How to Source Membrane Buttons Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for membrane buttons

In today’s rapidly evolving global market, sourcing high-quality membrane buttons can pose significant challenges for B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe. With a diverse array of options available, navigating through the complexities of types, applications, and supplier qualifications is crucial. Membrane buttons, known for their versatility and sleek design, are increasingly favored in various industries—from medical devices to consumer electronics. However, the task of identifying the right products that meet specific operational requirements can be daunting.

This comprehensive guide is designed to empower international B2B buyers by providing in-depth insights into membrane buttons. Readers will explore the different types of membrane switches, their applications across multiple sectors, and key factors to consider when vetting suppliers. Additionally, the guide will delve into cost considerations, customization options, and industry standards that can influence purchasing decisions. By synthesizing this information, buyers will be better equipped to make informed choices that align with their business needs and operational goals, ensuring they select the most suitable membrane buttons for their unique applications.

Understanding membrane buttons Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Tactile Membrane Switch | Provides physical feedback (click/snap) upon activation | Medical devices, industrial controls, consumer electronics | Pros: Enhanced user experience, clear feedback; Cons: May be less durable than non-tactile types. |

| Non-Tactile Membrane Switch | Lacks physical feedback; activation indicated by lights/sounds | HVAC systems, laboratory instruments, security systems | Pros: Higher resilience, easier to clean; Cons: No tactile feedback may hinder usability in some environments. |

| Graphic Overlay Membrane | Customizable graphics printed directly on the surface | Consumer products, control panels, appliances | Pros: High information density, aesthetic flexibility; Cons: Graphic wear over time may reduce visibility. |

| Silicone Rubber Keypad | Made from elastic silicone, resistant to extreme conditions | Medical electronics, fitness equipment, industrial machines | Pros: Excellent tactile response, robust environmental protection; Cons: Higher cost compared to standard membrane switches. |

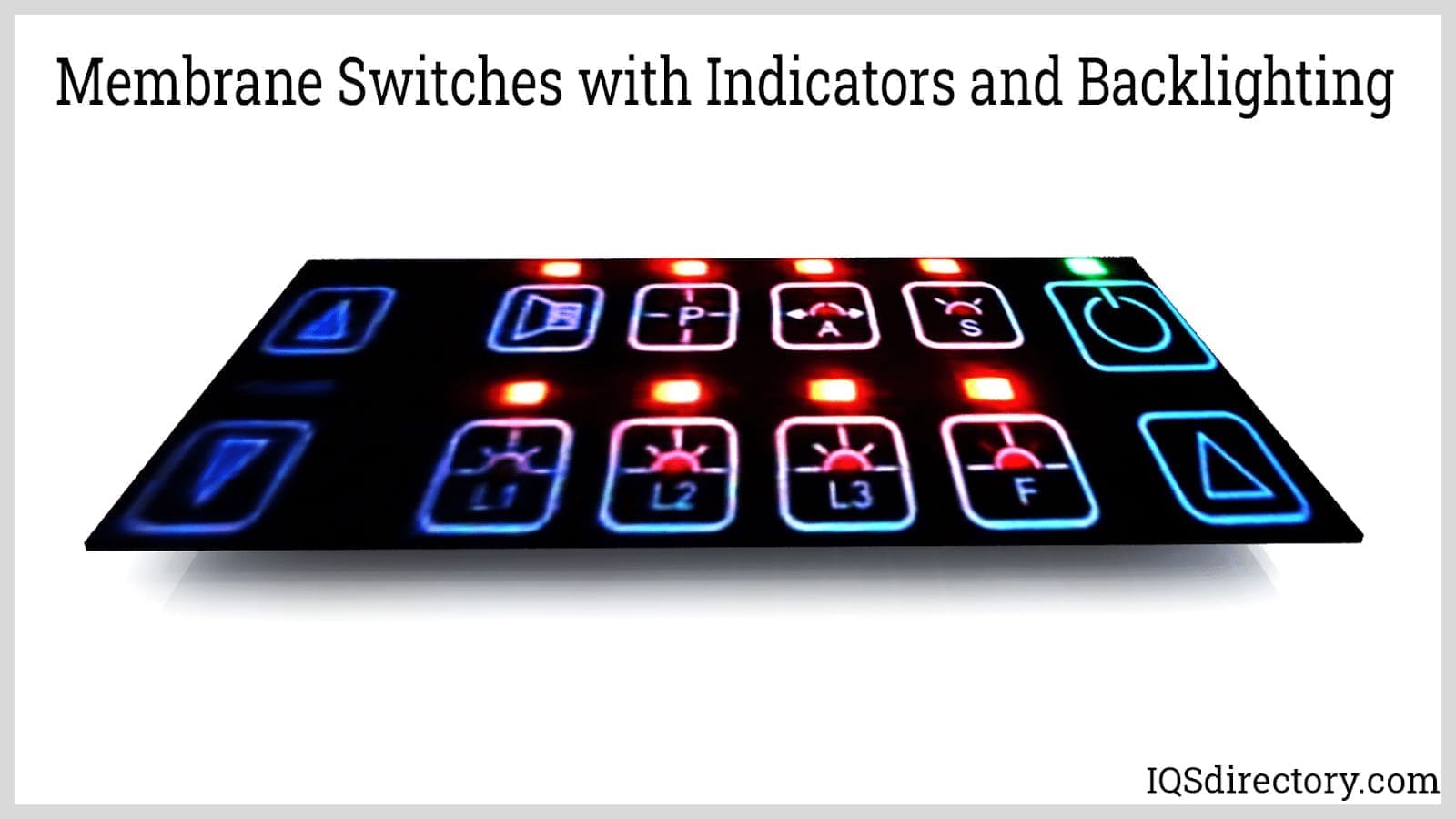

| Backlit Membrane Switch | Integrated lighting for visibility in low-light environments | Aerospace controls, automotive dashboards, emergency systems | Pros: Improved visibility, user-friendly in various conditions; Cons: Increased complexity may raise manufacturing costs. |

