How to Source Heart Rims Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for heart rims

In an increasingly competitive global market, B2B buyers face the critical challenge of sourcing high-quality heart rims that meet both performance and aesthetic demands. With a plethora of options available, navigating the complexities of specifications, pricing, and supplier reliability can be daunting. This guide serves as a comprehensive resource for international buyers, detailing various types of heart rims, their applications across different vehicle categories, and essential supplier vetting processes.

Buyers from diverse regions—including Africa, South America, the Middle East, and Europe—will find actionable insights into cost considerations, market trends, and the latest innovations in heart rim design. By emphasizing performance metrics and material quality, this guide empowers buyers to make informed purchasing decisions that align with their business objectives.

Additionally, we delve into regional supply chain dynamics, ensuring that you understand the nuances of sourcing from different markets, including Vietnam and Germany. With a focus on strategic insights and practical advice, this guide is designed to enhance your procurement process, ultimately leading to successful partnerships and optimal product selection in the ever-evolving automotive landscape.

Understanding heart rims Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Three-Piece Rims | Customizable width, depth, and finish options | High-performance vehicles, custom builds | Pros: Tailored fit, enhanced performance; Cons: Higher cost, more complex assembly. |

| One-Piece Rims | Lightweight and strong, typically a single mold | Standard vehicles, fleet applications | Pros: Cost-effective, easier to install; Cons: Limited customization options. |

| Forged Rims | Stronger and lighter due to the forging process | Racing, off-road vehicles | Pros: Superior strength-to-weight ratio; Cons: Higher price point, may require specialized suppliers. |

| Alloy Rims | Made from a mix of metals for durability and style | Everyday vehicles, aftermarket sales | Pros: Aesthetic appeal, good performance; Cons: Can be prone to damage from potholes. |

| Steel Rims | Heavy-duty construction, often less expensive | Commercial vehicles, winter applications | Pros: Cost-effective, durable; Cons: Heavier, less stylish than alloys. |

What Are the Characteristics of Three-Piece Rims?

Three-piece rims are designed for customization, allowing buyers to select the width, depth, and finish according to their specific requirements. These rims consist of three parts: the outer rim, the inner rim, and the center section, which can be tailored for performance or aesthetic preferences. B2B buyers in high-performance sectors, such as racing or custom vehicle builds, often prefer these rims for their adaptability and enhanced performance capabilities. However, the higher cost and complex assembly process may deter some buyers.

How Do One-Piece Rims Differ from Other Types?

One-piece rims are manufactured as a single unit, offering a lightweight and strong option for vehicles. Their simplicity in design makes them an ideal choice for standard vehicles and fleet applications, where cost-effectiveness and ease of installation are crucial. B2B buyers appreciate these rims for their affordability and reliability, though they may find limited customization options compared to three-piece variants. This makes one-piece rims a practical choice for businesses seeking efficiency.

What Makes Forged Rims Stand Out?

Forged rims are known for their exceptional strength and reduced weight, achieved through a specialized forging process. These rims are particularly favored in racing and off-road applications, where performance is paramount. B2B buyers in these sectors often prioritize the superior strength-to-weight ratio that forged rims provide, despite their higher price point. Sourcing these rims may require specialized suppliers, making them a more niche option in the market.

Why Choose Alloy Rims for Everyday Vehicles?

Alloy rims are composed of a mix of metals, providing a balance of durability and aesthetic appeal. They are commonly used in everyday vehicles and aftermarket sales, appealing to a wide range of buyers. B2B purchasers value alloy rims for their performance capabilities and stylish designs, although they can be susceptible to damage from harsh road conditions. This trade-off between aesthetics and durability is an important consideration for businesses targeting consumer markets.

When Are Steel Rims the Right Choice?

Steel rims are characterized by their heavy-duty construction and cost-effectiveness, making them a popular choice for commercial vehicles and winter applications. They offer durability and strength, essential for businesses operating in challenging environments. However, steel rims are heavier and less stylish than their alloy counterparts, which may limit their appeal in markets focused on aesthetics. B2B buyers should weigh the benefits of durability against the potential downsides of weight and design when considering steel rims for their fleets.

Key Industrial Applications of heart rims

| Industry/Sector | Specific Application of heart rims | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | Custom wheel designs for vehicles | Enhanced vehicle performance and aesthetics | Ensure compatibility with vehicle specifications and regulations. |

| Motorsport | High-performance racing wheels | Improved speed, handling, and safety in races | Focus on lightweight materials and durability under stress. |

| Heavy Machinery | Specialized rims for construction equipment | Increased stability and load-bearing capacity | Assess rim strength and compatibility with existing machinery. |

| Transportation | Durable rims for commercial vehicles | Reduced maintenance costs and improved fuel efficiency | Evaluate long-term wear and tear, and sourcing logistics. |

| Aftermarket Retail | Customized wheels for personal vehicles | Increased sales through unique offerings | Consider market trends and regional preferences for styles. |

How Are Heart Rims Utilized in Automotive Manufacturing?

