How to Source Hydraulic Rod Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for hydraulic rod

Navigating the complexities of the global market for hydraulic rods can be a daunting challenge for international B2B buyers. With diverse applications ranging from construction equipment to agricultural machinery, sourcing the right hydraulic rod is critical for ensuring operational efficiency and longevity. This comprehensive guide addresses the myriad aspects of hydraulic rod procurement, including types of rods, their specific applications, and essential considerations for supplier vetting and cost evaluation.

In today’s competitive landscape, particularly for buyers in regions such as Africa, South America, the Middle East, and Europe—where industries are rapidly evolving—making informed purchasing decisions is paramount. This guide empowers B2B buyers by providing actionable insights that streamline the sourcing process, helping to mitigate risks associated with quality and reliability.

By exploring the various types of hydraulic rods, understanding their specific applications, and learning how to evaluate suppliers effectively, readers will be equipped to navigate market challenges with confidence. Additionally, this guide delves into pricing structures and the factors influencing costs, ensuring that you can make economically sound decisions while meeting your operational needs. Whether you are in Nigeria, Saudi Arabia, or any other market, this resource is designed to enhance your procurement strategy and drive successful outcomes in your hydraulic systems.

Understanding hydraulic rod Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Induction Hardened Chrome Plated (IHCP) | High surface hardness (Rc58/60), excellent corrosion resistance | Heavy machinery, construction, mining | Pros: High durability, suitable for harsh environments. Cons: Higher cost due to hardening process. |

| Chrome Plated Only (CPO) | Softer steel base, lower hardness (Rc15/19), less expensive | Industrial plants, applications in protected environments | Pros: Cost-effective, adequate for low-impact use. Cons: Less durable, prone to damage in harsh conditions. |

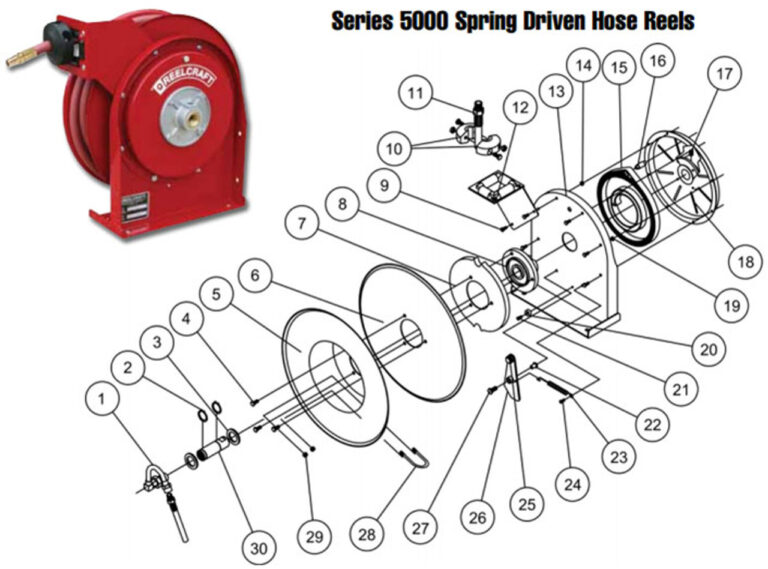

| Tie Rod Hydraulic Cylinders | Uses tie rods for structural support, available in various sizes | Agricultural equipment, automotive applications | Pros: Versatile, easily replaceable components. Cons: Limited in high-pressure applications compared to welded designs. |

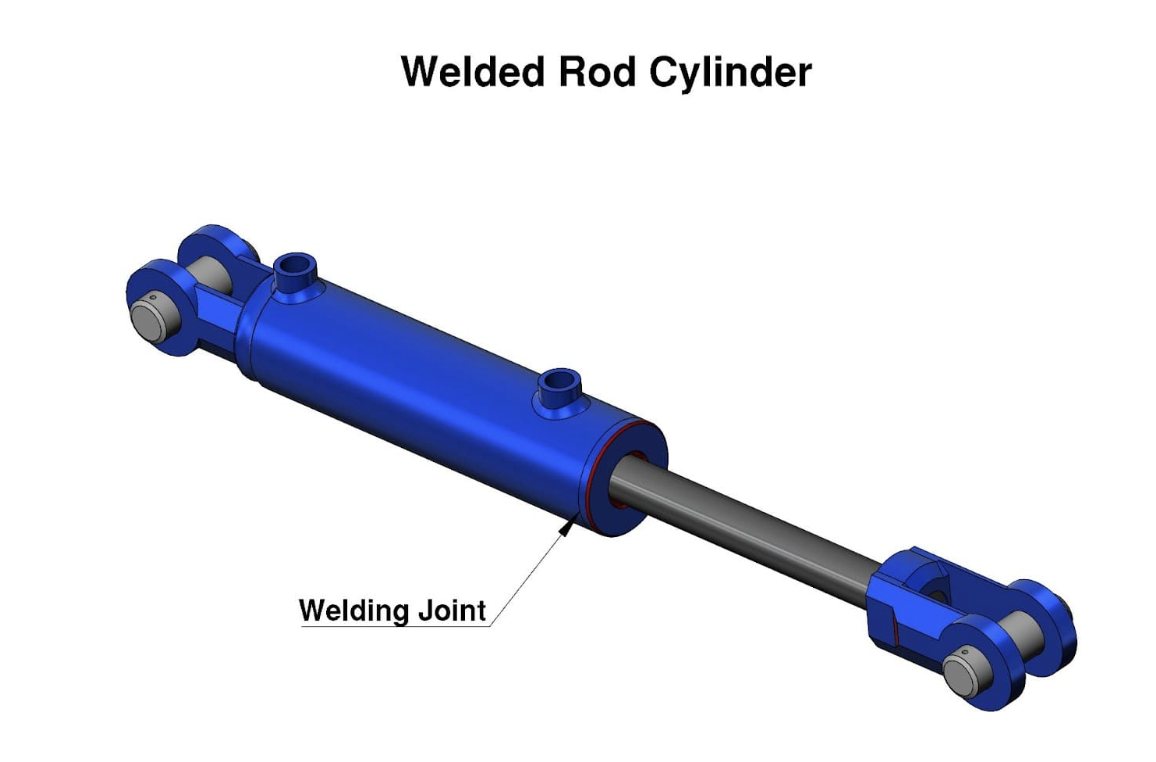

| Welded Rod Hydraulic Cylinders | Robust construction, welded for strength, can handle high pressures | Construction, material handling, waste management | Pros: High strength, suitable for demanding tasks. Cons: Difficult to repair if damaged. |

