How to Source Marvel Group Chicago Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for marvel group chicago

In today’s competitive landscape, sourcing high-quality workbenches and custom manufacturing solutions can pose significant challenges for international B2B buyers. Companies like Marvel Group Chicago stand out as leaders in this arena, offering a diverse range of products that cater to various industries, from manufacturing to education. This guide aims to demystify the complexities of navigating the global market for Marvel Group Chicago, equipping buyers with essential insights on product types, applications, supplier vetting processes, and cost considerations.

By exploring the extensive capabilities of Marvel Group Chicago, including metal fabricating, design engineering, and component assembly, this guide empowers buyers to make informed purchasing decisions. International purchasers from regions such as Africa, South America, the Middle East, and Europe, including markets like Saudi Arabia and Germany, will find actionable strategies tailored to their unique needs and expectations.

As you delve into this comprehensive resource, you will uncover valuable information that not only highlights the innovative solutions offered by Marvel Group but also provides critical guidance on how to establish fruitful partnerships with suppliers. With a focus on quality, efficiency, and value, this guide is designed to help you navigate the complexities of sourcing and ensure that your business remains competitive in a dynamic global marketplace.

Understanding marvel group chicago Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Industrial Workbenches | Heavy-duty construction, customizable dimensions, robust materials | Manufacturing, assembly lines | Pros: Durable, customizable for specific tasks. Cons: Higher upfront investment. |

| Laboratory Workbenches | Chemical-resistant surfaces, built-in storage, customizable configurations | Research facilities, laboratories | Pros: Safe for experiments, tailored to lab needs. Cons: May require longer lead times for customization. |

| Technical Workbenches | Adjustable height, integrated power outlets, specialized features | Engineering, technical services | Pros: Ergonomic, enhances productivity. Cons: Complexity may lead to higher costs. |

| Educational Workbenches | Durable, versatile designs for classrooms and training centers | Educational institutions, vocational training | Pros: Supports diverse learning activities. Cons: Limited customization compared to industrial options. |

| Modular Workstations | Flexible configurations, space-saving designs, easy to relocate | Offices, workshops, flexible workspaces | Pros: Adaptable to various environments, enhances collaboration. Cons: May lack robustness for heavy-duty tasks. |

What Are Industrial Workbenches and Their B2B Relevance?

Industrial workbenches are designed for heavy-duty applications, constructed with high-quality materials to withstand rigorous use in manufacturing and assembly environments. These workbenches often feature customizable dimensions to fit specific workflows and processes. B2B buyers should consider the long-term investment in durability and the potential for customization to meet unique operational needs, ensuring that the workbench can adapt as requirements evolve.

How Do Laboratory Workbenches Meet Unique Industry Demands?

Laboratory workbenches are specifically engineered to provide a safe and efficient workspace for scientific research and experiments. They typically include chemical-resistant surfaces and built-in storage solutions to accommodate various laboratory tools and materials. When purchasing, B2B buyers should evaluate the bench’s customization options to align with specific laboratory protocols and ensure compliance with safety regulations, as lead times may vary based on these custom features.

What Makes Technical Workbenches Ideal for Skilled Professionals?

Technical workbenches cater to engineers and technicians who require specialized workstations that enhance precision and productivity. Features such as adjustable height, integrated power outlets, and tool storage make these workbenches versatile for various technical tasks. B2B buyers should focus on ergonomics and functionality when selecting technical workbenches, as these factors can significantly impact the efficiency and comfort of skilled professionals during complex projects.

Why Choose Educational Workbenches for Learning Environments?

Educational workbenches are crafted to support diverse activities in classrooms and vocational training centers. Their durable and versatile designs accommodate various educational needs, from practical experiments to collaborative projects. When considering purchases, B2B buyers should assess how well these workbenches can adapt to different learning scenarios, while also keeping in mind that customization options may be limited compared to industrial variants.

What Are the Advantages of Modular Workstations for Dynamic Workspaces?

Modular workstations offer flexible configurations that can be easily adapted to changing workspace requirements, making them ideal for modern offices and collaborative environments. Their space-saving designs enable easy relocation and reconfiguration, enhancing teamwork and productivity. For B2B buyers, the adaptability of modular workstations is a significant advantage; however, they should also consider the potential trade-off in robustness compared to traditional workbenches, especially for heavy-duty applications.

Key Industrial Applications of marvel group chicago

| Industry/Sector | Specific Application of Marvel Group Chicago | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Industrial Workbenches for Assembly Lines | Enhanced productivity through ergonomic design | Material durability, customization options, lead times |

| Laboratory | Chemical-Resistant Laboratory Workbenches | Safety and functionality in research environments | Compliance with safety standards, customizable features |

| Education | Workbenches for Vocational Training | Practical training environments for students | Versatility in design, durability, and adaptability |

| Electro-Mechanical Assembly | Custom Workstations for Technical Assembly | Streamlined processes and improved efficiency | Integration capabilities, power supply options, layout |

| Inventory Management | Modular Storage Solutions | Optimized space utilization and inventory control | Load capacity, modularity, and accessibility |

How Are Industrial Workbenches Used in Manufacturing?

