How to Source Kevlar Cloth Fabric Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for kevlar cloth fabric

In the competitive landscape of industrial materials, sourcing high-quality Kevlar cloth fabric can pose significant challenges for B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. The demand for durable, heat-resistant, and cut-resistant materials has surged across various sectors, from automotive and aerospace to protective clothing and sporting goods. This guide offers a comprehensive exploration of Kevlar cloth fabric, covering essential aspects such as types, applications, supplier vetting processes, and cost considerations.

By delving into the nuances of Kevlar fabric, buyers will gain the insights needed to make informed purchasing decisions that align with their operational needs. This resource is designed to empower international B2B buyers, ensuring they understand the unique properties of Kevlar, its versatility in applications, and the importance of selecting reputable suppliers. Whether you’re in Saudi Arabia looking to enhance your protective gear offerings or in Germany seeking innovative solutions for composite materials, this guide will serve as your roadmap to navigating the global market for Kevlar cloth fabric. With actionable insights and expert recommendations, you can streamline your sourcing process and secure the best products for your business needs.

Understanding kevlar cloth fabric Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Kevlar® Plain Weave | Simple, strong weave providing good flexibility. | Protective clothing, automotive, aerospace. | Pros: Versatile, cost-effective. Cons: Limited abrasion resistance compared to specialty weaves. |

| Kevlar® Twill Weave | Diagonal pattern enhances durability and flexibility. | Sporting goods, military gear, industrial use. | Pros: High strength, better drape. Cons: Slightly higher cost than plain weave. |

| Kevlar®/Carbon Hybrid | Combines Kevlar® and carbon for enhanced strength. | Aerospace components, high-performance vehicles. | Pros: Lightweight, superior impact resistance. Cons: More complex processing may increase costs. |

| Kevlar® Felt | Non-woven fabric ideal for padding and insulation. | Protective gear, automotive interiors. | Pros: Excellent cushioning, thermal insulation. Cons: Less suitable for structural applications. |

| Kevlar® Tape | Strong, flexible tape for reinforcement. | Sealing, repairs, composite manufacturing. | Pros: Easy to apply, enhances joint strength. Cons: Limited in applications requiring fabric-like properties. |

