How to Source K20 Engine For Sale Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for k20 engine for sale

In the ever-evolving landscape of automotive performance, sourcing a reliable K20 engine for sale can pose significant challenges for international B2B buyers. With a myriad of options available, ranging from complete racing engines to remanufactured models, navigating this market requires a strategic approach to ensure quality, compatibility, and value. This guide is designed to empower buyers by providing comprehensive insights into the types of K20 engines available, their applications across various automotive platforms, and the critical factors to consider when vetting suppliers.

Understanding the nuances of engine specifications, such as horsepower ratings and intended uses, is vital for making informed purchasing decisions. Buyers from regions such as Africa, South America, the Middle East, and Europe, including prominent markets like Saudi Arabia and Germany, will benefit from our detailed analysis of pricing structures, shipping considerations, and warranty options. Furthermore, we delve into essential supplier evaluation criteria, ensuring that you partner with reputable manufacturers and distributors who can meet your specific needs. By the end of this guide, you will be equipped with the knowledge to navigate the global K20 engine market confidently, ensuring that your procurement aligns with your performance objectives and operational requirements.

Understanding k20 engine for sale Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| K20A Type R Engine | High-performance, VTEC technology, 2.0L capacity | Performance racing, aftermarket upgrades | Pros: Excellent power-to-weight ratio; Cons: Higher price point. |

| K20Z Engine | Updated version with improved fuel efficiency and emissions | Eco-friendly vehicle manufacturing | Pros: Better fuel economy; Cons: May lack raw power compared to K20A. |

| K20-KT1200 Crate Engine | Designed for turbocharged applications, exceeding 1200hp | Competitive racing, custom builds | Pros: Exceptional performance; Cons: Requires specialized maintenance. |

| K24A Engine | 2.4L variant with greater torque, compatible with K20 swaps | Versatile applications, performance tuning | Pros: Increased torque; Cons: Heavier than K20A, affecting handling. |

| Remanufactured K20 Engines | Refurbished engines with 35K-65K miles, often cost-effective | Replacement in older models, budget builds | Pros: Cost-effective; Cons: Limited warranty compared to new engines. |

What are the Key Characteristics of the K20A Type R Engine?

The K20A Type R engine is renowned for its high-performance capabilities, boasting VTEC technology and a 2.0L displacement. This engine is particularly suited for performance racing and aftermarket modifications, making it a favorite among racing teams and enthusiasts. When considering this engine, B2B buyers should evaluate its compatibility with various Honda models and its potential for high resale value due to its desirability in the racing community.

How Does the K20Z Engine Differ from Other Variants?

The K20Z engine is an updated iteration of the K20 series, emphasizing improved fuel efficiency and reduced emissions without sacrificing performance. This engine is ideal for eco-friendly vehicle manufacturers and businesses looking to comply with stringent environmental regulations. B2B buyers should assess the long-term cost savings associated with fuel efficiency versus the initial investment, especially in fleet operations.

What Makes the K20-KT1200 Crate Engine Suitable for Competitive Racing?

The K20-KT1200 is a specialized crate engine designed for turbocharged racing applications, capable of exceeding 1200hp. Its construction includes high-quality components tailored for durability under extreme conditions, making it perfect for competitive racing teams. Buyers should consider the engine’s maintenance needs, as it requires meticulous care and specialized knowledge to ensure optimal performance throughout racing seasons.

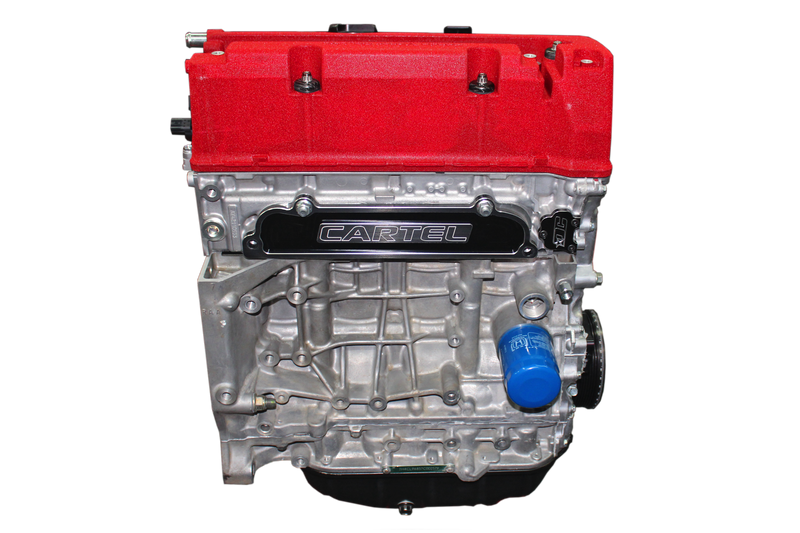

Illustrative image related to k20 engine for sale

In What Scenarios Would the K24A Engine Be Preferred?

The K24A engine, with its 2.4L capacity, provides greater torque than its K20 counterparts, making it suitable for applications that require strong low-end power. This engine is versatile and can be used in various performance tuning scenarios and vehicle swaps. B2B buyers should evaluate the trade-offs between torque and weight, as the K24A’s additional mass may impact handling characteristics in performance applications.

What Are the Benefits of Choosing Remanufactured K20 Engines?

Remanufactured K20 engines typically come with a mileage range of 35K to 65K, offering a cost-effective solution for businesses needing reliable replacements for older models. These engines can be an attractive option for budget-conscious buyers looking to maintain performance without the expense of new engines. However, potential buyers should consider the limited warranty and ensure they understand the remanufacturing process to avoid future issues.

Key Industrial Applications of k20 engine for sale

| Industry/Sector | Specific Application of k20 engine for sale | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Racing | High-performance racing vehicles | Enhanced speed and reliability for competitive edge | Proven performance history, adaptability to tuning, availability of parts for maintenance |

| Automotive Manufacturing | Engine swaps and custom builds for vehicles | Increased marketability and performance differentiation | Compatibility with existing vehicle models, regulatory compliance, and aftermarket support |

| Motorsports and Events | Specialty vehicles for motorsport events | Ability to meet stringent performance specifications | Supplier reputation, warranty options, and shipping logistics |

| Export and Resale | Reconditioning and resale in international markets | Potential for higher profit margins in emerging markets | Shipping regulations, customs clearance, and local demand trends |

| Performance Tuning | Custom tuning for modified street vehicles | Tailored performance enhancements for consumer satisfaction | Technical support for tuning, availability of compatible components, and tuning expertise |

How is the K20 Engine Used in Automotive Racing?

