How to Source Lr Pvc Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for lr pvc

In today’s competitive landscape, international B2B buyers face the critical challenge of sourcing high-quality LR PVC products that meet specific project requirements while ensuring cost-effectiveness. With applications ranging from electrical conduit systems to plumbing installations, understanding the nuances of LR PVC is paramount. This guide delves into the various types of LR PVC available, their applications, and the best practices for vetting suppliers across global markets, particularly targeting regions such as Africa, South America, the Middle East, and Europe, including key players like Germany and Saudi Arabia.

Navigating the complexities of sourcing LR PVC can be daunting, but this comprehensive resource empowers buyers to make informed purchasing decisions. By exploring essential factors such as product specifications, compliance standards, and market pricing, the guide equips businesses with the knowledge necessary to avoid common pitfalls. Additionally, it offers insights into establishing reliable supplier relationships, ensuring that your projects are supported by quality materials that adhere to local regulations and standards.

Whether you are a contractor seeking durable conduit solutions or a procurement officer aiming to streamline your supply chain, this guide is designed to enhance your understanding of the LR PVC market, ultimately leading to more strategic and profitable purchasing decisions.

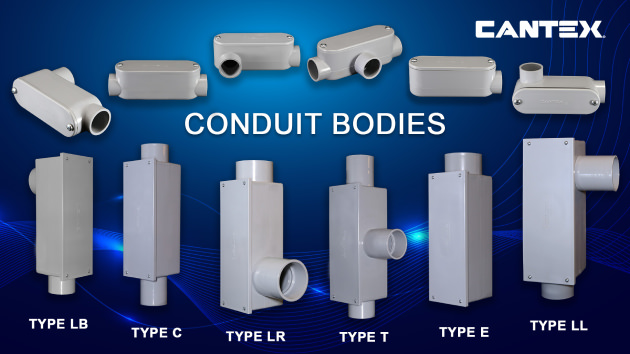

Understanding lr pvc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Type LR 1″ | Compact size, suitable for tight spaces, 90-degree turn | Indoor electrical installations | Pros: Space-saving, easy installation. Cons: Limited to smaller conduits. |

| Type LR 2″ | Larger capacity, robust construction, non-corrosive PVC | Industrial and commercial electrical systems | Pros: Durable, suitable for heavy-duty applications. Cons: Higher cost than smaller sizes. |

| Type LR 1.5″ | Versatile mid-size option, effective for most conduit runs | Residential and commercial wiring | Pros: Balanced size, good for various applications. Cons: May not fit in very tight spaces. |

| Schedule 40 LR | Standard thickness, widely used, compatible with various fittings | General electrical applications | Pros: Cost-effective, readily available. Cons: Not suitable for high-pressure applications. |

| Schedule 80 LR | Thicker walls for added strength, ideal for harsh environments | Heavy industrial use, outdoor installations | Pros: Enhanced durability, resistant to impact. Cons: More expensive, heavier to handle. |

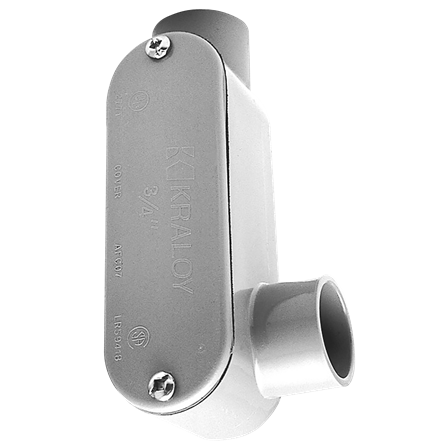

What Are the Key Characteristics of Type LR 1″ Conduit Bodies?

Type LR 1″ conduit bodies are designed for applications where space is limited. Their compact size allows for easy installation in tight areas while facilitating a 90-degree turn in a conduit run. These are ideal for indoor electrical installations, making them popular among B2B buyers in sectors like residential construction. While they are easy to install and save space, their size limits their use to smaller conduits.

How Does Type LR 2″ Differ from Other Sizes?

Type LR 2″ conduit bodies offer a larger capacity and robust construction. Made from non-corrosive PVC, they are well-suited for industrial and commercial electrical systems where durability is crucial. Their ability to handle a higher volume of conductors makes them a preferred choice for B2B buyers looking for reliable solutions in demanding environments. However, the higher cost compared to smaller sizes may be a consideration for budget-conscious buyers.

Why Choose Type LR 1.5″ Conduit Bodies?

The Type LR 1.5″ conduit body strikes a balance between size and capacity, making it versatile for both residential and commercial wiring applications. Its design allows for effective conduit runs without taking up too much space, making it a go-to option for many contractors. While it provides flexibility, buyers should consider that it may not fit in extremely tight spaces compared to the smaller 1″ variant.

Illustrative image related to lr pvc

What Are the Benefits of Schedule 40 LR Conduit Bodies?

Schedule 40 LR conduit bodies are the standard thickness option, making them widely used in general electrical applications. Their compatibility with various fittings makes them a cost-effective choice for many B2B buyers. While they are readily available and economical, they are not recommended for high-pressure applications, which may limit their use in certain industries.

When to Opt for Schedule 80 LR Conduit Bodies?

Schedule 80 LR conduit bodies feature thicker walls for added strength, making them ideal for harsh environments and heavy industrial use. They offer enhanced durability and resistance to impact, making them suitable for outdoor installations. However, the increased cost and weight can be drawbacks for buyers who need lightweight and cost-effective solutions.

