How to Source How To Install Concealed Hinges Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for how to install concealed hinges

As global markets evolve, the demand for stylish and functional cabinetry solutions has surged, making the installation of concealed hinges a critical component for businesses in the furniture and cabinetry sectors. Sourcing the right concealed hinges can be a complex task, especially when considering the diverse needs across regions such as Africa, South America, the Middle East, and Europe. This guide offers a comprehensive exploration of concealed hinges, covering various types, applications, and the critical considerations for selecting quality suppliers.

In an industry where aesthetics and functionality are paramount, understanding the nuances of concealed hinge installation can significantly enhance product offerings and customer satisfaction. This guide not only outlines the step-by-step installation process but also provides insights into cost considerations and supplier vetting strategies tailored for international buyers. By leveraging this knowledge, businesses can make informed purchasing decisions that align with market expectations and regulatory standards in their respective regions, ultimately ensuring a competitive edge in the global marketplace.

Empowering B2B buyers with practical insights, this resource is designed to streamline the sourcing process, enhance installation efficiency, and elevate the overall quality of cabinetry solutions offered. Whether you’re operating in Vietnam, Germany, or elsewhere, mastering the art of concealed hinge installation will position your business for success in an increasingly competitive landscape.

Understanding how to install concealed hinges Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Full Overlay Hinges | Doors cover entire face frame; sleek appearance | Modern cabinetry, retail displays | Pros: Aesthetically pleasing, easy to install. Cons: Limited to specific cabinet designs. |

| Partial Overlay Hinges | Doors partially cover the face frame; versatile | Residential and commercial cabinetry | Pros: Flexible design options. Cons: May require precise measurements for optimal fit. |

| Inset Hinges | Doors sit flush with the cabinet frame; traditional | High-end cabinetry, custom furniture | Pros: Elegant finish, space-saving. Cons: More complex installation, requires precise fitting. |

| Frameless Cabinet Hinges | Designed for cabinets without face frames; hidden | European-style kitchens, modern interiors | Pros: Maximizes interior space, contemporary look. Cons: Installation may require specialized tools. |

| Soft-Close Hinges | Prevents slamming; integrated damping mechanism | Family homes, commercial spaces | Pros: Enhances user experience, reduces wear. Cons: Typically higher cost than standard hinges. |

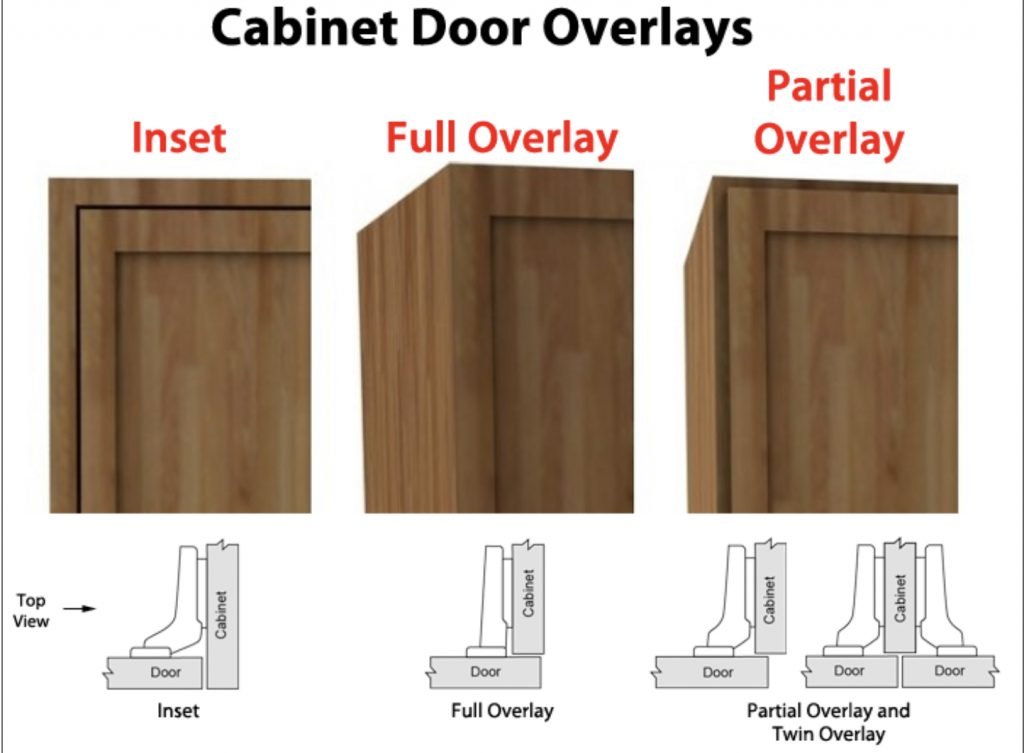

What are the Characteristics and Suitability of Full Overlay Hinges?

Full overlay hinges are designed for cabinetry where the doors completely cover the face frame, providing a seamless, modern look. They are particularly suitable for contemporary kitchen and bathroom designs, as well as retail displays where aesthetics are paramount. B2B buyers should consider the specific cabinet styles they are working with, as these hinges are only compatible with full overlay designs. Additionally, ease of installation makes them a popular choice for quick renovations.

Why Choose Partial Overlay Hinges for Versatile Applications?

Partial overlay hinges allow for flexibility in cabinet design, as the doors only partially cover the face frame. This type is commonly used in both residential and commercial cabinetry, making it a versatile option for various projects. When purchasing, B2B buyers should focus on the compatibility of these hinges with existing cabinetry and ensure accurate measurements are taken to achieve an optimal fit. Their adaptability makes them a preferred choice in diverse applications.

What Makes Inset Hinges Ideal for High-End Cabinetry?

Inset hinges are characterized by doors that sit flush within the cabinet frame, creating an elegant and sophisticated appearance. They are often used in high-end cabinetry and custom furniture where aesthetics and craftsmanship are prioritized. B2B buyers should be aware that the installation process is more complex, requiring precise fitting and measurements. However, the resulting finish is often worth the extra effort, making them a desirable option for luxury projects.

