How to Source Hd Hole Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for hd hole

In today’s competitive landscape, sourcing high-quality HD hole products can be a daunting challenge for international B2B buyers. With varying standards and specifications across regions, making informed purchasing decisions is crucial for ensuring operational efficiency and cost-effectiveness. This comprehensive guide delves into the diverse world of HD hole products, exploring various types, applications, and industry-specific needs. From heavy-duty hole cutters designed for tough materials to specialized diamond hole saws for precision drilling, our guide covers everything you need to know to navigate the complexities of the market.

Understanding the intricacies of supplier vetting is equally vital. This guide will equip you with the necessary insights to assess supplier reliability, quality assurance, and pricing strategies, enabling you to forge strong partnerships that align with your business goals. Whether you’re based in Africa, South America, the Middle East, or Europe, this resource is tailored to address the unique challenges faced by buyers in these regions, such as fluctuating supply chains and regional compliance standards.

By leveraging the information presented, you will be empowered to make strategic decisions that enhance productivity and minimize risks associated with sourcing HD hole products. Prepare to elevate your procurement strategy and ensure your business remains at the forefront of industry advancements.

Understanding hd hole Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heavy-Duty Hole Cutter | Carbide-tipped, thicker walls, designed for tough materials | Cutting cast iron, ductile iron, clay pipe | Pros: Durable, efficient for heavy-duty use. Cons: Higher upfront cost. |

| Diamond Hole Saw | High-grade diamonds, heat-resistant vacuum braze | Drilling in abrasive materials like tile, glass | Pros: Long-lasting, high performance. Cons: Requires specialized equipment. |

| HD Hole Punch | Designed for irrigation systems, robust construction | Drip irrigation setups | Pros: Easy to use, effective for irrigation. Cons: Limited to specific applications. |

| Black Hole® Pro HD Basket | Sturdy chain rack, deeper cage, high visibility chains | Disc golf courses, recreational facilities | Pros: Enhanced durability, quick assembly. Cons: Bulkier for transport. |

| HD Hole Saw | Variety of sizes, designed for heavy-duty applications | General construction, plumbing work | Pros: Versatile, can handle various materials. Cons: May require multiple sizes for different jobs. |

What are the characteristics and applications of Heavy-Duty Hole Cutters?

Heavy-Duty Hole Cutters are engineered for rigorous tasks, particularly in cutting through tough materials such as cast iron and ductile iron. They feature carbide-tipped blades with thicker walls, which enhance durability and allow for more cuts compared to standard models. These tools are commonly used in plumbing and construction applications, making them essential for B2B buyers seeking reliable, high-performance solutions. When purchasing, consider the cutter size and compatibility with existing drilling machines.

How do Diamond Hole Saws perform in abrasive material drilling?

Diamond Hole Saws are specifically designed for drilling through highly abrasive materials, including tile, stone, and glass. Utilizing high-grade diamonds and a heat-resistant vacuum braze, these saws deliver exceptional performance and extended tool life. B2B applications often include construction and renovation projects where precision is crucial. Buyers should evaluate the required diameter and ensure that the saw is compatible with their existing tools to maximize efficiency.

What role does the HD Hole Punch play in irrigation systems?

The HD Hole Punch is a vital tool for establishing drip irrigation systems, particularly in agricultural settings. Its robust construction allows for easy and effective punching of holes in tubing, facilitating water flow to plants. This tool is particularly advantageous for B2B buyers in the agricultural sector looking to optimize irrigation efficiency. When considering a purchase, assess the size and compatibility with the irrigation setup to ensure seamless integration.

What makes the Black Hole® Pro HD Basket suitable for recreational facilities?

The Black Hole® Pro HD Basket is designed for disc golf courses and recreational facilities, featuring a sturdy construction with a deeper cage and high visibility chains. This design minimizes weak pockets that can affect gameplay, making it a favorite among course designers. B2B buyers should consider the ease of assembly and transportability when selecting this product for commercial use, as its robust design may be bulkier than standard options but offers enhanced durability.

How versatile are HD Hole Saws for construction applications?

HD Hole Saws are available in a variety of sizes and are suitable for a wide range of heavy-duty applications, including general construction and plumbing work. Their design allows them to handle various materials, from wood to metal, making them a versatile choice for contractors. B2B buyers should consider the specific materials they will be working with and the range of sizes required to ensure they have the right tools for any job.

Key Industrial Applications of hd hole

| Industry/Sector | Specific Application of hd hole | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Infrastructure | Heavy-duty hole cutting for pipelines | Enhanced efficiency in installation and maintenance | Quality of materials, compatibility with existing machinery, and local availability |

| Agriculture & Irrigation | Drip irrigation systems installation | Improved water management and crop yield | Durability for local soil conditions, ease of installation, and cost-effectiveness |

| Manufacturing & Fabrication | Precision hole cutting in metal and composite materials | Higher production efficiency and reduced waste | Precision standards, machine compatibility, and after-sales support |

| Oil & Gas | Drilling through tough materials for pipeline access | Increased operational efficiency | Compliance with safety standards, durability, and supplier reliability |

| Mining | Core sampling and geological surveys | Accurate resource assessment | Tool longevity, resistance to harsh conditions, and availability of replacement parts |

How is ‘hd hole’ Used in Construction and Infrastructure Projects?

In the construction and infrastructure sector, heavy-duty hole cutters are essential for creating precise openings in pipelines and structural components. They are particularly effective when cutting through tough materials like cast iron and ductile iron. This capability allows companies to enhance their installation processes, minimizing downtime and ensuring that projects stay on schedule. For international buyers, considerations include sourcing equipment that meets local regulations and standards, as well as ensuring compatibility with existing machinery.