| Compact Hydraulic Cylinders | Smaller size, designed for tight spaces, lightweight materials | Robotics, precision machinery, automotive | Pros: Space-saving, lightweight. Cons: Limited power compared to larger cylinders. |

What are the characteristics of Induction Hardened Chrome Plated (IHCP) hydraulic rods?

Induction Hardened Chrome Plated (IHCP) hydraulic rods are known for their exceptional surface hardness and durability, achieved through a specific hardening process. This type of rod is ideal for heavy machinery operating in harsh environments, such as mining and construction, where wear and tear are common. When purchasing IHCP rods, buyers should consider factors like the specific hardness requirements for their applications, as well as the cost, which is typically higher due to the additional processing.

How does Chrome Plated Only (CPO) compare in terms of suitability?

Chrome Plated Only (CPO) hydraulic rods are constructed from softer steel, making them less expensive but also less durable than IHCP rods. They are commonly used in industrial settings where the environment is controlled, and the risk of impact damage is low. Buyers need to assess the operational conditions of their machinery to determine if CPO rods will suffice, balancing cost against the potential for more frequent replacements.

What are the benefits of using Tie Rod Hydraulic Cylinders?

Tie Rod Hydraulic Cylinders are characterized by their use of external tie rods that provide structural support. This design allows for easy maintenance and replacement of individual components, making them suitable for agricultural machinery and automotive applications. When considering tie rod cylinders, B2B buyers should evaluate the weight and pressure ratings to ensure compatibility with their equipment, as well as the ease of sourcing replacement parts.

Why choose Welded Rod Hydraulic Cylinders for demanding applications?

Welded Rod Hydraulic Cylinders are designed for high-pressure applications and are typically used in demanding environments, such as construction and waste management. Their robust construction provides strength and reliability, although they can be challenging to repair if damaged. Buyers should prioritize the intended application and the cylinder’s pressure ratings when selecting welded rod cylinders, as these factors significantly impact performance and longevity.

What makes Compact Hydraulic Cylinders suitable for specific uses?

Compact Hydraulic Cylinders are engineered for applications where space is limited, making them ideal for robotics and precision machinery. They are lightweight and designed to fit into confined areas without sacrificing performance. B2B buyers should consider the specific dimensions and weight capacity needed for their applications, ensuring that compact cylinders can handle the required load without compromising efficiency.

Key Industrial Applications of hydraulic rod

| Industry/Sector | Specific Application of Hydraulic Rod | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction Equipment | Hydraulic cylinders in excavators | Enhanced lifting capacity and operational efficiency | Quality materials to withstand harsh conditions and high pressures |

| Agriculture | Hydraulic rods in tractors and harvesters | Improved productivity and reduced downtime | Compatibility with specific machinery and environmental conditions |

| Mining | Hydraulic rods for drilling rigs | Increased durability and resistance to wear | Sourcing from suppliers with experience in high-stress applications |

| Waste Management | Hydraulic systems in compactors | Efficient waste processing and reduced operational costs | Reliability and ease of maintenance are crucial |

| Material Handling | Hydraulic rods in forklifts | Enhanced load handling and maneuverability | Ensuring the right dimensions and stroke lengths for specific tasks |

How is Hydraulic Rod Used in Construction Equipment?

In the construction industry, hydraulic rods are integral to the functionality of excavators and other heavy machinery. They enable the lifting and movement of substantial loads, thereby enhancing operational efficiency. Buyers from regions like Africa and South America must consider the local working conditions, such as dust and moisture, which can affect hydraulic rod performance. Selecting rods made from durable materials and designed for high-pressure applications is essential to minimize downtime and repair costs.

What Role Does Hydraulic Rod Play in Agriculture?

In agriculture, hydraulic rods are utilized in tractors and harvesters to facilitate various operations, including plowing, lifting, and transporting materials. The reliability of these rods directly impacts productivity, as equipment failures can lead to costly delays during peak seasons. Buyers in the Middle East and Europe should focus on sourcing hydraulic rods that are compatible with their specific machinery and capable of operating efficiently under varying weather conditions, ensuring optimal performance throughout the year.

How are Hydraulic Rods Essential for Mining Operations?

Mining operations rely heavily on hydraulic rods for drilling rigs and other heavy equipment. These rods must withstand extreme conditions, including high pressures and abrasive materials. International buyers, especially from regions with harsh mining environments, should prioritize sourcing from manufacturers that specialize in high-stress applications. Durability and resistance to wear are critical factors, as they directly influence operational efficiency and safety in mining operations.

Why are Hydraulic Rods Important in Waste Management?

In the waste management sector, hydraulic systems equipped with hydraulic rods are essential for the operation of compactors and other waste handling equipment. These rods facilitate the efficient processing of waste, thereby reducing operational costs and improving service delivery. Buyers should consider the reliability of the hydraulic components and the ease of maintenance when sourcing. Selecting high-quality hydraulic rods can lead to significant long-term savings and increased service efficiency.