In the automotive manufacturing sector, heart rims are integral for creating custom wheel designs tailored to specific vehicle models. These rims enhance both performance and aesthetics, allowing manufacturers to meet diverse consumer demands. International buyers, particularly in Africa and South America, must ensure that the rims comply with local safety regulations and vehicle specifications. This includes understanding the bolt pattern, offset, and load rating required for different vehicles, which can vary widely by region.

What Role Do Heart Rims Play in Motorsport Applications?

In motorsport, heart rims are designed for high-performance racing applications where speed and handling are critical. These rims are typically lightweight and constructed from advanced materials to withstand the rigors of racing conditions. Buyers in this sector, particularly from Europe and the Middle East, should prioritize sourcing rims that offer superior aerodynamic properties and heat dissipation. Additionally, the ability to customize these rims for specific race cars can provide a competitive edge, making it essential to engage with suppliers who specialize in motorsport products.

How Are Heart Rims Applied in Heavy Machinery?

Heavy machinery utilizes heart rims for specialized applications, such as construction equipment and agricultural vehicles. These rims need to provide increased stability and load-bearing capacity, essential for operating in rugged environments. For international buyers, especially in developing regions, it is crucial to assess the strength and durability of the rims to ensure they can withstand harsh working conditions. Sourcing considerations should include compatibility with existing machinery and the availability of replacement parts, as downtime can be costly.

Why Are Heart Rims Important for Commercial Transportation?

In the transportation sector, heart rims are vital for commercial vehicles, including trucks and buses. Durable rims contribute to reduced maintenance costs and improved fuel efficiency, which are significant concerns for fleet operators. Buyers from South America and Africa should evaluate the long-term wear and tear of rims, considering factors like road conditions and load requirements. Establishing relationships with reliable suppliers who can guarantee consistent quality and availability is essential for maintaining operational efficiency.

How Do Heart Rims Benefit Aftermarket Retail?

In the aftermarket retail sector, heart rims offer customization options for personal vehicles, allowing consumers to enhance their vehicles’ appearance and performance. Retailers can increase sales by providing unique offerings that cater to local market trends. International buyers, particularly in Europe and Asia, should consider regional preferences for styles and finishes, as these can greatly influence consumer purchasing decisions. Engaging with manufacturers who offer a wide range of designs and finishes can help retailers stay competitive in a dynamic market.

3 Common User Pain Points for ‘heart rims’ & Their Solutions

Scenario 1: Sourcing Quality Heart Rims for Diverse Markets

The Problem: B2B buyers, especially those in emerging markets like Africa and South America, often face significant hurdles when sourcing heart rims. The challenge lies not only in identifying suppliers who offer high-quality products but also in ensuring that these products meet local regulations and vehicle compatibility standards. Buyers may receive rims that do not fit their clients’ vehicles or, worse, are made of subpar materials, leading to safety issues and customer dissatisfaction.

The Solution: To overcome this issue, buyers should conduct thorough research on potential suppliers before making a purchase. This includes checking for certifications, customer reviews, and industry reputation. Establishing relationships with suppliers who specialize in the local automotive market can also provide insights into which rim specifications are most suitable for the region. Moreover, buyers should request detailed product information, including material composition, weight specifications, and compatibility details for various vehicle makes and models. Utilizing a checklist for assessing supplier reliability can streamline the sourcing process and mitigate risks associated with quality discrepancies.

Scenario 2: Navigating Complex Wheel Specifications

The Problem: Another pain point for B2B buyers is the complexity surrounding wheel specifications, such as bolt patterns, offsets, and sizes. Buyers might struggle with understanding how these specifications affect vehicle performance and safety. Misunderstandings can lead to ordering incorrect sizes or incompatible rims, resulting in costly returns and delays in fulfilling client orders.

The Solution: To navigate this complexity, buyers should invest time in educating themselves and their teams about wheel specifications and their implications. They can leverage online resources, attend industry workshops, or consult with wheel experts to gain a comprehensive understanding of the terminology and technicalities involved. Creating an internal knowledge base that outlines key specifications for heart rims, along with their impact on vehicle performance, can serve as a valuable reference for future orders. Additionally, buyers should always verify fitment through the vehicle’s specifications before placing orders, ensuring that they have the correct measurements and compatibility for their clients’ needs.

Scenario 3: Addressing Price Sensitivity and Value Perception

The Problem: Price sensitivity is a critical concern for B2B buyers, particularly in regions where budget constraints are a common issue. Buyers often struggle to balance the need for high-quality heart rims with the pressure to keep costs low. This can lead to difficult decisions about whether to invest in premium options or settle for lower-cost alternatives that may not perform as well.

The Solution: To address this challenge, buyers should focus on the total cost of ownership rather than just the initial purchase price. This involves considering factors such as durability, warranty, and customer service from suppliers. Engaging in negotiations with suppliers can yield discounts for bulk purchases or long-term contracts, allowing buyers to secure better pricing without sacrificing quality. Furthermore, conducting a comparative analysis of different rim options—factoring in performance, longevity, and customer satisfaction—can help buyers make informed decisions that align with their budget while still meeting their clients’ expectations. Highlighting these value propositions in sales presentations can also help justify the investment to end customers, reinforcing the benefits of choosing quality over cost.

Strategic Material Selection Guide for heart rims

What Are the Key Materials Used in Heart Rims and Their Properties?