Marvel Group Chicago provides industrial workbenches specifically designed for assembly lines and manufacturing processes. These workbenches are built to endure heavy-duty tasks, ensuring that they can withstand rigorous use in demanding environments. International buyers from regions such as Africa and South America can benefit from their ergonomic designs that enhance worker productivity and minimize fatigue. When sourcing, businesses should consider the materials used for durability, customization options to fit specific workflows, and lead times for delivery to ensure smooth operational transitions.

What Are the Benefits of Chemical-Resistant Laboratory Workbenches?

In laboratory settings, Marvel Group Chicago’s chemical-resistant workbenches are essential for conducting experiments safely. These workbenches feature surfaces that can withstand various chemicals, ensuring a safe and functional workspace. Buyers from the Middle East and Europe must prioritize compliance with safety standards and the availability of customizable features that meet specific laboratory requirements. This focus on safety and functionality not only protects personnel but also enhances the overall efficiency of research activities.

Why Are Workbenches Important for Educational Institutions?

Marvel Group Chicago also specializes in providing workbenches tailored for vocational training in educational institutions. These workbenches are designed to be durable and versatile, accommodating a range of educational activities. For buyers in Europe and the Middle East, investing in quality workbenches means creating practical training environments that prepare students for their future careers. Key considerations include the versatility of design to support various subjects and the durability needed to withstand frequent use.

How Do Custom Workstations Improve Electro-Mechanical Assembly?

For sectors involved in electro-mechanical assembly, Marvel Group Chicago offers custom workstations that streamline technical assembly processes. These workstations can be equipped with adjustable heights, integrated power supplies, and specialized tool storage, enhancing efficiency and precision. International buyers, particularly from Germany and Saudi Arabia, should focus on the integration capabilities of these workstations, ensuring they can seamlessly fit into existing production lines and workflows. This adaptability can significantly reduce assembly time and improve overall output quality.

What Are the Advantages of Modular Storage Solutions?

Marvel Group Chicago’s modular storage solutions provide businesses with optimized space utilization for inventory management. These systems are designed to enhance accessibility and organization, making it easier for companies to manage their supplies effectively. Buyers from diverse regions should consider factors such as load capacity and modularity to ensure the solution meets their specific storage needs. By investing in these storage solutions, businesses can achieve better inventory control, ultimately leading to increased operational efficiency.

3 Common User Pain Points for ‘marvel group chicago’ & Their Solutions

Scenario 1: Navigating Complex Customization Needs

The Problem: Many B2B buyers, especially those in specialized industries, face the challenge of sourcing customized solutions that align with their specific operational requirements. For instance, a manufacturing firm may require specialized workbenches tailored to unique processes, but they find it difficult to communicate their precise needs. This often leads to delays, miscommunication, and ultimately, a product that doesn’t meet their expectations, causing frustration and wasted resources.

The Solution: To effectively navigate this customization challenge with Marvel Group Chicago, buyers should initiate a comprehensive consultation early in the process. Engage with their engineering team to discuss your specific requirements in detail. Prepare a list of functional specifications, including dimensions, load capacities, and any additional features like integrated power outlets or ergonomic adjustments. Utilize Marvel’s expertise in design engineering to develop prototypes that can be evaluated before full-scale production. This proactive approach not only ensures that the final product aligns with your operational needs but also fosters a collaborative partnership that enhances overall satisfaction.

Scenario 2: Managing Timelines and Deliverables

The Problem: In the fast-paced world of manufacturing and production, meeting deadlines is critical. B2B buyers often encounter issues with suppliers who fail to deliver products on time, disrupting their production schedules. This can stem from a lack of transparency in the manufacturing process or misalignment of expectations regarding lead times, which ultimately jeopardizes project deadlines and can lead to significant financial losses.

The Solution: Buyers can mitigate risks related to timelines by establishing clear communication channels with Marvel Group Chicago from the outset. When placing an order, inquire about their production timelines and request regular updates on the status of your order. Utilize project management tools to set milestones and ensure that both parties are aligned on deliverables. Additionally, consider implementing a Just-In-Time (JIT) inventory strategy, which can help you manage stock levels effectively and reduce pressure on suppliers to meet urgent demands. By fostering a culture of transparency and collaboration, you can enhance your ability to meet deadlines consistently.

Scenario 3: Ensuring Quality and Compliance Standards

The Problem: For international B2B buyers, ensuring that products meet specific quality and compliance standards can be a daunting task. This is particularly true when dealing with manufacturers in different regions, where regulatory requirements may differ significantly. A company in Europe might struggle to ensure that the workbenches or components sourced from Marvel Group Chicago comply with EU safety regulations, risking non-compliance penalties and potential disruptions in operations.

The Solution: To address quality and compliance concerns, buyers should conduct thorough due diligence before finalizing any agreements. Start by requesting documentation that outlines Marvel Group Chicago’s quality assurance processes and certifications. Engage in discussions about their compliance with international standards, particularly those relevant to your industry. Furthermore, consider arranging for third-party inspections or audits during the manufacturing process to verify adherence to quality standards. This proactive approach not only protects your business from potential compliance issues but also builds a strong foundation of trust between your company and Marvel Group Chicago, fostering a long-term partnership focused on quality and reliability.