How Do Hydraulic Rods Enhance Material Handling?

In material handling applications, hydraulic rods are used in forklifts and other lifting equipment to improve load handling capabilities. They provide the necessary force to lift and maneuver heavy loads, which is crucial for warehouse operations. B2B buyers should ensure that the hydraulic rods they source meet specific dimensions and stroke lengths required for their machinery, optimizing performance and safety in material handling tasks.

Illustrative image related to hydraulic rod

3 Common User Pain Points for ‘hydraulic rod’ & Their Solutions

Scenario 1: Challenges with Hydraulic Rod Durability in Harsh Environments

The Problem:

B2B buyers in industries such as construction and mining often face significant challenges related to the durability of hydraulic rods. In harsh environments, these rods are subjected to extreme conditions, including high levels of dust, moisture, and abrasive materials. These factors can lead to premature wear, scoring, or corrosion, ultimately causing hydraulic failures that disrupt operations. The financial implications of downtime, coupled with the cost of frequent replacements, can severely impact a company’s bottom line.

The Solution:

To combat durability issues, it is essential to invest in high-quality hydraulic rods that are specifically designed for harsh conditions. Buyers should look for rods made from induction-hardened chrome-plated materials (IHCP), which offer superior resistance to wear and corrosion compared to standard rods. Additionally, consider sourcing rods with enhanced sealing systems that prevent fluid leaks and contamination. Regular maintenance, including inspections for wear and timely replacement of seals, can further extend the life of hydraulic rods. Implementing a proactive maintenance schedule will ensure equipment reliability and reduce overall costs associated with downtime and repairs.

Scenario 2: Difficulty in Sourcing Compatible Hydraulic Rods for Specialized Equipment

The Problem:

International buyers, particularly those in diverse markets such as Africa and South America, often encounter difficulties in sourcing hydraulic rods that are compatible with their specialized machinery. Many manufacturers produce unique models with specific dimensions and requirements, leading to challenges in finding the right replacement parts. This can result in extended lead times and increased costs, as buyers may need to resort to custom solutions or compromise on quality.

Illustrative image related to hydraulic rod

The Solution:

To alleviate sourcing challenges, buyers should establish strong relationships with reputable suppliers who have a broad inventory of hydraulic rods and can provide custom manufacturing services. It’s crucial to communicate the specific requirements of the machinery, including dimensions, stroke length, and pressure ratings, to ensure compatibility. Additionally, utilizing online databases and catalogs can streamline the search process. Engaging in direct communication with suppliers can also facilitate faster response times and provide insights into alternative solutions that may be readily available. Investing in a well-defined procurement strategy will enhance efficiency and reduce the risk of equipment downtime.

Scenario 3: High Maintenance Costs Due to Inadequate Hydraulic Rod Sealing

The Problem:

Many B2B buyers struggle with high maintenance costs stemming from inadequate sealing in hydraulic rods. Poorly designed or worn seals can lead to hydraulic fluid leaks, resulting in both environmental concerns and increased operational costs. This is particularly problematic in industries that rely heavily on hydraulic systems, as the loss of fluid not only affects performance but also requires frequent replenishment and maintenance.

The Solution:

To reduce maintenance costs associated with seal failures, buyers should prioritize sourcing hydraulic rods equipped with advanced sealing technologies. Look for suppliers that offer rods with dual or triple sealing systems, which provide enhanced protection against leaks and contamination. Regular training for maintenance personnel on proper installation and inspection of seals can also mitigate issues. Implementing a systematic approach to monitoring fluid levels and system performance will help identify potential seal failures before they escalate, further reducing maintenance costs. By investing in high-quality hydraulic rods and seals, companies can improve operational efficiency and minimize unexpected expenses.

Strategic Material Selection Guide for hydraulic rod

What Are the Key Materials for Hydraulic Rods and Their Properties?

When selecting materials for hydraulic rods, understanding the specific properties and performance characteristics of each option is crucial for ensuring reliability and efficiency in various applications. Below, we analyze four common materials used in hydraulic rod manufacturing: Chrome Plated Only (CPO) Steel, Induction Hardened Chrome Plated (IHCP) Steel, Stainless Steel, and Alloy Steel.

How Does Chrome Plated Only (CPO) Steel Perform in Hydraulic Applications?

CPO steel is typically made from 1045 steel and features a chrome plating that provides a smooth finish and some corrosion resistance. This material is suitable for applications where the environment is not overly harsh, as it can handle moderate pressure and temperature ranges.

Pros: CPO is cost-effective and easy to manufacture, making it ideal for mass-produced hydraulic rods. Its smooth surface enhances seal performance and reduces friction.

Illustrative image related to hydraulic rod

Cons: The durability is limited compared to other materials, as it is more susceptible to scoring and pitting. In high-impact environments, CPO rods may fail prematurely.

Impact on Application: CPO rods are best suited for less demanding applications, such as in agricultural machinery or light construction equipment.

Considerations for International Buyers: Compliance with standards like ASTM is essential, especially in regions such as Africa and South America, where local regulations may vary.

Why Choose Induction Hardened Chrome Plated (IHCP) Steel?

IHCP steel offers enhanced durability due to its induction hardening process, which increases surface hardness significantly. This material is ideal for high-stress applications where bending resistance is crucial.

Pros: IHCP rods are highly resistant to wear and can withstand harsh environments, making them suitable for heavy machinery and construction equipment.

Cons: The manufacturing process is more complex and costly than CPO, which may impact budget considerations for international buyers.

Impact on Application: IHCP rods excel in demanding applications, such as mining and excavation, where they encounter extreme conditions.

Considerations for International Buyers: Buyers should ensure that IHCP rods meet relevant international standards, such as DIN or JIS, particularly in Europe and the Middle East.

