How to Source Graphite Crucible Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for graphite crucible

Navigating the complexities of sourcing high-quality graphite crucibles can present significant challenges for international B2B buyers, particularly those operating in dynamic markets across Africa, South America, the Middle East, and Europe. Understanding the nuances of different types of graphite crucibles—ranging from clay-graphite to high-purity options—alongside their specific applications in metal melting and alloy processing, is crucial for making informed purchasing decisions. This guide delves deep into the multifaceted world of graphite crucibles, offering insights on their various types, applications, supplier vetting processes, and associated costs.

By equipping buyers with essential knowledge and actionable strategies, this comprehensive resource aims to demystify the global market for graphite crucibles. It focuses on practical aspects such as identifying reputable suppliers, evaluating product specifications, and assessing cost-effectiveness. Whether you are seeking to enhance your foundry operations or improve your manufacturing processes, this guide will empower you to navigate the procurement landscape with confidence. As you explore the intricacies of graphite crucible sourcing, you will gain the tools necessary to optimize your supply chain and ensure the highest quality standards for your industrial needs.

Understanding graphite crucible Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clay Graphite Crucibles | Made with a mix of clay and graphite, offering good thermal shock resistance. | Metal casting, jewelry making | Pros: Cost-effective, good for low to medium melting points. Cons: Limited lifespan at high temperatures. |

| High-Purity Graphite Crucibles | Manufactured from high-purity graphite, designed for high-temperature applications. | Semiconductor manufacturing, metal melting | Pros: Excellent thermal conductivity, long-lasting. Cons: Higher initial cost. |

| Silicon Carbide Crucibles | Reinforced with silicon carbide for enhanced strength and thermal stability. | High-temperature metal melting, glass production | Pros: Very durable, resistant to thermal shock. Cons: Heavier and more expensive than traditional options. |

| Electric Melting Crucibles | Specifically designed for electric melting furnaces, often featuring precise dimensions. | Jewelry and precious metal melting | Pros: Tailored for specific furnaces, ensures optimal melting. Cons: Limited versatility for other applications. |

| Graphite Foundry Crucibles | Typically larger and designed for foundry use, with variations in size and weight. | Large-scale metal casting | Pros: High capacity, suitable for various metals. Cons: Bulky and may require specialized handling. |

What Are the Key Characteristics of Clay Graphite Crucibles?

Clay graphite crucibles are a popular choice for various applications due to their combination of clay and graphite, which provides good thermal shock resistance. These crucibles are particularly suitable for metal casting and jewelry making, where lower to medium melting points are common. When considering a purchase, buyers should weigh the cost-effectiveness against the limited lifespan at high temperatures, as these crucibles may degrade faster than others under extreme conditions.

How Do High-Purity Graphite Crucibles Stand Out?

High-purity graphite crucibles are engineered from premium materials, making them ideal for high-temperature applications such as semiconductor manufacturing and metal melting. Their excellent thermal conductivity and durability justify the higher initial investment. For B2B buyers, the longevity and performance in critical processes can offset the upfront costs, making them a valuable addition to operations requiring precision and reliability.

What Advantages Do Silicon Carbide Crucibles Offer?

Silicon carbide crucibles are reinforced for enhanced strength and thermal stability, making them suitable for high-temperature metal melting and glass production. Their durability and resistance to thermal shock make them a preferred choice in demanding environments. However, the increased weight and cost may be considerations for buyers, especially those with budget constraints or specific handling capabilities.

Why Choose Electric Melting Crucibles for Specific Applications?

Electric melting crucibles are tailored for use in electric melting furnaces, ensuring precise dimensions that optimize the melting process. They are particularly advantageous for jewelry and precious metal melting. Buyers should consider the specific furnace compatibility and application needs, as these crucibles may not be suitable for broader uses outside electric melting environments.

What Should Buyers Know About Graphite Foundry Crucibles?

Graphite foundry crucibles are designed for large-scale metal casting, with various sizes and weights to accommodate different production needs. Their high capacity makes them ideal for operations requiring significant metal volumes. However, their bulkiness may necessitate specialized handling equipment, which is an important factor for buyers to consider when integrating these crucibles into their production workflows.

Key Industrial Applications of graphite crucible

| Industry/Sector | Specific Application of graphite crucible | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metal Casting | Melting and pouring non-ferrous metals (e.g., gold, silver) | High thermal conductivity enables efficient melting | Ensure high purity and thermal stability of the crucible |

| Semiconductor Manufacturing | Holding silicon during crystal growth | Maintains high purity levels essential for semiconductor quality | Evaluate crucible’s resistance to chemical reactions |

| Jewelry Production | Melting precious metals and alloys | Facilitates precise temperature control for quality casting | Look for customizable sizes and shapes |

| Glass and Ceramics | Melting glass materials for shaping | Provides durability and resistance to thermal shock | Assess compatibility with specific glass compositions |

| Chemical Processing | Holding reactive materials during high-temperature reactions | Enhances safety and efficiency in chemical processes | Confirm crucible’s chemical inertness and thermal resistance |

How is Graphite Crucible Used in Metal Casting?

In the metal casting industry, graphite crucibles are pivotal for melting and pouring non-ferrous metals such as gold and silver. Their high thermal conductivity allows for efficient heating, reducing energy costs and time. For international buyers, particularly in regions like Africa and South America, it is crucial to source crucibles that maintain high purity levels to avoid contamination of precious metals. Buyers should also consider the crucible’s thermal stability to withstand repeated heating cycles without degradation.

What Role Does Graphite Crucible Play in Semiconductor Manufacturing?

In semiconductor manufacturing, graphite crucibles are employed to hold silicon during the crystal growth process. This application is critical as it ensures that the silicon remains uncontaminated, which is essential for producing high-quality semiconductors. Buyers from the Middle East and Europe should prioritize sourcing crucibles that exhibit excellent resistance to chemical interactions, as impurities can severely affect semiconductor performance. Additionally, understanding the thermal properties of the crucibles is vital for maintaining the integrity of the silicon.

Why is Graphite Crucible Essential in Jewelry Production?

In the jewelry industry, graphite crucibles are extensively used for melting various precious metals and alloys. The ability of graphite to provide precise temperature control is significant for achieving high-quality castings. For B2B buyers, particularly from regions like Vietnam and Brazil, it is important to seek crucibles that can be customized to specific sizes and shapes, accommodating various jewelry designs. Furthermore, ensuring that the crucibles are compatible with different metals can enhance the production efficiency.