The K20 engine is a staple in the automotive racing sector, specifically designed for high-performance applications. It is commonly used in turbocharged race cars, where its ability to produce over 1200hp makes it a favorite among competitors. The engine’s construction ensures durability even under extreme conditions, allowing teams to maximize their performance throughout multiple racing rounds. B2B buyers in this sector must consider sourcing engines with proven performance records and robust support for maintenance to ensure longevity during races.

What are the Applications in Automotive Manufacturing?

In automotive manufacturing, the K20 engine is often utilized for engine swaps and custom builds, enhancing the performance of various vehicle models. This application allows manufacturers to differentiate their offerings in a competitive market by providing enhanced speed and efficiency. B2B buyers need to ensure that the K20 engine is compatible with their existing vehicle designs and meets local regulatory standards, which can vary significantly across regions, including Europe, Africa, and the Middle East.

Illustrative image related to k20 engine for sale

How Does the K20 Engine Benefit Motorsports and Events?

In the context of motorsports and events, the K20 engine is used in specialty vehicles that participate in competitive racing. These vehicles require engines that can meet specific performance metrics, ensuring they remain competitive in high-stakes environments. Buyers in this sector should focus on the supplier’s reputation for reliability and the availability of warranty options to mitigate risks associated with high-performance engines.

What is the Role of the K20 Engine in Export and Resale Markets?

The K20 engine also finds significant applications in export and resale markets, particularly in regions like Africa and South America, where demand for high-performance engines is growing. Businesses engaged in reconditioning these engines can achieve higher profit margins by capitalizing on the demand for quality performance parts. Buyers must navigate shipping regulations and customs clearance processes, ensuring compliance with local laws to facilitate smooth transactions.

How is the K20 Engine Used in Performance Tuning?

Performance tuning shops frequently use the K20 engine to enhance modified street vehicles, providing tailored performance upgrades to meet consumer expectations. This customization not only boosts vehicle performance but also enhances customer satisfaction and loyalty. B2B buyers in this space should prioritize sourcing engines that come with comprehensive technical support and readily available aftermarket components to facilitate effective tuning and modifications.

Illustrative image related to k20 engine for sale

3 Common User Pain Points for ‘k20 engine for sale’ & Their Solutions

Scenario 1: Difficulty in Ensuring Engine Quality and Authenticity

The Problem: B2B buyers often struggle to ascertain the quality and authenticity of K20 engines available for sale. With numerous suppliers offering various options, it can be challenging to differentiate between legitimate products and subpar imitations. Buyers may face risks such as purchasing engines with undisclosed wear or damage, leading to costly repairs and downtime for their operations.

The Solution: To mitigate this risk, buyers should prioritize sourcing engines from reputable suppliers who provide comprehensive documentation of their products. This includes detailed service histories, performance tests, and warranties. Engaging with suppliers who offer a traceable lineage of their engines—like verified mileage and previous usage—can significantly enhance confidence in the purchase. Additionally, conducting thorough market research and reading customer reviews can help identify trusted vendors. Establishing clear communication channels with suppliers to discuss engine specifications and performance expectations will further ensure that the purchased K20 engine meets the required standards for quality and reliability.

Scenario 2: Navigating Shipping and Logistics Challenges

The Problem: International B2B buyers often encounter logistical hurdles when purchasing K20 engines, particularly regarding shipping costs, customs clearance, and delivery times. These challenges can lead to unexpected delays, additional expenses, and complications in the supply chain, impacting project timelines and operational efficiency.

The Solution: To streamline the shipping process, buyers should collaborate closely with suppliers who have established international shipping capabilities. It is advisable to request detailed shipping quotes that include all potential fees, such as customs duties and taxes, upfront. Buyers can also benefit from using freight forwarders with experience in automotive parts shipping to facilitate a smoother customs process. Understanding the specific import regulations for their country can further prevent delays. Additionally, building a strong relationship with suppliers can lead to better shipping options and more efficient communication about delivery timelines, helping to ensure that engines arrive on schedule.

Scenario 3: Compatibility Issues with Specific Applications

The Problem: A common pain point for B2B buyers is the uncertainty surrounding the compatibility of K20 engines with their specific vehicle models or applications. This issue can lead to costly modifications or even engine failure if the wrong engine is purchased without proper validation.

Illustrative image related to k20 engine for sale

The Solution: To overcome compatibility challenges, buyers should conduct thorough research on the engine specifications and the intended application before making a purchase. This involves cross-referencing the engine’s compatibility with the specific vehicle models it is designed for, as well as understanding any necessary modifications that may be required for integration. Engaging with technical experts or engineers who specialize in automotive performance can provide invaluable insights into the compatibility of K20 engines. Moreover, suppliers should be encouraged to provide detailed compatibility information, including any specific vehicle applications and modifications required. This proactive approach will not only ensure that the correct engine is selected but also enhance the overall performance and longevity of the installation.

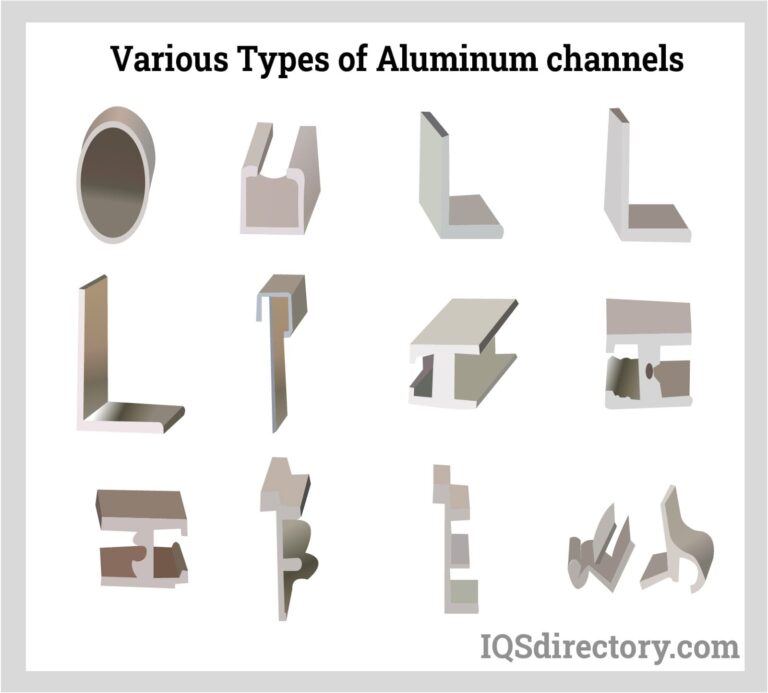

Strategic Material Selection Guide for k20 engine for sale

When selecting materials for the K20 engine, it is essential to consider various properties that impact performance, durability, and cost. The following analysis covers four common materials used in the construction of K20 engines, focusing on their properties, advantages, disadvantages, and implications for international B2B buyers.