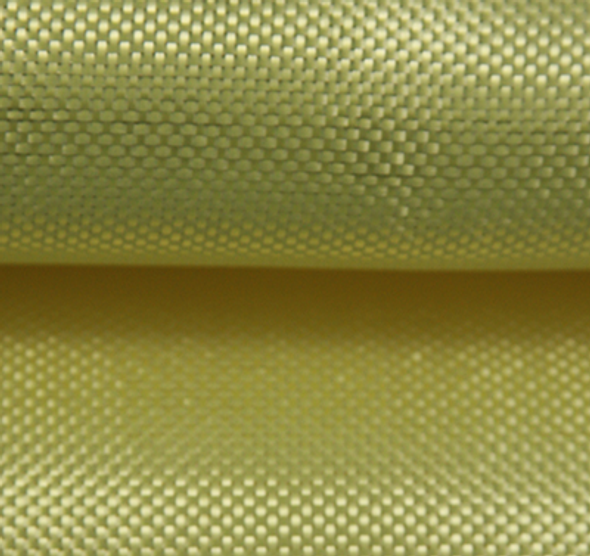

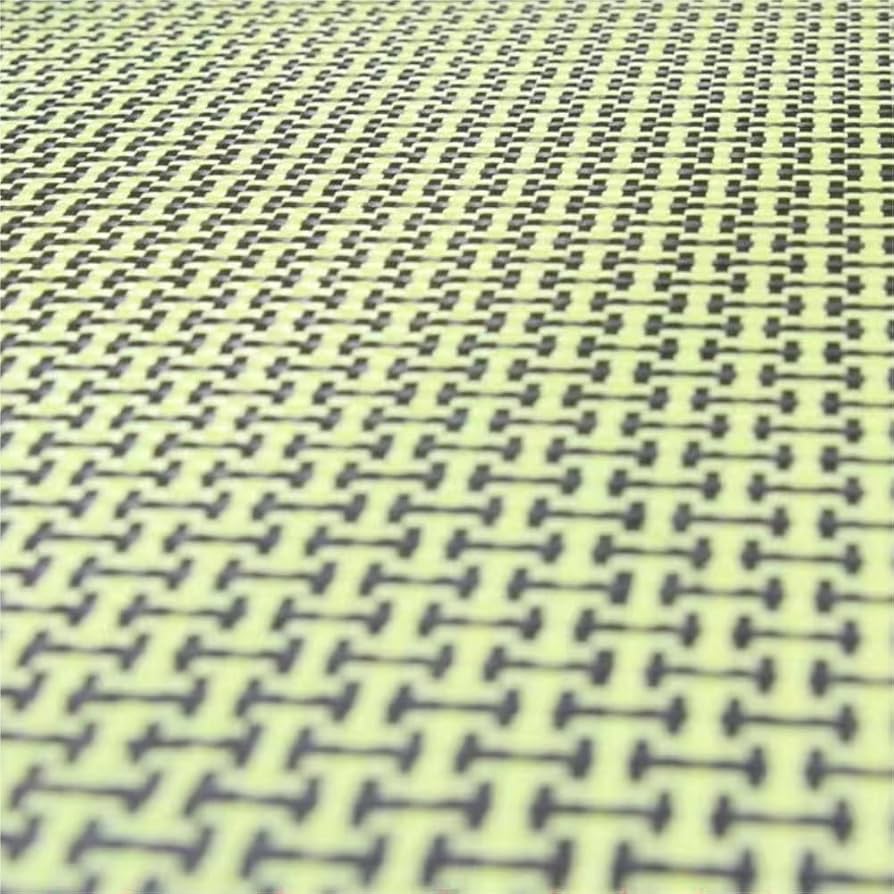

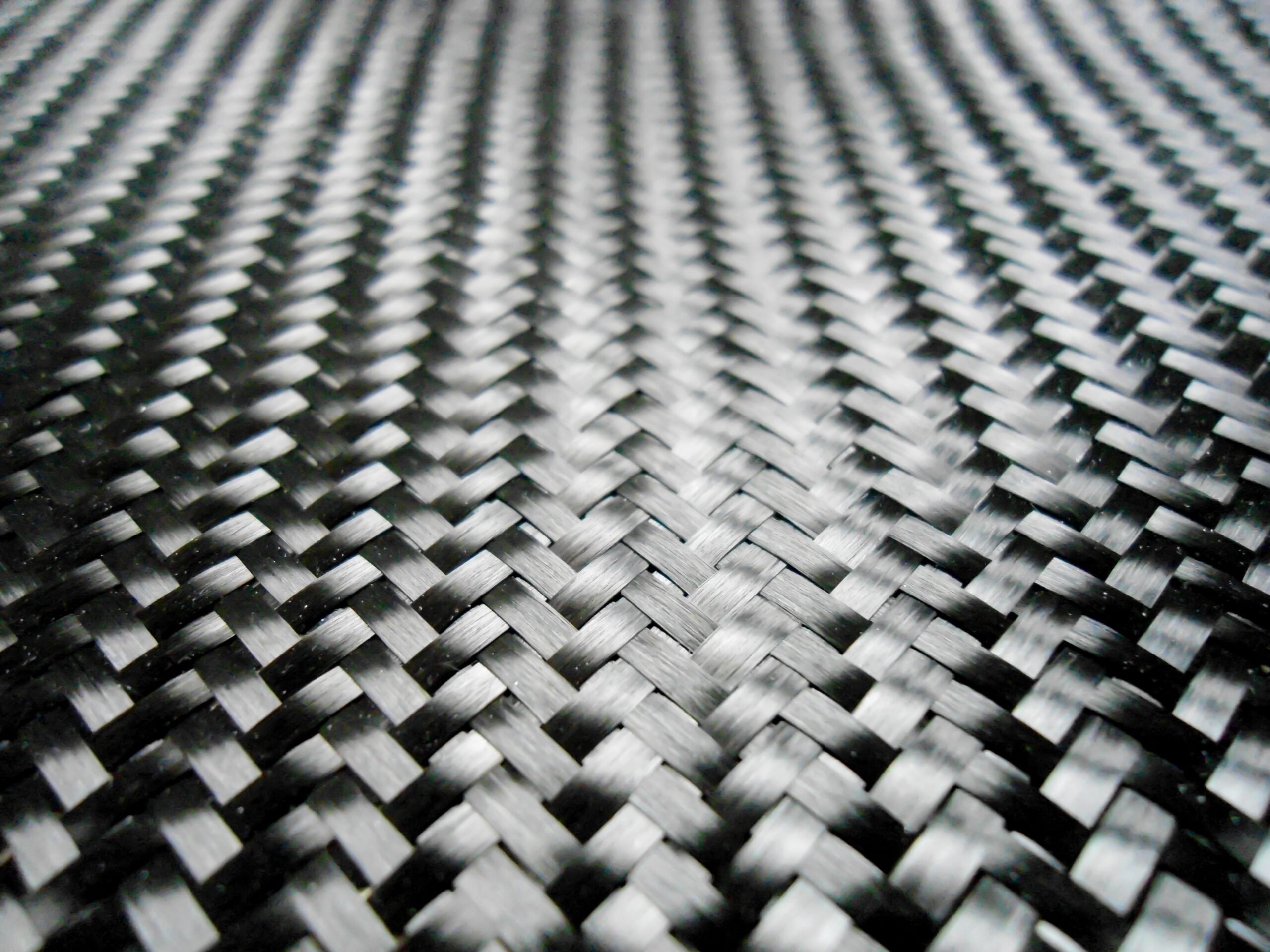

What Are the Characteristics of Kevlar® Plain Weave Fabric?

Kevlar® Plain Weave fabric is known for its straightforward design, which features a simple over-and-under weaving pattern. This structure grants it a good balance of strength and flexibility, making it a popular choice for various applications, including protective clothing and automotive components. When considering this type, buyers should evaluate its cost-effectiveness and versatility, while being aware that it may not offer the same level of abrasion resistance as more specialized fabrics.

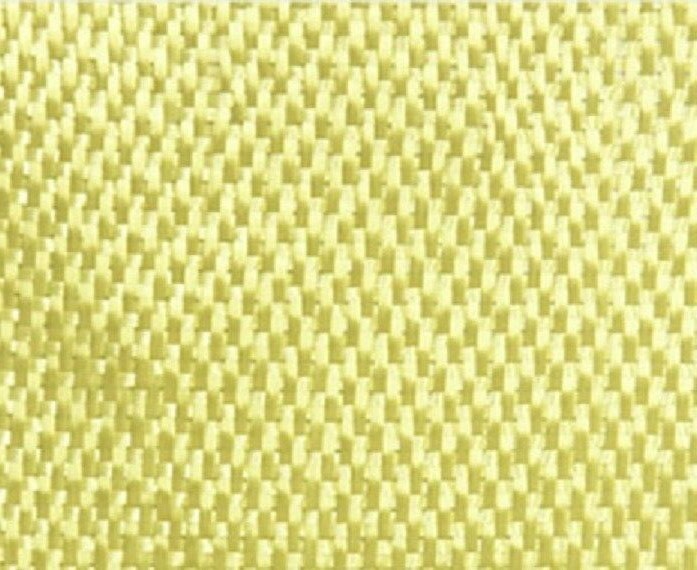

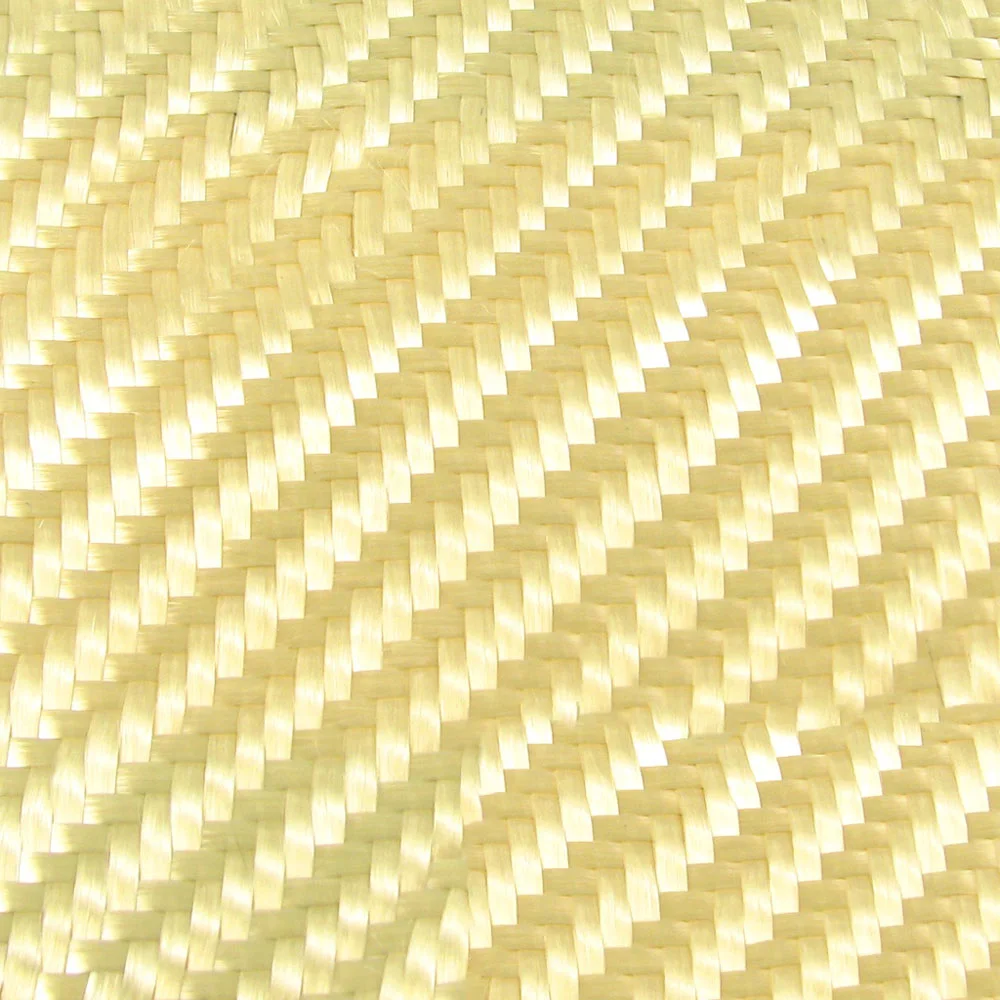

How Does Kevlar® Twill Weave Differ in Performance?

Kevlar® Twill Weave fabric is recognized for its diagonal pattern, which enhances both durability and flexibility. This makes it particularly suitable for applications requiring a combination of strength and comfort, such as sporting goods and military gear. B2B buyers should consider the higher cost associated with twill weaves, as well as their improved drape and aesthetic appeal, which can be important in consumer-facing products.