What Role Does ‘hd hole’ Play in Agriculture and Irrigation Systems?

In agriculture, hd hole applications are crucial for installing drip irrigation systems, which deliver water directly to plant roots. This method not only conserves water but also promotes healthier crop growth by providing consistent moisture. International buyers, especially in regions like Africa and South America, must consider the durability of the materials used to withstand local soil conditions and ensure that installation is straightforward to maximize efficiency and cost-effectiveness.

How Does ‘hd hole’ Facilitate Manufacturing and Fabrication?

In manufacturing, precision is key, and heavy-duty hole cutters are designed to deliver exact cuts in various materials, including metals and composites. This precision not only increases production efficiency but also reduces material waste, directly impacting a company’s bottom line. For B2B buyers, ensuring that the tools meet strict precision standards and are compatible with their existing equipment is vital for maintaining production flow.

In What Ways Does ‘hd hole’ Enhance Operations in the Oil & Gas Industry?

The oil and gas industry often requires drilling through tough materials to access pipelines or perform maintenance. Heavy-duty hole cutters facilitate this process, allowing for quicker and more efficient operations, which is critical in a sector where time is money. Buyers in this industry should prioritize suppliers that offer robust tools compliant with safety regulations and capable of withstanding harsh working conditions.

How is ‘hd hole’ Utilized in Mining Applications?

In mining, hd hole applications are vital for core sampling and geological surveys, which provide essential data for resource assessment. The ability to cut through hard materials efficiently is crucial for accurate results, impacting decision-making in resource extraction. Buyers should focus on sourcing tools that offer longevity and resistance to abrasive conditions, as well as ensuring that replacement parts are readily available to minimize downtime.

3 Common User Pain Points for ‘hd hole’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right HD Hole Cutter for Specific Applications

The Problem: B2B buyers often struggle with choosing the appropriate HD hole cutter for their specific needs, especially when dealing with diverse materials such as cast iron, ductile iron, or clay. This can lead to inefficiencies in their operations, increased costs due to purchasing incorrect tools, and project delays. For instance, a construction firm in Brazil may require hole cutters that can handle both ductile iron and cement-lined pipes but finds it challenging to differentiate between the various options available in the market.

The Solution: To mitigate this challenge, buyers should start by clearly defining their project requirements, including the types of materials they will be working with and the size of the holes needed. It is crucial to consult with manufacturers or suppliers who specialize in HD hole cutters to gain insights into the specific products that will meet their criteria. For example, utilizing heavy-duty carbide-tipped hole cutters, like the Reed HDHS1750, can ensure durability and efficiency. Additionally, buyers should request product specifications and performance data to compare options effectively. Investing time in understanding the nuances of each product can significantly enhance operational efficiency and reduce the likelihood of costly errors.

Scenario 2: Managing Supply Chain Delays for HD Hole Products

The Problem: International B2B buyers often face supply chain challenges, particularly when sourcing specialized HD hole products from overseas suppliers. Delays in shipping can stall critical projects, leading to dissatisfaction among clients and potential financial losses. For example, a company in Nigeria that relies on timely delivery of HD hole saws for a major infrastructure project may encounter unexpected shipping delays, which can jeopardize their contract commitments.

The Solution: To address supply chain concerns, businesses should diversify their supplier base and consider establishing relationships with local or regional suppliers who can provide HD hole products. This approach not only reduces lead times but also mitigates risks associated with international shipping. Additionally, implementing a Just-in-Time (JIT) inventory strategy can help manage stock levels and ensure that critical tools are available when needed. Regular communication with suppliers to monitor inventory levels and anticipated delivery dates can also aid in proactive planning. Buyers should also consider leveraging technology, such as supply chain management software, to track shipments and forecast potential delays effectively.

Scenario 3: Ensuring Proper Use and Maintenance of HD Hole Products

The Problem: Many B2B buyers underestimate the importance of proper usage and maintenance of HD hole products, which can lead to tool degradation and safety issues. For instance, a construction team in South America may not be fully aware of the best practices for using diamond HD hole saws, resulting in premature wear and tear, decreased efficiency, and increased costs for replacements.

The Solution: It is essential for buyers to invest in training and education for their teams on the correct usage and maintenance of HD hole products. This can include attending workshops provided by manufacturers, consulting online resources, or partnering with industry experts. Implementing a structured maintenance schedule can also prolong the lifespan of tools and enhance safety. For example, regularly inspecting and cleaning hole saws after use, as well as adhering to manufacturer guidelines for operation speeds and feed rates, can prevent operational mishaps. By fostering a culture of safety and efficiency through proper training, businesses can maximize their investment in HD hole products and ensure optimal performance on the job site.

Strategic Material Selection Guide for hd hole

What Are the Key Materials for HD Hole Applications?

When selecting materials for HD hole applications, it’s crucial to consider their properties, advantages, and limitations. This analysis focuses on four common materials: Carbon Steel, Stainless Steel, High-Speed Steel (HSS), and Diamond-Coated tools. Each material has distinct characteristics that can influence product performance and suitability for various applications.

How Does Carbon Steel Perform in HD Hole Applications?

Key Properties: Carbon steel is known for its high tensile strength and hardness, making it suitable for heavy-duty applications. It typically withstands high temperatures and pressures, which is essential for drilling operations.

Pros & Cons: The primary advantage of carbon steel is its durability and cost-effectiveness. However, its susceptibility to corrosion can be a significant drawback, particularly in humid or chemically aggressive environments. Additionally, manufacturing complexities can arise when heat treatment is required to enhance performance.

Impact on Application: Carbon steel is ideal for applications involving non-corrosive media. However, in regions with high humidity or exposure to corrosive substances, its longevity may be compromised.

