How to Source Hydraulic Piston Arm Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for hydraulic piston arm

Navigating the complexities of sourcing hydraulic piston arms can be a daunting challenge for international B2B buyers, particularly in emerging markets such as Africa, South America, the Middle East, and Europe. Understanding the diverse types of hydraulic piston arms, their applications, and the specifications that best suit your industry needs is crucial for making informed purchasing decisions. This guide serves as a comprehensive resource, delving into the various types of hydraulic cylinders available—ranging from single-acting to double-acting designs—while also highlighting their applications in sectors like construction, agriculture, and manufacturing.

In addition to providing a detailed overview of product specifications, this guide emphasizes the importance of supplier vetting to ensure quality and compliance with international standards. Buyers will find actionable insights on evaluating suppliers based on factors such as certifications, warranty offerings, and customer service. Furthermore, we address cost considerations, helping businesses understand pricing structures and potential return on investment.

By empowering international B2B buyers with critical knowledge and practical tools, this guide aims to streamline the sourcing process for hydraulic piston arms. Whether you are operating in Saudi Arabia, Vietnam, or elsewhere, our insights will equip you to navigate the global market with confidence, ensuring that your operations are supported by reliable and efficient hydraulic solutions.

Understanding hydraulic piston arm Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Single-Acting Hydraulic Cylinder | Operates in one direction; uses hydraulic pressure to extend only | Agriculture, Material Handling | Pros: Simple design, cost-effective. Cons: Limited functionality, cannot retract without external force. |

| Double-Acting Hydraulic Cylinder | Can extend and retract using hydraulic pressure in both directions | Construction, Manufacturing | Pros: Versatile, allows for more complex operations. Cons: Higher complexity and cost compared to single-acting cylinders. |

| Telescopic Hydraulic Cylinder | Multiple stages allow for extended stroke length in a compact form | Dump trucks, Lifting Equipment | Pros: Space-efficient, can achieve long strokes. Cons: More prone to wear and tear due to multiple moving parts. |

| Clevis End Hydraulic Cylinder | Features clevis ends for easy attachment and alignment | Agricultural Equipment, Loaders | Pros: Easy installation, robust design. Cons: Limited applications outside specific machinery. |

| Custom Hydraulic Cylinder | Tailored to specific requirements, including size and performance | Specialized Industrial Applications | Pros: Fully customizable, meets unique operational needs. Cons: Higher lead times and minimum order quantities. |

What are the Characteristics of Single-Acting Hydraulic Cylinders?

Single-acting hydraulic cylinders are characterized by their ability to operate in one direction, relying on hydraulic pressure to extend while using gravity or external force to retract. These cylinders are commonly used in applications such as agricultural machinery and material handling equipment. When considering a purchase, B2B buyers should evaluate the bore and rod diameter, as well as the required stroke length, to ensure compatibility with their existing equipment.

How Do Double-Acting Hydraulic Cylinders Work?

Double-acting hydraulic cylinders are designed to operate in both directions, allowing them to extend and retract through hydraulic pressure. This versatility makes them ideal for construction and manufacturing applications, where complex movement and control are necessary. Buyers should focus on the cylinder’s pressure rating and stroke length, as well as installation requirements, to ensure optimal performance in their specific applications.

What Makes Telescopic Hydraulic Cylinders Unique?

Telescopic hydraulic cylinders feature multiple stages, allowing them to achieve long strokes while maintaining a compact size. This design is particularly beneficial in applications like dump trucks and lifting equipment, where space is limited. When purchasing, B2B buyers should consider the maximum load capacity and the number of stages, as these factors will influence the cylinder’s performance and durability.

Why Choose Clevis End Hydraulic Cylinders?

Clevis end hydraulic cylinders are distinguished by their clevis fittings, which facilitate easy attachment and alignment to machinery. Commonly found in agricultural equipment and loaders, these cylinders are known for their robust construction and ease of installation. Buyers should assess the compatibility of clevis fittings with their existing machinery, as well as the cylinder’s stroke length and pressure ratings.

How Can Custom Hydraulic Cylinders Benefit Specific Industries?

Custom hydraulic cylinders are engineered to meet specific operational requirements, making them ideal for specialized industrial applications. These cylinders can be tailored in terms of size, pressure ratings, and design features to fit unique machinery needs. B2B buyers should be aware of the higher lead times and minimum order quantities associated with custom solutions, as these factors can impact project timelines and budgets.

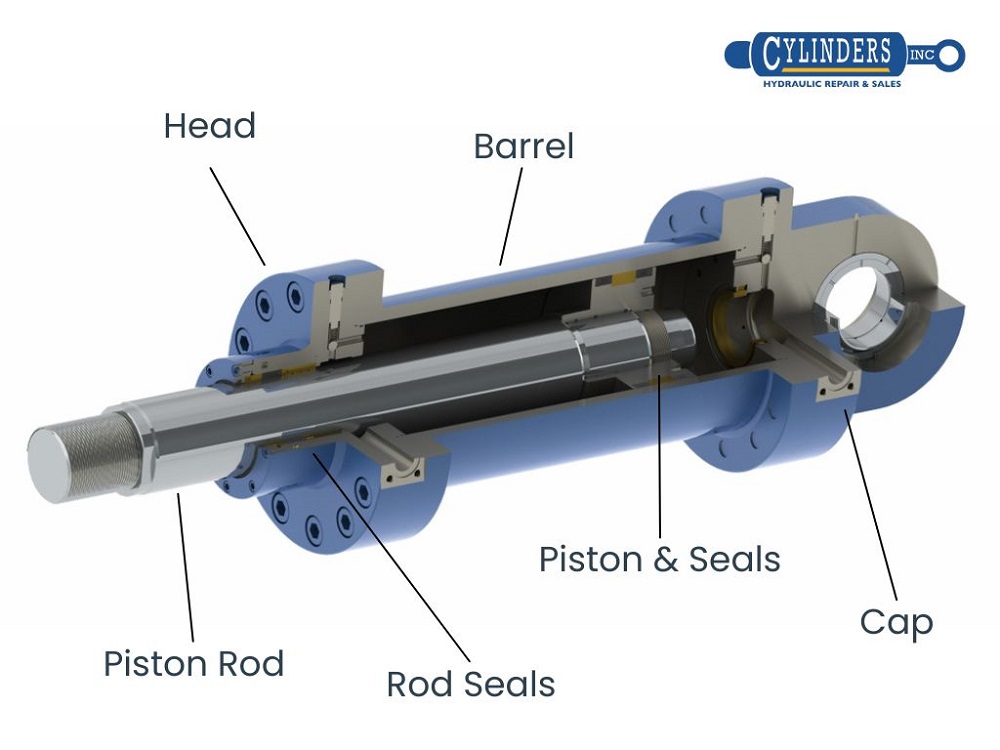

Illustrative image related to hydraulic piston arm

Key Industrial Applications of hydraulic piston arm

| Industry/Sector | Specific Application of Hydraulic Piston Arm | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Excavators and Loaders | Enhances efficiency and productivity in heavy lifting tasks | Ensure compatibility with existing machinery; consider load ratings and stroke lengths. |

| Agriculture | Tractors and Harvesters | Increases operational efficiency and reduces manual labor needs | Look for durability and resistance to harsh environments; evaluate bore and rod diameter options. |

| Manufacturing | Automated Assembly Lines | Streamlines production processes and improves precision | Assess the need for custom hydraulic cylinders based on specific machinery requirements. |

| Material Handling | Forklifts and Pallet Jacks | Improves load handling capabilities and reduces downtime | Evaluate size specifications and pressure ratings for optimal performance. |

| Waste Management | Compactors and Dumpsters | Enhances waste processing efficiency and reduces operational costs | Consider cylinder design for compact space; ensure reliable sealing for longevity. |

How is Hydraulic Piston Arm Used in Construction Equipment?