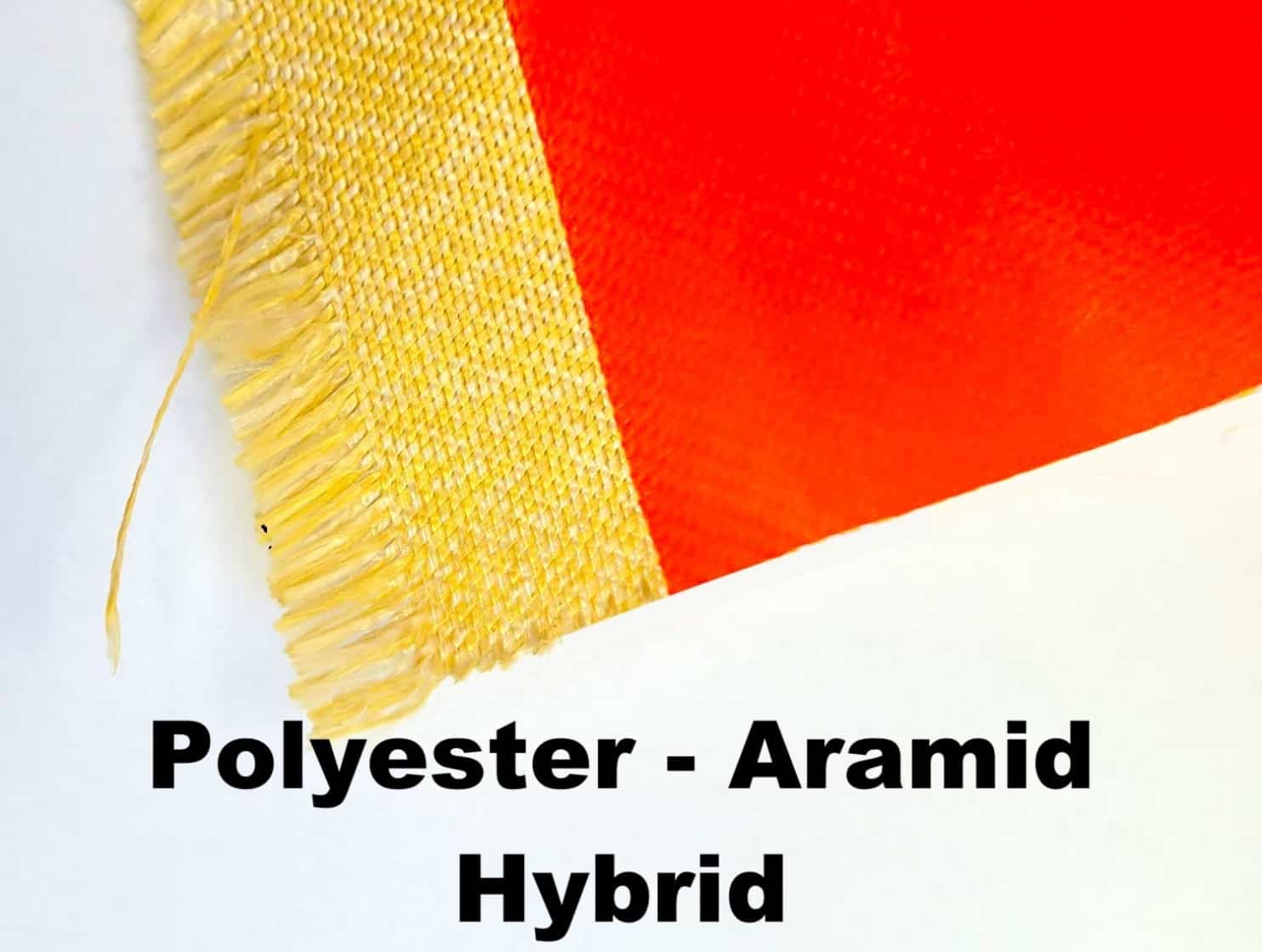

What Advantages Does Kevlar®/Carbon Hybrid Fabric Provide?

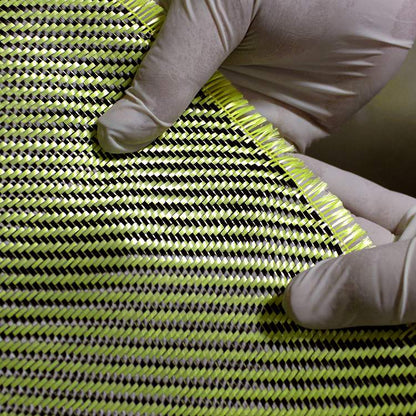

The Kevlar®/Carbon Hybrid fabric merges the strengths of both materials, resulting in a lightweight yet exceptionally strong product. This type is increasingly favored in high-performance sectors like aerospace and automotive industries, where weight reduction without compromising strength is critical. Buyers should note the potential for increased costs due to the complexity of processing this hybrid material, but the benefits in performance often justify the investment.

Why Choose Kevlar® Felt for Insulation and Padding?

Kevlar® Felt is a non-woven fabric that provides excellent cushioning and thermal insulation properties. It is ideal for applications in protective gear and automotive interiors, where comfort and safety are paramount. B2B purchasers should assess the suitability of this fabric for their intended use, recognizing that while it excels in padding, it may not be appropriate for structural applications that require woven fabric strength.

How is Kevlar® Tape Utilized in Various Industries?

Kevlar® Tape is a highly versatile product, known for its strong adhesive properties and flexibility. It is commonly used in sealing, repairs, and composite manufacturing, where it reinforces joints and seams. Buyers should appreciate the ease of application and the significant enhancement of joint strength that Kevlar® Tape offers. However, it is essential to note that its application is limited compared to woven fabrics, which may restrict its use in more demanding structural roles.

Key Industrial Applications of kevlar cloth fabric

| Industry/Sector | Specific Application of kevlar cloth fabric | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Aircraft fuselage and component reinforcement | Enhanced structural integrity and weight savings | Compliance with aerospace standards and certifications |

| Automotive | High-performance automotive parts | Improved safety and durability | Material compatibility with resins and adhesives |

| Personal Protective Equipment (PPE) | Bullet-resistant vests and protective clothing | Superior protection against cuts and impacts | Certifications for safety standards and performance |

| Marine | Boat hulls and components | Increased resistance to abrasion and impact | Water-resistant treatments and UV protection |

| Sports & Recreation | High-performance sporting goods (e.g., helmets) | Lightweight yet strong protection | Customization options for specific sports applications |

How is Kevlar Cloth Fabric Utilized in Aerospace Applications?

In the aerospace sector, Kevlar cloth fabric is integral for reinforcing aircraft fuselages and components. Its high strength-to-weight ratio allows for significant weight reductions while maintaining structural integrity. This is crucial for enhancing fuel efficiency and overall performance. International buyers, especially from regions like Europe and the Middle East, should prioritize suppliers who can demonstrate compliance with stringent aerospace standards, ensuring that the materials meet safety and regulatory requirements.

Illustrative image related to kevlar cloth fabric

What Role Does Kevlar Fabric Play in Automotive Manufacturing?

Kevlar cloth fabric finds extensive use in the automotive industry, particularly in high-performance parts such as brake pads, body panels, and safety equipment. Its exceptional durability and resistance to impacts enhance vehicle safety, making it a preferred choice for manufacturers aiming to meet rigorous safety standards. Buyers should consider sourcing Kevlar from suppliers who can provide detailed specifications, compatibility with various resins, and insights into the latest automotive regulations.

Why is Kevlar Important for Personal Protective Equipment?

In the PPE sector, Kevlar cloth fabric is renowned for its application in bullet-resistant vests and other protective gear. Its ability to absorb and disperse energy from impacts makes it a vital material for ensuring the safety of military personnel and law enforcement officers. When sourcing, international buyers must ensure that the products are certified according to relevant safety standards, such as NIJ ratings, to guarantee optimal protection.

How is Kevlar Used in Marine Applications?

In marine applications, Kevlar cloth fabric is utilized for constructing boat hulls and components, providing excellent resistance to abrasion and impacts from harsh marine environments. The lightweight nature of Kevlar helps in improving the speed and maneuverability of vessels. Buyers in the marine industry should focus on sourcing materials that offer enhanced UV protection and are treated for water resistance, ensuring longevity and performance in challenging conditions.

Illustrative image related to kevlar cloth fabric

What Benefits Does Kevlar Provide in Sports and Recreation?

Kevlar fabric is increasingly used in the sports and recreation industry, particularly in the production of high-performance sporting goods such as helmets and protective gear. Its lightweight yet robust characteristics ensure athletes receive the protection they need without sacrificing mobility. When sourcing for this sector, businesses should look for customization options that cater to specific sports requirements, as well as compliance with safety standards to ensure product reliability.

3 Common User Pain Points for ‘kevlar cloth fabric’ & Their Solutions

Scenario 1: Sourcing Quality Kevlar Fabric for High-Stress Applications

The Problem: B2B buyers, particularly those in industries like aerospace, automotive, and protective gear manufacturing, often struggle with sourcing high-quality Kevlar fabric that meets specific performance criteria. The challenge arises when suppliers provide inconsistent quality, leading to products that fail under stress, which can endanger lives or result in costly recalls. Buyers may also find it difficult to navigate the various grades of Kevlar, such as Kevlar 49, and understand which one best suits their application.

The Solution: To ensure sourcing the right Kevlar fabric, buyers should prioritize suppliers who specialize in industrial-grade Kevlar, like those offering Kevlar 49 specifically for composite reinforcement. Conducting a thorough supplier audit, including checking certifications and previous client testimonials, can help ensure quality. Additionally, buyers should request samples and conduct their own stress tests to verify performance under expected conditions. Engaging with suppliers to discuss specific application needs can also lead to tailored solutions, ensuring the fabric’s specifications align perfectly with project requirements.