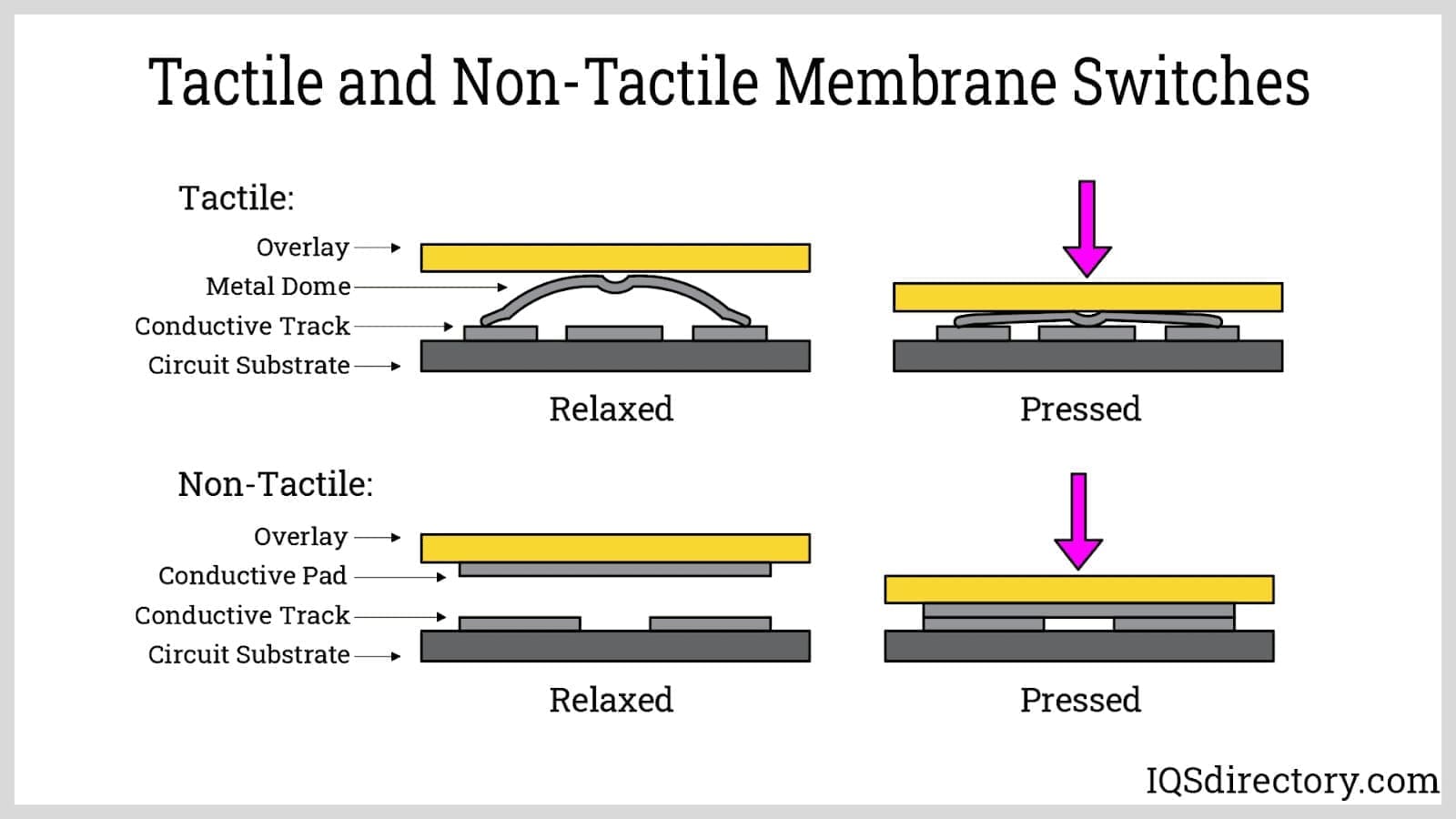

What are the Characteristics of Tactile Membrane Switches?

Tactile membrane switches are designed to provide a physical response when pressed, often characterized by a distinct click or snap. This feature enhances user interaction, making it suitable for applications where feedback is critical, such as medical devices and industrial controls. When considering procurement, B2B buyers should evaluate the switch’s durability and activation force, ensuring it meets specific operational requirements.

How Do Non-Tactile Membrane Switches Function?

Non-tactile membrane switches operate without physical feedback, signaling activation through visual or auditory cues. This type is particularly effective in environments where cleanliness is paramount, such as HVAC systems and laboratories. Buyers should focus on resilience and ease of cleaning when selecting non-tactile options, as these switches are often sealed to prevent contamination.

Why Choose Graphic Overlay Membranes?

Graphic overlay membranes allow for extensive customization, with graphics printed directly onto the switch surface. This feature is advantageous in consumer products and control panels, where clear labeling enhances usability. B2B buyers should consider the longevity of the graphics and the potential for wear over time, as these factors can impact the product’s overall effectiveness.