In the construction industry, hydraulic piston arms are integral to excavators and loaders, providing the necessary force for lifting and moving heavy materials. These hydraulic systems allow for precise control over movement, enabling operators to perform complex tasks with ease. For international buyers, particularly in regions like the Middle East and Africa, sourcing durable and efficient hydraulic cylinders that can withstand extreme working conditions is crucial. Key considerations include ensuring compatibility with existing equipment and understanding local standards for hydraulic performance.

What Role Does Hydraulic Piston Arm Play in Agriculture?

In agriculture, hydraulic piston arms are vital for tractors and harvesters, facilitating various tasks such as plowing, lifting, and transporting crops. The ability to automate these functions significantly reduces labor costs and increases productivity. Buyers from South America and Africa should focus on sourcing cylinders designed for agricultural applications, considering factors like resistance to environmental stressors and ease of maintenance. Customization options may be necessary to meet specific agricultural machinery requirements.

How is Hydraulic Piston Arm Essential in Manufacturing?

In manufacturing, hydraulic piston arms are utilized in automated assembly lines to enhance precision and efficiency. They enable machines to perform repetitive tasks with high accuracy, thereby increasing throughput and reducing errors. B2B buyers in Europe should look for cylinders that meet stringent quality standards, such as ISO certifications. Custom hydraulic solutions might be required to fit unique production line configurations, making supplier flexibility a key consideration.

Why is Hydraulic Piston Arm Important for Material Handling?

Material handling equipment like forklifts and pallet jacks relies on hydraulic piston arms for effective load management. These systems improve the speed and safety of moving goods, which is vital in warehouses and distribution centers. International buyers should prioritize sourcing hydraulic cylinders that offer robust performance under varying loads and conditions. It is essential to assess the specifications, including bore size and pressure ratings, to ensure optimal compatibility with handling equipment.

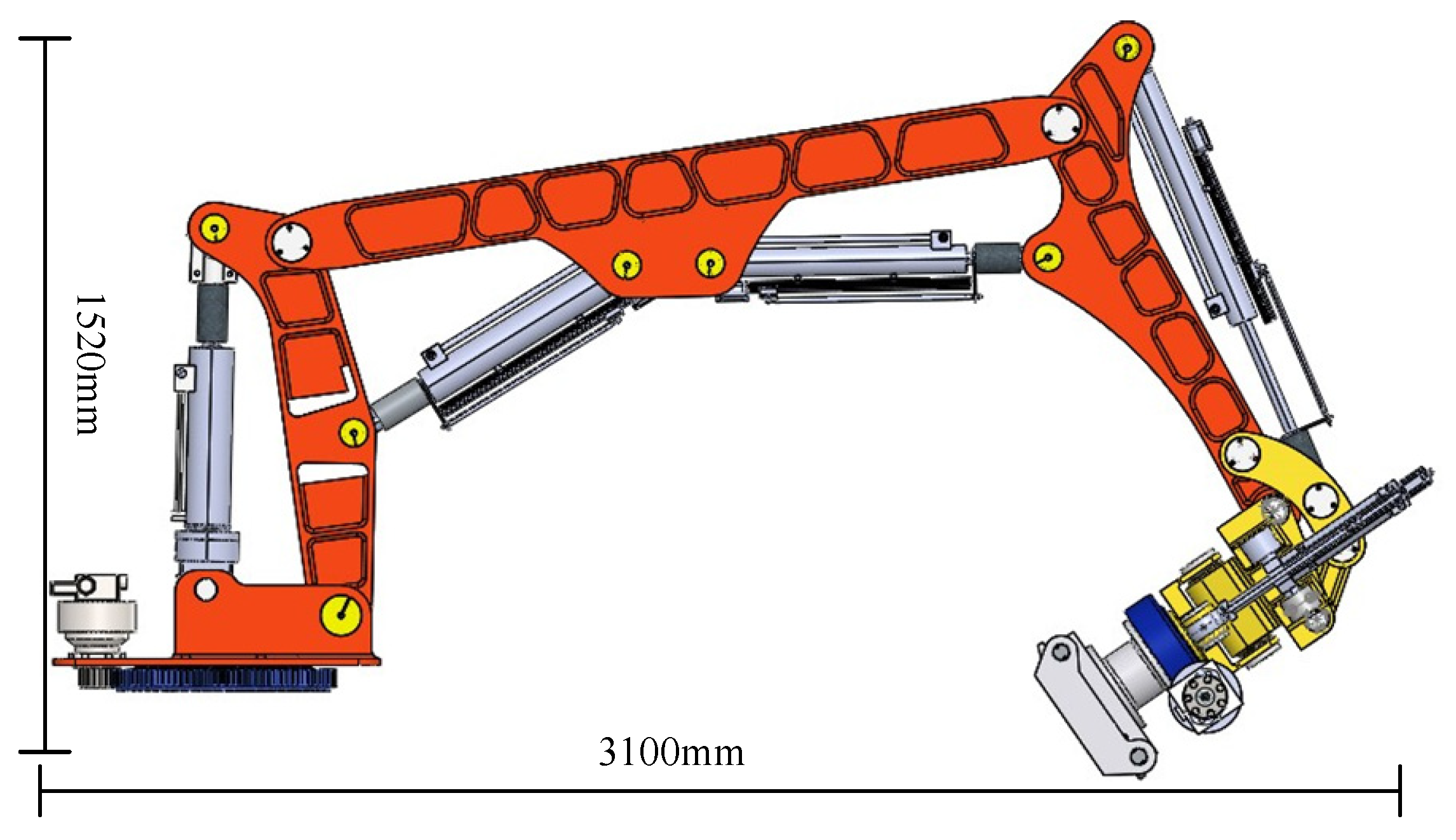

Illustrative image related to hydraulic piston arm

How is Hydraulic Piston Arm Utilized in Waste Management?