Scenario 2: Overcoming Misconceptions about Kevlar Fabric Durability

The Problem: Many B2B buyers mistakenly believe that all Kevlar fabrics are created equal in terms of durability and heat resistance. This misconception can lead to improper material selection for applications that require specific attributes, such as fire resistance or cut resistance. When using the wrong type of Kevlar, businesses may face increased operational risks and diminished product performance, resulting in financial losses and reputational damage.

Illustrative image related to kevlar cloth fabric

The Solution: Buyers should invest time in educating themselves about the different properties of Kevlar fabrics. For instance, understanding the differences between Kevlar used in protective clothing versus that used in composites is critical. Collaborating with a knowledgeable supplier can aid in identifying the right type of Kevlar for each application. Buyers should also request detailed data sheets that outline temperature tolerances, cut resistance ratings, and other relevant specifications. Implementing a consultation phase with the supplier can ensure that the selected fabric meets the unique demands of each project.

Scenario 3: Navigating the Costs of Kevlar Fabric Procurement

The Problem: B2B buyers often encounter challenges related to the high costs associated with Kevlar fabric procurement, particularly when dealing with fluctuating market prices and minimum order quantities that can strain budgets. This situation is exacerbated in regions like Africa and South America, where import tariffs and shipping costs can further inflate expenses. Buyers may find it difficult to justify these costs to stakeholders while ensuring product quality.

The Solution: To effectively manage costs, buyers should explore strategic partnerships with suppliers who offer bulk purchasing discounts or flexible minimum order quantities. Conducting market research to identify regional suppliers can also mitigate shipping costs and tariffs. Additionally, implementing a Just-In-Time (JIT) inventory strategy can help manage cash flow by reducing the need for large upfront purchases. Buyers can also consider alternative materials that incorporate Kevlar blends, which may offer a balance between performance and cost-effectiveness, providing a more economical solution without significantly compromising on quality.

Strategic Material Selection Guide for kevlar cloth fabric

What Are the Key Properties of Different Kevlar Cloth Fabrics?

When selecting Kevlar cloth fabrics for various applications, understanding the properties of different materials is essential for ensuring optimal performance. Here, we analyze several common types of Kevlar fabrics, focusing on their key properties, advantages, disadvantages, and implications for international buyers.

Kevlar 49 Fabric

Key Properties: Kevlar 49 is known for its high tensile strength and excellent thermal stability, withstanding temperatures up to 400°C. It exhibits low moisture absorption, which enhances its performance in humid environments.

Pros & Cons: The primary advantage of Kevlar 49 is its exceptional strength-to-weight ratio, making it ideal for applications requiring lightweight yet durable materials, such as aerospace and automotive components. However, its cost is relatively high compared to other fabrics, which may deter budget-conscious buyers.

Impact on Application: Kevlar 49 is particularly suited for applications in high-performance environments, such as aircraft fuselage panels and marine vessels. Its resistance to abrasion and impact makes it a preferred choice for protective gear.

Considerations for International Buyers: Buyers from regions such as Europe and the Middle East should ensure compliance with relevant standards like ASTM and DIN, as these certifications can affect market acceptance and regulatory approval.