What Are the Benefits of Using Stainless Steel for Hydraulic Rods?

Stainless steel, particularly grades like 316 and 304, is known for its excellent corrosion resistance and durability. This material is ideal for applications exposed to harsh chemicals or saline environments.

Pros: Stainless steel rods offer superior resistance to corrosion and can maintain their integrity in extreme conditions. They also have a longer lifespan, reducing replacement frequency.

Cons: The higher cost of stainless steel may deter budget-conscious buyers, and its manufacturing can be more complex.

Impact on Application: Stainless steel is particularly beneficial in industries like marine, chemical processing, and food production, where hygiene and corrosion resistance are paramount.

Considerations for International Buyers: Compliance with food safety standards and chemical compatibility is crucial, especially in regions with stringent regulations.

How Does Alloy Steel Compare for Hydraulic Rod Applications?

Alloy steel is often used for hydraulic rods due to its enhanced mechanical properties, including strength and toughness. This material can be tailored with various alloying elements to suit specific applications.

Pros: Alloy steel rods can be engineered for high strength and wear resistance, making them suitable for demanding applications.

Illustrative image related to hydraulic rod

Cons: The cost can vary widely depending on the alloying elements used, and the manufacturing process may be more complex.

Impact on Application: Alloy steel is ideal for heavy-duty applications in construction and mining, where high performance is essential.

Considerations for International Buyers: Buyers should be aware of the specific alloy compositions and ensure compliance with local regulations and standards.

Summary Table of Material Selection for Hydraulic Rods

| Material | Typical Use Case for hydraulic rod | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Chrome Plated Only (CPO) | Agricultural machinery | Cost-effective and easy to manufacture | Limited durability, prone to scoring | Low |

| Induction Hardened Chrome Plated (IHCP) | Heavy machinery and construction | Highly durable, resistant to wear | Higher manufacturing complexity and cost | High |

| Stainless Steel | Marine and chemical processing | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Alloy Steel | Construction and mining | High strength and toughness | Variable cost and complex manufacturing | Med to High |

This strategic material selection guide provides a comprehensive overview for B2B buyers looking to optimize their hydraulic rod purchases based on application needs and environmental conditions. Understanding these materials will help in making informed decisions that enhance performance and longevity in hydraulic systems.

Illustrative image related to hydraulic rod

In-depth Look: Manufacturing Processes and Quality Assurance for hydraulic rod

What Are the Main Stages in the Manufacturing Process of Hydraulic Rods?

The manufacturing of hydraulic rods involves a series of critical stages that ensure the final product meets rigorous performance standards. Understanding these stages can help B2B buyers identify reliable suppliers and assess the quality of hydraulic rods.

Material Preparation: What Materials Are Used in Hydraulic Rod Production?

The process begins with selecting high-quality materials, typically carbon steel or alloy steel, known for their strength and durability. The chosen material undergoes treatment to enhance its properties, such as induction hardening or chrome plating, which provides resistance against corrosion and wear. The steel is cut to the required lengths and undergoes surface preparation to remove any contaminants and ensure a clean base for subsequent processes.

How Are Hydraulic Rods Formed and Shaped?

Forming processes for hydraulic rods often include techniques such as machining, forging, and extrusion. In machining, the rods are turned on a lathe to achieve precise dimensions and surface finishes. Forging, on the other hand, shapes the metal through compressive forces, enhancing its structural integrity. Extrusion may also be employed, particularly for producing hollow rods, where heated material is pushed through a die to create the desired shape.

What Are the Key Assembly and Finishing Techniques in Hydraulic Rod Manufacturing?

Once the rods are formed, they undergo assembly processes that may include attaching end fittings or integrating seals essential for hydraulic functionality. This stage is crucial for ensuring that all components work seamlessly together.

Finishing techniques are equally important. Typically, this involves processes such as grinding and polishing to achieve a smooth surface finish, which is critical for optimal seal performance and to prevent leakage. Chrome plating is often applied at this stage to enhance corrosion resistance and durability.

Illustrative image related to hydraulic rod

How Is Quality Assurance Implemented in Hydraulic Rod Manufacturing?

Quality assurance (QA) is integral to the manufacturing process, ensuring that hydraulic rods meet international and industry-specific standards. Suppliers aiming for international markets, especially in regions like Africa, South America, the Middle East, and Europe, must adhere to recognized standards such as ISO 9001 for quality management systems, CE marking for product safety, and API standards for oil and gas applications.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are established at various stages throughout the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to verify compliance with specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process ensures adherence to operational standards and identifies any deviations early.

- Final Quality Control (FQC): The finished products undergo rigorous testing to confirm they meet all specifications and performance criteria before shipment.

What Testing Methods Are Commonly Used for Hydraulic Rods?

Several testing methods are utilized to ensure the reliability and performance of hydraulic rods:

- Hydraulic Testing: This involves pressurizing the rod to verify that it can withstand operational pressures without leakage.

- Dimensional Inspection: Precision measurements are taken to ensure that the rods meet specified tolerances.

- Surface Integrity Testing: Techniques such as ultrasonic testing or magnetic particle inspection are employed to detect any surface or subsurface defects that could compromise performance.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those sourcing from international suppliers, verifying quality control practices is essential. Here are some actionable steps:

- Supplier Audits: Conducting on-site audits of potential suppliers can provide insight into their manufacturing processes and quality assurance practices.

- Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including results from testing and inspections.

- Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s quality control practices and product quality.

What Are the Specific Quality Certification Nuances for International B2B Buyers?

When dealing with suppliers from different regions, it’s important to understand the nuances of quality certifications. For example, CE marking is crucial for products sold in Europe, while API certification is vital for those in the oil and gas sector. Buyers should ensure that the supplier holds the relevant certifications for their target market, as this can significantly impact product acceptance and regulatory compliance.