In the waste management sector, hydraulic piston arms are used in compactors and dumpsters to efficiently compress waste materials. This application not only enhances processing efficiency but also reduces the frequency of waste collection, leading to cost savings. Buyers from regions with growing urban waste management needs, such as the Middle East, should consider sourcing hydraulic cylinders that are designed for compact spaces and ensure high reliability. Understanding the specific design requirements and pressure ratings will be critical in selecting the right products for these applications.

3 Common User Pain Points for ‘hydraulic piston arm’ & Their Solutions

Scenario 1: Inconsistent Performance in Heavy-Duty Applications

The Problem: B2B buyers in sectors such as construction or agriculture often face challenges with hydraulic piston arms that fail to deliver consistent performance under heavy loads. This inconsistency can lead to equipment malfunction, project delays, and ultimately increased operational costs. Buyers may be frustrated when they invest in high-quality hydraulic components, only to find that the pistons cannot withstand the demands of their specific applications, leading to unexpected downtime and maintenance expenses.

The Solution: To mitigate this issue, it is crucial for buyers to thoroughly assess the specifications of hydraulic piston arms before making a purchase. Understanding the load capacity, stroke length, and material quality is essential. Buyers should consider selecting double-acting cylinders designed for heavy-duty applications, as these provide superior force in both directions, enhancing efficiency and reliability. Additionally, consulting with manufacturers about the intended application can lead to tailored solutions that match specific operational requirements. Regular maintenance checks and using hydraulic fluids suited for the operational environment can also prolong the life of the piston arms and ensure consistent performance.

Scenario 2: Difficulty in Sourcing Compatible Hydraulic Piston Arms

The Problem: International buyers often struggle to find hydraulic piston arms that are compatible with existing machinery, particularly when importing equipment from different regions. This issue is exacerbated by varying standards and specifications across manufacturers, which can lead to confusion and costly errors. Buyers may find themselves dealing with components that do not fit or operate effectively, resulting in wasted time and resources.

The Solution: To address sourcing challenges, buyers should prioritize working with reputable suppliers who offer detailed product specifications and compatibility information. Utilizing a standardized measurement system can help streamline the selection process. It is advisable to maintain open communication with suppliers, providing them with precise details about existing machinery, including model numbers and required specifications. Additionally, considering custom hydraulic piston arms can be beneficial. Many manufacturers offer bespoke solutions that ensure compatibility with specific applications, although buyers should be mindful of minimum order quantities and lead times.

Scenario 3: High Maintenance Costs Due to Wear and Tear

The Problem: Frequent wear and tear on hydraulic piston arms can lead to increased maintenance costs, which is a major pain point for B2B buyers. Over time, seals may degrade, rods may bend, and cylinders may develop leaks, resulting in the need for costly repairs or replacements. This situation is particularly pressing in industries like mining or construction, where hydraulic systems are subjected to harsh conditions and continuous operation.

The Solution: To reduce maintenance costs, buyers should invest in high-quality hydraulic piston arms made from durable materials that are resistant to wear and environmental factors. Selecting components with superior sealing technologies can significantly extend the lifespan of hydraulic systems. It is also advisable to implement a proactive maintenance schedule that includes regular inspections and timely replacements of worn components. Training personnel on proper usage and maintenance practices can further minimize wear and tear. Finally, buyers should consider investing in hydraulic fluid monitoring systems that can alert them to potential issues before they escalate into costly repairs.

Strategic Material Selection Guide for hydraulic piston arm

When selecting materials for hydraulic piston arms, it is crucial to consider various factors that influence performance, durability, and cost. Here, we will analyze four common materials used in hydraulic piston arms: carbon steel, stainless steel, aluminum, and composite materials. Each material has unique properties, advantages, and limitations that can significantly impact its application in different industries.

What are the Key Properties of Carbon Steel for Hydraulic Piston Arms?

Carbon steel is widely used in hydraulic piston arms due to its excellent strength and durability. It typically has a high tensile strength, making it suitable for high-pressure applications. Carbon steel can withstand temperatures up to 300°C (572°F) and pressures exceeding 2500 PSI, depending on the specific grade. Its corrosion resistance is moderate, often requiring additional coatings or treatments to enhance durability in harsh environments.

