How to Source Hottest Ebony Tube Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for hottest ebony tube

In today’s competitive landscape, sourcing the hottest ebony tube presents a unique challenge for international B2B buyers. As demand for high-quality ebony products surges, understanding the complexities of this market—ranging from product types and applications to supplier vetting and pricing—is essential. This guide serves as a comprehensive resource, designed to empower stakeholders across Africa, South America, the Middle East, and Europe—including key markets like Germany and Nigeria—to make informed purchasing decisions.

Navigating the global market for ebony tubes requires a deep dive into various aspects, such as the types of ebony available, their specific applications in industries like furniture, construction, and artistic endeavors, and the critical importance of thorough supplier vetting to ensure product quality and ethical sourcing. Additionally, understanding the cost factors involved will help buyers negotiate better deals and establish long-term partnerships.

By leveraging the insights and actionable strategies outlined in this guide, B2B buyers can confidently approach their sourcing needs, ensuring they not only meet their business requirements but also align with global sustainability standards. This resource is your key to unlocking the potential of the ebony tube market, enabling you to thrive in a dynamic and evolving industry.

Understanding hottest ebony tube Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Ebony Tube Hair Brushes | Made from durable materials, ergonomic design, various sizes | Hair salons, beauty supply wholesalers | Pros: High durability, user-friendly. Cons: Higher initial investment. |

| Ebony Tube for Plumbing | Resistant to heat and pressure, lightweight, non-corrosive | Construction, plumbing supply companies | Pros: Long lifespan, low maintenance. Cons: Limited availability in some regions. |

| Ebony Tube for Electrical Wiring | Insulated, flexible, lightweight, high conductivity | Electrical contractors, industrial suppliers | Pros: Enhanced safety, versatile applications. Cons: Potentially higher costs than alternatives. |

| Ebony Tube for Arts & Crafts | Variety of sizes and finishes, customizable, lightweight | Art supply stores, craft wholesalers | Pros: Creative versatility, appealing aesthetics. Cons: May require special ordering. |

| Ebony Tube for Furniture | Solid construction, various finishes, eco-friendly options | Furniture manufacturers, interior designers | Pros: Attractive appearance, sustainable. Cons: Can be more expensive than synthetic options. |

What Are the Key Characteristics of Ebony Tube Hair Brushes?

Ebony tube hair brushes are designed for professional use in salons, emphasizing durability and ergonomics. They come in various sizes to cater to different hair types and styles. Their construction often includes high-quality bristles that enhance styling efficiency. B2B buyers should consider the longevity and performance of these brushes, as they represent an investment in quality tools that can improve service delivery in salons.

How Do Ebony Tubes for Plumbing Stand Out?

Ebony tubes used in plumbing are known for their resistance to heat and pressure, making them ideal for a range of plumbing applications. Their lightweight nature and non-corrosive properties contribute to their appeal in construction and plumbing supply sectors. Buyers should evaluate the long lifespan and low maintenance requirements of these tubes, which can lead to cost savings over time, despite a potentially higher upfront cost.

What Makes Ebony Tubes Ideal for Electrical Wiring?

Ebony tubes designed for electrical wiring offer excellent insulation and flexibility, ensuring safety in various installations. Their lightweight design and high conductivity make them suitable for both residential and industrial applications. When purchasing, B2B buyers should weigh the enhanced safety features against the costs, as these tubes may be priced higher than conventional wiring materials.

Why Are Ebony Tubes Popular in Arts & Crafts?

Ebony tubes in arts and crafts are appreciated for their aesthetic appeal and versatility. Available in various sizes and finishes, they can be customized for different creative projects. Art supply stores and craft wholesalers benefit from stocking these tubes, as they cater to a wide range of artistic needs. Buyers should consider the potential for special orders, which can enhance their inventory offerings.

What Benefits Do Ebony Tubes Provide in Furniture Manufacturing?

Ebony tubes used in furniture manufacturing are characterized by their solid construction and eco-friendly options. They are often chosen for their attractive appearance and sustainability, appealing to environmentally conscious consumers. Furniture manufacturers and interior designers should assess the long-term value and aesthetic benefits of using ebony tubes, even though they may come at a higher price point compared to synthetic alternatives.

Key Industrial Applications of hottest ebony tube

| Industry/Sector | Specific Application of hottest ebony tube | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | High-end furniture components | Enhances aesthetic appeal and durability | Quality of wood, sustainability certifications, cost |

| Musical Instruments | Production of premium woodwind instruments | Superior acoustic properties for better sound quality | Source authenticity, wood aging process, acoustic testing |

| Automotive Industry | Interior trim and decorative elements | Provides a luxurious finish and increases resale value | Material sourcing regulations, durability standards |

| Construction & Architecture | Decorative elements in high-end construction projects | Adds elegance and value to luxury projects | Compliance with local regulations, environmental impact |

| Arts and Crafts | Crafting bespoke art pieces and sculptures | Unique aesthetic appeal that attracts collectors | Craftsmanship quality, sourcing of unique wood grains |

How is the hottest ebony tube utilized in furniture manufacturing?