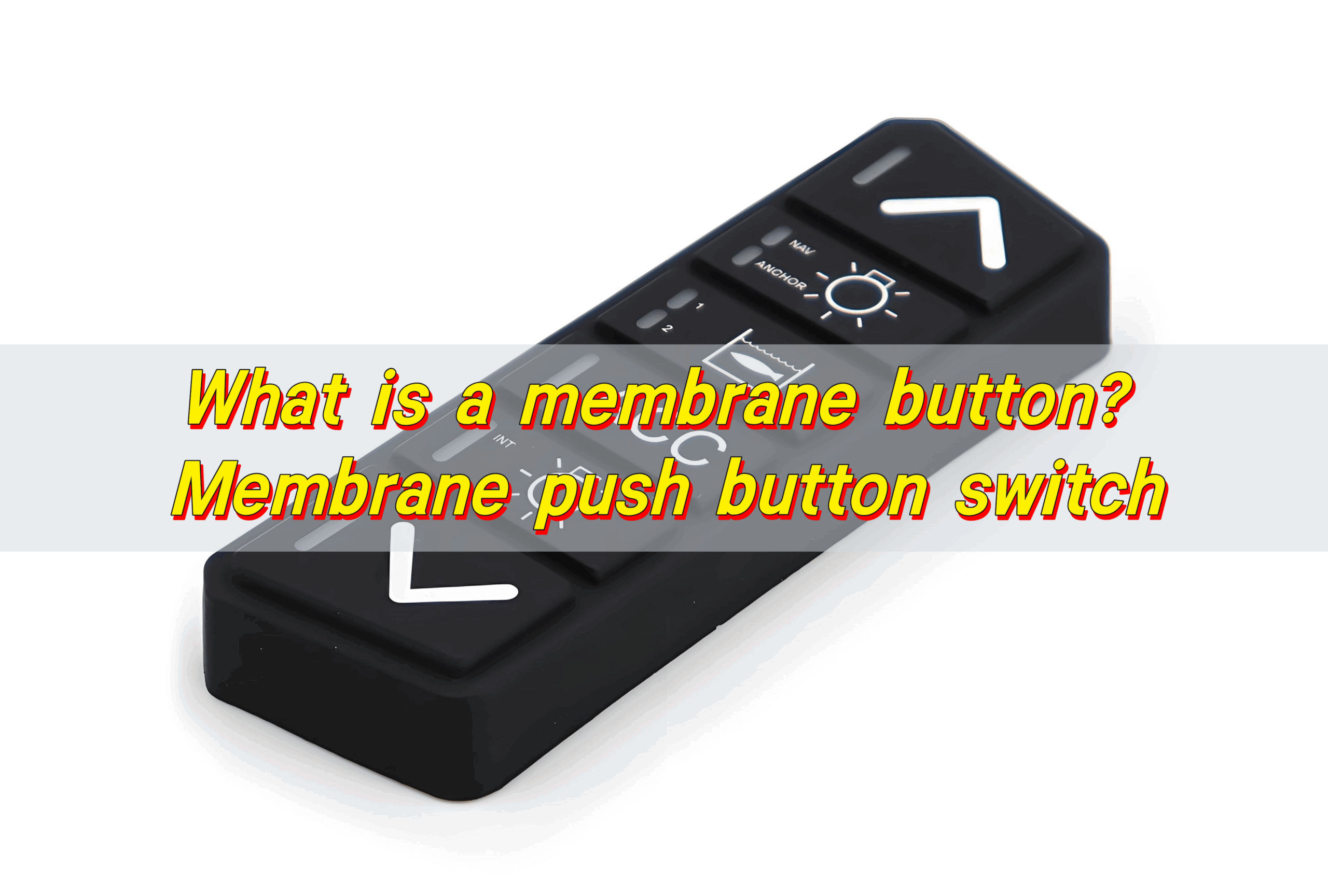

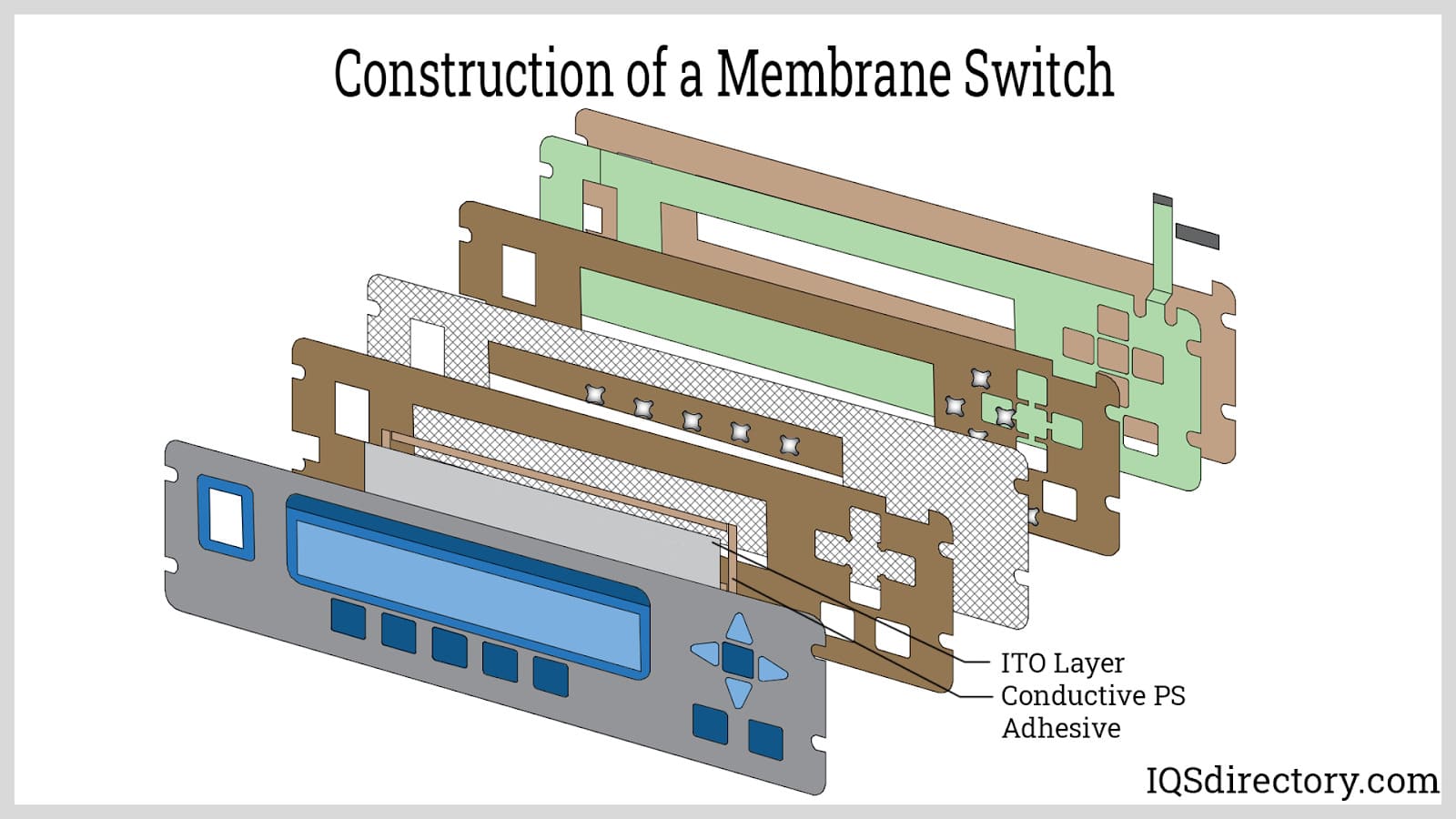

Illustrative image related to membrane buttons

What Advantages Do Silicone Rubber Keypads Offer?

Silicone rubber keypads are known for their excellent tactile feedback and resistance to harsh environmental conditions. Their use in medical electronics and fitness equipment highlights their reliability in demanding applications. When purchasing, buyers should assess the cost versus the benefits of durability and user experience, as these keypads can be more expensive than traditional options.

How Do Backlit Membrane Switches Enhance Usability?

Backlit membrane switches integrate lighting to improve visibility in low-light settings, making them ideal for aerospace and automotive applications. The added complexity of these switches can lead to higher manufacturing costs, so B2B buyers should weigh the benefits of enhanced visibility against budget constraints. Understanding the operational environment is crucial for making informed purchasing decisions regarding backlit options.

Key Industrial Applications of membrane buttons

| Industry/Sector | Specific Application of Membrane Buttons | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Medical Equipment | User interface for diagnostic devices | Enhanced hygiene and durability; easy to clean | Compliance with medical standards and certifications |

| Consumer Electronics | Control panels for home appliances | Compact design and customizable graphics | High-quality printing for clear labeling and branding |

| Industrial Machinery | Control panels in manufacturing equipment | Resistance to harsh environments and user-friendly interface | Material selection for durability and environmental factors |

| Agricultural Equipment | Operator interfaces in tractors and farm machinery | Improved functionality with tactile feedback | Adaptability to various weather conditions and rugged use |

| HVAC Systems | User interfaces for temperature control systems | Enhanced usability and reduced maintenance costs | Compatibility with existing systems and ease of installation |

How Are Membrane Buttons Used in Medical Equipment?

In the medical industry, membrane buttons are integral to the user interfaces of diagnostic devices, such as blood pressure monitors and infusion pumps. These buttons provide a sealed surface that minimizes contamination risks, making them easier to clean and maintain. For international buyers, especially in regions like Africa and the Middle East, sourcing options should consider compliance with medical device standards, ensuring that the switches can withstand rigorous sterilization processes without degradation.

What Role Do Membrane Buttons Play in Consumer Electronics?

Membrane buttons are commonly found in household appliances like microwaves and coffee makers. Their sleek design allows manufacturers to integrate intricate graphics directly onto the buttons, enhancing user experience. Buyers from South America and Europe should prioritize suppliers who can deliver high-quality printing and customization options that align with brand identity, ensuring clarity in labeling and functionality.

Why Are Membrane Buttons Essential in Industrial Machinery?

In manufacturing environments, membrane buttons are used in control panels for machinery, providing a user-friendly interface that can withstand harsh conditions. They are resistant to dust, moisture, and chemicals, which is crucial for maintaining operational efficiency. B2B buyers in regions with diverse industrial landscapes, such as Brazil and Saudi Arabia, should focus on sourcing durable materials that meet the specific environmental challenges of their operations.

How Do Membrane Buttons Enhance Agricultural Equipment?

In agricultural settings, membrane buttons are utilized in tractors and other machinery, providing operators with tactile feedback for improved control. This is particularly beneficial in noisy or vibration-heavy environments where visual confirmation might be difficult. Buyers should consider the buttons’ resilience to extreme weather conditions and their ability to function reliably under rugged use, which is critical for agricultural applications in diverse climates.

What Benefits Do Membrane Buttons Offer in HVAC Systems?

Membrane buttons serve as user interfaces for HVAC systems, allowing users to adjust settings for optimal comfort. Their design facilitates easy cleaning and maintenance, crucial for systems that require regular upkeep. When sourcing for this application, businesses should evaluate compatibility with existing systems and the ease of installation, ensuring that the buttons integrate seamlessly into various HVAC configurations.

3 Common User Pain Points for ‘membrane buttons’ & Their Solutions

Scenario 1: Difficulty in Customization for Diverse Applications

The Problem: B2B buyers often face challenges when attempting to customize membrane buttons for specific applications across various industries. Each application, whether in medical devices, industrial machinery, or consumer electronics, may have unique requirements such as size, tactile feedback, and environmental resistance. This complexity can lead to frustration, especially when suppliers cannot meet these specific needs, resulting in delays in product development and increased costs.

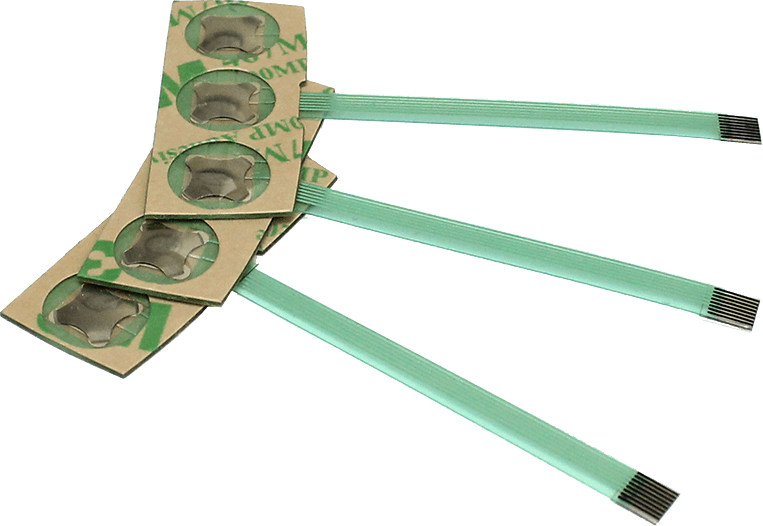

The Solution: To navigate this issue, buyers should prioritize manufacturers with extensive customization capabilities and a collaborative approach. Engage with suppliers who provide design consultation services, allowing for tailored solutions that meet your specific application needs. When specifying membrane buttons, clearly outline your requirements, including dimensions, material preferences, and operational conditions. Utilizing prototypes can also be invaluable; request samples to evaluate their performance in real-world scenarios before committing to a full order. This proactive approach not only mitigates customization challenges but also fosters a stronger partnership with the supplier.