How Do Frameless Cabinet Hinges Maximize Space?

Frameless cabinet hinges are specifically designed for cabinets that lack face frames, allowing for a maximized interior space and a sleek, contemporary aesthetic. This type is particularly popular in European-style kitchens and modern interiors. B2B buyers should consider the installation requirements, as frameless hinges may necessitate specialized tools or techniques. Their ability to create a seamless look makes them an attractive choice for modern cabinetry solutions.

What Advantages Do Soft-Close Hinges Offer for User Experience?

Soft-close hinges are designed to prevent cabinet doors from slamming shut, utilizing an integrated damping mechanism. This feature enhances the user experience, making them ideal for family homes and commercial spaces where safety and durability are important. While they typically come at a higher cost than standard hinges, the benefits of reduced wear and tear on cabinetry can justify the investment. B2B buyers should evaluate the long-term advantages when considering these hinges for their projects.

Key Industrial Applications of how to install concealed hinges

| Industry/Sector | Specific Application of how to install concealed hinges | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Installation of concealed hinges in cabinetry and furniture designs | Enhances aesthetics, functionality, and durability of products | Ensure compatibility with various door styles and weights |

| Hospitality | Use in hotel room cabinetry and restaurant kitchens | Provides a modern look while ensuring easy access and durability | Consider soft-close features for high-traffic environments |

| Retail Fixtures | Application in display cabinets and retail shelving | Improves visual appeal and accessibility of merchandise | Focus on hinges that support heavy glass or wooden doors |

| Residential Construction | Installation in new homes and renovations | Adds value to properties and meets modern design trends | Look for hinges that comply with local building codes |

| Office Furniture | Use in office cabinetry and storage solutions | Promotes a clean, organized workspace while maximizing space | Source hinges that allow for easy adjustments and repairs |

How Do Concealed Hinges Benefit Furniture Manufacturing?

In the furniture manufacturing sector, concealed hinges are integral for creating aesthetically pleasing cabinetry and furniture designs. These hinges not only enhance the visual appeal by maintaining a sleek look but also provide functional advantages, such as smooth operation and easy adjustments. For international buyers, especially from regions like Africa and South America, it’s crucial to source hinges that are compatible with various door styles and weights to ensure durability and performance under different climatic conditions.

What Role Do Concealed Hinges Play in the Hospitality Industry?

In the hospitality industry, concealed hinges are widely used in hotel room cabinetry and restaurant kitchens, where a modern appearance is essential. They facilitate seamless access to storage while maintaining a clean and attractive environment. For B2B buyers in the Middle East and Europe, considering hinges with soft-close features is vital, as these help to minimize noise and enhance guest experiences in high-traffic areas.

How Are Concealed Hinges Used in Retail Fixtures?

Retail fixtures often incorporate concealed hinges in display cabinets and shelving units to improve visual appeal and accessibility. This application ensures that merchandise is showcased effectively while providing a seamless customer experience. Buyers from South America and Europe should prioritize sourcing hinges that can support heavy glass or wooden doors, ensuring that they meet the demands of retail environments.

Why Are Concealed Hinges Important in Residential Construction?

In residential construction, concealed hinges are essential for both new builds and renovations, adding significant value to properties. Their ability to blend into cabinetry aligns with modern design trends that favor minimalism and clean lines. Buyers in Africa and Europe should be aware of local building codes when sourcing these hinges, ensuring compliance while enhancing the overall aesthetic and functionality of homes.

What Are the Advantages of Concealed Hinges in Office Furniture?

In the office furniture sector, concealed hinges are used in cabinetry and storage solutions to promote a clean and organized workspace. They maximize space while offering easy access to stored items. For international B2B buyers, sourcing hinges that allow for easy adjustments and repairs is crucial for maintaining office efficiency and ensuring long-term usability in various office environments.

3 Common User Pain Points for ‘how to install concealed hinges’ & Their Solutions

Scenario 1: Misalignment of Cabinet Doors After Installation

The Problem: One of the most common issues B2B buyers face when installing concealed hinges is the misalignment of cabinet doors. This can result in uneven gaps between doors or between the door and the cabinet frame, leading to an unprofessional appearance. Misalignment often stems from incorrect hinge placement or failure to account for variations in cabinet frame dimensions. Such problems can be particularly frustrating for businesses that rely on precise installations to meet client expectations.

The Solution: To avoid misalignment, buyers should emphasize accurate measurements during the installation process. Before drilling, ensure that the door’s height, width, and thickness are meticulously recorded. It’s advisable to use a combination square to mark hinge placement lines, ensuring they are parallel to the door edges. When installing, adjust the hinges before fully securing them; this allows for real-time adjustments. Consider using a shim to maintain even gaps during installation, making it easier to achieve proper alignment. Furthermore, investing in high-quality concealed hinges that offer fine-tuning features can significantly improve alignment outcomes, allowing for side-to-side and up-and-down adjustments even after the doors are hung.

Scenario 2: Difficulty in Selecting the Right Concealed Hinges

The Problem: B2B buyers often encounter challenges when it comes to selecting the appropriate concealed hinges for their specific cabinet designs. With various types of concealed hinges—such as full overlay, partial overlay, and inset hinges—making the right choice can be overwhelming. Incorrect hinge selection not only leads to installation issues but can also result in additional costs and project delays due to the need for replacements.

The Solution: To mitigate this issue, it is crucial to understand the specific requirements of the cabinets being used. Buyers should begin by assessing the cabinet design and door overlay type. For instance, full overlay hinges are ideal for doors that cover the entire cabinet frame, while inset hinges are suitable for doors that sit flush with the cabinet. Consult with hinge manufacturers or suppliers to obtain detailed specifications and compatibility information. Additionally, leveraging digital tools or hinge calculators available from manufacturers can help buyers make informed decisions. Ensuring that the chosen hinges are compatible with the door thickness and weight is essential for optimal performance and longevity.

Scenario 3: Challenges with Hinge Adjustments Post-Installation

The Problem: Even after a successful installation, B2B buyers may find themselves struggling with hinge adjustments to achieve the desired door alignment. Over time, cabinet doors can shift due to environmental factors, such as humidity or temperature changes, leading to functionality issues. If not addressed promptly, this can result in doors that do not close properly, which can compromise the aesthetic and operational integrity of cabinetry.