Strategic Material Selection Guide for marvel group chicago

What Are the Key Materials Used by Marvel Group Chicago?

Marvel Group Chicago employs a variety of materials in its manufacturing processes, each with distinct properties and applications. Understanding these materials can help B2B buyers make informed decisions regarding their specific needs.

Illustrative image related to marvel group chicago

What Are the Key Properties of Steel in Manufacturing?

Steel is one of the most commonly used materials at Marvel Group Chicago, particularly for workbenches and industrial applications. Its key properties include high tensile strength, excellent durability, and good weldability. Steel can withstand high temperatures and pressures, making it suitable for demanding environments.

Pros & Cons: The advantages of steel include its robustness and longevity, which contribute to lower long-term costs. However, it can be susceptible to corrosion if not properly treated, and the manufacturing process can be complex due to the need for specialized equipment.

Impact on Application: Steel is compatible with various media, including oils and chemicals, but its susceptibility to rust can be a concern in humid or corrosive environments.

Illustrative image related to marvel group chicago

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with standards such as ASTM and DIN for steel quality. In humid climates, additional coatings may be necessary to prevent corrosion.

How Does Aluminum Compare as a Manufacturing Material?

Aluminum is another popular choice, particularly for applications requiring lightweight materials without compromising strength. It has excellent corrosion resistance and is highly malleable, allowing for intricate designs.

Pros & Cons: Aluminum’s lightweight nature makes it easy to handle and transport, reducing shipping costs. However, it is generally more expensive than steel and may not be suitable for heavy-duty applications due to lower tensile strength.

Impact on Application: Aluminum is ideal for environments that require resistance to corrosion, such as laboratories and food processing areas. Its compatibility with a range of media makes it a versatile choice.

Considerations for International Buyers: Buyers should be aware of specific aluminum grades and their compliance with international standards, such as JIS in Japan and EN in Europe.

What Role Does Stainless Steel Play in Specialized Applications?

Stainless steel is a critical material for applications requiring superior corrosion resistance and hygiene, such as in medical and food processing environments. Its key properties include resistance to rust and staining, as well as high strength.

Pros & Cons: The key advantage of stainless steel is its durability and resistance to corrosion, making it suitable for harsh environments. However, it is more expensive than regular steel and can be challenging to machine due to its hardness.

Impact on Application: Stainless steel is ideal for applications involving food, pharmaceuticals, and chemicals, where cleanliness and safety are paramount.

Considerations for International Buyers: Compliance with health and safety standards is crucial, especially in regions like Europe where regulations are stringent. Buyers should also consider the specific grades of stainless steel required for their applications.

Illustrative image related to marvel group chicago

How Does Plastic Fit into Marvel Group’s Offerings?

Plastic materials, particularly high-density polyethylene (HDPE) and polypropylene, are used for applications that require chemical resistance and lightweight properties. These materials are non-corrosive and can be molded into complex shapes.

Pros & Cons: The primary advantage of plastic is its resistance to a wide range of chemicals, making it suitable for various industrial applications. However, plastics generally have lower strength compared to metals and may not be suitable for heavy-duty applications.

Impact on Application: Plastics are often used in environments where corrosion is a concern, such as in chemical processing. Their lightweight nature also facilitates easy handling and installation.

Illustrative image related to marvel group chicago

Considerations for International Buyers: Buyers should check for compliance with international standards for plastics, especially in applications involving food or pharmaceuticals, to ensure safety and quality.

Summary Table of Key Materials

| Material | Typical Use Case for Marvel Group Chicago | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Industrial workbenches | High durability and strength | Susceptible to corrosion | Medium |

| Aluminum | Lightweight workstations | Excellent corrosion resistance | Higher cost and lower strength | High |

| Stainless Steel | Medical and food processing equipment | Superior corrosion resistance | More expensive and hard to machine | High |

| Plastic | Chemical storage and lightweight applications | Chemical resistance and lightweight | Lower strength compared to metals | Low |

This guide serves as a comprehensive overview for international B2B buyers, enabling them to make informed decisions about material selection tailored to their specific operational needs.

In-depth Look: Manufacturing Processes and Quality Assurance for marvel group chicago

What Are the Key Stages in the Manufacturing Process at Marvel Group Chicago?

