How to Source Galvanized Wire Mesh Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for galvanized wire mesh

In the dynamic landscape of international trade, sourcing galvanized wire mesh poses unique challenges for B2B buyers. With its critical role in various applications, from construction to agriculture, understanding the intricacies of this product is essential for making informed purchasing decisions. This guide provides an in-depth exploration of the global market for galvanized wire mesh, addressing key areas such as product types, applications, supplier vetting, and cost considerations.

By delving into the diverse specifications of galvanized wire mesh, including mesh sizes and material options, buyers can identify the best solutions tailored to their specific needs. The guide also emphasizes the importance of selecting reliable suppliers, ensuring quality and compliance with international standards, which is particularly crucial for buyers in regions like Africa, South America, the Middle East, and Europe, including countries like Nigeria and Vietnam.

With actionable insights and comprehensive resources, this guide empowers B2B buyers to navigate the complexities of sourcing galvanized wire mesh effectively. By equipping themselves with knowledge on market trends and supplier options, buyers can enhance their procurement strategies and drive value for their organizations. Whether you are looking for cost-effective solutions or high-quality materials, this guide serves as an indispensable tool for informed decision-making in the global marketplace.

Understanding galvanized wire mesh Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Welded Wire Mesh | Interconnected wires at each joint, providing high strength and rigidity | Fencing, enclosures, and industrial applications | Pros: High durability, precise openings. Cons: Limited flexibility in applications. |

| Hexagonal Wire Mesh | Made from twisted wire, typically in a hexagonal pattern, allowing for lightweight yet strong construction | Gabions, erosion control, and animal enclosures | Pros: Lightweight, good drainage. Cons: Less structural integrity than welded options. |

| Chain Link Fencing | Open mesh design with a diamond pattern, typically used for security and fencing | Perimeter security, sports fields, and public areas | Pros: Cost-effective, easy to install. Cons: Less privacy and aesthetic appeal. |

| Vinyl Coated Wire Mesh | Galvanized wire coated with vinyl for enhanced corrosion resistance | Landscaping, garden fencing, and decorative applications | Pros: Attractive appearance, superior rust protection. Cons: Higher initial cost compared to non-coated options. |

| Stainless Steel Wire Mesh | Offers excellent corrosion resistance and longevity, available in various mesh sizes | Food processing, pharmaceutical, and marine applications | Pros: Exceptional durability, hygienic. Cons: Higher cost, heavier than galvanized alternatives. |