When selecting materials for heart rims, it’s essential to consider the properties that affect performance, durability, and cost. Below, we analyze four common materials used in the production of heart rims: aluminum alloys, steel, magnesium alloys, and carbon fiber composites.

How Do Aluminum Alloys Perform in Heart Rim Applications?

Aluminum alloys are widely favored in the automotive industry for their lightweight and excellent corrosion resistance. Typically, these alloys can withstand moderate temperature and pressure conditions, making them suitable for various applications. The primary advantage of aluminum is its strength-to-weight ratio, which enhances vehicle performance and fuel efficiency.

However, aluminum alloys can be more expensive than steel and may require more complex manufacturing processes, such as casting or forging. While they offer good durability, they may not perform as well under extreme conditions, such as high-impact scenarios. For international buyers, aluminum rims must comply with standards like ASTM and JIS, which can vary by region, particularly in markets like Europe and the Middle East.

What Are the Benefits and Limitations of Steel for Heart Rims?

Steel is known for its exceptional strength and durability, making it a common choice for heart rims, particularly in heavy-duty applications. It has high temperature and pressure ratings, which contribute to its robustness. Steel rims are also more cost-effective compared to aluminum, making them an attractive option for budget-conscious buyers.

On the downside, steel is heavier than aluminum, which can negatively impact vehicle performance and fuel efficiency. Additionally, steel is prone to corrosion if not properly treated, requiring regular maintenance. International buyers should consider local regulations regarding weight limits and corrosion resistance, especially in humid climates prevalent in regions like Africa and South America.

How Do Magnesium Alloys Compare for Heart Rim Applications?

Magnesium alloys are known for their lightweight properties and high strength, making them an appealing choice for performance-oriented applications. They offer excellent thermal conductivity and can withstand high temperatures, which is beneficial in high-performance automotive scenarios.

However, magnesium alloys can be more expensive than both aluminum and steel, and their manufacturing process can be complex. They are also more susceptible to corrosion, requiring protective coatings. For international buyers, it’s crucial to ensure that magnesium rims meet relevant compliance standards, particularly in Europe, where safety regulations are stringent.

What Role Do Carbon Fiber Composites Play in Heart Rim Manufacturing?

Carbon fiber composites are increasingly being used for high-end heart rims due to their lightweight nature and exceptional strength. They offer excellent performance characteristics, including high resistance to temperature and pressure, making them suitable for high-performance vehicles.

The primary drawback of carbon fiber is its high cost and the complexity involved in manufacturing. Additionally, while carbon fiber is strong, it can be brittle, leading to potential failure under certain conditions. Buyers in international markets should be aware of the specific certifications required for carbon fiber products, particularly in regions like Germany, where advanced material standards are enforced.

Summary Table of Material Properties for Heart Rims

| Material | Typical Use Case for heart rims | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Lightweight performance vehicles | Excellent strength-to-weight ratio | Higher cost and complex manufacturing | Medium |

| Steel | Heavy-duty applications | Exceptional strength and durability | Heavier, prone to corrosion | Low |

| Magnesium Alloys | Performance-oriented vehicles | Lightweight and high strength | Expensive and corrosion-prone | High |

| Carbon Fiber Composites | High-end performance vehicles | Exceptional strength and lightweight | High cost and potential brittleness | High |

This analysis provides a comprehensive overview of the materials used in heart rims, equipping international B2B buyers with the insights necessary for informed decision-making. Understanding the properties, advantages, and limitations of each material can lead to better product selection aligned with specific application needs and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for heart rims

What Are the Main Stages in the Manufacturing Process of Heart Rims?

The manufacturing of heart rims involves several critical stages that ensure quality and performance. Each stage is designed to transform raw materials into high-quality finished products.

Material Preparation

The first step in the manufacturing process is the preparation of raw materials. Typically, high-grade aluminum alloys or steel are used due to their strength-to-weight ratio. The selected materials undergo rigorous testing to confirm their chemical composition and mechanical properties. Suppliers often provide certificates of analysis (CoA) to verify material quality. This stage may also involve cutting the raw materials into specific shapes and sizes to facilitate the next steps.

Forming Techniques

Once the materials are prepared, the next phase is forming. This is where the initial shaping of the heart rims occurs. Common techniques include:

- Casting: Involves pouring molten metal into molds to create the desired rim shape. This method is efficient for producing complex designs but requires careful temperature control to avoid defects.

- Forging: This process involves shaping the material through compressive forces, resulting in denser and stronger rims. Forged rims often have superior performance characteristics, making them a preferred choice for high-performance vehicles.

- Rolling: In this technique, metal sheets are rolled into the desired thickness and shape. This method is particularly useful for creating larger rims and ensures uniform thickness.

Each of these methods has its advantages, and the choice largely depends on the intended application and performance requirements of the heart rims.

Assembly Process

Following the forming stage, assembly takes place. For multi-piece rims, this involves fitting the rim halves together and securing them with bolts or welding. The assembly process must be precise to maintain structural integrity and balance. Automated systems are often employed to enhance accuracy and speed during this stage.