How Do Graphite Crucibles Benefit Glass and Ceramics Industries?

Graphite crucibles are also utilized in the glass and ceramics industries for melting raw materials. Their durability and resistance to thermal shock make them ideal for high-temperature applications. For international buyers, especially in developing markets, it is essential to evaluate the crucible’s compatibility with specific glass compositions to prevent reactions that could compromise the final product. Sourcing crucibles that can withstand extreme temperatures without cracking is vital for maintaining production quality.

What Advantages Do Graphite Crucibles Offer in Chemical Processing?

In chemical processing, graphite crucibles are used to hold reactive materials during high-temperature reactions. Their inert nature enhances safety and efficiency, making them a preferred choice for various chemical applications. Buyers from Africa and South America should consider the crucible’s chemical inertness and thermal resistance, as these factors are crucial for preventing unwanted reactions and ensuring process reliability. Understanding the specific requirements of the materials being processed will guide buyers in selecting the appropriate crucible.

3 Common User Pain Points for ‘graphite crucible’ & Their Solutions

Scenario 1: Inconsistent Quality of Graphite Crucibles

The Problem: B2B buyers often encounter significant variability in the quality of graphite crucibles sourced from different suppliers. This inconsistency can lead to unexpected failures during high-temperature processes, resulting in operational downtime, increased scrap rates, and ultimately financial loss. Buyers may find themselves dealing with crucibles that crack or degrade faster than expected, which not only affects production efficiency but also impacts the purity of the materials being processed.

The Solution: To mitigate quality issues, B2B buyers should prioritize sourcing crucibles from reputable manufacturers that provide comprehensive product specifications and certifications. Conducting thorough research into suppliers’ production processes, including their quality control measures, can help identify those who consistently deliver high-quality products. Additionally, it’s beneficial to request samples for testing before placing bulk orders. By establishing long-term relationships with trusted suppliers and engaging in regular quality audits, buyers can ensure they receive crucibles that meet their specific operational needs and standards.

Scenario 2: High Costs Associated with Crucible Failure

The Problem: The failure of graphite crucibles can lead to substantial financial repercussions, particularly in industries where high-volume melting processes are the norm. When a crucible fails, not only does it result in the loss of the crucible itself, but it can also cause material waste and additional labor costs for cleanup and replacement. This scenario is particularly critical for manufacturers in sectors like metal casting, where margins are often tight.

The Solution: To combat high costs linked to crucible failures, it is essential to conduct a thorough analysis of the melting requirements and the specific materials being used. Buyers should select crucibles designed to withstand the particular chemical and thermal stresses of their applications. Investing in higher-grade crucibles that offer enhanced durability may have a higher upfront cost but can lead to significant long-term savings by reducing replacement frequency and minimizing material waste. Additionally, implementing a proactive maintenance schedule for crucibles can extend their lifespan and improve overall operational efficiency.

Scenario 3: Difficulty in Matching Crucible Specifications with Equipment

The Problem: Many B2B buyers face challenges in matching the specifications of graphite crucibles with the equipment they use, such as melting furnaces or induction systems. Mismatched sizes or types can lead to inefficient melting processes, increased energy consumption, and suboptimal product quality. This scenario often arises when companies expand their operations or switch to different metals that require specific crucible characteristics.

The Solution: To overcome this challenge, buyers should engage in detailed consultations with equipment manufacturers to fully understand the specifications required for their melting systems. Providing them with the operational parameters—such as temperature ranges, material types, and melting methods—can help in selecting the most suitable crucibles. Furthermore, maintaining an inventory of various crucible sizes and types can allow for flexibility in operations and quick adjustments when changing production requirements. Establishing a feedback loop with both suppliers and equipment manufacturers can also enhance understanding and alignment, ensuring that the chosen crucibles are well-suited for the intended applications.

Strategic Material Selection Guide for graphite crucible

What Are the Key Materials Used in Graphite Crucibles?

When selecting a graphite crucible for industrial applications, understanding the various materials and their properties is crucial. Here, we analyze four common materials used in graphite crucibles, focusing on their performance characteristics, advantages, disadvantages, and considerations for international buyers.

Which Types of Graphite Are Commonly Used in Crucibles?

1. Clay Graphite

Key Properties: Clay graphite crucibles are known for their excellent thermal conductivity and stability at high temperatures, typically rated for use up to 1600°C. They exhibit good resistance to thermal shock, making them suitable for various melting applications.