In the furniture manufacturing sector, the hottest ebony tube is primarily used to create high-end components such as table legs, frames, and veneers. Known for its rich color and dense grain, ebony enhances the aesthetic appeal of furniture while providing exceptional durability. B2B buyers in this industry should prioritize sourcing high-quality, sustainably harvested ebony to meet consumer demand for eco-friendly products. Additionally, understanding the supply chain, including certifications and ethical sourcing practices, is crucial for maintaining brand integrity.

What role does the hottest ebony tube play in musical instruments?

The hottest ebony tube is essential in the production of premium woodwind instruments, such as clarinets and oboes. Its dense structure contributes to superior acoustic properties, resulting in better sound quality and resonance. For international buyers, particularly in regions like Europe and South America, sourcing ebony that meets specific tonal requirements is vital. Additionally, buyers should consider the aging process of the wood, as it significantly impacts the instrument’s performance and longevity.

How is the hottest ebony tube incorporated into the automotive industry?

In the automotive industry, the hottest ebony tube is used for interior trim and decorative elements, offering a luxurious finish that enhances the overall aesthetic of vehicles. This application not only improves the vehicle’s appeal but also increases its resale value. Buyers should focus on sourcing ebony that meets stringent durability standards, ensuring that the material withstands wear and tear. Compliance with automotive material regulations is also a key consideration for B2B buyers in this sector.

What are the benefits of using the hottest ebony tube in construction and architecture?

The hottest ebony tube serves as a decorative element in high-end construction projects, such as luxury homes and commercial buildings. Its unique appearance adds elegance and value, making it a sought-after material for architects and designers. B2B buyers must ensure compliance with local building regulations and consider the environmental impact of sourcing ebony. Additionally, they should assess the quality and sustainability of the wood to align with modern eco-conscious building practices.

How does the hottest ebony tube enhance arts and crafts applications?

In the arts and crafts sector, the hottest ebony tube is utilized for crafting bespoke art pieces and sculptures. Its unique grain patterns and rich color make it an attractive choice for artists and collectors alike. Buyers should focus on the craftsmanship quality and the sourcing of unique wood grains to create distinctive pieces that stand out in the market. Understanding the artistic value and potential market demand for these creations can significantly influence sourcing decisions.

3 Common User Pain Points for ‘hottest ebony tube’ & Their Solutions

Scenario 1: Sourcing Quality Ebony Tubes for Manufacturing

The Problem: B2B buyers often face challenges in sourcing high-quality ebony tubes that meet their specific manufacturing needs. The market is flooded with suppliers, but not all provide consistent quality or reliable delivery timelines. Issues such as variations in wood density, grain patterns, and finishing can affect the final product’s integrity. Buyers may also struggle to find suppliers who can provide adequate documentation regarding sustainability practices and material certifications, which is increasingly important for compliance and brand reputation.

The Solution: To overcome these challenges, buyers should establish strong relationships with reputable suppliers known for their quality and reliability. Start by conducting thorough research and requesting samples before making bulk orders. Look for suppliers who provide detailed specifications and certifications related to the ebony they offer. It’s beneficial to request third-party testing results to ensure the material meets industry standards. Additionally, consider leveraging technology by using platforms that aggregate supplier ratings and reviews, allowing for informed decision-making. Building long-term partnerships with trusted suppliers can also lead to better pricing and priority service, ensuring a steady supply of high-quality ebony tubes.

Scenario 2: Managing Inventory and Supply Chain Disruptions

The Problem: Inventory management can be a significant pain point for B2B buyers dealing with ebony tubes, especially in regions where logistical challenges are common. Supply chain disruptions, such as delays in shipping or unexpected increases in demand, can lead to stockouts and halted production lines. Buyers may find it difficult to forecast demand accurately, resulting in either overstocking or understocking, which ties up capital and can lead to waste if the material is not utilized in time.

The Solution: Implementing a robust inventory management system that utilizes real-time data can help mitigate these issues. Consider using software that integrates with your procurement and sales platforms to provide accurate forecasting based on historical sales data and market trends. Establish safety stock levels for critical materials like ebony tubes to cushion against unexpected demand spikes. Additionally, diversifying your supplier base can help create a more resilient supply chain, enabling you to source ebony from multiple suppliers if one faces disruption. Regularly communicating with suppliers about their lead times and potential challenges can also facilitate better planning and contingency strategies.

Illustrative image related to hottest ebony tube

Scenario 3: Ensuring Sustainability and Ethical Sourcing

The Problem: With the growing emphasis on sustainability and ethical sourcing in the global marketplace, B2B buyers are increasingly pressured to ensure that the ebony tubes they procure are sourced responsibly. Buyers may face scrutiny from consumers and regulatory bodies regarding the environmental impact of their purchases. This can lead to concerns about the legality of the wood being used, as well as the potential for negative publicity if the sourcing practices do not align with sustainability standards.

The Solution: To address these concerns, buyers should prioritize sourcing from suppliers who can provide clear documentation of their sourcing practices. Look for suppliers who are certified by recognized organizations that promote sustainable forestry, such as the Forest Stewardship Council (FSC). Engaging in direct communication with suppliers to understand their supply chain and sustainability initiatives is crucial. Additionally, consider implementing a supplier audit process to ensure compliance with your sustainability criteria. Educating your procurement team on the importance of ethical sourcing and keeping up with industry trends can further enhance your company’s commitment to sustainability, building trust and loyalty with your customer base.