Illustrative image related to kevlar cloth fabric

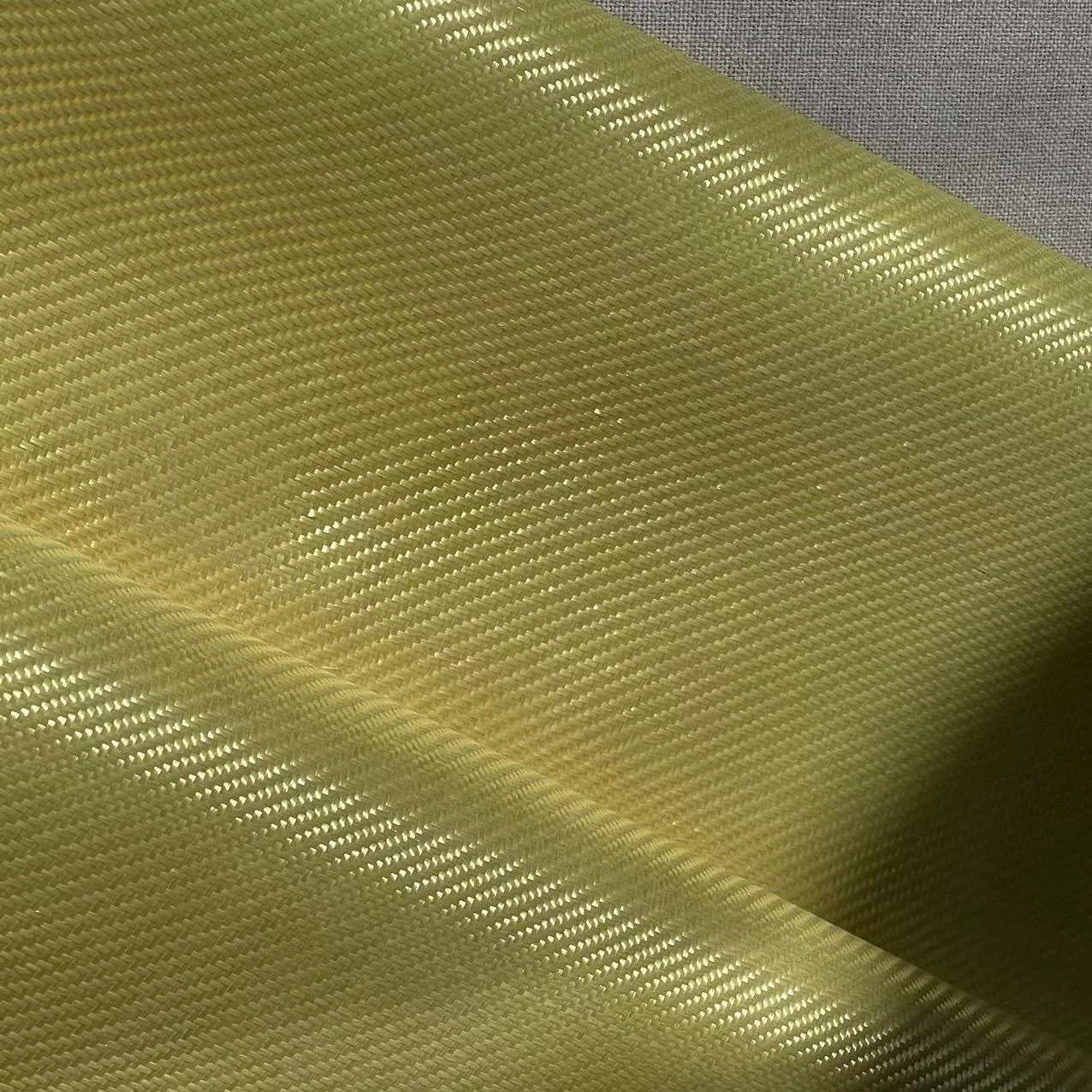

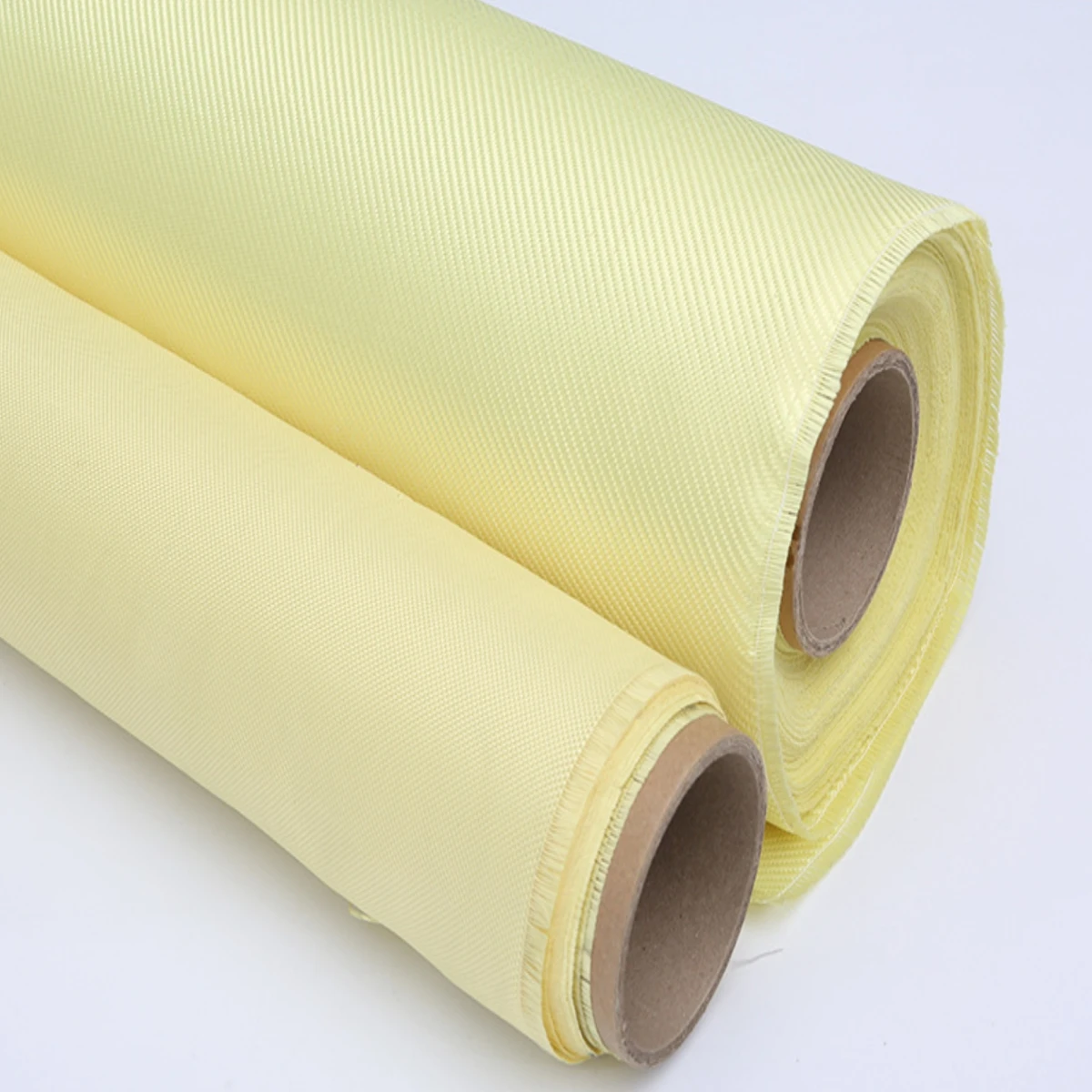

Kevlar Twill Weave Fabric

Key Properties: This fabric features a unique twill weave that enhances flexibility and drape while maintaining high strength. It also offers improved resistance to fraying and tearing compared to plain weaves.

Pros & Cons: The twill weave provides a softer feel, making it suitable for applications like protective clothing and gear. However, the manufacturing complexity can lead to higher production costs, which may be a concern for large-scale production.

Impact on Application: This type of fabric is ideal for applications requiring comfort and durability, such as tactical vests and outdoor gear. Its flexibility allows for a better fit, enhancing user comfort.

Considerations for International Buyers: Buyers should be aware of the specific requirements for protective clothing in their regions, as regulations may dictate the types of materials that can be used in personal protective equipment (PPE).

Illustrative image related to kevlar cloth fabric

Kevlar/Carbon Hybrid Fabric

Key Properties: Combining Kevlar with carbon fiber results in a fabric that offers both impact resistance and enhanced stiffness. This hybrid fabric can withstand high temperatures and has excellent chemical resistance.

Pros & Cons: The hybrid nature provides a significant advantage in applications where both strength and weight are critical, such as in automotive and aerospace industries. However, the complexity of manufacturing these hybrid fabrics can lead to higher costs.

Impact on Application: This fabric is particularly effective in applications requiring both lightweight and high-strength materials, such as in the production of racing cars and high-performance boats.

Considerations for International Buyers: Buyers should consider the specific performance characteristics required in their applications and ensure that the hybrid fabric meets local standards for safety and performance.

Kevlar Felt

Key Properties: Kevlar felt is known for its excellent thermal insulation and sound absorption properties. It is also highly resistant to cuts and punctures.

Pros & Cons: The primary advantage of Kevlar felt is its versatility in applications ranging from protective clothing to industrial insulation. However, it may not provide the same level of structural integrity as woven fabrics, limiting its use in load-bearing applications.

Impact on Application: This material is commonly used in protective gear and as a lining in various products, including bags and clothing. Its insulating properties make it suitable for applications requiring thermal protection.

Considerations for International Buyers: Buyers should ensure that the felt meets any specific regulatory requirements for insulation materials in their respective regions, particularly in the construction and automotive sectors.

Summary Table of Kevlar Cloth Fabrics

| Material | Typical Use Case for kevlar cloth fabric | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Kevlar 49 | Aerospace components | High strength-to-weight ratio | Relatively high cost | High |

| Kevlar Twill Weave | Protective clothing | Enhanced flexibility and comfort | Higher manufacturing complexity | Medium |

| Kevlar/Carbon Hybrid | Racing cars, high-performance boats | Combines impact resistance with lightweight design | Higher production costs | High |

| Kevlar Felt | Protective gear, industrial insulation | Excellent thermal insulation and sound absorption | Limited structural integrity | Medium |

This guide provides essential insights into the strategic selection of Kevlar cloth fabrics, enabling B2B buyers to make informed decisions tailored to their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for kevlar cloth fabric

What Are the Main Stages of the Manufacturing Process for Kevlar Cloth Fabric?

The manufacturing process of Kevlar cloth fabric involves several critical stages that ensure the final product meets the high-performance standards expected by B2B buyers.

-

Material Preparation: The process begins with the procurement of Kevlar fibers, specifically DuPont™ KEVLAR® fibers known for their strength and durability. These fibers are produced through polymerization, where the precursor chemicals undergo a series of reactions to create aromatic polyamides. Following this, the fibers are spun into strands, which can then be cut or left in continuous lengths depending on the application.

-

Forming: Once the fibers are ready, they are woven into cloth using a loom. The weaving process can vary, with options including plain weave, twill weave, or even advanced hybrid weaves that combine Kevlar with carbon or fiberglass for enhanced performance. The choice of weave impacts the fabric’s final properties, such as flexibility, strength, and resistance to abrasion.

-

Assembly: In some cases, especially for composite applications, the Kevlar fabric may be layered or combined with resins (epoxy, vinyl ester, or polyester) to create laminates. This assembly stage is crucial as it determines the final strength and utility of the product. Techniques such as vacuum bagging or autoclaving are often used to ensure optimal bonding and curing of the materials.

-

Finishing: The final stage involves treatments that enhance the fabric’s characteristics, such as flame retardant coatings, UV protection, or water repellency. Finishing processes may also include cutting, dyeing, or printing to meet specific aesthetic or functional requirements. Quality checks are integral at this stage to ensure that the fabric meets the desired specifications.

How Is Quality Assurance Implemented in Kevlar Fabric Manufacturing?

Quality assurance (QA) is paramount in the manufacturing of Kevlar fabrics to ensure that they meet stringent international standards and customer expectations.

-

What International Standards Apply to Kevlar Fabric Production?

Manufacturers often adhere to recognized international standards such as ISO 9001 for quality management systems. This standard ensures that companies consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific certifications such as CE marking (for products sold in the European Economic Area) and API specifications (for oil and gas applications) may be relevant depending on the intended use of the Kevlar fabric. -

What Are the Key Quality Control Checkpoints in Kevlar Fabric Production?

Quality control is typically divided into several checkpoints:

– Incoming Quality Control (IQC): At this stage, raw materials, including Kevlar fibers and any additives, are inspected for compliance with specifications.

– In-Process Quality Control (IPQC): This involves monitoring the manufacturing process itself, ensuring that each stage (weaving, bonding, finishing) meets quality standards. Regular checks during weaving can prevent defects such as misalignment or inadequate tension.

– Final Quality Control (FQC): Once the fabric is completed, it undergoes rigorous testing to verify its performance characteristics. This includes tensile strength tests, abrasion resistance tests, and thermal stability assessments. -

Which Testing Methods Are Commonly Used for Kevlar Fabrics?