Conclusion: How Do Manufacturing Processes and Quality Assurance Impact Your Purchase Decisions?

Understanding the manufacturing processes and quality assurance practices for hydraulic rods is critical for B2B buyers. Not only does it allow for informed purchasing decisions, but it also ensures that the products meet the necessary performance and safety standards. By focusing on suppliers that prioritize quality control and adhere to international standards, buyers can mitigate risks and enhance the reliability of their hydraulic systems.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hydraulic rod’

Introduction

Sourcing hydraulic rods for industrial applications involves a careful assessment of your needs, potential suppliers, and the specific characteristics of the products available in the market. This guide provides a practical checklist to help B2B buyers navigate the procurement process effectively, ensuring that you select high-quality hydraulic rods suitable for your operations.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical to ensure that the hydraulic rod meets your operational requirements. Consider factors such as rod diameter, length, material type (e.g., chrome-plated or induction-hardened), and stroke length. These specifications will guide your search and help suppliers provide the most relevant options.

- Key considerations:

- Load capacity and pressure ratings.

- Environmental conditions where the rod will be used (e.g., exposure to harsh elements).

Step 2: Research Market Trends and Innovations

Stay informed about the latest trends and technological advancements in hydraulic rod design and manufacturing. This knowledge can inform your purchasing decisions and help you identify products that offer enhanced durability and performance.

Illustrative image related to hydraulic rod

- What to look for:

- Innovations in materials that improve resistance to wear and corrosion.

- New manufacturing techniques that enhance the precision and reliability of hydraulic rods.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, it’s essential to conduct a thorough evaluation. This involves requesting detailed company profiles, product catalogs, and references from other customers, particularly those in your industry or region.

- Why this matters:

- A reputable supplier is more likely to provide high-quality products and reliable service.

- Understand their manufacturing capabilities and quality control processes to gauge their reliability.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers possess relevant industry certifications and compliance with international standards. Certifications can be indicative of a supplier’s commitment to quality and safety.

- Look for:

- ISO certifications that demonstrate adherence to quality management systems.

- Industry-specific certifications that may apply to hydraulic components.

Step 5: Request Samples and Test Performance

Before finalizing your order, request samples of the hydraulic rods for testing. Evaluate their performance under conditions that mimic your operational environment.

Illustrative image related to hydraulic rod

- Testing should include:

- Assessing the rod’s durability against expected loads and environmental conditions.

- Checking for proper sealing and functionality to prevent leaks and ensure efficiency.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, delivery schedules, and warranty terms. Clear agreements on these aspects can prevent misunderstandings and ensure a smooth procurement process.

- Important points to cover:

- Bulk order discounts or pricing tiers.

- Lead times and shipping arrangements, especially for international purchases.

Step 7: Establish a Relationship for Future Needs

Building a strong relationship with your supplier can be beneficial for future orders and support. Open communication channels can lead to better service and potential discounts or priority treatment for urgent needs.

- Consider:

- Setting up regular check-ins to discuss product performance and any new requirements.

- Engaging in collaborative discussions for any custom solutions or modifications needed.

Following this checklist will help you make informed decisions when sourcing hydraulic rods, ensuring that your procurement process is efficient and aligned with your business goals.

Comprehensive Cost and Pricing Analysis for hydraulic rod Sourcing

What Are the Key Cost Components in Hydraulic Rod Pricing?

When sourcing hydraulic rods, understanding the underlying cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Common materials include chrome-plated steel and induction-hardened steel, with the latter being more expensive due to its enhanced durability and resistance to wear.

-

Labor: Labor costs can vary widely depending on the manufacturing location. Regions with lower labor costs may offer competitive pricing, but quality and expertise should not be compromised.

-

Manufacturing Overhead: This encompasses expenses related to production facilities, utilities, and administrative costs. Suppliers with efficient manufacturing processes may pass savings onto buyers.

-

Tooling: Specialized tooling for producing hydraulic rods can add to initial costs. However, suppliers with advanced machinery may reduce costs over time through efficient production.

-

Quality Control (QC): Rigorous QC processes ensure that the hydraulic rods meet industry standards. While this adds to the cost, it is essential for reliability and performance.

-

Logistics: Shipping costs, including freight and customs duties, play a significant role in the total cost. Buyers should consider the distance from suppliers and the complexity of the shipping process.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market demand and competition.

How Do Pricing Influencers Affect Hydraulic Rod Costs?

Several factors can influence the pricing of hydraulic rods:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often qualify for bulk pricing discounts. Establishing a long-term relationship with suppliers may also lead to better pricing structures.

-

Specifications and Customization: Unique specifications or custom designs can increase costs. Clear communication of requirements can help manage expectations and costs effectively.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like ISO) often command a premium. Buyers should weigh the cost against the performance benefits.

-

Supplier Factors: The reputation and reliability of suppliers can affect pricing. Established suppliers may charge more but offer better quality assurance and service.

-

Incoterms: Understanding Incoterms (International Commercial Terms) is crucial for cost management. They define responsibilities for shipping, insurance, and tariffs, impacting the total landed cost.

What Are Essential Buyer Tips for Sourcing Hydraulic Rods?

B2B buyers should adopt strategic approaches when sourcing hydraulic rods:

-

Negotiation: Engage suppliers in discussions about pricing, especially when placing large orders. Leverage competitive quotes to negotiate better terms.

-

Cost-Efficiency: Focus on the Total Cost of Ownership (TCO), which includes not only the purchase price but also maintenance, downtime, and operational efficiency over the product’s lifecycle.

-

Pricing Nuances for International Buyers: For buyers in regions like Africa, South America, the Middle East, and Europe, currency fluctuations and geopolitical factors can affect pricing. It’s advisable to factor in potential tariff changes and local regulations.