Finishing Touches

The final stage of manufacturing is finishing, which enhances both aesthetics and performance. This may include:

- Surface Treatment: Processes like anodizing, powder coating, or painting to improve corrosion resistance and appearance.

- Machining: Precision machining is performed to ensure that all mounting surfaces are flat and true, allowing for a perfect fit on the vehicle.

- Polishing: For aesthetic appeal, rims may undergo polishing to achieve a high-gloss finish.

How Is Quality Assurance Implemented in Heart Rim Manufacturing?

Quality assurance (QA) is a crucial aspect of heart rim manufacturing, ensuring that products meet international standards and customer expectations.

What Are the Key International Standards for Quality Assurance?

Many manufacturers adhere to international quality standards such as ISO 9001, which provides a framework for consistent quality management systems. Compliance with these standards demonstrates a commitment to quality and customer satisfaction.

Additionally, specific industry certifications may be relevant, including:

- CE Marking: Indicates conformity with health, safety, and environmental protection standards for products sold within the European Economic Area.

- API Standards: Relevant for rims used in the automotive and industrial sectors, ensuring products meet rigorous performance criteria.

What Are the Critical Checkpoints in Quality Control?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to identify defects early and ensure compliance with specifications. Key checkpoints include:

- Incoming Quality Control (IQC): Verification of raw materials upon arrival to ensure they meet required standards.

- In-Process Quality Control (IPQC): Continuous monitoring during manufacturing to catch deviations from specifications in real-time.

- Final Quality Control (FQC): Comprehensive testing of finished products before shipment, including dimensional checks, visual inspections, and performance testing.

What Common Testing Methods Are Used in Quality Assurance?

Various testing methods are employed to ensure that heart rims meet performance and safety standards. These methods may include:

- Tensile Testing: Measures the strength and ductility of the material to ensure it can withstand operational stresses.

- Impact Testing: Assesses the rim’s resistance to sudden forces or impacts.

- Fatigue Testing: Evaluates how the rims perform under repeated stress over time, simulating real-world driving conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control practices is essential. Here are some actionable strategies:

- Supplier Audits: Conducting on-site audits of manufacturing facilities allows buyers to assess compliance with quality standards and practices directly.

- Requesting Quality Reports: Suppliers should provide detailed QC reports that outline the testing methods used, results obtained, and any corrective actions taken.

- Third-Party Inspections: Engaging independent inspection agencies can provide an unbiased assessment of a supplier’s quality control processes and the products being manufactured.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers face unique challenges regarding quality control, including variations in regulatory standards and potential language barriers. It is crucial to:

- Understand Local Regulations: Familiarize yourself with the regulations governing the import and use of heart rims in your region.

- Establish Clear Communication: Ensure that all quality requirements are clearly communicated and understood by both parties to avoid misunderstandings.

- Build Long-Term Relationships: Cultivating strong relationships with suppliers can enhance trust and facilitate better communication regarding quality expectations.

By understanding the manufacturing processes and quality assurance measures in place, B2B buyers can make informed decisions when sourcing heart rims, ensuring they receive products that meet their specific needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘heart rims’

Introduction

When sourcing heart rims for your business, having a systematic approach can streamline the process and ensure you make informed decisions. This guide serves as a checklist for B2B buyers, particularly in Africa, South America, the Middle East, and Europe, helping you navigate the complexities of procuring these essential automotive components.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring the heart rims you procure meet your performance and aesthetic needs. Consider factors such as size, bolt pattern, offset, and material type.

– Size and Fitment: Verify the diameter and width appropriate for your vehicle models.

– Material Considerations: Decide between alloy or forged rims based on durability and weight requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers who specialize in heart rims. Look for suppliers with a proven track record and positive reviews in the industry.

– Industry Reputation: Use platforms like LinkedIn or trade associations to gauge supplier credibility.

– Geographical Considerations: Ensure suppliers have experience shipping to your region, as this can affect delivery times and costs.

Step 3: Evaluate Supplier Certifications

Before committing to a supplier, verify their certifications and compliance with industry standards. This step is vital to ensure quality and safety in the products you are purchasing.

– ISO Certification: Look for suppliers with ISO certifications, indicating adherence to international quality standards.

– Safety Standards: Check if the rims meet relevant safety regulations in your target markets.

Step 4: Request Samples

Obtaining samples allows you to assess the quality and performance of the heart rims firsthand. This step is essential for validating the supplier’s claims and ensuring the product meets your specifications.

– Quality Assessment: Inspect the finish, weight, and overall construction of the rims.

– Testing Performance: If possible, conduct tests to evaluate durability and compatibility with your vehicles.

Step 5: Negotiate Terms and Pricing

Engage in discussions with potential suppliers to negotiate pricing, payment terms, and delivery schedules. This is where you can secure the best deal while ensuring the supplier can meet your needs.

– Bulk Discounts: Inquire about pricing tiers for larger orders to maximize savings.

– Payment Flexibility: Consider options for payment plans or financing, especially if you’re making a significant investment.

Step 6: Establish Logistics and Delivery Plans

Plan the logistics of shipping and delivery early in the process to avoid delays. Understanding shipping options and timelines can help you manage inventory effectively.

– Shipping Options: Discuss various shipping methods and their costs to find the most efficient solution.