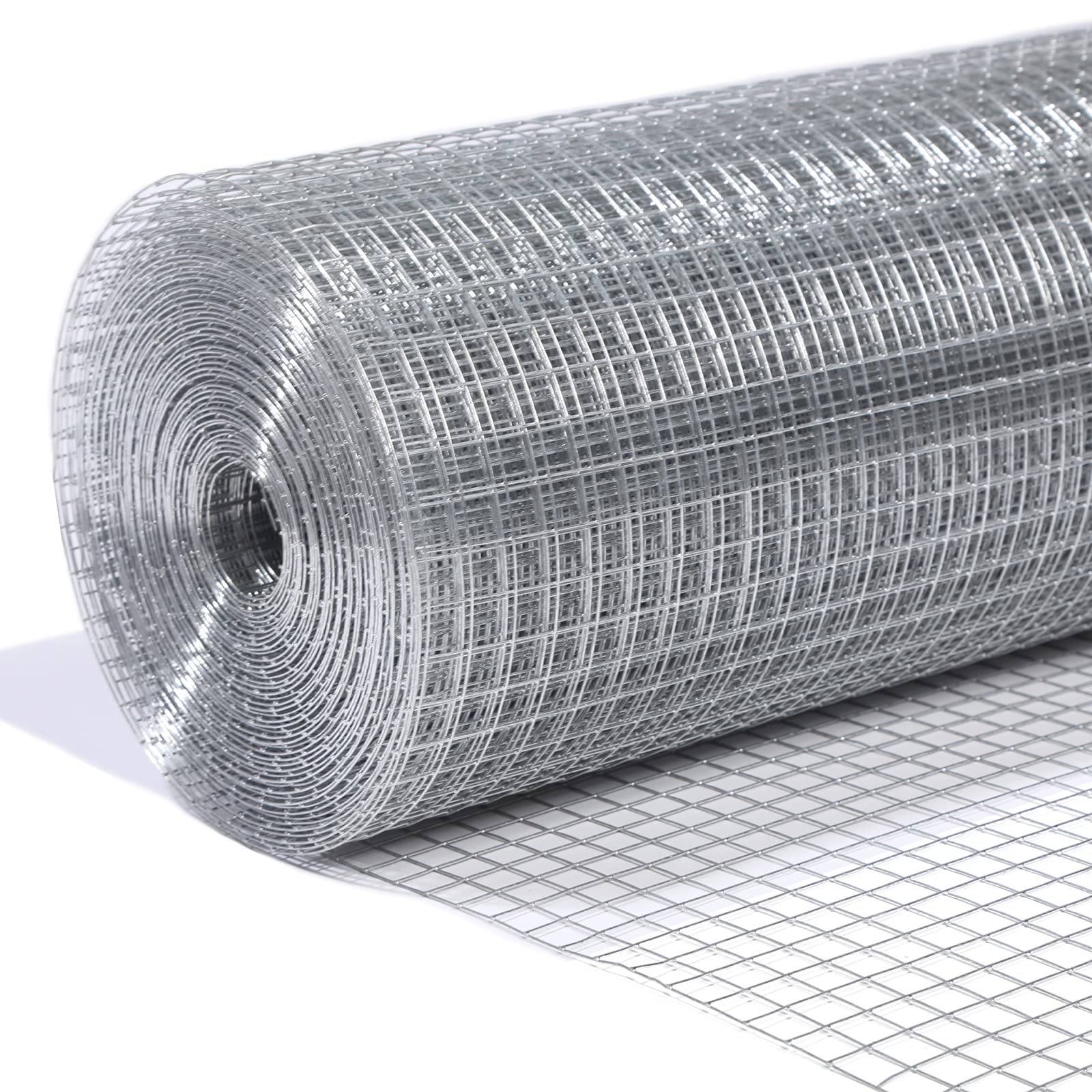

What are the Characteristics and Suitability of Welded Wire Mesh?

Welded wire mesh consists of wires that are welded together at each intersection, creating a robust and rigid structure. This type is particularly suitable for applications requiring high strength and stability, such as fencing and industrial enclosures. B2B buyers should consider the gauge of the wire and the size of the openings, as these factors influence the mesh’s load-bearing capacity and suitability for specific applications. While it is durable and offers precise openings, its rigidity may limit flexibility in certain uses.

How Does Hexagonal Wire Mesh Perform in Various Applications?

Hexagonal wire mesh is characterized by its unique twisted wire construction, forming a lightweight yet strong mesh. It is commonly used in gabions for erosion control, as well as for animal enclosures due to its good visibility and drainage properties. Buyers should consider the wire diameter and mesh size when purchasing, as these factors affect its strength and application suitability. While it provides excellent drainage and is easy to transport, it may not offer the same structural integrity as welded wire mesh.

What Are the Advantages of Chain Link Fencing for Security Needs?

Chain link fencing features an open mesh design with a diamond pattern, making it a popular choice for security applications. Its primary use is in perimeter security for commercial properties, sports fields, and public areas. B2B buyers appreciate its cost-effectiveness and ease of installation, but they should be mindful of its limitations in terms of privacy and aesthetics. While it offers a secure barrier, additional measures may be necessary for enhanced privacy.