What Are the Key Properties of Aluminum in K20 Engines?

Aluminum is widely used in engine components due to its excellent strength-to-weight ratio and thermal conductivity. It typically has a temperature rating up to 300°C and offers good corrosion resistance, especially when anodized. The lightweight nature of aluminum contributes to improved fuel efficiency and performance.

Pros: Aluminum is relatively easy to machine, making it suitable for complex shapes and designs. Its lightweight properties enhance overall vehicle performance, particularly in racing applications.

Cons: While aluminum is durable, it can be less resistant to high-stress conditions compared to other metals. It may require additional coatings or treatments to enhance its wear resistance.

Impact on Application: Aluminum is compatible with various engine fluids, including oil and coolant, but care must be taken to avoid galvanic corrosion when paired with dissimilar metals.

Considerations for International Buyers: Buyers from regions with high humidity, like parts of Africa and South America, should ensure that aluminum components are treated to prevent corrosion. Compliance with standards such as ASTM or JIS is crucial for ensuring quality.

How Does Cast Iron Benefit K20 Engine Durability?

Cast iron is often used in engine blocks and cylinder heads due to its high wear resistance and ability to withstand high temperatures and pressures. It can handle temperatures exceeding 500°C and provides excellent vibration damping properties.

Pros: Cast iron is highly durable and can endure significant mechanical stress, making it ideal for high-performance applications. Its cost-effectiveness is another advantage, particularly for mass production.

Cons: The weight of cast iron can be a disadvantage in performance applications, where reducing weight is critical. Additionally, it is more challenging to machine than aluminum.

Impact on Application: Cast iron is compatible with various engine fluids, but its brittleness can lead to cracking under extreme conditions.

Considerations for International Buyers: Buyers in Europe, particularly Germany, may prefer cast iron for its durability. Compliance with DIN standards is essential to ensure quality and reliability.

What Role Does Steel Play in K20 Engine Components?

Steel is commonly used for components like crankshafts, camshafts, and connecting rods due to its high tensile strength and toughness. It can withstand high temperatures and pressures, with some grades rated for temperatures over 600°C.

Illustrative image related to k20 engine for sale

Pros: Steel’s strength allows for thinner components without compromising durability, making it suitable for high-performance applications. It also offers good fatigue resistance.

Cons: Steel is heavier than aluminum, which may impact overall engine weight. Additionally, it can be more expensive than aluminum or cast iron, depending on the grade.

Impact on Application: Steel components are compatible with various engine fluids, but they may require protective coatings to prevent corrosion.

Considerations for International Buyers: Buyers from the Middle East should consider the impact of high temperatures on steel components and ensure they select appropriate grades. Compliance with ASTM standards is vital for quality assurance.

How Does Composite Material Enhance Engine Performance?

Composite materials, such as carbon fiber or reinforced plastics, are increasingly used in engine applications for components like intake manifolds and valve covers. They offer excellent strength-to-weight ratios and can withstand moderate temperatures.

Illustrative image related to k20 engine for sale

Pros: Composites can significantly reduce weight, enhancing engine performance and fuel efficiency. They also resist corrosion and chemical degradation.

Cons: The manufacturing process for composites can be complex and costly. They may not be suitable for high-stress components due to lower tensile strength compared to metals.

Impact on Application: Composites are generally compatible with engine fluids but require careful consideration of thermal expansion properties.

Illustrative image related to k20 engine for sale

Considerations for International Buyers: Buyers from regions with advanced automotive industries, like Germany, may favor composite materials for their performance benefits. Compliance with relevant standards is essential for ensuring quality.

Summary Table of Material Selection for K20 Engine

| Material | Typical Use Case for K20 engine for sale | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Engine blocks, cylinder heads | Lightweight, good thermal conductivity | Less resistant to high-stress conditions | Medium |

| Cast Iron | Engine blocks, cylinder heads | Highly durable, cost-effective | Heavy and brittle under extreme stress | Low |

| Steel | Crankshafts, camshafts, connecting rods | High tensile strength, good fatigue resistance | Heavier, potentially more expensive | Medium to High |

| Composite | Intake manifolds, valve covers | Excellent strength-to-weight ratio | Complex manufacturing process | High |

This strategic material selection guide provides valuable insights for international B2B buyers looking to make informed decisions regarding K20 engine components. By understanding the properties and implications of each material, buyers can optimize their procurement strategies to meet performance and durability requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for k20 engine for sale

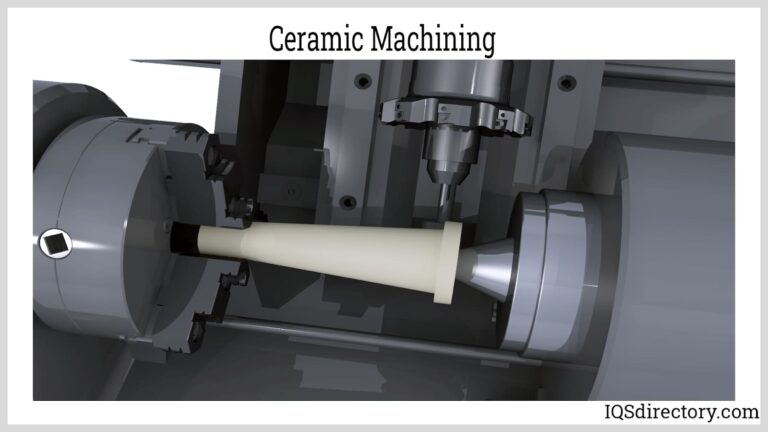

What Are the Key Stages in the Manufacturing Process for K20 Engines?

Manufacturing a K20 engine involves several critical stages that ensure quality and performance. The main stages of the manufacturing process typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: High-quality raw materials, such as aluminum for the engine block and steel for internal components, are sourced from reputable suppliers. These materials undergo rigorous inspection to ensure they meet industry standards. This stage may also involve heat treatment processes to enhance the durability and performance of components.