The Solution: Buyers should familiarize themselves with the adjustment features of their selected concealed hinges. Most concealed hinges allow for three types of adjustments: side-to-side, up-and-down, and in-and-out. Regularly checking these adjustments is advisable, particularly in climates with fluctuating temperatures or humidity levels. To make adjustments, locate the screws on the hinge arm and mounting plate, and follow the manufacturer’s guidelines for fine-tuning. It’s also beneficial to create a maintenance schedule to review door alignment periodically. Training staff on these adjustment techniques can empower teams to address alignment issues proactively, ensuring cabinetry remains functional and visually appealing over time.

Strategic Material Selection Guide for how to install concealed hinges

What Materials Are Commonly Used for Concealed Hinges?

When selecting materials for concealed hinges, it’s crucial to consider their properties and how they align with the specific requirements of your application. Here, we analyze four common materials: stainless steel, zinc alloy, brass, and plastic. Each material has distinct characteristics that can impact performance, durability, and overall suitability for various environments.

How Does Stainless Steel Perform in Concealed Hinges?

Stainless steel is a popular choice for concealed hinges due to its excellent corrosion resistance and strength. This material can withstand high temperatures and pressures, making it suitable for a range of applications, from residential to commercial settings. The key advantage of stainless steel hinges is their durability; they are less likely to warp or bend under stress. However, they can be more expensive than other materials, which may be a consideration for budget-conscious buyers.

For international buyers, compliance with standards such as ASTM A240 for stainless steel is essential. Countries in Europe and the Middle East often have strict regulations regarding material quality, which stainless steel meets effectively. However, in regions like Africa and South America, the availability of high-grade stainless steel may vary, impacting procurement strategies.

What Benefits Does Zinc Alloy Offer for Concealed Hinges?

Zinc alloy is another common material used for concealed hinges, particularly in applications where cost-effectiveness is a priority. Zinc alloys are generally more affordable than stainless steel and provide decent corrosion resistance, making them suitable for indoor applications. They are lightweight and easy to manufacture, which can simplify the installation process.

However, zinc alloy hinges may not perform well in high-humidity environments, as they are prone to corrosion over time. For international buyers, it is important to consider local climate conditions and ensure that the chosen zinc alloy meets relevant standards, such as DIN EN 1386 in Europe. This can help mitigate issues related to premature failure in humid regions.

Why Choose Brass for Concealed Hinges?

Brass is often chosen for its aesthetic appeal and moderate strength. It provides a classic look that can enhance the overall design of cabinetry and furniture. Brass hinges are resistant to corrosion, particularly in dry environments, making them suitable for decorative applications. However, they can be more expensive than zinc alloy and may require more maintenance to retain their appearance.

From a B2B perspective, buyers in Europe and the Middle East may prefer brass for high-end applications, while those in Africa and South America might find it less accessible due to higher costs. Compliance with standards like JIS H 3250 for brass materials can also be a consideration for international procurement.

How Do Plastic Hinges Compare in Terms of Performance?

Plastic hinges are gaining popularity due to their lightweight nature and resistance to corrosion. They are often used in applications where moisture is a concern, such as in kitchens or bathrooms. Plastic hinges are typically the most cost-effective option, making them attractive for budget-sensitive projects.

However, they may lack the strength and durability of metal hinges, which can limit their use in heavy-duty applications. International buyers should consider the specific requirements of their projects, as plastic hinges may not meet the same performance standards as metal options. Compliance with local regulations regarding plastic materials is also essential, particularly in regions with stringent environmental laws.

Summary of Material Selection for Concealed Hinges

| Material | Typical Use Case for how to install concealed hinges | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-end cabinetry and commercial applications | Excellent corrosion resistance and durability | Higher cost compared to other materials | High |

| Zinc Alloy | Indoor applications and budget-friendly projects | Cost-effective and lightweight | Prone to corrosion in high humidity | Low |

| Brass | Decorative furniture and cabinetry | Aesthetic appeal and moderate corrosion resistance | Higher cost and maintenance requirements | Medium |

| Plastic | Moisture-prone environments like kitchens and baths | Lightweight and corrosion-resistant | Limited strength for heavy-duty use | Low |

By understanding the properties and implications of these materials, B2B buyers can make informed decisions that align with their operational needs and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for how to install concealed hinges

What Are the Key Stages in the Manufacturing Process of Concealed Hinges?

The manufacturing process of concealed hinges involves several critical stages that ensure the final product meets quality standards and functional requirements. These stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Concealed Hinges?

The first step in manufacturing concealed hinges is the preparation of materials. Manufacturers typically use high-quality metals such as stainless steel, brass, or zinc alloys, selected for their strength, durability, and resistance to corrosion.

-

Material Selection: Suppliers often provide material certifications to verify the quality and specifications of the metals used. This documentation is crucial for B2B buyers to ensure they are sourcing reliable products.

-

Cutting and Shaping: The raw materials are cut into appropriate sizes using laser cutting or shearing techniques. This is followed by shaping processes such as stamping or forging, where the hinge components are formed to the required specifications.

-

Surface Treatment: After cutting and shaping, the components undergo surface treatment processes like galvanization, powder coating, or anodizing to enhance their corrosion resistance and aesthetic appeal.

What Techniques Are Utilized in Forming Concealed Hinges?

The forming stage is essential for achieving the precise geometry of concealed hinges. Key techniques include:

-

Stamping: This technique involves using a die to shape the metal into specific forms. Precision stamping is critical to ensure that the hinge components align perfectly during assembly.

-

Machining: CNC (Computer Numerical Control) machining is often employed to achieve tight tolerances and complex shapes that cannot be easily formed through stamping alone. This step ensures the hinge fits seamlessly within the cabinet structure.

-

Bending and Forming: Some components may require bending to create specific angles or shapes. This process is performed using hydraulic or mechanical presses, ensuring uniformity across batches.

How Are Concealed Hinges Assembled?