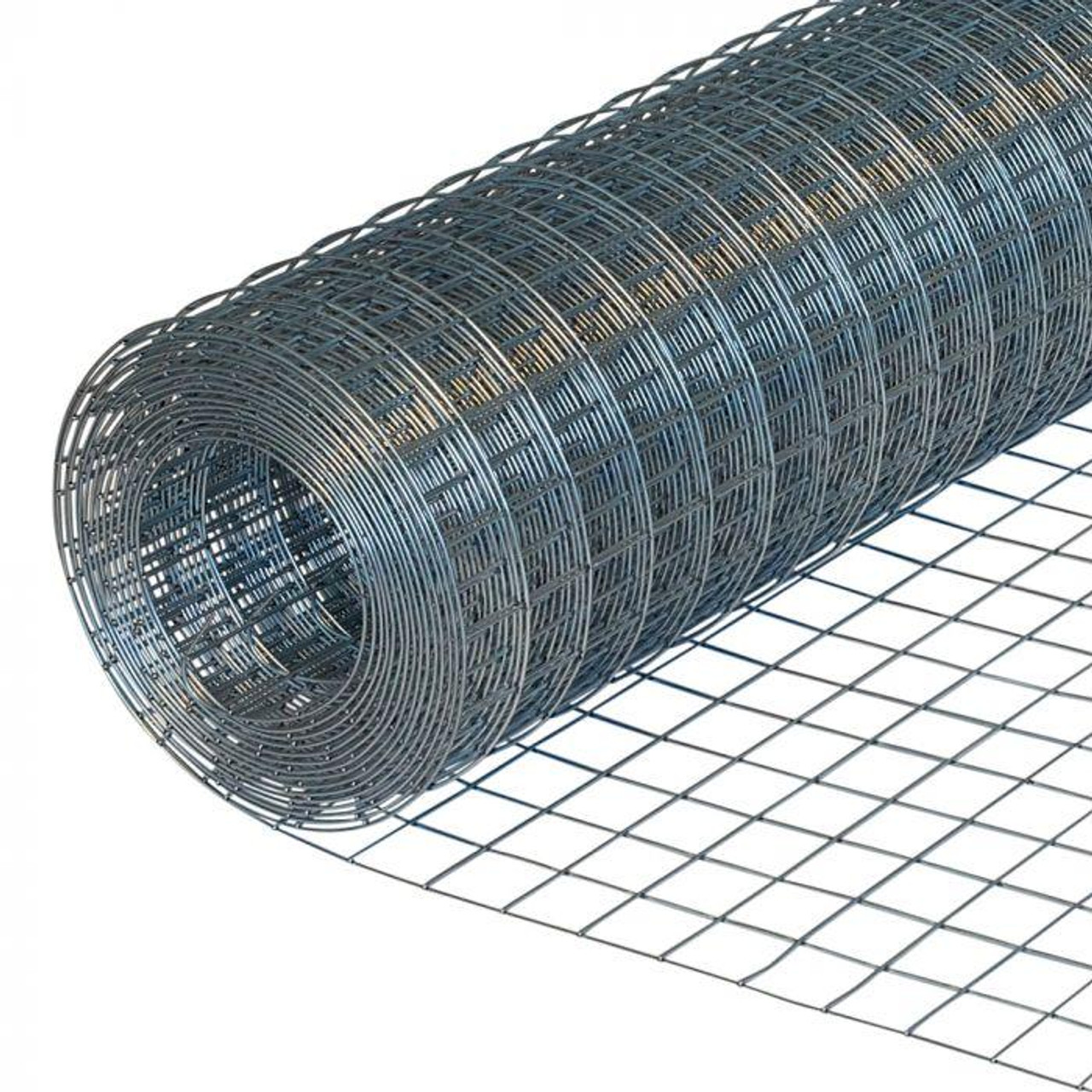

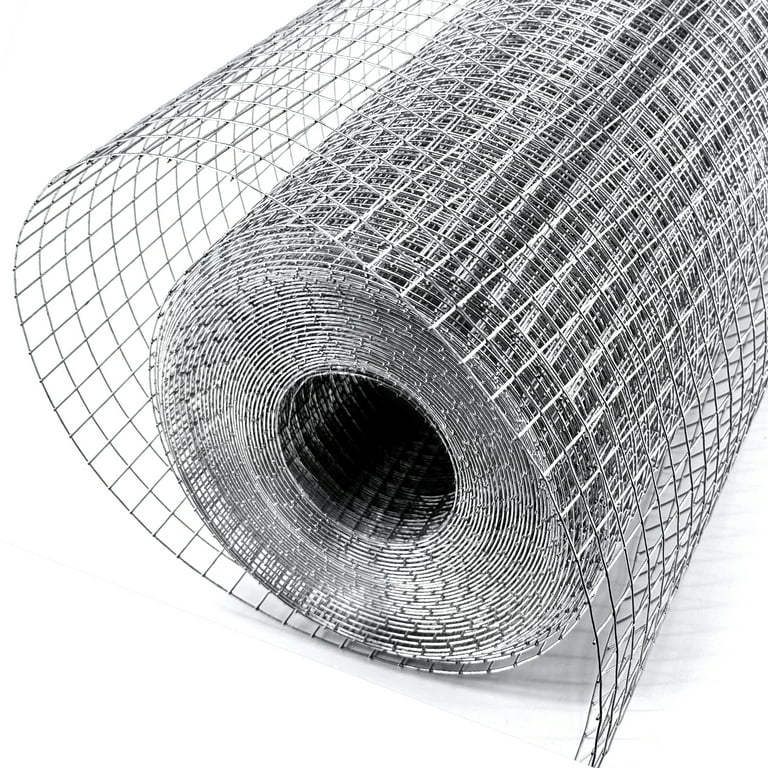

Illustrative image related to galvanized wire mesh

Why Choose Vinyl Coated Wire Mesh for Landscaping and Decorative Use?

Vinyl coated wire mesh is a galvanized wire product that has been coated in vinyl to provide additional corrosion resistance and an attractive finish. This type is ideal for landscaping, garden fencing, and decorative applications. When purchasing, buyers should consider the color options and thickness of the coating, as these can impact both aesthetics and durability. While it offers superior rust protection and visual appeal, the initial cost is generally higher than that of non-coated alternatives.

In What Scenarios is Stainless Steel Wire Mesh the Best Option?

Stainless steel wire mesh is renowned for its exceptional corrosion resistance and longevity, making it suitable for demanding environments such as food processing, pharmaceuticals, and marine applications. Buyers should focus on the mesh size and wire diameter, as these factors influence both functionality and compliance with industry standards. Though it provides outstanding durability and is hygienic, the cost can be significantly higher compared to galvanized wire mesh, which may be a consideration for budget-conscious buyers.

Key Industrial Applications of galvanized wire mesh

| Industry/Sector | Specific Application of galvanized wire mesh | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Building | Reinforcement in concrete and masonry structures | Enhances structural integrity and load-bearing capacity | Ensure compliance with local building codes and standards |

| Agriculture & Farming | Livestock fencing and crop protection | Protects crops and livestock from predators and harsh weather | Consider mesh size and gauge suitable for specific animals |