Considerations for International Buyers: Buyers from regions such as Africa and South America should ensure compliance with local standards, as carbon steel may not meet specific regulations regarding corrosion resistance.

What Are the Benefits of Using Stainless Steel for HD Hole Applications?

Key Properties: Stainless steel offers excellent corrosion resistance, making it suitable for a wide range of environments. It maintains its strength at elevated temperatures and is less prone to rust compared to carbon steel.

Pros & Cons: The key advantage of stainless steel is its durability and resistance to oxidation, which extends the lifespan of tools and equipment. However, it is generally more expensive than carbon steel and can be more challenging to machine due to its toughness.

Impact on Application: Stainless steel is particularly effective in applications involving corrosive media or where hygiene is critical, such as in the food and pharmaceutical industries.

Considerations for International Buyers: Compliance with international standards like ASTM or DIN is essential, especially in Europe, where stringent regulations may apply. Buyers should also consider the availability of stainless steel products in their local markets.

Why Choose High-Speed Steel (HSS) for HD Hole Applications?

Key Properties: High-Speed Steel is known for its ability to withstand high temperatures without losing hardness. It is often used in cutting tools and offers a good balance of toughness and wear resistance.

Pros & Cons: HSS is advantageous due to its ability to maintain sharpness over extended use, making it cost-effective in the long run. However, it is more brittle than other materials, which can lead to chipping or breaking under excessive stress.

Impact on Application: HSS is suitable for drilling through tough materials, including metals and composites, making it versatile for various industries.

Considerations for International Buyers: Buyers should be aware of the manufacturing standards and certifications required in their regions, as HSS tools may need to comply with specific quality benchmarks.

How Do Diamond-Coated Tools Enhance HD Hole Applications?

Key Properties: Diamond-coated tools are engineered for extreme durability and wear resistance. They can cut through the hardest materials, including ceramics and composites, thanks to the hardness of diamond.

Pros & Cons: The key advantage of diamond-coated tools is their exceptional lifespan and performance in abrasive applications. However, they are typically the most expensive option and may require specialized handling and storage.

Impact on Application: These tools are ideal for high-precision drilling in demanding environments, making them suitable for industries like aerospace and automotive.

Considerations for International Buyers: International buyers should consider the availability of diamond-coated tools and their compliance with local standards, as well as the potential need for specialized training for handling these tools.

Summary of Material Selection for HD Hole Applications

| Material | Typical Use Case for hd hole | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | General drilling in non-corrosive environments | Cost-effective and durable | Susceptible to corrosion | Medium |

| Stainless Steel | Applications requiring corrosion resistance | Excellent durability and hygiene | Higher cost and machining complexity | High |

| High-Speed Steel (HSS) | Cutting through tough materials | Maintains sharpness over time | Brittle and prone to chipping | Medium |

| Diamond-Coated Tools | High-precision drilling in abrasive materials | Exceptional lifespan and performance | High cost and specialized handling required | High |

This material selection guide provides B2B buyers with critical insights into the properties, advantages, and limitations of various materials used in HD hole applications. Understanding these factors will enable informed decision-making tailored to specific operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for hd hole

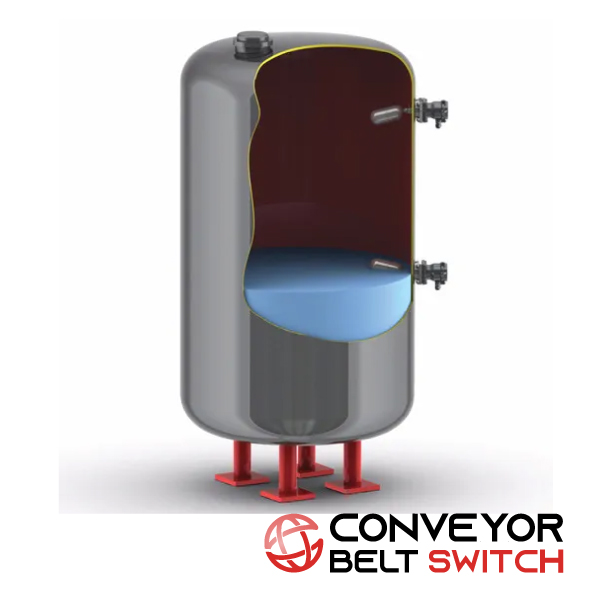

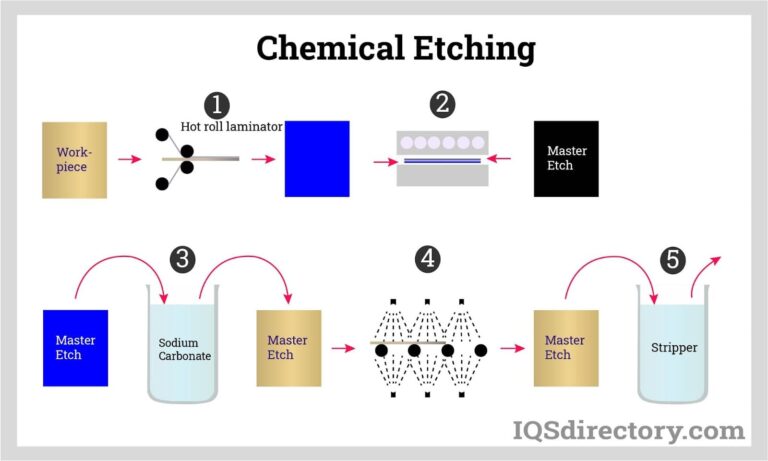

What Are the Key Stages in the Manufacturing Process for HD Holes?

The manufacturing of HD holes, particularly in products such as hole cutters and punches, involves several critical stages that ensure the end product meets the required specifications for durability and performance.