Key Industrial Applications of lr pvc

| Industry/Sector | Specific Application of lr pvc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Building | Electrical conduit systems | Provides safe and efficient routing of electrical wiring | Ensure compliance with local electrical codes and standards |

| Telecommunications | Cable management and protection | Enhances durability and reduces maintenance costs | Source from certified manufacturers for reliability |

| Oil & Gas | Protective casing for electrical installations | Prevents corrosion and damage in harsh environments | Verify material specifications for chemical resistance |

| Manufacturing | Wiring and cable pathways | Increases operational efficiency and safety | Consider bulk purchasing options to reduce costs |

| Agriculture | Irrigation control systems | Facilitates water management and distribution | Assess local availability and logistics for timely delivery |

How is lr pvc used in the construction and building industry?

In the construction and building sector, lr pvc is predominantly used for electrical conduit systems. These conduits ensure safe routing of electrical wiring, minimizing risks of electrical hazards. The durability of lr pvc prevents rust and corrosion, making it ideal for both indoor and outdoor installations. For international buyers, especially from regions like Africa and the Middle East, it is crucial to source products that comply with local electrical codes and standards to avoid compliance issues.

What role does lr pvc play in telecommunications?

In telecommunications, lr pvc is essential for cable management and protection. It provides a robust casing that guards against physical damage and environmental factors, thereby extending the lifespan of the cables. This is particularly valuable in regions with extreme weather conditions. B2B buyers should prioritize sourcing from certified manufacturers to ensure the reliability and quality of the products used in their infrastructure.

Illustrative image related to lr pvc

Why is lr pvc important in the oil and gas industry?

In the oil and gas industry, lr pvc serves as a protective casing for electrical installations. Given the harsh environmental conditions typical of oil fields, the non-corrosive nature of lr pvc is a significant advantage, preventing damage and ensuring safety. Buyers in this sector must verify that the materials meet specific chemical resistance standards to ensure long-term performance in challenging environments.

How does lr pvc enhance manufacturing processes?

Within manufacturing, lr pvc is utilized for wiring and cable pathways. Its lightweight yet durable properties contribute to increased operational efficiency by simplifying installations and reducing maintenance requirements. For businesses, sourcing lr pvc in bulk can lead to significant cost savings. Buyers should consider logistics and supplier reliability to ensure timely delivery of materials to maintain production schedules.

What advantages does lr pvc offer in agricultural applications?

In agriculture, lr pvc is used in irrigation control systems, facilitating effective water management and distribution. Its resistance to environmental degradation ensures that these systems remain functional over time, which is crucial for maintaining crop yields. International buyers should assess local availability and logistics to ensure that they can receive supplies promptly, which is vital for seasonal agricultural operations.

3 Common User Pain Points for ‘lr pvc’ & Their Solutions

Scenario 1: Difficulty in Sourcing High-Quality LR PVC Products

The Problem: B2B buyers often struggle to find reliable suppliers of high-quality LR PVC conduit bodies. In regions like Africa and South America, where infrastructure is rapidly developing, buyers may encounter inconsistent product availability or face challenges verifying the quality of the materials. This can lead to project delays, increased costs, and potential safety hazards if subpar products are used.

The Solution: To ensure the sourcing of high-quality LR PVC products, buyers should establish partnerships with reputable manufacturers and distributors who have a proven track record in the industry. Conducting thorough research on suppliers, including checking for certifications and compliance with international standards, is crucial. Additionally, leveraging local distributors who understand regional market dynamics can enhance sourcing efficiency. Requesting samples for testing and evaluation before committing to bulk purchases can also mitigate risks and ensure that the products meet the necessary quality requirements.

Illustrative image related to lr pvc

Scenario 2: Challenges in Installation and Compatibility with Existing Systems

The Problem: Another common pain point for B2B buyers is the installation challenges associated with LR PVC conduit bodies. Many buyers are faced with existing electrical systems that may not be compatible with new LR PVC installations. This often leads to unexpected costs and project timelines being extended as teams work to modify or adapt systems to accommodate the new products.

The Solution: To address installation challenges, buyers should invest in comprehensive training for their teams on the specific installation requirements for LR PVC conduit bodies. Providing detailed specifications and installation guides from manufacturers can aid in understanding compatibility issues. Additionally, buyers should consider consulting with electrical engineers or contractors who specialize in conduit installations to assess existing systems and recommend any necessary modifications ahead of time. Implementing a phased approach to installation, where teams can progressively adapt to the new products, can also help reduce disruptions and ensure seamless integration.

Scenario 3: Misunderstanding Product Specifications and Standards

The Problem: B2B buyers often face confusion regarding the specifications and standards of LR PVC products, especially when dealing with multiple suppliers or products that may have slight variations. This misunderstanding can lead to purchasing errors, such as buying the wrong size or type of conduit body, resulting in project delays and increased costs.

The Solution: To combat the misunderstanding of product specifications, buyers should invest in creating a centralized database or a reference guide that details all necessary specifications, including size, material types, and applicable standards for LR PVC conduit bodies. This resource should be easily accessible to all team members involved in the procurement process. Furthermore, engaging directly with suppliers for clarification on specifications and requesting documentation that outlines product compliance with relevant standards can enhance understanding. Regular training sessions on product knowledge for the procurement team can also be beneficial, ensuring that everyone is on the same page regarding the technical aspects of the materials being sourced.