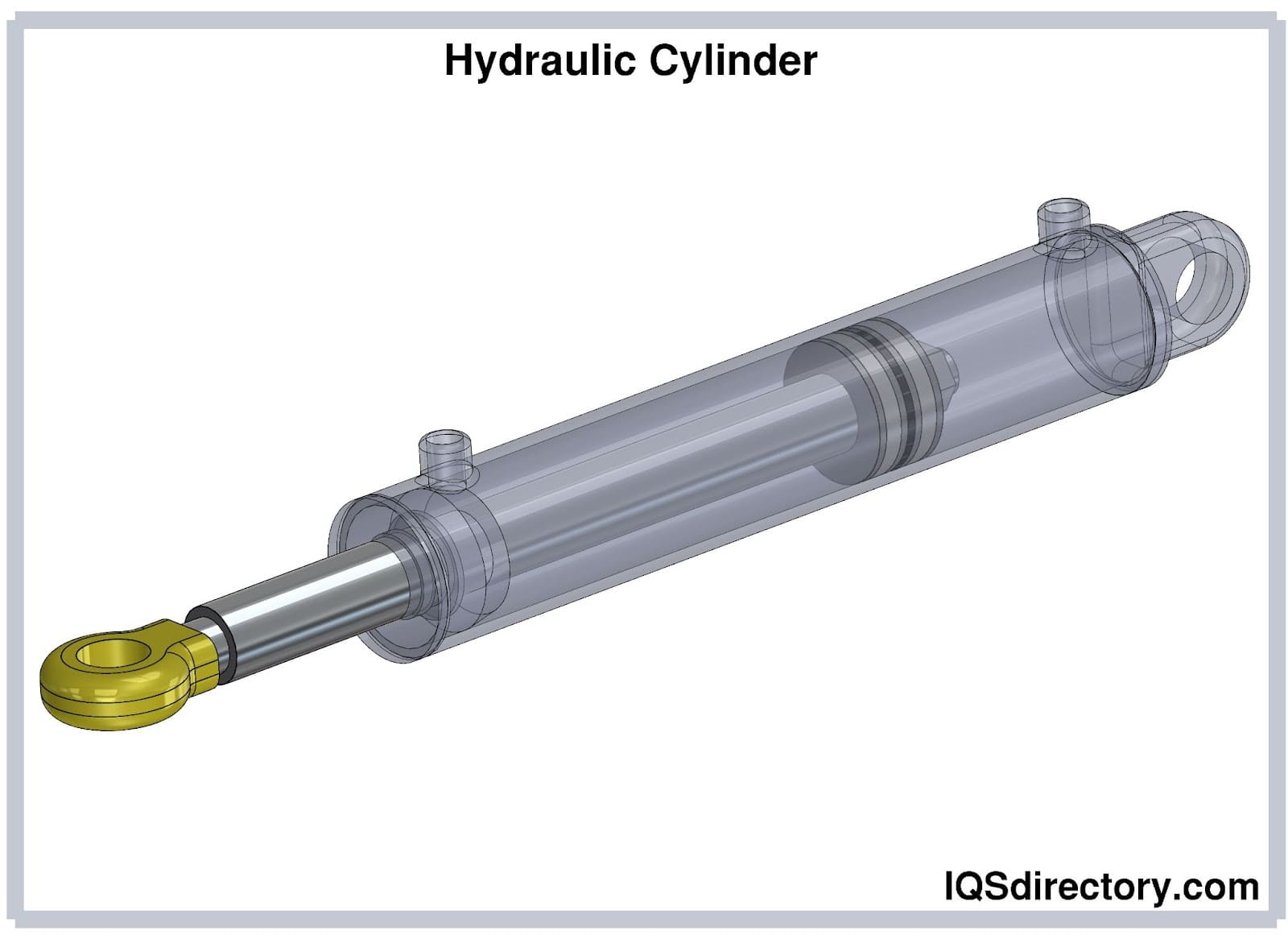

Illustrative image related to hydraulic piston arm

Pros and Cons: Carbon steel is relatively inexpensive and easy to machine, making it a cost-effective choice for many applications. However, its susceptibility to corrosion can be a significant drawback, especially in humid or chemically aggressive environments. This necessitates protective coatings, which can increase manufacturing complexity and costs.

Impact on Application: Carbon steel is compatible with various hydraulic fluids, but its performance may degrade in the presence of corrosive media. Buyers in regions with high humidity or saline environments, such as coastal areas in Africa or the Middle East, should consider this factor.

How Does Stainless Steel Compare for Hydraulic Piston Arms?

Stainless steel, particularly grades like 304 and 316, is renowned for its corrosion resistance and strength. It can withstand temperatures up to 800°C (1472°F) and is suitable for high-pressure applications. Its resistance to oxidation and corrosion makes it ideal for environments where exposure to moisture or chemicals is a concern.

Pros and Cons: The primary advantage of stainless steel is its longevity and reduced maintenance needs, which can lead to lower lifecycle costs. However, it is more expensive than carbon steel and can be more challenging to machine, increasing manufacturing complexity.

Impact on Application: Stainless steel is compatible with a wide range of hydraulic fluids and is often preferred in food processing, pharmaceuticals, and marine applications. Buyers from regions with stringent health and safety regulations, such as Europe, will find stainless steel an attractive option.

What are the Benefits of Using Aluminum for Hydraulic Piston Arms?

Aluminum is lightweight and has excellent corrosion resistance, making it an attractive option for hydraulic piston arms in applications where weight is a critical factor. It can handle temperatures up to 150°C (302°F) and pressures around 1500 PSI. Aluminum’s natural oxide layer provides a degree of corrosion resistance, but it may require additional coatings for enhanced durability.

Pros and Cons: The lightweight nature of aluminum allows for easier handling and installation, which can reduce labor costs. However, its lower strength compared to steel means it may not be suitable for high-load applications. Additionally, aluminum can be more expensive than carbon steel.

Impact on Application: Aluminum is compatible with various hydraulic fluids, but its lower pressure rating limits its use in heavy-duty applications. Buyers from industries focused on lightweight machinery, such as aerospace or automotive sectors in South America, may prefer aluminum for its performance benefits.

How Do Composite Materials Perform in Hydraulic Piston Arms?

Composite materials, such as carbon fiber reinforced polymers, are gaining traction in hydraulic piston arm applications due to their high strength-to-weight ratio and excellent corrosion resistance. Composites can operate effectively at temperatures up to 200°C (392°F) and pressures varying significantly based on the specific formulation.

Pros and Cons: The major advantage of composites is their lightweight nature combined with high strength, which can enhance overall system efficiency. However, they are often more expensive than traditional metals and may require specialized manufacturing processes, complicating production.

Impact on Application: Composites are suitable for hydraulic systems exposed to corrosive environments and can be tailored for specific media compatibility. Buyers in innovative sectors or those seeking to reduce weight in hydraulic systems, such as in the Middle East’s growing renewable energy sector, may find composites particularly beneficial.

| Material | Typical Use Case for hydraulic piston arm | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General industrial applications | Cost-effective and strong | Susceptible to corrosion | Low |

| Stainless Steel | Food processing, pharmaceuticals | Excellent corrosion resistance | Higher cost and machining complexity | High |

| Aluminum | Aerospace, automotive applications | Lightweight and easy to handle | Lower strength under high loads | Medium |

| Composite | High-tech industries, renewable energy | High strength-to-weight ratio | Expensive and complex to manufacture | High |

In conclusion, the selection of materials for hydraulic piston arms should align with the specific requirements of the application, considering factors such as environmental conditions, performance expectations, and budget constraints. International buyers should also be mindful of compliance with local standards and regulations when making material choices.

In-depth Look: Manufacturing Processes and Quality Assurance for hydraulic piston arm

What Are the Main Stages in the Manufacturing Process of Hydraulic Piston Arms?

The manufacturing process of hydraulic piston arms is a multi-stage operation that ensures precision, performance, and reliability. This process typically includes four main stages: material preparation, forming, assembly, and finishing.

Illustrative image related to hydraulic piston arm

-

Material Preparation: The process begins with sourcing high-quality raw materials such as steel or aluminum, known for their strength and durability. These materials undergo rigorous inspection to confirm they meet specified mechanical and chemical properties. This step is crucial as the quality of the raw materials directly influences the performance of the hydraulic piston arm.