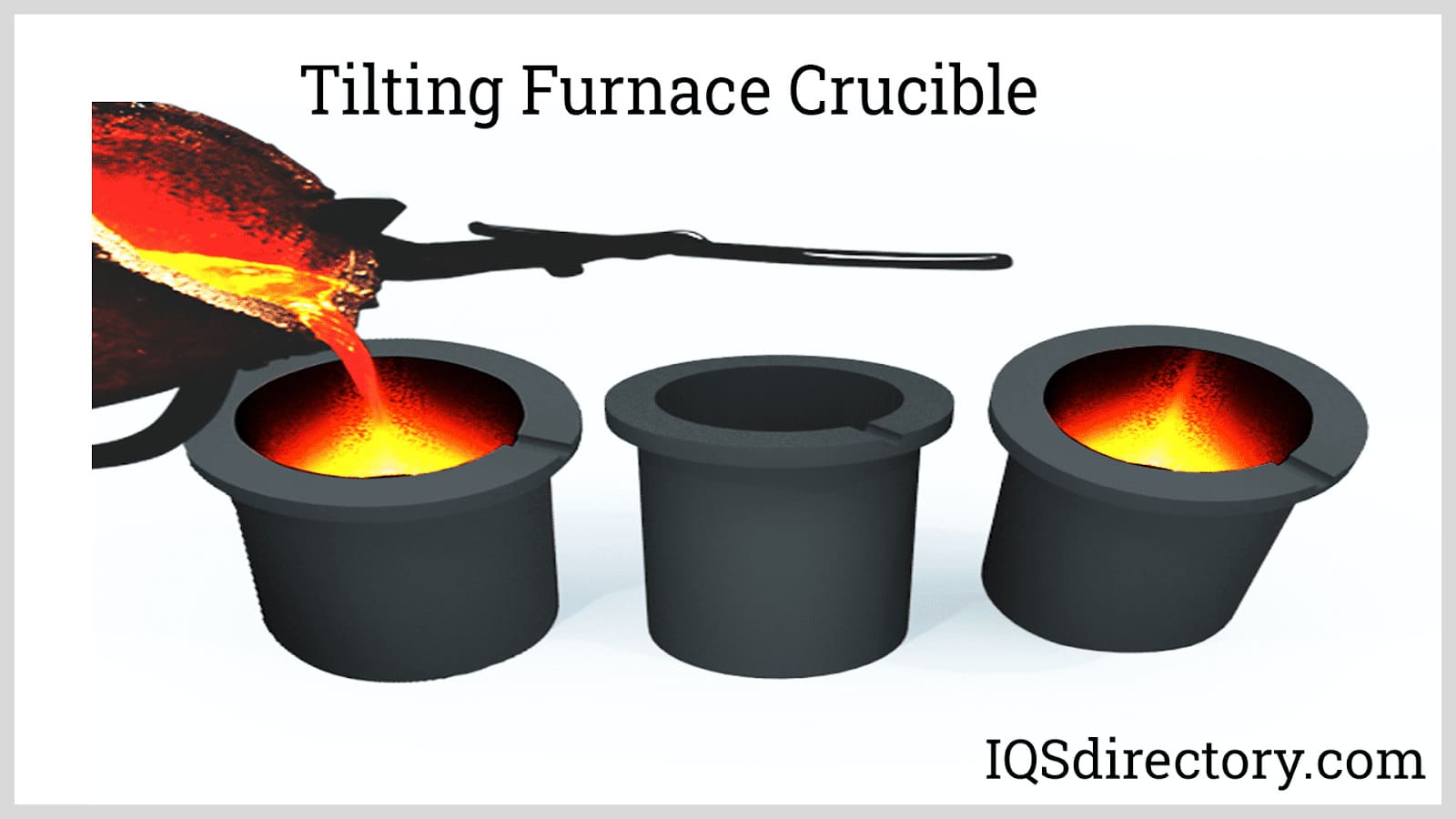

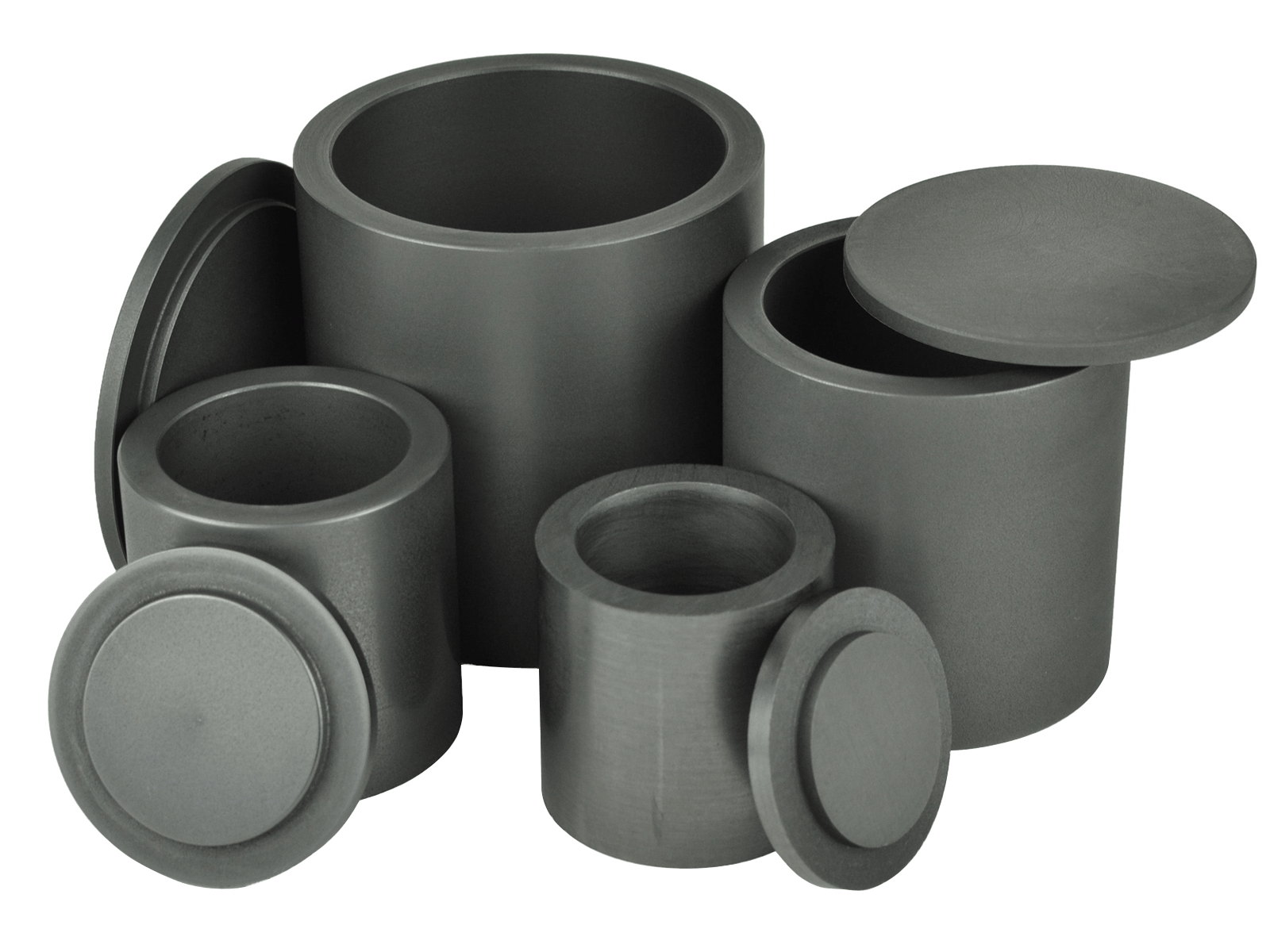

Illustrative image related to graphite crucible

Pros & Cons: The primary advantage of clay graphite is its affordability and ease of manufacturing. However, it can be less durable than other materials, leading to a shorter lifespan in high-demand applications.

Impact on Application: Clay graphite crucibles are ideal for melting non-ferrous metals like gold and silver. However, they may not be suitable for high-purity silicon processing due to potential contamination.

International Considerations: Buyers from regions like Africa and South America should ensure compliance with local standards, such as ASTM or DIN, particularly in industries requiring high-quality metal production.

2. Isostatically Graphite

Key Properties: Isostatically pressed graphite crucibles offer superior density and mechanical strength. They can withstand temperatures exceeding 3000°C, making them ideal for high-performance applications.