– Customs and Duties: Be aware of any import duties or customs regulations that may apply to your order.

Step 7: Build a Long-term Relationship

Once you have successfully procured heart rims, focus on building a long-term relationship with your supplier. This can lead to better pricing, priority service, and insights into new products.

– Regular Communication: Maintain ongoing dialogue to address any issues and discuss future needs.

– Feedback Loop: Provide constructive feedback to help suppliers improve their offerings and service.

By following this checklist, B2B buyers can navigate the sourcing process for heart rims effectively, ensuring they make decisions that align with their operational needs and market demands.

Comprehensive Cost and Pricing Analysis for heart rims Sourcing

When sourcing heart rims, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This analysis delves into the cost components, price influencers, and practical tips to optimize sourcing strategies.

What Are the Key Cost Components for Heart Rims?

The cost of heart rims can be broken down into several components:

-

Materials: The type of materials used significantly impacts the overall cost. High-grade alloys or specialized materials for enhanced performance can lead to higher prices. Buyers should consider the trade-off between material quality and cost-effectiveness.

-

Labor: Labor costs vary by region and manufacturing practices. In countries with higher labor costs, such as Germany, manufacturers may pass these expenses onto buyers. Conversely, sourcing from regions with lower labor costs, like parts of Africa or South America, may provide cost savings.

-

Manufacturing Overhead: This includes expenses related to factory operations, utilities, and administrative costs. Efficient manufacturing processes can minimize overhead, which is beneficial for pricing.

-

Tooling: Initial tooling costs can be substantial, especially for custom designs. Buyers should inquire about tooling fees and amortization over production runs to better understand long-term costs.

-

Quality Control (QC): Implementing rigorous QC processes ensures product reliability but can add to costs. Buyers should weigh the importance of quality certifications against pricing.

-

Logistics: Shipping costs, including freight and insurance, can vary widely based on destination. Buyers must consider Incoterms to understand which party bears these costs, impacting the total price.

-

Margin: Supplier profit margins also affect pricing. Understanding the market dynamics and supplier competition can help negotiate better deals.

How Do Price Influencers Affect Heart Rim Costs?

Several factors can influence the pricing of heart rims:

-

Volume/MOQ: Minimum order quantities (MOQ) and bulk purchasing can significantly lower per-unit costs. Buyers should assess their needs against supplier MOQs for cost efficiency.

-

Specifications and Customization: Custom features, such as specific finishes or unique designs, typically incur additional costs. Buyers should specify requirements clearly to avoid unexpected expenses.

-

Material Quality and Certifications: High-quality materials and industry certifications (like ISO or TUV) can increase costs but may offer better performance and durability. Buyers should evaluate the necessity of certifications based on their market requirements.

-

Supplier Factors: Supplier reliability, reputation, and location play critical roles. Established suppliers with a track record of quality may charge more but provide greater assurance of product performance.

What Negotiation Tips Can Help Buyers Optimize Costs?

-

Understand Total Cost of Ownership (TCO): Beyond the initial purchase price, consider maintenance, replacement, and resale values. A lower upfront cost may lead to higher long-term expenses if quality is compromised.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing and favorable terms. Regular communication can foster trust and open doors for negotiation.

-

Benchmark Pricing: Research market prices and competitor offerings to strengthen negotiation positions. Having concrete data can help in discussing pricing with suppliers.

-

Flexibility on Specifications: Being open to alternative materials or designs can lead to cost reductions. Suppliers often have suggestions for adjustments that can lower prices without compromising quality.

What Should International Buyers Consider When Sourcing?

For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, understanding local market conditions and regulations is essential. Currency fluctuations, import tariffs, and trade agreements can all impact the final cost. Additionally, clear communication regarding Incoterms is vital to avoid misunderstandings about shipping responsibilities and costs.

In conclusion, a comprehensive understanding of the cost structure, price influencers, and strategic negotiation can significantly enhance the sourcing process for heart rims. Buyers should approach procurement with diligence, ensuring they evaluate both immediate costs and long-term implications to achieve optimal value.

Disclaimer: The prices mentioned in this analysis are indicative and may vary based on market conditions and specific supplier negotiations.

Alternatives Analysis: Comparing heart rims With Other Solutions

Exploring Alternatives to Heart Rims for Enhanced Performance

In the competitive landscape of automotive solutions, B2B buyers often seek alternatives that can deliver similar performance to heart rims. Understanding these options is crucial for making informed purchasing decisions. This analysis compares heart rims with two alternative solutions: forged aluminum wheels and multi-piece wheels, examining their distinct attributes in terms of performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Heart Rims | Forged Aluminum Wheels | Multi-Piece Wheels |

|---|---|---|---|

| Performance | Excellent for weight distribution and handling | Superior strength and lightweight | Customizable performance based on configuration |

| Cost | Moderate price range | Higher initial investment | Variable pricing, often higher due to complexity |

| Ease of Implementation | Generally straightforward installation | Requires precision fitting | More complex assembly process |

| Maintenance | Low maintenance needs | Moderate; requires periodic checks | Higher due to multiple components needing attention |

| Best Use Case | Street performance and daily driving | High-performance racing and heavy-duty applications | Custom builds and show cars |

What Are the Benefits and Drawbacks of Forged Aluminum Wheels?