| Environmental Management | Erosion control and soil stabilization | Prevents soil erosion and promotes vegetation growth | Assess the durability against local climatic conditions |

| Mining & Quarrying | Support for screening and separation processes | Increases efficiency in material handling and processing | Verify material compatibility with extracted minerals |

| Industrial Manufacturing | Filtration in various production processes | Improves product quality and operational efficiency | Evaluate mesh specifications for chemical resistance |

How is Galvanized Wire Mesh Utilized in Construction and Building?

In the construction industry, galvanized wire mesh is primarily used for reinforcing concrete and masonry structures. Its corrosion-resistant properties ensure longevity, making it ideal for various applications, including slabs, walls, and ceilings. By enhancing structural integrity, galvanized wire mesh helps prevent cracking and shifting, which can lead to costly repairs. Buyers should ensure compliance with local building codes and standards, particularly in regions like Africa and South America, where regulatory requirements may differ significantly.

What Role Does Galvanized Wire Mesh Play in Agriculture and Farming?

In agricultural settings, galvanized wire mesh serves as an effective solution for livestock fencing and crop protection. It prevents predators from accessing livestock and protects crops from harsh weather conditions. The mesh’s durability is crucial for maintaining the safety and productivity of farms. Buyers must consider the appropriate mesh size and gauge that suits their specific agricultural needs, particularly in diverse climates found in regions like Nigeria and Vietnam.