Several testing methods are employed to evaluate the performance of Kevlar fabrics:

– Tensile Testing: Measures the fabric’s strength by applying force until failure.

– Abrasion Resistance Testing: Assesses how well the fabric withstands wear and tear.

– Thermal Testing: Determines the fabric’s ability to maintain integrity at elevated temperatures.

– Impact Resistance Testing: Evaluates how well the fabric can absorb shock, crucial for applications in protective clothing.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential to ensure they receive high-quality products.

-

What Steps Can Buyers Take to Conduct Supplier Audits?

Buyers should consider conducting on-site audits of potential suppliers. This allows them to observe the manufacturing processes, review quality control documentation, and evaluate the facilities. Audits can provide insights into a supplier’s commitment to quality and compliance with international standards. -

How Can Buyers Access Quality Control Reports?

Requesting quality control reports from suppliers is another effective way to verify their quality assurance practices. These reports should detail the results of various tests conducted on the fabrics, including compliance with relevant standards. Buyers should ensure that these reports are recent and relevant to the specific products they intend to purchase. -

What Role Do Third-Party Inspections Play in Ensuring Quality?

Engaging third-party inspection services can add an additional layer of assurance. These independent organizations can conduct random inspections and testing of the products before they are shipped, providing an unbiased assessment of the fabric’s quality.

What Are the QC and Certification Nuances for International Buyers?

Understanding the nuances of quality control and certification is crucial for B2B buyers operating in diverse markets.

Illustrative image related to kevlar cloth fabric

-

How Do Regional Standards Affect Quality Assurance?

Different regions may have varying standards and regulations regarding Kevlar fabrics. For instance, the European Union has strict CE marking requirements, while other regions may not have such stringent regulations. Buyers must be aware of these differences and ensure that their suppliers comply with the relevant standards for their target market. -

What Are the Implications of Non-Compliance?

Non-compliance with international standards can lead to significant repercussions, including product recalls, legal liabilities, and damage to reputation. Buyers should prioritize suppliers who demonstrate a robust commitment to quality assurance and compliance with applicable regulations. -

How Can Buyers Build Long-Term Relationships with Quality Suppliers?

Establishing long-term relationships with reliable suppliers involves regular communication and collaboration on quality issues. Buyers should engage in discussions about quality expectations, share feedback on product performance, and work together to resolve any issues that arise. This partnership approach can lead to improved quality and innovation in product offerings.

By understanding the manufacturing processes and quality assurance practices associated with Kevlar cloth fabric, B2B buyers can make informed decisions that ensure they acquire high-quality materials suited for their specific applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘kevlar cloth fabric’

Introduction

Navigating the procurement process for Kevlar cloth fabric can be complex, especially for international B2B buyers across diverse regions such as Africa, South America, the Middle East, and Europe. This guide provides a structured checklist to help you effectively source Kevlar fabric, ensuring you make informed decisions that meet your specific requirements.

Step 1: Define Your Technical Specifications

Start by clearly outlining the technical requirements for the Kevlar fabric you need. Consider factors such as weight, weave type (plain, twill, or hybrid), and specific applications (e.g., protective clothing, automotive parts, or aerospace components).

– Why it Matters: Precise specifications will guide your supplier search and ensure you receive materials that meet your performance standards.

Step 2: Research Supplier Capabilities

Investigate potential suppliers to understand their capabilities and product offerings. Look for suppliers with a proven track record in manufacturing Kevlar fabrics, particularly those that specialize in aramid fibers.

– What to Look For: Focus on their production methods, quality control processes, and the range of Kevlar products they offer, such as woven cloths, chopped strand mats, or specialty fabrics.

Step 3: Evaluate Supplier Certifications

Verify that your shortlisted suppliers have relevant certifications that demonstrate compliance with international quality standards, such as ISO 9001 or specific industry certifications for safety and performance.

– Importance: Certifications provide assurance of quality and reliability, which is critical when sourcing materials for high-stakes applications like personal protective equipment or aerospace components.

Step 4: Request Samples for Testing

Before finalizing your supplier, request samples of the Kevlar fabric to evaluate its properties firsthand. This allows you to assess factors like texture, flexibility, and durability.

– Testing Focus: Conduct tests for abrasion resistance, heat resistance, and tensile strength to ensure the material meets your project’s requirements.

Step 5: Inquire About Customization Options

Discuss with suppliers the possibility of customizing the Kevlar fabric to suit your specific needs. This may include variations in color, weight, or additional treatments like flame retardancy or water resistance.

– Benefits of Customization: Tailored solutions can enhance the performance of the final product, making it more suitable for its intended application.

Step 6: Understand Pricing and Payment Terms

Get a clear breakdown of pricing structures, including bulk discounts, minimum order quantities, and payment terms. This transparency will help you budget effectively and avoid unexpected costs.

– Key Considerations: Be aware of any additional costs such as shipping, taxes, or tariffs, especially when sourcing from international suppliers.

Step 7: Establish Clear Communication Channels

Effective communication is crucial for successful procurement. Ensure that you have established clear lines of communication with your chosen supplier, including points of contact for order tracking and issue resolution.

– Why It’s Important: Strong communication can facilitate smoother transactions and quicker responses to any issues that may arise during the sourcing process.

Illustrative image related to kevlar cloth fabric

By following this checklist, B2B buyers can streamline their procurement process for Kevlar cloth fabric, ensuring they select the right supplier and material for their specific needs.

Comprehensive Cost and Pricing Analysis for kevlar cloth fabric Sourcing

What Are the Key Cost Components in Kevlar Cloth Fabric Sourcing?

When sourcing Kevlar cloth fabric, understanding the cost structure is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The cost of raw Kevlar fiber, typically sourced from manufacturers like DuPont, significantly impacts overall pricing. Kevlar is a high-performance synthetic fiber, and fluctuations in its market price can affect the final cost.

-

Labor: The skilled labor required for weaving and processing Kevlar fabric can vary by region. Labor costs in countries with lower wage standards may result in more competitive pricing, but it’s crucial to assess the quality of workmanship.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and facility operations. Efficient manufacturing processes can help reduce overhead costs, which can be passed on to buyers.

-

Tooling: Specialized machinery and tools for fabric production can be a significant investment. Suppliers may amortize these costs over larger production runs, influencing pricing based on order size.

-

Quality Control: Stringent QC processes ensure compliance with international safety and performance standards, particularly for applications in protective gear. These processes add to the cost but are vital for maintaining product integrity.

-

Logistics: Shipping costs, especially for international transactions, can vary widely based on distance, Incoterms, and shipping methods. Buyers should consider logistics as a critical component of total costs.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. Understanding the competitive landscape can help buyers gauge reasonable margins for negotiation.

How Do Price Influencers Affect Kevlar Fabric Costs?

Several factors influence the pricing of Kevlar cloth, which can vary significantly across different regions, including Africa, South America, the Middle East, and Europe.

Illustrative image related to kevlar cloth fabric

-

Volume/MOQ: Minimum order quantities (MOQ) can affect pricing. Larger orders often lead to economies of scale, resulting in lower per-unit costs. Negotiating favorable terms can yield better pricing.

-

Specifications and Customization: Customized products may incur additional costs. Buyers should clearly define their requirements to avoid unexpected charges.

-

Materials and Quality Certifications: The grade of Kevlar used (e.g., Kevlar 49) and any certifications (e.g., ISO standards) can influence the price. Higher quality fabrics command premium pricing but offer better performance.

-

Supplier Factors: The supplier’s reputation, reliability, and production capacity can impact pricing. Established suppliers may charge more but offer superior quality and service.

-

Incoterms: Understanding Incoterms is crucial for international buyers. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) affect how costs are calculated and who bears the risk during shipping.

What Buyer Tips Can Help Optimize Costs in Kevlar Fabric Procurement?

To enhance cost-efficiency in sourcing Kevlar cloth fabric, international buyers should consider the following strategies:

-

Negotiate Wisely: Leverage volume commitments and long-term relationships to negotiate better pricing. Transparent discussions about expectations can lead to mutually beneficial agreements.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider factors such as durability, maintenance, and lifecycle costs. A more expensive fabric may offer better longevity and performance, ultimately reducing overall costs.

-

Understand Pricing Nuances: Be aware of regional pricing variations. Markets in Europe may have different pricing dynamics compared to those in Africa or South America. Conduct thorough market research to make informed decisions.