Strategic Material Selection Guide for hottest ebony tube

When selecting materials for the hottest ebony tube, it is essential to consider properties that impact product performance, durability, and compliance with international standards. Below, we analyze four common materials used in manufacturing ebony tubes, focusing on their key properties, advantages, disadvantages, and implications for international B2B buyers.

What are the Key Properties of Aluminum for Ebony Tubes?

Aluminum is a lightweight metal known for its excellent corrosion resistance and thermal conductivity. It typically has a temperature rating up to 150°C (302°F) and can withstand moderate pressure, making it suitable for various applications. Its lightweight nature facilitates ease of handling and installation.

Pros: Aluminum is relatively inexpensive and easy to manufacture, allowing for cost-effective production. Its corrosion resistance makes it ideal for humid environments, commonly found in regions like Africa and South America.

Cons: While durable, aluminum can be less robust than other metals, particularly under high-stress conditions. It may also require additional treatments to enhance its strength and performance.

Illustrative image related to hottest ebony tube

Impact on Application: Aluminum is compatible with a wide range of media, including water and air, but may not be suitable for aggressive chemicals. Buyers should consider the specific media involved in their applications.

How Does Stainless Steel Compare for Ebony Tubes?

Stainless steel is renowned for its strength and corrosion resistance, with a temperature rating exceeding 300°C (572°F). This material is ideal for applications requiring durability and resistance to harsh environments.

Pros: Stainless steel offers exceptional strength, making it suitable for high-pressure applications. It also complies with various international standards, including ASTM and DIN, which is crucial for B2B buyers in Europe and the Middle East.

Cons: The primary downside is its higher cost compared to aluminum and other materials. Additionally, stainless steel can be more complex to manufacture, requiring specialized equipment and processes.

Illustrative image related to hottest ebony tube

Impact on Application: Stainless steel’s compatibility with aggressive chemicals and high temperatures makes it suitable for diverse applications, including those in the oil and gas sector. Buyers must ensure that the specific grade of stainless steel meets their operational requirements.

What Role Does PVC Play in Ebony Tube Applications?

Polyvinyl chloride (PVC) is a widely used plastic known for its versatility and cost-effectiveness. It has a temperature rating of around 60°C (140°F) and is suitable for low-pressure applications.

Pros: PVC is lightweight, easy to handle, and resistant to many chemicals, making it a popular choice for various applications. Its lower cost compared to metals can be a significant advantage for budget-conscious buyers.

Cons: PVC has lower temperature and pressure ratings, limiting its use in high-stress applications. It may also degrade under UV exposure, which is a consideration for outdoor applications.

Impact on Application: PVC is suitable for applications involving water and some chemicals, but it may not be appropriate for high-temperature or high-pressure situations. Buyers should evaluate the specific conditions of their applications before selecting PVC.

Illustrative image related to hottest ebony tube

How Does Copper Measure Up for Ebony Tubes?

Copper is a highly conductive metal with excellent thermal and electrical properties. It can handle temperatures up to 200°C (392°F) and is known for its antimicrobial properties.

Pros: Copper’s excellent conductivity makes it ideal for applications requiring heat transfer, such as in HVAC systems. Its natural antimicrobial properties can be beneficial in plumbing applications.

Cons: Copper is more expensive than aluminum and PVC, and its susceptibility to corrosion in certain environments can be a drawback. Additionally, it can be heavier than alternative materials.

Impact on Application: Copper is compatible with a range of media, including water and gases, but buyers must consider potential corrosion issues in specific environments. Compliance with international standards is also essential for B2B buyers.

Illustrative image related to hottest ebony tube

Summary Table of Material Selection for Hottest Ebony Tube

| Material | Typical Use Case for hottest ebony tube | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Lightweight structural applications | Excellent corrosion resistance | Lower strength under high stress | Low |

| Stainless Steel | High-pressure industrial applications | Exceptional strength and durability | Higher cost and manufacturing complexity | High |

| PVC | Plumbing and low-pressure systems | Cost-effective and lightweight | Limited temperature/pressure ratings | Low |

| Copper | HVAC and plumbing applications | Excellent thermal/electrical conductivity | Higher cost and corrosion susceptibility | Med |

Selecting the right material for the hottest ebony tube is critical for ensuring performance, durability, and compliance with international standards. By understanding the properties and implications of each material, B2B buyers can make informed decisions that align with their operational needs and market requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for hottest ebony tube

What Are the Key Stages in the Manufacturing Process of the Hottest Ebony Tube?

The manufacturing process of the hottest ebony tube involves several critical stages, each essential for ensuring that the final product meets the high standards expected by B2B buyers. Understanding these stages can help buyers make informed decisions when selecting suppliers.

Material Preparation: How Is Ebony Wood Selected and Processed?

The first step in the manufacturing process is the careful selection and preparation of ebony wood. High-quality ebony, renowned for its density and rich color, is sourced primarily from sustainable forests. Suppliers must ensure that they adhere to international regulations concerning the harvesting of endangered species, such as the CITES (Convention on International Trade in Endangered Species).