-

Disclaimer on Indicative Prices: Be aware that prices for hydraulic rods can fluctuate based on market conditions. Always seek updated quotes and clarify that indicative prices may change.

In conclusion, understanding the cost structure and pricing influencers is essential for making informed purchasing decisions in the hydraulic rod market. By applying these insights, B2B buyers can enhance their procurement strategies and achieve better pricing outcomes.

Alternatives Analysis: Comparing hydraulic rod With Other Solutions

Exploring Alternatives to Hydraulic Rods for Industrial Applications

When considering hydraulic rods for various industrial applications, it’s essential to evaluate alternative solutions that can deliver similar functionality and performance. By comparing hydraulic rods with alternatives such as electric actuators and pneumatic cylinders, buyers can make informed decisions tailored to their specific operational needs. Below is a comparative analysis of these options.

| Comparison Aspect | Hydraulic Rod | Electric Actuator | Pneumatic Cylinder |

|---|---|---|---|

| Performance | High force output and precision | Moderate force, precise control | Fast operation, less precision |

| Cost | Moderate initial cost | Higher upfront cost | Lower initial cost |

| Ease of Implementation | Relatively easy to install | Requires electrical setup | Simple installation |

| Maintenance | Moderate, requires seal checks | Low, minimal wear components | Moderate, requires air supply maintenance |

| Best Use Case | Heavy machinery, construction | Robotics, automation systems | Packaging, light assembly tasks |

In-Depth Analysis of Alternatives

Electric Actuators

Electric actuators utilize electrical energy to produce motion, making them an effective alternative to hydraulic rods. They offer precise control over speed and position, which is crucial in applications like robotics and automation. However, the initial investment is typically higher due to the need for electrical infrastructure. Maintenance is minimal, as they have fewer moving parts and do not rely on hydraulic fluids, making them ideal for environments where cleanliness is paramount. Nevertheless, they may not deliver the same force output as hydraulic systems, limiting their use in heavy-duty applications.

Pneumatic Cylinders

Pneumatic cylinders operate using compressed air, providing rapid movement and force generation. They are a cost-effective solution for lighter-duty applications such as packaging and assembly lines. Their installation is straightforward, often requiring less space compared to hydraulic systems. However, pneumatic cylinders may lack the precision and force stability offered by hydraulic rods, making them less suitable for tasks that require high accuracy. Maintenance involves ensuring a consistent air supply and checking for leaks, which can introduce downtime if not managed properly.

Conclusion: Making the Right Choice for Your Application

Selecting the appropriate solution for your industrial needs involves analyzing your specific application requirements, including force, precision, and operational environment. Hydraulic rods excel in heavy-duty applications, while electric actuators are suitable for precision tasks that require less force. Pneumatic cylinders offer a budget-friendly option for lighter tasks but may compromise on precision. Understanding these alternatives will empower B2B buyers to choose the right technology that aligns with their operational goals and budget constraints, ultimately enhancing productivity and efficiency in their processes.

Essential Technical Properties and Trade Terminology for hydraulic rod

What Are the Key Technical Properties of Hydraulic Rods?

When selecting hydraulic rods, understanding their technical specifications is crucial for ensuring performance and reliability in various applications. Here are some essential properties to consider:

1. Material Grade

Hydraulic rods are typically made from high-strength steel or chrome-plated steel. The material grade influences the rod’s durability and resistance to wear and corrosion. For instance, Induction Hardened Chrome Plated (IHCP) rods offer superior resistance to impact and fatigue, making them suitable for harsh environments like mining or construction. Choosing the right material grade can significantly affect the lifespan and maintenance costs of hydraulic systems.

2. Diameter and Stroke Length

The diameter of the rod directly impacts the cylinder’s force output, while the stroke length determines the range of motion. For example, a larger diameter rod can handle higher pressure but may require a larger cylinder. These dimensions should align with the specific machinery requirements to optimize performance and avoid operational inefficiencies.

3. Tolerance Levels

Tolerance refers to the permissible limit of variation in a physical dimension. High tolerance levels in hydraulic rods are essential to ensure a proper fit within the hydraulic cylinder, thereby preventing leaks and enhancing seal performance. In industries where precision is critical, such as aerospace or automotive, maintaining strict tolerance standards can prevent costly failures.

Illustrative image related to hydraulic rod

4. Surface Finish

The surface finish of a hydraulic rod affects both the performance and longevity of the component. A smooth, polished surface reduces friction between the rod and seals, minimizing wear and extending the lifespan of both parts. Hard chrome plating is commonly used for its durability and corrosion resistance, making it ideal for high-demand applications.

5. Hardness Rating

The hardness of a hydraulic rod is measured on the Rockwell scale, indicating its resistance to deformation and wear. For example, a hardness rating of Rc58-60 is typical for IHCP rods, providing an excellent balance between toughness and brittleness. Understanding hardness ratings helps buyers select the appropriate rod for specific operational conditions.

What Common Trade Terms Should B2B Buyers Know?

Familiarity with industry jargon is vital for effective communication and negotiation in the hydraulic rod market. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture components that are used in the production of another company’s end product. In the hydraulic industry, an OEM might produce hydraulic rods for equipment manufacturers. Working with OEMs can ensure compatibility and reliability in hydraulic systems.

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest number of units a supplier is willing to sell. Understanding MOQs helps buyers manage inventory costs and negotiate better terms, especially when planning for large-scale projects.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to request pricing and terms for specific products. Providing detailed specifications in an RFQ can lead to more accurate quotes and better procurement outcomes.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that define the responsibilities of buyers and sellers. They clarify who is responsible for shipping, insurance, and tariffs, which is particularly important for international buyers to avoid unexpected costs.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the goods. Understanding lead times is essential for project planning and inventory management, especially in industries with tight deadlines.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions that enhance operational efficiency and minimize costs in their hydraulic systems.