1. Material Preparation

The first stage of manufacturing involves selecting the appropriate materials. High-density carbide, for instance, is often used for hole cutters due to its toughness and wear resistance. Suppliers typically source these materials from certified vendors to ensure quality. The material is then cut into manageable sizes before undergoing further processing.

2. Forming Techniques

Once the materials are prepared, they undergo various forming techniques. This may include forging, casting, or machining, depending on the product type. For HD hole cutters, machining is common, where the material is shaped using CNC machines to achieve precise dimensions. These machines can create intricate designs that enhance the product’s functionality, such as the specific tooth patterns found in hole saws.

3. Assembly Process

After forming, components are assembled. This stage is crucial, particularly for products that involve multiple parts, such as hole saws with interchangeable blades. Manufacturers often employ automated assembly lines to improve efficiency while ensuring that each component is accurately fitted. Quality assurance checks are integrated into this phase to catch any assembly errors early.

4. Finishing Touches

The final stage in the manufacturing process involves finishing treatments. This may include surface coating, grinding, or polishing to enhance durability and appearance. For HD hole products, coatings like powder or matte finishes are applied to prevent rust and wear. This not only improves the product’s lifespan but also meets aesthetic expectations for B2B buyers.

How Do Quality Assurance Practices Ensure Product Reliability?

Quality assurance (QA) is an integral part of the manufacturing process, especially for international B2B transactions where compliance with various standards is paramount.

Adherence to International Standards

Manufacturers often comply with international quality standards such as ISO 9001, which outlines criteria for a quality management system. This certification ensures that companies consistently provide products that meet customer and regulatory requirements. In addition, industry-specific certifications such as CE (Conformité Européenne) and API (American Petroleum Institute) may also be applicable, particularly for products used in the oil and gas sector.

Key Quality Control Checkpoints

To maintain high standards, manufacturers implement various quality control checkpoints throughout the production process:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon delivery. Suppliers often provide certificates of compliance to verify the quality of materials received.

-

In-Process Quality Control (IPQC): This stage occurs during manufacturing, where ongoing inspections and tests are performed to ensure that the production process adheres to set specifications.

-

Final Quality Control (FQC): At this stage, finished products undergo thorough testing to ensure they meet performance criteria. This may include functionality tests, dimensional checks, and visual inspections.

What Testing Methods Are Commonly Used in the Quality Assurance Process?

Various testing methods are employed to ensure the performance and safety of HD hole products:

-

Durability Testing: Products undergo stress tests to assess their resistance to wear and tear. For instance, hole cutters may be subjected to repetitive cutting cycles to evaluate their longevity.

-

Dimensional Accuracy Testing: Precise measurements are taken to verify that products meet specified dimensions. This is critical for products that must fit specific equipment or applications.

-

Performance Testing: This involves operational tests where the product is used in real-world conditions to ensure it performs as expected. For example, hole saws may be tested on different materials to assess cutting efficiency.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially those in regions like Africa, South America, the Middle East, and Europe, it is crucial to verify supplier quality control processes to mitigate risks associated with subpar products.

Conducting Supplier Audits

One of the most effective ways to ensure a supplier’s commitment to quality is through audits. Buyers can request to perform or obtain third-party audits that assess the supplier’s manufacturing processes, quality control measures, and adherence to international standards. These audits can reveal the supplier’s capabilities and reliability.

Requesting Quality Reports

Buyers should also ask for quality assurance reports that detail the results of various tests performed on the products. These reports should outline the methodologies used, results obtained, and any corrective actions taken if standards were not met.

Third-Party Inspections

Engaging third-party inspection services can provide an unbiased assessment of the product quality before shipment. These inspections can cover aspects from material quality to final product tests, ensuring compliance with the buyer’s specifications and industry standards.

What Are the Quality Control Nuances for International Buyers?

International buyers need to be aware of specific nuances in quality control that can vary by region. For instance, compliance with local regulations may differ, and understanding these is vital for smooth transactions. Additionally, buyers should consider:

-

Cultural Differences: Different regions may have varying approaches to quality and reliability. Establishing clear communication regarding quality expectations is essential.

-

Logistical Considerations: The shipping process can impact product quality. Buyers should ensure that suppliers implement adequate packaging and handling practices to prevent damage during transit.

-

Regulatory Compliance: Buyers must ensure that products comply with both their local regulations and the standards of the supplier’s country. This is particularly important in industries like construction and manufacturing, where safety standards are stringent.

By understanding these manufacturing processes and quality assurance practices, international B2B buyers can make informed decisions when sourcing HD hole products, ensuring they receive reliable, high-quality solutions tailored to their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘hd hole’

Introduction

This guide provides a comprehensive checklist for B2B buyers seeking to procure HD hole products, such as hole cutters, punches, and saws. With various applications across industries, understanding the essential steps in sourcing these tools will ensure you make informed purchasing decisions that align with your operational needs.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for your HD hole products. Consider the materials you will be working with—whether it’s metal, concrete, or tile—and the size and depth of the holes needed. Precise specifications help in narrowing down the suitable products and suppliers, ensuring compatibility with your existing tools and machinery.

- Material Compatibility: Ensure the products are designed for the specific materials you will be cutting.

- Size and Capacity: Identify the diameter and cutting depth necessary for your applications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that specialize in HD hole products. Look for companies with a strong reputation in your industry and positive reviews from other B2B buyers. This step is crucial for ensuring quality and reliability in your procurement process.

- Industry Experience: Prefer suppliers with a proven track record in your specific sector.

- Customer Testimonials: Seek feedback from previous clients to gauge satisfaction levels and product performance.