-

Forming: The prepared materials are then subjected to various forming techniques, including casting, machining, and forging. Casting is commonly used for the engine block, while precision machining is utilized for critical components like the cylinder head and crankshaft. Advanced CNC (Computer Numerical Control) machines are employed to achieve exact specifications, ensuring every part fits perfectly.

-

Assembly: This stage is crucial as it brings together all the individual components. Skilled technicians assemble the engine in a cleanroom environment to minimize contamination. Each assembly step is documented, and components are checked against specifications to maintain consistency.

-

Finishing: The final stage involves applying protective coatings, quality checks, and detailing. This may include polishing surfaces, applying anti-corrosion treatments, and ensuring that the engine meets aesthetic and functional specifications. The engines are then packaged for shipping, ensuring they are secure and protected during transit.

How Is Quality Assurance Integrated Throughout the K20 Engine Manufacturing Process?

Quality assurance (QA) is an integral part of the K20 engine manufacturing process. It encompasses various international standards and industry-specific regulations that guarantee product reliability and safety.

-

International Standards Compliance: Many manufacturers adhere to ISO 9001, which outlines a framework for quality management systems. This certification ensures that processes are in place for continuous improvement and customer satisfaction. Additionally, compliance with standards such as CE marking indicates that the product meets EU safety, health, and environmental protection standards.

-

Quality Checkpoints: Throughout the manufacturing process, several quality checkpoints are established:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to verify their quality before production begins.

– In-Process Quality Control (IPQC): During manufacturing, continuous monitoring and testing are conducted to ensure that each component meets specified tolerances.

– Final Quality Control (FQC): After assembly, the complete engine undergoes rigorous testing to check for functionality, performance, and emissions compliance. -

Common Testing Methods: Various testing methods are employed, including:

– Dynamometer Testing: Evaluates engine performance under various load conditions.

– Leak Testing: Ensures that there are no leaks in the engine assembly, particularly in the cooling and oil systems.

– Non-Destructive Testing (NDT): Techniques such as ultrasonic testing and X-ray inspection are used to detect internal flaws without damaging the components.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial to ensuring that they receive high-quality products.

Illustrative image related to k20 engine for sale

-

Supplier Audits: Conducting supplier audits is an effective way to assess the quality management processes in place. These audits can include evaluating the manufacturing facility, quality control procedures, and compliance with international standards.

-

Requesting Quality Reports: Buyers should request detailed quality reports that outline the testing methods used, results of tests, and any certifications obtained. These reports provide transparency and reassurance about the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the manufacturing processes and quality controls in place. These agencies can conduct random checks and provide certificates that confirm compliance with specified standards.

What Are the Quality Control Nuances for International B2B Buyers?

When sourcing K20 engines, international buyers must be aware of several nuances related to quality control:

-

Understanding Regional Standards: Different regions may have specific quality and safety standards. For example, European buyers may prioritize CE marking, while buyers in the Middle East may focus on local regulatory compliance. Understanding these nuances helps buyers make informed decisions.

-

Logistics and Supply Chain Considerations: Quality control extends beyond manufacturing. Buyers should consider the logistics of shipping and handling. Ensuring that the engines are transported in a manner that protects them from damage is crucial for maintaining quality.

-

Post-Sale Support and Warranty: Buyers should inquire about the warranty and post-sale support offered by the supplier. A robust warranty program reflects the manufacturer’s confidence in their product quality and provides peace of mind for buyers.

Conclusion

The manufacturing and quality assurance processes for K20 engines are complex and multifaceted. Understanding these processes is vital for B2B buyers seeking reliable, high-performance engines. By focusing on the manufacturing stages, quality assurance practices, and verification methods, international buyers can ensure they make informed purchasing decisions that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘k20 engine for sale’

In today’s competitive automotive market, sourcing a K20 engine requires a structured approach to ensure you make informed decisions that align with your business needs. This guide provides a comprehensive checklist to facilitate your procurement process, helping you to navigate the complexities of international B2B transactions effectively.

Step 1: Define Your Technical Specifications

Understanding the specific technical requirements for the K20 engine is crucial. Determine the horsepower, torque, and compatibility with existing vehicles or applications. This clarity will guide your supplier discussions and ensure the engine meets your performance expectations.

– Key considerations:

– Intended use (e.g., racing, daily driving)

– Required modifications or customizations

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in K20 engines. Look for companies with a solid reputation in the industry and positive reviews from previous clients. This step is vital to avoid potential pitfalls associated with less reputable suppliers.

– Sources to explore:

– Online marketplaces

– Automotive forums and communities

Step 3: Evaluate Supplier Certifications

Before making a commitment, verify that the suppliers possess the necessary certifications and quality assurances. Certifications such as ISO standards or specific automotive quality certifications can indicate the reliability and quality of their products.

– Questions to ask:

– Do they follow industry best practices?

– Can they provide documentation of their quality control processes?

Step 4: Request Detailed Product Information

Engage suppliers by requesting comprehensive product specifications and performance data for the K20 engines. This includes details about the engine’s assembly, materials used, and any testing conducted. Having this information helps in assessing the product’s suitability for your needs.

– Specific details to inquire about:

– Engine history (new, remanufactured, or used)

– Warranty information

Step 5: Compare Pricing and Shipping Options

Once you have a shortlist of potential suppliers, compare their pricing structures and shipping options. Consider not only the base price of the engine but also shipping costs, estimated delivery times, and any potential tariffs or customs fees. This step is crucial for budgeting and planning your procurement strategy.

– Factors to consider:

– Total landed cost

– Delivery timelines and reliability

Step 6: Negotiate Terms and Conditions

After selecting a preferred supplier, engage in negotiations to establish favorable terms and conditions. This includes payment terms, warranty coverage, and return policies. A clear understanding of these aspects can protect your investment and ensure a smooth transaction.

– Key negotiation points:

– Payment methods and timelines

– Warranty duration and conditions

Step 7: Finalize the Purchase Agreement

Once all terms are agreed upon, ensure that a formal purchase agreement is drafted and signed. This document should encapsulate all aspects discussed, including specifications, pricing, and delivery terms. Having a formal agreement mitigates risks and provides a reference point for both parties.

– Important elements to include:

– Detailed product description

– Clear timelines for delivery and payment

Illustrative image related to k20 engine for sale

By following this checklist, B2B buyers can streamline their procurement process for K20 engines, ensuring a successful transaction that meets their operational requirements.

Comprehensive Cost and Pricing Analysis for k20 engine for sale Sourcing

What are the Key Cost Components for Sourcing K20 Engines?