Strategic Material Selection Guide for lr pvc

What Are the Key Materials Used in LR PVC Conduit Bodies?

When selecting materials for LR PVC conduit bodies, it is essential to consider various options that meet specific performance requirements and application needs. The most common materials include PVC, CPVC, fiberglass, and metal (such as aluminum or steel). Each material has unique properties, advantages, and limitations that can significantly impact the effectiveness of the conduit in various environments.

How Does PVC Perform as a Material for LR PVC Conduit Bodies?

Key Properties: PVC (Polyvinyl Chloride) is known for its excellent electrical insulation properties, lightweight nature, and resistance to corrosion. It typically operates effectively within a temperature range of -40°F to 140°F (-40°C to 60°C) and is suitable for low-pressure applications.

Pros & Cons: The advantages of PVC include its affordability, ease of installation, and non-conductive nature, making it ideal for electrical applications. However, it can become brittle at low temperatures and is not suitable for high-pressure applications. Additionally, PVC may not be compatible with certain solvents and chemicals, limiting its use in specific environments.

Impact on Application: PVC is widely used in residential and commercial electrical installations, particularly in areas where moisture and corrosion are concerns. Its lightweight nature allows for easy handling and installation, reducing labor costs.

Considerations for International Buyers: Compliance with international standards such as ASTM and DIN is crucial when sourcing PVC materials. Buyers from regions like Africa and South America should ensure that products meet local regulations regarding electrical safety and environmental impact.

What Are the Benefits of CPVC for LR PVC Conduit Bodies?

Key Properties: CPVC (Chlorinated Polyvinyl Chloride) offers higher temperature resistance compared to standard PVC, typically handling temperatures up to 200°F (93°C). It also possesses excellent chemical resistance, making it suitable for harsher environments.

Pros & Cons: The main advantage of CPVC is its ability to withstand higher temperatures and aggressive chemicals, which makes it ideal for industrial applications. However, CPVC is generally more expensive than PVC and may require specialized fittings and installation techniques, increasing overall project costs.

Impact on Application: CPVC is commonly used in industrial settings where chemical exposure is likely, such as in chemical processing plants. Its durability and resistance to corrosion make it a preferred choice for applications requiring long-term reliability.

Considerations for International Buyers: Buyers should be aware of the specific chemical compatibility requirements for CPVC in their applications. Additionally, they should verify that the products comply with relevant international standards, particularly in regions with stringent safety regulations like Germany and the Middle East.

How Does Fiberglass Compare as a Material for LR PVC Conduit Bodies?

Key Properties: Fiberglass is known for its high strength-to-weight ratio and resistance to both corrosion and extreme temperatures. It can typically handle temperatures up to 300°F (149°C) and is non-conductive.

Pros & Cons: The primary advantage of fiberglass is its durability and resistance to environmental factors, making it suitable for outdoor and industrial applications. However, it is often more expensive than PVC and CPVC, and its installation can be more complex due to the need for specialized tools.

Impact on Application: Fiberglass conduit bodies are ideal for applications in harsh environments, such as oil and gas industries, where exposure to corrosive substances is a concern. Their longevity can lead to reduced maintenance costs over time.

Considerations for International Buyers: Buyers should consider local availability and the potential need for specialized installation training. Compliance with international standards for fiberglass products is also essential, particularly in regions with strict safety regulations.

What Are the Advantages and Limitations of Metal Conduit Bodies?

Key Properties: Metal conduit bodies, such as those made from aluminum or steel, offer excellent strength and durability. They can withstand high temperatures and mechanical stress, making them suitable for heavy-duty applications.

Pros & Cons: The main advantage of metal conduit is its robustness and ability to provide additional protection against physical damage. However, metal can be prone to corrosion, especially in humid environments, unless properly coated. Additionally, metal conduit bodies are generally heavier and may require more labor-intensive installation processes.

Impact on Application: Metal conduit bodies are often used in industrial and commercial settings where heavy machinery and equipment are present. Their strength makes them ideal for protecting wiring in high-traffic areas.

Considerations for International Buyers: Buyers should assess the local environmental conditions and ensure that the metal conduit bodies are treated to resist corrosion. Compliance with international standards for metal products is also critical, especially in regions with specific safety requirements.

Summary Table of Material Options for LR PVC Conduit Bodies

| Material | Typical Use Case for lr pvc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| PVC | Residential and commercial electrical work | Affordable and easy to install | Brittle at low temperatures, limited chemical compatibility | Low |

| CPVC | Industrial applications with chemicals | Higher temperature and chemical resistance | More expensive, requires specialized fittings | Medium |

| Fiberglass | Harsh environments (oil & gas) | High durability and corrosion resistance | Higher cost, complex installation | High |

| Metal | Heavy-duty industrial/commercial settings | Excellent strength and protection | Prone to corrosion, heavier installation | Medium |

In-depth Look: Manufacturing Processes and Quality Assurance for lr pvc

What Are the Main Stages of Manufacturing LR PVC Products?

The manufacturing process for LR PVC (Long Radius Polyvinyl Chloride) products involves several key stages that ensure the final product meets the required specifications for quality and performance. Understanding these stages is crucial for B2B buyers who are looking for reliable suppliers.

