How to Source How To Install Push Pull Throttle Cables Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for how to install push pull throttle cables

In the fast-evolving landscape of global manufacturing and automotive industries, understanding how to install push pull throttle cables is crucial for maintaining optimal performance and safety. As international B2B buyers navigate the complexities of sourcing these essential components, they face challenges such as ensuring compatibility, selecting the right materials, and adhering to various regional regulations. This comprehensive guide addresses these concerns by providing detailed insights into different types of push pull throttle cables, their applications across various vehicle types, and best practices for installation.

Buyers will gain access to vital information on supplier vetting processes, helping them identify reputable manufacturers and distributors, particularly in diverse markets across Africa, South America, the Middle East, and Europe, including key players like Germany and Saudi Arabia. Additionally, the guide outlines cost considerations, enabling businesses to make informed financial decisions that align with their operational budgets.

By empowering B2B buyers with actionable knowledge and practical advice, this guide not only enhances their understanding of push pull throttle cables but also facilitates informed purchasing decisions, ultimately leading to improved operational efficiency and safety in their respective industries.

Understanding how to install push pull throttle cables Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Push/Pull Cable | Dual cable system; pull opens throttle, push closes | Motorcycles, ATVs, performance vehicles | Pros: Enhanced safety; reliable operation. Cons: Requires precise installation and adjustments. |

| Teflon-Lined Push/Pull Cable | Low friction Teflon liner; reduces wear and tear | High-performance racing, off-road vehicles | Pros: Smooth operation; longer lifespan. Cons: Higher cost than standard cables. |

| Adjustable Push/Pull Cable | In-line adjusters for cable tension | Custom motorcycles, specialty vehicles | Pros: Easy fine-tuning; adaptable to various setups. Cons: May require additional maintenance. |

| Heavy-Duty Push/Pull Cable | Reinforced materials for extreme conditions | Industrial machinery, heavy equipment | Pros: Durability in harsh environments; reduced failure risk. Cons: Heavier and potentially more difficult to install. |

| Marine-Grade Push/Pull Cable | Corrosion-resistant materials for marine environments | Boats, marine vehicles | Pros: Long-lasting in saltwater conditions; reliable performance. Cons: Limited to specific applications; higher price point. |

What Are the Key Characteristics of Standard Push/Pull Cables?

Standard push/pull cables are designed for dual operation, where one cable opens the throttle and the other closes it. This system enhances safety, particularly in high-speed applications like motorcycles and ATVs, as it ensures the throttle returns to idle even if the return spring fails. Buyers should consider the installation complexity and the need for periodic adjustments to maintain optimal performance.

How Do Teflon-Lined Push/Pull Cables Enhance Performance?

Teflon-lined push/pull cables feature a low-friction liner that minimizes wear on the inner cable, providing smoother operation and longer service life. These cables are particularly well-suited for high-performance racing and off-road vehicles where reliability is critical. When purchasing, consider the increased cost against the benefits of reduced friction and maintenance.

What Are the Advantages of Adjustable Push/Pull Cables?

Adjustable push/pull cables come equipped with in-line adjusters that allow for easy fine-tuning of cable tension. This feature is especially beneficial in custom motorcycle builds and specialty vehicles where precise throttle control is required. While they offer adaptability, buyers should be aware that they may necessitate more frequent maintenance to ensure optimal performance.

Why Choose Heavy-Duty Push/Pull Cables for Industrial Applications?

Heavy-duty push/pull cables are constructed from reinforced materials to withstand extreme conditions, making them ideal for industrial machinery and heavy equipment. Their durability reduces the risk of failure in harsh environments. However, buyers should consider the weight and installation challenges associated with these robust cables.

What Makes Marine-Grade Push/Pull Cables Essential for Marine Vehicles?

Marine-grade push/pull cables are specifically designed to resist corrosion from saltwater, ensuring reliable operation in marine environments. They are crucial for boats and other marine vehicles where exposure to harsh elements is a concern. Buyers should evaluate their specific marine applications to justify the higher price point associated with these specialized cables.

Key Industrial Applications of how to install push pull throttle cables

| Industry/Sector | Specific Application of how to install push pull throttle cables | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Installation in high-performance vehicles for enhanced throttle control | Improved safety and performance in critical situations | Quality of materials, compliance with safety standards |

| Marine Engineering | Use in boat throttle systems to ensure reliable engine control | Enhanced safety during navigation and maneuvering | Corrosion resistance, compatibility with marine environments |

| Agricultural Equipment | Installation in tractors and harvesters for efficient engine operation | Increased productivity and reduced downtime | Durability under harsh conditions, availability of replacement parts |

| Motorcycle and Powersports | Application in racing bikes for precise throttle response | Enhanced rider safety and performance at high speeds | Lightweight materials, precision engineering |

| Industrial Machinery | Use in heavy machinery for precise control of operations | Improved operational efficiency and safety | Customization options, compatibility with existing systems |

How is ‘how to install push pull throttle cables’ utilized in Automotive Manufacturing?

In the automotive manufacturing sector, push-pull throttle cables are vital for high-performance vehicles where precise throttle control is essential. These cables replace traditional single throttle systems, providing redundancy that enhances safety—especially in high-speed scenarios. Buyers in this sector must prioritize sourcing cables made from high-quality materials that meet stringent safety standards, as any failure could lead to catastrophic outcomes during operation.

What role do push pull throttle cables play in Marine Engineering?

In marine engineering, push-pull throttle cables are crucial for reliable engine control in boats and vessels. These cables ensure that throttle response is immediate and accurate, which is essential for safe navigation and maneuvering, particularly in challenging marine conditions. B2B buyers should focus on sourcing cables that are corrosion-resistant and designed to perform reliably in harsh marine environments, as these factors significantly influence the longevity and effectiveness of the throttle system.

How are push pull throttle cables applied in Agricultural Equipment?

Within the agricultural sector, push-pull throttle cables are used in tractors and harvesters to facilitate efficient engine operation. These cables allow for smooth throttle control, which is vital for optimizing performance during critical tasks such as planting and harvesting. Buyers must consider the durability of the cables, ensuring they can withstand the rigors of agricultural use, including exposure to dirt, moisture, and extreme temperatures, while also ensuring that replacement parts are readily available.