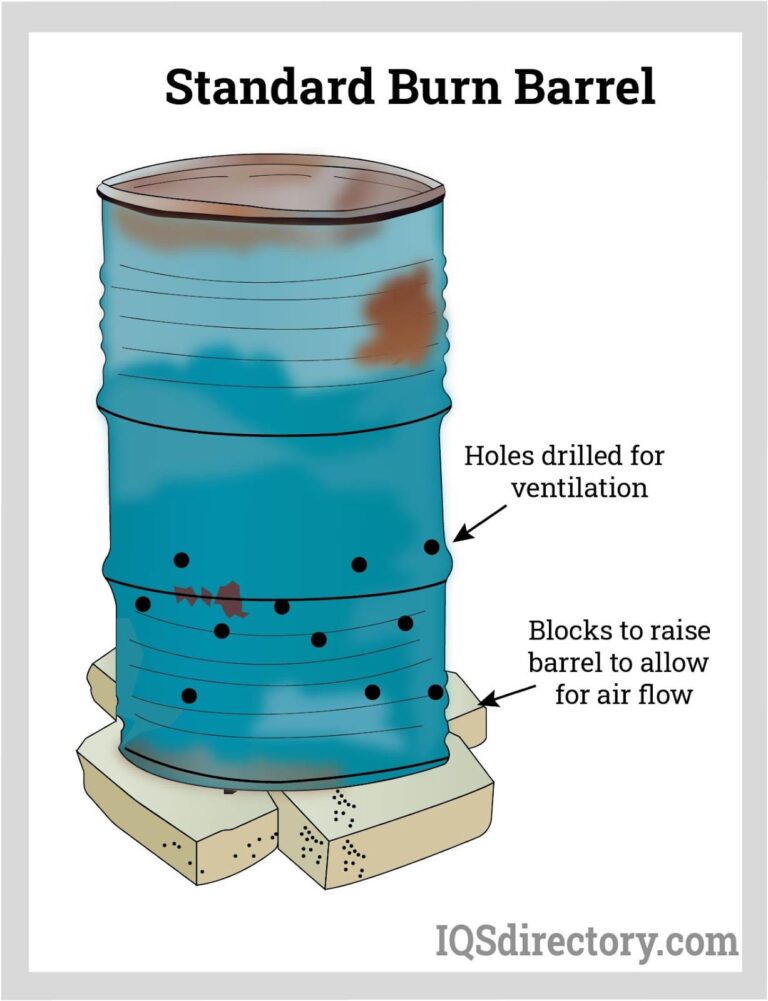

Illustrative image related to galvanized wire mesh

How Does Galvanized Wire Mesh Aid Environmental Management?

Galvanized wire mesh is also widely used in environmental management, particularly for erosion control and soil stabilization. The mesh helps prevent soil erosion by providing a barrier that supports vegetation growth, which is essential in maintaining healthy ecosystems. For international buyers, it is important to assess the durability of the mesh against local climatic conditions, ensuring it can withstand harsh weather prevalent in various regions.

In What Ways is Galvanized Wire Mesh Beneficial for Mining and Quarrying?

In the mining and quarrying sectors, galvanized wire mesh is utilized for screening and separation processes. It enhances operational efficiency by facilitating the sorting of different materials, which is essential for effective resource extraction. Buyers should verify the compatibility of the mesh material with the specific minerals being extracted, as this can impact the overall efficiency and longevity of the equipment used.

How is Galvanized Wire Mesh Applied in Industrial Manufacturing?

In industrial manufacturing, galvanized wire mesh is commonly used for filtration processes. Its precise mesh sizes allow for effective filtration of various substances, improving product quality and operational efficiency. Buyers need to evaluate the mesh specifications to ensure chemical resistance, especially when dealing with aggressive substances in manufacturing processes. This consideration is crucial for maintaining equipment integrity and minimizing downtime.

3 Common User Pain Points for ‘galvanized wire mesh’ & Their Solutions

Scenario 1: Sourcing Quality Galvanized Wire Mesh for Diverse Applications

The Problem: B2B buyers often face difficulties in sourcing high-quality galvanized wire mesh that meets specific project requirements. In many cases, the available options may not align with the desired specifications, such as wire diameter, mesh size, or coating thickness. This can lead to project delays, increased costs, and potential rework, particularly in industries like construction, agriculture, and manufacturing where precision is key. Buyers may also struggle with understanding the differences between various types of galvanized wire mesh, leading to suboptimal purchasing decisions.