Material Preparation: How Is the Raw Material for LR PVC Processed?

The first stage of manufacturing involves sourcing high-quality PVC resin. This resin is typically produced through the polymerization of vinyl chloride monomer. Once the resin is obtained, it undergoes a drying process to remove moisture, which is critical for maintaining the integrity of the final product. Additives such as stabilizers, lubricants, and impact modifiers may also be mixed in at this stage to enhance the performance characteristics of the PVC.

Forming: What Techniques Are Used to Shape LR PVC Products?

The forming stage primarily involves extrusion and molding techniques. In extrusion, the prepared PVC mixture is fed into an extruder, where it is heated and forced through a die to create long sections of conduit or fittings. For more complex shapes, injection molding may be employed, where the PVC is heated until it becomes pliable and then injected into a mold. This stage requires precise temperature control and pressure settings to ensure uniformity and consistency in the products.

Illustrative image related to lr pvc

Assembly: How Are Different Components of LR PVC Products Joined?

After forming, the next step involves assembling any additional components, such as lids, gaskets, and screws for conduit bodies. This may involve manual assembly or automated processes, depending on the scale of production. In some cases, adhesive bonding techniques might be used to ensure airtight and watertight seals, particularly for products meant for outdoor or high-moisture environments.

Finishing: What Final Treatments Are Applied to LR PVC Products?

The finishing stage includes surface treatments and quality checks. Products may undergo additional processes such as trimming, polishing, and application of protective coatings. This is also when products are marked for identification, often including relevant certifications or compliance markings. Ensuring that the finishing process meets international standards is crucial, as it directly affects the product’s durability and marketability.

What Quality Assurance Measures Are Essential for LR PVC Manufacturing?

Quality assurance is a critical aspect of the manufacturing process, particularly for B2B buyers who need assurance that the products will meet both local and international standards.

Which International Standards Should B2B Buyers Look For?

For LR PVC products, adherence to international quality standards such as ISO 9001 is essential. This standard outlines the requirements for a quality management system, ensuring that manufacturers consistently produce products that meet customer and regulatory requirements. Additionally, certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) certifications for products used in the oil and gas industry may be relevant.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is typically divided into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon delivery to ensure they meet specified quality standards.

- In-Process Quality Control (IPQC): During the manufacturing process, ongoing inspections are conducted to monitor critical parameters such as temperature, pressure, and dimensional accuracy.

- Final Quality Control (FQC): Once the products are finished, they undergo a final inspection and testing phase to ensure they meet all specifications and standards before shipping.

What Common Testing Methods Are Used for LR PVC Products?

Common testing methods for LR PVC products include:

- Dimensional Inspection: Ensuring that products meet specified dimensions and tolerances.

- Mechanical Testing: Evaluating tensile strength, impact resistance, and flexibility.

- Chemical Resistance Testing: Checking the product’s durability against various chemicals it may encounter in its intended use.

- Electrical Testing: For products designed for electrical applications, ensuring that they meet electrical insulation and conductivity standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of potential suppliers:

What Audits and Reports Should Buyers Request?

Requesting documentation of quality audits, both internal and external, is essential. Suppliers should provide reports that detail their compliance with international standards and any corrective actions taken in response to previous audits. Regular audits by third-party organizations can also serve as an independent verification of a supplier’s commitment to quality.

How Important Are Third-Party Inspections for Quality Assurance?

Third-party inspections can provide an unbiased assessment of a supplier’s manufacturing processes and quality control measures. Buyers may consider hiring independent inspectors to evaluate the manufacturing facility and conduct product testing. This can be particularly important for buyers from regions such as Africa and South America, where local regulations may differ significantly from international standards.

What Are the Nuances of Quality Control and Certification for International Buyers?

Understanding the nuances of quality control and certification is vital for international buyers. Different regions may have varying requirements for certifications, and ensuring compliance can impact market access.

How Do Regional Regulations Affect Quality Assurance?

For example, buyers in Europe must ensure that products meet CE marking requirements, while those in the Middle East may need to adhere to specific local standards. Buyers should be aware of these regional differences and confirm that suppliers are equipped to meet them.

What Should Buyers Know About Certification Validity and Renewal?

Certifications are not always permanent; they often require renewal and periodic reassessment. Buyers should inquire about the validity of a supplier’s certifications and any plans for renewal. This ensures that they are partnering with a manufacturer committed to maintaining high standards over time.

Illustrative image related to lr pvc

In summary, understanding the manufacturing processes and quality assurance measures associated with LR PVC products is crucial for B2B buyers. By focusing on the details of manufacturing stages, quality control checkpoints, and certification nuances, buyers can make informed decisions and establish reliable partnerships in the global marketplace.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘lr pvc’

In today’s competitive global market, sourcing high-quality LR PVC (Long Radius Polyvinyl Chloride) products is essential for businesses involved in electrical and construction projects. This step-by-step checklist will guide B2B buyers through the procurement process, ensuring they make informed decisions while securing the best materials for their needs.

Step 1: Define Your Technical Specifications

Understanding the specific requirements of your project is crucial. Define the size, type, and application of the LR PVC products you need. Consider factors such as:

– Conduit Size: Determine the appropriate diameter (e.g., 1 inch, 2 inches) based on your electrical system’s needs.

– Schedule Rating: Identify whether you need Schedule 40 or Schedule 80 products based on environmental conditions and installation requirements.