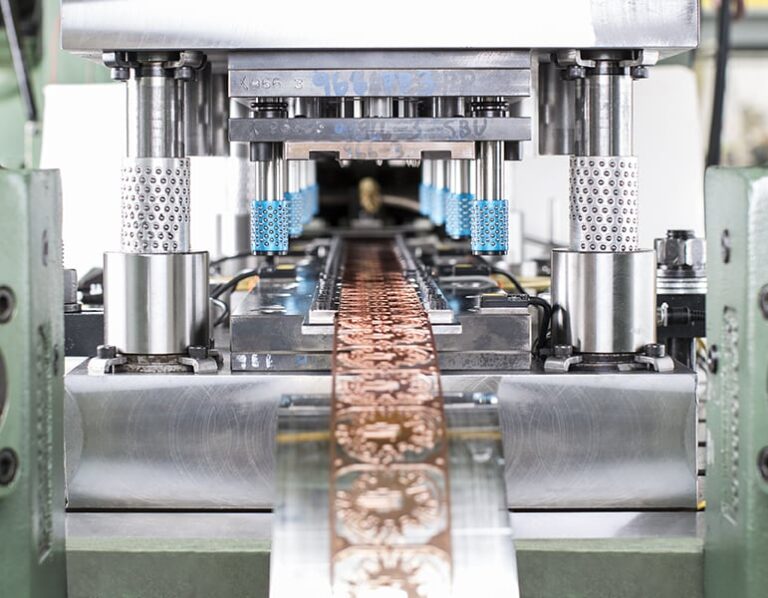

Marvel Group Chicago employs a comprehensive manufacturing process that is designed to ensure high-quality outputs and efficiency in production. The primary stages of their manufacturing process include material preparation, forming, assembly, and finishing.

Material Preparation: The process begins with careful selection and preparation of raw materials, which may include metals and other components. Marvel Group emphasizes sourcing high-quality materials to ensure durability and performance in the final products. Advanced material handling systems are utilized to minimize waste and maximize efficiency.

Forming: In this stage, the prepared materials undergo various forming techniques such as cutting, bending, and welding. Marvel Group employs state-of-the-art machinery and technology to perform these operations, ensuring precision and consistency. Techniques like laser cutting and CNC machining are commonly used to create components with tight tolerances, which are critical for maintaining quality standards.

Assembly: Following the forming process, the next step is assembly, where individual components are brought together to create the final product. Marvel Group utilizes skilled labor and automated systems to ensure that assembly is done correctly and efficiently. The assembly process is closely monitored to prevent defects and ensure that each product meets the specified design requirements.

Finishing: The final stage involves finishing processes such as powder coating, painting, or surface treatment. This stage not only enhances the aesthetic appeal of the products but also improves their resistance to corrosion and wear. Marvel Group’s color matching powder-coat service allows for customization, catering to specific client requirements and industry standards.

How Does Marvel Group Ensure Quality Assurance Throughout the Manufacturing Process?

Quality assurance is a cornerstone of Marvel Group’s manufacturing philosophy. The company adheres to several international and industry-specific standards to guarantee the quality of its products.

ISO 9001 Certification: Marvel Group is ISO 9001 certified, which signifies a commitment to quality management systems that meet international standards. This certification ensures that processes are continuously monitored and improved, thereby enhancing customer satisfaction and operational efficiency.

Industry-Specific Standards: Depending on the industry served, Marvel Group complies with additional standards such as CE for European markets and API for oil and gas applications. These certifications provide assurance that products meet stringent safety and performance criteria.

What Are the Key Quality Control Checkpoints Used by Marvel Group?

Marvel Group implements a multi-tiered quality control system with specific checkpoints throughout the manufacturing process:

Incoming Quality Control (IQC): Upon receiving materials, a thorough inspection is conducted to verify compliance with specifications. This includes checking for defects, verifying material certifications, and ensuring that all components meet the necessary standards.

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections and tests are conducted to ensure that operations are performed correctly. This includes monitoring equipment performance, evaluating process parameters, and conducting interim tests on components.

Final Quality Control (FQC): Before products are shipped, a final inspection is carried out to verify that the finished products meet all specifications and quality standards. This may involve functional testing, dimensional checks, and surface inspections to ensure that the products are ready for customer delivery.

Which Testing Methods Are Commonly Used for Quality Assurance at Marvel Group?

Marvel Group employs various testing methods to validate the quality and performance of its products. Common testing methods include:

- Dimensional Inspection: Utilizing precision measurement tools to ensure that all dimensions conform to specifications.

- Functional Testing: Conducting performance tests to verify that products operate as intended in their respective environments.

- Material Testing: Performing tests to assess the mechanical properties of materials used in production, such as tensile strength, hardness, and fatigue resistance.

- Surface Testing: Evaluating coatings and finishes for consistency, adhesion, and resistance to corrosion or wear.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential to ensure reliability and compliance. Here are several strategies to validate Marvel Group’s QC processes:

- Audits: Buyers can request on-site audits to review manufacturing processes, quality control systems, and compliance with international standards. This provides firsthand insight into the supplier’s operations.

- Quality Reports: Suppliers should provide documentation of quality control measures, including inspection reports, test results, and certifications. Reviewing these documents can help buyers assess the supplier’s commitment to quality.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality control practices. These agencies can conduct audits and tests independently, ensuring credibility in their findings.

What Are the Specific Quality Control Considerations for International B2B Buyers?

When dealing with international suppliers like Marvel Group, buyers from regions such as Africa, South America, the Middle East, and Europe should consider the following quality control nuances:

Illustrative image related to marvel group chicago

- Cultural and Regulatory Differences: Understanding the regulatory environment in the supplier’s country can impact quality expectations. Buyers should familiarize themselves with local standards and practices.

- Language Barriers: Communication is crucial in quality assurance. Buyers should ensure that any contractual agreements and quality specifications are clearly understood by both parties to avoid misunderstandings.

- Logistics and Supply Chain: International shipping can introduce risks to product quality. Buyers should inquire about the supplier’s logistics practices and how they ensure product integrity during transit.