Pros & Cons: The key advantage of isostatically pressed graphite is its exceptional durability and resistance to wear. However, the manufacturing process is complex and more expensive, which can be a limiting factor for some buyers.

Impact on Application: These crucibles are well-suited for applications involving aggressive media, such as molten aluminum and silicon. Their high-temperature capabilities make them essential for industries demanding precision.

International Considerations: Buyers in Europe and the Middle East should consider the certifications and quality standards of suppliers to ensure reliability, especially in high-stakes industries like aerospace and automotive.

3. Molded Graphite

Key Properties: Molded graphite crucibles are crafted through a molding process that allows for tailored shapes and sizes. They typically have good thermal conductivity and can operate at temperatures around 2500°C.

Pros & Cons: The flexibility in design is a significant advantage, allowing for custom solutions. However, they may have lower mechanical strength compared to isostatically pressed options, making them less suitable for high-stress applications.

Impact on Application: Molded graphite is often used in jewelry making and small-scale metal casting. Their adaptability makes them popular among artisans and small manufacturers.

Illustrative image related to graphite crucible

International Considerations: Buyers should be aware of local regulations regarding material sourcing and environmental impact, particularly in regions with stringent manufacturing laws.

4. Graphite Composite

Key Properties: Graphite composites combine graphite with other materials (like ceramics) to enhance properties like corrosion resistance and thermal stability. These crucibles can withstand temperatures up to 2000°C.

Pros & Cons: The main advantage is their enhanced durability and resistance to chemical attack, making them suitable for a wider range of applications. However, they tend to be more expensive due to the complex manufacturing processes involved.

Impact on Application: Graphite composites are ideal for high-purity applications, such as semiconductor manufacturing, where contamination must be minimized.

Illustrative image related to graphite crucible

International Considerations: For international buyers, particularly in Asia and South America, understanding the specific requirements for semiconductor materials is essential, as compliance with international standards is critical.

Summary Table of Material Selection for Graphite Crucibles

| Material | Typical Use Case for graphite crucible | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Clay Graphite | Melting non-ferrous metals | Affordable and easy to manufacture | Less durable, shorter lifespan | Low |

| Isostatically Graphite | High-performance applications | Exceptional durability and strength | Complex and expensive manufacturing | High |

| Molded Graphite | Jewelry making and small-scale casting | Flexible design options | Lower mechanical strength | Medium |

| Graphite Composite | Semiconductor manufacturing | Enhanced durability and corrosion resistance | More expensive due to complex processes | High |

This guide provides a comprehensive overview of the critical materials used in graphite crucibles, highlighting their properties, advantages, and considerations for international buyers. By understanding these factors, businesses can make informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for graphite crucible

What Are the Main Stages of Manufacturing Graphite Crucibles?

The manufacturing process of graphite crucibles involves several critical stages, each essential for ensuring the final product meets the rigorous demands of industrial applications. The main stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality graphite powder, which is often mixed with binding agents to enhance strength and thermal resistance. This mixture is subjected to various treatments, such as drying and milling, to achieve the desired particle size and consistency. Ensuring the purity of the graphite is crucial, as impurities can affect the crucible’s performance during melting processes.

-

Forming: The prepared material undergoes forming techniques, which may include pressing, molding, or extrusion. In pressing, the graphite mixture is compacted into specific shapes under high pressure, typically using hydraulic presses. Molding involves pouring the mixture into pre-designed molds, where it is allowed to set. This stage is critical, as the shape and density of the crucible directly influence its thermal conductivity and durability.

-

Assembly: Although graphite crucibles are typically single-piece products, some designs may require assembly with additional components, such as lids or handles. This stage ensures that all parts fit together seamlessly and are securely attached, which is vital for maintaining structural integrity during high-temperature operations.

-

Finishing: The final stage involves finishing processes such as machining, where the crucibles are precision-cut to meet specific dimensional tolerances. This may also include surface treatments to enhance the crucible’s resistance to thermal shock and erosion. Finishing ensures that the crucibles not only meet performance standards but also aesthetic requirements, which can be important for branding in a competitive market.

Which Key Techniques Are Used in Graphite Crucible Manufacturing?

Several advanced techniques are employed throughout the manufacturing process to optimize the quality and performance of graphite crucibles. These include:

-

Isostatic Pressing: This technique applies uniform pressure from all directions, ensuring a denser and more uniform product. Isostatic pressing is particularly beneficial for high-performance crucibles that must withstand extreme temperatures and corrosive environments.

-

Sintering: After forming, crucibles may undergo sintering, a process that involves heating the material below its melting point to enhance its strength and thermal stability. Sintering helps in achieving a strong bond between graphite particles, improving the crucible’s overall performance.

-

Graphitization: In some cases, crucibles are subjected to graphitization, where they are heated to very high temperatures in an inert atmosphere. This process transforms the bonded graphite into a more crystalline form, significantly enhancing the crucible’s thermal and electrical conductivity.

What Are the Quality Control Standards for Graphite Crucibles?

Quality assurance is paramount in the manufacturing of graphite crucibles, particularly for international B2B buyers who require consistency and reliability. Various standards govern quality control, including:

-

ISO 9001: This international standard focuses on quality management systems and is crucial for ensuring that manufacturers consistently meet customer and regulatory requirements. Compliance with ISO 9001 indicates that a supplier has effective quality management practices in place.

-

CE Marking: For products sold in Europe, CE marking signifies compliance with EU safety, health, and environmental protection standards. This is particularly relevant for buyers in Europe who need assurance that products meet stringent regulatory requirements.

-

API Standards: In industries such as oil and gas, adherence to American Petroleum Institute (API) standards can be critical. These standards ensure that materials can withstand the specific stresses encountered in these demanding environments.

How Are Quality Control Checkpoints Implemented in Graphite Crucible Production?

Quality control in graphite crucible production is typically implemented through various checkpoints throughout the manufacturing process. These include:

-

Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials upon arrival to ensure they meet specified standards. Graphite powder and binding agents are tested for purity and particle size before being accepted for production.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks are made to monitor parameters such as temperature, pressure, and density. Any deviations from established norms can lead to immediate corrective actions, preventing defective products from moving forward in the production line.

-

Final Quality Control (FQC): After finishing, each crucible is subjected to rigorous testing to ensure it meets all design specifications. This may include dimensional checks, thermal shock resistance tests, and visual inspections for surface defects.

