How to Source Latch Push Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for latch push

In the fast-paced world of global commerce, sourcing reliable components like latch push mechanisms can pose significant challenges for international B2B buyers. These critical hardware elements, designed for seamless door operation in various applications, require careful consideration to ensure functionality, durability, and aesthetic appeal. This guide delves deep into the diverse types of latch push options available, including touch latches and push-to-open systems, while highlighting their specific applications in industries ranging from furniture manufacturing to architectural design.

Navigating the complexities of supplier vetting is essential for securing quality latch push solutions. This comprehensive resource will equip buyers from Africa, South America, the Middle East, and Europe—such as those in Saudi Arabia and Brazil—with the insights needed to make informed purchasing decisions. Key topics include evaluating supplier reliability, understanding pricing structures, and recognizing the importance of compliance with international standards.

By empowering businesses with actionable knowledge and strategies, this guide aims to streamline the procurement process, helping you select the right latch push products that meet your operational needs while enhancing your overall product offering. Whether you are looking to innovate your current designs or seeking replacements for existing hardware, this guide serves as your go-to resource for navigating the global market effectively.

Understanding latch push Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Touch Latch | Invisible installation, activated by a gentle push | Cabinet doors, furniture, closets | Pros: Clean look, easy to use. Cons: May require precise installation. |

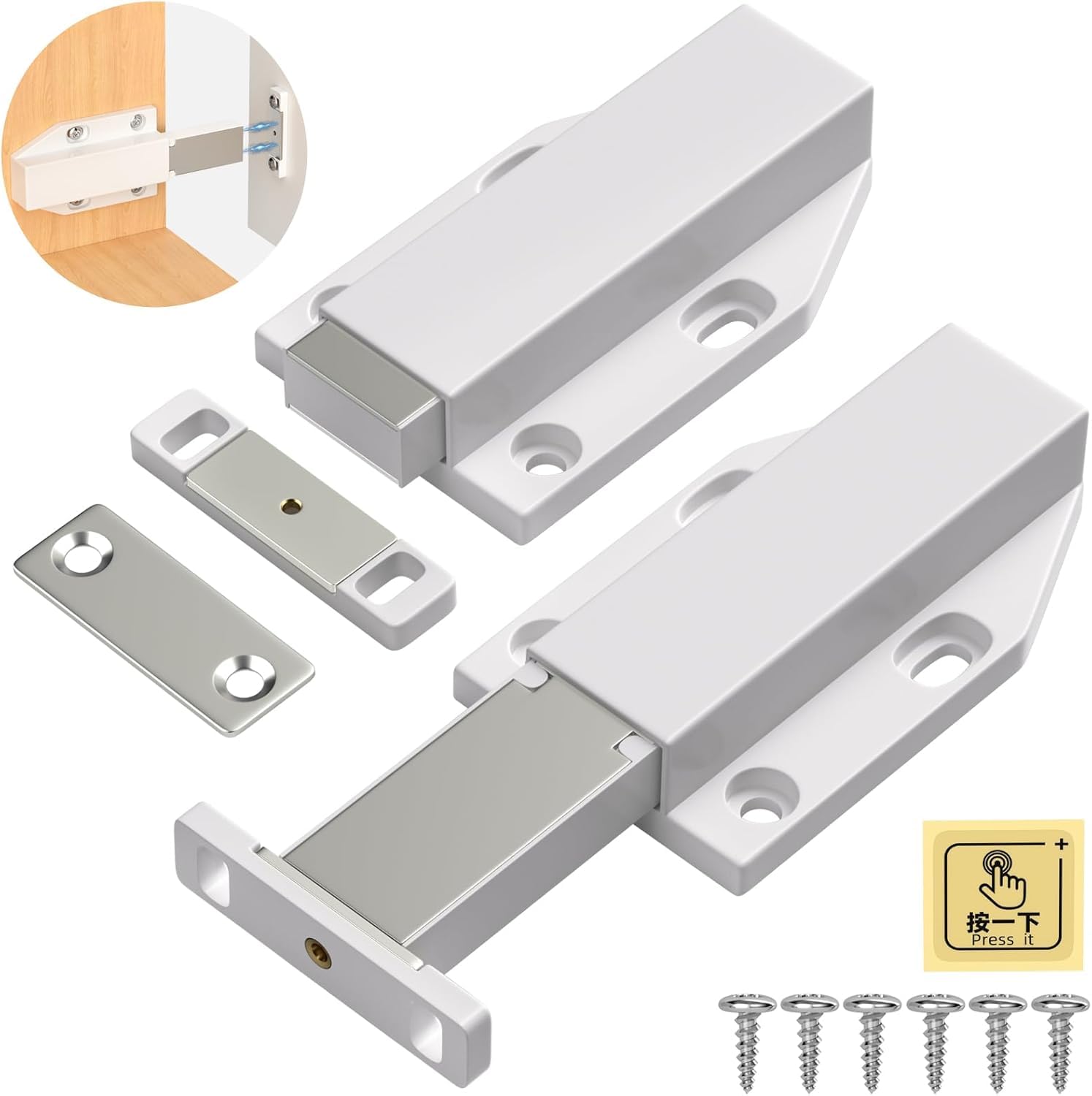

| Magnetic Push-to-Open Latch | Utilizes magnetic force for operation, ideal for heavy doors | Walk-in closets, pantry doors | Pros: Strong hold, no protruding handles. Cons: Potential misalignment issues. |

| Heavy-Duty Touch Latch | Designed for solid core or heavy doors, robust spring action | Commercial settings, heavy cabinetry | Pros: Durable, reliable for high-traffic areas. Cons: Higher cost, installation complexity. |

| Invisible Touch Latch | Completely concealed when closed, no external hardware visible | High-end cabinetry, modern furniture | Pros: Aesthetic appeal, seamless design. Cons: Installation may require customization. |

| Auxiliary Pusher | Additional mechanism for challenging installations | Small spaces, closets with vacuum issues | Pros: Enhances functionality, adaptable. Cons: Additional cost, may complicate installation. |

What Are the Key Characteristics of Touch Latches?

Touch latches are designed for ease of use and aesthetic appeal, featuring an invisible mechanism that allows doors to open with a simple push. They are commonly used in cabinetry and furniture, providing a clean look without visible hardware. For B2B buyers, the installation process is crucial; precise alignment is necessary to ensure proper functionality. These latches are particularly suitable for environments where a minimalist design is prioritized, making them ideal for high-end furniture manufacturers.

How Do Magnetic Push-to-Open Latches Function?

Magnetic push-to-open latches leverage magnetic force to secure and release doors, making them an excellent choice for heavy doors up to 275 lbs. They are ideal for applications such as walk-in closets and pantry doors, where a seamless design is desired. B2B buyers should consider the door weight and size when selecting this type of latch, as misalignment can lead to operational issues. The absence of handles enhances the aesthetic, but buyers must ensure proper installation to avoid complications.

What Makes Heavy-Duty Touch Latches Stand Out?