Illustrative image related to membrane buttons

Scenario 2: Concerns About Durability and Performance

The Problem: Durability is a critical concern for B2B buyers, particularly in industries where membrane buttons are exposed to harsh conditions, such as extreme temperatures, moisture, or chemical exposure. Buyers may worry about the longevity of membrane buttons and their ability to maintain functionality over time, especially in high-use environments. A failure in this aspect can lead to costly repairs, replacements, and disruptions in operations.

The Solution: To address durability concerns, buyers should focus on selecting membrane buttons designed with robust materials and construction methods. Inquire about the specific materials used in the overlays and layers, such as polycarbonate or polyester, which offer enhanced resistance to scratches and chemicals. Additionally, ask for performance testing results that demonstrate the buttons’ resilience under various environmental conditions. Establishing clear communication with suppliers about your operational environment will enable them to recommend the most suitable membrane switches. Regular maintenance and cleaning protocols should also be implemented to extend the lifespan of the membrane buttons, ensuring they continue to perform optimally.

Scenario 3: User Experience and Accessibility Challenges

The Problem: In applications where user experience is paramount, B2B buyers often struggle with ensuring that membrane buttons are intuitive and accessible for all users, including those with disabilities or in challenging environments. If the buttons lack tactile feedback or are not designed for ease of use, it can lead to user frustration and errors, ultimately impacting product effectiveness and customer satisfaction.

The Solution: To improve user experience, buyers should consider the integration of tactile membrane switches that provide physical feedback upon activation. This is particularly beneficial for users who may not be able to rely on visual cues. When designing the interface, work closely with UX specialists to create a layout that is both logical and user-friendly. Additionally, consider incorporating features such as larger buttons or symbols that are easy to understand. Testing the buttons with actual users during the development phase can provide invaluable insights into usability and accessibility. By prioritizing user-centered design principles, B2B buyers can create more effective and satisfying interactions with their products, ultimately enhancing overall customer satisfaction.

Illustrative image related to membrane buttons

Strategic Material Selection Guide for membrane buttons

What Are the Key Materials for Membrane Buttons?

When selecting materials for membrane buttons, it is crucial for B2B buyers to consider their properties, advantages, and limitations. The choice of material can significantly impact the performance, durability, and overall suitability of the membrane buttons for specific applications. Here, we analyze four common materials used in the production of membrane buttons: polyester, polycarbonate, silicone rubber, and acrylic.

How Does Polyester Perform in Membrane Buttons?

Polyester is a widely used material for membrane buttons due to its excellent clarity and durability. It can withstand temperatures ranging from -40°C to 120°C and offers good chemical resistance against oils and solvents. The primary advantage of polyester is its affordability and ease of printing, making it suitable for high-volume production.

However, polyester can be less resistant to UV light compared to other materials, which may lead to fading over time, particularly in outdoor applications. For international buyers, especially in regions like Africa and the Middle East, it’s important to ensure that the polyester used complies with local standards for durability and chemical resistance.

Illustrative image related to membrane buttons

What Are the Benefits of Polycarbonate in Membrane Buttons?

Polycarbonate is known for its high impact resistance and ability to withstand extreme temperatures, ranging from -40°C to 125°C. This material is particularly advantageous in environments where mechanical stress or harsh conditions are expected. Polycarbonate buttons can be designed with tactile feedback, enhancing user interaction.

On the downside, polycarbonate is generally more expensive than polyester, which may affect budget considerations for large-scale projects. Additionally, it can be prone to scratching, necessitating coatings for enhanced durability. Buyers in Europe and South America should consider compliance with standards such as ASTM and ISO when sourcing polycarbonate materials.

Why Choose Silicone Rubber for Membrane Buttons?

Silicone rubber is often favored for its excellent tactile feedback and resistance to extreme temperatures, making it ideal for applications in medical devices and outdoor equipment. This material can endure temperatures from -60°C to 200°C and is highly resistant to aging and environmental factors.

While silicone rubber provides superior durability, it is typically more expensive than polyester and polycarbonate. The manufacturing process can also be more complex, which may lead to longer lead times. For international buyers, especially in regions like Brazil and Saudi Arabia, understanding local regulations regarding silicone use in electronics is essential.

What Role Does Acrylic Play in Membrane Buttons?

Acrylic is another viable option for membrane buttons, known for its optical clarity and lightweight properties. It can withstand temperatures from -30°C to 80°C and offers good resistance to UV light, making it suitable for outdoor applications. Acrylic can be easily molded into various shapes, allowing for creative designs.

However, acrylic is less durable than polycarbonate and can be susceptible to scratching and impact damage. Its cost is generally moderate, making it a good middle-ground option for buyers looking for balance between performance and affordability. Compliance with international standards such as JIS and DIN is crucial for ensuring product quality.

Summary Table of Material Properties for Membrane Buttons

| Material | Typical Use Case for membrane buttons | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Consumer electronics, appliances | Affordable and easy to print | Less UV resistance | Low |

| Polycarbonate | Medical devices, industrial controls | High impact resistance | More expensive, prone to scratching | High |

| Silicone Rubber | Medical devices, outdoor equipment | Excellent tactile feedback | Higher cost, complex manufacturing | High |

| Acrylic | Outdoor applications, signage | Good optical clarity | Less durable, susceptible to scratches | Medium |

This strategic material selection guide provides essential insights for B2B buyers looking to make informed decisions regarding membrane buttons. By understanding the properties and implications of each material, companies can better align their product designs with market demands and regulatory standards.

In-depth Look: Manufacturing Processes and Quality Assurance for membrane buttons