The assembly stage combines the various components into a functional hinge. This process typically includes:

-

Component Assembly: Each hinge consists of multiple parts, including hinge cups, mounting plates, and arms. These parts are assembled in a controlled environment to prevent contamination and ensure alignment.

-

Fastening: Screws or rivets are used to secure the components together. Automated assembly lines may use robotic arms for precision and speed, enhancing efficiency while maintaining quality.

-

Final Adjustments: Once assembled, the hinges are adjusted to ensure smooth operation. This may involve testing the soft-close mechanisms and ensuring that the hinges can be fine-tuned for alignment.

What Are the Final Finishing Processes for Concealed Hinges?

The finishing stage enhances the aesthetic quality and durability of the concealed hinges. Key processes include:

-

Surface Finishing: Techniques such as polishing, coating, or painting are applied to provide a visually appealing finish and protect against wear and corrosion.

-

Quality Control Inspections: Before packaging, hinges undergo rigorous inspections to check for defects in finish, functionality, and adherence to specifications.

-

Packaging: Proper packaging ensures that hinges are protected during transportation and storage, reducing the risk of damage.

What Quality Control Measures Are Implemented for Concealed Hinges?

Quality control (QC) is vital throughout the manufacturing process to ensure that concealed hinges meet international and industry-specific standards.

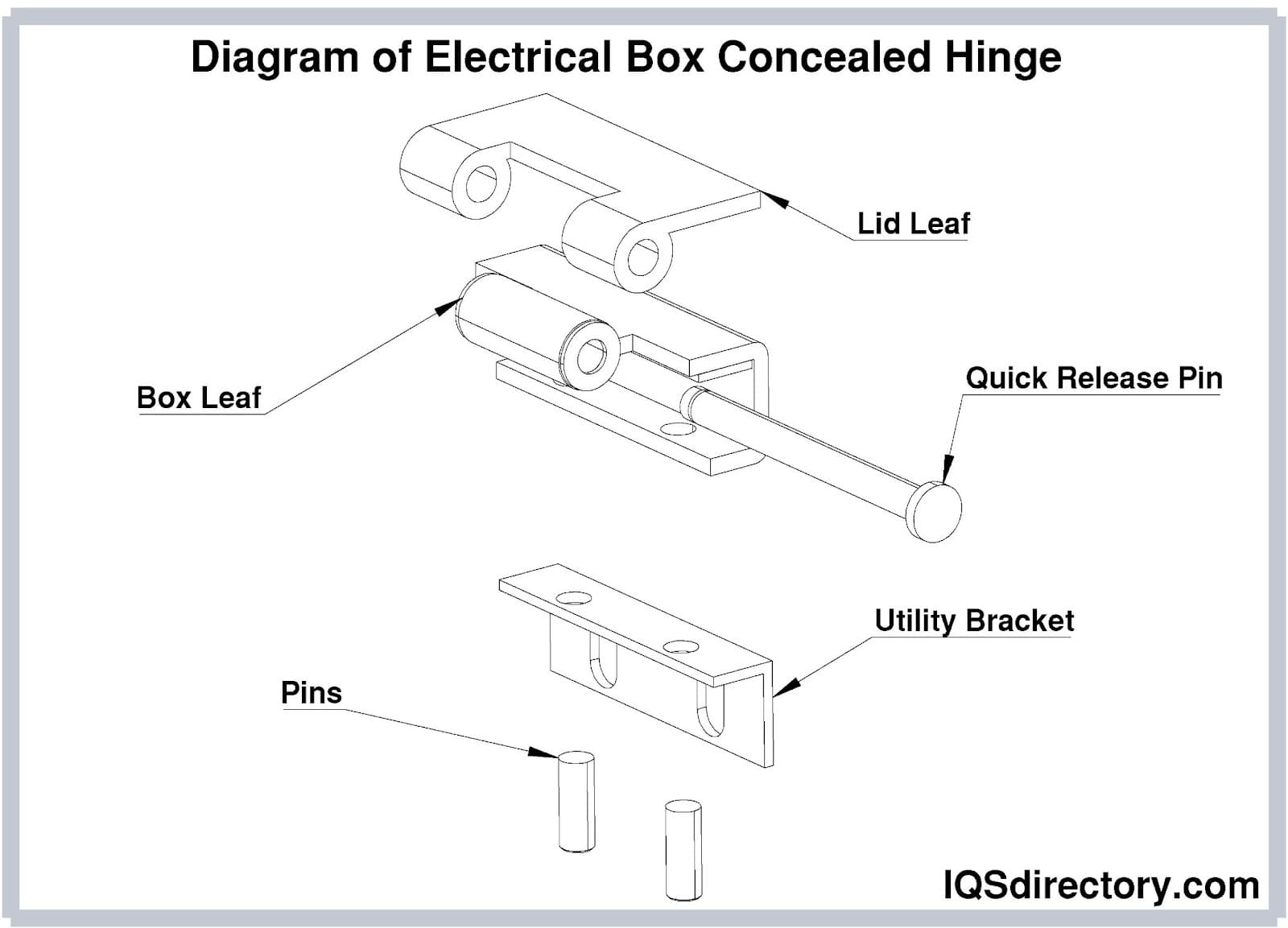

Illustrative image related to how to install concealed hinges

Which International Standards Apply to Concealed Hinges Manufacturing?

B2B buyers should be aware of various international standards that govern the manufacturing of concealed hinges:

-

ISO 9001: This quality management standard ensures that manufacturers maintain consistent quality in their processes and products. Compliance with ISO 9001 can be a strong indicator of a supplier’s reliability.

-

CE Marking: For products sold in the European market, CE marking indicates compliance with health, safety, and environmental protection standards. This certification is essential for B2B buyers in Europe.

-

API Standards: For specialized applications, such as those in the oil and gas industry, manufacturers may adhere to API specifications, ensuring that the hinges can withstand extreme conditions.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality checkpoints are integrated at various stages of the manufacturing process to catch defects early:

-

Incoming Quality Control (IQC): Upon receiving raw materials, manufacturers conduct inspections to verify material specifications and quality.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, inspectors monitor processes to ensure adherence to standards, checking for dimensional accuracy and functional performance.