Step 3: Evaluate Product Quality

Assess the quality of the HD hole products by reviewing technical specifications and certifications. High-quality tools are essential for durability and efficiency in demanding applications, reducing the risk of breakdowns and costly downtime.

- Material Specifications: Look for products made from high-grade materials, such as carbide-tipped or diamond-coated options.

- Warranty and Support: Ensure the supplier offers a warranty and technical support for their products.

Step 4: Verify Supplier Certifications

Confirm that potential suppliers hold necessary industry certifications and standards. Certifications ensure that the products meet safety and quality regulations, which is particularly important when sourcing for international operations.

- ISO Certifications: Check for ISO quality management certifications, which indicate adherence to international standards.

- Safety Standards: Ensure products comply with local and international safety regulations.

Step 5: Request Samples and Demonstrations

Before finalizing your order, request samples or product demonstrations. This allows you to evaluate the performance and suitability of the HD hole tools firsthand. It’s an important step to ensure that the products meet your operational requirements.

- Trial Periods: Ask if the supplier offers a trial period or return policy for products that do not meet your expectations.

- Performance Testing: Evaluate the tools in real-world conditions to assess their effectiveness.

Step 6: Negotiate Pricing and Terms

Engage in negotiations regarding pricing, payment terms, and delivery schedules. Transparent discussions can lead to better deals and long-term partnerships, which are essential for ongoing supply needs.

- Bulk Purchase Discounts: Inquire about pricing incentives for bulk orders or long-term contracts.

- Flexible Payment Terms: Discuss payment options that align with your financial planning.

Step 7: Finalize Your Order and Logistics

Once you have selected a supplier and agreed on terms, finalize your order. Pay attention to logistics, including shipping and delivery timelines, to ensure that the products arrive when needed for your projects.

- Shipping Options: Choose reliable shipping methods that align with your timeline.

- Customs and Duties: Be aware of any import duties or customs regulations that may affect delivery in your region.

By following this practical checklist, you can streamline your sourcing process for HD hole products, ensuring you choose the right tools for your business needs while fostering strong supplier relationships.

Comprehensive Cost and Pricing Analysis for hd hole Sourcing

What Are the Key Cost Components in HD Hole Sourcing?

When sourcing HD hole products, understanding the cost structure is essential for effective budgeting and price negotiation. The primary cost components include:

-

Materials: The quality of raw materials significantly influences pricing. For instance, high-grade diamonds used in diamond hole saws or heavy-duty carbide-tipped materials in hole cutters can elevate costs but also enhance durability and performance.

-

Labor: Skilled labor required for manufacturing can vary by region. Areas with higher labor costs may reflect this in product pricing, impacting overall sourcing decisions.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce overhead, thereby lowering the final product price.

-

Tooling: The initial investment in tooling for specialized products, such as customized HD hole cutters, can be significant. This cost is often amortized over the production volume, affecting unit prices.

-

Quality Control (QC): Rigorous QC processes ensure product reliability but add to manufacturing costs. Certifications and testing for compliance with international standards can further influence prices.

-

Logistics: Shipping costs, including freight and insurance, are critical, especially for international buyers. The geographical distance from suppliers can significantly impact logistics expenses.

-

Margin: Suppliers typically apply a markup to cover their costs and profit. Understanding a supplier’s margin can provide leverage during negotiations.

What Influences the Pricing of HD Hole Products?

Several factors can influence the pricing of HD hole products, making it essential for buyers to be aware of these when negotiating:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, making it advantageous for businesses to plan accordingly.

-

Specifications and Customization: Customized products tailored to specific applications may incur additional costs. Standardized products, on the other hand, are generally less expensive due to streamlined production processes.

-

Materials and Quality Certifications: The choice of materials directly affects durability and performance. Products that come with quality certifications (e.g., ISO, PDGA) may command higher prices but can be justified by their longevity and reliability.

-

Supplier Factors: Supplier reputation, reliability, and payment terms can all influence pricing. Established suppliers may charge a premium for their proven track record and customer service.

-

Incoterms: Understanding the terms of shipping and delivery is crucial. Different Incoterms can shift costs and responsibilities, impacting the total price paid by the buyer.

How Can Buyers Negotiate Better Prices on HD Hole Products?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, effective negotiation strategies can lead to significant savings:

-

Leverage Total Cost of Ownership (TCO): Consider not just the purchase price but the overall costs associated with maintenance, durability, and efficiency over the product’s lifecycle. Highlighting TCO in negotiations can justify higher initial costs if long-term savings are evident.

-

Explore Alternative Suppliers: Diversifying suppliers can create competition, leading to better pricing. Research and engage with multiple vendors to find the best value.

-

Build Relationships: Establishing long-term relationships with suppliers may yield better prices and terms. Trust and reliability can often lead to favorable negotiations.

-

Be Informed: Knowledge about market prices, material costs, and manufacturing processes can empower buyers during negotiations. Understanding the nuances of the industry will allow for more effective discussions.

-

Consider Local Sourcing: For buyers in regions like Brazil and Nigeria, exploring local suppliers may reduce logistics costs and lead to faster delivery times, enhancing overall efficiency.

What Should International Buyers Keep in Mind Regarding Pricing Nuances?

International buyers must be aware of specific nuances that can affect pricing:

-

Currency Fluctuations: Exchange rates can impact costs significantly, so consider hedging strategies or fixed-price agreements to mitigate risks.

-

Import Duties and Taxes: Be mindful of the additional costs incurred from customs duties and local taxes, which can add significantly to the total price.

-

Shipping Delays: Longer lead times can affect project timelines. Ensure that the selected suppliers can meet delivery schedules to avoid unnecessary costs associated with delays.