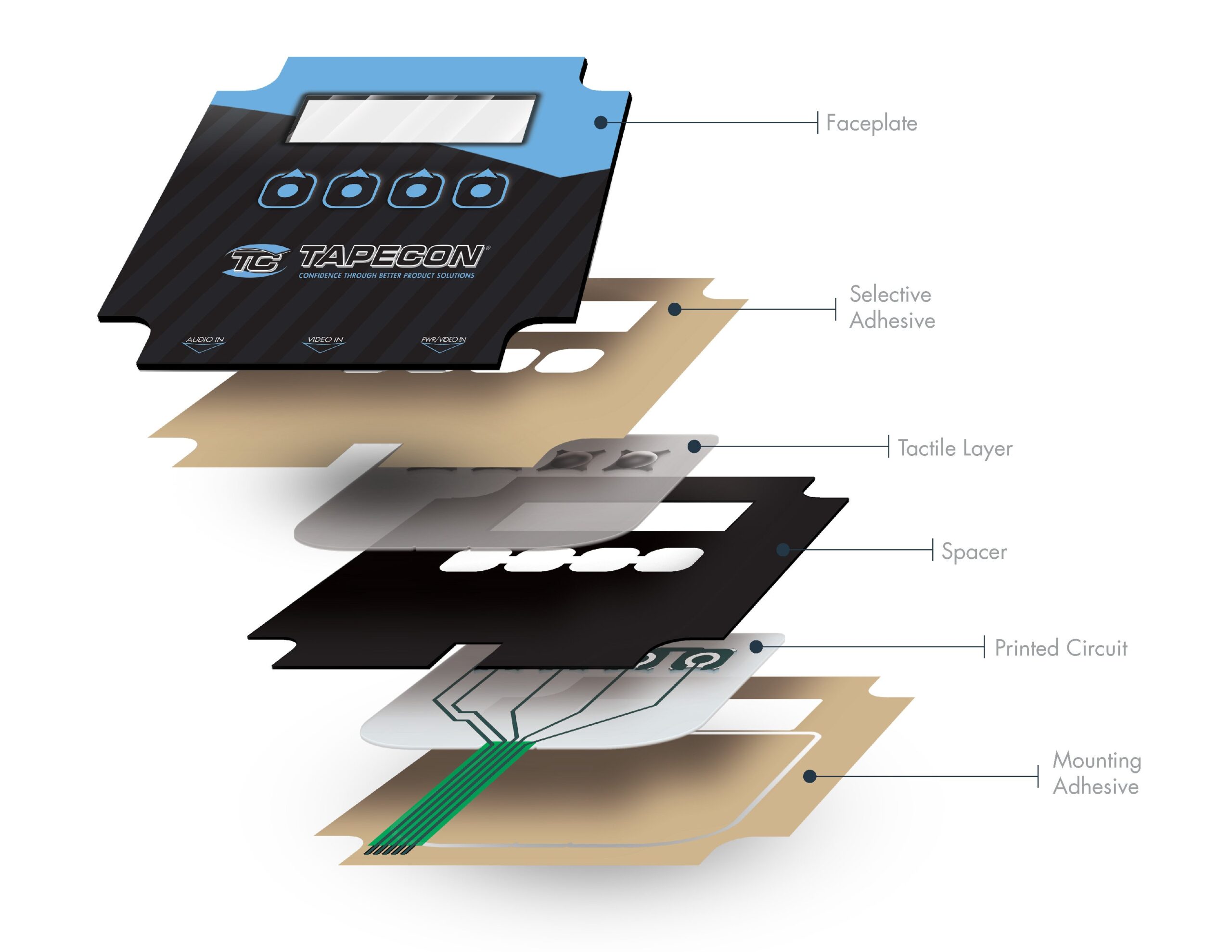

What Are the Main Stages in the Manufacturing Process of Membrane Buttons?

The manufacturing process of membrane buttons involves several critical stages, each essential for ensuring that the final product meets the required specifications for functionality, durability, and aesthetics.

Material Preparation

The first stage in the manufacturing of membrane buttons is material preparation. This involves selecting the appropriate materials, typically polycarbonate or polyester for the graphic overlay, and conductive inks for the printed circuit layers. The choice of materials is crucial, as they must withstand various environmental conditions, including temperature fluctuations, moisture, and potential chemical exposure. Suppliers often utilize advanced software for material selection to ensure compatibility with the intended application.

Illustrative image related to membrane buttons

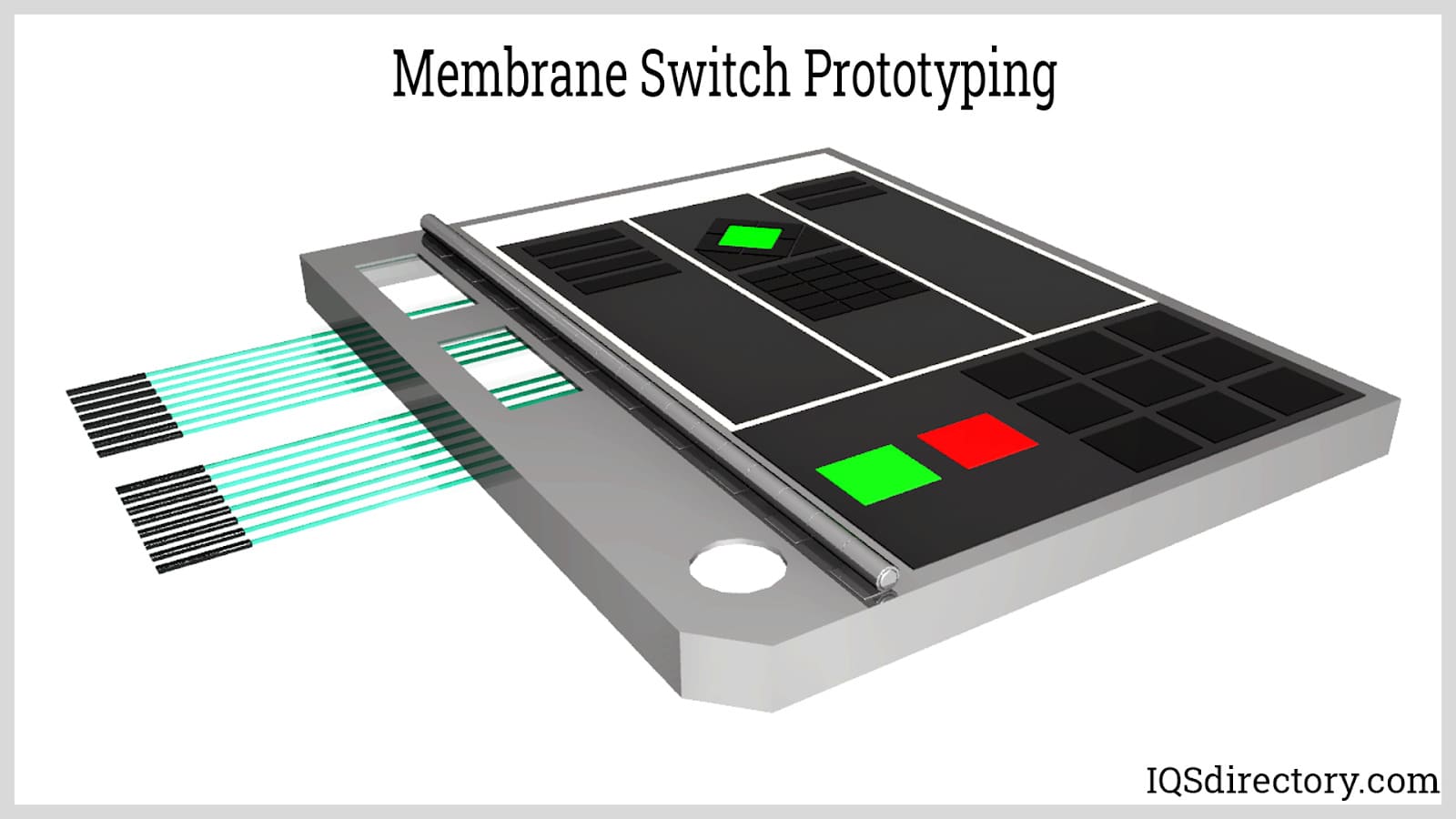

Forming Techniques

Once the materials are prepared, the forming stage begins. This typically includes the printing of graphics and circuit patterns onto the membrane layers using techniques such as screen printing or digital printing. Screen printing is widely used for its efficiency in producing high-quality, durable graphics, while digital printing allows for more intricate designs with shorter lead times. Additionally, laser cutting may be employed to shape the overlays and other components precisely. This stage is critical as it directly impacts the usability and visual appeal of the membrane switch.

Assembly Process

The assembly stage involves layering the various components to create the final membrane switch. This process typically consists of stacking the graphic overlay, adhesive layers, circuit layers, and any additional elements such as tactile domes or spacers. The assembly must be executed with precision to ensure that the switches function correctly and provide tactile feedback when pressed. Automated assembly lines are often utilized to enhance efficiency and reduce the likelihood of human error.

Finishing Touches

The final stage of manufacturing is the finishing process, which may include applying protective coatings, conducting visual inspections, and preparing the product for shipping. Finishing touches are vital to enhance the durability of the membrane buttons, ensuring they can withstand wear and tear over time. Quality checks are conducted at various points throughout the manufacturing process to identify and rectify any defects before the product reaches the customer.

How Is Quality Assurance Implemented in Membrane Button Production?

Quality assurance (QA) is an integral part of the manufacturing process for membrane buttons, ensuring that the final products meet international standards and customer expectations.

What International Standards Are Relevant for Membrane Buttons?

For B2B buyers, understanding the relevant international standards is crucial. ISO 9001 is a widely recognized standard that outlines requirements for a quality management system. Compliance with ISO 9001 ensures that manufacturers consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE (Conformité Européenne) for products sold in the European market and API (American Petroleum Institute) standards for applications in the oil and gas industry may also apply.

What Are the Key Quality Control Checkpoints?