Once sourced, the wood undergoes a rigorous drying process to reduce moisture content, which is vital for preventing warping and cracking. This step often employs kiln drying, where the wood is placed in a controlled environment to achieve optimal moisture levels.

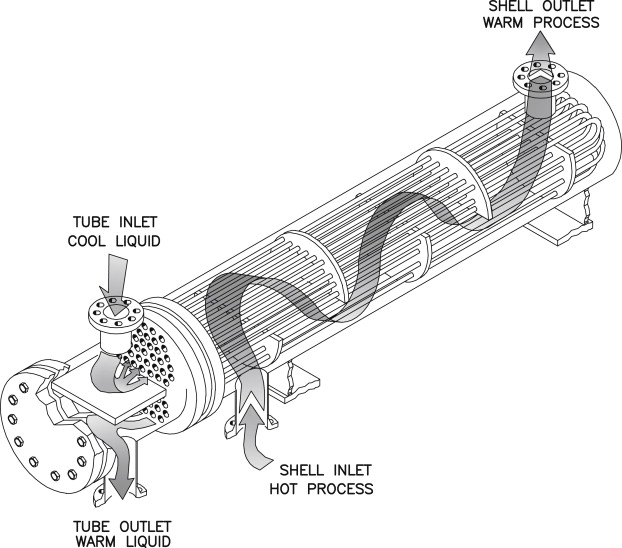

Forming: What Techniques Are Used to Shape the Ebony Tube?

After preparation, the next stage is forming. The wood is cut into rough shapes using saws and other cutting tools. CNC (Computer Numerical Control) machines are commonly employed for precision cutting, ensuring that the dimensions meet specified tolerances. This technology allows for intricate designs that can be replicated consistently, which is crucial for manufacturers supplying large orders.

Following rough cutting, the pieces are shaped into tubes through processes such as turning on a lathe. This method helps achieve the desired diameter and wall thickness while maintaining the aesthetic qualities of the ebony.

Assembly: How Are Components Joined in the Manufacturing Process?

In the assembly phase, if the ebony tube consists of multiple components (such as fittings or attachments), these parts are carefully joined together. Adhesives or mechanical fasteners may be used, depending on the design specifications.

Quality assurance is critical during this stage, as the integrity of the assembly impacts the final product’s performance. Manufacturers often employ jigs and fixtures to hold components in place, ensuring accurate alignment and reducing the risk of defects.

Finishing: What Steps Are Involved in the Final Touches?

The finishing stage is where the ebony tube truly shines. This process may include sanding, polishing, and applying protective coatings. Sanding removes any rough edges, while polishing enhances the wood’s natural luster.

Coatings, often a blend of oils or lacquers, serve to protect the wood from environmental factors and enhance its durability. Quality control during finishing is essential, as the appearance of the final product significantly influences buyer perception.

What International Standards and Quality Control Measures Should B2B Buyers Expect?

Quality assurance in the manufacturing of ebony tubes involves adhering to both international standards and industry-specific regulations. For B2B buyers, understanding these standards is crucial for verifying product quality.

What Are the Key International Standards Relevant to Ebony Tube Manufacturing?

One of the most recognized international standards is ISO 9001, which sets criteria for quality management systems. Compliance with ISO 9001 indicates that a manufacturer has effective processes in place for ensuring consistent quality.

Additionally, industry-specific certifications such as CE (Conformité Européenne) may be applicable, particularly for products intended for the European market. This certification demonstrates compliance with health, safety, and environmental protection standards.

What Quality Control Checkpoints Should Be in Place?

Quality control checkpoints are vital throughout the manufacturing process. B2B buyers should look for the following checkpoints:

Illustrative image related to hottest ebony tube

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Throughout the manufacturing process, regular inspections should occur to identify defects before they progress further.

-

Final Quality Control (FQC): Before products are packaged and shipped, a final inspection ensures that all items meet quality standards and specifications.

What Common Testing Methods Are Utilized in Quality Assurance?

To maintain high-quality standards, manufacturers employ various testing methods. These can include:

-

Visual Inspections: Simple yet effective for identifying surface defects or inconsistencies.

-

Dimensional Testing: Ensures that the product meets the required specifications using calipers and gauges.

-

Durability Testing: Involves subjecting the product to stress tests to evaluate its performance under various conditions.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control measures is essential to mitigate risks. Here are several approaches:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request documentation related to quality control audits. This includes reports from internal audits, third-party inspections, and certifications. A reputable supplier should be transparent about their quality control processes and willing to share relevant documentation.

Why Are Third-Party Inspections Important?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s manufacturing processes and quality control measures. These inspections can help identify potential issues and ensure compliance with international standards.

What Are the Nuances of Quality Control for International B2B Buyers?

B2B buyers from diverse regions, including Africa, South America, the Middle East, and Europe, may encounter unique challenges in quality control. Understanding regional regulations and expectations is vital for smooth transactions.

How Do Regional Regulations Impact Quality Assurance?

Different regions may have specific regulations affecting product quality, such as environmental standards in the EU or import regulations in African countries. Buyers should familiarize themselves with these regulations to ensure compliance.

Why Is Communication Critical in Quality Control?