By focusing on these critical aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when partnering with Marvel Group Chicago, ensuring they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘marvel group chicago’

Introduction

This practical sourcing guide aims to provide international B2B buyers with a clear and actionable checklist for procuring products and services from Marvel Group Chicago. With a focus on quality manufacturing and engineering partnerships, this guide will help you navigate the essential steps to ensure a successful procurement process.

Step 1: Identify Your Specific Needs

Before reaching out to suppliers, clearly define your technical specifications and requirements. Consider the types of products you need, such as industrial workbenches or custom metal fabrications. This clarity will enable you to communicate effectively with Marvel Group and ensure that their offerings align with your project needs.

Step 2: Research Marvel Group’s Capabilities

Familiarize yourself with the full range of services and products offered by Marvel Group. Their capabilities include metal fabricating, design engineering, and inventory management. Understanding these aspects will help you determine if they can meet your specific requirements and provide added value.

Step 3: Evaluate Supplier Certifications and Standards

Verify the certifications and quality standards upheld by Marvel Group. Look for ISO certifications, compliance with safety regulations, and any industry-specific standards that may apply. This step is crucial as it ensures that you are partnering with a reputable supplier who maintains high-quality manufacturing practices.

Illustrative image related to marvel group chicago

Step 4: Request Detailed Quotes

Engage with Marvel Group by requesting detailed quotes based on your specifications. Ensure that the quotes include pricing, lead times, and terms of service. A comprehensive quote will allow you to compare costs and timelines effectively, enabling better decision-making.

Step 5: Assess Customization Options

Inquire about customization capabilities for your products. Marvel Group specializes in tailoring solutions to meet diverse client needs, from design modifications to specific material choices. Understanding their flexibility in customization will help you create a product that fits your operational requirements perfectly.

Step 6: Review Past Client Case Studies

Request case studies or references from Marvel Group showcasing their past work, particularly in industries similar to yours. This will provide insight into their experience, problem-solving abilities, and customer satisfaction levels. Learning from previous projects can help you gauge their reliability and performance.

Step 7: Establish Communication Protocols

Set up clear communication channels with Marvel Group. Determine who your primary contact will be and how often you will receive updates throughout the procurement process. Effective communication is essential to address any potential issues promptly and ensure that your project stays on track.

Illustrative image related to marvel group chicago

By following these steps, B2B buyers can effectively source products and services from Marvel Group Chicago, ensuring a smooth and successful procurement experience.

Comprehensive Cost and Pricing Analysis for marvel group chicago Sourcing

What Are the Key Cost Components in Sourcing from Marvel Group Chicago?

When considering sourcing from the Marvel Group in Chicago, understanding the cost structure is crucial for international B2B buyers. The primary components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The choice of materials significantly impacts the overall cost. The Marvel Group offers various options tailored to specific needs, from standard metals to specialized alloys. Buyers should assess their material requirements based on durability, functionality, and cost-effectiveness.

-

Labor: Skilled labor is essential for quality manufacturing. The Marvel Group employs experienced engineers and technicians, which can elevate labor costs. However, this investment often results in superior product quality and reliability.

-

Manufacturing Overhead: This includes expenses related to the facility, utilities, and administrative costs. With a state-of-the-art 150,000-square-foot facility, Marvel maintains a high level of operational efficiency, which can influence pricing.

-

Tooling: Custom tooling may be necessary for specialized components. The initial investment in tooling can be substantial but is often amortized over larger production runs, making it more cost-effective for high-volume orders.

-

Quality Control: Ensuring product quality through rigorous QC processes is a hallmark of Marvel Group’s operations. While this adds to the overall cost, it reduces the risk of defects and returns, ultimately benefiting the buyer.

-

Logistics: Shipping and handling costs can vary based on the destination. For international buyers, understanding the logistics involved in transporting goods from Chicago to their location is essential for accurate pricing.

-

Margin: Marvel Group’s pricing will include a margin that reflects their service level, product quality, and market positioning. Understanding this can help buyers gauge the value they are receiving.

How Do Price Influencers Impact Sourcing Decisions?

Several factors can influence the pricing structure when sourcing from Marvel Group.

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs. Buyers should consider their purchasing strategy to maximize cost efficiency.

-

Specifications and Customization: Custom products tailored to specific requirements can incur additional costs. Buyers must weigh the benefits of customization against potential price increases.

-

Materials and Quality Certifications: Premium materials and certifications (e.g., ISO, ASTM) can elevate costs but provide assurance of quality and compliance. Buyers in regulated industries should prioritize these factors.

-

Supplier Factors: The Marvel Group’s reputation, reliability, and service level can justify a higher price point. Establishing a strong relationship with the supplier can lead to better pricing and terms.

-

Incoterms: Understanding the terms of shipping and delivery (Incoterms) is vital for international transactions. They dictate who bears the cost and risk during transit, influencing the overall cost structure.

What Are the Best Negotiation Tips for International B2B Buyers?

To achieve favorable pricing and terms when sourcing from Marvel Group, international buyers should consider the following strategies:

-

Negotiation: Engaging in open discussions about pricing, especially for larger volumes, can lead to discounts. Buyers should come prepared with market research to support their negotiation stance.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO) rather than just the purchase price. Assessing the long-term value, including maintenance and operational costs, can justify a higher upfront investment.