-

Final Quality Control (FQC): Before products are shipped, final inspections are conducted to verify that all components function correctly and meet specified criteria.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s QC practices is crucial to ensure the reliability of concealed hinges.

-

Supplier Audits: Conducting on-site audits can provide insight into the manufacturing processes and QC measures in place. This hands-on approach helps buyers assess the supplier’s capabilities and commitment to quality.

-

Quality Reports: Requesting detailed quality reports can help buyers understand the frequency of inspections, defect rates, and corrective actions taken by the manufacturer.

-

Third-Party Inspections: Utilizing third-party inspection services can provide an impartial assessment of the manufacturer’s quality control processes and product quality.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers should consider several nuances when navigating the quality control landscape:

-

Cultural Differences: Understanding cultural attitudes towards quality and manufacturing can help in building effective relationships with suppliers across different regions.

-

Regulatory Compliance: Buyers should be aware of local regulations that may impact product quality and safety standards, especially when importing goods.

-

Communication: Clear communication regarding quality expectations and standards is essential to ensure that suppliers understand and meet the buyer’s requirements.

In conclusion, the manufacturing processes and quality assurance measures for concealed hinges are critical to delivering high-quality products. By understanding these processes and implementing thorough verification practices, B2B buyers can confidently source concealed hinges that meet their specific needs, ensuring reliability and satisfaction in their applications.

Illustrative image related to how to install concealed hinges

Practical Sourcing Guide: A Step-by-Step Checklist for ‘how to install concealed hinges’

Introduction

This guide serves as a practical checklist for B2B buyers looking to procure concealed hinges and understand their installation. Concealed hinges not only provide a sleek and modern aesthetic but also enhance the functionality of cabinetry. By following these steps, you will ensure that you select the right products and understand the installation process, ultimately leading to successful project outcomes.

Step 1: Define Your Technical Specifications

Before sourcing concealed hinges, it is essential to establish the technical specifications required for your project. This includes determining the type of hinges needed based on cabinet design—full overlay, partial overlay, or inset hinges. Additionally, consider the weight and size of the cabinet doors, as these factors will dictate the strength and number of hinges required.

- Door Thickness: Measure the thickness of your cabinet doors to ensure compatibility with the selected hinges.

- Weight Capacity: Assess the weight of the doors to determine the appropriate hinge type and quantity.

Step 2: Research and Identify Reliable Suppliers

Once you have your specifications, research potential suppliers who specialize in concealed hinges. Look for suppliers with a proven track record in your target market regions, such as Africa, South America, and Europe. A reliable supplier will have a range of products that meet your needs and provide comprehensive support.

- Industry Reputation: Check reviews and testimonials from other businesses to gauge supplier reliability.

- Product Range: Ensure the supplier offers various hinge types and features, including soft-close options.

Step 3: Evaluate Supplier Certifications and Compliance

It’s crucial to verify that the suppliers you consider comply with relevant industry standards and regulations. Certifications ensure that the products meet quality and safety benchmarks, which is particularly important in international markets.

Illustrative image related to how to install concealed hinges

- ISO Certifications: Look for ISO certifications that demonstrate adherence to quality management systems.

- Local Compliance: Ensure that products meet local regulations in your target markets, which can vary significantly.

Step 4: Request Samples for Quality Assessment

Before finalizing your order, request samples of the concealed hinges. This will allow you to assess the quality, finish, and functionality of the hinges firsthand. Evaluating samples can prevent costly mistakes later on.

- Material Quality: Inspect the material for durability and resistance to wear and tear.

- Functionality: Test the hinge operation to ensure smooth movement and adjustability.

Step 5: Discuss Pricing and Terms

Engage in discussions regarding pricing, minimum order quantities, and payment terms with your selected suppliers. Understanding the financial implications upfront can help you budget effectively and prevent unexpected costs.

- Bulk Discounts: Inquire about discounts for larger orders, which can significantly impact your overall costs.

- Payment Flexibility: Negotiate payment terms that align with your cash flow needs, especially for large orders.

Step 6: Plan for Installation and Support

After securing your hinges, ensure you have a clear plan for installation. Some suppliers may offer installation guides or support, which can be beneficial for your team.

- Installation Manuals: Request comprehensive installation manuals or guides to facilitate the process.

- Technical Support: Confirm if the supplier provides technical support in case you encounter issues during installation.

Step 7: Establish a Maintenance Schedule

Concealed hinges require periodic maintenance to ensure longevity and smooth operation. Establish a maintenance schedule that includes regular inspections and cleaning to prevent issues down the line.

- Cleaning Protocols: Outline cleaning methods to avoid damage to the hinges.

- Adjustment Checks: Schedule periodic checks for adjustments to ensure doors remain aligned and functional.

By following this checklist, B2B buyers can efficiently source concealed hinges and successfully implement them in their projects, ensuring high-quality outcomes and customer satisfaction.

Comprehensive Cost and Pricing Analysis for how to install concealed hinges Sourcing

What Are the Key Cost Components for Installing Concealed Hinges?

When analyzing the cost structure for installing concealed hinges, it’s essential to break down the various components that contribute to the overall expense. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

-

Materials: The type and quality of concealed hinges significantly influence costs. Standard hinges may range from $1 to $5 per unit, while premium or specialty options can exceed $20. Additional materials include screws, shims, and lubricants, which may add approximately $0.50 to $2 per door.

-

Labor: Labor costs can vary widely based on the region and the complexity of the installation. In regions with higher labor costs, such as parts of Europe, installation might range from $50 to $150 per hour. Conversely, in developing regions, labor may be available at lower rates, typically between $20 and $50 per hour.

-

Manufacturing Overhead: This includes costs related to production facilities, utilities, and employee salaries. Manufacturing overhead can account for 10-20% of the total production cost, depending on the efficiency of the manufacturing process.

-

Tooling: Depending on the installation scale, initial tooling costs for drills, bits, and other specialized equipment can range from $100 to $500. For large-scale projects, these costs can be amortized over numerous installations, reducing the per-unit cost.