Maintaining open lines of communication with suppliers is essential for addressing any quality concerns promptly. Regular updates and discussions regarding quality expectations can help prevent misunderstandings and ensure product satisfaction.

Conclusion

The manufacturing processes and quality assurance measures for the hottest ebony tube are complex and multifaceted. By understanding the stages of production, relevant standards, and verification methods, B2B buyers can make informed decisions when sourcing products. Prioritizing quality not only ensures compliance with international standards but also enhances customer satisfaction and brand reputation in the competitive global market.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hottest ebony tube’

To assist international B2B buyers in sourcing the hottest ebony tube, this guide provides a structured checklist designed to streamline the procurement process. By following these steps, you can ensure that you select the best suppliers and products that meet your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for ensuring that the ebony tube meets your operational requirements. Consider factors such as size, material quality, and intended application. This clarity will help you communicate effectively with suppliers and avoid misunderstandings.

- Size and Dimensions: Specify the exact measurements required for your project.

- Material Quality: Identify any specific standards or grades of ebony that are necessary for durability and performance.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in ebony tube products. Utilize platforms like trade directories, industry forums, and trade shows to gather a list of manufacturers and distributors.

- Supplier Reputation: Look for reviews and testimonials from other buyers to assess the reliability of potential suppliers.

- Product Range: Ensure that the supplier offers a comprehensive range of ebony tubes to meet various needs.

Step 3: Evaluate Supplier Certifications

Before finalizing any agreements, verify that your selected suppliers have the necessary certifications and comply with industry standards. This step is crucial for ensuring product quality and ethical sourcing.

- Quality Certifications: Check for certifications like ISO 9001, which indicate adherence to quality management standards.

- Sustainability Compliance: Confirm that the supplier sources ebony sustainably to avoid legal and ethical issues.

Step 4: Request Samples

Requesting samples from potential suppliers is an essential step in the evaluation process. This allows you to assess the quality and suitability of the ebony tubes before making a larger commitment.

- Quality Assessment: Examine the samples for quality, finish, and performance.

- Testing: If applicable, conduct any necessary tests to ensure the product meets your specifications.

Step 5: Negotiate Terms and Pricing

Once you have identified a suitable supplier, engage in negotiations to finalize terms and pricing. This step is vital for establishing a mutually beneficial agreement.

- Volume Discounts: Inquire about discounts for bulk purchases or long-term contracts.

- Payment Terms: Discuss payment options that align with your financial strategy, including upfront payments or credit terms.

Step 6: Review Shipping and Delivery Options

Consider logistics when sourcing ebony tubes, including shipping methods and delivery times. Efficient logistics can significantly impact your supply chain effectiveness.

Illustrative image related to hottest ebony tube

- Shipping Methods: Evaluate the reliability and cost-effectiveness of different shipping options.

- Lead Times: Ensure that delivery schedules align with your project timelines to avoid delays.

Step 7: Establish a Communication Plan

Lastly, create a clear communication plan with your supplier to ensure ongoing collaboration. Effective communication is essential for addressing any issues that may arise during the procurement process.

- Point of Contact: Designate a specific contact person for both parties to streamline communication.

- Regular Updates: Schedule regular updates to discuss order status and any potential concerns.

By following this comprehensive checklist, you can navigate the sourcing process for the hottest ebony tube effectively, ensuring that you make informed decisions that benefit your business.

Comprehensive Cost and Pricing Analysis for hottest ebony tube Sourcing

What Are the Key Cost Components in Sourcing Hottest Ebony Tubes?

When sourcing ebony tubes, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The quality of ebony wood significantly impacts the price. Higher quality materials, sourced sustainably, may command a premium. Prices can vary based on the region from which the wood is sourced, with African ebony typically being more expensive due to its rarity.

-

Labor: Skilled labor is necessary for the crafting of high-quality ebony tubes. Labor costs can vary significantly between regions. For example, labor in African countries may be lower compared to European standards, but the skill level and craftsmanship can affect the final product’s quality.

-

Manufacturing Overhead: This includes the costs associated with operating machinery, utilities, and facilities. Efficient manufacturing processes can help reduce overhead, thereby lowering the overall cost of the product.

-

Tooling: Initial tooling costs for creating molds and machinery specific to ebony tube production can be substantial. These costs are typically amortized over the production volume, meaning higher orders can reduce the per-unit cost.

-

Quality Control (QC): Ensuring that each tube meets quality standards is crucial. Implementing strict QC processes adds to the cost but is essential for maintaining product integrity, especially for international markets where quality certifications may be required.

-

Logistics: Transportation costs can vary based on shipping methods, distance, and the chosen Incoterms. Import duties and taxes also play a significant role in the total cost, particularly for international buyers.

-

Margin: Suppliers will include a profit margin in their pricing, which can vary based on market demand, competition, and the perceived value of the product.

How Do Price Influencers Affect Sourcing Decisions for Ebony Tubes?

Several factors can influence the pricing of ebony tubes:

-

Volume and Minimum Order Quantity (MOQ): Bulk orders often lead to significant cost savings. Suppliers may offer lower prices per unit for larger quantities, making it crucial to assess your needs accurately.