Heavy-duty touch latches are engineered for solid core or heavy doors, providing robust spring action for reliable operation. They are commonly used in commercial settings and heavy cabinetry, where durability is essential. B2B buyers should evaluate the latch’s weight capacity and installation requirements, as these latches may come at a higher price point. While they offer excellent performance in high-traffic areas, the complexity of installation may require professional assistance.

Why Choose Invisible Touch Latches for Modern Applications?

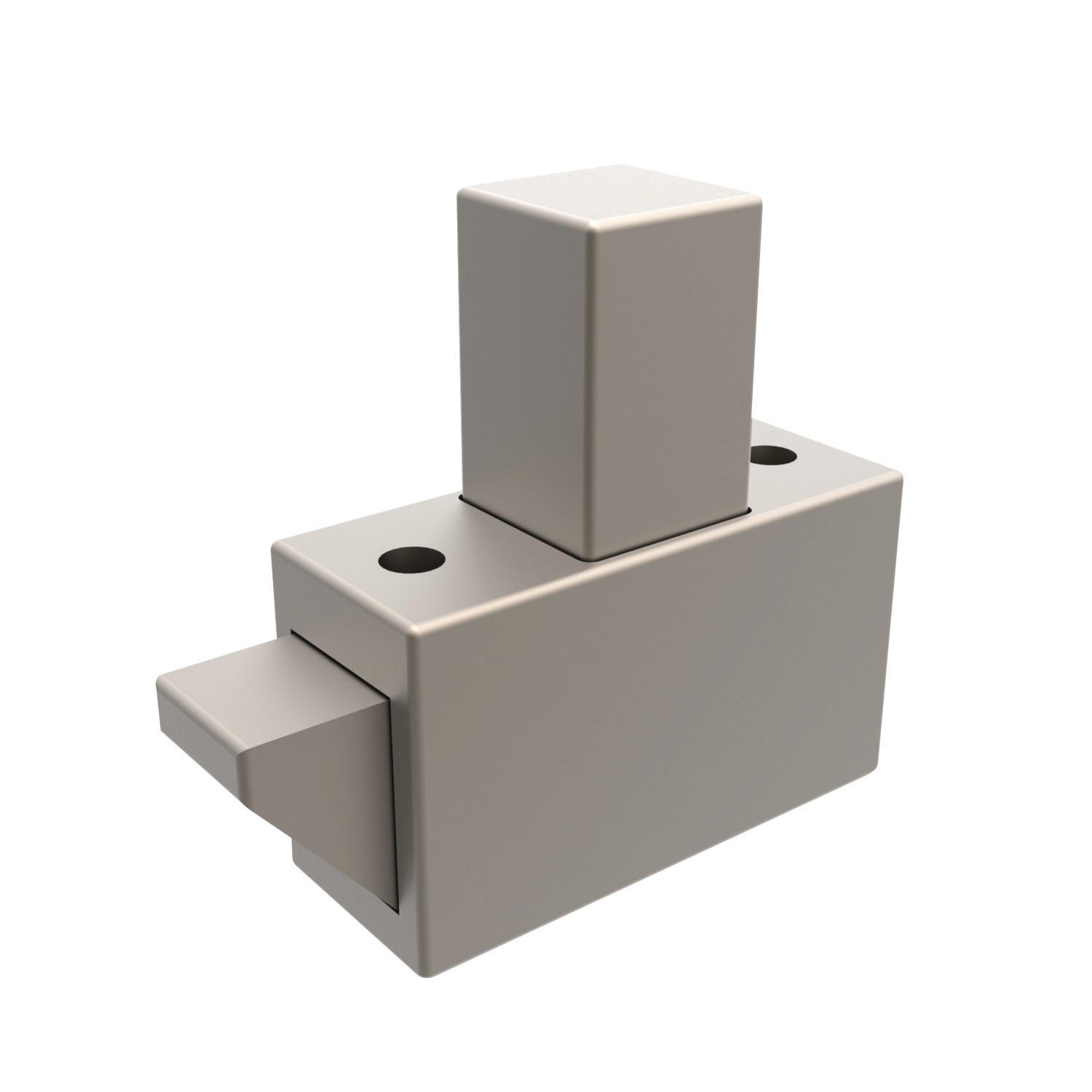

Invisible touch latches offer a fully concealed design, making them perfect for high-end cabinetry and modern furniture applications. These latches eliminate the need for visible hardware, contributing to a sleek and seamless appearance. For B2B buyers, the customization required for installation may be a consideration, as it can vary based on the project. The aesthetic appeal is a significant advantage, but ensuring compatibility with existing designs is essential for successful integration.

How Can Auxiliary Pushers Enhance Latch Functionality?

