-

Research Market Prices: Familiarize yourself with the market rates for nylon bristle brushes in your region. This knowledge can enhance your negotiation position.

-

Consider Local Suppliers: For buyers in Africa, South America, the Middle East, and Europe, sourcing locally can reduce shipping costs and lead times, improving overall value.

-

Understand Pricing Nuances for International Trade: Currency fluctuations, import duties, and local regulations can impact the final cost of goods. Buyers should factor these elements into their pricing strategy.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and obtain multiple quotes to ensure the best pricing for your needs.

Alternatives Analysis: Comparing nylon bristle brush for cleaning With Other Solutions

Exploring Alternatives to Nylon Bristle Brushes for Cleaning

When it comes to cleaning applications, nylon bristle brushes are widely recognized for their effectiveness and versatility. However, businesses may also consider alternative cleaning solutions that can meet their specific requirements. This analysis compares nylon bristle brushes against other cleaning technologies, helping B2B buyers make informed decisions based on performance, cost, and application needs.

| Comparison Aspect | Nylon Bristle Brush For Cleaning | Electric Cleaning Machines | Microfiber Cloths |

|---|---|---|---|

| Performance | Excellent for scrubbing and precision cleaning; durable and resistant to solvents. | High efficiency for large areas; ideal for deep cleaning with less manual effort. | Effective for dusting and general cleaning; gentle on surfaces. |

| Cost | Generally low cost, with prices varying based on size and type. | Higher initial investment; long-term savings on labor and cleaning products. | Low cost; reusable and washable, reducing waste. |

| Ease of Implementation | Simple to use; requires no special training. | Requires training for effective operation and maintenance. | Easy to use; no special skills needed. |

| Maintenance | Requires regular cleaning and occasional bristle replacement. | Requires regular maintenance and servicing; may need replacement parts. | Minimal maintenance; can be machine washed. |

| Best Use Case | Ideal for detailed cleaning in various industries, including janitorial and automotive. | Best for large-scale cleaning operations in commercial spaces like hospitals and warehouses. | Suitable for everyday cleaning tasks in offices and homes. |

In-Depth Analysis of Alternative Solutions

Electric Cleaning Machines

Electric cleaning machines, such as floor scrubbers or pressure washers, offer a robust alternative to manual cleaning tools. Their performance is particularly advantageous in large facilities where efficiency is paramount. While they require a higher initial investment, the long-term savings in labor costs and increased cleaning speed can justify the expense. However, they necessitate operator training and regular maintenance, which may not be feasible for all businesses.

Microfiber Cloths

Microfiber cloths present a cost-effective cleaning solution that is gaining popularity across various industries. Their ability to capture dust and dirt without the need for chemical cleaners makes them an eco-friendly choice. Microfiber cloths are low-cost and reusable, reducing waste over time. However, they may not provide the same level of scrubbing power as nylon bristle brushes, making them less suitable for heavy-duty cleaning tasks.

Making the Right Choice for Your Cleaning Needs

In conclusion, selecting the right cleaning solution depends on the specific requirements of your business. Nylon bristle brushes excel in detailed cleaning tasks, providing durability and versatility. In contrast, electric cleaning machines are better suited for large-scale operations that prioritize efficiency, while microfiber cloths offer a sustainable and budget-friendly option for general cleaning. B2B buyers should assess their cleaning needs, budget constraints, and operational capabilities to choose the most effective solution for their requirements. By considering these factors, businesses can ensure they invest in a cleaning method that optimally balances performance, cost, and ease of use.

Illustrative image related to nylon bristle brush for cleaning

Essential Technical Properties and Trade Terminology for nylon bristle brush for cleaning

What Are the Key Technical Properties of Nylon Bristle Brushes for Cleaning?

When selecting nylon bristle brushes for cleaning applications, it is essential to understand several technical properties that influence performance, durability, and cost-effectiveness. Here are critical specifications to consider:

-

Material Grade: Nylon brushes are often made from varying grades of nylon, which can impact their strength, flexibility, and resistance to chemicals. Higher-grade nylon, such as nylon 6/6, offers superior durability and resistance to wear, making it suitable for industrial applications. Choosing the right material grade can enhance the longevity of the brush and reduce replacement costs.

-

Bristle Diameter: The diameter of the bristles typically ranges from 0.003 inches to 0.125 inches, depending on the intended use. Thicker bristles provide more scrubbing power, while thinner bristles are better suited for delicate surfaces. Understanding the appropriate bristle diameter is crucial for ensuring effective cleaning without damaging surfaces.