Quality control (QC) involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): At this initial stage, raw materials are inspected upon arrival to ensure they meet the specified quality standards before being used in production.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor the production stages. This includes checking the accuracy of printed graphics and circuit patterns, as well as ensuring proper alignment during assembly.

-

Final Quality Control (FQC): After assembly, a comprehensive inspection is performed. This includes functional testing to verify that the membrane buttons operate as intended and that they meet durability standards.

What Common Testing Methods Are Used for Membrane Buttons?

Testing methods for membrane buttons vary based on application requirements but typically include:

-

Electrical Testing: Verifying the conductivity of the circuits and ensuring that the buttons respond correctly when pressed.

-

Environmental Testing: Assessing the buttons’ performance under different environmental conditions, such as temperature extremes and exposure to moisture or chemicals.

-

Tactile Feedback Testing: For tactile membrane switches, testing is conducted to ensure that the tactile feedback meets user requirements, including the force required to activate the switch.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is critical for mitigating risks and ensuring product reliability.

What Steps Should Buyers Take for Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control capabilities. Buyers should consider the following steps:

Illustrative image related to membrane buttons

-

Request Documentation: Ask for quality assurance documentation, including certifications, quality management system reports, and records of past audits.

-

Conduct On-Site Visits: If feasible, visiting the manufacturing facility allows buyers to observe the production process and QA practices firsthand.

-

Review Test Reports: Request access to testing reports, including results from IQC, IPQC, and FQC stages. This information can provide insights into the supplier’s commitment to quality.

-

Evaluate Third-Party Inspections: Inquire whether the manufacturer engages third-party inspection services. Independent verification can enhance confidence in the supplier’s quality claims.

What Are the Quality Control Nuances for International Buyers?

B2B buyers from different regions may encounter unique quality control nuances. For instance:

-

Regulatory Compliance: Buyers must be aware of the specific regulatory requirements in their region. For example, products sold in Europe must comply with CE standards, while those in the Middle East may have different certification requirements.

-

Cultural Differences: Understanding cultural attitudes towards quality can also influence supplier relationships. In some regions, personal relationships and trust may play a significant role in business dealings.

-

Supply Chain Considerations: International buyers should consider potential supply chain disruptions and ensure that their suppliers have contingency plans in place to maintain quality during unforeseen events.

By understanding the manufacturing processes and quality assurance measures for membrane buttons, B2B buyers can make informed decisions, ensuring they partner with reliable suppliers that meet their quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘membrane buttons’

In the competitive landscape of B2B procurement, sourcing membrane buttons requires a strategic approach to ensure quality, functionality, and cost-effectiveness. This guide provides a step-by-step checklist to help international buyers navigate the complexities of procuring membrane switches, ensuring they make informed decisions tailored to their specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is essential for successful procurement. Consider factors such as the intended application, required durability, environmental conditions, and user interface design. This clarity helps in communicating your needs to suppliers and ensures that the products meet your operational requirements.

Step 2: Identify the Suitable Type of Membrane Switch

Membrane switches come in various types, including tactile and non-tactile options. Assess your application to determine which type best suits your needs:

– Tactile switches provide physical feedback, ideal for applications requiring confirmation of activation.

– Non-tactile switches are better for environments prone to contamination, as they offer a more sealed design.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers to ensure they align with your business needs. Request company profiles, product samples, and references from other clients in your industry. Look for suppliers with a proven track record in manufacturing membrane switches, as this can significantly impact the quality and reliability of your order.

Step 4: Verify Supplier Certifications and Compliance

Ensure that your chosen suppliers comply with relevant industry standards and certifications. This is particularly important in regulated sectors such as medical and aerospace. Verify certifications such as ISO 9001 or RoHS compliance, which indicate adherence to quality management systems and environmental regulations, respectively.

Step 5: Request Customization Options

One of the key advantages of membrane switches is their high level of customization. Discuss your design preferences, including graphic overlays, colors, and branding elements. Understanding the scope of customization available can help you create a product that aligns with your brand identity and user experience goals.

Step 6: Assess Production Capabilities and Lead Times

Evaluate the production capabilities of your suppliers to ensure they can meet your volume requirements. Discuss lead times for production and delivery, especially if you have tight project deadlines. A reliable supplier should provide a clear timeline and be able to scale production if needed.

Step 7: Negotiate Pricing and Terms

Once you have identified a suitable supplier, engage in negotiations to establish favorable pricing and payment terms. Consider factors such as bulk order discounts, payment schedules, and warranty provisions. A well-negotiated agreement can enhance your overall procurement strategy and reduce costs.

By following this checklist, B2B buyers can effectively navigate the sourcing process for membrane buttons, ensuring they select the right products that meet their technical and business requirements.

Comprehensive Cost and Pricing Analysis for membrane buttons Sourcing

What Are the Key Cost Components for Membrane Buttons?

When sourcing membrane buttons, understanding the cost structure is crucial for B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to membrane buttons

-

Materials: The choice of materials significantly impacts the overall cost. Common materials include polyester, polycarbonate for overlays, and conductive inks for circuitry. Higher quality or specialty materials, such as those providing enhanced durability or chemical resistance, will increase costs.

-

Labor: Labor costs can vary based on the complexity of the design and the manufacturing processes involved. Automated processes may reduce labor costs, but custom designs typically require skilled labor for assembly and quality assurance.

-

Manufacturing Overhead: This includes costs associated with the facility, utilities, and equipment maintenance. Overhead costs can fluctuate based on the location of the manufacturer and their operational efficiency.

-

Tooling: Custom tooling for specific designs can be a significant upfront expense. This cost can be amortized over larger production runs, making it essential to consider volume when negotiating prices.

-

Quality Control: Implementing rigorous QC measures ensures product reliability and compliance with industry standards. While this incurs additional costs, it can prevent costly recalls or product failures in the long run.

-

Logistics: Transportation costs depend on the shipping method, distance, and whether the supplier includes Incoterms that dictate who bears responsibility for shipping risks. International logistics can add complexity and costs, especially if customs duties apply.

-

Margin: Finally, the supplier’s profit margin plays a role in pricing. This can vary significantly based on the supplier’s market positioning, brand reputation, and competitive landscape.

How Do Price Influencers Affect Membrane Button Costs?

Several factors can influence the pricing of membrane buttons, particularly for international B2B buyers.

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Higher volumes typically lead to better pricing due to economies of scale, while lower quantities may incur higher per-unit costs.

-

Specifications and Customization: Custom designs that require unique features or specific performance criteria will generally cost more. Buyers should weigh the benefits of customization against the added costs.

-

Material Choices: The selection of materials not only affects durability and functionality but also the price. High-performance materials will increase costs, so it’s essential to balance quality and budget.

-

Quality and Certifications: Compliance with industry standards and certifications can add to the costs. However, investing in certified products can enhance the product’s marketability and reduce liability risks.

-

Supplier Factors: The reputation, reliability, and service level of the supplier can also influence pricing. Suppliers with robust customer support and proven track records may command higher prices.

-

Incoterms: Understanding Incoterms is vital for international shipping. They define the responsibilities of buyers and sellers, impacting total costs, including shipping, insurance, and duties.

What Are the Best Buyer Tips for Cost-Efficiency in Sourcing Membrane Buttons?

For international buyers, particularly from regions like Africa, South America, the Middle East, and Europe, here are strategic tips to ensure cost-effective sourcing:

-

Negotiate Terms: Always negotiate pricing and payment terms with suppliers. Explore options for bulk discounts or flexible payment schedules to optimize cash flow.

-

Focus on Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider maintenance, replacement costs, and potential savings from higher-quality products, which can lead to long-term cost efficiencies.

-

Research Suppliers Thoroughly: Vet suppliers based on their production capabilities, quality standards, and customer reviews. A reliable supplier may save costs associated with defects and delays.

-

Consider Regional Suppliers: When possible, partner with local suppliers to reduce shipping costs and lead times, especially for urgent projects.

-

Be Aware of Pricing Nuances: Understand that prices may fluctuate based on market demand, currency exchange rates, and geopolitical factors. Regularly review contracts and pricing agreements to ensure competitiveness.