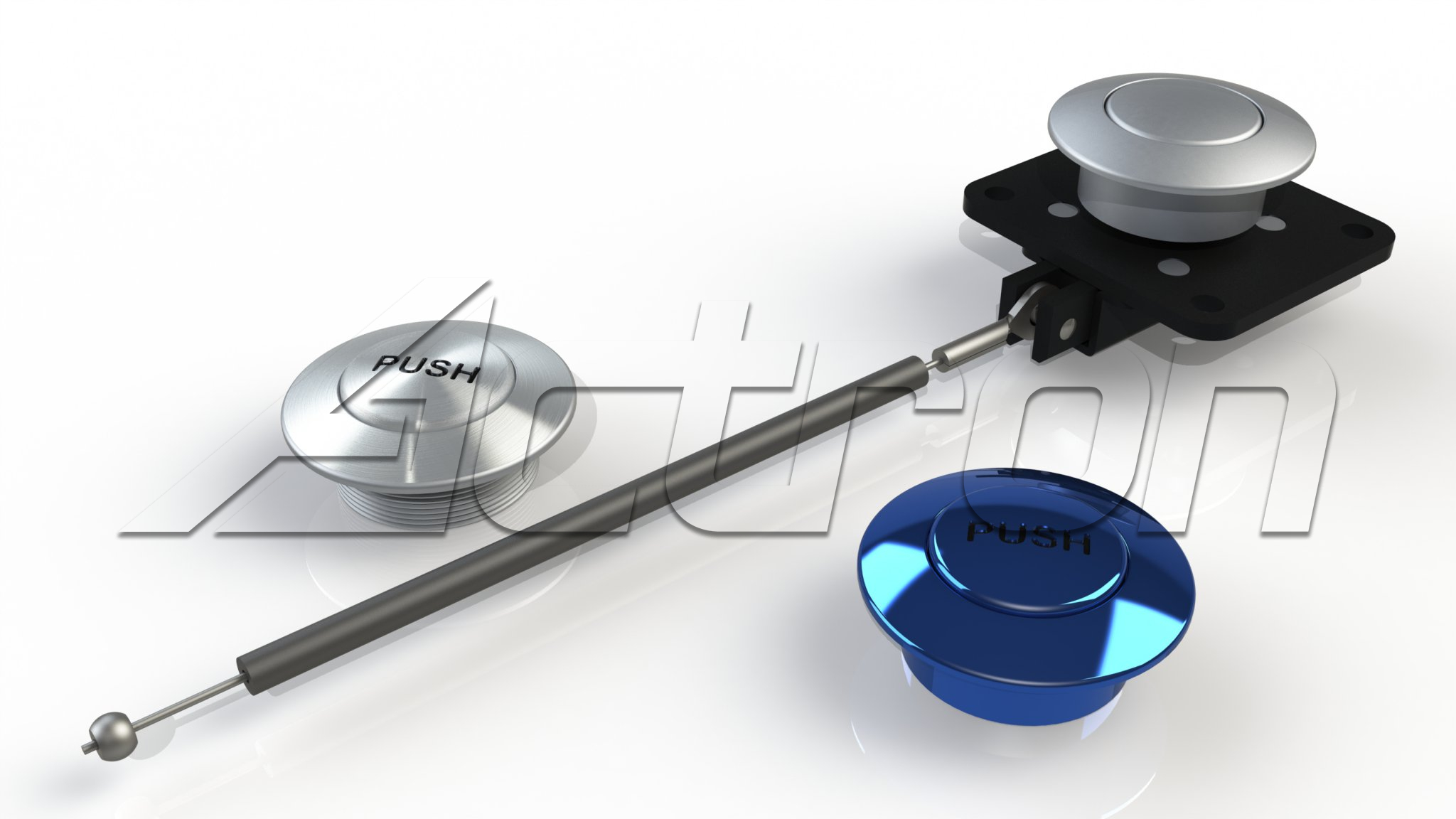

Auxiliary pushers are supplementary mechanisms that improve the functionality of touch latches, particularly in small spaces or areas prone to vacuum conditions. They can be used alongside regular or heavy-duty latches to facilitate easier door opening. B2B buyers should assess the specific needs of their installation environments when considering auxiliary pushers, as they can add complexity and cost to the overall project. Despite these factors, they provide valuable adaptability for challenging applications.

Key Industrial Applications of latch push

| Industry/Sector | Specific Application of latch push | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Integrated touch latches in cabinets and furniture | Enhances aesthetic appeal by eliminating visible hardware | Ensure compatibility with various door types and weights; consider durability of materials. |

| Automotive | Touch latches for vehicle storage compartments | Improves user experience with seamless access and closure | Focus on strength and reliability under varying environmental conditions; lightweight options preferred. |

| Commercial Construction | Push-to-open latches for office partitions and doors | Facilitates easy access while maintaining clean lines in design | Assess for heavy-duty options suitable for high-traffic areas; check for compliance with safety regulations. |

| Retail Displays | Invisible touch latches for showcase cabinets | Protects merchandise while providing a sleek look | Evaluate ease of installation and security features; consider options that accommodate different display sizes. |

| Home Automation | Smart touch latches in automated cabinetry | Integrates with smart home systems for enhanced convenience | Look for compatibility with existing automation technologies; prioritize energy efficiency and security features. |

How Is ‘Latch Push’ Used in Furniture Manufacturing?

In the furniture manufacturing sector, latch push mechanisms are increasingly integrated into cabinets and furniture pieces to enhance aesthetic appeal. By eliminating visible hardware such as knobs and handles, manufacturers can create sleek, modern designs that attract consumers looking for minimalism. For international buyers, it’s crucial to source touch latches that accommodate various door types and weights, ensuring that they meet durability standards and can withstand frequent use.

What Role Do Touch Latches Play in the Automotive Industry?

In the automotive industry, touch latches are utilized in vehicle storage compartments, allowing for seamless access to tools and equipment. This application not only improves user experience but also contributes to the overall design aesthetic of the vehicle. Buyers in regions like Brazil and Saudi Arabia should prioritize sourcing latches that are strong and reliable, as they must withstand varying environmental conditions while remaining lightweight for efficiency.

Why Are Push-to-Open Latches Important in Commercial Construction?

Push-to-open latches are vital in commercial construction, particularly for office partitions and doors. These latches facilitate easy access while maintaining clean lines in interior design, which is essential for modern workspaces. B2B buyers should consider heavy-duty options that can endure high traffic and comply with safety regulations, ensuring that they provide both functionality and style in commercial environments.

How Can Retail Displays Benefit from Invisible Touch Latches?

In the retail sector, invisible touch latches are used in showcase cabinets to protect merchandise while providing a sleek look. This application is particularly appealing to retailers aiming for a high-end presentation. When sourcing these latches, it’s essential to evaluate ease of installation and security features to safeguard valuable items, especially in competitive markets across Africa and Europe.

What Advantages Do Smart Touch Latches Offer in Home Automation?

Smart touch latches are becoming integral in home automation, allowing for seamless integration with automated cabinetry systems. This technology provides enhanced convenience for users, enabling them to operate cabinets and doors with minimal effort. Buyers should focus on sourcing latches that are compatible with existing automation technologies while prioritizing energy efficiency and robust security features to meet the demands of modern living.