Forged aluminum wheels are known for their exceptional strength-to-weight ratio. This makes them ideal for high-performance applications where weight savings can significantly enhance speed and handling. However, the upfront cost of forged wheels is generally higher than that of heart rims, which may deter budget-conscious buyers. Additionally, the installation process can be more complex due to the precision fitting required, and regular checks are necessary to ensure optimal performance.

How Do Multi-Piece Wheels Compare in Customization and Maintenance?

Multi-piece wheels offer unparalleled customization options, allowing buyers to tailor their wheels to specific aesthetic and performance needs. This flexibility makes them a popular choice for show cars and custom builds. However, the complexity of multi-piece wheels can lead to higher costs and more demanding maintenance requirements, as each component must be regularly inspected and maintained. The assembly process is also more involved, which could lead to increased labor costs during installation.

Conclusion: How Should B2B Buyers Choose the Right Wheel Solution?

When selecting between heart rims and their alternatives, B2B buyers should consider their specific needs and applications. Heart rims provide a balanced option for those seeking reliable performance at a moderate cost, making them suitable for everyday use. In contrast, forged aluminum wheels are the go-to for those prioritizing performance and strength, albeit at a higher price point. Multi-piece wheels cater to those desiring customization but come with increased maintenance demands and costs. Ultimately, understanding the unique advantages and limitations of each option will empower buyers to make informed decisions that align with their operational requirements and budget constraints.

Essential Technical Properties and Trade Terminology for heart rims

What Are the Key Technical Properties of Heart Rims?

Understanding the essential technical properties of heart rims is crucial for international B2B buyers, especially those involved in the automotive and manufacturing sectors. Here are several key specifications that should be considered:

-

Material Grade

Heart rims are typically constructed from aluminum alloy or steel. Aluminum rims are lighter and offer better performance in terms of fuel efficiency and handling. On the other hand, steel rims are generally more durable and cost-effective. The choice of material impacts overall vehicle performance, longevity, and aesthetic appeal, making it a critical factor for buyers. -

Diameter and Width

The diameter and width of heart rims are fundamental specifications that determine fitment and performance. Rims are available in various sizes, commonly ranging from 15 to 22 inches in diameter. Width measurements, which can range from 7 to 12 inches, influence tire compatibility and vehicle handling characteristics. Proper sizing is essential to ensure optimal performance and safety. -

Offset and Backspacing

Offset refers to the distance between the wheel’s mounting surface and its centerline. A positive offset means the mounting surface is closer to the front of the wheel, while a negative offset indicates it is closer to the back. Backspacing is the measurement from the mounting surface to the back edge of the rim. These specifications affect the vehicle’s track width, alignment, and overall stability. Understanding offset and backspacing is crucial for ensuring that the rims do not interfere with the vehicle’s suspension components. -

Bolt Pattern

The bolt pattern, typically expressed as a series of numbers (e.g., 5×120), indicates the number of bolt holes and the distance between them. This specification is vital for compatibility with the vehicle’s hub. Ensuring the correct bolt pattern is essential for safe installation and operation, making it a non-negotiable aspect for B2B buyers. -

Weight

The weight of the rim can influence vehicle dynamics, including acceleration, braking, and fuel efficiency. Lighter rims can enhance performance, while heavier options may provide additional durability. Buyers must assess their specific performance needs against weight considerations to make informed purchasing decisions. -

Finish Options

The aesthetic appeal of heart rims is often enhanced by various finish options such as chrome, matte, or polished surfaces. The finish not only impacts visual appeal but also plays a role in corrosion resistance and maintenance. Buyers should consider the environmental conditions in which the rims will be used when selecting finish options.

What Are Common Trade Terms in the Heart Rim Industry?

Familiarizing yourself with industry jargon is crucial for effective communication and negotiation in the B2B market. Here are some common terms you should know:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts that are used in the original assembly of vehicles. Understanding whether a rim is OEM or an aftermarket product can affect quality, compatibility, and warranty considerations. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps buyers plan their inventory and budget effectively, especially when sourcing from international suppliers. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers asking for price quotes on specific products. This process is essential for comparing costs, negotiating terms, and making informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding the delivery of goods. Understanding these terms is crucial for determining shipping costs, risks, and obligations, particularly in international transactions. -

Fitment

This term refers to how well a wheel or rim fits a specific vehicle. Proper fitment ensures safety and performance, making it a key consideration for buyers when selecting heart rims. -

Backorder

A backorder occurs when a product is not currently available but can be delivered at a later date. Buyers should be aware of potential backorder situations to manage timelines and customer expectations effectively.

By grasping these technical properties and trade terms, B2B buyers can navigate the heart rim market with greater confidence and make informed purchasing decisions that align with their operational needs.

Navigating Market Dynamics and Sourcing Trends in the heart rims Sector

What Are the Current Market Dynamics and Key Trends in the Heart Rims Sector?