What Testing Methods Are Commonly Used for Graphite Crucibles?

To ensure the highest quality, various testing methods are employed, including:

-

Thermal Conductivity Testing: This measures how well the crucible can conduct heat, which is crucial for its performance in high-temperature applications.

-

Density Measurement: The density of the crucible is assessed to ensure that it meets the required specifications, as density affects thermal stability and durability.

-

Mechanical Strength Testing: This evaluates the crucible’s ability to withstand mechanical stresses during use. Tests may include compressive strength and flexural strength assessments.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers can take several steps to verify a supplier’s quality control processes:

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures firsthand. This can provide valuable insights into the supplier’s operational standards.

-

Requesting Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including results from various tests and inspections. Regular quality reports can demonstrate ongoing compliance with industry standards.

-

Third-Party Inspections: Engaging independent third-party inspectors can add an additional layer of verification. These inspectors can evaluate the supplier’s processes and products against international standards, providing unbiased assessments.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, should be aware of specific quality control nuances:

-

Regulatory Compliance: Different regions may have varying regulatory requirements. Buyers should familiarize themselves with local standards and ensure that suppliers can meet these regulations.

-

Cultural Considerations: Understanding cultural differences in business practices can facilitate better communication and collaboration with suppliers. This can be crucial when negotiating quality standards and expectations.

-

Logistical Challenges: International shipping can introduce additional risks, such as damage during transit. Buyers should consider suppliers that offer robust packaging and shipping solutions to mitigate these risks.

By understanding the manufacturing processes and quality assurance measures associated with graphite crucibles, B2B buyers can make informed decisions, ensuring they source high-quality products that meet their specific needs.

Illustrative image related to graphite crucible

Practical Sourcing Guide: A Step-by-Step Checklist for ‘graphite crucible’

Introduction

This sourcing guide is designed to assist B2B buyers in effectively procuring graphite crucibles, essential components in various industrial applications, including metal casting and jewelry manufacturing. By following this checklist, buyers can ensure they select the right products that meet their specific requirements and standards.

Step 1: Define Your Technical Specifications

Begin by identifying the technical specifications necessary for your application. Consider factors such as size, capacity, and material composition of the crucible. Clearly defined specifications help streamline the sourcing process and ensure compatibility with your existing equipment.

- Key Considerations:

- Determine the melting point and thermal conductivity required for your operations.

- Assess the specific types of metals or materials you will be working with to avoid material degradation.

Step 2: Research and Identify Potential Suppliers

Conduct thorough research to compile a list of potential suppliers. Look for companies that specialize in graphite crucibles and have a proven track record in your industry. This step is critical to ensure you partner with reliable and experienced suppliers.

- Where to Look:

- Industry directories and trade shows.

- Online marketplaces and supplier databases.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that your shortlisted suppliers have the necessary certifications and compliance with international standards. Certifications such as ISO 9001 indicate a commitment to quality management and consistent production processes.

- What to Check:

- Look for certifications relevant to your industry, such as ASTM standards for materials.

- Ensure suppliers can demonstrate adherence to environmental and safety regulations.

Step 4: Request Samples for Quality Assessment

Before placing a bulk order, request samples of the graphite crucibles to assess their quality. This step allows you to evaluate the product firsthand and determine if it meets your specifications and performance expectations.

- Sample Evaluation:

- Test the crucibles under actual working conditions to ensure they withstand the required temperatures and conditions.

- Check for any signs of degradation or material flaws.

Step 5: Negotiate Pricing and Terms

Once you have selected a supplier, engage in negotiations regarding pricing, payment terms, and delivery schedules. Transparent communication about your budget and expectations can lead to a mutually beneficial agreement.

- Negotiation Tips:

- Discuss bulk purchase discounts or loyalty programs for future orders.

- Clarify the lead times for production and delivery to avoid any disruptions in your operations.

Step 6: Review Shipping and Delivery Options

Consider the shipping and delivery options provided by your supplier. Efficient logistics are crucial for ensuring that your graphite crucibles arrive on time and in good condition.

- What to Confirm:

- Check if the supplier offers international shipping, especially if you are sourcing from different regions.

- Understand the packaging used to protect the crucibles during transit.

Step 7: Establish a Long-term Relationship

After a successful purchase, aim to establish a long-term relationship with your supplier. Building a partnership can lead to better pricing, priority service, and tailored solutions for your future needs.

- Benefits of a Long-term Relationship:

- Consistent quality and reliability in supply.

- Opportunities for joint product development and innovation.

By following these steps, B2B buyers can navigate the complexities of sourcing graphite crucibles effectively, ensuring they make informed decisions that align with their operational needs.

Comprehensive Cost and Pricing Analysis for graphite crucible Sourcing

What Are the Key Cost Components in Graphite Crucible Manufacturing?

Understanding the cost structure of graphite crucibles is essential for B2B buyers to make informed sourcing decisions. The primary cost components include:

-

Materials: The quality of graphite used directly impacts the performance and price of the crucible. High-purity graphite is more expensive but offers better thermal conductivity and longevity. Additional materials such as binders and other additives can also influence costs.

-

Labor: Labor costs vary depending on the region and the complexity of the manufacturing process. Skilled labor is often required for machining and finishing processes, which can add to the overall expense.

-

Manufacturing Overhead: This includes utilities, facility costs, and indirect labor. Efficient manufacturing processes can help minimize overhead costs, making it crucial for buyers to understand a supplier’s operational efficiency.

-

Tooling: The initial investment in molds and tooling for crucible production can be significant. However, suppliers often amortize these costs over large production runs, impacting pricing based on order volume.

-

Quality Control (QC): Rigorous QC processes are necessary to ensure product reliability and performance. This may involve testing for thermal shock resistance and purity, which can add to the overall cost.

-

Logistics: Transportation costs can vary widely based on the supplier’s location and the buyer’s destination. Additionally, international shipping may involve customs duties and tariffs, which should be factored into the total cost.

-

Margin: Suppliers typically add a profit margin to cover their costs and ensure sustainability. Understanding the typical margin in your industry can help you gauge the reasonableness of a quote.

How Do Price Influencers Affect Graphite Crucible Sourcing?

Several factors can influence the pricing of graphite crucibles, particularly for international buyers:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to better pricing per unit due to economies of scale. Buyers should negotiate MOQs to maximize cost efficiency.