Why are push pull throttle cables important in Motorcycle and Powersports?

In the motorcycle and powersports industry, the installation of push-pull throttle cables is critical for enhancing throttle response in racing bikes. This dual-cable system ensures that in the event of a failure, the throttle can still return to idle, which is paramount for rider safety at high speeds. B2B buyers should prioritize lightweight materials that do not compromise performance while also considering precision engineering to ensure optimal functionality under extreme conditions.

How do push pull throttle cables improve Industrial Machinery operations?

In the realm of industrial machinery, push-pull throttle cables facilitate precise control over machinery operations, which is essential for maintaining safety and efficiency. These cables are integral to various machines, allowing operators to manage engine speed and power output effectively. Buyers should seek customization options to ensure compatibility with existing systems, along with high-quality materials that guarantee durability and reliability in demanding industrial environments.

3 Common User Pain Points for ‘how to install push pull throttle cables’ & Their Solutions

Scenario 1: Difficulty in Identifying Cable Compatibility and Sizing

The Problem: One significant challenge faced by B2B buyers, particularly in sectors like automotive or machinery, is ensuring that the push-pull throttle cables they source are compatible with their specific equipment. Mismatched cables can lead to operational failures, safety risks, and costly downtime. Given the variety of models and configurations available, it can be a daunting task to determine the correct dimensions and specifications needed for installation.

The Solution: To mitigate this issue, buyers should prioritize sourcing cables from reputable manufacturers who provide comprehensive specifications and compatibility charts. Before placing an order, it is essential to measure the original cable’s length, diameter, and attachment points accurately. Additionally, consulting with manufacturers or suppliers who can offer expert guidance on the specific applications of their products can greatly reduce the risk of compatibility issues. Utilizing digital resources or CAD models can also aid in visualizing how the cables will fit into the existing systems. This proactive approach ensures that the correct cables are procured, leading to smoother installations and enhanced operational efficiency.

Scenario 2: Challenges with Cable Installation and Routing

The Problem: Another common pain point is the complexity involved in the actual installation and routing of push-pull throttle cables. Improper routing can lead to cable binding, excessive wear, or even failure during operation, posing serious safety hazards. Many B2B buyers may encounter difficulties in accessing tight spaces or ensuring that the cables are correctly aligned, which can result in frustration and extended downtime.

The Solution: To facilitate a more straightforward installation process, it is advisable to create a detailed plan before commencing the installation. Documenting the routing path of the original cables can serve as a valuable reference. Additionally, investing in tools like cable lubricants and guides can ease the installation process. A step-by-step approach, starting with the pull cable and ensuring all connections are secure before adjusting the throttle, can minimize errors. Regular training sessions or workshops on best practices for cable installation can also empower technical teams, enhancing their confidence and efficiency during the installation process.