The heart rims market is experiencing significant growth driven by a combination of rising automotive sales, increasing consumer demand for customizability, and advancements in manufacturing technologies. Global drivers such as the proliferation of electric vehicles (EVs) and the growing popularity of high-performance cars have created a robust demand for lightweight, durable, and aesthetically appealing wheel designs. B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, are increasingly looking for products that not only meet performance standards but also align with evolving design trends.

Emerging B2B technology trends, including online sourcing platforms and advanced logistics solutions, are reshaping how buyers engage with suppliers. International buyers are leveraging these platforms to access a wider variety of options, streamline purchasing processes, and negotiate better pricing. Additionally, data analytics and artificial intelligence are becoming integral in predicting market trends and consumer preferences, enabling businesses to make informed sourcing decisions.

Furthermore, the demand for customization is prompting manufacturers to offer a broader range of designs, sizes, and finishes, catering to diverse market needs. As a result, B2B buyers must remain agile and responsive to these market dynamics to optimize their sourcing strategies effectively.

How Is Sustainability Shaping the Sourcing Practices in the Heart Rims Sector?

Sustainability has become a pivotal consideration in the sourcing of heart rims, with businesses increasingly prioritizing eco-friendly materials and ethical supply chains. The environmental impact of manufacturing processes is under scrutiny, prompting suppliers to adopt greener practices. This shift includes using recyclable materials and reducing waste during production, which not only helps the environment but also aligns with consumer preferences for sustainable products.

B2B buyers are now seeking suppliers that can demonstrate their commitment to sustainability through certifications and transparent sourcing practices. Certifications such as ISO 14001 for environmental management and adherence to the Global Reporting Initiative (GRI) standards are becoming essential indicators of a supplier’s ethical standing. Additionally, sourcing from suppliers who utilize renewable energy in their manufacturing processes can help businesses enhance their corporate social responsibility profiles.

Incorporating ‘green’ materials in the production of heart rims not only reduces environmental impact but can also appeal to a growing segment of environmentally-conscious consumers. As the market evolves, B2B buyers must prioritize partnerships with suppliers committed to sustainable practices to stay competitive and meet regulatory requirements.

What Is the Historical Context of the Heart Rims Sector?

The evolution of the heart rims sector can be traced back to the early 20th century when vehicle manufacturers began focusing on performance and aesthetics. Initially, rims were made from steel, prioritizing durability over design. However, as automotive technology advanced and consumer preferences shifted, the introduction of aluminum alloys and later, carbon fiber, transformed the market.

In the late 20th century, the customization trend gained momentum, leading to a proliferation of aftermarket options that catered to enthusiasts seeking to enhance their vehicles’ performance and style. Today, heart rims are not just functional components; they are vital to a vehicle’s identity, reflecting the owner’s taste and lifestyle. This historical context provides B2B buyers with insights into the changing dynamics of consumer demand, emphasizing the importance of adaptability in sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of heart rims

-

How do I ensure the quality of heart rims before purchase?

To ensure the quality of heart rims, start by requesting samples from potential suppliers. Evaluate these samples for material quality, finish, and adherence to specifications. Additionally, ask for certifications that demonstrate compliance with international standards, such as ISO or SAE. Conducting a factory audit or using third-party inspection services can also provide deeper insights into manufacturing processes and quality control measures. -

What factors should I consider when choosing a supplier for heart rims?

When selecting a supplier for heart rims, consider their experience in the industry, reputation, and production capabilities. Assess their ability to meet your specific requirements, including customization options and minimum order quantities (MOQs). Additionally, check for customer reviews and references, and evaluate their logistics capabilities to ensure timely delivery. A supplier with a robust after-sales support system can also enhance your purchasing experience. -

What are the common customization options available for heart rims?

Customization options for heart rims typically include size, color, finish, and bolt pattern. Many manufacturers offer a variety of designs, including one-piece and multi-piece configurations. You can also request specific offsets and backspacing to suit particular vehicle models. Discuss your customization needs upfront with your supplier to ensure they can accommodate your requests within your desired timeline. -

What is the typical minimum order quantity (MOQ) for heart rims?

The minimum order quantity (MOQ) for heart rims can vary significantly between suppliers, often ranging from 50 to 100 pieces. Factors influencing MOQ include production capacity, material availability, and the complexity of customization. When negotiating with suppliers, be clear about your needs and explore the possibility of lower MOQs, especially if you are a new buyer or testing a market. -

What payment terms should I expect when sourcing heart rims internationally?

Payment terms can vary widely among suppliers, typically ranging from 30% upfront and 70% upon delivery to full payment before production. It’s crucial to clarify these terms early in negotiations. Consider using secure payment methods such as letters of credit or escrow services to mitigate risk. Additionally, be aware of potential currency fluctuations and international transaction fees when dealing with cross-border payments. -

How can I handle logistics and shipping for heart rims purchased internationally?

When managing logistics for international purchases of heart rims, work closely with your supplier to understand shipping options, costs, and delivery timelines. Consider using freight forwarders who specialize in automotive parts to streamline the process. Be proactive in discussing customs duties and regulations specific to your country to avoid unexpected delays. Establishing a clear communication channel with your supplier can help resolve any logistical issues that may arise. -

What quality assurance measures should I request from suppliers of heart rims?