-

Pricing Nuances for International Transactions: Be aware of currency fluctuations, import duties, and taxes that may affect pricing. Buyers should factor these into their total costs and negotiate terms that mitigate risks associated with international transactions.

-

Build Relationships: Establishing a rapport with suppliers can enhance negotiation outcomes. Trust can lead to better service, pricing, and access to exclusive deals.

Disclaimer on Indicative Prices

While the analysis provides insights into potential costs and pricing structures, it is important to note that actual prices may vary based on specific project requirements, market conditions, and individual negotiations. Always request detailed quotes tailored to your needs for accurate budgeting.

Alternatives Analysis: Comparing marvel group chicago With Other Solutions

In the competitive landscape of manufacturing and workbench solutions, businesses often seek alternatives to find the best fit for their operational needs. This analysis compares the Marvel Group Chicago against alternative solutions that offer similar capabilities in metal fabrication and workbench manufacturing. Understanding the differences in performance, cost, implementation, maintenance, and best use cases can help international B2B buyers make informed decisions.

Illustrative image related to marvel group chicago

| Comparison Aspect | Marvel Group Chicago | Alternative 1: RDM Industrial Products Inc. | Alternative 2: Pro-Line |

|---|---|---|---|

| Performance | High-quality, customizable workbench solutions with a focus on durability and ergonomics. | Offers a wide range of industrial products, including customizable workstations. | Known for modular workbenches that provide flexibility and scalability. |

| Cost | Higher price point due to premium materials and custom solutions. | Competitive pricing with options for budget-conscious buyers. | Mid-range pricing, often providing good value for modular designs. |

| Ease of Implementation | Comprehensive support from design to delivery, but longer lead times for custom orders. | Quick turnaround for standard products, with some customization available. | Easy assembly and installation, ideal for businesses needing immediate solutions. |

| Maintenance | Robust support and after-sales service; requires standard upkeep based on usage. | Offers maintenance services, but support may vary by distributor. | Generally low-maintenance, with a focus on user-friendly designs. |

| Best Use Case | Ideal for businesses requiring tailored solutions for heavy-duty applications. | Suitable for a variety of industrial environments needing reliable workstations. | Best for companies looking for flexible, space-saving workbench solutions. |

What Are the Advantages and Disadvantages of RDM Industrial Products Inc.?

RDM Industrial Products Inc. provides a diverse range of industrial products, including workstations tailored to various sectors. The primary advantage of RDM is its competitive pricing, making it a viable option for businesses with budget constraints. Additionally, their standard products often have quick turnaround times, which can be beneficial for urgent needs. However, while they do offer customization, the range may not be as extensive as that of the Marvel Group, potentially limiting options for businesses seeking specific functionalities.

How Does Pro-Line Compare in Terms of Flexibility?

Pro-Line is recognized for its modular workbench solutions, which offer significant flexibility and scalability. This adaptability allows businesses to easily reconfigure their workspaces as needs change. The primary strength of Pro-Line is its user-friendly assembly process, making it an attractive option for companies looking to implement solutions swiftly. On the downside, while Pro-Line’s modular approach is advantageous for many, it may not provide the same level of robustness required for heavy-duty applications that the Marvel Group specializes in.

Conclusion: How Can B2B Buyers Choose the Right Solution?

When evaluating the right solution for their specific needs, B2B buyers must consider factors such as performance requirements, budget constraints, and the urgency of implementation. The Marvel Group Chicago excels in delivering high-quality, customizable solutions for businesses with demanding applications. In contrast, alternatives like RDM Industrial Products and Pro-Line may provide cost-effective and flexible options, respectively, for businesses with different priorities. Ultimately, the decision should align with the company’s operational goals and the specific demands of their industry. By carefully weighing these aspects, buyers can make informed choices that enhance productivity and operational efficiency.

Essential Technical Properties and Trade Terminology for marvel group chicago

What Are the Key Technical Properties Relevant to Marvel Group Chicago?

Understanding the essential technical properties when considering products from Marvel Group Chicago is crucial for making informed purchasing decisions. Here are some critical specifications relevant to their offerings:

-

Material Grade:

Material grade refers to the quality and specifications of the materials used in manufacturing. For instance, steel grades like ASTM A36 or A992 are commonly used in metal fabrication due to their strength and durability. This property is vital for B2B buyers, as it directly affects the performance, longevity, and safety of the products being manufactured. -

Tolerance:

Tolerance is the permissible limit of variation in a physical dimension or measured value. Precision engineering often requires tight tolerances, which ensure that parts fit together correctly and function as intended. For manufacturers, maintaining strict tolerances is essential to minimize waste and improve product quality, which can significantly impact production costs and timelines. -

Load Capacity:

Load capacity indicates the maximum weight or force that a workbench or component can safely support. This property is particularly important for industrial workbenches used in manufacturing settings, where heavy equipment or materials may be handled. Knowing the load capacity helps B2B buyers ensure that the workstations will meet their operational needs without compromising safety. -

Surface Finish:

The surface finish refers to the texture and smoothness of a material’s surface, which can affect both aesthetics and functionality. For example, powder-coated finishes are commonly used for workbenches to enhance durability and corrosion resistance. A good surface finish not only improves the product’s lifespan but also its overall appearance, which can be essential for client-facing operations. -

Ergonomics:

Ergonomics in workstation design ensures that products enhance user comfort and efficiency. Features like adjustable heights or tool storage can significantly improve productivity and reduce workplace injuries. B2B buyers must consider ergonomic properties to create a safer and more efficient work environment for their employees.