-

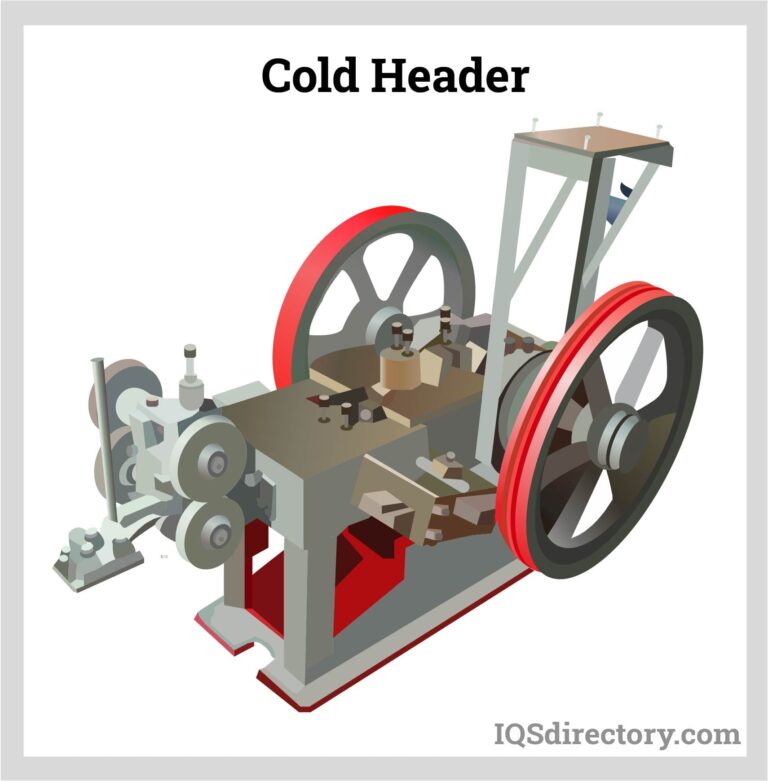

Forming: In this stage, the prepared materials are shaped into the desired components using various techniques, such as machining, forging, and casting. Machining involves removing excess material to achieve precise dimensions, while forging enhances the material’s strength through deformation. Advanced technologies, such as CNC (Computer Numerical Control) machining, are often employed to ensure high accuracy and repeatability in forming components.

-

Assembly: Once individual components are formed, they are assembled into the hydraulic piston arm. This stage may include welding, bolting, or other fastening methods to ensure structural integrity. It is essential that assembly is performed in a controlled environment to minimize contamination and defects. The assembly process is often accompanied by rigorous inspections to ensure that all parts fit together seamlessly.

-

Finishing: The final stage focuses on surface treatments and coatings to enhance the hydraulic piston arm’s performance and longevity. Techniques such as anodizing, painting, or applying anti-corrosion coatings are commonly used. These finishes not only improve aesthetics but also protect against wear and environmental factors, ensuring the hydraulic piston arm can withstand harsh operating conditions.

How Is Quality Assurance Implemented in Hydraulic Piston Arm Manufacturing?

Quality assurance (QA) is vital in the production of hydraulic piston arms to ensure they meet international and industry-specific standards. A robust QA process typically includes several checkpoints and methodologies.

-

Relevant International Standards: Compliance with standards such as ISO 9001:2015 is crucial for manufacturers aiming to ensure consistent quality. This certification indicates that a company has established a quality management system that meets global standards. Additionally, industry-specific certifications like CE (Conformité Européenne) for European markets and API (American Petroleum Institute) for oil and gas applications further validate the manufacturer’s adherence to quality norms.

-

Quality Control Checkpoints: Effective QA processes include several checkpoints throughout the manufacturing cycle:

– Incoming Quality Control (IQC): This initial inspection focuses on raw materials and components before they enter the production line. Ensuring that materials meet specifications helps prevent defects downstream.

– In-Process Quality Control (IPQC): During the manufacturing stages, continuous monitoring occurs to identify any deviations from quality standards. This proactive approach allows for immediate corrective actions, reducing waste and rework.

– Final Quality Control (FQC): At the end of the production process, the finished hydraulic piston arms undergo comprehensive testing to verify their performance and safety. This may involve pressure testing, dimensional checks, and functional testing. -

Common Testing Methods: Various testing methods are employed to validate the quality and functionality of hydraulic piston arms. These include:

– Hydraulic Testing: Assessing the arm’s ability to withstand operational pressures without leaking or failing.

– Dimensional Inspection: Using precision tools to measure critical dimensions, ensuring they meet specifications.

– Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or magnetic particle inspection help identify internal flaws without damaging the component.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from diverse regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to ensure reliable sourcing.

-

Supplier Audits: Conducting audits of potential suppliers can provide valuable insights into their manufacturing processes and quality assurance practices. An audit typically reviews compliance with international standards, production capabilities, and overall quality management systems.

-

Quality Assurance Reports: Requesting quality assurance reports from suppliers can help buyers understand the level of control exercised throughout the manufacturing process. These reports often detail testing methods, results, and corrective actions taken for any identified issues.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s quality control measures. These inspections can occur at various stages of production, providing transparency and confidence in the supplier’s capabilities.

-

Certification Verification: Buyers should verify the authenticity of certifications claimed by suppliers. This can typically be done through the issuing bodies, ensuring that the supplier is indeed compliant with the relevant standards.

What Are the Quality Control Nuances for International Buyers?

International B2B buyers face unique challenges in ensuring quality control due to varying regulations and standards across regions. Here are some nuances to consider:

Illustrative image related to hydraulic piston arm

-

Regulatory Compliance: Buyers should be aware of the specific regulations and standards applicable in their region. For example, products sold in Europe must comply with CE marking requirements, while those in the Middle East may need to adhere to local standards. Understanding these regulations is crucial for successful market entry.

-

Cultural and Communication Differences: Navigating cultural differences can impact quality assurance practices. Establishing clear communication channels and expectations can help mitigate misunderstandings and ensure that quality standards are met consistently.

-

Shipping and Logistics: The transportation of hydraulic piston arms can pose risks to their integrity. Buyers should work with suppliers to ensure that appropriate packaging and handling procedures are in place to prevent damage during transit.

-

After-Sales Support: Quality assurance does not end with the delivery of the hydraulic piston arms. Buyers should consider the supplier’s after-sales support, including warranty policies and responsiveness to issues. A reliable supplier will provide ongoing support, ensuring that any quality concerns are promptly addressed.

By understanding these manufacturing processes and quality assurance practices, B2B buyers can make informed decisions when sourcing hydraulic piston arms, ensuring they invest in products that meet their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hydraulic piston arm’

In today’s global marketplace, sourcing hydraulic piston arms requires a systematic approach to ensure you acquire the right components for your applications. This checklist serves as a practical guide for international B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Understanding your specific needs is crucial before initiating the sourcing process. Determine the bore diameter, rod diameter, stroke length, and pressure requirements of the hydraulic piston arm. This clarity will help you communicate effectively with suppliers and ensure that the products meet your operational demands.

Step 2: Research and Identify Potential Suppliers

Start by compiling a list of reputable suppliers who specialize in hydraulic piston arms. Look for manufacturers with a strong track record, especially those certified under ISO 9001:2015 or equivalent standards. Utilize online platforms, industry directories, and trade shows to find suppliers that cater to your geographical region.

Illustrative image related to hydraulic piston arm

Step 3: Evaluate Supplier Certifications

Supplier certifications are indicative of quality and reliability. Ensure that your chosen suppliers have necessary certifications and comply with international industry standards. This step helps mitigate risks related to product performance and safety, which are vital for maintaining operational integrity.

Step 4: Request Detailed Product Information

Engage with potential suppliers to obtain detailed specifications of their hydraulic piston arms. This includes materials used, design features, and performance metrics. Understanding these aspects will allow you to compare options accurately and choose a product that aligns with your operational needs.