-

Specifications and Customization: Custom specifications can significantly impact pricing. Buyers requiring specialized sizes or features should expect to pay a premium.

-

Materials: The choice of graphite grade affects both performance and price. Higher grades may be necessary for specific applications, but they come at a higher cost.

-

Quality and Certifications: Suppliers with certifications for quality assurance can command higher prices. Buyers should consider the value of these certifications in relation to their application needs.

-

Supplier Factors: Supplier reputation, reliability, and service capabilities can influence pricing. Established suppliers with a track record of quality may charge more but can offer greater peace of mind.

-

Incoterms: The agreed-upon Incoterms can affect pricing by determining who is responsible for shipping, insurance, and tariffs. Understanding these terms is crucial for international transactions.

What Are the Best Buyer Tips for Cost-Efficient Sourcing of Graphite Crucibles?

To enhance cost efficiency and secure favorable pricing, consider the following strategies:

-

Negotiate Effectively: Engage suppliers in discussions about pricing, especially when placing larger orders. Highlighting your potential for future business can provide leverage in negotiations.

-

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, consider the TCO, which includes maintenance, durability, and potential downtime costs. A higher initial price may be justified by longer lifespan and lower operational costs.

-

Understand Pricing Nuances for International Sourcing: Be aware of currency fluctuations, international tariffs, and local regulations that may affect pricing. Establish relationships with suppliers who understand the local market dynamics in your region.

-

Request Samples: Before committing to large orders, request samples to evaluate quality. This can prevent costly mistakes down the line and ensure that the crucibles meet your specific requirements.

-

Stay Informed on Market Trends: Keep abreast of market conditions affecting graphite prices and availability. Understanding these trends can help you anticipate pricing changes and make strategic purchasing decisions.

Conclusion

Pricing for graphite crucibles involves a complex interplay of various cost components and influencers. By understanding these factors and employing strategic sourcing tips, B2B buyers can optimize their procurement processes and achieve better pricing outcomes. Always remember that prices can fluctuate, and obtaining multiple quotes can help ensure competitive pricing.

Alternatives Analysis: Comparing graphite crucible With Other Solutions

Understanding Alternatives to Graphite Crucibles

When evaluating the use of graphite crucibles, it’s essential for B2B buyers to consider alternative solutions that may provide similar or enhanced benefits. This analysis will compare graphite crucibles with two viable alternatives: ceramic crucibles and metal crucibles. Each option has its unique characteristics that may cater to specific industrial needs, particularly in melting and processing metals in various regions, including Africa, South America, the Middle East, and Europe.

Comparison Table

| Comparison Aspect | Graphite Crucible | Ceramic Crucible | Metal Crucible |

|---|---|---|---|

| Performance | Excellent thermal conductivity; suitable for high temperatures. | Good thermal resistance; limited to specific metals. | High durability; may withstand extreme conditions. |

| Cost | Moderate cost, varies by size and quality. | Generally lower cost but can vary based on type. | Higher initial cost due to material and manufacturing. |

| Ease of Implementation | Easy to use, compatible with many furnaces. | Requires careful handling; can be fragile. | Typically straightforward, but may need specialized equipment. |

| Maintenance | Requires regular checks for wear and tear. | Minimal maintenance; however, can crack under thermal shock. | Low maintenance; durable but may corrode over time. |

| Best Use Case | Ideal for high-temperature metal melting and casting. | Suitable for lower-temperature applications and specific alloys. | Best for high-volume production and robust industrial applications. |

Detailed Breakdown of Alternatives

Ceramic Crucibles

Ceramic crucibles are made from high-temperature resistant materials such as alumina. They are advantageous due to their lower cost compared to graphite crucibles and their ability to handle specific melting applications, particularly for non-ferrous metals. However, they can be fragile and susceptible to thermal shock, which may limit their usability in high-temperature environments. Their performance in terms of thermal resistance is commendable, but they may not be suitable for every application, particularly those requiring high thermal conductivity.

Metal Crucibles

Metal crucibles, typically made from steel or other alloys, offer excellent durability and can withstand extreme conditions, making them suitable for high-volume industrial applications. They provide significant mechanical strength and can be reused multiple times, which can justify their higher initial cost. However, metal crucibles may not provide the same level of thermal conductivity as graphite, which could impact melting efficiency. Additionally, they may require specialized equipment for use, making them less flexible than graphite crucibles.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate crucible for your industrial processes, it’s crucial to assess your specific requirements, including the types of metals being melted, the temperatures involved, and the volume of production. Graphite crucibles are often preferred for their excellent thermal properties and versatility, especially in high-temperature applications. However, ceramic and metal crucibles can also be effective in certain scenarios, offering cost benefits or durability. By understanding the unique advantages and limitations of each option, B2B buyers can make informed decisions that align with their operational needs and budget considerations.

Essential Technical Properties and Trade Terminology for graphite crucible

What Are the Key Technical Properties of Graphite Crucibles for B2B Buyers?

When selecting graphite crucibles, understanding their technical properties is essential for ensuring optimal performance in various applications. Here are some critical specifications to consider:

-

Material Grade: Graphite crucibles are typically made from different grades of graphite, which can affect their thermal conductivity, strength, and resistance to chemical reactions. Higher-grade graphite provides better performance and durability, particularly in high-temperature environments. For B2B buyers, selecting the appropriate material grade can lead to longer crucible life and reduced downtime.

-

Thermal Conductivity: This property indicates how efficiently heat is transferred through the crucible material. High thermal conductivity is crucial for applications involving metals and alloys, as it ensures uniform melting and reduces the risk of thermal shock. Buyers must assess their specific melting needs to choose a crucible that optimizes energy efficiency and minimizes wastage.

-

Density: The density of a graphite crucible impacts its strength and thermal stability. Crucibles with higher density can withstand greater mechanical stress and are less prone to cracking under temperature fluctuations. For B2B transactions, specifying the right density can lead to improved product consistency and reliability in production processes.

-

Tolerance: Tolerance refers to the allowable deviation from specified dimensions in manufacturing. Precise tolerances are vital for ensuring that crucibles fit correctly in melting furnaces and other equipment. For international buyers, understanding tolerance levels can prevent costly mismatches and enhance operational efficiency.

-

Melting Point: The maximum temperature a crucible can withstand before degradation is essential for applications involving high-temperature metals. Knowing the melting point helps buyers avoid material failure during critical operations, ensuring safety and efficiency in production.