-

Cultural Differences: Understanding cultural nuances in negotiation styles can facilitate better communication and outcomes.

Disclaimer

Prices mentioned in the guide are indicative and may vary based on market conditions, supplier pricing strategies, and regional economic factors. Always conduct thorough research and engage in direct negotiations to ascertain the most accurate pricing.

Alternatives Analysis: Comparing hd hole With Other Solutions

Exploring Alternatives to ‘Hd Hole’ Solutions

In the quest for optimal drilling solutions, understanding the alternatives to the ‘hd hole’ is crucial for international B2B buyers. This analysis will compare ‘hd hole’ technology against two viable alternatives: the Reed HD Hole Cutter and the Norske Diamond HD Hole Saws. Each option offers unique advantages and may better suit specific applications depending on the buyer’s requirements.

| Comparison Aspect | ‘Hd Hole’ | Reed HD Hole Cutter | Norske Diamond HD Hole Saws |

|---|---|---|---|

| Performance | High durability for various materials | Heavy-duty carbide-tipped for cast iron and ductile iron | Best-in-class for abrasive materials |

| Cost | Moderate pricing, starting around $60 | Higher cost at approximately $162 | Variable, $13.19 to $31.19 per piece |

| Ease of Implementation | Simple setup, user-friendly | Requires compatible drilling machines | Easy to use with standard drills |

| Maintenance | Low maintenance required | Moderate; blade replacement needed | Low; diamond tips have long life |

| Best Use Case | General drilling applications | Ideal for industrial pipe cutting | Excellent for tiles, stone, and glass |

What Are the Pros and Cons of the Reed HD Hole Cutter?

The Reed HD Hole Cutter is designed for heavy-duty applications, particularly effective in cutting through tough materials like cast iron and ductile iron. Its carbide-tipped design ensures longevity and performance, making it a go-to for industrial projects. However, this solution requires specific drilling machines (like the Reed DM2100), which can limit its versatility. Additionally, while the upfront cost is higher than ‘hd hole’, its efficiency in demanding environments can justify the investment.

How Do Norske Diamond HD Hole Saws Compare?

Norske Diamond HD Hole Saws are specifically engineered to tackle abrasive materials such as tile, stone, and glass. Their diamond-tipped design ensures exceptional durability and performance, making them ideal for construction and renovation projects. The cost-effectiveness of these hole saws is noteworthy, with prices ranging from $13.19 to $31.19, depending on the size. However, they may not perform as well on tougher metals compared to the Reed HD Hole Cutter, making them less suitable for industrial pipe work.

Conclusion: How Should B2B Buyers Choose the Right Solution?

When selecting a drilling solution, B2B buyers must consider their specific needs, including the types of materials to be drilled, the required durability, and budget constraints. If the primary application involves heavy-duty metal cutting, the Reed HD Hole Cutter may be the most effective option despite its higher cost. Conversely, for general drilling tasks or work with abrasive materials, ‘hd hole’ or Norske Diamond HD Hole Saws offer excellent performance at a more accessible price point. Ultimately, understanding the nuances of each option will empower buyers to make informed decisions that align with their operational requirements.

Essential Technical Properties and Trade Terminology for hd hole

What Are the Key Technical Properties of HD Hole Products?

When evaluating HD hole products, understanding their technical specifications is crucial for B2B buyers. Here are some essential properties to consider:

-

Material Grade: The material grade indicates the quality and durability of the HD hole product. For instance, heavy-duty carbide-tipped hole cutters, like those used in the Reed HDHS1750, are designed with thicker walls and larger carbides, which enhance their longevity and cutting capability. B2B buyers should prioritize products made from high-grade materials to ensure they can withstand rigorous usage, especially in demanding environments like construction or industrial applications.

-

Cutting Diameter: This specification refers to the size of the hole that the tool can create. Products like the Reed HD hole cutter come in various sizes, such as 1 ¾ inches. Selecting the correct cutting diameter is essential for ensuring compatibility with the specific pipes or materials being worked on, which can prevent costly errors and delays in projects.

-

Tolerance: Tolerance defines the allowable deviation from a specified dimension. In the context of HD hole products, tighter tolerances may be necessary for applications requiring precision, such as plumbing or electrical installations. Understanding tolerance levels helps buyers select tools that will deliver the accuracy needed for their specific tasks.

-

Weight and Portability: The weight of the HD hole tools can affect ease of handling and transportation. For example, portable HD hole saws should be lightweight yet robust enough to handle the rigors of job site conditions. Buyers should consider the balance between durability and portability, particularly if the tools will be used in various locations.

-

Cutting Speed: This property indicates how quickly a tool can efficiently cut through materials. Products like diamond HD hole saws are engineered for high performance, ensuring that they can handle tough materials while maintaining speed. Faster cutting speeds can lead to increased productivity on job sites, making this an important factor for B2B buyers.

-

Warranty and Durability: Many HD hole products come with warranties that indicate the manufacturer’s confidence in their durability. A longer warranty period often suggests a robust design and high-quality manufacturing. Buyers should evaluate warranty terms as they reflect the expected lifespan and reliability of the products.

What Common Trade Terms Should B2B Buyers Know When Purchasing HD Hole Products?

Familiarity with industry jargon is essential for B2B buyers to navigate procurement processes effectively. Here are some common terms related to HD hole products:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships helps buyers identify trusted sources for high-quality products that meet industry standards.

-

MOQ (Minimum Order Quantity): MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers as it affects budget planning and inventory management, particularly for businesses that may not require large quantities of HD hole products.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to request pricing and terms for specific products. B2B buyers should utilize RFQs to obtain competitive pricing and detailed information on HD hole products, enabling informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are standardized terms used in international trade to define the responsibilities of buyers and sellers. Familiarity with Incoterms helps buyers understand shipping costs, risks, and delivery obligations associated with their orders, especially when sourcing HD hole products from global suppliers.