Step 2: Research Potential Suppliers

Start by compiling a list of potential suppliers. Look for manufacturers and distributors that specialize in electrical conduit products. Key aspects to consider include:

– Product Range: Ensure they offer a variety of LR PVC options to meet your specifications.

– Reputation: Check online reviews, testimonials, and case studies to gauge their reliability and product quality.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, it’s essential to verify their certifications. This ensures that the products meet industry standards and regulations. Look for:

– UL Listings: Ensure the products are UL-listed for safety and performance.

– ISO Certifications: Suppliers with ISO certifications demonstrate quality management and consistent performance.

Step 4: Request Product Samples

Obtaining samples can help you assess the quality and suitability of the LR PVC products. This step allows you to:

– Inspect Quality: Check for durability, finish, and overall construction.

– Test Fit: Ensure that the samples fit your existing conduit systems and meet your technical specifications.

Illustrative image related to lr pvc

Step 5: Compare Pricing and Terms

Once you’ve narrowed down your options, compare the pricing and terms offered by each supplier. Consider:

– Bulk Pricing Discounts: Inquire about discounts for larger orders, which can significantly impact your overall costs.

– Payment Terms: Evaluate payment options, including net terms, to manage cash flow effectively.

Step 6: Confirm Delivery and Logistics

Understanding the logistics involved in your order is crucial for timely project execution. Confirm:

– Lead Times: Ask about estimated delivery times and whether they can meet your project deadlines.

– Shipping Costs: Factor in shipping fees to get a complete picture of the total cost.

Step 7: Establish a Communication Plan

Effective communication with your supplier is vital for a smooth procurement process. Set up a plan to:

– Regular Updates: Schedule check-ins to receive updates on order status and address any issues promptly.

– Feedback Loop: Create a channel for feedback to ensure that any concerns are addressed quickly and efficiently.

By following this checklist, B2B buyers can navigate the complexities of sourcing LR PVC products, ensuring that they select the best materials for their projects while maintaining quality and cost-effectiveness.

Comprehensive Cost and Pricing Analysis for lr pvc Sourcing

What Are the Key Cost Components for LR PVC Sourcing?

When sourcing LR PVC products, understanding the cost structure is crucial for international B2B buyers. The main components of the cost include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The primary component, PVC material costs can vary significantly based on global oil prices and supplier availability. Buyers should consider bulk purchasing to reduce per-unit costs.

-

Labor: Labor costs depend on the manufacturing location. Regions with lower labor costs can provide significant savings, but this must be balanced against potential quality issues.

-

Manufacturing Overhead: This includes utilities, maintenance, and facility costs, which can impact pricing. Suppliers with efficient operations typically pass savings onto buyers.

-

Tooling: Initial tooling costs can be significant, especially for customized products. Buyers must assess whether the tooling investment aligns with their order volume.

-

Quality Control: Ensuring compliance with international standards involves costs for testing and certification. Products that meet stringent quality certifications often command higher prices but ensure reliability.

-

Logistics: Transportation and shipping costs can vary based on destination, mode of transport, and Incoterms. Understanding these can help buyers optimize their supply chain.

-

Margin: Suppliers add a profit margin to their costs, which can vary. Negotiating terms can help in reducing this margin, especially for high-volume orders.

How Do Price Influencers Affect LR PVC Costs?

Several factors influence the pricing of LR PVC products, making it essential for buyers to understand their impact.

-

Volume/MOQ: Minimum order quantities (MOQ) often dictate pricing. Larger orders typically result in lower unit costs due to economies of scale.

-

Specifications and Customization: Custom specifications can increase costs. Standardized products are generally more cost-effective than customized solutions, so buyers should assess their needs carefully.

-

Materials and Quality: The quality of PVC and additional materials used directly affect the price. Higher-quality materials may incur a premium but can lead to lower maintenance costs over time.

-

Supplier Factors: Supplier reliability, reputation, and production capacity can all influence pricing. Engaging with multiple suppliers can provide leverage in negotiations.

-

Incoterms: Understanding shipping terms is critical. Different Incoterms can shift costs and risks between buyers and sellers, impacting the total cost of ownership.

What Tips Can Help Buyers Negotiate Better Prices for LR PVC?

International B2B buyers should adopt strategic approaches when negotiating prices for LR PVC.

-

Research and Compare: Conduct thorough market research to understand price ranges and supplier capabilities. Comparing multiple quotes can reveal the best value options.

-

Negotiate Terms: Leverage order volume and long-term relationships to negotiate better pricing and payment terms. Establishing a partnership can yield discounts and favorable terms.

-

Consider Total Cost of Ownership: While initial prices are important, consider long-term costs associated with quality, maintenance, and logistics. Sometimes, paying a bit more upfront can save money over time.

-

Be Aware of Pricing Nuances: International buyers must be cautious of currency fluctuations, tariffs, and import duties that could affect final pricing.

-

Utilize Local Market Knowledge: Engage local representatives or consultants who understand the market dynamics and can provide insights into the best suppliers and pricing strategies.

Disclaimer on Indicative Prices

It is important to note that the prices for LR PVC products can vary widely based on market conditions, supplier pricing strategies, and specific product requirements. The figures presented in this analysis are indicative and should be verified with suppliers for current pricing and terms.