3 Common User Pain Points for ‘latch push’ & Their Solutions

Scenario 1: Difficult Installation and Compatibility Issues

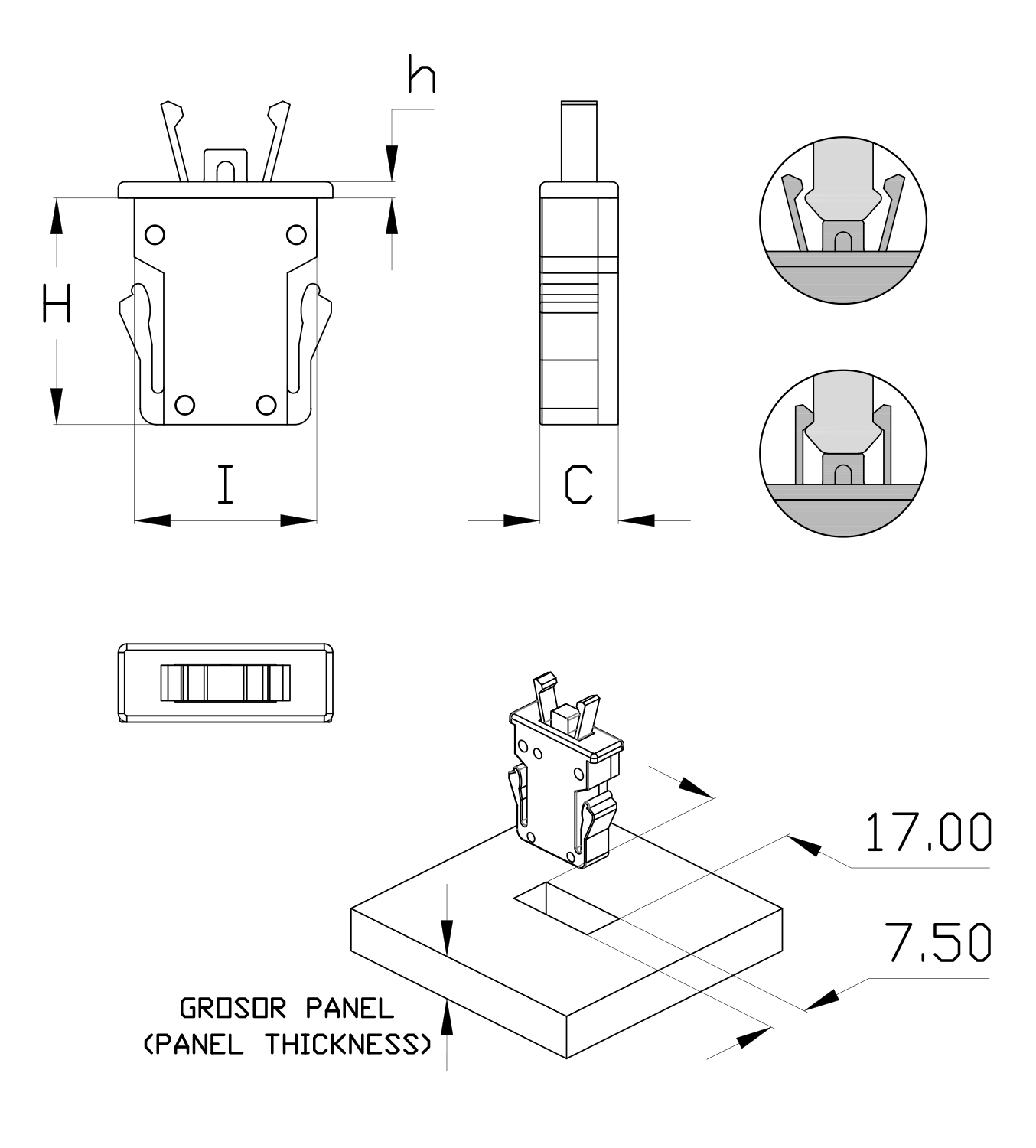

The Problem: B2B buyers often face significant challenges when installing latch push systems, particularly when it comes to compatibility with existing door designs. In many cases, businesses have a variety of door styles, materials, and thicknesses that require precise specifications for effective installation. Buyers may find themselves with a latch that is incompatible with their doors, leading to frustration, wasted time, and additional costs for returns or exchanges.

The Solution: To mitigate installation and compatibility issues, it’s essential for buyers to conduct thorough pre-purchase research. This includes measuring door thickness, understanding the door material, and assessing the existing hardware setup. Buyers should consult manufacturers’ specifications and installation guides to ensure they select a latch push system that meets their specific needs. Additionally, seeking out suppliers that provide comprehensive customer support and installation assistance can further ease the process. Utilizing modular latch systems that offer adjustable components can also enhance compatibility across various door types, making future installations more straightforward.

Scenario 2: Insufficient Latch Strength for Heavy Doors

The Problem: Many businesses utilize heavy doors, such as those found in warehouses, industrial facilities, or upscale retail environments. A common pain point arises when the latch push system fails to provide adequate strength to securely hold these doors closed or allow for smooth operation. This can lead to safety hazards, operational inefficiencies, and potential damage to the doors or frames, ultimately impacting the bottom line.

The Solution: To address issues related to latch strength, buyers should prioritize sourcing heavy-duty latch push systems specifically designed for robust applications. It’s advisable to look for products with high weight ratings and significant push force capabilities. For instance, products like the Sugatsune heavy-duty magnetic touch latch can handle doors weighing up to 275 lbs. Buyers should also consider implementing additional reinforcement measures, such as auxiliary pushers or secondary locking mechanisms, to enhance security and performance. Engaging with suppliers who offer customization options can further ensure that the latch systems are appropriately tailored to the operational demands of heavier doors.

Scenario 3: Aesthetic and Functional Design Compromises

The Problem: In the pursuit of modern, minimalist design, many B2B buyers encounter the challenge of balancing aesthetics with functionality when selecting latch push systems. Traditional hardware can detract from the sleek appearance of contemporary spaces, leading to a mismatch between the desired aesthetic and practical hardware solutions. This can be particularly problematic in high-end commercial environments where design integrity is paramount.

The Solution: To achieve both aesthetic appeal and functionality, buyers should consider invisible or concealed latch push systems that eliminate the need for visible handles or knobs. Products like invisible touch latches not only maintain a clean, modern look but also provide effective functionality. When selecting these systems, it’s important to assess their installation requirements and ensure they are compatible with the intended door design. Buyers should also explore options that allow for customization in finishes and materials to align with the overall design vision. Collaborating with suppliers who understand design trends can lead to innovative solutions that meet both aesthetic and operational requirements.

Strategic Material Selection Guide for latch push

What Are the Key Properties of Common Materials Used in Latch Push Applications?

When selecting materials for latch push mechanisms, it is essential to consider their properties, performance, and suitability for specific applications. This analysis focuses on four common materials: brass, stainless steel, zinc alloy, and plastic. Each material has distinct characteristics that can influence product performance and longevity.

How Does Brass Perform in Latch Push Applications?

Brass is a popular choice for latch push components due to its excellent corrosion resistance and aesthetic appeal. Key properties include a temperature rating of up to 300°F (149°C) and good mechanical strength. The alloy’s natural resistance to tarnishing makes it ideal for decorative applications.

Pros: Brass offers durability and a premium look, making it suitable for high-end products. It is relatively easy to machine and can be finished in various ways.

Cons: The main limitation of brass is its cost, which can be higher than other materials. It may also be less suitable for environments with high humidity or exposure to harsh chemicals.

Illustrative image related to latch push

Impact on Application: Brass is compatible with a wide range of media, including air and water, but may not perform well in acidic or alkaline environments.

Considerations for International Buyers: Brass components must comply with international standards such as ASTM B16 and EN 12164. Buyers in regions like Europe and the Middle East often prefer brass for its aesthetic qualities, while those in Africa and South America may prioritize cost.

What Advantages Does Stainless Steel Offer for Latch Push Mechanisms?

Stainless steel is renowned for its strength and corrosion resistance, making it an excellent choice for latch push applications in challenging environments. It can withstand temperatures up to 1,500°F (815°C) and is resistant to rust and staining.

Pros: The durability and strength of stainless steel make it ideal for heavy-duty applications. It is also easy to clean and maintain, which is advantageous in sanitary environments.

Cons: The primary drawback is its cost, which is generally higher than brass and plastic. Additionally, stainless steel can be more challenging to machine, increasing manufacturing complexity.

Impact on Application: Stainless steel is compatible with a variety of media, including water, chemicals, and oils, making it versatile for different applications.

Considerations for International Buyers: Buyers should ensure compliance with standards such as ASTM A240 and ISO 9444. In regions like Saudi Arabia and Brazil, preference for stainless steel is often driven by its durability in harsh climates.

Why Choose Zinc Alloy for Latch Push Applications?

Zinc alloy is frequently used in latch push mechanisms due to its good mechanical properties and cost-effectiveness. It has a temperature rating of around 400°F (204°C) and is generally resistant to corrosion.

Pros: Zinc alloy is lightweight, easy to cast, and can be produced at a lower cost compared to brass and stainless steel. It also allows for intricate designs.

Cons: While it is durable, zinc alloy may not be suitable for high-stress applications, as it can be less robust than brass or stainless steel.

Impact on Application: Zinc alloy is compatible with various media but may not perform well in extreme conditions or with aggressive chemicals.