-

Specifications and Customization: Custom designs or specific dimensions can increase costs. Buyers should communicate their requirements clearly to avoid unexpected charges.

-

Materials and Quality Certifications: Tubes made from sustainably sourced or certified ebony may have a higher price point. Buyers should evaluate the importance of these certifications based on their market requirements.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge more due to their proven quality and reliability, which can be worth the investment.

-

Incoterms: Understanding the terms of shipment (e.g., FOB, CIF) can help buyers manage costs effectively. Different Incoterms can affect who bears the costs and risks during transportation.

What Tips Can Help Buyers Negotiate Better Prices for Ebony Tubes?

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and terms. Regular communication can foster trust and encourage suppliers to provide better deals.

-

Focus on Total Cost of Ownership (TCO): Buyers should consider not just the purchase price but also maintenance, durability, and potential resale value. A higher upfront cost may be justified if the product lasts longer or performs better.

-

Stay Informed About Market Trends: Keeping abreast of industry trends and price fluctuations can provide leverage during negotiations. Understanding market demand can help buyers negotiate better prices.

-

Be Prepared to Walk Away: Sometimes, the best negotiation tactic is to be willing to explore other suppliers. This can give buyers leverage and help them secure more favorable terms.

-

Tailor Negotiation Strategies by Region: Different cultures approach negotiations differently. Understanding the negotiation style common in the supplier’s region can enhance communication and result in better deals.

Conclusion

Sourcing ebony tubes involves navigating a complex cost structure influenced by various factors. By understanding these components and price influencers, international B2B buyers can make informed decisions, negotiate effectively, and optimize their sourcing strategies. It is advisable to approach negotiations with a comprehensive understanding of the total cost of ownership and market dynamics to secure the best value for their investment.

Alternatives Analysis: Comparing hottest ebony tube With Other Solutions

In the rapidly evolving landscape of B2B solutions, identifying the right product or method to meet specific needs is crucial. The ‘hottest ebony tube’ represents a popular choice in its category, but various alternatives exist that may better suit particular requirements. This section explores viable alternatives, comparing their features and benefits to help international buyers make informed decisions.

| Comparison Aspect | Hottest Ebony Tube | Alternative 1: High-Performance Plastic Tube | Alternative 2: Metal Tube |

|---|---|---|---|

| Performance | High flexibility and durability | Excellent temperature resistance | Superior strength and rigidity |

| Cost | Moderate price point | Lower initial cost but shorter lifespan | Higher upfront cost |

| Ease of Implementation | Easy to install and use | Requires specialized fittings | Moderate complexity in installation |

| Maintenance | Low maintenance | Moderate maintenance needed for durability | High durability with minimal upkeep |

| Best Use Case | Ideal for flexible applications | Suitable for high-temperature environments | Best for heavy-duty industrial applications |

What Are the Benefits of High-Performance Plastic Tubes?

High-performance plastic tubes are designed to withstand extreme temperatures and pressures, making them suitable for a variety of industrial applications. They are lightweight and often more cost-effective than alternatives, providing a good balance between performance and price. However, their lifespan may be shorter than that of metal tubes, which can result in higher long-term costs due to the need for replacements.

How Do Metal Tubes Compare to Hottest Ebony Tubes?

Metal tubes are characterized by their exceptional strength and rigidity, making them the ideal choice for heavy-duty applications, such as construction and manufacturing. They can handle significant loads and resist deformation, ensuring longevity. However, metal tubes typically have a higher initial cost and may require specialized installation techniques, which could lead to increased labor expenses. Additionally, they are heavier, which can complicate transport and installation in some settings.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting between the hottest ebony tube and its alternatives, B2B buyers should consider their specific application requirements, budget constraints, and long-term maintenance plans. The hottest ebony tube excels in flexibility and ease of use, making it suitable for various scenarios, while high-performance plastic tubes offer a cost-effective solution for environments with temperature challenges. On the other hand, metal tubes provide unmatched strength for demanding applications, albeit at a higher cost. By assessing these factors, buyers can make a well-informed decision tailored to their operational needs.

Essential Technical Properties and Trade Terminology for hottest ebony tube

What Are the Key Technical Properties of the Hottest Ebony Tube?

Understanding the critical specifications of the hottest ebony tube is essential for international B2B buyers. Here are the primary technical properties to consider:

1. Material Grade

The material grade of an ebony tube indicates its quality and suitability for specific applications. High-quality ebony tubes are typically made from dense, durable wood, ensuring longevity and resistance to wear. For B2B buyers, selecting the right material grade is crucial as it impacts the product’s performance, aesthetic appeal, and overall value.

Illustrative image related to hottest ebony tube

2. Diameter and Wall Thickness

The diameter and wall thickness of ebony tubes are vital specifications that determine their load-bearing capacity and fit for various applications. Standard diameters can range from small (e.g., 25mm) to larger sizes (e.g., 100mm), while wall thickness affects strength. Buyers must specify these dimensions to ensure compatibility with existing systems and to meet engineering requirements.

3. Surface Finish

The surface finish refers to the texture and treatment of the tube’s outer layer. Common finishes include natural, polished, or matte. A high-quality finish not only enhances the aesthetic appeal but also provides protection against environmental factors. B2B buyers should consider the desired finish based on the end-use, such as decorative items or functional components.