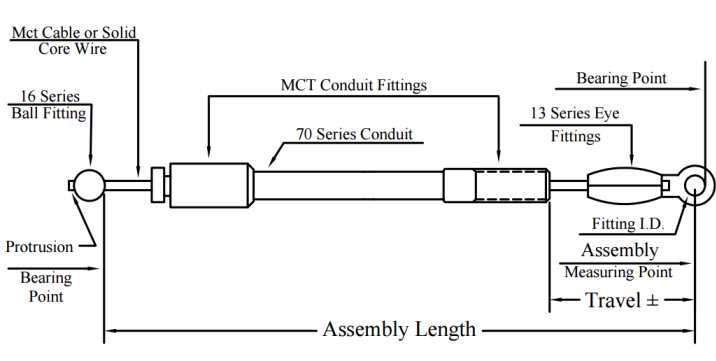

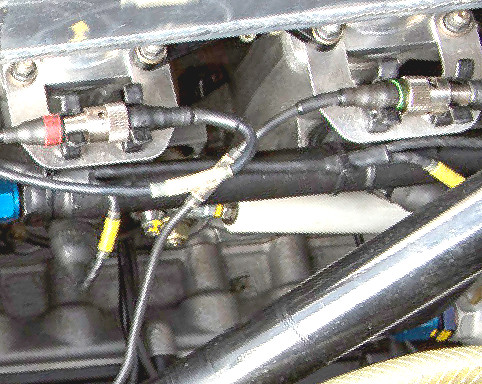

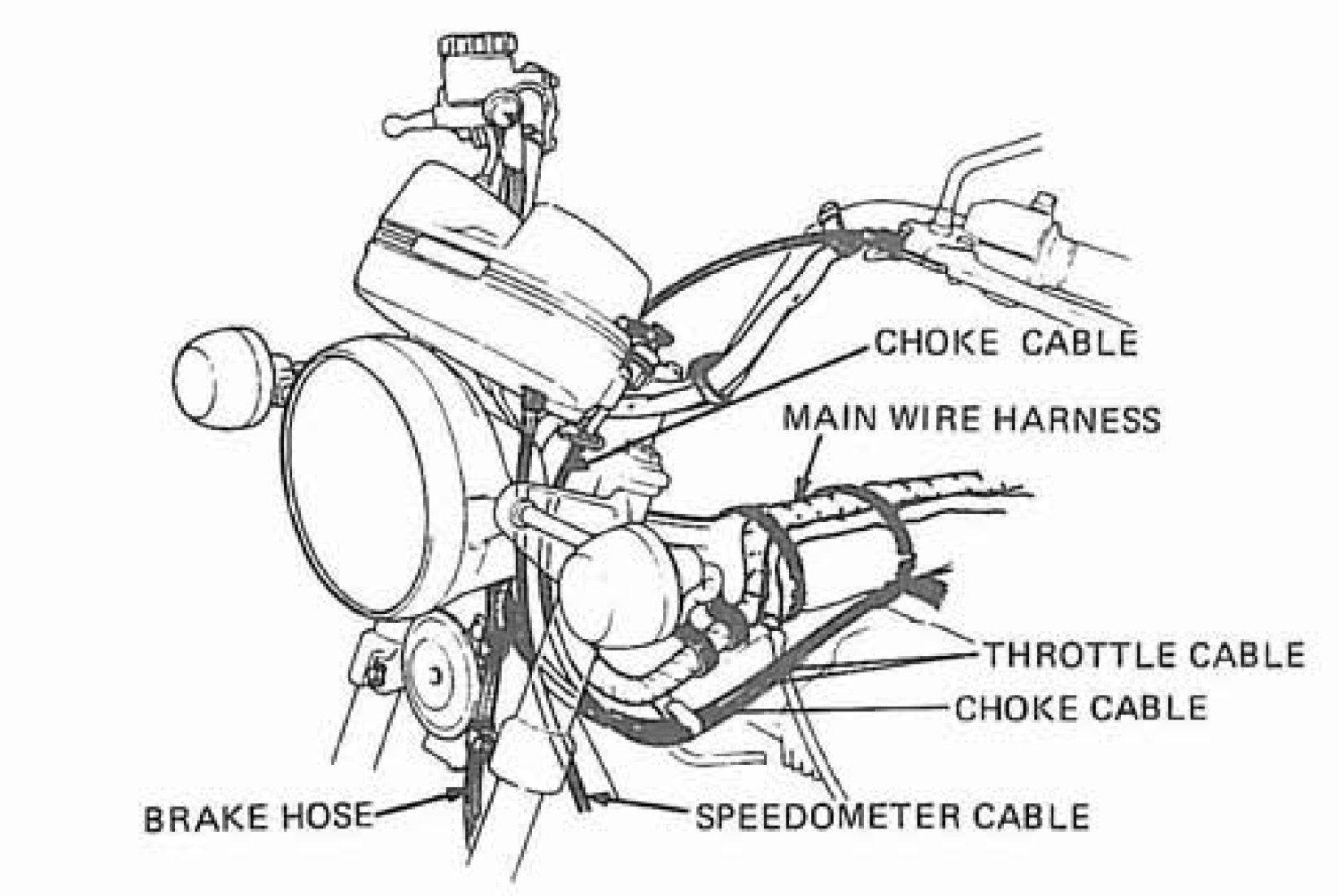

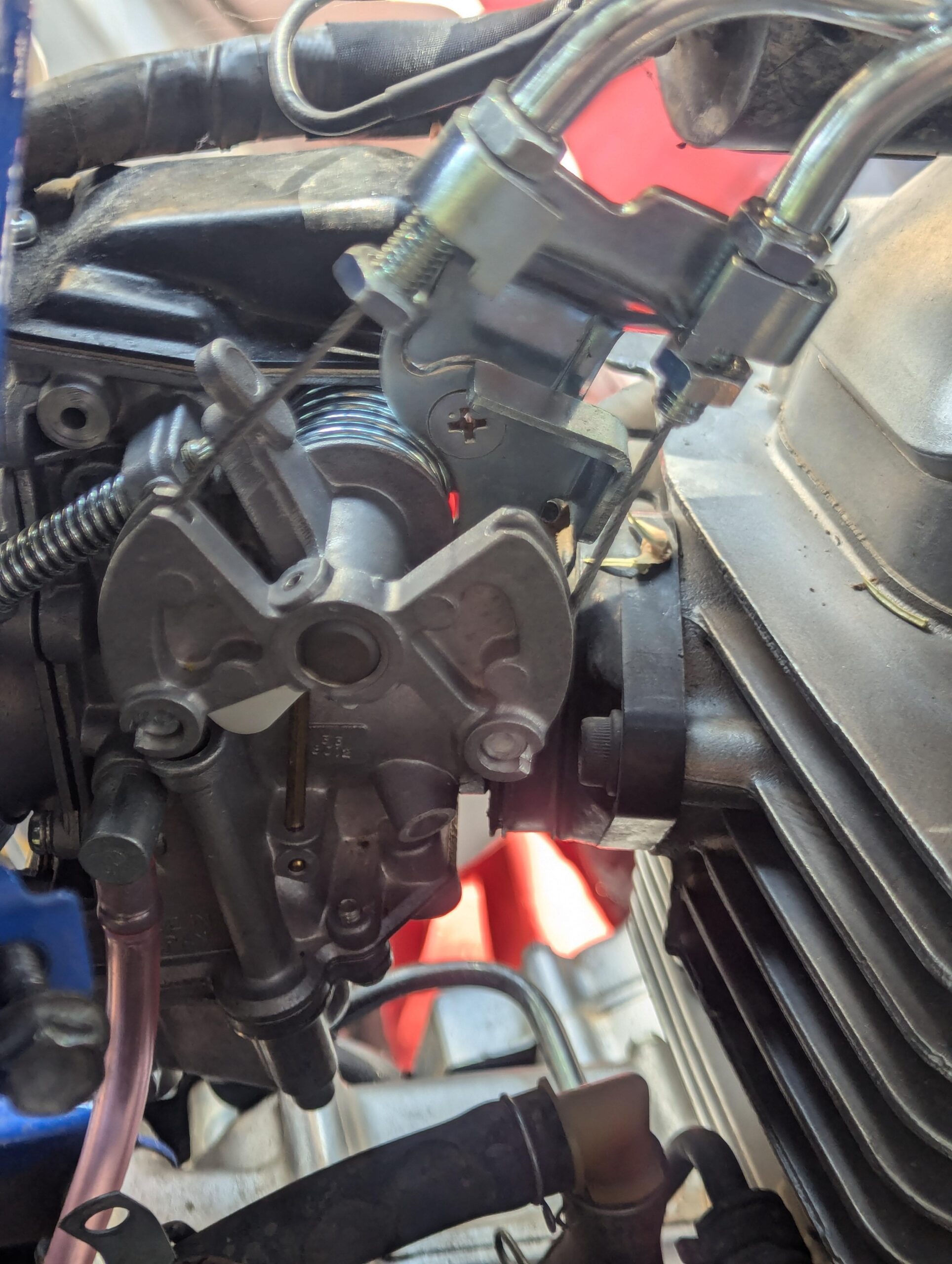

Illustrative image related to how to install push pull throttle cables

Scenario 3: Maintenance and Adjustment Issues Post-Installation

The Problem: After the initial installation, many B2B buyers face ongoing challenges related to the maintenance and adjustment of push-pull throttle cables. Cables can stretch, leading to excessive free play or binding, which can adversely affect performance and safety. Buyers may struggle with understanding the correct maintenance routines or adjusting the cables properly, which can result in increased operational costs and equipment reliability issues.