Request detailed quality assurance documentation from suppliers, including inspection reports, testing protocols, and any relevant certifications. Inquire about their quality control processes throughout the manufacturing cycle, such as material inspection and final product testing. Establishing a clear QA agreement with your supplier can help ensure that the heart rims meet your specifications and reduce the risk of defects upon delivery. -

How do I navigate trade regulations when importing heart rims?

To navigate trade regulations when importing heart rims, familiarize yourself with the import laws of your country, including tariffs, quotas, and safety standards. Consult with customs brokers who can provide insights into the documentation required for your imports. Additionally, stay informed about any trade agreements that may benefit your transactions, and ensure that your suppliers comply with international shipping regulations to facilitate a smooth import process.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 6 Heart Rims Manufacturers & Suppliers List

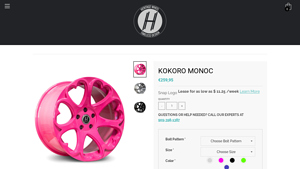

1. Kokoro – MonoC Wheels

Domain: heritagewheel.com

Registered: 2016 (9 years)

Introduction: {‘name’: ‘Kokoro MonoC’, ‘price’: ‘$299.00’, ‘description’: ‘Aftermarket wheels featuring a unique heart-shaped design, constructed from high-quality materials. Available in various sizes, bolt patterns, and finishes.’, ‘sizes’: [{‘size’: ’18×8.5+35′, ‘bolt_patterns’: [‘5×100’, ‘5×114.3’], ‘finishes’: [‘Classic Silver’, ‘Sakura Pink’, ‘Midnight Black (5×114.3 only)’]}, {‘size’: ’18×9.5+22′, ‘bolt_…

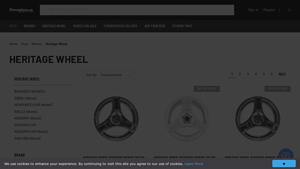

2. Heritage Wheels – BUSHIDO MONOC

Domain: threepiece.us

Registered: 2014 (11 years)

Introduction: Heritage Wheels in stock starting at $233. Available sizes: 15, 17, 18, 19, 20 inches. Various models include BUSHIDO MONOC, with options for different bolt patterns (5×120, 5×115) and offsets (+12, +35, +38). Colors available include Chrome and White. Prices range from $339.00 to $399.00 depending on the specific model and specifications.

3. KOKORO – Heart Wheels

Domain: instagram.com

Registered: 2004 (21 years)

Introduction: This company, KOKORO – Heart Wheels, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

4. Heart Car Rims – Kokoro Monoc Wheel Design

Domain: pinterest.com

Introduction: Heart Car Rims, Pink Car, White Wheels, Kokoro Monoc Wheel Design, heart wheels, heart lug nuts, Pink Mustang Car Designs, Paint Pink Car Accessories, Tires lettering stickers, Good year Eagle F1, 4 wheels, 1.25/for 14 to 24 car model, material: PVC, year: Any year, color: white, red, letters height: 32mm, original licensed product, waterproof, easy to clean, layer vulcanized patented material, al…

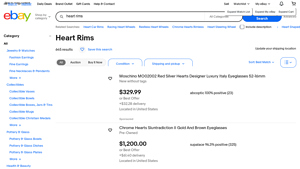

5. KOKORO MonoC Wheel Rim – 18×8.5 Heart Silver

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: 1. Heritage KOKORO MonoC Wheel Rim 5×100 18 x 8.5 inch x 35 Heart Silver SLT7023 – Brand New – Price: $1,199.95 – Free delivery – Located in United States – 39 watchers

2. PERFORMANCE MACHINE HEART REAR WHEEL FOR HARLEY CHOPPER MOTORCYCLE – 18 X 5.5 – New (Other) – Price: $800.00 – Delivery: +$75.00 in 2-4 days – Located in United States – 32 watchers

3. Heritage KOKORO 5×114.3 20×10+45 Pink Heart…

6. Custom Forged – Pink Heart Wheels

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom forged pink heart wheels, designed to fit over large calipers, size 19.5 inches.

Strategic Sourcing Conclusion and Outlook for heart rims

In the evolving landscape of the heart rims market, strategic sourcing emerges as a pivotal factor for international B2B buyers. By leveraging robust supplier relationships and understanding regional market dynamics, businesses can secure high-quality products at competitive prices. The diversity in designs and specifications—ranging from the sleek Bushido MonoC to the innovative Kokoro MonoC—highlights the importance of aligning product offerings with consumer preferences across different markets, particularly in Africa, South America, the Middle East, and Europe.

Furthermore, as sustainability becomes increasingly significant, sourcing from manufacturers that prioritize eco-friendly practices can enhance brand reputation and attract environmentally conscious consumers. Buyers should also consider the potential for long-term partnerships with suppliers to ensure a steady supply chain and improved negotiation leverage.

Looking ahead, the heart rims market is poised for growth driven by rising automotive trends and consumer customization demands. Now is the time for international buyers to engage with reputable suppliers, explore new designs, and establish strategic partnerships that will not only meet current demands but also position their businesses for future success. Embrace this opportunity to enhance your product offerings and drive competitive advantage in your market.