Alternatives Analysis: Comparing lr pvc With Other Solutions

Exploring Alternatives to LR PVC: A Comparative Analysis

In the realm of electrical conduit systems, selecting the right material is crucial for ensuring durability, cost-effectiveness, and ease of installation. LR PVC conduit bodies are popular for their non-corrosive properties and versatility. However, various alternatives exist that may better suit specific applications or operational needs. Below is a detailed comparison of LR PVC against other viable solutions, providing B2B buyers with actionable insights.

Illustrative image related to lr pvc

| Comparison Aspect | LR PVC | Alternative 1: Rigid Metal Conduit (RMC) | Alternative 2: Flexible Non-Metallic Conduit (FNC) |

|---|---|---|---|

| Performance | Excellent resistance to corrosion and UV damage. | High durability and impact resistance; suitable for harsh environments. | Good flexibility and ease of installation; suitable for tight spaces. |

| Cost | Generally low-cost, affordable for large projects. | Higher initial investment due to material and labor. | Moderate cost, typically lower than RMC but higher than LR PVC. |

| Ease of Implementation | Straightforward installation; lightweight and easy to handle. | Requires special tools for cutting and threading; heavier. | Quick installation with fewer tools required; flexible design allows for easy bending. |

| Maintenance | Low maintenance; does not rust or corrode. | Requires periodic inspections for corrosion and physical damage. | Low maintenance; however, potential for wear in high-friction areas. |

| Best Use Case | Ideal for residential and commercial installations in non-hazardous areas. | Best for industrial applications where durability is paramount. | Suitable for temporary installations and areas requiring frequent adjustments. |

Detailed Breakdown of Alternatives

Rigid Metal Conduit (RMC)

RMC is renowned for its robust nature and ability to withstand significant physical impact and environmental stressors. It is often employed in industrial settings where protection from mechanical damage is essential. While its strength and durability make it an excellent choice, the drawbacks include a higher cost and the need for specialized installation tools. Additionally, RMC can be prone to corrosion, necessitating regular maintenance checks, which can add to the overall lifecycle cost.

Flexible Non-Metallic Conduit (FNC)

FNC is a versatile option that excels in applications requiring adaptability and ease of installation. Its lightweight structure allows for quick deployment, making it ideal for temporary setups or areas with complex layouts. However, FNC may not offer the same level of protection as RMC in harsh environments. While it provides a good balance between cost and flexibility, its lifespan can be shorter in high-friction applications, requiring careful consideration of the installation environment.

Conclusion: How to Choose the Right Solution for Your Needs

When deciding between LR PVC and its alternatives, B2B buyers should assess their specific project requirements, including environmental conditions, budget constraints, and installation capabilities. LR PVC stands out for its affordability and low maintenance, making it a strong choice for standard applications. In contrast, RMC offers superior durability for industrial needs, while FNC provides flexibility for unique configurations. By evaluating these factors, buyers can make informed decisions that align with their operational goals and project specifications.

Essential Technical Properties and Trade Terminology for lr pvc

What Are the Key Technical Properties of LR PVC?

When considering LR PVC (Long Radius Polyvinyl Chloride) for your projects, understanding its technical specifications is crucial for making informed purchasing decisions. Here are some essential properties to keep in mind:

-

Material Grade

LR PVC is typically made from high-quality, non-conductive PVC that ensures durability and resistance to corrosion. This material grade is vital for applications in electrical conduits, as it helps prevent rust and degradation over time, ensuring longevity and reliability in installations. -

Size and Dimensions

Common sizes include 1-inch, 1.5-inch, and 2-inch diameters, with specific lengths and widths that cater to various project requirements. For instance, a 2-inch LR conduit body might measure 9.875 inches in length and 3.063 inches in width. Accurate sizing is essential for compatibility with existing systems and to ensure optimal performance. -

Schedule Rating

LR PVC conduit bodies are available in Schedule 40 and Schedule 80 ratings, indicating the wall thickness and pressure ratings. Schedule 40 is typically sufficient for most applications, while Schedule 80 is preferred for more demanding environments. Understanding these ratings helps buyers select the right product for their specific needs, ensuring compliance with local codes and standards. -

UL Listing and Certifications

Many LR PVC products are UL listed, meaning they meet the safety standards set by Underwriters Laboratories. Certification adds credibility and assurance regarding the product’s safety and performance, which is critical for B2B buyers who must adhere to regulatory requirements in their regions. -

Temperature Resistance

LR PVC can typically withstand a range of temperatures, making it suitable for both indoor and outdoor applications. This property is essential for buyers in diverse climates, ensuring that the materials will perform reliably regardless of environmental conditions. -

Non-conductive Properties

The non-conductive nature of PVC makes it ideal for electrical applications, reducing the risk of electrical hazards. For businesses involved in electrical installations, this property is a key consideration in ensuring safety and compliance with industry standards.

What Are Common Trade Terms in the LR PVC Industry?