Step 5: Assess Customization Options

Every business has unique requirements, and many suppliers offer customization for hydraulic piston arms. Inquire about the possibility of tailoring features such as mounting ends, stroke lengths, and materials. Custom solutions can enhance compatibility with your equipment and optimize performance.

Illustrative image related to hydraulic piston arm

Step 6: Check References and Reviews

Before finalizing your supplier, conduct due diligence by checking references and customer reviews. Reach out to other businesses that have sourced similar products to gauge their experiences. This step can provide insights into the supplier’s reliability, customer service, and product performance.

Step 7: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Ensure that the contract includes warranty details, especially regarding the durability and performance of the hydraulic piston arms. Clear agreements will protect your interests and establish a solid foundation for the partnership.

By following this checklist, B2B buyers can navigate the complexities of sourcing hydraulic piston arms effectively, ensuring that they make informed decisions that support their operational goals.

Comprehensive Cost and Pricing Analysis for hydraulic piston arm Sourcing

What Are the Key Cost Components in Hydraulic Piston Arm Sourcing?

When sourcing hydraulic piston arms, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of materials greatly affects the cost. High-strength steel or aluminum alloys are common, but prices can fluctuate based on market demand and supply chain conditions.

-

Labor: Manufacturing hydraulic piston arms involves skilled labor, especially in assembly and quality control processes. Labor costs can vary significantly depending on the region, affecting the overall pricing.

-

Manufacturing Overhead: This includes indirect costs such as utilities, equipment maintenance, and facility costs. Efficient operations can minimize overhead, influencing the final product price.

-

Tooling: Custom tooling for specific designs or sizes can lead to higher initial costs. However, these costs can be amortized over larger production runs.

-

Quality Control (QC): Ensuring compliance with international standards and certifications (like ISO) may incur additional costs but is critical for reliability and safety.

-

Logistics: Freight costs, customs duties, and warehousing can significantly impact total expenses, particularly for international shipments.

-

Margin: Suppliers will typically add a margin to cover their costs and generate profit. This margin can vary based on market conditions and competition.

How Do Price Influencers Impact Hydraulic Piston Arm Costs?

Several factors can influence the pricing of hydraulic piston arms:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to lower per-unit costs due to economies of scale. Suppliers may offer discounts for bulk purchases, so negotiating the MOQ can yield significant savings.

-

Specifications and Customization: Custom designs or specific performance characteristics can increase costs. Buyers should be clear about their requirements to avoid unnecessary expenditures.

-

Materials and Quality Certifications: The choice of materials and certifications impacts not just the cost but also the durability and performance of the hydraulic piston arms. Higher quality materials may lead to higher upfront costs but can offer better long-term value.

-

Supplier Factors: The supplier’s location, reputation, and production capabilities can influence pricing. Established suppliers with proven track records may command higher prices but can provide better reliability.

-

Incoterms: The terms of shipping can affect the total cost. Understanding Incoterms (like FOB or CIF) is essential for calculating landed costs and ensuring that there are no hidden charges.

What Are the Best Negotiation Strategies for International Buyers?

For B2B buyers, especially those from Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to cost savings:

-

Understand Total Cost of Ownership (TCO): Consider not just the initial purchase price but also maintenance, operational costs, and potential downtime. This holistic view can help justify a higher initial investment if it leads to lower long-term costs.

-

Leverage International Trade Agreements: Familiarize yourself with trade agreements that may reduce tariffs and duties, thus lowering overall costs.

-

Build Relationships with Suppliers: Establishing strong relationships can lead to better pricing, preferential treatment, and improved service. Trust can be a significant factor in negotiations.

-

Be Transparent About Your Needs: Clearly communicate your specifications and budget constraints. Suppliers appreciate clarity and may offer tailored solutions that fit your needs.

-

Explore Multiple Suppliers: Obtaining quotes from various suppliers can provide leverage in negotiations and help identify the best overall value.

Conclusion: What Should International Buyers Keep in Mind?

When sourcing hydraulic piston arms, understanding the comprehensive cost structure and price influencers is vital for making informed purchasing decisions. By focusing on the total cost of ownership and employing effective negotiation strategies, international buyers can maximize their investments. Always remember that indicative prices may fluctuate based on market conditions, so continuous market research is essential for securing the best deals.

Alternatives Analysis: Comparing hydraulic piston arm With Other Solutions

In the realm of industrial applications, hydraulic piston arms are widely recognized for their efficiency in generating mechanical force. However, several alternative solutions can also fulfill similar operational requirements. This analysis explores the strengths and weaknesses of hydraulic piston arms compared to other viable technologies, providing B2B buyers with essential insights to make informed decisions.

| Comparison Aspect | Hydraulic Piston Arm | Telescopic Hydraulic Cylinder | Electric Actuator |

|---|---|---|---|

| Performance | High force output; suitable for heavy-duty tasks | Excellent for compact spaces; multiple stages increase reach | Lower force output; ideal for precision tasks |

| Cost | Moderate initial investment; long-term savings on maintenance | Higher upfront costs; effective for heavy lifting | Lower initial cost; potential higher energy costs |

| Ease of Implementation | Requires hydraulic system setup; moderate complexity | Installation can be complex due to multiple stages | Simple electrical setup; easy to integrate with automation systems |

| Maintenance | Regular maintenance required; hydraulic fluid management | Similar maintenance needs; more complex due to multiple components | Low maintenance; fewer moving parts |

| Best Use Case | Construction, agriculture, and material handling | Dump trucks, loading equipment, and compacting applications | Robotics, automated assembly lines, and applications needing precise control |

What Are the Advantages and Disadvantages of Telescopic Hydraulic Cylinders?

Telescopic hydraulic cylinders are designed for applications requiring extended reach without occupying significant space. They consist of multiple stages, allowing them to extend far beyond their retracted length. The primary advantage of telescopic cylinders is their ability to deliver substantial force in confined spaces, making them ideal for equipment like dump trucks and cranes. However, they typically come with higher initial costs and require more complex installation and maintenance, potentially making them less suitable for some buyers looking for straightforward solutions.

How Do Electric Actuators Compare to Hydraulic Piston Arms?

Electric actuators serve as an alternative to hydraulic systems, particularly in applications where precision and control are paramount. They are generally easier to install and integrate into existing automation systems due to their electrical nature. The cost of electric actuators can be lower upfront, but they may incur higher operational costs due to energy consumption, especially in heavy-duty applications. While they excel in environments requiring fine movement and repeatability, their lower force output limits their effectiveness in high-load applications compared to hydraulic piston arms.

How to Choose the Right Solution for Your Needs?

When evaluating the best solution for your operational requirements, consider factors such as the specific application, required force output, available budget, and maintenance capabilities. Hydraulic piston arms excel in heavy-duty scenarios, while telescopic cylinders provide versatility in tight spaces. On the other hand, electric actuators offer ease of use and precision, making them ideal for automation.