-

Seek Multiple Quotes: Obtaining quotes from various suppliers can provide insights into market rates and help identify the best value proposition.

-

Stay Informed on Market Trends: Keep abreast of changes in raw material costs, labor markets, and global supply chain issues that may affect pricing.

Disclaimer on Indicative Prices

Prices for Kevlar cloth fabric can fluctuate based on market conditions and supplier policies. It is advisable for buyers to obtain updated quotes and confirm pricing details directly with suppliers before making purchasing decisions.

Alternatives Analysis: Comparing kevlar cloth fabric With Other Solutions

Introduction: Understanding Alternatives to Kevlar Cloth Fabric

In the competitive landscape of materials used for protective clothing and composite applications, selecting the right fabric is crucial for meeting specific requirements. Kevlar cloth fabric, renowned for its strength and durability, is often a go-to choice. However, various alternatives exist, each with unique properties that may better suit particular applications or budget constraints. Understanding these options enables buyers to make informed decisions that align with their operational needs.

Comparison Table

| Comparison Aspect | Kevlar Cloth Fabric | Carbon Fiber | Fiberglass |

|---|---|---|---|

| Performance | High strength, abrasion-resistant, temperature stable | Extremely high tensile strength, lightweight | Moderate strength, good insulation |

| Cost | Higher cost per square meter | Very high cost per square meter | Lower cost per square meter |

| Ease of Implementation | Requires specialized techniques for lamination | Complex manufacturing process, requires skilled labor | Easier to work with, widely available |

| Maintenance | Low maintenance, resistant to wear | Requires protective coatings for longevity | Moderate maintenance, susceptible to UV degradation |

| Best Use Case | Protective clothing, aerospace, automotive | High-performance sports equipment, automotive components | Insulation, construction materials |

Detailed Breakdown of Alternatives

Carbon Fiber

Carbon fiber is a high-performance material known for its exceptional strength-to-weight ratio. It is lighter than Kevlar and offers superior rigidity, making it ideal for applications in aerospace and high-performance automotive industries. However, the primary drawback is its cost, which is significantly higher than Kevlar. Additionally, the manufacturing process is complex and requires specialized skills, which can increase production time and costs. Carbon fiber is best suited for applications where weight reduction and performance are paramount.

Fiberglass

Fiberglass is a composite material made from fine glass fibers, offering moderate strength and excellent insulation properties. It is considerably less expensive than both Kevlar and carbon fiber, making it a cost-effective alternative for many applications. Fiberglass is easier to work with and is widely available, which can reduce lead times for projects. However, it does not match the strength and durability of Kevlar, especially in high-stress environments. Fiberglass is best used in applications where insulation and cost are more critical than the ultimate strength of the material.

Illustrative image related to kevlar cloth fabric

Conclusion: Choosing the Right Solution for Your Needs

When selecting between Kevlar cloth fabric and its alternatives, it is essential for B2B buyers to consider their specific application requirements, budget constraints, and performance expectations. Kevlar excels in high-stress environments requiring durability and heat resistance, making it ideal for protective gear and aerospace applications. In contrast, carbon fiber is suited for high-performance applications where weight is critical, while fiberglass serves well in cost-sensitive projects where moderate strength is sufficient. By evaluating these factors, buyers can choose the most appropriate material to meet their operational goals efficiently.

Essential Technical Properties and Trade Terminology for kevlar cloth fabric

What Are the Key Technical Properties of Kevlar Cloth Fabric for B2B Buyers?

When sourcing Kevlar cloth fabric, understanding its technical properties is crucial for making informed purchasing decisions. Here are some essential specifications:

1. Material Grade

The most common grade of Kevlar used in industrial applications is Kevlar 49. This grade is specifically designed for composite reinforcement, offering high tensile strength and durability. For B2B buyers, selecting the appropriate material grade ensures that the fabric meets the performance requirements of their end products, whether for aerospace, automotive, or protective clothing applications.

Illustrative image related to kevlar cloth fabric

2. Tensile Strength

Tensile strength is a measure of how much force a material can withstand while being stretched. Kevlar boasts an impressive tensile strength of approximately 5 times that of steel at the same weight. This property is vital for applications requiring high durability and resistance to wear and tear, making it a preferred choice for protective gear and aerospace components.

3. Temperature Resistance

Kevlar fabrics can withstand high temperatures, with a melting point around 400°C (752°F). This property is essential for applications in environments that experience extreme heat, such as aerospace and automotive industries. For B2B buyers, this means reduced risk of material failure and improved safety in high-temperature scenarios.

4. Abrasion Resistance

The fabric exhibits excellent abrasion resistance, making it suitable for applications exposed to rough conditions, such as outdoor gear or industrial wear. B2B buyers should consider this property to ensure longevity and performance in demanding environments, thus providing better value over time.

5. Weight and Flexibility

Kevlar fabrics are lightweight yet strong, allowing for comfortable wear without compromising protection. This aspect is particularly important for manufacturers of protective clothing and gear, as it enhances user comfort and mobility, leading to higher user satisfaction.

Illustrative image related to kevlar cloth fabric

6. UV Resistance

While raw Kevlar is susceptible to UV degradation, treated versions can resist UV radiation better. Understanding this property is crucial for buyers in regions with high sun exposure, ensuring that the products maintain their integrity over time.

What Are Common Trade Terms Relevant to Kevlar Cloth Fabric?

Familiarizing yourself with industry jargon can facilitate smoother transactions and negotiations. Here are some key terms to understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of Kevlar, OEMs might require specific fabric specifications to integrate into their products. Understanding OEM requirements helps B2B buyers align their sourcing strategies with market needs.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest number of units a supplier is willing to sell. For Kevlar fabrics, MOQs can vary significantly based on grade and supplier. Knowing the MOQ helps buyers plan their inventory and budget effectively, ensuring they meet production demands without incurring excess costs.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific materials or products. For buyers of Kevlar fabric, issuing an RFQ can lead to competitive pricing and better terms, making it an essential step in the procurement process.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping and delivery terms. Familiarity with these terms helps buyers understand their obligations and rights, reducing risks in cross-border procurement of Kevlar fabrics.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is crucial for B2B buyers to ensure they meet project timelines and avoid delays in production.

Illustrative image related to kevlar cloth fabric

6. Certification Standards

These are industry-recognized standards that materials must meet to ensure safety and performance. For Kevlar fabrics, certifications might include fire resistance or ballistic protection ratings. Buyers should seek suppliers that provide certified products to guarantee compliance with relevant regulations and industry standards.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing Kevlar cloth fabric, ensuring they select the right materials for their specific applications while navigating the complexities of international trade.

Navigating Market Dynamics and Sourcing Trends in the kevlar cloth fabric Sector

What Are the Key Market Dynamics and Trends Influencing the Kevlar Cloth Fabric Sector?

The Kevlar cloth fabric market is experiencing dynamic growth, driven by increasing demand across various sectors such as automotive, aerospace, and protective clothing. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, consider sourcing strategies, it is crucial to recognize that Kevlar’s unique properties—such as high tensile strength, durability, and thermal resistance—make it a preferred choice for applications ranging from bulletproof vests to high-performance sports equipment.

Emerging trends indicate a shift towards composite materials that integrate Kevlar with other fibers, like carbon and fiberglass, enhancing performance while reducing weight. This trend is particularly significant in the aerospace and automotive industries, where fuel efficiency and safety are paramount. Additionally, the digital transformation of the supply chain is leading to increased use of advanced technologies, such as blockchain for transparency and AI for predictive analytics, which can help buyers make informed decisions about their sourcing strategies.

Illustrative image related to kevlar cloth fabric

As the global economy evolves, international buyers must also consider regional market dynamics, such as fluctuating raw material prices and geopolitical factors that may impact supply chains. For instance, the ongoing developments in the Middle East and Africa present both opportunities and challenges, requiring buyers to remain agile and well-informed about local market conditions.

How Is Sustainability Shaping Sourcing Decisions in the Kevlar Fabric Market?

Sustainability has become a pivotal factor in sourcing decisions within the Kevlar cloth fabric sector. The environmental impact of production processes, particularly regarding resource consumption and waste generation, is under scrutiny. International buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes the use of eco-friendly materials and manufacturing processes that minimize carbon footprints.