Navigating Market Dynamics and Sourcing Trends in the hydraulic rod Sector

What Are the Current Market Dynamics and Key Trends in the Hydraulic Rod Sector?

The hydraulic rod sector is experiencing significant transformation, driven by several global factors. One of the primary drivers is the increasing demand for hydraulic systems across various industries, such as construction, agriculture, and manufacturing. As urbanization accelerates, particularly in regions like Africa and South America, the need for efficient and reliable machinery is paramount. Additionally, advancements in hydraulic technology are leading to the development of more compact, durable, and efficient hydraulic rods, enhancing overall system performance.

Illustrative image related to hydraulic rod

Emerging B2B technologies, including IoT integration and predictive maintenance, are shaping sourcing trends. Buyers are increasingly looking for suppliers who can offer smart hydraulic solutions that provide real-time data on performance and wear, reducing downtime and maintenance costs. Moreover, the trend towards customization is gaining momentum, with buyers seeking tailored solutions that meet specific operational requirements.

For international B2B buyers, understanding regional market dynamics is essential. In Europe, stringent regulations around safety and environmental standards are pushing manufacturers to invest in higher-quality hydraulic rods. Conversely, in the Middle East and Africa, while cost remains a significant factor, there is a growing recognition of the value of quality and durability in hydraulic components, especially in harsh operating environments. Buyers are advised to keep abreast of these shifts to ensure they source the most suitable products for their needs.

How Does Sustainability Impact Sourcing in the Hydraulic Rod Sector?

Sustainability has become a critical consideration in the hydraulic rod sector. The environmental impact of manufacturing processes, including resource extraction and waste generation, is under increasing scrutiny. B2B buyers are now prioritizing suppliers who adopt sustainable practices, such as reducing energy consumption and minimizing waste during production.

Illustrative image related to hydraulic rod

Ethical sourcing is equally important, as buyers seek to ensure that their supply chains are free from exploitation and environmentally harmful practices. This includes verifying that raw materials are sourced responsibly and that manufacturers comply with ethical labor standards. The demand for ‘green’ certifications is on the rise, with buyers looking for products made from recycled materials or those that have a lower carbon footprint.

Furthermore, companies that embrace sustainability often enjoy enhanced brand reputation and customer loyalty, which can translate into competitive advantages. Therefore, B2B buyers should consider not only the immediate costs but also the long-term benefits of partnering with environmentally responsible suppliers in the hydraulic rod sector.

What is the Evolution of Hydraulic Rod Technology?

The evolution of hydraulic rod technology has been remarkable, evolving from basic mechanical components to sophisticated, engineered solutions that enhance performance and reliability. Initially, hydraulic rods were primarily made from carbon steel, limiting their durability and resistance to wear. However, advancements in material science have introduced chrome-plated and induction-hardened rods that offer superior strength and corrosion resistance.

Illustrative image related to hydraulic rod

In recent years, the introduction of smart technology has further revolutionized the sector. Today, hydraulic rods can be equipped with sensors that monitor their performance and health, providing valuable data that helps prevent failures and optimize maintenance schedules. This evolution not only improves operational efficiency but also aligns with the growing trend of digital transformation across industries.

As the hydraulic rod sector continues to innovate, international B2B buyers must stay informed about these advancements to make informed purchasing decisions that meet their operational needs and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of hydraulic rod

-

How do I choose the right hydraulic rod for my machinery?

Selecting the right hydraulic rod involves considering several factors including the rod’s diameter, material type, stroke length, and operating pressure. Assess the specific application and environmental conditions where the rod will be used. For instance, if your machinery operates in harsh environments, opt for induction hardened chrome plated rods for enhanced durability. Additionally, consult with your suppliers about compatibility with existing hydraulic systems to ensure optimal performance. -

What are the advantages of using chrome-plated hydraulic rods?

Chrome-plated hydraulic rods offer superior resistance to corrosion, wear, and pitting, which are crucial for maintaining seal integrity and preventing fluid leaks. The smooth surface of chrome plating enhances lubrication, thereby reducing friction and prolonging the rod’s lifespan. These rods are particularly beneficial in applications where reliability is critical, such as in heavy machinery or hydraulic systems exposed to the elements. -

What should I consider when vetting suppliers for hydraulic rods?

When vetting suppliers, focus on their industry experience, product quality certifications, and customer service reputation. Evaluate their manufacturing processes, particularly the materials used and quality control measures in place. Request references or case studies from previous clients, especially those in similar industries or geographical regions. Additionally, assess their logistical capabilities to ensure timely delivery and support for your operations. -

Can I customize hydraulic rods to fit specific applications?

Yes, many suppliers offer customization options for hydraulic rods, including variations in size, stroke length, and material. Customization can optimize performance for specific applications, such as those requiring specific resistance to environmental factors or unique operational pressures. Be prepared to discuss your requirements in detail, including any testing or certifications needed for compliance in your region. -

What is the minimum order quantity (MOQ) for hydraulic rods?

The MOQ for hydraulic rods varies by supplier and often depends on the type of rod and customization options. Typically, suppliers may set MOQs to ensure production efficiency and cost-effectiveness. When sourcing, communicate your needs clearly to negotiate MOQs that align with your project requirements. Some suppliers might offer flexibility for smaller orders, particularly if they seek to build long-term relationships. -

What payment terms are commonly offered for international purchases of hydraulic rods?

Payment terms can vary widely among suppliers, but common options include advance payment, letters of credit, or payment upon delivery. For international transactions, consider using secure payment methods that offer buyer protection. Discuss payment terms upfront to avoid misunderstandings, and ensure they align with your financial capabilities and project timelines. -

How do I ensure the quality of hydraulic rods before purchase?