What Trade Terms Should B2B Buyers Know When Engaging with Marvel Group Chicago?

Familiarity with industry jargon can streamline communication and enhance negotiations. Here are several essential trade terms relevant to Marvel Group Chicago:

-

OEM (Original Equipment Manufacturer):

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding this term is crucial for B2B buyers looking to source components for their products or who need to ensure compatibility with existing systems. -

MOQ (Minimum Order Quantity):

MOQ refers to the smallest number of units that a supplier is willing to sell. Knowing the MOQ helps buyers manage inventory levels and budget effectively, especially when dealing with large-scale manufacturing projects. -

RFQ (Request for Quotation):

An RFQ is a document sent to suppliers requesting a quote for specific products or services. It is an essential tool for B2B buyers to obtain competitive pricing and evaluate potential suppliers based on their offerings. -

Incoterms (International Commercial Terms):

Incoterms are a set of predefined international trade terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers. Familiarity with these terms helps B2B buyers understand shipping logistics, risk management, and cost allocation in international transactions. -

Lead Time:

Lead time is the amount of time from placing an order to receiving it. Understanding lead times is crucial for B2B buyers to plan their production schedules and manage inventory effectively, ensuring that operations run smoothly. -

Customization:

Customization refers to the ability to modify products based on specific client needs. This term is particularly relevant in the context of Marvel Group Chicago, where personalized engineering partnerships can lead to tailored solutions that fit unique operational requirements.

By grasping these technical properties and trade terms, B2B buyers can effectively navigate the complexities of sourcing products from Marvel Group Chicago, ultimately enhancing their procurement strategies and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the marvel group chicago Sector

What Are the Current Market Dynamics and Key Trends Impacting International B2B Buyers in the Marvel Group Chicago Sector?

The Marvel Group Chicago operates within a dynamic landscape shaped by several global drivers that influence B2B manufacturing and sourcing decisions. As industries seek to optimize operational efficiency, the shift towards automation and advanced manufacturing technologies is gaining momentum. International buyers from regions such as Africa, South America, the Middle East, and Europe (notably Germany and Saudi Arabia) are increasingly looking for suppliers who can provide not only high-quality products but also adaptability in production processes. The demand for custom solutions, such as specialized workstations and components, is rising, as businesses strive to enhance productivity and tailor their operations to specific needs.

Emerging trends in digital sourcing and supply chain management are also reshaping how international buyers engage with manufacturers. Utilizing platforms for real-time collaboration and data sharing facilitates better decision-making and strengthens partnerships. Moreover, the importance of comprehensive material sourcing strategies, encompassing everything from metal fabrication to inventory management, cannot be overstated. Buyers are prioritizing suppliers like the Marvel Group, who can offer a full suite of services from design engineering to final assembly, ensuring a seamless integration of products into their operations.

How is Sustainability and Ethical Sourcing Integrated into B2B Practices at Marvel Group Chicago?

Sustainability is becoming a critical factor for B2B buyers in today’s marketplace, driven by both regulatory pressures and consumer demand for environmentally responsible practices. The Marvel Group Chicago recognizes this shift and is committed to minimizing its environmental impact through sustainable manufacturing practices. This includes leveraging energy-efficient technologies and sourcing materials that meet stringent environmental standards.

Illustrative image related to marvel group chicago

International buyers are increasingly favoring partners who demonstrate a commitment to ethical supply chains. Certifications such as ISO 14001 for environmental management systems are becoming essential indicators of a supplier’s dedication to sustainable practices. Furthermore, the use of ‘green’ materials in production processes not only enhances product appeal but also aligns with the values of socially-conscious businesses. Buyers from regions with strict environmental regulations, such as Europe, will find that partnering with the Marvel Group can help them meet compliance requirements while enhancing their brand reputation.

What is the Historical Context of the Marvel Group Chicago and Its Significance for B2B Relationships?

Founded in 1946, the Marvel Group has a rich history of innovation in custom manufacturing and metal fabrication. Its evolution from a local manufacturer to a trusted partner for global enterprises underscores the importance of quality, efficiency, and customer-centric service in building long-term B2B relationships. Over the decades, the company has adapted to changing market conditions and technological advancements, continually enhancing its capabilities to meet the diverse needs of its clients.

As part of the Accurate Family of Companies, the Marvel Group leverages a vast network of resources and expertise, making it a formidable player in the manufacturing sector. This historical context is significant for international B2B buyers, as it highlights the company’s stability and reliability in delivering high-quality products tailored to specific industry demands. By understanding the Marvel Group’s evolution, buyers can better appreciate the value of forging partnerships with an established leader in the manufacturing landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of marvel group chicago

-

How can I ensure the quality of products from Marvel Group Chicago?