The Solution: Establishing a routine maintenance schedule is crucial for prolonging the life of push-pull throttle cables. Buyers should educate their teams on the importance of regular checks for cable tension and free play, ideally measuring the free play every few months. Implementing a simple visual inspection checklist can help identify issues before they escalate. Additionally, leveraging technology, such as remote monitoring systems, can provide real-time data on cable performance, alerting teams to potential problems early. By fostering a culture of proactive maintenance, companies can significantly reduce the risk of cable failure and ensure consistent performance across their equipment.

Strategic Material Selection Guide for how to install push pull throttle cables

What Materials Are Commonly Used for Push Pull Throttle Cables?

When selecting materials for push pull throttle cables, several options are prevalent in the industry, each with unique properties that impact performance, durability, and suitability for various applications. Below are analyses of four common materials used in the manufacturing of these cables.

1. Stainless Steel

Key Properties:

Stainless steel is renowned for its excellent corrosion resistance and high tensile strength. It can withstand a wide range of temperatures, making it suitable for various environments. Its durability ensures a longer lifespan under mechanical stress.

Pros & Cons:

The primary advantage of stainless steel is its resistance to rust and corrosion, which is crucial in humid or saline environments. However, it can be more expensive than other materials and may require more complex manufacturing processes, increasing overall costs.

Impact on Application:

Stainless steel cables are ideal for applications where exposure to moisture or corrosive elements is a concern, such as in marine or off-road vehicles. They also perform well under high-pressure conditions.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure compliance with ASTM standards for stainless steel grades. Countries like Germany may have specific regulations regarding material quality and environmental impact.

2. Nylon

Key Properties:

Nylon is a lightweight, flexible material with good resistance to abrasion and chemicals. It can operate effectively within a temperature range of -40°C to 100°C.

Illustrative image related to how to install push pull throttle cables

Pros & Cons:

Nylon cables are cost-effective and easier to manufacture, making them a popular choice for many applications. However, they may not be as durable as metal options and can degrade under prolonged exposure to UV light or extreme temperatures.

Impact on Application:

Nylon is suitable for applications where weight reduction is essential, such as in motorcycles and lightweight vehicles. However, its lower tensile strength compared to metal cables limits its use in high-stress environments.

Considerations for International Buyers:

Buyers should be aware of local regulations regarding the use of synthetic materials, especially in regions like Africa and South America, where environmental concerns are increasingly prominent.

Illustrative image related to how to install push pull throttle cables

3. PTFE (Polytetrafluoroethylene)

Key Properties:

PTFE is known for its exceptional chemical resistance and low friction properties. It can handle temperatures up to 260°C, making it suitable for high-heat applications.

Pros & Cons:

The primary advantage of PTFE is its ability to reduce friction, leading to smoother operation of throttle cables. However, it can be more expensive than other materials and may require specialized manufacturing techniques.

Impact on Application:

PTFE cables are particularly beneficial in applications where high temperatures and chemical exposure are prevalent, such as in racing or industrial machinery.

Considerations for International Buyers:

International buyers should ensure that PTFE materials comply with relevant safety and environmental standards, such as those set by the European Union.

4. PVC (Polyvinyl Chloride)

Key Properties:

PVC is a versatile plastic that offers good chemical resistance and durability. It operates effectively within a temperature range of -15°C to 60°C.

Illustrative image related to how to install push pull throttle cables

Pros & Cons:

PVC is cost-effective and widely available, making it a popular choice for many applications. However, it may not perform well under extreme temperatures or mechanical stress compared to metal options.

Impact on Application:

PVC cables are suitable for low-stress applications where cost is a significant factor, such as in consumer vehicles. However, they may not be ideal for high-performance or heavy-duty applications.

Considerations for International Buyers:

Buyers should be aware of the regulations surrounding the use of PVC, particularly in Europe, where there are strict guidelines regarding the use of certain chemicals in plastics.

Summary Table of Material Selection for Push Pull Throttle Cables

| Material | Typical Use Case for how to install push pull throttle cables | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Marine and off-road vehicles | Excellent corrosion resistance | Higher cost and manufacturing complexity | High |

| Nylon | Motorcycles and lightweight vehicles | Cost-effective and lightweight | Lower durability and UV degradation | Low |

| PTFE | Racing and industrial machinery | Low friction and high-temperature resistance | Higher cost and specialized manufacturing | High |

| PVC | Consumer vehicles | Cost-effective and widely available | Poor performance under extreme conditions | Low |

This strategic material selection guide provides insights into the various materials available for push pull throttle cables, helping international B2B buyers make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for how to install push pull throttle cables

What Are the Main Stages in the Manufacturing Process of Push Pull Throttle Cables?

The manufacturing of push pull throttle cables involves several critical stages that ensure the final product meets both performance and quality standards. Understanding these stages is essential for B2B buyers, particularly those sourcing from international markets.

Material Preparation: What Materials Are Used?

The first step in the manufacturing process is material selection, where high-quality raw materials are crucial. Typically, manufacturers use stainless steel for the inner wire due to its strength and resistance to corrosion. The outer casing often consists of PVC or PTFE (Teflon), which reduces friction and enhances the cable’s longevity. Additionally, various fittings and connectors are made from durable metals to withstand environmental factors.

During material preparation, suppliers must ensure that all materials comply with international standards, such as ISO 9001, which governs quality management systems. This compliance is vital for B2B buyers to ensure they are investing in reliable products.

Forming: How Are the Cables Shaped?

Once materials are selected, the forming process begins. This involves cutting the stainless steel wire to the desired length and shaping it to create the cable’s core. Advanced techniques like wire drawing and annealing are often employed to enhance the wire’s flexibility and strength. The outer casing is then extruded or molded around the core, ensuring a snug fit.

Forming is a critical stage where precision matters. Any misalignment during this process can lead to improper cable function, affecting throttle response. B2B buyers should inquire about the equipment and techniques used by manufacturers to ensure they meet the necessary tolerances.

Illustrative image related to how to install push pull throttle cables

Assembly: What Goes into the Final Product?