Considerations for International Buyers: Compliance with standards such as ASTM B240 is essential. Buyers from Africa and South America may prefer zinc alloy for its affordability, while European markets may focus on its performance.

What Role Does Plastic Play in Latch Push Mechanisms?

Plastic materials, such as nylon or polypropylene, are often utilized in latch push designs for their lightweight and cost-effective properties. They typically have a temperature rating of around 200°F (93°C) and are resistant to moisture.

Pros: Plastic is versatile and can be molded into complex shapes, making it ideal for custom designs. It is also non-corrosive and lightweight.

Cons: The main limitation of plastic is its lower mechanical strength compared to metals, which may restrict its use in high-load applications.

Impact on Application: Plastic is suitable for environments where corrosion is a concern, but it may not withstand extreme temperatures or heavy loads.

Considerations for International Buyers: Compliance with standards like ASTM D638 is important. Buyers in regions like the Middle East may favor plastic for its lightweight nature, while European buyers may be cautious about its long-term durability.

Summary Table of Material Selection for Latch Push

| Material | Typical Use Case for latch push | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | Decorative cabinet latches | Excellent corrosion resistance | Higher cost | High |

| Stainless Steel | Heavy-duty industrial latches | Exceptional strength and durability | More challenging to machine | High |

| Zinc Alloy | Cost-effective latches | Lightweight and easy to cast | Lower strength than metals | Medium |

| Plastic | Lightweight and moisture-resistant latches | Versatile and non-corrosive | Lower mechanical strength | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, helping them make informed decisions based on performance, cost, and application suitability.

In-depth Look: Manufacturing Processes and Quality Assurance for latch push

What Are the Key Stages in the Manufacturing Process for Latch Push Products?

The manufacturing of latch push products involves several critical stages, each ensuring the final product meets both functional and aesthetic standards. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: Which Materials Are Commonly Used?

The first stage in manufacturing latch push products is material preparation. Typically, high-quality materials such as solid brass, stainless steel, and durable plastics are used. Brass is favored for its strength and resistance to corrosion, making it ideal for various environments, including humid regions. In contrast, plastics are often employed for internal components due to their lightweight and versatile properties. Suppliers should provide Material Safety Data Sheets (MSDS) to confirm the safety and compliance of materials used.

How Are Latch Push Products Formed?

Once materials are prepared, the forming process begins. This involves techniques such as die casting, injection molding, and machining. Die casting is commonly used for creating metal components, where molten metal is injected into a mold to create precise shapes. For plastic parts, injection molding is preferred, allowing for complex designs and high-volume production. Machining may be employed for finishing touches, ensuring that parts fit together seamlessly. Understanding these techniques can help buyers assess the capabilities of potential suppliers.

What Does the Assembly Process Entail?

The assembly stage combines the various components into the final latch push product. This stage may involve manual labor or automated processes, depending on the complexity and volume of production. Skilled workers often perform critical tasks such as aligning and securing parts, while automated systems handle repetitive actions, enhancing efficiency. Buyers should inquire about the assembly methods used by suppliers, as this can impact product consistency and quality.

What Finishing Techniques Are Used to Enhance Product Quality?

After assembly, finishing techniques are applied to improve the latch push product’s appearance and durability. Common finishing processes include plating, polishing, and coating. Plating, such as chrome or nickel plating, not only enhances aesthetics but also provides a protective layer against corrosion. Polishing creates a smooth surface, while coatings can add color or additional protective properties. Buyers should request information on the finishing processes to ensure they align with their quality standards.

How Is Quality Assurance Implemented in Latch Push Manufacturing?

Quality assurance (QA) is vital in the production of latch push products, ensuring that each unit meets specified requirements. A robust QA process helps minimize defects and ensures compliance with international standards.

What International Standards Should Buyers Be Aware Of?

B2B buyers should prioritize suppliers that adhere to international quality standards, such as ISO 9001, which outlines criteria for a quality management system. Compliance with these standards indicates a commitment to quality and continuous improvement. Additionally, industry-specific certifications like CE (for products sold in Europe) and API (for oil and gas equipment) may apply, depending on the product’s intended use.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are essential at various stages of production. Incoming Quality Control (IQC) checks the quality of raw materials before they enter the production process. In-Process Quality Control (IPQC) monitors the manufacturing process to catch defects early. Finally, Final Quality Control (FQC) ensures that the finished products meet all specifications before shipment. Buyers should inquire about the specific QC processes implemented by potential suppliers.

Illustrative image related to latch push

What Common Testing Methods Are Employed?

Testing methods for latch push products often include functional tests, durability tests, and environmental tests. Functional tests assess whether the latch operates correctly under various conditions. Durability tests simulate long-term use to evaluate wear and tear. Environmental tests expose products to extreme temperatures and humidity to ensure they perform reliably in diverse conditions. Understanding these testing methods can help buyers gauge product reliability.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers have several options for verifying a supplier’s quality control processes. Conducting supplier audits is an effective method to assess compliance with quality standards and manufacturing capabilities. Buyers can also request quality assurance reports and certifications, which provide documentation of the supplier’s adherence to international and industry standards.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can add an extra layer of assurance. These independent organizations can conduct comprehensive evaluations of manufacturing processes, quality control systems, and product testing. This is particularly important for international buyers who may not be able to visit suppliers in person. Third-party inspections help ensure that products meet the required standards before shipment.

Illustrative image related to latch push

What Are the Unique QC Considerations for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of regional compliance requirements and potential trade regulations. Each market may have specific standards that products must meet to ensure safety and efficacy. Understanding these nuances can help buyers avoid costly compliance issues and ensure smooth importation.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance practices for latch push products is crucial for B2B buyers. By focusing on material selection, manufacturing techniques, and quality control measures, buyers can make informed decisions that align with their needs and expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘latch push’

To aid B2B buyers in successfully procuring ‘latch push’ mechanisms, this guide offers a structured approach that emphasizes critical steps in the sourcing process. By following this checklist, you can ensure that your procurement aligns with your operational needs and quality standards.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the first and most crucial step in sourcing latch push systems. Consider the type of latch needed—regular or heavy-duty—based on the weight and size of the doors. Additionally, determine the required material (e.g., brass, plastic) and finish (e.g., satin chrome, matte black) to ensure compatibility with your existing hardware.

Illustrative image related to latch push

- Weight Capacity: Specify the maximum weight the latch needs to support, as this will influence the type of latch to procure.

- Installation Requirements: Identify whether the latch will be installed on inset or overlay doors, as this affects design compatibility.

Step 2: Research Supplier Options

Conduct thorough research to identify potential suppliers who specialize in latch push systems. Look for suppliers with a proven track record and positive reviews from previous customers in similar industries or regions.

- Market Presence: Assess how long the supplier has been in business and their reputation in the market.

- Product Range: Ensure the supplier offers a variety of latch options to meet diverse requirements.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, vet them thoroughly to ensure reliability and quality. Request company profiles, product catalogs, and references from buyers in similar industries.

- Certifications: Check for relevant certifications that indicate compliance with industry standards, such as ISO or CE marking.