-

Quality Control (QC): Ensuring that the hinges meet safety and quality standards is crucial. QC processes can add around 5-10% to the total production cost. Investing in quality ensures fewer returns and replacements, ultimately saving money.

-

Logistics: Shipping and handling costs can vary based on the distance and mode of transportation. International shipping can inflate costs, especially for bulk orders. Logistics expenses can typically account for 5-15% of the total cost.

-

Margin: Suppliers typically add a profit margin of 10-30% over the total cost of production, influenced by competition and market demand.

What Influences Pricing for Concealed Hinges?

Several factors can influence pricing in the concealed hinge market:

-

Volume/MOQ: Larger orders often qualify for discounts, significantly reducing the per-unit cost. Minimum order quantities (MOQ) can vary by supplier, so negotiating terms is crucial.

-

Specifications/Customization: Custom hinges or those with specific features (like soft-close mechanisms) will generally cost more. Understanding your requirements upfront can prevent costly modifications later.

-

Materials and Quality Certifications: Premium materials and certifications (e.g., ISO, CE) can lead to higher prices. Buyers should assess whether these certifications are necessary for their projects.

-

Supplier Factors: Supplier reliability, reputation, and location can impact pricing. Established suppliers may charge more due to brand trust, while newer or less known suppliers might offer lower prices to enter the market.

-

Incoterms: The terms of shipping and delivery (Incoterms) can also affect total costs. Buyers should be aware of who is responsible for shipping fees, insurance, and duties, which can vary by region.

How Can Buyers Negotiate for Better Prices on Concealed Hinges?

To achieve cost efficiency, buyers should adopt several strategies:

-

Negotiate Bulk Purchases: Leverage large orders to negotiate better prices. Suppliers are often willing to provide discounts for higher quantities.

-

Consider Total Cost of Ownership: Evaluate the long-term costs associated with the hinges, including maintenance and potential replacements. Choosing higher-quality hinges may have a higher upfront cost but can save money over time.

-

Research Market Prices: Understanding the market landscape helps buyers negotiate effectively. Being informed about competitor pricing and features allows for more advantageous discussions with suppliers.

-

Explore Local Suppliers: In regions such as Africa and South America, sourcing from local suppliers can reduce shipping costs and lead times, potentially providing a better overall value.

-

Stay Flexible with Specifications: If possible, be open to alternative materials or designs that can reduce costs without compromising quality.

Disclaimer on Indicative Prices

The prices mentioned are indicative and can vary based on factors such as supplier agreements, geographic location, and market conditions. Buyers should conduct thorough market research and obtain multiple quotes to ensure competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing how to install concealed hinges With Other Solutions

Introduction to Alternative Solutions for Concealed Hinges Installation

When considering cabinet hardware, concealed hinges present a modern, sleek option, but they are not the only solution available. B2B buyers often weigh the benefits of concealed hinges against other types of hinges and mounting solutions. This analysis will compare the installation of concealed hinges with traditional exposed hinges and pivot hinges, allowing buyers to make informed decisions based on their specific needs.

Comparison Table

| Comparison Aspect | How To Install Concealed Hinges | Traditional Exposed Hinges | Pivot Hinges |

|---|---|---|---|

| Performance | Provides a seamless look; adjustable for perfect alignment | Visible; limited adjustability | Offers smooth operation but requires more space |

| Cost | Moderate cost; varies by quality | Generally lower cost | Higher cost due to complexity |

| Ease of Implementation | Requires precise measurements and tools | Simple installation process | More complex; may require additional support |

| Maintenance | Low maintenance; occasional lubrication needed | Moderate; visible wear may be more noticeable | Moderate; hinges can wear over time |

| Best Use Case | High-end cabinetry, modern interiors | Budget-friendly projects, casual use | Commercial applications, heavy doors |

Detailed Breakdown of Alternatives

Traditional Exposed Hinges

Traditional exposed hinges are the most recognizable type of hinge, often made from metal and visible when the cabinet doors are closed. They are generally easier to install, as they require less precise measurements and fewer tools. However, their visibility can detract from the overall aesthetic of modern cabinetry. While they are usually lower in cost, the trade-off comes in the form of limited adjustability, which can complicate alignment and lead to uneven gaps over time. These hinges are best suited for budget-conscious projects or situations where aesthetics are less critical.

Pivot Hinges

Pivot hinges operate differently from concealed and traditional hinges, allowing doors to pivot on a point rather than swing open from a side. This design can create a striking visual impact, especially in large or heavy doors commonly found in commercial settings. While pivot hinges provide a smooth operation, their installation can be more complex and may require additional structural support. They tend to be more expensive than both concealed and exposed hinges due to their intricate design and engineering requirements. Maintenance is moderate, as they can wear over time, but they are ideal for situations where door weight and space constraints are a consideration.

Conclusion: How Should B2B Buyers Choose the Right Solution?

Selecting the appropriate hinge installation method is critical for achieving the desired functionality and aesthetics in cabinetry. For buyers focused on a modern, clean look, concealed hinges are often the best choice despite their slightly higher installation complexity. In contrast, those with budget constraints or less emphasis on visual appeal may find traditional exposed hinges more suitable. Lastly, for commercial applications requiring heavy-duty performance, pivot hinges could offer the best solution. Assessing specific project requirements, budget, and desired outcomes will guide B2B buyers in making the right decision for their unique needs.

Essential Technical Properties and Trade Terminology for how to install concealed hinges

What Are the Key Technical Properties of Concealed Hinges?