In the assembly stage, the cables are fitted with end fittings, such as nipples and connectors. This process often involves crimping, which securely attaches these fittings to the cable ends. The assembly must be done with care, as improper crimping can lead to cable failure during operation.

B2B buyers should look for manufacturers that employ skilled labor and utilize automated machinery for consistent quality. The assembly stage is also where manufacturers may implement additional features, such as lubrication points, which can enhance the cable’s performance over time.

Finishing: How Are Cables Prepared for Market?

The finishing stage includes several processes that prepare the throttle cables for market. This often involves coating the outer casing for added protection against environmental factors, such as moisture and dirt. Manufacturers may also conduct final inspections to ensure that each cable meets specifications.

Illustrative image related to how to install push pull throttle cables

Quality assurance checks during this stage are crucial. Cables are often tested for flexibility, tensile strength, and overall functionality. B2B buyers should ensure that the manufacturer provides documentation of these tests to verify the product’s reliability.

What Are the Key Quality Assurance Standards for Push Pull Throttle Cables?

Quality assurance is a vital aspect of the manufacturing process for push pull throttle cables. It ensures that the final product is safe, reliable, and meets international standards. B2B buyers must understand the various quality assurance practices to make informed purchasing decisions.

International Standards: Which Ones Should Buyers Look For?

For push pull throttle cables, adherence to international standards such as ISO 9001 is essential. This standard focuses on quality management systems and helps organizations ensure they meet customer and regulatory requirements. Additionally, certifications like CE (Conformité Européenne) are crucial for products sold within the European market, indicating compliance with health and safety standards.

Illustrative image related to how to install push pull throttle cables

B2B buyers sourcing from Africa, South America, the Middle East, and Europe should prioritize suppliers with robust quality assurance certifications. This not only guarantees product quality but also facilitates smoother trade across borders.

What Are the QC Checkpoints Throughout the Manufacturing Process?

Quality control (QC) is integral at various checkpoints throughout the manufacturing process. Common checkpoints include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified requirements.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the production process and ensure that all parameters remain within acceptable limits.

-

Final Quality Control (FQC): After assembly, the finished products undergo comprehensive testing to ensure they function correctly and meet all quality standards.

These checkpoints help catch defects early in the process, reducing waste and ensuring a high-quality final product.

What Common Testing Methods Are Used for Quality Assurance?

Manufacturers employ various testing methods to verify the performance and durability of push pull throttle cables. These may include:

-

Tensile Testing: This measures the cable’s ability to withstand pulling forces without breaking.

-

Flexibility Testing: Cables are bent at different angles to ensure they maintain functionality without kinking.

-

Environmental Testing: Cables may be exposed to extreme temperatures, moisture, and other conditions to simulate real-world usage.

B2B buyers should ask suppliers about their testing procedures and request reports that confirm compliance with relevant standards.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that they are working with reliable suppliers, B2B buyers should take proactive steps to verify quality control practices. Here are some actionable strategies:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality assurance practices. This can be done internally or through third-party audit services.

-

Request Quality Reports: Suppliers should provide documentation of their quality control processes, including IQC, IPQC, and FQC reports. These documents offer transparency into their manufacturing operations.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of product quality before shipment. This is particularly valuable for international transactions where buyers may not have immediate access to suppliers.

-

Certifications Verification: Buyers should verify the authenticity of certifications like ISO 9001 and CE. This can often be done through official certification bodies or regulatory agencies.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances when sourcing push pull throttle cables. Understanding these differences can mitigate risks and enhance supply chain efficiency:

Illustrative image related to how to install push pull throttle cables

-

Regulatory Compliance: Different countries have varying regulations regarding product safety and quality. Buyers should familiarize themselves with the specific requirements of their target markets.

-

Cultural Differences: Communication styles and expectations regarding quality may differ across regions. Building strong relationships with suppliers can help overcome these barriers.

-

Supply Chain Considerations: Time zone differences and logistical challenges can impact the quality assurance process. Buyers should establish clear timelines and expectations to ensure smooth operations.

In summary, understanding the manufacturing processes and quality assurance practices for push pull throttle cables is crucial for B2B buyers. By focusing on material preparation, forming, assembly, finishing, and stringent QC measures, buyers can ensure they source high-quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to install push pull throttle cables’

Introduction

Installing push/pull throttle cables is a critical task for ensuring smooth and reliable engine performance in various machinery, especially in motorcycles and vehicles. This guide offers a step-by-step checklist designed for B2B buyers looking to procure the necessary components and services for installing these cables effectively. By following this checklist, you can ensure that your installation process is efficient and meets safety and operational standards.

Step 1: Define Your Technical Specifications

Understanding the specific requirements for your push/pull throttle cables is essential. This includes knowing the length, material, and compatibility with your machinery. Ensure that the specifications align with the manufacturer’s recommendations to avoid issues during installation and operation.

Step 2: Research Quality Suppliers

Identifying reliable suppliers is crucial for obtaining high-quality cables. Look for suppliers with a strong reputation in the industry, verified through customer reviews and testimonials. Pay attention to their product offerings, ensuring they provide cables that meet your defined specifications.

Illustrative image related to how to install push pull throttle cables

Step 3: Evaluate Potential Suppliers

Before committing to a purchase, it’s vital to thoroughly vet suppliers. Request detailed company profiles, case studies, and references from buyers in similar industries or regions. This evaluation will help you gauge their experience and reliability, ensuring that you choose a supplier capable of meeting your needs.

Step 4: Verify Supplier Certifications

Ensure that your selected suppliers have the necessary certifications and comply with industry standards. Certifications can indicate quality assurance and adherence to safety regulations, which is especially important in regions with stringent compliance requirements. Look for ISO certifications and other relevant industry-specific credentials.

Step 5: Assess After-Sales Support and Warranty

Inquire about the after-sales support provided by your suppliers. Quality support can include installation guidance, maintenance recommendations, and warranty terms. A strong warranty can protect your investment by covering any defects or issues that may arise after installation.

Step 6: Request Samples for Testing

Before placing a large order, request samples of the push/pull throttle cables. Testing these samples can help you verify compatibility, quality, and performance in your specific application. This step is essential to prevent potential issues after full-scale installation.