To ensure product quality, B2B buyers should request detailed information about Marvel Group’s quality assurance processes. They have a dedicated engineering team that focuses on quality at every production stage. Additionally, buyers can ask for samples or prototypes to assess the materials and craftsmanship. It’s also beneficial to inquire about certifications, such as ISO standards, which demonstrate adherence to international quality benchmarks. -

What customization options does Marvel Group Chicago offer for workbenches?

Marvel Group provides extensive customization options for their workbenches, including adjustable heights, various surface materials, and integrated storage solutions. Buyers can discuss specific requirements during the consultation phase, allowing for tailored designs that meet unique operational needs. Customization can also extend to colors and finishes, ensuring that products align with branding or specific environmental requirements. -

What are the minimum order quantities (MOQ) for products from Marvel Group?

The minimum order quantities can vary based on the specific product and customization requirements. Generally, Marvel Group is flexible and can accommodate both small and large orders, but it’s advisable to discuss your needs with their sales team. For international buyers, understanding MOQs can help in planning inventory and ensuring cost-effectiveness in procurement. -

What payment terms can I expect when ordering from Marvel Group Chicago?

Marvel Group typically offers a range of payment options tailored to international buyers, including wire transfers, letters of credit, and potentially payment plans for larger orders. It’s important for buyers to discuss specific terms upfront to ensure clarity. Understanding payment terms helps in budgeting and managing cash flow effectively during the procurement process. -

How does Marvel Group Chicago handle international shipping and logistics?

Marvel Group collaborates with reputable logistics partners to manage international shipping efficiently. They provide various shipping options to accommodate different timelines and budget considerations. Buyers should inquire about shipping costs, delivery timelines, and customs handling processes to ensure seamless logistics. Having clear communication on these aspects can prevent delays and additional costs. -

What steps should I take to vet Marvel Group as a supplier?

To vet Marvel Group, buyers should conduct thorough research, including checking customer reviews, requesting references, and assessing their industry reputation. Engaging in direct communication with their sales and engineering teams can provide insight into their responsiveness and expertise. Additionally, visiting their facility or arranging a virtual tour can help gauge their manufacturing capabilities and overall professionalism. -

How can I address potential issues with product delivery?

In the event of delivery issues, communication is key. Buyers should maintain open lines with Marvel Group, addressing concerns as soon as they arise. Establishing a clear contract outlining delivery expectations and penalties for delays can also help mitigate risks. Furthermore, implementing a contingency plan for critical supplies ensures that business operations remain uninterrupted. -

What after-sales support does Marvel Group Chicago provide?

Marvel Group is committed to customer satisfaction and offers robust after-sales support, including product maintenance guidance and troubleshooting assistance. Buyers should inquire about warranty details and available support channels, such as dedicated account managers or customer service representatives. Having reliable after-sales support can enhance the long-term relationship and ensure that any issues are promptly addressed.

Top 2 Marvel Group Chicago Manufacturers & Suppliers List

1. The Marvel Group, Inc. – Electro-Mechanical Assembly

Domain: mfg.com

Introduction: The Marvel Group, Inc. specializes in Electro-Mechanical Assembly and offers a range of custom manufacturing services including Metal Fabricating, Design Engineering, Component Final Assembly, Color Matching, Powder Coating, Prototyping, Material Sourcing, and Inventory Management. Their manufacturing capabilities include various fabrication techniques such as Welding, Sheet Metal Forming, and Wir…

2. The Marvel Group – AV Furniture Solutions

Domain: av-iq.com

Registered: 2011 (14 years)

Introduction: The Marvel Group offers a variety of products including: 1. AV Furniture – 367 products 2. AV Carts – 108 products 3. Credenzas – 4 products 4. Lecterns & Podiums – 12 products 5. Multimedia Desks & Workstations – 54 products 6. Office Chairs – 43 products 7. Tables – 146 products 8. Displays & Monitors – 48 products 9. Special Application Displays – 48 products. Specific models include: Rounded E…

Strategic Sourcing Conclusion and Outlook for marvel group chicago

The Marvel Group stands as a cornerstone in the custom manufacturing landscape, emphasizing a personalized engineering partnership that ensures high-quality output aligned with clients’ needs. Their extensive range of capabilities—including metal fabricating, design engineering, and component assembly—enables them to support diverse sectors from industrial manufacturing to educational institutions. For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, engaging with the Marvel Group offers strategic sourcing advantages that enhance operational efficiency and product quality.

As global markets continue to evolve, the importance of strategic sourcing becomes increasingly evident. Partnering with a reliable manufacturer like the Marvel Group not only facilitates access to innovative solutions but also ensures timely delivery and budget adherence. This reliability is crucial for businesses looking to maintain competitiveness in their respective markets.

Looking ahead, the Marvel Group is poised to expand its reach and capabilities, inviting international buyers to explore how their tailored solutions can meet specific industry demands. By leveraging the strengths of a trusted U.S. manufacturer, companies can position themselves for success in an interconnected global economy. Connect with the Marvel Group today to discover how they can help elevate your business operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to marvel group chicago