-

Brush Length and Trim: The overall length and trim of the brush affect its reach and scrubbing effectiveness. For instance, longer brushes can clean hard-to-reach areas, while specific trim shapes (e.g., tapered or flat) are designed for particular cleaning tasks. Selecting the right brush length and trim can optimize cleaning efficiency in various applications.

-

Temperature Resistance: Nylon bristles can withstand a range of temperatures, but specific grades are better suited for high-temperature environments, such as in industrial cleaning applications. Knowing the temperature resistance is vital for ensuring the brush maintains its integrity under operational conditions.

-

Chemical Resistance: Certain nylon formulations are resistant to solvents and chemicals, making them ideal for cleaning tasks involving harsh substances. This property is critical for industries such as automotive or manufacturing, where exposure to chemicals is common. Understanding chemical resistance helps in selecting brushes that will not degrade over time.

-

Fill Density: The density of the bristle fill can influence the brush’s cleaning capability. A higher fill density often results in more effective debris removal but may require more effort to use. Assessing fill density allows buyers to balance cleaning power with ease of use.

What Are Common Trade Terms Associated with Nylon Bristle Brushes?

Understanding industry jargon is crucial for effective communication and negotiation in B2B transactions. Here are several common terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or products that are used in another company’s end product. For nylon bristle brushes, OEMs may supply brushes that are incorporated into larger cleaning systems. This relationship often requires attention to quality standards and specifications.

-

MOQ (Minimum Order Quantity): MOQ denotes the smallest quantity of products a supplier is willing to sell. For nylon bristle brushes, knowing the MOQ can help businesses plan their inventory and budget effectively. This is particularly important for international buyers who may need to manage shipping costs.

-

RFQ (Request for Quotation): An RFQ is a document that a buyer sends to suppliers requesting pricing and other details for specific products. When sourcing nylon bristle brushes, issuing an RFQ allows buyers to compare offers and select the best supplier based on price, quality, and delivery terms.

-

Incoterms (International Commercial Terms): These are predefined commercial terms published by the International Chamber of Commerce that outline the responsibilities of buyers and sellers in international trade. Understanding Incoterms is essential for B2B buyers to clarify who is responsible for shipping, insurance, and tariffs when importing nylon bristle brushes.

-

Lead Time: This term refers to the time it takes from placing an order until it is received. In the context of nylon bristle brushes, understanding lead times helps businesses manage their cleaning supplies and avoid disruptions in operations.

-

Certification Standards: Various industry certification standards (such as ISO) may apply to cleaning brushes, ensuring they meet specific quality and safety guidelines. Familiarity with these certifications can help buyers ensure compliance and quality assurance in their cleaning products.

By grasping these essential properties and trade terminologies, B2B buyers can make informed decisions when procuring nylon bristle brushes for cleaning, ensuring they meet their operational needs and standards.

Navigating Market Dynamics and Sourcing Trends in the nylon bristle brush for cleaning Sector

What Are the Current Market Dynamics and Key Trends in the Nylon Bristle Brush for Cleaning Sector?

The nylon bristle brush market is witnessing significant growth globally, driven by increasing demand across various sectors including janitorial services, industrial cleaning, and consumer products. Key trends include the rising adoption of advanced materials and technologies that enhance the durability and efficacy of cleaning tools. For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, understanding these dynamics is crucial. The emphasis on multifunctional and specialized brushes, such as those designed for specific surfaces or applications, is becoming more pronounced. For instance, brushes tailored for tile and grout cleaning are gaining popularity, reflecting a shift towards targeted cleaning solutions.

Illustrative image related to nylon bristle brush for cleaning

Moreover, the integration of e-commerce platforms is transforming sourcing strategies, enabling buyers to access a broader range of products from suppliers worldwide. B2B buyers are increasingly leveraging online marketplaces to compare prices, evaluate product specifications, and read customer reviews, which supports informed purchasing decisions. Additionally, the emergence of smart cleaning technologies—such as brushes that can integrate with automated cleaning systems—presents new opportunities for suppliers and buyers alike. As sustainability becomes a priority, sourcing nylon bristle brushes that align with eco-friendly practices is also emerging as a key consideration for many businesses.

How Is Sustainability and Ethical Sourcing Influencing the Nylon Bristle Brush Market?

Sustainability and ethical sourcing are becoming critical factors in the purchasing decisions of B2B buyers in the nylon bristle brush sector. The environmental impact of plastic production, including nylon, has prompted businesses to seek suppliers who prioritize eco-friendly practices. This includes using recycled materials in manufacturing, minimizing waste, and adopting energy-efficient production methods. For instance, brushes made from recycled nylon not only reduce environmental impact but also appeal to a growing segment of environmentally-conscious consumers and businesses.