-

Chemical Resistance: The ability of a graphite crucible to resist chemical reactions with the materials it holds is crucial, especially for processes involving reactive metals or alloys. Buyers should evaluate the chemical compatibility of crucibles to avoid contamination and ensure product purity.

What Common Trade Terms Should B2B Buyers of Graphite Crucibles Know?

Familiarity with trade terminology can streamline procurement processes and facilitate better communication between buyers and suppliers. Here are some essential terms:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that are sold under another company’s brand. For buyers, understanding OEM relationships can help in sourcing high-quality crucibles that meet specific equipment requirements.

-

MOQ (Minimum Order Quantity): This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to assess whether they can meet the supplier’s terms, especially when dealing with bulk purchases.

-

RFQ (Request for Quotation): This formal process involves asking suppliers for price estimates for specific products or services. Utilizing RFQs allows buyers to compare pricing, terms, and lead times from different suppliers, ensuring they make informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are standardized trade terms used in international sales contracts that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is essential for international B2B buyers to understand their obligations and mitigate risks in global transactions.

-

Lead Time: This term indicates the time required from placing an order to receiving the goods. Understanding lead times helps buyers plan their production schedules and manage inventory levels effectively.

-

Certification: This refers to the process of verifying that a product meets specific standards or regulations. For graphite crucibles, certifications can include quality control and compliance with industry standards, providing buyers with assurance of product reliability and performance.

By grasping these technical properties and trade terms, international B2B buyers can make more informed decisions, ensuring they select the right graphite crucibles for their specific needs and operational requirements.

Navigating Market Dynamics and Sourcing Trends in the graphite crucible Sector

What are the Key Trends Shaping the Global Graphite Crucible Market?

The graphite crucible market is witnessing significant transformation driven by various global factors. The increasing demand for high-purity materials in sectors like metallurgy, jewelry, and electronics is propelling the market forward. Notably, the rise in electric arc furnace (EAF) usage in steel production has further fueled the need for efficient and durable crucibles that can withstand extreme temperatures. Additionally, advancements in manufacturing technologies, such as 3D printing and precision machining, are allowing for customized solutions that cater to specific client requirements, enhancing the overall efficiency of operations.

Emerging technologies in sourcing, such as blockchain for supply chain transparency and AI-driven analytics for demand forecasting, are becoming pivotal. These technologies not only streamline the procurement process but also mitigate risks associated with supply chain disruptions. For international B2B buyers, particularly in regions like Africa, South America, and the Middle East, understanding local market dynamics and leveraging these technologies can provide a competitive edge. Collaboration with suppliers who utilize sustainable practices and advanced manufacturing processes is also becoming a strategic focus, driving innovation and resilience in supply chains.

How is Sustainability Influencing the Sourcing of Graphite Crucibles?

Sustainability is increasingly becoming a priority in the graphite crucible sector. The environmental impact of graphite mining and processing has raised concerns, prompting buyers to seek suppliers who adhere to ethical sourcing practices. Ethical supply chains that prioritize environmental stewardship not only comply with regulatory requirements but also enhance brand reputation and customer loyalty.

The demand for ‘green’ certifications is on the rise, with buyers looking for materials that are sourced sustainably and produced with minimal environmental impact. This includes the use of recycled graphite and renewable energy in manufacturing processes. B2B buyers should prioritize partnerships with suppliers who can demonstrate their commitment to sustainability through certifications and transparent practices. By aligning with these principles, businesses can not only contribute to environmental conservation but also tap into a growing market segment that values ethical sourcing.

Illustrative image related to graphite crucible

What is the Historical Context of Graphite Crucibles in B2B Sourcing?

The history of graphite crucibles dates back to ancient civilizations, where they were used for metal smelting and refining. Over time, advancements in materials science have led to the development of high-performance crucibles capable of withstanding extreme temperatures and corrosive environments. The introduction of clay-bonded graphite crucibles in the 19th century marked a significant evolution, allowing for improved thermal conductivity and durability.

In the modern context, the graphite crucible market has adapted to the demands of various industries, including metal casting, jewelry making, and electronics. The focus has shifted towards high-purity graphite materials to meet stringent quality standards. This evolution reflects broader trends in B2B sourcing, where quality, efficiency, and sustainability are paramount. Understanding this historical context allows buyers to appreciate the advancements in crucible technology and the importance of sourcing from reputable suppliers who prioritize innovation and ethical practices.

Frequently Asked Questions (FAQs) for B2B Buyers of graphite crucible

-

How do I choose the right graphite crucible for my application?

Selecting the appropriate graphite crucible depends on several factors, including the type of metal or material being melted, the melting temperature, and the size of your furnace. For high-temperature applications, ensure that the crucible can withstand the required heat without degrading. Consider the chemical compatibility of the crucible material with your melt; for instance, certain alloys may react with graphite. It’s also essential to evaluate the crucible’s dimensions to ensure it fits your equipment. Consulting with suppliers about your specific needs can help you make a more informed choice. -

What are the common issues faced with graphite crucibles during use?

Graphite crucibles can face various challenges, including thermal shock, chemical erosion, and wear from repeated use. Thermal shock may occur if there are rapid temperature changes, leading to cracks. Chemical erosion can happen when certain metals, particularly aluminum, interact negatively with the graphite, causing infiltration and degradation. Regular monitoring and proper handling can mitigate these issues. Consider using a crucible with a protective coating for applications prone to such reactions, and always adhere to recommended temperature limits. -

What is the minimum order quantity (MOQ) for graphite crucibles?

The minimum order quantity for graphite crucibles varies by supplier and may depend on factors like the crucible type, customization requirements, and geographic location. Generally, MOQs can range from a few pieces for standard products to larger quantities for custom designs. When sourcing, inquire about bulk pricing options as ordering in larger quantities often results in cost savings. Additionally, some suppliers may offer flexible terms for first-time buyers or smaller businesses, so it’s beneficial to communicate your needs directly with them. -

What payment terms should I expect when purchasing graphite crucibles internationally?

Payment terms for international purchases of graphite crucibles can vary widely depending on the supplier and the buyer’s location. Common options include advance payment, letter of credit, or net payment terms (e.g., net 30 or net 60 days). Some suppliers may require partial payment upfront, especially for customized orders. It’s crucial to clarify these terms before finalizing your order to avoid any misunderstandings. Additionally, be aware of potential currency fluctuations and transaction fees associated with international payments. -

How can I ensure the quality of graphite crucibles from suppliers?