- Customer Feedback: Look for testimonials or case studies that reflect the supplier’s ability to meet deadlines and maintain product quality.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the latch push systems. Testing samples will help you assess the quality, functionality, and suitability of the product for your specific application.

- Installation Test: Ensure that the latch can be easily installed and functions as intended without any complications.

- Performance Evaluation: Test the latch under real-life conditions to gauge its durability and reliability.

Step 5: Review Pricing and Terms

Gather detailed pricing information from each supplier, including any additional costs such as shipping, handling, or import duties, especially if sourcing internationally.

Illustrative image related to latch push

- Bulk Discounts: Inquire about bulk purchase discounts or long-term contract options that may provide cost savings.

- Payment Terms: Understand the payment terms, including deposits, payment methods, and credit options.

Step 6: Negotiate Contractual Terms

Once you have selected a supplier, engage in negotiations to finalize the terms of the contract. Ensure that all critical aspects such as delivery timelines, warranty conditions, and return policies are clearly outlined.

- Delivery Schedule: Confirm the expected delivery timeline and any penalties for late delivery.

- Warranty Coverage: Review warranty terms to ensure adequate protection against defects or malfunctions.

Step 7: Establish a Communication Plan

Effective communication is essential for a smooth procurement process. Establish a clear line of communication with the supplier to address any issues or questions that may arise during the ordering and delivery process.

- Point of Contact: Designate a specific contact person from both your team and the supplier for streamlined communication.

- Regular Updates: Set expectations for regular updates regarding order status and any potential delays.

By following these steps, B2B buyers can effectively navigate the procurement of latch push systems, ensuring that their sourcing aligns with quality standards and operational needs.

Illustrative image related to latch push

Comprehensive Cost and Pricing Analysis for latch push Sourcing

What Are the Key Cost Components in Latch Push Sourcing?

When sourcing latch push mechanisms, it’s vital to understand the comprehensive cost structure involved. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Common materials used for latch pushes include brass, plastic, and zinc alloys. Higher quality materials typically yield better durability and aesthetics but at a higher cost.

-

Labor: Labor costs can vary based on the manufacturing location. Countries with lower labor costs may offer cheaper products, but this may compromise quality. It’s essential to evaluate the balance between cost and quality.

-

Manufacturing Overhead: This includes utilities, rent, and other fixed costs associated with production. Overhead can fluctuate based on the efficiency of the manufacturing processes employed.

-

Tooling: Initial costs for tooling can be substantial, especially for custom designs. For standard products, these costs are spread over larger production volumes, reducing per-unit expenses.

-

Quality Control (QC): Effective QC processes ensure product reliability and compliance with industry standards. Investing in robust QC can prevent costly defects and returns, thereby influencing the overall cost structure.

-

Logistics: Shipping costs, including freight and customs duties, are critical to consider, especially for international transactions. The choice of shipping methods (air vs. sea) and Incoterms can significantly affect total logistics expenses.

-

Margin: Suppliers typically add a margin to cover their costs and profit. Understanding industry standard margins can help buyers negotiate better deals.

How Do Price Influencers Impact Latch Push Costs?

Several factors influence the pricing of latch push products, particularly in the B2B context:

-

Volume/MOQ: Bulk orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate minimum order quantities (MOQs) that align with their needs to optimize pricing.

-

Specifications and Customization: Customized solutions may incur additional costs due to specific manufacturing requirements. Buyers must assess whether the benefits of customization justify the higher prices.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, CE) can increase costs but are often necessary for certain applications or markets, particularly in regulated industries.

-

Supplier Factors: The reputation, reliability, and location of the supplier can impact pricing. Established suppliers may command higher prices due to their proven quality and service levels.

-

Incoterms: The choice of Incoterms affects logistics costs and responsibilities. Understanding terms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can help buyers manage their total cost of ownership effectively.

What Tips Can Buyers Use for Cost-Efficiency in Latch Push Sourcing?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, the following strategies can enhance cost-efficiency:

-

Negotiate Terms: Engage in discussions with suppliers about pricing, payment terms, and discounts for larger orders. Building a good relationship can lead to better deals over time.

-

Consider Total Cost of Ownership (TCO): Beyond the purchase price, consider the lifetime costs associated with the latch push, including maintenance, potential replacements, and operational efficiency.

-

Research Pricing Nuances: Different markets may have varying price structures due to local demand, currency fluctuations, and economic conditions. Understanding these nuances can provide leverage during negotiations.

-

Evaluate Local Suppliers: For buyers in Africa and South America, sourcing from local manufacturers can reduce shipping costs and lead times, potentially offsetting any quality concerns associated with lower-cost products.

-

Stay Informed on Market Trends: Keeping abreast of material costs, industry standards, and technological advancements can help buyers make informed sourcing decisions.

Disclaimer

The prices mentioned in this analysis are indicative and may vary based on market conditions, supplier agreements, and specific product requirements. Always consult with multiple suppliers to obtain accurate pricing tailored to your needs.

Alternatives Analysis: Comparing latch push With Other Solutions

Understanding Alternatives for Latch Push Solutions

In the realm of door hardware, selecting the right latch mechanism is crucial for functionality, aesthetics, and user experience. While latch push mechanisms offer significant advantages, it is beneficial for B2B buyers to consider alternative solutions that may better fit specific requirements. This analysis will compare latch push systems with two viable alternatives: magnetic door latches and traditional knob/pull systems.

Comparison Table

| Comparison Aspect | Latch Push | Magnetic Door Latch | Traditional Knob/Pull System |

|---|---|---|---|

| Performance | Reliable for light to heavy doors; requires a push action to open. | Strong magnetic force; ideal for full-size doors. | Provides a straightforward opening mechanism. |

| Cost | Moderate initial investment; varies by model. | Typically higher due to magnetic components. | Generally lower cost; widely available. |

| Ease of Implementation | Requires precise installation; may need auxiliary components in tight spaces. | Easier installation with hidden screws; clean appearance. | Simple installation; minimal adjustments needed. |

| Maintenance | Low maintenance; occasional adjustments may be needed. | Very low maintenance; durable magnetic components. | Higher maintenance due to wear on knobs and pulls. |

| Best Use Case | Ideal for modern or minimalistic designs; works well in residential and commercial settings. | Best for concealed doors or spaces where handles are impractical. | Suitable for traditional door applications; versatile across various designs. |

In-Depth Analysis of Alternatives

Magnetic Door Latch

Magnetic door latches, such as the Sugatsune ML-ZN80, offer a robust solution for heavier doors, supporting weights up to 275 lbs. These latches operate by using a strong magnetic force, allowing doors to latch and unlatch with a simple push. The installation process is straightforward, often featuring hidden mounting screws for a clean aesthetic. However, the cost can be higher than latch push systems, primarily due to the advanced magnetic technology. This solution is particularly effective in settings where a seamless, handle-free design is desired, such as in modern homes or commercial spaces.

Illustrative image related to latch push

Traditional Knob/Pull System

Traditional knob and pull systems are ubiquitous and known for their ease of use and installation. They are generally lower in cost and widely available, making them a practical choice for various applications. However, they do require more maintenance over time, as wear and tear can affect their functionality. Additionally, knobs and pulls can detract from a sleek, modern appearance, making them less suitable for contemporary designs. Despite these drawbacks, their versatility and reliability make them a staple in many environments, particularly in traditional settings.