When sourcing K20 engines for sale, various cost components play a crucial role in determining the total expenditure. These components include:

-

Materials: The quality of materials used significantly affects the engine’s performance and durability. Premium components such as forged pistons, high-strength rods, and advanced cylinder head designs come at a higher cost but can lead to better performance.

-

Labor: Skilled labor is necessary for the assembly and testing of high-performance engines. The cost of labor can vary depending on the region, expertise required, and the complexity of the assembly.

-

Manufacturing Overhead: This encompasses the indirect costs related to production, including facility costs, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize these overheads.

-

Tooling: Custom tooling for precision manufacturing can be a significant upfront investment. However, it leads to better quality control and consistency in production.

-

Quality Control (QC): Rigorous testing and quality assurance protocols are essential, especially for high-performance engines. The cost of QC ensures that the engines meet performance standards and can significantly reduce warranty claims.

-

Logistics: Shipping costs can vary based on the origin, destination, and shipping method. International buyers must consider customs duties and import taxes, which can add to the overall cost.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the standard margins in the industry can help buyers negotiate better prices.

How Do Price Influencers Affect the Sourcing of K20 Engines?

Several factors influence the pricing of K20 engines, including:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in bulk often leads to discounts. Buyers should assess their needs to negotiate favorable terms based on volume.

-

Specifications and Customization: Custom-engineered solutions may incur additional costs. Buyers should weigh the benefits of customization against standard options.

-

Material Quality and Certifications: Engines built with certified materials may command higher prices but provide assurance of reliability and performance. Buyers should verify supplier certifications to ensure compliance with industry standards.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers may charge a premium for their products, but they often offer better support and warranty options.

-

Incoterms: Understanding the shipping terms (Incoterms) is vital for international transactions. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can impact the total landed cost of the engines.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing K20 Engines?

To optimize sourcing costs for K20 engines, buyers can adopt several strategies:

-

Negotiate Effectively: Engage in discussions with suppliers to find mutually beneficial pricing arrangements. Leverage bulk purchasing or long-term contracts to secure better rates.

-

Consider Total Cost of Ownership (TCO): Look beyond the initial purchase price. Factor in maintenance, expected lifespan, and potential resale value when evaluating options.

-

Understand Pricing Nuances for International Buyers: Buyers from regions like Africa, South America, the Middle East, and Europe should be aware of currency fluctuations, import regulations, and logistics challenges that may affect pricing.

-

Research Market Trends: Stay informed about market fluctuations and emerging technologies. Understanding trends can help buyers make informed decisions and negotiate better prices.

Conclusion

Sourcing K20 engines involves a multifaceted cost structure that requires careful consideration of various components and influencers. By understanding these factors, international B2B buyers can make strategic decisions that optimize their sourcing processes and enhance overall cost-efficiency. Always remember that indicative prices can vary widely based on specifications, supplier reputation, and market conditions.

Illustrative image related to k20 engine for sale

Alternatives Analysis: Comparing k20 engine for sale With Other Solutions

Introduction: Why Consider Alternatives to the K20 Engine?

When exploring options for high-performance engines, particularly in the context of racing or performance vehicles, it’s essential to consider not just the K20 engine for sale, but also viable alternatives that may better suit specific needs or budgets. Different engines offer varying performance levels, costs, maintenance requirements, and use cases that can significantly impact a buyer’s decision. This analysis will compare the K20 engine against two notable alternatives: the K24 engine and the SR20DET engine.

Comparison Table

| Comparison Aspect | K20 Engine For Sale | K24 Engine | SR20DET Engine |

|---|---|---|---|

| Performance | Up to 1200hp with turbo; high RPM capability | Up to 300hp naturally aspirated; good torque | Up to 400hp with turbo; strong tuning potential |

| Cost | $5,999 – $13,445 | $1,195 – $1,495 | $3,000 – $5,000 |

| Ease of Implementation | Requires advanced tuning and installation | Easier to swap; compatible with many models | Moderate difficulty; requires custom mounts |

| Maintenance | High maintenance; needs regular check-ups | Moderate; reliable with proper care | Higher maintenance due to turbo components |

| Best Use Case | Competitive racing; maximum performance | Daily driving or mild performance upgrades | Drifting and motorsport applications |

Detailed Breakdown of Alternatives

K24 Engine

The K24 engine, often seen as a sibling to the K20, offers a slightly larger displacement that translates to improved torque and overall drivability. With prices ranging from $1,195 to $1,495, it is a more budget-friendly option. The K24 is easier to install due to its compatibility with various Honda models, making it an attractive choice for both enthusiasts and everyday drivers. However, while it provides decent performance, it does not match the K20’s high-end power output, which may be a drawback for those looking for competitive racing capabilities.

SR20DET Engine

The SR20DET is a turbocharged engine known for its tuning potential and robust performance. With a power output of up to 400hp, it’s particularly popular in drifting and motorsport communities. Priced between $3,000 and $5,000, the SR20DET strikes a balance between performance and cost. However, installation can be moderately complex, requiring custom mounts and modifications. Additionally, maintenance can be more demanding due to the turbo components, which may require more frequent attention. Despite these challenges, its strong aftermarket support and tuning community make it an appealing option for performance enthusiasts.

Conclusion: How to Choose the Right Engine for Your Needs

When selecting an engine, B2B buyers should consider their specific requirements, such as the intended use of the vehicle, budget constraints, and maintenance capabilities. The K20 engine stands out for its exceptional performance in competitive environments, while the K24 engine offers a balance of reliability and cost-effectiveness for everyday use. The SR20DET, meanwhile, is ideal for those focused on motorsport and tuning. Ultimately, the right choice will depend on the buyer’s unique priorities and how each engine aligns with their performance goals and operational needs.

Illustrative image related to k20 engine for sale

Essential Technical Properties and Trade Terminology for k20 engine for sale

What Are the Key Technical Properties of K20 Engines for Sale?