Ethical sourcing is equally vital, as buyers seek to ensure that their supply chains are free from labor exploitation and adhere to fair trade practices. Certifications such as Global Organic Textile Standard (GOTS) and OEKO-TEX® can provide assurance regarding the environmental and social responsibility of suppliers.

Moreover, innovations in recycling processes for aramid fibers are gaining traction. By integrating recycled materials into the production of Kevlar fabrics, manufacturers can contribute to a circular economy while meeting the growing demand for sustainable products. Buyers who emphasize these aspects in their sourcing strategies can not only align with global sustainability goals but also enhance their brand reputation and customer loyalty.

What Is the Historical Context of Kevlar Fabric Development and Its Implications for B2B Buyers?

Kevlar, a registered trademark of DuPont, was developed in the 1960s and has evolved significantly since its introduction. Initially recognized for its exceptional strength-to-weight ratio, Kevlar has become synonymous with high-performance protective materials. Its initial applications in bulletproof vests and military gear have expanded to include a wide range of industries, including automotive, aerospace, and sports.

The historical evolution of Kevlar underscores the importance of innovation in meeting market demands. For B2B buyers, understanding the development trajectory of Kevlar can provide insights into its applications and performance characteristics, which are critical for making informed sourcing decisions. As manufacturers continue to explore new composites and hybrid materials, buyers are encouraged to stay abreast of advancements that may enhance the functionality and cost-effectiveness of Kevlar products in their specific applications.

By recognizing these historical and current trends, international buyers can navigate the complexities of the Kevlar cloth fabric market more effectively, ensuring they make strategic sourcing decisions that align with their operational goals and market needs.

Illustrative image related to kevlar cloth fabric

Frequently Asked Questions (FAQs) for B2B Buyers of kevlar cloth fabric

-

How do I choose the right Kevlar cloth fabric for my application?

Choosing the right Kevlar cloth fabric depends on the specific requirements of your project. Consider factors such as the intended use (e.g., protective clothing, automotive parts, or aerospace applications), required strength, abrasion resistance, and temperature tolerance. Different weave patterns (plain, twill, or hybrid) offer varying levels of flexibility and strength. It’s also crucial to assess compatibility with resins if you are creating composites. Consulting with suppliers about your needs can help you identify the optimal fabric type. -

What are the key benefits of using Kevlar cloth fabric in industrial applications?

Kevlar cloth fabric offers numerous advantages, including high tensile strength, lightweight properties, and excellent resistance to abrasion and heat. Its durability makes it ideal for use in protective gear, automotive components, and aerospace applications. Additionally, Kevlar is known for its ability to maintain structural integrity at elevated temperatures, which is crucial for industries exposed to extreme conditions. These properties not only enhance product performance but also improve safety for end-users. -

What is the typical minimum order quantity (MOQ) for Kevlar cloth fabric?

Minimum order quantities (MOQ) for Kevlar cloth fabric can vary significantly among suppliers. Generally, MOQs can range from a few meters to several hundred meters, depending on the manufacturer and the specific fabric type. For bulk orders, suppliers may offer discounts or flexible terms. It’s advisable to discuss your specific needs with potential suppliers to negotiate MOQs that align with your business requirements. -

How do I verify the quality of Kevlar fabric before making a purchase?

To ensure the quality of Kevlar fabric, request samples from suppliers before placing a bulk order. Evaluate the fabric’s tensile strength, weave integrity, and resistance to wear and tear through physical tests. Additionally, inquire about certifications and compliance with industry standards. A reputable supplier should provide documentation regarding the fabric’s specifications and performance characteristics. Customer reviews and case studies can also offer insights into the reliability of the product. -

What payment terms can I expect when sourcing Kevlar cloth fabric internationally?

Payment terms for international purchases of Kevlar cloth fabric can vary widely by supplier. Common options include upfront payment, letter of credit, or payment upon delivery. It’s essential to clarify terms during negotiations to avoid misunderstandings. Suppliers may also offer flexible payment plans for larger orders. Ensure to discuss currency considerations and any potential additional costs, such as tariffs or shipping fees, to accurately assess the total investment. -

What are the logistics considerations when importing Kevlar cloth fabric?

When importing Kevlar cloth fabric, consider factors such as shipping methods, customs clearance, and lead times. Choose a reliable shipping partner experienced in handling textile imports to ensure smooth logistics. Understand the import regulations and duties applicable in your country to avoid unexpected delays or costs. Additionally, communicate with your supplier about packaging and labeling requirements to facilitate efficient handling upon arrival. -

Can Kevlar cloth fabric be customized for specific applications?

Yes, Kevlar cloth fabric can often be customized to meet specific application requirements. Many suppliers offer options for different weave patterns, weights, and coatings to enhance properties such as water resistance or fire retardancy. Discuss your unique needs with suppliers, including any specific dimensions, colors, or treatments required. Customization may affect lead times and pricing, so it’s advisable to plan accordingly. -

How do I ensure supplier reliability when sourcing Kevlar cloth fabric?

To ensure supplier reliability, conduct thorough research before making a commitment. Evaluate potential suppliers based on their industry reputation, years of experience, and customer reviews. Request references from previous clients and inquire about their production capabilities and quality control processes. Consider visiting the supplier’s facility if possible, or utilize third-party auditing services to assess their operational standards. Establishing clear communication and trust is vital for a successful long-term partnership.

Top 3 Kevlar Cloth Fabric Manufacturers & Suppliers List

1. US Composites – KEVLAR® 49 Aramid Fabrics

Domain: uscomposites.com

Registered: 2000 (25 years)

Introduction: KEVLAR® 49 Aramid Fabrics: Structural grade aramid cloth for composite reinforcement. Requires saturation with epoxy, polyester, or vinyl ester resins. Not ballistic grade (KEVLAR® 29) or for clothing/body armor. Lightweight fabric for light reinforcement (model building). 1.7oz Style 5120: Weight: 1.7osy, Weave: Plain, Thickness: .004″, Width: 38″, Price: $35.00/yard (discounts for bulk). Moderat…

2. PC Composites – KEVLAR 120

Domain: pccomposites.com

Registered: 2002 (23 years)

Introduction: Kevlar dry fabrics include Kevlar 49 and Kevlar 29, designed for composite reinforcement. They can be used with epoxy, polyester, or vinyl ester resins to create rigid laminates. Key products include:

– KEVLAR 120: Plain weave aramid fabric, certified to AMS 3902 STYLE 120, temperature range -320°F to 800°F, 43% lighter than fiberglass with double the strength.

– KEVLAR 285: 4-harness satin weave…

3. Sweet Composites – Kevlar and Graphite Fabrics

Domain: sweetcomposites.com

Registered: 2005 (20 years)

Introduction: Sweet Composites LLC offers a range of Kevlar and Graphite fabrics. Key details include:

**Kevlar Fabrics:**

– **Style 4580:** 3.5 oz non-woven felt, used for canoe skid plates, thickness ~100 mils visually, ~20±5 mils with micrometer.

– **Style 500:** 13×13, 1420 denier, 5 oz plain weave, thickness ~11 mils.

– **Style 120:** 34×34, 195 denier, 1.7 oz plain weave, thickness ~4 mils.

– **Styl…

Strategic Sourcing Conclusion and Outlook for kevlar cloth fabric

In the rapidly evolving market for Kevlar cloth fabric, strategic sourcing emerges as a crucial element for businesses aiming to secure high-quality materials that meet specific application needs. The unique properties of Kevlar—such as its high tensile strength, heat resistance, and durability—make it an invaluable resource across diverse industries, from aerospace and automotive to protective clothing and sporting goods. By partnering with reputable suppliers and manufacturers, international B2B buyers can ensure they are obtaining the best materials while optimizing costs and supply chain efficiency.

As global demand for advanced materials continues to rise, particularly in regions like Africa, South America, the Middle East, and Europe, businesses must remain proactive in their sourcing strategies. This means not only evaluating suppliers based on product quality but also considering their ability to provide consistent delivery and support.

Looking ahead, the market for Kevlar fabric is poised for growth, driven by innovations in composite materials and increasing applications in safety and protection. Now is the time for B2B buyers to leverage strategic sourcing initiatives to enhance their competitive edge and ensure they are well-positioned to capitalize on future opportunities.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to kevlar cloth fabric

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.