Making the Right Choice for Your Business Needs

When considering the best solution for your door hardware needs, B2B buyers should evaluate their specific requirements, including door weight, design aesthetics, and budget constraints. Latch push systems excel in modern applications where a clean look is paramount, while magnetic door latches provide strength and ease of use for heavier doors. Conversely, traditional knob/pull systems offer a cost-effective and reliable option but may not align with contemporary design principles. Ultimately, the decision should be guided by the intended use case and the long-term value each solution provides.

Essential Technical Properties and Trade Terminology for latch push

What Are the Essential Technical Properties of Latch Push Mechanisms?

In the realm of latch push mechanisms, understanding critical specifications is vital for making informed purchasing decisions. Below are some key technical properties that B2B buyers should consider:

-

Material Grade

The material used in latch push mechanisms significantly affects their durability and performance. Common materials include solid brass, stainless steel, and plastic. Brass and stainless steel offer excellent corrosion resistance, making them suitable for environments with high humidity or exposure to chemicals. Choosing the right material ensures longevity, reducing the frequency of replacements and maintenance costs. -

Load Capacity

Load capacity refers to the maximum weight a latch can support without failing. This is particularly important for heavy doors, which may require heavy-duty latches designed to handle significant force. For example, some magnetic touch latches can support doors weighing up to 275 lbs. Understanding load capacity helps in selecting the right latch for specific applications, ensuring safety and functionality. -

Spring Action Strength

The strength of the spring mechanism within the latch determines how effectively it can engage and disengage. A stronger spring action is crucial for heavy doors and can be a deciding factor for applications requiring frequent use. B2B buyers should evaluate whether a regular or heavy-duty model is needed, as this will influence both the user experience and product longevity. -

Installation Type

Latch mechanisms come in various installation types, including surface-mounted, concealed, and integrated designs. Surface-mounted latches are easier to install but may be less aesthetically pleasing, while concealed latches offer a clean look and can be hidden from view. Understanding installation types allows buyers to choose products that align with their design preferences and installation capabilities. -

Tolerance Levels

Tolerance levels refer to the allowable variation in dimensions and performance of the latch. High tolerance levels ensure better functionality and fit, especially in precision applications. For instance, a latch designed for a specific door thickness will require precise measurements to avoid operational issues. In B2B transactions, communicating tolerance requirements can help prevent costly errors and rework.

What Are Common Trade Terms Related to Latch Push Mechanisms?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common terms associated with latch push mechanisms:

Illustrative image related to latch push

-

OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of latch push mechanisms, OEMs are crucial for businesses looking to source high-quality components for their products. Understanding the OEM landscape helps buyers identify reliable suppliers and ensure product compatibility. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. This term is particularly relevant for B2B buyers who need to manage inventory levels and costs. Knowing the MOQ can influence purchasing decisions, especially for smaller businesses or those testing new products. -

RFQ (Request for Quotation)

An RFQ is a formal document used by buyers to request price quotes from suppliers. In the latch push market, issuing an RFQ can help buyers compare prices, specifications, and lead times. Crafting a detailed RFQ is essential for obtaining accurate quotes and fostering competitive pricing. -

Incoterms (International Commercial Terms)

Incoterms are a set of standardized terms used in international trade to define the responsibilities of buyers and sellers. They clarify issues like shipping costs, insurance, and risk transfer. Understanding Incoterms is crucial for B2B buyers engaged in cross-border transactions, ensuring clarity and reducing disputes. -

Lead Time

Lead time refers to the duration between placing an order and receiving the product. In the latch push industry, lead times can vary based on production schedules and shipping logistics. Recognizing lead times helps businesses plan their inventory and project timelines effectively.

By familiarizing themselves with these essential technical properties and trade terminology, B2B buyers can make more informed decisions regarding latch push mechanisms, ultimately enhancing their procurement strategies and operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the latch push Sector

What Are the Key Market Dynamics and Trends Influencing the Latch Push Sector?

The latch push sector is experiencing significant growth driven by several global factors. The increasing demand for sleek and minimalist designs in residential and commercial spaces has led to a surge in the adoption of touch latches and push-to-open mechanisms. These products not only enhance aesthetic appeal but also improve functionality, making them particularly attractive to designers and architects. Additionally, the rise in smart home technologies is influencing sourcing trends, with manufacturers integrating electronic components into traditional latch systems, creating new opportunities for B2B buyers.

Emerging B2B tech trends, such as automation and digital sourcing platforms, are reshaping how international buyers engage with suppliers. For instance, platforms that facilitate real-time inventory checks and order tracking are gaining traction among buyers from Africa, South America, the Middle East, and Europe. This shift toward digitalization enables businesses to streamline procurement processes, enhance supply chain efficiency, and reduce lead times. Furthermore, the focus on customization and personalization in product offerings is compelling manufacturers to adopt flexible production methods, allowing for tailored solutions that meet specific client needs.

How Is Sustainability and Ethical Sourcing Shaping the Latch Push Sector?

Sustainability has become a cornerstone of modern B2B purchasing decisions, significantly influencing the latch push sector. Manufacturers are increasingly prioritizing eco-friendly materials and processes to minimize environmental impact. For instance, the use of recycled metals and sustainably sourced plastics in latch production not only reduces waste but also appeals to environmentally conscious buyers.

Illustrative image related to latch push

Ethical sourcing is equally important, particularly for international buyers who are keen to understand the provenance of the materials used in their products. Implementing transparent supply chains and obtaining certifications such as ISO 14001 (Environmental Management) or Forest Stewardship Council (FSC) certification can enhance credibility and foster trust among buyers. These certifications indicate a commitment to sustainability and ethical practices, which can be a decisive factor in procurement decisions, especially in markets like Saudi Arabia and Brazil where consumer awareness of sustainability issues is growing.

What Is the Evolution of Latch Push Technology and Its Relevance to B2B Buyers?

The latch push technology has evolved significantly over the decades, moving from traditional mechanical latches to sophisticated touch and push-to-open systems. Initially, latches were primarily functional, with little regard for design. However, as design aesthetics gained importance in architecture and furniture, manufacturers began to innovate, leading to the development of touch latches that provide a seamless look without protruding hardware.

Today, the integration of technology into latch systems, including magnetic and electronic latches, reflects an ongoing trend towards convenience and enhanced user experience. This evolution is relevant for B2B buyers as it opens avenues for differentiation in their product offerings and allows them to cater to a broader range of client preferences. Understanding this evolution can help buyers make informed decisions about the products they source, ensuring they remain competitive in a rapidly changing market landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of latch push

-

How do I solve installation issues with latch push products?

To resolve installation challenges with latch push products, ensure that you follow the manufacturer’s installation instructions carefully. It’s crucial to install the latch directly behind the area where the door will be pushed to operate effectively. If you’re facing issues such as the door not releasing, check the alignment and ensure that all screws are properly tightened. Using an auxiliary pusher can help in cases where vacuum conditions affect door operation, providing additional support for smooth functionality. -

What is the best latch push option for heavy doors?