When considering the acquisition of K20 engines, understanding the technical specifications is crucial for making informed purchasing decisions. Below are several key properties that international B2B buyers should be aware of:

-

Engine Displacement

The K20 engine typically has a displacement of 2.0 liters. Engine displacement refers to the total volume of all the cylinders in an engine and is a fundamental determinant of the engine’s power output. A larger displacement often correlates with higher power, making it essential for buyers focused on performance applications. -

Boost Pressure

Many K20 engines, particularly those designed for racing, can handle significant boost pressures, often exceeding 60 psi. Boost pressure indicates the amount of forced air entering the engine, which can dramatically enhance horsepower. Understanding the boost capabilities is vital for buyers in high-performance markets, as it directly affects the engine’s performance under various conditions. -

Material Composition

High-performance K20 engines often use rigid ductile iron sleeves and forged aluminum pistons. The material choice impacts the engine’s durability, weight, and overall efficiency. Buyers should consider the long-term performance and maintenance implications of these materials, especially in demanding environments. -

RPM Range

K20 engines are designed to operate at high RPMs, often reaching up to 11,000 RPM. The RPM range is critical for performance tuning, as it affects how the engine delivers power throughout its operational spectrum. Buyers need to ensure that the engine’s performance characteristics align with their specific application requirements. -

Valvetrain Configuration

The K20 typically features a dual overhead cam (DOHC) setup with VTEC technology, allowing for variable valve timing. This configuration improves efficiency and performance across various RPM ranges. B2B buyers should appreciate how valvetrain design influences not only performance but also emissions and fuel consumption. -

Maintenance Considerations

Engines like the K20 are built with ease of maintenance in mind, often featuring deburred surfaces to prevent injuries during service. Understanding maintenance requirements is essential for buyers looking to minimize downtime and enhance the longevity of their investments.

What Are the Common Trade Terms Related to K20 Engine Sales?

Navigating the purchase of K20 engines also involves familiarizing oneself with industry jargon. Here are some key terms that buyers should know:

-

OEM (Original Equipment Manufacturer)

This term refers to parts made by the manufacturer of the original engine. Understanding OEM specifications can help buyers discern quality and compatibility, ensuring that they are purchasing parts that will fit and perform as expected. -

MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is essential for B2B buyers to gauge initial investment requirements and to plan inventory effectively. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to request pricing and terms for specific products. It is a crucial step in the procurement process that helps buyers compare offers and make informed decisions. -

Incoterms (International Commercial Terms)

These are standardized terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms is vital for B2B buyers to understand shipping costs, risks, and delivery obligations. -

Aftermarket

This term refers to parts and accessories that are not sourced from the original manufacturer but are designed to fit and function in the same way. Buyers should evaluate aftermarket options for potential cost savings and improved performance. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. Understanding lead times is critical for planning and ensuring that operations run smoothly without unexpected delays.

Equipped with this knowledge of technical properties and industry terminology, B2B buyers can navigate the K20 engine market with greater confidence and clarity, leading to more strategic purchasing decisions.

Navigating Market Dynamics and Sourcing Trends in the k20 engine for sale Sector

What Are the Current Market Dynamics and Key Trends in the K20 Engine for Sale Sector?

The global market for K20 engines is shaped by several critical drivers, including the increasing demand for high-performance automotive components, a growing trend towards vehicle customization, and the rise of motorsports. International B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly focused on sourcing engines that can enhance vehicle performance while also being reliable and durable. The K20 engine, known for its robust architecture and tuning potential, has gained traction among performance enthusiasts and racing teams looking for competitive advantages.

Emerging sourcing trends highlight the shift towards online marketplaces that facilitate direct purchasing from manufacturers and specialized suppliers. Buyers are increasingly leveraging technology to compare products, assess specifications, and evaluate supplier credibility. The rise of e-commerce in this sector means that B2B buyers are more informed and can access a broader range of products, including remanufactured and JDM (Japanese Domestic Market) engines, which often offer superior quality at competitive prices.

Additionally, the market is experiencing a notable shift towards customization, as buyers seek engines that can be tailored to specific performance needs. This trend is particularly prevalent in regions with established automotive cultures, where buyers are more inclined to invest in high-performance parts. The emphasis on quality assurance and detailed product specifications is also gaining importance, as buyers are increasingly demanding transparency regarding engine performance metrics and build quality.

How Are Sustainability and Ethical Sourcing Addressed in the K20 Engine for Sale Sector?

Sustainability and ethical sourcing are becoming increasingly important in the automotive components industry, including the K20 engine market. The environmental impact of manufacturing processes, particularly in engine production, has prompted buyers to seek out suppliers who prioritize sustainable practices. This includes the use of recycled materials, energy-efficient manufacturing processes, and responsible waste management.

B2B buyers are also showing a preference for suppliers that can provide certifications for their products, such as ISO 14001 for environmental management or certifications for using eco-friendly materials. These certifications not only enhance the credibility of suppliers but also align with the growing demand for corporate social responsibility among businesses worldwide.

Furthermore, as consumers become more environmentally conscious, the demand for ‘green’ products is reflected in the sourcing decisions of B2B buyers. Companies that offer K20 engines with a focus on reduced emissions or improved fuel efficiency can gain a competitive edge in the marketplace. This trend is particularly relevant in regions like Europe, where stringent environmental regulations are influencing purchasing decisions.

Illustrative image related to k20 engine for sale

What Is the Historical Context of K20 Engines in the Automotive Industry?

The Honda K20 engine was first introduced in the early 2000s as part of Honda’s K-series lineup, quickly establishing itself as a favorite among performance enthusiasts. Its lightweight design, high-revving capabilities, and VTEC technology made it a popular choice for both OEM applications and aftermarket modifications. Initially found in models such as the Honda Civic and Acura RSX, the K20 engine gained notoriety in motorsports for its versatility and performance potential.

Over the years, the K20 has evolved, with various iterations offering improvements in power output and efficiency. The rise of the JDM market has further fueled its popularity, as buyers seek authentic performance engines for customization and racing applications. Today, the K20 engine remains a staple in both the aftermarket and motorsports sectors, appealing to a diverse range of B2B buyers looking for high-quality, performance-oriented solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of k20 engine for sale

-

How do I ensure the quality of a K20 engine before purchasing?

To guarantee the quality of a K20 engine, request detailed specifications and build sheets from the supplier. Look for engines that are meticulously assembled with high-quality components, such as proprietary sleeve designs and premium valvetrain components. It’s also beneficial to ask for warranty information and any testing certifications. Establishing a direct line of communication with the manufacturer can provide insights into their quality control processes and maintenance recommendations, ensuring you make an informed purchase. -

What is the best K20 engine for high-performance racing?

For high-performance racing, the K20-KT1200 is among the best options available, engineered for SFWD and Outlaw Class applications. This engine is capable of exceeding 1200hp, designed to handle extreme boost levels and maintain performance consistency over multiple runs. Its specialized components, such as the tool steel billet turbo cam and precision CNC cylinder head, are tailored for durability and responsiveness, making it an ideal choice for competitive racing environments. -

What factors should I consider when sourcing a K20 engine internationally?