4. Tolerance Levels

Tolerance levels define the allowable variations in dimensions during manufacturing. Tight tolerances ensure that the ebony tubes fit precisely in their intended applications, reducing the risk of failure or defects. For B2B buyers, understanding tolerance levels is crucial for quality assurance and maintaining operational efficiency.

5. Weight and Density

The weight and density of ebony tubes are significant factors in their handling and shipping. High-density ebony is heavier, which may affect transportation costs and logistics. Buyers should evaluate these properties to optimize supply chain efficiency and minimize costs.

What Common Trade Terminology Should B2B Buyers Know?

Navigating the world of ebony tubes requires familiarity with specific trade terminology. Here are some essential terms that B2B buyers should understand:

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of ebony tubes, buyers may work with OEMs to ensure that the tubes meet specific design and quality standards required for their products.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest amount of product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers as it impacts inventory levels and overall purchasing strategy. Buyers should negotiate MOQs to align with their production needs without overcommitting resources.

Illustrative image related to hottest ebony tube

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing and terms for a specific quantity of goods. For ebony tubes, issuing an RFQ allows buyers to compare offers from multiple suppliers, ensuring they receive the best value.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms published by the International Chamber of Commerce (ICC). They clarify the responsibilities of buyers and sellers in international transactions, such as who bears shipping costs and insurance. Familiarity with Incoterms is essential for B2B buyers to mitigate risks and ensure smooth transactions.

5. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times for ebony tubes is vital for B2B buyers to plan their production schedules and manage customer expectations effectively.

By grasping these essential properties and trade terms, B2B buyers can make informed decisions, ensuring the successful procurement of the hottest ebony tubes for their business needs.

Navigating Market Dynamics and Sourcing Trends in the hottest ebony tube Sector

What Are the Current Market Dynamics and Key Trends in the Ebony Tube Sector?

The ebony tube sector is experiencing significant transformation driven by various global factors, including rising demand for high-quality materials, technological advancements, and an increasingly competitive marketplace. As international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, seek reliable suppliers, understanding these dynamics is crucial for strategic sourcing. The demand for ebony tubes is fueled by their applications in various industries such as construction, automotive, and consumer goods, where durability and aesthetic appeal are paramount.

Emerging B2B tech trends include the adoption of digital platforms for sourcing and procurement, enhancing transparency and efficiency in supply chains. E-commerce platforms and B2B marketplaces are making it easier for buyers to access global suppliers, compare prices, and analyze product quality. Moreover, the use of data analytics in procurement processes is helping businesses make informed decisions based on market trends, supplier performance, and consumer preferences.

In addition to technological advancements, sustainability is becoming a central theme in sourcing strategies. Buyers are increasingly looking for suppliers that comply with environmental regulations and promote sustainable practices, reflecting a broader societal shift towards responsible consumption. As a result, suppliers who can demonstrate sustainability credentials are likely to gain a competitive edge in this evolving market landscape.

Illustrative image related to hottest ebony tube

How Is Sustainability Influencing the Sourcing of Ebony Tubes?

Sustainability and ethical sourcing are no longer optional but essential components of the B2B landscape, particularly in the ebony tube sector. The environmental impact of sourcing practices is under intense scrutiny, with buyers increasingly favoring suppliers that prioritize sustainable methods. This includes the responsible harvesting of raw materials, adherence to environmental regulations, and minimizing carbon footprints throughout the supply chain.

The significance of ethical supply chains cannot be overstated, especially for international buyers. Consumers are becoming more conscious of the origins of their products, and companies that fail to demonstrate ethical practices risk damaging their reputations. Certifications like FSC (Forest Stewardship Council) and PEFC (Programme for the Endorsement of Forest Certification) are becoming critical for suppliers seeking to prove their commitment to sustainability. These certifications assure buyers that the materials are sourced from responsibly managed forests that provide environmental, social, and economic benefits.

Additionally, the trend towards ‘green’ materials is reshaping the ebony tube market. Buyers are increasingly interested in products made from reclaimed or recycled materials, which not only reduce waste but also align with the growing demand for eco-friendly solutions. This shift towards sustainability is not merely a trend; it is a fundamental change in the way businesses approach sourcing and production.

How Has the Ebony Tube Sector Evolved Over Time?

The evolution of the ebony tube sector is marked by significant shifts in consumer preferences, technological advancements, and regulatory frameworks. Historically, ebony was primarily valued for its aesthetic qualities and durability in luxury goods, particularly in furniture and musical instruments. However, as industries expanded and diversified, the applications of ebony tubes broadened, encompassing sectors such as construction and automotive manufacturing.

In recent years, the global focus on sustainability has prompted a reevaluation of sourcing practices within the ebony sector. Buyers are now more inclined to seek suppliers who can provide transparency in their supply chains and demonstrate a commitment to ethical sourcing. This evolution reflects a broader trend in the B2B landscape, where sustainability and social responsibility are becoming key drivers of business strategy. As the market continues to evolve, staying informed about these trends will be vital for buyers looking to navigate the complexities of sourcing in the ebony tube sector effectively.