For heavy doors, such as solid core or oversized models, a heavy-duty latch push is recommended. Products like Sugatsune’s heavy-duty magnetic touch latch can support doors weighing up to 275 lbs, offering robust performance with an 11 kg push force. This type of latch eliminates the need for handles, allowing for a clean aesthetic while ensuring reliable operation. Always verify specifications and load capacity to match your specific door requirements. -

How can I ensure the quality of latch push products before purchasing?

To ensure quality, request samples from potential suppliers before committing to larger orders. Look for certifications or quality assurance processes they have in place, such as ISO certification. Additionally, reading customer reviews and checking the supplier’s history can provide insight into product reliability. Engaging in direct communication with the supplier can also help clarify any uncertainties about product materials and manufacturing standards. -

What are typical minimum order quantities (MOQ) for latch push products?

Minimum order quantities for latch push products can vary significantly by supplier and region. Typically, MOQs range from 50 to 500 units for standard products. However, some suppliers may offer lower MOQs for specific items or during promotional periods. When negotiating, consider discussing your requirements and exploring options for smaller trial orders to assess product suitability before scaling up. -

What payment terms should I expect when sourcing latch push products internationally?

Payment terms can vary widely depending on the supplier and your negotiation outcomes. Common terms include a 30% deposit upfront with the balance due before shipment or upon receipt of goods. Some suppliers may offer letters of credit or PayPal for secure transactions. Always clarify payment methods and terms in your contract to prevent any misunderstandings and ensure a smooth transaction process. -

How do I handle logistics for importing latch push products?

When importing latch push products, coordinate with your supplier to understand shipping options, including air freight for speed or sea freight for cost-effectiveness. Ensure all customs documentation is complete, including invoices and packing lists. Engage a reliable freight forwarder familiar with regulations in your country to streamline the import process. Additionally, consider potential tariffs or duties that may apply to your shipment. -

Can latch push products be customized for specific applications?

Yes, many manufacturers offer customization options for latch push products to meet specific application needs. This may include variations in size, finish, or even design features to fit unique door styles. When discussing customization, provide detailed specifications and be clear about your requirements. It’s also wise to ask for prototypes or samples of customized products before placing larger orders to ensure they meet your expectations. -

What should I consider regarding warranty and after-sales support for latch push products?

When sourcing latch push products, inquire about the warranty terms and after-sales support offered by the supplier. A good warranty typically covers defects in materials and workmanship for a specified period, often ranging from one to five years. Additionally, assess the supplier’s commitment to customer service, including responsiveness to inquiries and their process for handling returns or replacements. This will ensure you receive adequate support throughout the product lifecycle.

Top 8 Latch Push Manufacturers & Suppliers List

1. Sugatsune – Push-To-Open Door Latch

Domain: sugatsune.com

Registered: 1996 (29 years)

Introduction: This company, Sugatsune – Push-To-Open Door Latch, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Invisible Touch Latch – Full Size Doors

Domain: hardwaresource.com

Registered: 1996 (29 years)

Introduction: Invisible Touch Latch for Full Size Doors

– SKU: 310494

– Price: $49.67 (Regular Duty / Satin Brass) to $67.29 (Heavy Duty / Satin Bronze)

– Available Models: Regular Duty and Heavy Duty

– Finishes: Satin Brass, Satin Bronze, Satin Chrome

– Description: Touch latch that is invisible from the outside, providing a clean look without the need for knobs or pulls. Best installed behind where the door w…

3. Door Closers USA – Push Bar Door Latch

Domain: doorclosersusa.com

Registered: 2016 (9 years)

Introduction: Push Bar Door Latch | Exit Devices

– List Price: $665.24

– Savings: $

– Item Return Policy: Assembled Per Order, Non-Returnable

– Device Rating: Panic Rated With Dogging Feature (Not Fire Rated), Fire Rated, No Dogging Feature

– Door Size Options: 36″ Wide Door (Standard), 48″ Wide Door

– Outside Handle Options: No Thanks, Outside Lock Cylinder, Pull Escutcheon Lever Handle – Entrance Function, E…

4. JetPress – Push-Push Latches

Domain: jetpress.com

Registered: 1996 (29 years)

Introduction: Push-Push Latches are designed to secure doors without external handles, featuring a simple push-to-open and push-to-close operation. Key specifications include:

– Types: Push To Open Catch, Push To Open Latch

– Variants: Damper, Heavy Duty, Large, Light Duty, Non Magnetic, Rebounder

– Holding Force: 3 KG (70 – 82N)

– Height: 15 mm, 21.3 mm

– Length: 21 mm, 37 mm, 57 mm, 75 mm, 83.5 mm

– Wid…

5. Titus Plus – Push Latch

Domain: titusplus.com

Registered: 2006 (19 years)

Introduction: Push Latch is a touch opening solution designed for effortless opening of doors and drawers without handles, compatible with standard hinges and drawers. It allows for maximum efficiency and flexibility, creating clean lines and a timeless look. The mechanism activates close to the ‘touch opening point’ on the side opposite to hinges, requiring a minimum gap of 12mm between the drawer and cabinet …

6. Rockler – Magnetic Touch Latch

Domain: rockler.com

Registered: 1997 (28 years)

Introduction: This company, Rockler – Magnetic Touch Latch, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Reddit – Push Latch Mechanism

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Push latch mechanism, similar to the one from IKEA (Utrusta Push Opener), used for cabinet doors and drawers.

8. Hafele – Heavy Duty Magnetic Push Latch

Domain: hafele.com

Registered: 1997 (28 years)

Introduction: Heavy Duty Magnetic Push Latch

– Magnet allows tolerance with 1.5° swivel

– Hidden mounting screw design for clean appearance

– Cycle tested to 100,000 openings

– 25 mm (31/32″) stroke

– Area of application: For heavy-duty applications using full-sized flush doors

– Material: Catch housing: Zinc; Strike: Stainless steel

– Item numbers: 246.65.331 (Black), 246.65.731 (White)

Strategic Sourcing Conclusion and Outlook for latch push

In summary, the strategic sourcing of latch push products offers significant advantages for international B2B buyers, particularly those operating in diverse markets across Africa, South America, the Middle East, and Europe. By prioritizing quality and innovative designs—such as touch latches that eliminate the need for traditional handles—companies can enhance product aesthetics and functionality. Heavy-duty options are particularly beneficial for robust applications, ensuring longevity and reliability.

Investing in strategic sourcing not only ensures access to superior products but also fosters stronger supplier relationships, ultimately leading to cost savings and improved supply chain efficiency. As the demand for sleek, handle-free solutions grows, buyers are encouraged to explore the latest advancements in latch technology, which can streamline operations and elevate customer satisfaction.

Looking ahead, international buyers should embrace the opportunities presented by emerging trends in latch push solutions. By staying informed and proactive, businesses can position themselves at the forefront of innovation and meet the evolving needs of their markets. Engaging with reputable suppliers and leveraging strategic sourcing practices will be key to achieving sustainable growth and competitive advantage in this dynamic landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.