Disclaimer

The prices discussed in this analysis are indicative and may vary based on market conditions, specific project requirements, and supplier negotiations. Always consult with multiple suppliers to obtain accurate and up-to-date pricing for your specific needs.

Alternatives Analysis: Comparing membrane buttons With Other Solutions

When selecting user interface solutions, businesses often evaluate various technologies to meet their operational needs. Membrane buttons, known for their compact design and versatile functionality, face competition from several alternatives. This section compares membrane buttons with two viable alternatives: mechanical switches and touch screens, providing insight into their respective advantages and drawbacks.

| Comparison Aspect | Membrane Buttons | Mechanical Switches | Touch Screens |

|---|---|---|---|

| Performance | Reliable, momentary action; good tactile feedback (if tactile) | High durability; excellent tactile feedback | High versatility; multi-functional |

| Cost | Generally lower cost; affordable materials | Higher initial cost; more complex manufacturing | Higher cost due to technology and components |

| Ease of Implementation | Simple integration into designs; customizable | More complex; requires precise fitting | Requires software integration; may need calibration |

| Maintenance | Low maintenance; easy to clean | Moderate; can wear down over time | Higher; screen damage and software issues possible |

| Best Use Case | Ideal for compact devices, medical equipment, and environments needing hygiene | Suitable for heavy machinery and environments with high wear | Best for applications requiring dynamic user interfaces and rich content |

What Are the Pros and Cons of Mechanical Switches as an Alternative to Membrane Buttons?

Mechanical switches provide a tactile feel and are known for their durability and reliability in high-use applications. They are often preferred in environments where feedback is critical, such as in industrial settings. However, they typically have a higher cost and require more complex installation processes compared to membrane buttons. Their bulkier design can also limit their use in compact electronic devices. Additionally, they may require more maintenance over time, as moving parts can wear down and fail.

How Do Touch Screens Compare to Membrane Buttons?

Touch screens offer a modern, sleek interface that allows for dynamic interaction with devices. They are highly versatile, supporting various applications from simple button presses to complex gestures. However, touch screens generally come with a higher price tag due to the technology involved and may require sophisticated software integration. Maintenance can be a concern, as screens can be prone to damage and may require regular updates or calibrations. While they provide a rich user experience, they may not be the best choice for environments that require tactile feedback or where users may be wearing gloves.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Choosing the right user interface solution depends on the specific requirements of the application. B2B buyers should consider factors such as the operational environment, user interaction needs, cost constraints, and maintenance capabilities. For compact devices that prioritize affordability and hygiene, membrane buttons may be the best fit. In contrast, mechanical switches are suitable for heavy-duty applications requiring durability, while touch screens are ideal for applications demanding a modern interface and complex functionalities. By assessing these aspects, buyers can make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for membrane buttons

What are the Key Technical Properties of Membrane Buttons?

Understanding the technical specifications of membrane buttons is crucial for B2B buyers, especially when selecting components for various applications. Here are some critical specifications to consider:

-

Material Grade

Membrane buttons are typically made from materials such as polyester or polycarbonate. The choice of material affects durability, flexibility, and resistance to environmental factors like moisture and chemicals. Higher-grade materials ensure longer product life and reliability, which is essential for industries like medical and industrial applications where equipment must withstand rigorous use. -

Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In membrane buttons, tight tolerances ensure that the switches function correctly and fit perfectly within the designated space. This is especially important in custom applications where even minor discrepancies can lead to malfunctions or misalignment, impacting user experience and device performance. -

Activation Force

This specification defines the amount of pressure required to activate a membrane switch. It is an important factor for user comfort and usability. A lower activation force may be preferred in consumer electronics, while a higher force might be necessary in industrial settings to prevent accidental activation. Understanding this helps in designing user interfaces that cater to the intended audience. -

Environmental Resistance

Membrane buttons are often designed to resist environmental factors such as dust, moisture, and temperature extremes. This property is critical for applications in harsh environments, such as outdoor equipment or medical devices, where reliability is paramount. Buyers should assess the environmental conditions their products will face to select appropriate membrane switches. -

Lifecycle and Durability

Lifecycle refers to the number of activations a membrane button can endure before failure. This is crucial for applications requiring frequent use, such as in fitness equipment or industrial controls. High durability reduces the need for replacements, saving costs in the long run.

What are Common Trade Terms Related to Membrane Buttons?

Familiarity with industry terminology can streamline communication and negotiations in the B2B space. Here are some essential terms:

-

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. In the context of membrane buttons, understanding OEM relationships is vital for sourcing quality components that meet specific design and performance standards. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. This term is crucial for budgeting and inventory management. Buyers should negotiate MOQs that align with their production needs while ensuring they do not overstock or run short on essential components. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to invite them to bid on providing specific goods or services. It typically includes details about the product specifications, quantities, and delivery timelines. Using an RFQ helps buyers obtain competitive pricing and ensures they receive accurate information from multiple suppliers. -

Incoterms (International Commercial Terms)

Incoterms are a set of standardized trade terms used in international contracts to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with these terms can help buyers understand their obligations and rights during the procurement process, minimizing risks associated with international transactions. -

Customization Options

This term refers to the ability to tailor membrane buttons to meet specific design and functional requirements, such as size, shape, graphics, and tactile feedback. Customization is essential for manufacturers looking to create unique products that stand out in the market.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that align with their operational needs and strategic goals, ultimately enhancing product performance and market competitiveness.

Navigating Market Dynamics and Sourcing Trends in the membrane buttons Sector

What Are the Key Drivers Influencing the Membrane Buttons Market?

The membrane buttons market is witnessing significant growth driven by various global factors. The increasing demand for user-friendly interfaces in consumer electronics, medical devices, and industrial controls is a primary catalyst. As the trend towards miniaturization continues, membrane buttons offer a space-efficient solution compared to traditional mechanical switches. Emerging technologies, such as the integration of biometric sensors and touch-sensitive functionalities, are also enhancing the capabilities of membrane buttons, making them more attractive to manufacturers.

International B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, are increasingly prioritizing suppliers who can provide customized solutions tailored to specific industry needs. For instance, sectors such as healthcare and foodservice are looking for membrane buttons that comply with stringent hygiene standards and can withstand harsh environments. Furthermore, the rise of smart technology is prompting manufacturers to incorporate advanced features into their membrane switches, ensuring they remain competitive in a rapidly evolving market.

What Are the Current Sourcing Trends in the Membrane Buttons Sector?

In terms of sourcing trends, international buyers are focusing on establishing long-term partnerships with manufacturers who demonstrate innovation and reliability. The shift towards just-in-time (JIT) manufacturing is gaining traction, allowing businesses to reduce inventory costs while ensuring the availability of the latest technologies. Additionally, the demand for quick turnaround times is pushing suppliers to enhance their production capabilities, often leveraging automation and digital technologies.

Illustrative image related to membrane buttons

Another notable trend is the increasing importance of supply chain transparency. Buyers are seeking suppliers who can provide detailed information about the sourcing of raw materials and the manufacturing process. This focus on transparency is driven by a growing awareness of ethical considerations and sustainability in production practices.

How Does Sustainability Impact the Membrane Buttons Market?

Sustainability has become a critical factor in the membrane buttons sector, with buyers increasingly concerned about the environmental impact of their sourcing decisions. The production processes for membrane buttons can involve harmful chemicals and materials, which raises questions about their ecological footprint. As such, manufacturers are being urged to adopt greener practices, such as using environmentally friendly inks and recyclable materials in their products.

The importance of ethical supply chains is also gaining prominence, as businesses strive to align with consumer preferences for sustainable and socially responsible products. Certifications such as ISO 14001 for environmental management systems and RoHS compliance for hazardous substances are becoming standard requirements for suppliers. By prioritizing suppliers with ‘green’ certifications, international B2B buyers can ensure they contribute to a more sustainable industry while also enhancing their brand reputation.

What Is the Brief Evolution of Membrane Buttons in the B2B Context?