The Solution: To overcome sourcing challenges, B2B buyers should conduct thorough market research to identify reputable suppliers who specialize in galvanized wire mesh. Establishing relationships with manufacturers or distributors that offer a wide range of options can ensure that specific needs are met. Buyers should request detailed specifications from suppliers, including wire gauge, mesh size, and coating type, to ensure compatibility with their applications. Utilizing samples for testing before bulk purchasing can also minimize the risk of receiving inadequate materials. Engaging in conversations with suppliers about their production processes can provide insights into the quality and durability of their products, enabling informed decision-making.

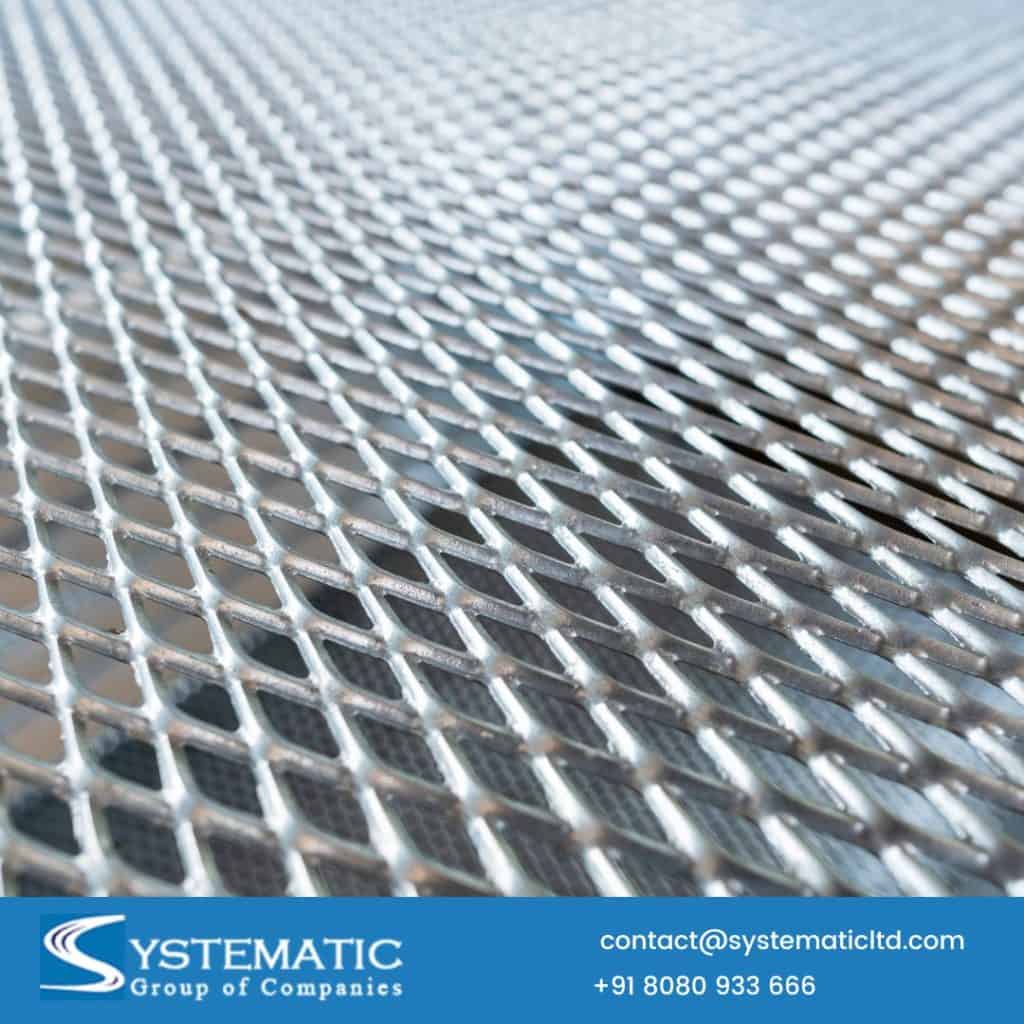

Illustrative image related to galvanized wire mesh

Scenario 2: Understanding the Impact of Environmental Conditions on Galvanized Wire Mesh

The Problem: Many B2B buyers overlook the impact of environmental conditions on the performance of galvanized wire mesh. For instance, areas with high humidity or exposure to corrosive elements can significantly affect the longevity and effectiveness of the mesh. Buyers may find that the wire mesh they have chosen deteriorates faster than expected, leading to increased maintenance costs and potential safety hazards, particularly in agricultural or industrial settings.