To ensure quality, request detailed specifications and certifications from suppliers, including material composition and manufacturing processes. Ask for samples or conduct a site visit if feasible. Additionally, inquire about warranty policies and after-sales support, as these can indicate the supplier’s confidence in their product quality. Quality assurance processes, such as third-party testing, can also provide additional assurance. -

What logistics considerations should I keep in mind when importing hydraulic rods?

When importing hydraulic rods, consider shipping methods, customs regulations, and potential tariffs or taxes that may apply. Work with suppliers who have experience in international shipping to navigate logistics smoothly. Ensure that all necessary documentation, such as invoices and certificates of origin, is in order to avoid delays at customs. Additionally, factor in lead times for production and delivery to align with your project schedules.

Top 8 Hydraulic Rod Manufacturers & Suppliers List

1. Magister Hydraulics – Hydraulic Cylinders

Domain: magisterhyd.com

Registered: 2014 (11 years)

Introduction: Hydraulic Cylinders – 1″ Rod | Magister Hydraulics Shop includes various types such as AG Clevis, Clevis End, Cross Tube, Dump Trailer, Loader, Log Splitter, Pin Eye, Snow Plow, Swivel Ball, Swivel Eye, Tang, Tie Rod, Universal, Rephasing, Stroke Control, and Top link cylinders. Key specifications include: Bore sizes of 1.5 in and 1.75 in, Stroke lengths ranging from 4 in to 58.25 in, Action type …

2. Hydraulic Supply – Hydraulic Cylinders

Domain: hydraulic-supply.com

Registered: 1997 (28 years)

Introduction: Hydraulic Cylinders – Explore our extensive range of hydraulic cylinders, engineered to deliver unmatched performance across various applications.

3. Bailey Hydraulics – Tie-Rod Hydraulic Cylinders

Domain: baileyhydraulics.com

Registered: 2013 (12 years)

Introduction: Tie-rod hydraulic cylinders are designed for light to medium duty applications and can be repaired or re-packed if necessary. Key specifications include: Bore sizes ranging from 2 in to 5 in, Stroke lengths from 4 in to 36 in, PSI ratings of 2500 to 3000, and various pin and rod diameters. The products are backed by 45 years of Bailey expertise and offer free ground shipping on qualified orders ov…

4. CRCONLINE – Tie Rod for Hydraulic Cylinder

Domain: crconline.com

Registered: 2000 (25 years)

Introduction: Tie Rod for Hydraulic Cylinder – 1144 Carbon Steel

5. Danfoss – Tie-Rod Hydraulic Cylinders

Domain: danfoss.com

Registered: 1995 (30 years)

Introduction: Tie-rod hydraulic cylinders by Danfoss improve performance and safety in hydraulic systems. They are available in ISO metric and NFPA standards with a wide range of bore and stroke sizes. Key features include:

– Easy installation and maintenance

– Durability and long life with high strength steel heads, caps, and tubing

– Dependable and reliable operation

– Easy interchangeability with interch…

6. Grainger – Tie-Rod Hydraulic Cylinders

Domain: grainger.com

Registered: 1994 (31 years)

Introduction: This company, Grainger – Tie-Rod Hydraulic Cylinders, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

7. Rugged Made – Tie Rod Cylinder 4 Bore

Domain: ruggedmade.com

Registered: 2012 (13 years)

Introduction: {“Cylinder Type”:”Tie Rod”,”Bore Diameter”:”4 inch”,”Stroke Length”:”24 inch”,”Rod Diameter”:”1.5 inch”,”Max Working Pressure”:”2500 PSI”,”Work Ports”:”1/2 inch NPT”,”Clevis Pin Diameter”:”1 inch”,”Retracted Length”:”34.25 inch (pin to pin)”,”Extended Length”:”58.25 inch (pin to pin)”,”Cylinder Length”:”36.33 inch (retracted, edge to edge)”,”Column Load”:”31445 lbs”,”Product Weight”:”70.20 lbs”,”B…

8. Northlake Steel – Hydraulic Cylinder Rods & Chrome Plated Bars

Domain: northlakesteel.com

Registered: 2001 (24 years)

Introduction: Hydraulic Cylinder Rod and Chrome Plated Bar from Northlake Steel.

– Types: Chrome Plated (CPO) and Induction Hardened + Chrome Plated (IH-CP)

– Diameter: CPO up to 16″ Rd (Imperial and metric sizes), IH-CP up to 12″ Rd (Imperial and metric sizes)

– Length: Standard lengths up to 45′ long, longer lengths available upon request

– Grades: Typical grades include 1045, 1050, 10V45, 4140HT, 4150HT,…

Strategic Sourcing Conclusion and Outlook for hydraulic rod

In conclusion, effective strategic sourcing of hydraulic rods is essential for optimizing operational efficiency and reducing long-term costs in various industries. By prioritizing quality, durability, and compatibility with existing machinery, international B2B buyers can ensure that they procure the best solutions tailored to their specific needs. It’s crucial to assess the materials used, such as induction-hardened chrome plating versus standard chrome, to avoid common pitfalls like seal damage and leakage.

Furthermore, maintaining a strong supplier relationship can lead to better pricing, timely delivery, and access to advanced technologies that enhance performance. As markets in Africa, South America, the Middle East, and Europe continue to evolve, aligning with reliable manufacturers and distributors will be key to staying competitive.

Looking ahead, now is the time for businesses to invest in robust hydraulic rod solutions that not only meet current demands but also anticipate future growth. By leveraging strategic sourcing practices, buyers can position themselves for success in an increasingly global market. Take the next step in your procurement strategy—evaluate your current suppliers and consider exploring new partnerships that align with your long-term goals.

Illustrative image related to hydraulic rod

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.