Step 7: Plan for Installation and Maintenance

Lastly, consider the logistics of the installation process, including the tools and personnel needed. Ensure that your team is trained or has access to resources that provide clear installation instructions. Additionally, establish a maintenance schedule for regular checks on the cables to prolong their lifespan and ensure optimal performance.

By following this checklist, B2B buyers can ensure a successful procurement process for push/pull throttle cables, leading to enhanced operational efficiency and safety in their machinery.

Comprehensive Cost and Pricing Analysis for how to install push pull throttle cables Sourcing

What Are the Key Cost Components for Installing Push Pull Throttle Cables?

When analyzing the cost structure for installing push pull throttle cables, several components come into play. These include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The primary material costs stem from the throttle cables themselves, which may vary in price based on specifications such as length, diameter, and material quality (e.g., stainless steel, Teflon-lined cables). Additionally, associated components like cable ends, adjusters, and lubricants contribute to the overall material cost.

-

Labor: Labor costs encompass the hours spent on installation, which can vary based on the complexity of the installation and the experience level of the technician. In regions with higher labor costs, such as Western Europe, this can significantly impact the overall pricing structure.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as facility maintenance, utilities, and administrative expenses. Understanding these costs can provide insights into the pricing strategies of suppliers.

-

Tooling and Equipment: Depending on the installation environment, specialized tools may be required, increasing the cost. Suppliers may also charge for the use of their proprietary tools, which can add to the overall expense of the project.

-

Quality Control (QC): Ensuring that the throttle cables meet safety and performance standards is crucial. The costs associated with quality checks and certifications can vary widely, particularly in markets with stringent regulations.

-

Logistics: Transportation costs can significantly affect pricing, especially for international buyers. Import duties, shipping fees, and customs clearance processes should be factored into the total cost.

-

Margin: Suppliers often include a profit margin that reflects their operational costs and desired profitability. This can vary based on market conditions and competition.

How Do Price Influencers Affect the Cost of Push Pull Throttle Cables?

Several factors can influence the pricing of push pull throttle cables, particularly for B2B buyers in diverse regions.

Illustrative image related to how to install push pull throttle cables

-

Volume and Minimum Order Quantity (MOQ): Suppliers often provide tiered pricing based on order volume. Higher quantities can lead to significant savings, making it beneficial for businesses to consolidate orders.

-

Specifications and Customization: Customized throttle cables designed for specific applications may incur additional costs. Buyers should assess whether standard options meet their needs to avoid unnecessary expenses.

-

Material Quality and Certifications: Higher quality materials or certified products can command higher prices, but they often offer better durability and performance, leading to lower total cost of ownership (TCO) over time.

-

Supplier Factors: Relationships with suppliers can influence pricing. Long-standing partnerships may provide leverage for better rates. Additionally, regional suppliers may offer competitive pricing due to lower operational costs.

-

Incoterms: Understanding shipping terms (Incoterms) is crucial for international buyers. Terms such as FOB (Free On Board) or CIF (Cost, Insurance, and Freight) can impact the final landed cost of the product.

What Tips Can B2B Buyers Use to Optimize Costs When Sourcing Push Pull Throttle Cables?

B2B buyers can employ various strategies to enhance cost efficiency in sourcing push pull throttle cables:

-

Negotiation: Engage suppliers in discussions about pricing, particularly for bulk orders. Leverage competitive quotes from multiple suppliers to negotiate better terms.

-

Total Cost of Ownership (TCO): Evaluate the long-term costs associated with a product rather than just the initial purchase price. Consider factors like maintenance, replacement frequency, and performance to assess TCO effectively.

-

Research Regional Differences: Be aware of regional pricing trends and labor costs. For example, sourcing from suppliers in lower-cost regions can yield savings, but ensure they meet quality standards.

-

Stay Informed About Market Changes: Monitor fluctuations in material costs and supply chain disruptions, as these can affect pricing. Keeping abreast of market trends can help buyers make timely purchasing decisions.

-

Utilize Technology: Implement procurement technologies or platforms that facilitate price comparisons and streamline the sourcing process, making it easier to find the best deals.

By understanding these cost components, price influencers, and strategic tips, B2B buyers can make informed decisions regarding the installation and sourcing of push pull throttle cables, ultimately leading to better project outcomes and cost savings.

Alternatives Analysis: Comparing how to install push pull throttle cables With Other Solutions

Exploring Alternatives to Installing Push Pull Throttle Cables

When considering the installation of throttle control systems, various methods can achieve similar operational goals. Each alternative offers unique advantages and disadvantages that may align better with specific applications or business needs. Understanding these options is crucial for international B2B buyers seeking efficient and reliable throttle systems.

| Comparison Aspect | How To Install Push Pull Throttle Cables | Throttle By Wire Technology | Single Cable Throttle System |

|---|---|---|---|

| Performance | High reliability with dual cable system | Enhanced responsiveness and precision | Adequate for basic applications |

| Cost | Moderate (cable and components) | Higher initial investment | Lower initial cost |

| Ease of Implementation | Requires careful routing and adjustments | Generally easier installation with fewer components | Simple installation process |

| Maintenance | Regular maintenance needed for longevity | Minimal maintenance required | Moderate maintenance needed |

| Best Use Case | High-performance applications (e.g., racing) | Modern vehicles and high-tech applications | Budget-friendly or simpler machines |

Throttle By Wire Technology: Pros and Cons

Throttle by wire technology replaces traditional cables with electronic signals to control throttle position. This system offers enhanced responsiveness, allowing for real-time adjustments based on driver input and vehicle conditions. The primary advantages include reduced weight and the elimination of cable stretch issues. However, the initial investment can be significantly higher, and reliance on electronic components may introduce vulnerabilities to electrical failures, requiring careful consideration for businesses operating in environments with extreme conditions.

Single Cable Throttle System: Pros and Cons

The single cable throttle system is a simpler alternative that employs one cable for throttle operation. This method is cost-effective, making it appealing for budget-conscious projects or less demanding applications. Installation is straightforward, and the maintenance requirements are moderate. However, it lacks the redundancy and safety features of push pull systems, making it less suitable for high-performance or safety-critical applications where reliability is paramount. Businesses focused on performance might find this option limiting.