B2B buyers should thoroughly assess their unique needs and operational conditions, weighing the pros and cons of each solution. By doing so, they can select the most appropriate technology that aligns with their business objectives, ensuring efficient and effective operations.

Essential Technical Properties and Trade Terminology for hydraulic piston arm

What Are the Key Technical Properties of Hydraulic Piston Arms?

Hydraulic piston arms are vital components in various industrial applications, and understanding their technical specifications is crucial for B2B buyers. Here are some of the critical specifications to consider:

-

Material Grade

– Hydraulic piston arms are typically constructed from high-strength steel or aluminum alloys. The choice of material affects durability, weight, and resistance to corrosion. High-grade materials ensure that the piston arm can withstand significant loads and harsh environments, making it essential for industries like construction and agriculture. -

Bore Diameter

– The bore diameter refers to the inner diameter of the cylinder where the piston moves. This specification is crucial because it directly influences the force output and the hydraulic fluid flow rate. A larger bore diameter can generate more power, making it suitable for heavy-duty applications. Buyers should match bore sizes to the requirements of their hydraulic systems to ensure optimal performance. -

Stroke Length

– Stroke length is the distance the piston travels from its fully retracted to fully extended position. It is critical for determining the range of motion in machinery. Selecting the right stroke length ensures that the hydraulic piston arm can perform its intended function without limitations, which is particularly important in applications like material handling and lifting. -

Operating Pressure

– This specification indicates the maximum pressure the hydraulic system can handle. Operating pressure is critical in determining the performance and safety of the hydraulic piston arm. Buyers must ensure that the piston arm can operate efficiently within the pressure limits of their hydraulic system to prevent failures or accidents. -

Tolerance Levels

– Tolerance levels refer to the permissible limits of variation in physical dimensions of the hydraulic components. Tight tolerances are essential for ensuring proper fit and function, especially in applications requiring high precision. Understanding these tolerances can help buyers avoid compatibility issues and ensure smooth operation. -

Weight Capacity

– This property defines the maximum load the hydraulic piston arm can handle safely. It is an essential consideration for buyers in industries like construction and logistics, where heavy lifting is common. Choosing a piston arm with an adequate weight capacity is crucial to prevent structural failures and ensure operational safety.

What Are Common Trade Terms Used in the Hydraulic Piston Industry?

Familiarity with industry terminology can streamline communication and negotiations between buyers and suppliers. Here are some essential trade terms:

Illustrative image related to hydraulic piston arm

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. Understanding whether a hydraulic piston arm is an OEM product can help buyers assess quality and compatibility with existing machinery. -

MOQ (Minimum Order Quantity)

– MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is vital for B2B buyers to plan their inventory and budget effectively, especially when dealing with custom hydraulic solutions. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers requesting pricing information and terms for specific products. Utilizing RFQs can help buyers compare offers from different suppliers, ensuring they secure the best deal for hydraulic piston arms. -

Incoterms (International Commercial Terms)

– These are standardized trade terms used in international transactions to define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding Incoterms is essential for international B2B transactions to clarify cost responsibilities and risk management. -

Lead Time

– Lead time refers to the period between placing an order and receiving the product. Knowing the lead time helps buyers plan their projects and manage schedules effectively, ensuring that hydraulic piston arms are available when needed. -

Hydraulic Fluid Compatibility

– This term pertains to the types of hydraulic fluids that can be safely used with a specific piston arm. Compatibility is critical for maintaining the efficiency and longevity of hydraulic systems. Buyers should verify that the piston arm is compatible with their existing hydraulic fluids to avoid performance issues.

Incorporating these technical properties and trade terms into the procurement process can significantly enhance decision-making for B2B buyers in the hydraulic piston arm market.

Navigating Market Dynamics and Sourcing Trends in the hydraulic piston arm Sector

What Are the Current Market Dynamics and Key Trends in the Hydraulic Piston Arm Sector?

The hydraulic piston arm sector is witnessing significant evolution due to globalization and technological advancements. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe increasingly seek robust and efficient hydraulic solutions, market demand is being driven by several key factors. Firstly, the growth in industries such as construction, agriculture, and manufacturing is propelling the need for high-performance hydraulic systems. Buyers are focusing on sourcing products that offer durability and reliability, essential for rigorous applications.

Emerging technologies like IoT and automation are reshaping sourcing strategies. Companies are now looking for suppliers who can provide smart hydraulic systems that allow for real-time monitoring and predictive maintenance. This trend is particularly relevant in markets like Saudi Arabia and Vietnam, where industrialization is rapidly advancing. Additionally, customization is becoming a priority, with buyers seeking manufacturers that can tailor hydraulic piston arms to specific operational needs, ensuring optimal performance in diverse environments.

Sourcing trends are also shifting towards suppliers that demonstrate transparency and flexibility. International buyers are increasingly scrutinizing the entire supply chain, favoring partners who can provide detailed insights into manufacturing processes and lead times. This dynamic creates opportunities for suppliers who can offer comprehensive product specifications and responsive customer service.

How Is Sustainability and Ethical Sourcing Impacting the Hydraulic Piston Arm Market?

Sustainability is no longer a secondary concern but a primary driver in the hydraulic piston arm sector. The environmental impact of manufacturing processes has prompted B2B buyers to prioritize suppliers committed to sustainable practices. This includes the use of eco-friendly materials and energy-efficient manufacturing methods. Buyers from regions with stringent environmental regulations, such as Europe, are particularly vigilant in assessing the sustainability credentials of their suppliers.

Ethical sourcing is equally important, as companies seek to ensure their supply chains are free from exploitation and harmful practices. Buyers are increasingly demanding certifications that demonstrate adherence to ethical standards, such as ISO 14001 for environmental management and ISO 9001 for quality assurance. Suppliers that can showcase these certifications not only enhance their credibility but also align with the values of socially responsible businesses.

In terms of materials, there is a growing interest in sourcing hydraulic piston arms made from recycled or sustainably sourced materials. This trend is supported by innovations in material science, allowing for the development of high-performance hydraulic components that minimize environmental footprints. Buyers who prioritize these aspects can differentiate themselves in competitive markets and build stronger relationships with environmentally conscious clients.

Illustrative image related to hydraulic piston arm

What Is the Brief Evolution and History of Hydraulic Piston Arms?

The hydraulic piston arm has undergone significant transformations since its inception in the mid-20th century. Initially designed for basic lifting tasks, advancements in hydraulic technology have expanded their applications across various sectors. The introduction of double-acting cylinders and telescopic designs has allowed for greater versatility and efficiency in hydraulic systems.

Over the years, the integration of computer-aided design (CAD) and simulation software has revolutionized the manufacturing process, enabling the production of more precise and reliable hydraulic components. This evolution has been particularly beneficial for international B2B buyers who require customized solutions that meet specific operational demands.