When sourcing a K20 engine internationally, consider the supplier’s reputation, shipping options, and import regulations in your country. Ensure the supplier has experience with international trade and can provide necessary documentation, such as customs paperwork and compliance certifications. Additionally, inquire about lead times and the availability of technical support. Understanding local laws regarding engine imports is crucial to avoid complications. -

What are the typical payment terms for purchasing K20 engines in bulk?

Payment terms can vary by supplier, but commonly, international B2B transactions involve options like wire transfers, letters of credit, or payment upon delivery. It’s advisable to negotiate terms that work for both parties, potentially including a deposit upfront and the balance upon receipt. Ensure that you clarify currency options and any additional fees related to payment processing to avoid unexpected costs. -

How can I verify a supplier’s credibility when buying K20 engines?

To verify a supplier’s credibility, conduct thorough research, including checking online reviews, testimonials, and industry ratings. Request references from previous clients, and consider reaching out to them for firsthand feedback. Additionally, assess the supplier’s presence at trade shows or industry events, as this can indicate stability and commitment to their business. A credible supplier will also have transparent policies regarding warranties and returns. -

What are the minimum order quantities (MOQ) for K20 engines?

Minimum order quantities for K20 engines can vary significantly based on the supplier. While some manufacturers may allow single-unit purchases, others might require bulk orders to ensure cost-effectiveness. It’s essential to clarify the MOQ upfront and explore options for smaller orders if necessary. Some suppliers may offer flexibility or discounts for larger quantities, making it worthwhile to discuss your specific needs. -

What logistics considerations should I keep in mind when importing K20 engines?

When importing K20 engines, consider shipping methods, costs, and transit times. Choose between air freight for faster delivery or sea freight for cost efficiency, keeping in mind the engine’s weight and size. Additionally, ensure that the supplier provides proper packaging to prevent damage during transit. Understanding your local customs procedures and potential tariffs is vital to avoid delays and extra charges. -

Can I customize the K20 engine for my specific application?

Yes, many suppliers offer customization options for K20 engines to meet specific performance requirements. Customizations can include modifications to the engine’s compression ratio, camshaft selection, or even specific tuning for different fuel types. Discuss your application needs with the supplier, who can provide recommendations based on their expertise and available components. It’s essential to ensure that any modifications align with your performance goals and comply with local regulations.

Top 9 K20 Engine For Sale Manufacturers & Suppliers List

1. eBay – K20 Engine Listings

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: K20 Engine listings on eBay include various models and conditions such as: 02-06 JDM Acura RSX Base Model K20A 2.0L iVTEC Engine (Pre-Owned, $1,349.00), Honda Civic MK8 FN2 2006-2011 K20Z4 2.0 Type-R Engine (Pre-Owned, $2,154.01), 06-11 Honda Civic SI K24A 2.4l 200HP Replacement K20A Engine (Pre-Owned, $1,399.00), Honda Civic B18C4 Engine (Pre-Owned, $4,728.15), K20A FD2 type r bottom block (Pre-O…

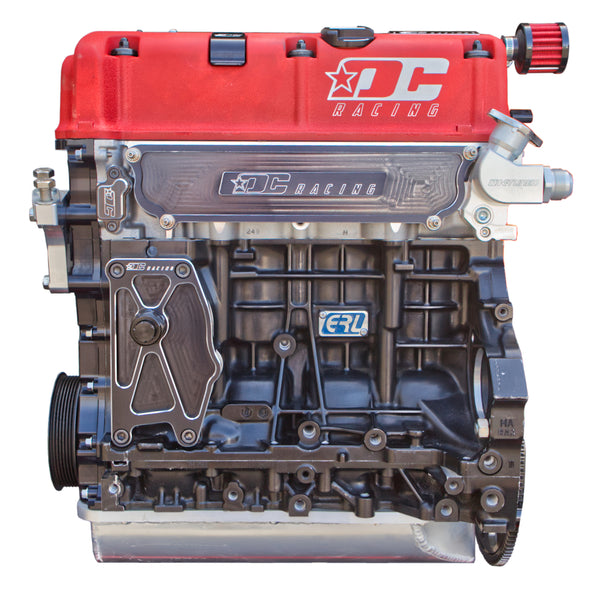

2. 4 Piston Racing – K20-KT1200 2.1L Complete Engine

Domain: 4pistonracing.com

Registered: 2015 (10 years)

Introduction: K20-KT1200 2.1L Complete Engine – SFWD Turbo Race Engine

Price: $13,445.00 USD

Key Features:

– Designed for SFWD and Outlaw Class turbocharged race cars

– Capable of exceeding 1200hp

– Assembled with high-quality components for durability and performance

– Supports 60+psi boost

– Purpose-built cylinder head with a specialized valve job

– Tool steel billet turbo cam for power up to 11k rpm

– Enha…

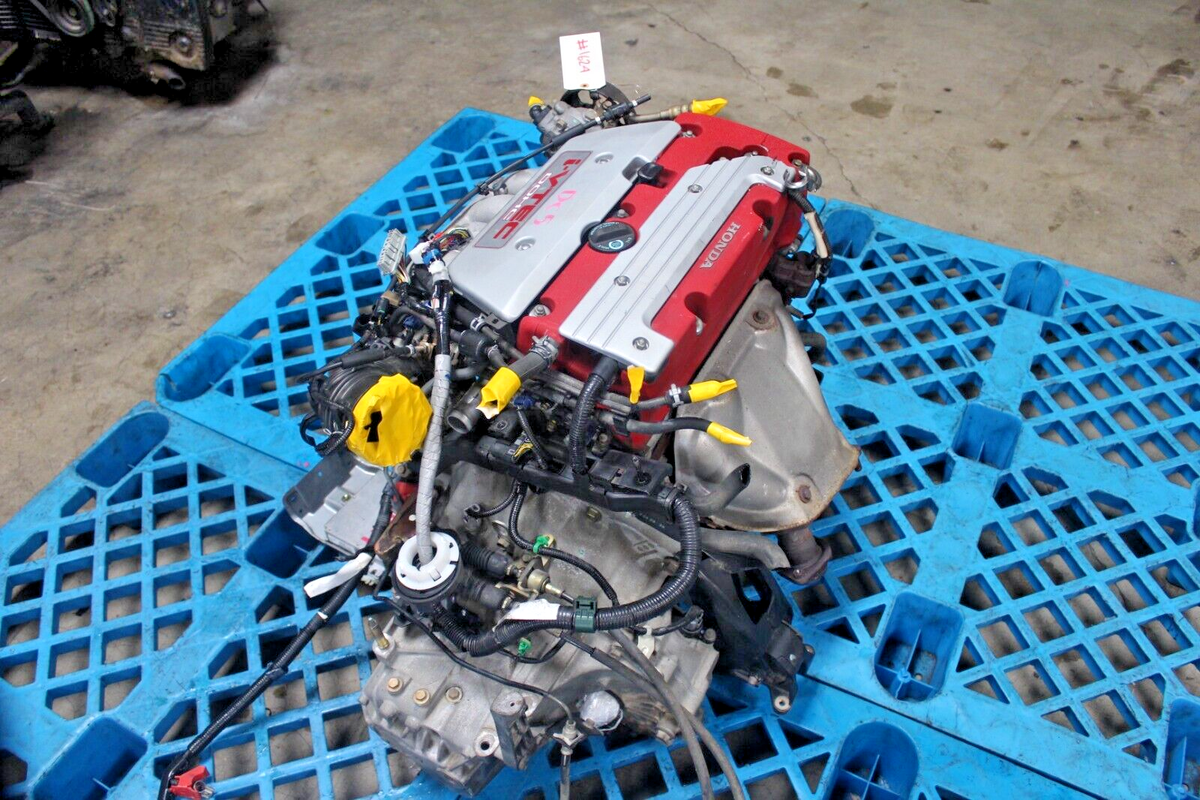

3. JDM Engine Depot – Honda K-Series Engines

Domain: jdmenginedepotinc.com

Registered: 2017 (8 years)

Introduction: Honda K-Series Engines for Sale with mileage ranging from 45,000 to 65,000 miles. Available models include: 2003-2006 Honda Element 2.4L DOHC 4CYL IVTEC Engine JDM K24A priced at $999.00, 2007-2011 Honda Element Engine 2.4L DOHC 4CYL IVTEC JDM K24A priced at $999.00, 2003-2007 Honda Accord 2.4L DOHC 4CYL IVTEC Engine JDM K24A priced at $999.00, 2002-2005 Honda Civic Type R EP3 2.0L 4CYL Engine Tra…

4. Honda – K20A Final Drive Set

Domain: hmotorsonline.com

Registered: 2002 (23 years)

Introduction: This company, Honda – K20A Final Drive Set, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. JDM Racing – K20A & K24A High-Performance Motors

Domain: jdmracingmotors.com

Registered: 2005 (20 years)

Introduction: JDM K20A Acura RSX Type R DC5 and K24A motors are high-performance engines designed for Honda vehicles. The K20A engine is known for its 2.0L displacement, producing approximately 220 horsepower and 206 Nm of torque. It features a DOHC i-VTEC system, enhancing performance and efficiency. The K24A engine, with a 2.4L displacement, offers a balance of power and torque, making it suitable for various…

6. Honda – K20 Engine

Domain: allamericanmotorshub.com

Registered: 2025 (0 years)

Introduction: {“Product Name”: “Honda K20 Engine”, “SKU”: “HOND-013”, “Category”: “Honda”, “Price Range”: “$699.00 – $1,000.00”, “Conditions”: “Used”, “Miles”: “70000-130000”, “Year Compatibility”: “2001-2020”, “Warranty”: “Up to 3 Months”, “Engine Type”: “2.0L Inline-4”, “Horsepower”: “155 – 306 hp”, “Fuel Type”: “Gasoline”, “Availability”: “In Stock”, “Shipping”: “Nationwide Available”, “Use Case”: “Ideal for…

7. JDM Orlando – K20A Engine

Domain: jdmorlandoinc.com

Registered: 2013 (12 years)

Introduction: K20A Engine for Sale – Part of Honda’s K-series, found in 04-08 Honda Accord, 02-06 Acura Integra, and 02-05 Honda Civic Si. Four-cylinder, four-stroke engine introduced in 2001. Features roller rockers to reduce friction, DOHC valvetrain, and a distributorless ignition system with individual coils for each spark plug. The K20A has a 2.0L displacement, produces 155 or 158 horsepower depending on t…

8. Honda – Civic TYPE R K20A Engine with Transmission

Domain: nearautosparts.com

Registered: 2022 (3 years)

Introduction: {“Product Name”: “Honda Civic TYPE R K20A K20 2.0L Engine with Transmission”, “Price”: “$4,200.00”, “Condition”: “Used”, “Mileage”: “37,000”, “Engine Code”: “K20A K20”, “Transmission”: “6-Speed LSD”, “Cylinder Arrangement”: “Inline 4”, “Displacement”: “2.0L”, “Fuel Type”: “Gasoline/Petrol”, “Cooling System”: “Liquid Cooled”, “Max Power”: “200hp”, “Torque”: “202Nm”, “Weight”: “132kg”, “Included Com…

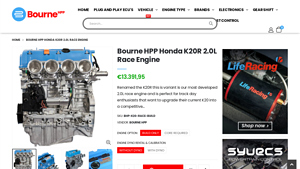

9. Bourne HPP – K20R 2.0L Race Engine

Domain: bournehpp.com

Registered: 2019 (6 years)

Introduction: {“name”: “Bourne HPP Honda K20R 2.0L Race Engine”, “sku”: “BHP-K20-RACE-BUILD”, “price”: {“build_only_without_dyno”: “$15,738.00”, “build_only_with_dyno”: “$17,258.00”}, “description”: “Renamed the K20R, this variant is our most developed 2.0L race engine and is perfect for track day enthusiasts that want to upgrade their current K20 into a competitive engine.”}

Strategic Sourcing Conclusion and Outlook for k20 engine for sale

In the competitive landscape of performance engines, particularly the K20 series, strategic sourcing becomes a vital component for international B2B buyers. Understanding the nuances of engine specifications, such as the unique features of the K20-KT1200 designed for turbocharged racing, can significantly influence purchasing decisions. Buyers should prioritize suppliers that offer comprehensive product details, including build quality, compatibility, and maintenance requirements, ensuring long-term reliability and performance.

The K20 engine’s adaptability across various models, from the Honda Civic to the Acura RSX, underscores its versatility and appeal in diverse markets, including Africa, South America, the Middle East, and Europe. As demand for high-performance engines continues to rise globally, sourcing from reputable suppliers that provide thorough product specifications and support services will be crucial.

Looking ahead, B2B buyers are encouraged to engage with suppliers who not only offer competitive pricing but also emphasize quality and service. By doing so, you can secure a strategic advantage in your automotive projects. Explore your options today and position your business for success in the dynamic engine market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.