Furthermore, ethical supply chains are gaining traction, with buyers increasingly demanding transparency regarding sourcing practices. This trend is particularly relevant for international buyers who are keen to ensure that their products are sourced responsibly, aligning with their corporate social responsibility (CSR) goals. Certifications such as ISO 14001 for environmental management systems or the Global Recycled Standard (GRS) for recycled materials can enhance supplier credibility in this regard.

As the market shifts towards sustainable practices, suppliers who can demonstrate compliance with green certifications and sustainable sourcing will likely gain a competitive edge. This focus on sustainability not only helps in meeting regulatory requirements but also enhances brand reputation and customer loyalty.

Illustrative image related to nylon bristle brush for cleaning

What Is the Evolution of the Nylon Bristle Brush Industry?

The nylon bristle brush industry has evolved significantly over the decades, transitioning from traditional natural bristles to synthetic materials. This shift began in the mid-20th century when nylon was introduced as a durable and versatile alternative, offering enhanced performance in various cleaning applications. The advantages of nylon—such as resistance to moisture, chemicals, and wear—have made it a preferred material for cleaning brushes across numerous sectors.

As consumer preferences have shifted towards more efficient and specialized cleaning tools, manufacturers have adapted by innovating designs and expanding their product lines. This evolution reflects broader trends in consumer behavior, with an increasing emphasis on hygiene, efficiency, and sustainability. Today, the nylon bristle brush market is characterized by a diverse range of products tailored for specific cleaning needs, highlighting the industry’s responsiveness to market demands and technological advancements.

In conclusion, understanding the dynamics of the nylon bristle brush market, including sustainability and ethical sourcing practices, is essential for B2B buyers aiming to make informed purchasing decisions and align with modern consumer expectations.

Illustrative image related to nylon bristle brush for cleaning

Frequently Asked Questions (FAQs) for B2B Buyers of nylon bristle brush for cleaning

-

How do I choose the right nylon bristle brush for my cleaning needs?

Selecting the appropriate nylon bristle brush depends on the specific cleaning task at hand. Consider the surface material you need to clean—soft bristles are ideal for delicate surfaces, while stiff bristles are better for tougher grime. Additionally, evaluate the brush size and shape, as certain designs, like tapered or specialty brushes, may be more effective for specific applications, such as cleaning tubes or corners. It’s advisable to request samples from suppliers to test performance before making a bulk purchase. -

What is the best nylon bristle brush for industrial cleaning applications?

For industrial cleaning applications, look for nylon bristle brushes that feature stiff bristles, which can effectively tackle heavy-duty grime and debris. Brushes specifically designed for industrial use often have ergonomic handles for better grip and control. Additionally, consider brushes that are resistant to chemicals and solvents, as these will withstand harsh cleaning agents used in various industries. Consulting with suppliers about their product specifications and performance ratings can help identify the best options for your needs. -

What are the minimum order quantities (MOQ) for nylon bristle brushes?

Minimum order quantities (MOQ) for nylon bristle brushes vary by supplier and can depend on factors such as brush type and customization options. Typically, MOQs range from 100 to 1,000 units for standard brushes, while customized options may have higher MOQs. It’s essential to discuss your requirements with potential suppliers and negotiate terms that align with your business’s needs and budget. Always inquire about bulk pricing discounts, as ordering larger quantities can lead to significant savings. -

How can I vet suppliers for nylon bristle brushes in international markets?

When vetting suppliers, start by checking their industry certifications, such as ISO or compliance with international quality standards. Request references from previous clients, particularly those in your region, to gauge reliability and service quality. Consider visiting the supplier’s facility, if possible, or using third-party inspection services to assess their manufacturing processes. Online platforms and trade shows can also provide insights into supplier reputations and product offerings. -

What payment terms should I expect when sourcing nylon bristle brushes?

Payment terms can vary significantly among suppliers. Common terms include a deposit upon order confirmation (usually 30-50%) with the balance due before shipment. Some suppliers may offer net payment terms based on your creditworthiness and relationship with them. It’s advisable to negotiate terms that provide flexibility while ensuring you are protected in case of order issues. Always confirm payment methods accepted, such as wire transfers or letters of credit, to avoid complications. -

What quality assurance measures should I look for in nylon bristle brushes?

Quality assurance measures are crucial for ensuring that the nylon bristle brushes meet performance expectations. Look for suppliers who conduct regular quality checks throughout the manufacturing process, including material inspections and final product testing. Ask if they provide certifications or reports that detail compliance with industry standards. Additionally, consider requesting a trial order to evaluate the brushes’ performance and durability before committing to larger purchases. -

What logistics considerations should I be aware of when importing nylon bristle brushes?