Frequently Asked Questions (FAQs) for B2B Buyers of hottest ebony tube

1. How do I ensure the quality of ebony tubes before purchasing?

To ensure the quality of ebony tubes, it’s vital to request samples from potential suppliers. Conduct thorough quality checks, including visual inspections and possibly third-party testing for durability and material specifications. Additionally, consider suppliers with established reputations and positive reviews from other businesses. Establishing a quality assurance protocol and discussing it with your supplier can help maintain consistent quality in your orders.

2. What is the best way to vet suppliers of ebony tubes?

The best way to vet suppliers is to conduct comprehensive due diligence, which includes checking their business licenses, certifications, and industry reputation. Look for reviews from previous clients and request references. Engaging in direct communication can also provide insights into their customer service and reliability. Consider using platforms that specialize in B2B transactions for added security and transparency in your supplier choices.

3. Are there customization options available for ebony tubes?

Many suppliers offer customization options for ebony tubes, including different sizes, finishes, and even branding options. When discussing your requirements, clearly outline your specifications and inquire about the minimum order quantities (MOQs) for customized products. Customization can enhance your product’s market appeal, so ensure that the supplier has the capability to meet your design requirements without compromising quality.

4. What is the typical minimum order quantity (MOQ) for ebony tubes?

The MOQ for ebony tubes varies by supplier and can depend on factors such as customization and production capacity. Generally, MOQs may range from a few dozen to several hundred units. When negotiating with suppliers, express your needs and explore the possibility of lower MOQs, especially if you’re testing the market or starting a new product line.

5. What payment terms should I expect when ordering ebony tubes internationally?

Payment terms for international orders of ebony tubes can vary significantly. Common arrangements include upfront payments, letters of credit, or installment payments based on shipment milestones. It’s crucial to clarify these terms before finalizing your order. Discussing flexible payment options can benefit both parties, ensuring that you have security while allowing suppliers to manage their cash flow.

6. How can I ensure timely delivery of my ebony tube orders?

To ensure timely delivery, establish clear deadlines with your supplier and discuss logistics in detail. Opt for suppliers who have a proven track record of on-time deliveries. Additionally, consider using third-party logistics providers who specialize in international shipping to streamline the process. Maintaining open communication throughout the order and shipping process can help address any potential delays proactively.

7. What are the shipping options for ebony tubes when importing?

Shipping options for ebony tubes typically include air freight, which is faster but more expensive, and sea freight, which is more cost-effective for larger quantities. When choosing a shipping method, consider factors such as budget, delivery timelines, and the urgency of your needs. Work with your supplier to determine the best logistics strategy that aligns with your operational requirements.

8. How do I handle customs clearance for ebony tube shipments?

Handling customs clearance for ebony tube shipments involves ensuring that all necessary documentation is in order, including invoices, packing lists, and any required certifications. Collaborate with your supplier to obtain the correct customs paperwork. Engaging a customs broker can simplify the process, ensuring compliance with local regulations and minimizing the risk of delays or additional fees during customs clearance.

Top 3 Hottest Ebony Tube Manufacturers & Suppliers List

1. Hot Ebony Tube – Free Ebony Porn Videos

Domain: hotebonytube.com.siteindices.com

Registered: 2019 (6 years)

Introduction: Hot Ebony Tube: Black Porn Videos & Ebony XXX Movies For Free. Features include a free ebony porn tube with a variety of black XXX videos sorted into categories and provided in top quality. The site is for 18+ only and guarantees 100% pleasure. Estimated worth: US $395,252. Daily unique visitors: 30,080. Daily ads revenue: US $216. Monthly ads revenue: US $6,497. Yearly ads revenue: US $79,050.

2. Sur.ly – Hot Ebony Tube

Domain: sur.ly

Introduction: Hot Ebony Tube offers free black porn videos and ebony XXX movies sorted into categories and provided in top quality. The site is for 18+ only and guarantees 100% pleasure. It has been in operation for 16 years, with a server location in the Netherlands. The site supports SSL-encrypted connections and is marked as having excellent trustworthiness, although it has a very poor child safety rating.

3. Getty Images – Black Ebony Video Clips

Domain: gettyimages.com

Registered: 1999 (26 years)

Introduction: This company, Getty Images – Black Ebony Video Clips, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for hottest ebony tube

In navigating the competitive landscape of ebony tube sourcing, international buyers from Africa, South America, the Middle East, and Europe are well-positioned to leverage strategic sourcing practices. A focused approach can enhance supplier relationships, optimize costs, and ensure the consistent quality of products. By prioritizing partnerships with reputable manufacturers and distributors, businesses can secure the hottest ebony tubes that meet market demands while adhering to sustainability and ethical standards.

As the global demand for high-quality ebony products continues to rise, it is imperative for B2B buyers to stay informed about market trends and emerging suppliers. Engaging in proactive sourcing strategies will not only mitigate risks but also foster innovation and adaptability within supply chains.

Looking ahead, the potential for growth in the ebony tube market is substantial. Buyers are encouraged to explore new avenues for collaboration and investment, ensuring they remain at the forefront of industry developments. Embrace the opportunity to enhance your product offerings and satisfy customer needs by strategically sourcing the finest ebony tubes today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.