Making the Right Choice for Your Business Needs

In determining the best throttle control solution, B2B buyers should evaluate their specific application requirements, budget constraints, and long-term maintenance capabilities. For high-performance applications, investing in push pull throttle cables or throttle by wire technology may provide the necessary reliability and responsiveness. Conversely, for simpler machinery or budget-sensitive projects, a single cable throttle system could suffice. Ultimately, the decision should align with both immediate operational needs and future scalability considerations.

Illustrative image related to how to install push pull throttle cables

Essential Technical Properties and Trade Terminology for how to install push pull throttle cables

What Are the Key Technical Properties of Push Pull Throttle Cables?

When considering the installation of push pull throttle cables, understanding critical specifications is essential for ensuring functionality and safety. Below are several vital properties that B2B buyers should prioritize:

1. Material Grade

Push pull throttle cables are typically constructed from high-grade stainless steel or other corrosion-resistant materials. The choice of material impacts durability, resistance to environmental factors, and overall performance. For international buyers, especially in humid or corrosive environments, selecting the right material grade is crucial for longevity and reliability.

2. Cable Length and Tolerance

Cable length must be precise to ensure proper operation without excess slack or tension. Tolerance levels, usually measured in millimeters, dictate how much variation is acceptable in the cable length. Accurate measurements are vital during installation, as improper lengths can lead to cable binding or inefficient throttle response, potentially affecting vehicle performance.

3. Flexibility and Bend Radius

The flexibility of the cable is determined by its construction and materials. A proper bend radius is necessary to prevent kinking or binding during operation. For B2B buyers, understanding the flexibility specifications can help in choosing the right cable for specific applications, especially in compact or intricate mechanical designs.

4. Temperature Rating

Throttle cables must withstand varying temperatures without compromising performance. A specified temperature rating indicates the operational limits of the cable material, ensuring it functions effectively in extreme conditions. For businesses operating in diverse climates, this property is essential for maintaining equipment reliability.

5. Lubrication Requirements

The inner cable often requires specific lubrication to ensure smooth operation and to minimize wear. Knowing the recommended lubricants—such as light oils versus heavy greases—is vital for maintenance and can significantly impact the cable’s lifespan. Buyers should consider the maintenance routines of their equipment when selecting cables.

6. Pull and Push Force Ratings

These ratings indicate how much force is required to operate the throttle effectively. Understanding the force ratings is essential for ensuring compatibility with the vehicle’s throttle mechanism and for preventing premature wear or failure during operation.

What Are Common Trade Terms Related to Push Pull Throttle Cables?

Navigating the trade landscape requires familiarity with specific jargon. Here are several common terms relevant to the procurement and installation of push pull throttle cables:

1. OEM (Original Equipment Manufacturer)

OEM refers to components made by the manufacturer of the original product. For B2B buyers, sourcing OEM cables ensures compatibility and quality, as they are designed to meet the specific requirements of the original system.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product a supplier is willing to sell. Understanding MOQ is crucial for businesses, as it can affect inventory levels and purchasing strategies, particularly for international buyers managing logistics and storage.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit pricing for specific products or services. In the context of throttle cables, submitting an RFQ can help businesses compare offers and select the best supplier based on price, quality, and delivery terms.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers in international transactions, including shipping, insurance, and tariffs. Understanding these terms is essential for B2B buyers to mitigate risks and clarify obligations in cross-border transactions.

5. Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the product. For businesses, knowing the lead time for push pull throttle cables can aid in planning and inventory management, particularly in industries with tight deadlines.

6. Warranty

A warranty is a guarantee provided by the manufacturer regarding the product’s performance and quality over a specified period. For B2B buyers, understanding warranty terms is important for risk management and ensuring long-term reliability of the components purchased.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions that enhance their operations and ensure the effective installation of push pull throttle cables.

Navigating Market Dynamics and Sourcing Trends in the how to install push pull throttle cables Sector

What Are the Current Market Dynamics and Key Trends in the Push Pull Throttle Cable Sector?

The global market for push pull throttle cables is witnessing significant transformations driven by advancements in automotive technology, increasing safety regulations, and rising demand for high-performance vehicles. Notably, the push for enhanced safety features has made the dual cable system essential, particularly in regions with stringent automotive standards, such as Germany and Saudi Arabia. This necessity is compounded by the growing popularity of motorcycles and high-speed vehicles in emerging markets across Africa and South America.

Emerging B2B technology trends are reshaping how manufacturers and suppliers approach sourcing. The integration of digital tools for inventory management and supply chain optimization is helping companies reduce lead times and improve operational efficiency. E-commerce platforms are also gaining traction, allowing international buyers to source components more easily and transparently. Additionally, the trend towards customization is becoming prevalent, with buyers seeking tailored solutions that meet specific application requirements.

Another notable dynamic is the increasing focus on quality and reliability. As performance standards rise, the demand for high-grade materials, such as marine-grade stainless steel and PTFE liners, is on the rise, ensuring smoother operation and longer-lasting products. This shift is particularly relevant for B2B buyers who prioritize durability and performance in competitive markets.

How Are Sustainability and Ethical Sourcing Influencing the Push Pull Throttle Cable Market?

Sustainability is becoming a crucial factor in the sourcing of push pull throttle cables. With growing environmental awareness, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes the use of eco-friendly materials and processes that minimize environmental impact. The adoption of “green” certifications, such as ISO 14001, is becoming a requirement for many buyers, particularly in Europe, where regulations around sustainability are stringent.

Illustrative image related to how to install push pull throttle cables

Ethical sourcing is equally important, as buyers seek to ensure that their supply chains are free from exploitation and that labor practices meet international standards. Transparency in sourcing practices is critical; companies that can provide traceability of their materials and demonstrate compliance with ethical labor practices are more likely to gain trust and secure long-term partnerships. For instance, sourcing cables made from recycled materials or utilizing renewable energy sources during manufacturing can significantly enhance a company’s reputation and appeal to environmentally conscious buyers.

What Is the Historical Context of Push Pull Throttle Cables in the B2B Sector?

The evolution of push pull throttle cables can be traced back to the early days of motor vehicles, where single cable systems were the norm. However, as performance demands increased, particularly in racing and high-performance applications, the limitations of single cable systems became apparent. The introduction of push pull systems provided a more reliable and safer means of throttle control, allowing for better responsiveness and redundancy.