Logistics considerations include shipping methods, customs regulations, and delivery timelines. Assess whether the supplier offers shipping services or if you need to arrange freight forwarding. Understand the customs duties and tariffs applicable to importing brushes in your region, as this can impact overall costs. It’s also wise to plan for potential delays in shipping and customs clearance, especially during peak seasons or global disruptions. -

Can I customize nylon bristle brushes to meet specific needs?

Yes, many suppliers offer customization options for nylon bristle brushes. Customizations can include variations in bristle stiffness, brush shape, size, and handle design. When discussing customization with suppliers, provide detailed specifications and any necessary prototypes to ensure the final product meets your requirements. Keep in mind that custom orders may have higher MOQs and longer lead times, so plan accordingly to align with your project timelines.

Top 5 Nylon Bristle Brush For Cleaning Manufacturers & Suppliers List

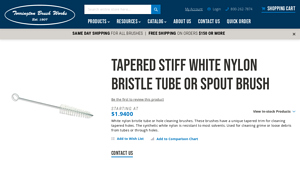

1. Torrington Brushes – Tapered Stiff White Nylon Bristle Tube Brush

Domain: torringtonbrushes.com

Registered: 1999 (26 years)

Introduction: Tapered Stiff White Nylon Bristle Tube or Spout Brush; Starting Price: $1.94; Item Numbers: 06122, 06776; Features: Unique tapered trim for cleaning tapered holes; Material: Synthetic white nylon, resistant to most solvents; Use: Cleaning grime or loose debris from tubes or through holes; Sizes: 06122 – 12″ overall length, fill diameter .014, brush part length 5″, diameter 3/4″ to 1 1/4″; 06776 – …

2. IKEA – Bristle Brush

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Bristle brushes are considered the best cleaning tool for cast iron cookware. They are non-abrasive, can easily reach into the bends of pans, and have a stiff scraping edge similar to a pan scraper. A specific recommendation is the $.79 bristle brush from IKEA.

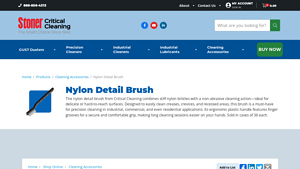

3. Critical Cleaning – Detail Nylon Brush 36 Pack

Domain: criticalcleaning.com

Registered: 1999 (26 years)

Introduction: DETAIL NYLON BRUSH 36 pack

– Ideal for delicate or hard-to-reach surfaces

– Combines stiff nylon bristles with non-abrasive cleaning action

– Ergonomic plastic handle with finger grooves for secure grip

– Designed for precision cleaning in industrial, commercial, and residential applications

– Effective for cleaning crevices, corners, and recessed areas

– Durable construction for frequent use in i…

4. Duraline Systems – Nylon Instrument Cleaning Brush

Domain: duralinesystems.com

Registered: 2012 (13 years)

Introduction: Product Name: Nylon Instrument Cleaning Brush 7″ long

Price: $29.00

Product Code: C-CB-N

Pack Size: 3 brushes per pack

Length: 7 inches

Bristle Material: Nylon

Features:

– Can be sterilized in autoclave

– Intended for cleaning surgical instruments, devices, and equipment

– Latex free

– Ideal for hard to reach places without scratching delicate surfaces

5. MRi Equip – Nylon Bristle Instrument Brush

Domain: mriequip.com

Registered: 2002 (23 years)

Introduction: Nylon Bristle Instrument Brush is a durable and reusable brush used to clean cleaning tools, instruments and miscellaneous parts. It is autoclavable. Available models: TW-5524 (Qty – 3) and TW-5525 (Qty – 12). MSRP: $39.39 – $134.88.

Strategic Sourcing Conclusion and Outlook for nylon bristle brush for cleaning

In summary, strategic sourcing of nylon bristle brushes is essential for international B2B buyers looking to enhance their cleaning product offerings. The versatility of nylon bristles makes them suitable for a wide range of applications, from industrial cleaning to household use, ensuring that businesses can meet diverse customer needs. By focusing on quality, suppliers can significantly impact operational efficiency and customer satisfaction, leading to long-term partnerships and repeat business.

Investing in reliable suppliers who understand the nuances of local markets in regions such as Africa, South America, the Middle East, and Europe is crucial. This approach not only optimizes costs but also fosters innovation in product design and functionality, enhancing competitive advantage. Buyers should also consider bulk purchasing options to maximize savings and streamline logistics.

As the global market continues to evolve, embracing sustainability and eco-friendly practices will further position your brand favorably. Moving forward, international B2B buyers are encouraged to explore new supplier relationships and innovative products in the nylon bristle brush sector to stay ahead of market trends and meet growing consumer demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to nylon bristle brush for cleaning