Understanding industry jargon can significantly enhance communication and negotiation with suppliers. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of LR PVC, an OEM may supply conduit bodies that are branded under different labels. B2B buyers often seek OEMs for consistent quality and reliability. -

MOQ (Minimum Order Quantity)

MOQ refers to the smallest quantity of a product that a supplier is willing to sell. For LR PVC products, MOQs can vary widely, impacting inventory management and cash flow for businesses. Understanding MOQs is crucial for planning purchases and ensuring sufficient stock levels. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For buyers interested in LR PVC, issuing an RFQ helps gather competitive quotes and facilitates informed decision-making based on price, delivery times, and other factors. -

Incoterms (International Commercial Terms)

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is essential for B2B buyers involved in cross-border purchases of LR PVC, as they dictate shipping responsibilities, risk transfer, and payment terms. -

Lead Time

This term indicates the time taken from placing an order to receiving it. Understanding lead times is critical for effective project planning, especially for businesses that rely on timely delivery of LR PVC materials to meet project deadlines. -

BOM (Bill of Materials)

A BOM is a comprehensive list of materials, components, and sub-assemblies required to construct a product. For projects involving LR PVC, a well-defined BOM helps streamline procurement and ensures all necessary items are ordered in the correct quantities.

By grasping these technical properties and industry terms, B2B buyers can navigate the LR PVC market more effectively, ensuring they select the right products for their needs while optimizing their procurement processes.

Illustrative image related to lr pvc

Navigating Market Dynamics and Sourcing Trends in the lr pvc Sector

What Are the Current Market Dynamics and Key Trends in the LR PVC Sector?

The LR PVC sector is currently experiencing significant growth driven by various global factors. Increasing urbanization and infrastructure development in emerging markets, particularly in Africa and South America, are fueling demand for electrical conduit systems. Additionally, the rise of smart cities and sustainable building practices in regions like Europe and the Middle East is pushing the adoption of durable and non-corrosive materials such as PVC.

Emerging B2B technology trends, such as automation in manufacturing and enhanced supply chain management systems, are streamlining sourcing processes and improving product quality. Digital platforms are increasingly utilized for procurement, allowing international buyers to access a broader range of suppliers and negotiate better terms. This trend is particularly beneficial for buyers in regions like Germany and Saudi Arabia, where efficiency and reliability are paramount.

Moreover, the global emphasis on energy efficiency and cost reduction is prompting manufacturers to innovate, resulting in new product offerings that meet evolving regulatory standards. As such, international B2B buyers must stay informed about these market dynamics to make strategic sourcing decisions that align with their operational goals.

How Is Sustainability Influencing Sourcing Decisions in the LR PVC Market?

Sustainability is becoming a critical factor in sourcing decisions within the LR PVC sector. The environmental impact of production processes and the materials used is under increasing scrutiny. Buyers are increasingly prioritizing suppliers who demonstrate commitment to sustainable practices and ethical sourcing. This shift is crucial for companies looking to enhance their corporate social responsibility (CSR) profiles and appeal to environmentally conscious consumers.

Green certifications and eco-friendly materials are gaining traction among manufacturers and suppliers. For instance, products that are UL listed and made from recyclable materials are becoming preferred choices for B2B buyers. This trend is particularly pronounced in Europe, where regulatory frameworks often require compliance with stringent environmental standards. Buyers in the Middle East and Africa are also beginning to recognize the long-term cost benefits of investing in sustainable products, as they contribute to energy savings and reduced waste over time.

Illustrative image related to lr pvc

Incorporating sustainability into sourcing strategies not only helps mitigate environmental impact but also positions companies as leaders in responsible business practices, enhancing brand reputation and customer loyalty.

How Has the LR PVC Sector Evolved Over Time?

The LR PVC sector has undergone significant evolution since its inception, adapting to changing market needs and technological advancements. Initially used primarily for electrical applications, LR PVC conduit systems have expanded in scope due to their durability, cost-effectiveness, and resistance to corrosion.

As industries have sought more efficient and reliable electrical solutions, the adoption of PVC conduit bodies has surged. Manufacturers have responded by developing new designs that cater to specific applications, such as improved configurations for installation ease and enhanced functionality. This evolution reflects broader trends in construction and electrical engineering, where the focus is increasingly on sustainable and resilient infrastructure.

As the sector continues to evolve, international B2B buyers must keep abreast of these developments to leverage new opportunities and enhance their procurement strategies effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of lr pvc

-

How do I choose the right type of LR PVC conduit body for my project?

Selecting the appropriate LR PVC conduit body depends on several factors, including the size of the conduit, the specific application, and environmental conditions. For instance, consider the pipe size (commonly available in 1, 1.5, and 2 inches) and ensure compatibility with Schedule 40 or 80 conduits. Additionally, assess the installation environment—some conduit bodies are designed for outdoor use and are resistant to UV rays and moisture. Consulting with a supplier about your specific needs can help you make an informed decision. -

What are the advantages of using LR PVC conduit bodies in electrical installations?

LR PVC conduit bodies offer several advantages, including durability, non-conductivity, and resistance to corrosion. They are lightweight, making them easier to handle and install compared to metal alternatives. Moreover, the design allows for a 90-degree turn in conduit runs while providing access for maintenance, splicing, and tapping conductors. These features make LR PVC conduit bodies an efficient choice for both residential and commercial electrical systems. -

What should I consider when sourcing LR PVC conduit bodies internationally?

When sourcing LR PVC conduit bodies internationally, consider factors such as compliance with local standards and regulations, shipping costs, and delivery timelines. It’s crucial to verify that the products meet the necessary certifications (e.g., UL, CSA) for safety and reliability in your region. Additionally, assess the supplier’s reputation, quality control processes, and customer support capabilities to ensure a smooth procurement process. -

What is the typical minimum order quantity (MOQ) for LR PVC conduit bodies?