The evolution of membrane buttons can be traced back to the late 20th century when they first emerged as a cost-effective alternative to traditional mechanical switches. Their design allowed for greater flexibility in product development, leading to widespread adoption across various industries, including automotive, medical, and consumer electronics.

Initially, membrane buttons were primarily used in low-tech applications; however, advancements in materials and technology have significantly broadened their use. Today, they are integral to modern user interfaces, offering enhanced functionality and design versatility. The shift towards automation and smart devices has further propelled the evolution of membrane buttons, making them indispensable in the current technological landscape. For B2B buyers, understanding this evolution helps in appreciating the value and potential of membrane buttons in their product offerings.

Illustrative image related to membrane buttons

Frequently Asked Questions (FAQs) for B2B Buyers of membrane buttons

-

How do I choose the right membrane button for my application?

Choosing the right membrane button involves assessing your specific application needs, such as environmental conditions, user interaction, and design requirements. Consider whether you need tactile feedback or prefer a non-tactile option. Additionally, think about the durability required, as some applications may demand resistance to chemicals or moisture. Collaborating with a supplier who offers design support can help ensure the selected membrane buttons align with your product specifications and functionality. -

What are the advantages of using membrane buttons over mechanical switches?

Membrane buttons offer several advantages, including a slim profile, ease of cleaning, and customization options. They are resistant to dust and moisture, making them ideal for environments where contamination is a concern. Additionally, membrane switches can be designed with graphics printed directly onto the surface, enhancing usability. Overall, they are more cost-effective than mechanical switches, especially for applications requiring a compact design. -

What customization options are available for membrane buttons?

Customization for membrane buttons can include various aspects such as size, shape, colors, graphics, and tactile feedback. Suppliers often provide options for embossing, backlighting, and integrating logos or branding elements. Discussing your specific needs with the manufacturer will help ensure that the final product meets your expectations. Custom designs can also enhance user experience, making controls intuitive and accessible. -

What is the minimum order quantity (MOQ) for membrane buttons?

Minimum order quantities for membrane buttons can vary significantly based on the manufacturer and the complexity of the design. Typically, MOQs can range from a few hundred to several thousand units. It’s important to clarify these details upfront with your supplier, especially if you are a small business or a startup. Some manufacturers may offer lower MOQs for prototyping or initial runs, which can be beneficial for testing market response. -

How do I vet a supplier for membrane buttons?

Vetting a supplier involves researching their industry experience, certifications, and customer reviews. Check for quality assurance processes and compliance with international standards relevant to your market. Request samples of previous work to assess quality and suitability. Additionally, engaging in direct communication can help gauge their responsiveness and willingness to collaborate on design and customization needs. -

What payment terms should I expect when sourcing membrane buttons internationally?

Payment terms can vary widely among suppliers but generally include options like upfront payment, partial payment before production, or payment upon delivery. It’s essential to negotiate terms that align with your cash flow and risk tolerance. Be aware of potential additional costs such as taxes, tariffs, and shipping fees. Using secure payment methods and establishing clear contracts can mitigate risks associated with international transactions. -

What quality assurance processes should be in place for membrane buttons?

Quality assurance for membrane buttons should include rigorous testing at various stages of production, from material selection to final assembly. Common practices include visual inspections, electrical testing, and environmental testing to ensure durability and functionality. Request documentation of the quality control processes from your supplier to ensure they meet your standards and the specific requirements of your industry. -

How can I ensure timely logistics and delivery of my membrane buttons?

To ensure timely logistics, it’s crucial to establish clear communication with your supplier regarding lead times and shipping methods. Consider using suppliers who have experience in international shipping and can provide tracking information. Discuss potential delays upfront and plan for contingencies in your project timeline. Additionally, familiarize yourself with customs regulations in your country to prevent unexpected hold-ups during the import process.

Top 7 Membrane Buttons Manufacturers & Suppliers List

1. Butler Technologies – Membrane Switches

Domain: butlertechnologies.com

Registered: 1999 (26 years)

Introduction: Membrane switches are electrical devices that turn a circuit on and off, constructed of flexible layers over a printed circuit. They are used in various industries including medical, industrial controls, and consumer electronics. Membrane switches are cost-effective, low profile, and can fulfill functions of touch screens with fewer circuits and voltage requirements. They come in two types: tactil…

2. Reddit – Tactile vs. Membrane Buttons in Gaming Controllers

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: The discussion revolves around the preference between tactile and membrane buttons on gaming controllers. Users share their experiences, noting that while tactile (mechanical) buttons provide a clicky feel, they may be stiffer and harder to actuate, which can affect performance in fast-paced games. Membrane buttons are often described as more reliable for rapid actions, despite some users feeling …

3. General Label – Membrane Switches

Domain: general-label.com

Registered: 1999 (26 years)

Introduction: General Label offers high-quality, individually tested membrane switches for various industries. Membrane switches are thin electronic circuits that allow user interaction through pressure. They can be customized for specific applications and environments, with options including: Tactile Membrane Switches (provide tactile feedback), Non-Tactile Membrane Switches (lack tactile feedback), Metal Dome…

4. Marking Systems – Membrane Switches

Domain: markingsystems.com

Registered: 1997 (28 years)

Introduction: High-Quality Membrane Switches for Diverse Applications, including Rubber Keypad, Backlit Rubber Keypads, Senstouch, Sealed Membrane, Captive Touch Screen, Silver/Copper Flex, Duraswitch, Dead Front Metal Membrane Keypad.

5. Matrix Orbital – Membrane Keypad

Domain: matrixorbital.com

Registered: 1998 (27 years)

Introduction: Membrane keypad is a key input device that uses physical pressure to detect switch closure. It features a slim, lightweight profile with built-in tactile and audio feedback. Key life is estimated at 1 million touches. Often includes an adhesive backing for mounting on rigid surfaces. Ideal for industrial applications requiring minimal input.

6. CSi Keyboards – Mechanical vs Membrane Keypads

Domain: csikeyboards.com

Registered: 1997 (28 years)

Introduction: Key Differences Between Mechanical and Membrane Keypads: 1. Construction: Membrane keypads have no separate moving parts and feature pressure pads on a flat circuit, while mechanical switches utilize metal domes for tactile feedback. 2. Maintenance & Sealing: Membrane keypads are easier to clean and seal due to their embedded design, preventing dust and debris from entering the circuitry. 3. Cost:…

7. Silicone Dynamics – Membrane Switches

Domain: siliconedynamics.net

Registered: 2009 (16 years)

Introduction: Membrane switches are a cost-effective alternative to mechanical switches, commonly used in silicone keypads and electronic devices. They consist of four layers, with the top layer made of silicone for flexibility and ease of cleaning. Membrane switches can be printed on PET or ITO with conductive copper/silver ink. They can be backlit using various methods: LED backlights for individual keys, opt…

Strategic Sourcing Conclusion and Outlook for membrane buttons

What Are the Key Benefits of Strategic Sourcing for Membrane Buttons?

In summary, strategic sourcing of membrane buttons presents significant advantages for businesses across various industries. By prioritizing quality and customization, organizations can ensure that their user interfaces are not only functional but also aesthetically pleasing and aligned with brand values. Membrane switches offer a range of benefits, including ease of cleaning, slim profiles, and accessibility for diverse users, making them a versatile choice for applications in medical, industrial, and consumer electronics.

How Can Businesses Leverage Membrane Buttons for Competitive Advantage?

For international B2B buyers from Africa, South America, the Middle East, and Europe, investing in high-quality membrane buttons can enhance product performance while reducing costs. The growing demand for innovative user interfaces presents an opportunity to differentiate your offerings in the marketplace. By collaborating with experienced manufacturers who provide full-scale production and customization options, businesses can optimize their supply chain and elevate their product design.

What Should Be the Next Steps for B2B Buyers?

As you consider integrating membrane buttons into your product lineup, take the time to evaluate potential suppliers based on their industry experience, technological capabilities, and customer support. Engaging with knowledgeable partners will help you stay ahead in a competitive landscape. Embrace the future of user interface design and explore the possibilities that membrane switches offer for your business growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.