As industries continue to evolve, so too do the expectations for hydraulic piston arms. The focus has shifted from merely functional components to sophisticated systems capable of integrating with modern automation and IoT technologies. This ongoing evolution highlights the importance of staying informed about market trends and sourcing strategies to ensure access to the latest innovations in hydraulic technology.

Illustrative image related to hydraulic piston arm

Frequently Asked Questions (FAQs) for B2B Buyers of hydraulic piston arm

-

How do I select the right hydraulic piston arm for my application?

Choosing the right hydraulic piston arm involves evaluating several key specifications such as bore diameter, rod diameter, and stroke length. Consider the specific requirements of your application, including load capacity, operating pressure, and whether you need a single-acting or double-acting cylinder. Additionally, assess the material and coating options to ensure durability and resistance to environmental factors. Consulting with manufacturers or suppliers can provide tailored recommendations based on your operational needs. -

What is the best hydraulic piston arm for heavy-duty applications?

For heavy-duty applications, double-acting hydraulic piston arms are often the best choice due to their ability to generate force in both directions, enhancing efficiency and control. Look for models designed for high-pressure operations, with robust construction and features like reinforced seals and heavy-duty rods. Brands that manufacture hydraulic cylinders to ISO 9001 standards typically offer the reliability needed for demanding environments, ensuring optimal performance in construction, agriculture, and material handling. -

What customization options are available for hydraulic piston arms?

Many suppliers offer customization options for hydraulic piston arms, allowing you to tailor specifications to your unique requirements. Customizations can include variations in bore and rod diameters, stroke lengths, mounting configurations, and seal types. You can also specify the materials used, coating finishes, and even branding options such as packaging and labeling. Be sure to discuss your needs with the manufacturer, as minimum order quantities may apply for customized products. -

What are the minimum order quantities (MOQs) for hydraulic piston arms?

Minimum order quantities can vary significantly between suppliers, especially for customized hydraulic piston arms. Typically, MOQs can range from as few as 10 units for standard products to 50 or more for custom designs. It is essential to clarify these details upfront with your supplier, particularly if you are looking to test a new product or introduce it into your operations. Understanding MOQs can help in budgeting and planning your inventory effectively. -

What payment terms should I expect when sourcing hydraulic piston arms internationally?

Payment terms can vary widely based on the supplier and the nature of the transaction. Common arrangements include upfront payment, a deposit with the balance due upon delivery, or net payment terms that allow for payment within a set period after receipt of goods. Ensure that you discuss payment methods, such as wire transfers or letters of credit, and confirm any additional fees, such as transaction costs or currency conversion fees, to avoid surprises. -

How can I ensure quality assurance when sourcing hydraulic piston arms?

To ensure quality assurance, request certifications from your supplier, such as ISO 9001, which indicates adherence to international quality management standards. Ask for detailed product specifications, including testing reports and material certifications. It’s also beneficial to establish a quality control process that includes inspections upon receipt of goods. Engaging with suppliers who offer warranties or guarantees can provide additional assurance regarding the performance and durability of the hydraulic piston arms. -

What logistics considerations should I keep in mind when importing hydraulic piston arms?

Logistics considerations are crucial when importing hydraulic piston arms. Evaluate shipping options, including freight costs and delivery times, to determine the most efficient method for your needs. Be aware of customs regulations and duties applicable in your region, as these can affect overall costs and delivery timelines. Working with a reliable logistics partner can streamline the import process, ensuring compliance with international trade regulations and timely delivery of your products. -

What are the most common applications for hydraulic piston arms in different industries?

Hydraulic piston arms are widely used across various industries, including construction, agriculture, manufacturing, and material handling. In construction, they power equipment like excavators and cranes. In agriculture, they are essential for machinery such as tractors and plows. Manufacturing utilizes hydraulic pistons in assembly lines and robotic arms. Understanding the specific application requirements in your industry can guide you in selecting the most suitable hydraulic piston arm to enhance operational efficiency.

Top 3 Hydraulic Piston Arm Manufacturers & Suppliers List

1. Magister Hydraulics – Hydraulic Cylinders

Domain: magisterhyd.com

Registered: 2014 (11 years)

Introduction: Hydraulic Cylinders for Sale | Magister Hydraulics Shop includes various types of hydraulic cylinders such as AG Clevis, Clevis End, Cross Tube, Dump Trailer, Loader, Log Splitter, Pin Eye, Snow Plow, Swivel Ball, Swivel Eye, Tang, Tie Rod, Universal, Rephasing, Stroke Control, and Top link cylinders. The shop also offers hydraulic power units, hydraulic control valves, hydraulic gear pumps, hydra…

2. Bailey Hydraulics – Telescopic Hydraulic Cylinders

Domain: baileyhydraulics.com

Registered: 2013 (12 years)

Introduction: Telescopic hydraulic cylinders are designed for applications requiring a compact retracted dimension with a longer stroke. They are generally single acting and available in two to five stages. Common mounting options include trunnion and cross-tube. Key specifications include:

– Stroke lengths ranging from 40.38 in to 145 in.

– PSI ratings of 2000 to 2500.

– Column loads from 25,100 lbs to 100,520…

3. Lunchbox Sessions – Hydraulic Cylinders

Domain: lunchboxsessions.com

Registered: 2007 (18 years)

Introduction: Hydraulic cylinders, also known as linear actuators, consist of key components including: 1. Barrel – the outer structure where the rod moves in and out. 2. Rod – extends from the barrel. 3. Piston – attached to the rod, nearly contacts the bore. 4. Bore – the inside diameter of the barrel. 5. O-Rings – prevent high pressure oil from leaking. 6. Backup Rings – prevent o-rings from extruding. 7. Gl…

Strategic Sourcing Conclusion and Outlook for hydraulic piston arm

What Are the Key Takeaways for Strategic Sourcing of Hydraulic Piston Arms?

In conclusion, the strategic sourcing of hydraulic piston arms presents a valuable opportunity for businesses seeking to enhance operational efficiency and performance. By prioritizing quality, reliability, and compliance with international standards, buyers can ensure that they select hydraulic cylinders that meet their specific application needs. Understanding the various options—such as single-acting versus double-acting cylinders, or custom specifications—enables companies to make informed purchasing decisions that align with their operational demands.

How Can International Buyers Leverage These Insights?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, the importance of establishing strong relationships with reputable manufacturers cannot be overstated. Engaging with suppliers who maintain high-quality standards and offer robust warranties will mitigate risks associated with equipment failure and downtime. Furthermore, as industries evolve, staying abreast of technological advancements in hydraulic solutions will be crucial for maintaining a competitive edge.

What Steps Should You Take Next?

As you consider your next procurement strategy, take the time to evaluate your operational requirements, explore various supplier options, and leverage the insights gained from this guide. By doing so, you not only enhance your operational capabilities but also position your business for sustained growth in a rapidly changing market landscape. Take the next step towards optimizing your hydraulic solutions and reach out to trusted suppliers today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.