-

Lead Time: This term refers to the time it takes from placing an order until the product is received. Understanding lead times is critical for project planning, as delays can significantly impact timelines and budgets.

-

Durability Rating: This rating indicates how well a product can withstand wear and tear. For HD hole products, a higher durability rating signifies a longer lifespan and lower replacement costs, making it an important consideration for B2B buyers aiming for cost-effective solutions.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing HD hole products, ensuring they choose the right tools for their specific needs and projects.

Navigating Market Dynamics and Sourcing Trends in the hd hole Sector

What Are the Current Market Dynamics and Key Trends Affecting the HD Hole Sector?

The HD hole sector is experiencing significant shifts driven by globalization, technological advancements, and evolving consumer demands. International B2B buyers from regions such as Africa, South America, the Middle East, and Europe are increasingly seeking high-quality, durable products that can withstand rigorous applications. The rise of e-commerce platforms and digital marketplaces has made it easier for buyers to access a wider range of suppliers, leading to more competitive pricing and better product availability. Additionally, the integration of smart technologies into manufacturing processes is enhancing product quality and operational efficiency, allowing companies to respond quickly to changing market conditions.

Emerging trends in the sector include a growing focus on customization and the development of specialized tools that cater to specific industry needs. For instance, heavy-duty hole cutters and diamond hole saws are being designed with advanced materials to improve longevity and performance. B2B buyers are also prioritizing suppliers who can demonstrate innovation in product design and functionality. Moreover, the emphasis on sustainability is reshaping sourcing strategies, as companies aim to align with environmentally conscious practices and meet regulatory standards.

How Is Sustainability and Ethical Sourcing Influencing B2B Decisions in the HD Hole Sector?

Sustainability has become a pivotal consideration for B2B buyers in the HD hole sector, reflecting a broader global trend towards responsible sourcing and manufacturing. The environmental impact of production processes is under scrutiny, prompting companies to adopt more sustainable practices. This includes utilizing recycled materials, reducing waste, and minimizing energy consumption throughout the supply chain.

Ethical sourcing is equally important, as buyers are increasingly aware of the social implications of their purchasing decisions. This encompasses ensuring fair labor practices and transparency in the supply chain. Certifications such as ISO 14001 for environmental management and Fair Trade can enhance supplier credibility and attract conscientious buyers. By prioritizing suppliers that adhere to these standards, businesses can not only improve their corporate social responsibility (CSR) profile but also mitigate risks associated with unethical practices.

What Is the Historical Context of the HD Hole Sector and Its Evolution?

The HD hole sector has evolved significantly over the decades, adapting to technological advancements and changing market demands. Initially, hole-cutting tools were rudimentary, primarily designed for basic applications. However, as industries progressed, so did the need for more sophisticated tools capable of handling tougher materials and more complex tasks.

The introduction of carbide-tipped and diamond-infused tools marked a turning point, enhancing durability and efficiency. The shift towards automated manufacturing processes has further transformed the sector, allowing for greater precision and consistency in production. Today, the HD hole sector stands as a testament to innovation, with a diverse array of products that cater to various industrial needs, positioning itself as a crucial component in many B2B operations.

By understanding these market dynamics, sustainability considerations, and historical context, international B2B buyers can make informed sourcing decisions that align with their operational goals and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of hd hole

-

How do I solve the issue of selecting the right HD hole cutter for my drilling needs?

Choosing the right HD hole cutter requires understanding your specific application. Consider the material you will be cutting—such as cast iron, ductile iron, or abrasive materials like tile and glass. Evaluate the cutter’s features, such as the thickness of the walls and the type of carbide used, to ensure durability and performance. Additionally, consult with manufacturers or suppliers who can provide tailored recommendations based on your operational requirements and the drilling machines you are using. -

What is the best HD hole cutter for drilling through concrete and masonry?

For drilling through concrete and masonry, a diamond-tipped HD hole cutter is often the best choice. These cutters are designed to withstand the hardness of materials like brick, stone, and concrete. Look for products that utilize high-grade diamonds and feature a heat-resistant vacuum braze for extended bit life. Ensure the cutter’s size matches your project specifications, and verify that it is compatible with your drilling equipment. -

What factors should I consider when vetting suppliers for HD hole products?

When vetting suppliers, prioritize their industry experience, product quality, and customer reviews. Assess their certifications and compliance with international standards, particularly if you’re importing products. Request samples to evaluate the quality of the HD hole cutters. Additionally, inquire about their manufacturing processes, lead times, and after-sales support to ensure they can meet your business needs consistently. -

What are the typical minimum order quantities (MOQ) for HD hole products?

MOQs can vary significantly depending on the supplier and the specific product line. Generally, for HD hole cutters and similar tools, MOQs might range from 50 to 200 units. However, some suppliers may offer flexibility for first-time buyers or for customized orders. It’s advisable to discuss your requirements directly with suppliers to negotiate terms that align with your purchasing strategy and inventory management. -

What payment terms are commonly offered for international purchases of HD hole products?

Payment terms for international purchases can vary by supplier but often include options such as advance payment, letters of credit, or net payment terms (e.g., net 30 or net 60 days). Some suppliers might require a deposit upfront, especially for custom orders. It’s crucial to clarify these terms during negotiations to ensure they align with your financial capabilities and cash flow management. -

How can I ensure quality assurance (QA) when sourcing HD hole products internationally?