The Solution: To mitigate the effects of environmental conditions, B2B buyers should specify the appropriate type of galvanized wire mesh based on the intended application and exposure environment. For instance, opting for PVC-coated galvanized wire mesh can provide additional protection against corrosion in harsh conditions. Buyers should also seek guidance from suppliers regarding the best practices for installation and maintenance, which can enhance the lifespan of the mesh. Regular inspections and maintenance routines should be established to identify signs of wear early, allowing for timely replacements and minimizing downtime.

Scenario 3: Ensuring Compliance with Industry Standards and Regulations

The Problem: Compliance with industry standards and regulations is crucial for B2B buyers, especially in sectors such as construction and manufacturing. However, navigating the complexities of these regulations can be challenging. Buyers may inadvertently purchase galvanized wire mesh that does not meet local or international standards, leading to legal repercussions, project delays, and potential financial penalties.

The Solution: B2B buyers should familiarize themselves with relevant industry standards, such as ASTM and ISO specifications for galvanized wire mesh. Collaborating with suppliers who are knowledgeable about these regulations can provide valuable insights into compliant products. It is advisable to request certification documents that verify that the galvanized wire mesh meets the necessary standards. Additionally, engaging in industry forums or workshops can enhance buyers’ understanding of compliance requirements and best practices. Staying proactive in regulatory matters will not only ensure compliance but also enhance the buyer’s reputation within their industry, fostering trust with clients and stakeholders.