To ensure quality, conduct thorough due diligence on potential suppliers. Request certifications, such as ISO 9001, that indicate adherence to quality management standards. Ask for product samples to assess their performance in real-world applications. Additionally, seek reviews and testimonials from other customers to gauge satisfaction levels. Establish clear quality assurance protocols in your purchasing agreement, including specifications for testing and inspection upon receipt, to minimize risks associated with defective products. -

What logistics considerations should I keep in mind when sourcing graphite crucibles?

When sourcing graphite crucibles internationally, logistics play a crucial role in ensuring timely and safe delivery. Consider shipping methods (air vs. sea), lead times, and customs regulations in your country. Ensure that your supplier can provide adequate packaging to prevent damage during transport. It’s also wise to partner with a logistics provider experienced in handling industrial goods, as they can assist with customs clearance and offer insights into best practices for shipping internationally. -

Can graphite crucibles be customized for specific applications?

Yes, many suppliers offer customization options for graphite crucibles to meet specific application needs. Customizations can include alterations in size, shape, and material composition to enhance performance under particular melting conditions. When requesting a custom crucible, provide detailed specifications, including the type of material to be melted, the desired melting capacity, and any specific thermal or chemical resistance requirements. Collaborating closely with the supplier during the design phase can lead to optimal results. -

What are the benefits of using graphite crucibles over other materials?

Graphite crucibles offer several advantages compared to alternatives like ceramic or metal crucibles. They have excellent thermal conductivity, allowing for efficient heat distribution during melting. Graphite is also resistant to thermal shock, making it suitable for high-temperature applications. Additionally, graphite crucibles are chemically inert to many metals, which minimizes contamination risks. Their lightweight nature makes handling easier, and they can be manufactured in various shapes and sizes to fit different furnace designs, providing versatility for various industrial applications.

Top 8 Graphite Crucible Manufacturers & Suppliers List

1. Graphite Store – Premium Quality Graphite Crucibles

Domain: graphitestore.com

Registered: 2002 (23 years)

Introduction: Premium Quality Graphite Crucibles for Industrial and Jewelry Applications. Available in various grades including GR001CC and GR030. Capacities range from 5-50 troy oz. Sizes include outside diameters from 1.000 to over 7.500 inches and depths from 2.000 to over 10.000 inches. Prices range from $87.93 to $518.42 depending on size and grade.

2. ProCast™ – Clay Graphite Foundry Crucibles

Domain: pmcsupplies.com

Registered: 2013 (12 years)

Introduction: [{‘name’: ‘ProCast™ No 3 – 4 Kg Clay Graphite Foundry Crucible’, ‘price’: ‘€13,95’, ‘rating’: ‘★★★★★’, ‘availability’: ‘Unavailable’}, {‘name’: ‘ProCast™ No 1 – 1 Kg Clay Graphite Foundry Crucible’, ‘price’: ‘€8,95’, ‘availability’: ‘Unavailable’}, {‘name’: ‘ProCast™ No 8 – 10 Kg Clay Graphite Foundry Crucible’, ‘price’: ‘€24,95’, ‘availability’: ‘Unavailable’}, {‘name’: ‘ProCast™ No 1.5 – 2 Kg Cl…

3. IQS Directory – Graphite Crucibles

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Graphite crucibles are containers used for melting and pouring metals like gold, silver, aluminum, and brass. They are valued for superior thermal conductivity, resilience to high temperatures, and minimal thermal expansion. Graphite crucibles endure rapid temperature changes and resist chemical wear from acidic and alkaline solutions. They are made from natural crystalline carbon combined with fi…

4. Reddit – Clay Graphite Crucible Ingredients

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Ingredients for making a clay graphite crucible: 40% graphite flakes, 25% fireclay, 15% crushed high fire clay body (porcelain, particle size 1mm-2mm), 10% silicone carbide, 5% borosilicate powder (crushed borosilicate glass), 3% alumina powder, 2% aluminum or magnesium powder. The crucible can sustain temperatures of 700-1400°C. Key properties include thermal conductivity, thermal stability, and …

5. MSE Supplies – High Purity Graphite Crucibles

Domain: msesupplies.com

Registered: 2014 (11 years)

Introduction: This company, MSE Supplies – High Purity Graphite Crucibles, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. eBay – Graphite Crucible Products

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: Graphite Crucible products available on eBay include various types and sizes suitable for melting metals such as gold, silver, and brass. Notable listings include:

– Hardin HD-2343SS 110V Stainless Steel Tabletop Melting Furnace priced at $371.99 (new) and $100.00 (used).

– A25 Salamander Crucible Clay Graphite for melting non-ferrous metals priced at $255.95 (new).

– QWORK Ceramic Crucible Bowl s…

7. Pepetools – Graphite Crucible for Kerr Electro-Melt Furnace

Domain: pepetools.com

Registered: 1999 (26 years)

Introduction: Graphite Crucible for Kerr Electro-Melt Furnace

8. CdoCast – Graphite Crucibles

Domain: cdocast.com

Registered: 2018 (7 years)

Introduction: Graphite Crucible: Widely used in gold, silver, aluminum, and copper smelting in metallurgy, casting, machinery, and chemical industries. Suitable for various furnaces including electric, medium frequency, and high frequency. Features include high strength, large volume density, acid erosion resistance, and long service life (3-5 times that of clay graphite crucibles). Silicon Carbide (SiC) Crucib…

Strategic Sourcing Conclusion and Outlook for graphite crucible

As the demand for graphite crucibles continues to rise across various industries, strategic sourcing becomes essential for international B2B buyers. Understanding the unique properties of graphite, including its high thermal conductivity and resistance to thermal shock, allows companies to make informed purchasing decisions. Buyers should prioritize suppliers that not only offer a diverse range of crucibles but also demonstrate a commitment to quality and innovation.

By establishing strong relationships with manufacturers and leveraging local and international supply chains, businesses can ensure timely delivery and competitive pricing. This strategic approach not only mitigates risks associated with supply disruptions but also enhances operational efficiency.

Looking ahead, the market for graphite crucibles is poised for growth, driven by advances in technology and increasing applications in metal casting, jewelry making, and more. Buyers from Africa, South America, the Middle East, and Europe should take proactive steps to explore partnerships with reliable suppliers and stay updated on market trends. Embracing a forward-thinking sourcing strategy will not only secure a competitive edge but also foster sustainability in their operations. Now is the time to act—engage with leading suppliers and position your business for success in the evolving landscape of graphite crucible applications.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.