Minimum order quantities for LR PVC conduit bodies can vary significantly among suppliers, typically ranging from 50 to 500 units. It’s essential to discuss MOQs with potential suppliers upfront to ensure they align with your purchasing requirements. Some suppliers may offer flexibility in MOQs for first-time orders or bulk purchases, so negotiating can be beneficial. Always consider your project scale and future needs when determining the right quantity. -

How can I vet suppliers of LR PVC conduit bodies effectively?

To vet suppliers of LR PVC conduit bodies, start by checking their certifications and compliance with industry standards. Look for reviews and testimonials from previous clients to gauge their reliability and product quality. Request samples to assess the product firsthand and inquire about their manufacturing processes and quality assurance measures. Additionally, ensure they have a solid logistics plan in place for timely delivery, especially if you’re sourcing internationally. -

What payment terms are commonly offered for international purchases of LR PVC conduit bodies?

Payment terms for international purchases of LR PVC conduit bodies typically include options like advance payment, letter of credit, or payment upon delivery. Many suppliers may require a deposit upfront, especially for larger orders, while others might offer net payment terms (e.g., Net 30 or Net 60). It’s advisable to clarify payment terms before finalizing the order to avoid misunderstandings and ensure smooth transactions. -

What quality assurance measures should I look for when purchasing LR PVC conduit bodies?

When purchasing LR PVC conduit bodies, seek suppliers who implement stringent quality assurance measures. This includes regular testing of materials to ensure compliance with industry standards, inspections during the manufacturing process, and certifications from recognized organizations. Requesting documentation such as test reports or compliance certificates can help verify the product’s quality and safety, ensuring that it meets your project’s requirements. -

How can I ensure efficient logistics and delivery for my LR PVC conduit body order?

To ensure efficient logistics and delivery of your LR PVC conduit body order, communicate your timeline and delivery requirements clearly with your supplier. Consider choosing suppliers who have experience with international shipping and can provide tracking information. It may also be beneficial to work with logistics partners who specialize in handling construction materials to facilitate smoother customs clearance and delivery. Always confirm shipping costs and estimated delivery times upfront to avoid unexpected delays.

Top 4 Lr Pvc Manufacturers & Suppliers List

1. Cantex – 2 Inch Conduit Body Type LR

Domain: gmesupply.com

Registered: 2004 (21 years)

Introduction: {‘product_name’: ‘Cantex 2 Inch Conduit Body Type LR’, ‘model_number’: ‘1592096’, ‘stock_number’: ‘BSE-1592096’, ‘price’: ‘$19.99’, ‘description’: ‘The Cantex 2 Inch Conduit Body Type LR provides pull, splice, and tap access for conductors in a conduit system along with a change in direction.’, ‘features’: [‘Type LR Conduit Bodies are used to make a 90-degree turn in a conduit run with one opening…

2. Mrsupply – PVC Type LR Conduit Body 1 1/2 inch Schedule 40

Domain: mrsupply.com

Registered: 2002 (23 years)

Introduction: {“Product Type”: “PVC Type LR Conduit Bodies”, “Pipe Size”: “1 1/2 inch”, “Schedule”: “40”}

3. AEROS USA – Conduit Bodies

Domain: aerosusa.com

Registered: 2010 (15 years)

Introduction: Conduit bodies are junctures that connect protective raceways for electrical wires. They come in various types, each redirecting wires uniquely. Key types include:

1. LR Conduit Body: L shape, two hubs, redirects raceway by 90 degrees.

2. LL Conduit Body: L shape, two hubs, exits on the left side.

3. LB Conduit Body: Right angle, two hubs, access point on the back.

4. T-Shaped Conduit Body: Th…

4. Elliot Electric – 1-1/2 PVC Type LR Condulet

Domain: elliottelectric.com

Registered: 1997 (28 years)

Introduction: {“product_id”: “5133654”, “product_name”: “1-1/2″ PVC Type LR Condulet”, “category”: “PVC & Accessories”}

Strategic Sourcing Conclusion and Outlook for lr pvc

What Are the Key Takeaways for Strategic Sourcing of LR PVC?

In the evolving landscape of electrical infrastructure, LR PVC conduit bodies present a robust solution for international buyers seeking reliability and efficiency. Strategic sourcing of these materials not only ensures compliance with local standards but also enhances project execution by minimizing downtime and maintenance costs. The durability of non-conductive PVC, resistant to rust and corrosion, positions it as a preferred choice across various applications, particularly in regions experiencing rapid industrial growth, such as Africa and the Middle East.

How Can B2B Buyers Leverage Strategic Sourcing for Competitive Advantage?

For buyers in Europe and South America, focusing on suppliers that offer comprehensive product ranges, including Schedule 40 and 80 conduit options, can streamline procurement processes. Engaging with manufacturers known for quality assurance and timely delivery will further bolster supply chain efficiency. Additionally, exploring local partnerships can help mitigate shipping costs and improve responsiveness to market demands.

What Does the Future Hold for LR PVC Sourcing?

As global infrastructure projects continue to expand, the demand for high-quality LR PVC conduit bodies will likely increase. International B2B buyers are encouraged to stay ahead of market trends by investing in strategic sourcing initiatives. Embrace innovation and sustainability in your procurement practices to not only enhance operational efficiency but also contribute to environmentally conscious projects. Partner with reliable suppliers today to secure your position in the competitive landscape of electrical infrastructure.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to lr pvc

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.