Over the decades, the technology has advanced, with innovations such as the use of Teflon liners to reduce friction and enhance performance. Today, push pull throttle cables are not only a standard feature in high-performance vehicles but are also becoming increasingly common in everyday automotive applications. This historical context underscores the importance of sourcing high-quality components that meet modern performance and safety standards, making it essential for B2B buyers to stay informed about advancements in this sector.

In conclusion, understanding the market dynamics, sustainability practices, and historical developments of push pull throttle cables equips international B2B buyers with the knowledge needed to make informed sourcing decisions that align with their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of how to install push pull throttle cables

-

How do I solve issues with throttle cable binding during installation?

To resolve throttle cable binding, first ensure the cables are correctly routed without sharp bends or kinks that could impede movement. Check that the cables are not too tight and have appropriate free play—typically 2-3mm. If binding persists, inspect for any obstructions or physical damage to the cable housing. Proper lubrication of the inner cable and ensuring the cable is not in contact with heat sources can also alleviate binding issues. Conduct a thorough check by moving the handlebars lock to lock while monitoring cable operation. -

What is the best way to adjust the free play on push/pull throttle cables?

Adjusting the free play on push/pull throttle cables is essential for smooth operation. Begin by identifying the adjustment points, usually located at the throttle grip and the carburetor. To adjust, loosen the lock nuts on the adjusters, then turn the adjuster to achieve the desired free play of 2-3mm. After adjustment, tighten the lock nuts and perform a test by twisting the throttle to ensure there’s no binding. Regular checks and adjustments will help maintain optimal performance and safety. -

What common mistakes should I avoid when installing push/pull throttle cables?

Common mistakes during installation include incorrect routing of cables, failing to lubricate the inner cable, and neglecting to adjust free play. Ensure that you follow the original cable routing as a guide and avoid tight bends. Additionally, always connect the pull cable first for easier access and ensure that the cables are not pinched or in contact with hot surfaces. Finally, perform a thorough operational check before completing the installation to ensure everything functions correctly. -

How can I verify the quality of push/pull throttle cables from suppliers?

To ensure quality, source cables from reputable manufacturers with certifications for durability and performance. Request samples or detailed specifications, including materials used, such as marine-grade stainless steel for inner wires and PFTE liners for low friction. Look for customer reviews or case studies demonstrating reliability in similar applications. Establishing a relationship with suppliers that offer warranties and robust customer support is also crucial in maintaining quality standards. -

What customization options should I consider when sourcing throttle cables?

Customization options can include varying lengths, materials, and specific fittings tailored to your application. Discuss with suppliers about the ability to modify cable lengths according to your equipment’s specifications. Consider options for different coatings or insulation that may enhance performance in specific environments, such as marine or off-road conditions. Ensure that the supplier can accommodate these requests without significant delays or increased costs. -

What are the typical minimum order quantities (MOQs) for throttle cables in international trade?

MOQs for throttle cables can vary significantly based on the supplier and the complexity of the customization required. Generally, for standard products, MOQs can range from 50 to 200 units. However, for customized cables, MOQs may be higher due to increased production costs. Always clarify MOQs upfront and discuss potential for smaller trial orders, especially if you are testing a new supplier or product line. -

What payment terms should I expect when purchasing throttle cables internationally?

Payment terms can vary by supplier and region, but common practices include upfront payments, deposits, or net 30 to 60 days post-delivery. For international transactions, consider using secure payment methods such as letters of credit or escrow services to protect both parties. Always negotiate terms that align with your cash flow needs and the supplier’s policies, and ensure you understand any currency exchange implications. -

How can I ensure timely logistics and delivery of throttle cables?

To ensure timely logistics, partner with suppliers who have established shipping processes and reliable carriers. Discuss lead times for production and shipping upfront, and consider using freight forwarders experienced in handling international shipments. Track shipments to stay updated on delivery schedules, and factor in customs clearance times, particularly when importing to regions with stringent regulations. Building strong relationships with logistics partners can also facilitate smoother operations.

Top 3 How To Install Push Pull Throttle Cables Manufacturers & Suppliers List

1. Motion Pro – Throttle Cable Sets

2. Honda – Throttle Cable Issues

Domain: forums.sohc4.net

Registered: 2001 (24 years)

Introduction: 1978 Honda CB550; Push throttle cable; Pull cable is slightly longer than push cable; Issue with push cable being 5mm short; Cables need to be fitted at carb end before adjustments; Different cables for different bike models; Possible mix-up with cable types; Cables purchased from 4into1.com and local bike shop; Reference to Clymer manual for correct setup; Discussion about functionality with only…

3. Advrider – Push/Pull Throttle Cables

Domain: advrider.com

Registered: 2001 (24 years)

Introduction: Push/Pull throttle cables are designed to provide a safety mechanism for motorcycle throttle control. The push cable is intended to assist in closing the throttle, while the pull cable opens it. The discussion highlights that if one cable seizes, the other may also be affected, leading to potential throttle sticking issues. Some users have removed the push cable for a lighter throttle pull and qui…

Strategic Sourcing Conclusion and Outlook for how to install push pull throttle cables

In conclusion, the successful installation of push-pull throttle cables is essential for ensuring optimal performance and safety in various applications. Key takeaways include the importance of proper cable routing, lubrication, and adjustment to minimize free play. By prioritizing these aspects, businesses can significantly enhance the longevity and efficiency of their throttle systems, reducing operational disruptions and maintenance costs.

Strategic sourcing plays a vital role in this process. By collaborating with reliable suppliers who provide high-quality materials and components, companies can ensure that their throttle cables meet industry standards and regulatory requirements. This is particularly critical in international markets such as Africa, South America, the Middle East, and Europe, where compliance and quality can influence market entry and competitive positioning.

As we look to the future, it is imperative for B2B buyers to actively seek partnerships with manufacturers who not only understand the nuances of throttle cable technology but also offer ongoing support and expertise. Engaging with reputable suppliers will not only streamline your installation processes but will also bolster your operational resilience. Take the next step—explore innovative sourcing solutions to elevate your business’s performance in the global marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.