When selecting concealed hinges for installation, understanding their technical properties is crucial for ensuring compatibility and performance. Here are several essential specifications to consider:

-

Material Grade

The material grade of concealed hinges typically includes options like stainless steel, brass, or zinc alloys. Stainless steel is preferred for its corrosion resistance and durability, making it ideal for humid environments or outdoor applications. The choice of material affects the hinge’s longevity and suitability for different markets, particularly where climate conditions vary significantly. -

Load Capacity

Load capacity refers to the maximum weight a hinge can support. This specification is vital for ensuring that the hinge can handle the weight of the cabinet door without sagging or failing. When dealing with larger doors, such as those found in commercial applications, selecting hinges with a higher load capacity is essential to maintain structural integrity. -

Cup Depth and Diameter

Concealed hinges require specific cup depths and diameters for proper installation. The standard cup size is typically 35mm in diameter, but variations exist depending on the hinge type. The cup depth must be accurately drilled to allow for a flush fit, influencing the overall aesthetics and function of the cabinet door. -

Adjustability Range

The adjustability range of concealed hinges allows for fine-tuning the door’s position after installation. This property is crucial for achieving perfect alignment, especially in environments where cabinets may not be perfectly square. The ability to make adjustments in multiple directions (side-to-side, up-and-down, and in-and-out) enhances user satisfaction and reduces the need for rework. -

Finishes and Coatings

The finish or coating applied to concealed hinges impacts both appearance and performance. Options include brushed nickel, chrome, and powder-coated finishes. These finishes not only enhance aesthetic appeal but also provide additional protection against wear and corrosion, making them suitable for various applications in different markets.

What Are Common Trade Terms in Concealed Hinge Sourcing?

Understanding industry jargon can significantly enhance communication and negotiation with suppliers. Here are several key terms relevant to the procurement of concealed hinges:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of concealed hinges, working with OEMs can ensure that you receive high-quality products that meet specific design requirements, often leading to better integration with your cabinets. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is essential for budget planning and inventory management. Suppliers often have MOQs to ensure that production costs are covered, which can affect smaller businesses looking to source hinges for limited projects. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price quotes from suppliers for specific products or services. When sourcing concealed hinges, submitting an RFQ helps clarify requirements and obtain competitive pricing, allowing B2B buyers to make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are a set of rules that define the responsibilities of sellers and buyers in international transactions. Familiarity with Incoterms is crucial for understanding shipping costs, risks, and responsibilities, especially when sourcing hinges from international suppliers across regions like Africa, South America, the Middle East, and Europe. -

Lead Time

Lead time refers to the amount of time it takes for a supplier to fulfill an order after it is placed. Knowing the lead time for concealed hinges is important for project planning and ensures that materials arrive on schedule, thereby minimizing disruptions in installation processes.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions, ensuring that their concealed hinge installations meet both functional and aesthetic expectations.

Navigating Market Dynamics and Sourcing Trends in the how to install concealed hinges Sector

What Are the Global Drivers Influencing the Concealed Hinges Market?

The market for concealed hinges is experiencing significant growth driven by several global factors. The increasing demand for modern, aesthetic cabinetry solutions is a primary driver, particularly in residential and commercial sectors. As more consumers opt for sleek, minimalist designs, the preference for concealed hinges that provide a seamless appearance without visible hardware is surging. Additionally, the rise of DIY home improvement projects, fueled by digital platforms and tutorial content, is empowering end-users to install these hinges themselves, which is influencing sourcing decisions.

Illustrative image related to how to install concealed hinges

Emerging technologies are also reshaping the B2B landscape for concealed hinges. Innovations in manufacturing processes, such as the use of advanced materials and automated production lines, are enhancing product quality and reducing lead times. For international buyers, particularly those from Africa, South America, the Middle East, and Europe, this means access to a broader range of high-quality products at competitive prices. Furthermore, the ongoing digital transformation is leading to improved supply chain transparency and efficiency, making it easier for buyers to source concealed hinges from reputable suppliers across the globe.

How Are Sustainability and Ethical Sourcing Shaping the Concealed Hinges Industry?

Sustainability has become a cornerstone of modern B2B procurement practices, particularly in the hardware sector. The environmental impact of manufacturing processes and materials used in concealed hinges is under scrutiny, prompting companies to adopt greener practices. Suppliers are increasingly expected to provide products that are not only functional but also environmentally friendly, which includes using recycled materials or sustainably sourced timber.

Ethical sourcing is also gaining prominence, with buyers prioritizing suppliers who demonstrate a commitment to fair labor practices and community engagement. Certifications such as Forest Stewardship Council (FSC) for wood products or ISO 14001 for environmental management systems are becoming essential for suppliers to showcase their dedication to sustainability. For B2B buyers, particularly those in regions like Europe where regulatory standards are stringent, partnering with ethically compliant manufacturers can enhance brand reputation and ensure compliance with local laws.

What is the Evolution of Concealed Hinges in the B2B Market?

The evolution of concealed hinges can be traced back to their initial introduction as a solution for aesthetic cabinetry. Originally designed for high-end furniture, concealed hinges have become increasingly accessible, with advancements in manufacturing technology making them available at a lower cost. Over the years, the integration of soft-close mechanisms and adjustable features has enhanced their appeal, allowing for more precise installation and improved user experience.

As the global market has expanded, so has the variety of concealed hinges available, catering to diverse needs across different sectors, from residential to commercial applications. This evolution reflects broader trends in the B2B marketplace, where customization and innovation are key differentiators. As international buyers seek reliable, high-quality products, the evolution of concealed hinges continues to align with market demands for both functionality and design.

What Should International Buyers Consider When Sourcing Concealed Hinges?

International buyers should focus on key factors when sourcing concealed hinges, including product compatibility with local cabinetry standards, the reputation of manufacturers, and supply chain reliability. Understanding the specific needs of different markets—such as the preference for soft-close features in Europe versus more traditional options in other regions—can guide effective sourcing strategies. Additionally, leveraging digital tools and platforms for supplier research can enhance the procurement process, ensuring that buyers are well-informed about the latest trends and product offerings.

In conclusion, the concealed hinges market is poised for growth, driven by aesthetic preferences, technological advancements, and a strong focus on sustainability. For B2B buyers, navigating these dynamics effectively can lead to enhanced product offerings and improved customer satisfaction.

Frequently Asked Questions (FAQs) for B2B Buyers of how to install concealed hinges

-

How do I solve uneven gaps around cabinet doors when installing concealed hinges?

Uneven gaps can arise from incorrect hinge placement or misalignment during installation. To solve this, first ensure that the hinges are installed at the same height on both the cabinet and door. Use the side-to-side adjustment screw on the hinge arm to align the door with the cabinet frame. If the cabinet itself is not level, you may need to shim the cabinet or adjust the mounting plates accordingly. Regularly check your measurements and adjustments to maintain uniform gaps. -

What is the best type of concealed hinge for different cabinet styles?