To ensure quality assurance, establish clear specifications and standards before placing an order. Request documentation of compliance with relevant quality certifications. Consider conducting third-party inspections or audits of the manufacturing facility before shipment. Maintaining open communication with suppliers throughout the production process can also help address any quality concerns early on. -

What logistics considerations should I keep in mind when importing HD hole products?

Logistics considerations include understanding shipping methods, costs, and delivery times. Evaluate whether the supplier offers drop shipping or if you need to arrange transportation. Be aware of customs regulations and potential tariffs in your country to avoid unexpected costs. Collaborating with a freight forwarder can streamline the logistics process and ensure that your products arrive safely and on time. -

Are there customization options available for HD hole products?

Many suppliers offer customization options for HD hole products, including sizes, coatings, and packaging. Customization can enhance functionality or branding for your specific market. Discuss your requirements directly with the supplier to explore available options and associated costs. This proactive approach can lead to tailored solutions that better meet the unique demands of your projects.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Top 8 Hd Hole Manufacturers & Suppliers List

1. HD Hole – Hardcore HD XXX Clips

Domain: hdhole.com

Registered: 2015 (10 years)

Introduction: HARDCORE PORN @ HD Hole, Selection of 1,561,983 hottest HARDCORE HD XXX clips, 100% Free, New videos added daily, Categories include: Hardcore, Anal, Amateur, BBW, BDSM, Interracial, Lesbian, MILF, and many more. Popular pornstars featured.

2. Own Brand – A51 HD Hole Punch

Domain: myhomco.com

Registered: 2013 (12 years)

Introduction: This company, Own Brand – A51 HD Hole Punch, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. MVP Disc Sports – Black Hole® Pro HD

Domain: mvpdiscsports.com

Registered: 2010 (15 years)

Introduction: Black Hole® Pro HD features a sturdier chain rack, deeper cage, and stronger base constructed with thick 8mm wire. It has a seamless black matte powder coating and a double chain tiered design with 24 high visibility zinc coated heavy duty course weighted chains (12 outer, 12 inner) with equidistant orientation for zero weak pockets. It fits standard PDGA height and size regulations and assembles …

4. Reed – HDHS1750 Hole Cutter

Domain: drainageproducts.us

Registered: 2009 (16 years)

Introduction: Reed HDHS1750 1 3/4″ HD Hole Cutter for Drilling Machines 04355

5. Milwaukee – 1 H.D. Hole Saw Vari Pitch

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”: “Milwaukee 1″ H.D. Hole Saw Vari Pitch”, “Model Number”: “49-56-1000”, “Condition”: “New”, “Blade Material”: “Bi-Metal”, “Item Diameter”: “1 inch”, “Color”: “Red”, “Material Cut”: “Multi-Purpose”, “Type”: “Hole Saw”, “Manufacturer Warranty”: “Does Not Apply”, “Package Quantity”: “1”, “Country/Region of Manufacture”: “United States”, “Item Weight”: “0.4 LB”, “Teeth per Inch”: “4/6″…

6. Norske Tools – Diamond HD Hole Saws

Domain: norsketools.com

Registered: 2015 (10 years)

Introduction: {“product_name”: “Diamond HD Hole Saws”, “brand”: “Norske Tools”, “description”: “1-Pc Industrial Diamond Hole Saws are engineered to stand up to the hardest, most abrasive materials on the job site.”, “price_range”: “USD $13.19 – USD $31.19”, “features”: [“Utilizes high-grade diamonds and heat-resistant vacuum braze”, “Best-in-class performance for extreme bit life”, “For drilling holes in abrasi…

7. APT – 9/16X1/2 HD HOLE CUTTER

Domain: kbctools.com

Registered: 1998 (27 years)

Introduction: {‘brand’: ‘APT’, ‘item_name’: ‘9/16″X1/2″ HD HOLE CUTTER’, ‘item_number’: ‘1-069-005’, ‘recommended_use’: ‘hand held air or electric drill motors, light duty drill press applications’, ‘material’: ‘High Speed Steel’, ‘fractional_size’: ‘9/16″‘, ‘number_of_flutes’: 4, ‘pilot_drill_diameter’: ‘1/4″‘, ‘shank_diameter’: ‘1/2″‘, ‘item_weight’: ‘0.05 lbs’, ‘regular_price’: ‘$63.37’, ‘sale_price’: ‘$34.8…

8. Utilimaster – HD Hole Loc w/ PDL Latch Aeromst

Domain: amparts.utilimaster.com

Registered: 1997 (28 years)

Introduction: {“Product Name”: “HD HOLE LOC W/PDL LTCH AEROMST”, “Part Number”: “06530124”, “Price”: “$619.38”, “Availability”: “Call for availability”}

Strategic Sourcing Conclusion and Outlook for hd hole

In today’s global market, strategic sourcing for HD hole products is essential for optimizing procurement processes and enhancing supply chain efficiency. By leveraging high-quality offerings such as heavy-duty hole cutters, diamond hole saws, and specialized tools, businesses can significantly improve their operational capabilities. These products not only offer durability and performance but also contribute to long-term cost savings through reduced maintenance and downtime.

B2B buyers from regions like Africa, South America, the Middle East, and Europe should prioritize suppliers who provide comprehensive solutions tailored to their unique needs. Establishing partnerships with manufacturers that emphasize quality and reliability will ensure that companies can meet their project demands effectively. Moreover, understanding the market dynamics and regional preferences can facilitate better decision-making and foster sustainable business relationships.

Looking ahead, international buyers are encouraged to explore innovative sourcing strategies and embrace digital platforms for more streamlined procurement processes. As the demand for HD hole products continues to grow, aligning with trusted suppliers will be crucial for maintaining competitive advantage and driving business success. Engage today with leading manufacturers to secure the tools that will elevate your operations and support your future growth.