The best type of concealed hinge depends on your cabinet style. For full overlay cabinets, full overlay hinges are ideal as they cover the entire face frame. Partial overlay hinges are suitable for cabinets where doors partially overlap the frame. Inset hinges work well for doors that sit flush with the cabinet. For frameless cabinets, frameless hinges are the right choice. Always consider door thickness and weight to select hinges that will provide adequate support and functionality. -

What are the common challenges faced during the installation of concealed hinges?

Common challenges include misalignment of doors, uneven gaps, and difficulty in closing. Misalignment can often be resolved through careful measurement and adjustment of the hinges. Uneven gaps may require repositioning the hinges or shimming the cabinet. If doors do not close properly, check that the hinge cup holes are drilled to the correct depth. Additionally, ensure that all screws are tightened securely to prevent movement. Thorough preparation and patience can help mitigate these issues. -

How can I ensure the quality of concealed hinges when sourcing internationally?

To ensure quality when sourcing concealed hinges, vet suppliers thoroughly. Look for manufacturers with a proven track record, positive customer reviews, and certifications that meet international standards. Request product samples to evaluate the hinges’ material, finish, and functionality. Additionally, inquire about their quality assurance processes and any warranties they offer. Establishing a strong relationship with suppliers can also facilitate better quality control and responsiveness to your needs. -

What are the minimum order quantities (MOQs) for concealed hinges in B2B transactions?

MOQs for concealed hinges vary by supplier and can depend on factors such as the type of hinge and customization options. Typically, manufacturers may set MOQs ranging from 100 to 1000 units to ensure production efficiency and cost-effectiveness. Always clarify MOQs with potential suppliers during the negotiation phase. If your needs are lower than their MOQ, some suppliers may offer flexibility or suggest alternative solutions, such as joining with other buyers for bulk purchases. -

What payment terms are standard in international B2B transactions for concealed hinges?

Standard payment terms in international B2B transactions typically include options like a 30% deposit upfront and the remaining balance before shipment. Some suppliers may accept letters of credit or payment upon delivery for larger orders. It’s essential to negotiate terms that protect both parties, ensuring that payment milestones align with delivery schedules. Always review the supplier’s payment policies and consider using escrow services for added security in high-value transactions. -

How can I customize concealed hinges to meet specific project requirements?

Customization options for concealed hinges can include variations in size, finish, weight capacity, and additional features like soft-close mechanisms. When discussing customization with suppliers, clearly outline your specifications and intended application. Many manufacturers are willing to accommodate custom requests, but be prepared to meet minimum order quantities and possibly longer lead times. Requesting prototypes can help ensure that the customized hinges meet your design and functionality needs before committing to a larger order. -

What logistics considerations should I keep in mind when importing concealed hinges?

When importing concealed hinges, consider logistics factors such as shipping methods, customs regulations, and lead times. Choose a reliable freight forwarder familiar with your destination country’s import laws. Be aware of any tariffs or duties that may apply to your order. It’s also crucial to plan for potential delays and ensure that your supply chain can accommodate them. Establishing clear communication with your supplier about shipping timelines and tracking can help streamline the process.

Top 4 How To Install Concealed Hinges Manufacturers & Suppliers List

1. This Old House – Concealed Cabinet Hinges

Domain: thisoldhouse.com

Registered: 1998 (27 years)

Introduction: Concealed cabinet hinges are hardware components that remain hidden when a cabinet door is closed, providing a clean, seamless look. They support the weight of the door while allowing smooth operation and easy adjustability. Common types include: Full overlay hinges (for doors that completely cover the cabinet face frame), Partial overlay hinges (for doors that partially cover the face frame), Ins…

2. Woodshop Diaries – Concealed Hinges

Domain: woodshopdiaries.com

Registered: 2016 (9 years)

Introduction: Concealed hinges (also referred to as European hinges) are used for installing cabinet doors and are favored for being hidden in the finished project, inexpensive, and easy to adjust. They consist of a hinge cup that is installed onto the door and a mounting plate that attaches the hinge to the cabinet. The installation requires a concealed hinge jig, clamp, drill/driver, and screwdriver. There ar…

3. Kreg Tool – Concealed Hinge Jig

Domain: learn.kregtool.com

Registered: 1999 (26 years)

Introduction: Concealed Hinge Jig, Cabinet Door Mounting Jig

4. Ana White – Concealed Hinges

Domain: ana-white.com

Registered: 2010 (15 years)

Introduction: Concealed Hinges (also known as Euro Hinges) are ideal for adding doors to cabinetry projects. They are hidden behind the door for a clean look, available at most home improvement stores, reasonably priced, and easy to open and close without needing a magnetic clasp. They are adjustable with a screwdriver and can be installed with basic knowledge.

Key Features:

– Types: Face Frame and Frameless

…

Strategic Sourcing Conclusion and Outlook for how to install concealed hinges

In the realm of cabinetry, the installation of concealed hinges offers a blend of aesthetic appeal and functional efficiency. By understanding the nuances of hinge selection, precise measurements, and meticulous installation techniques, international B2B buyers can enhance their offerings and elevate customer satisfaction. The importance of strategic sourcing cannot be overstated—identifying reliable suppliers who provide high-quality concealed hinges can significantly reduce operational risks and ensure consistency in project outcomes.

Furthermore, as you navigate the global marketplace, consider the growing demand for modern cabinetry solutions across regions like Africa, South America, the Middle East, and Europe. Emphasizing innovative hardware, such as concealed hinges, not only meets consumer preferences but also positions your business as a leader in design and functionality.

Illustrative image related to how to install concealed hinges

Looking ahead, seize the opportunity to invest in training and resources that empower your teams to execute precise installations. By doing so, you not only enhance your product offerings but also foster long-term relationships with clients seeking quality and reliability. Take the next step in your sourcing strategy—partner with trusted manufacturers and explore the latest trends in concealed hinge technology to stay ahead in a competitive market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.