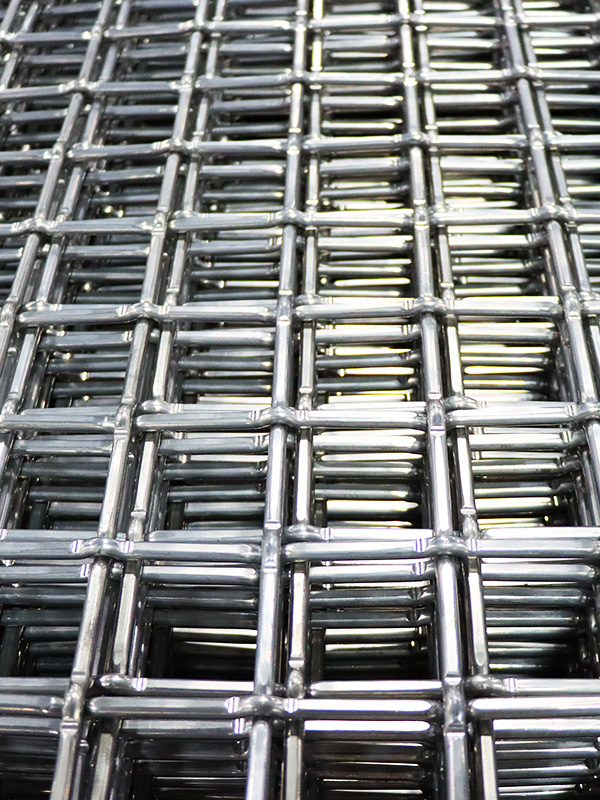

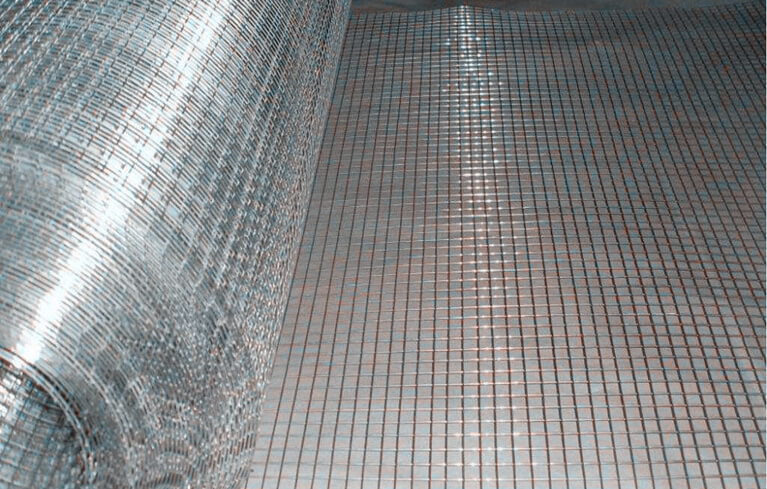

Illustrative image related to galvanized wire mesh

Strategic Material Selection Guide for galvanized wire mesh

What are the Key Properties of Common Materials Used in Galvanized Wire Mesh?

When selecting galvanized wire mesh for various applications, understanding the properties of the materials involved is crucial for ensuring optimal performance. The most common materials used in the production of galvanized wire mesh include carbon steel, stainless steel, aluminum, and vinyl-coated wire. Each material has unique characteristics that impact its durability, cost, and suitability for specific applications.

How Does Carbon Steel Perform in Galvanized Wire Mesh Applications?

Key Properties: Carbon steel is known for its high tensile strength and ability to withstand heavy loads. It is typically galvanized to enhance its corrosion resistance, making it suitable for outdoor applications.

Pros & Cons: The primary advantage of carbon steel is its cost-effectiveness and strength. However, it may be susceptible to rust if the galvanization wears off over time, particularly in humid or coastal environments.

Impact on Application: Carbon steel galvanized wire mesh is often used in fencing, construction, and industrial applications where strength is critical.

Illustrative image related to galvanized wire mesh

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards, as well as ASTM specifications for quality assurance.

What Advantages Does Stainless Steel Offer for Galvanized Wire Mesh?

Key Properties: Stainless steel is highly resistant to corrosion and staining, making it ideal for applications in harsh environments. It maintains its integrity under high temperatures and pressures.

Pros & Cons: The primary advantage of stainless steel is its long lifespan and low maintenance requirements. However, it is generally more expensive than other materials, which may affect budget constraints for some projects.

Impact on Application: Stainless steel wire mesh is commonly used in food processing, medical applications, and environments where hygiene is paramount.

Considerations for International Buyers: Buyers should be aware of the specific grades of stainless steel required for their applications, as well as compliance with international standards like JIS and DIN.

Illustrative image related to galvanized wire mesh

How Does Aluminum Compare as a Material for Galvanized Wire Mesh?

Key Properties: Aluminum is lightweight and resistant to corrosion, making it easy to handle and install. It also provides good strength-to-weight ratios.

Pros & Cons: The lightweight nature of aluminum is a significant advantage for applications requiring mobility or ease of installation. However, it may not provide the same level of strength as carbon or stainless steel, which could limit its use in heavy-duty applications.

Impact on Application: Aluminum wire mesh is often used in architectural applications, such as decorative screens or plant trellises, where aesthetics are important.

Considerations for International Buyers: Buyers should consider the specific alloy used, as different alloys can have varying properties. Compliance with local standards is also essential.

What Role Does Vinyl-Coated Wire Play in Galvanized Wire Mesh?

Key Properties: Vinyl-coated wire mesh combines the strength of galvanized steel with an additional layer of PVC, enhancing its corrosion resistance and providing a more aesthetically pleasing finish.

Pros & Cons: The vinyl coating offers excellent weather resistance and is available in various colors, making it suitable for decorative applications. However, the coating can be prone to chipping, which may expose the underlying steel to corrosion.

Impact on Application: Vinyl-coated wire mesh is commonly used in residential fencing and landscaping applications where appearance and durability are important.

Considerations for International Buyers: Buyers should verify the quality of the vinyl coating and ensure compliance with local regulations regarding materials used in construction.

Illustrative image related to galvanized wire mesh

Summary of Material Selection for Galvanized Wire Mesh

| Material | Typical Use Case for galvanized wire mesh | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Fencing, construction | Cost-effective and strong | Susceptible to rust | Low |

| Stainless Steel | Food processing, medical applications | Highly durable and low maintenance | Higher cost | High |

| Aluminum | Architectural screens, plant trellises | Lightweight and easy to install | Lower strength compared to steel | Medium |

| Vinyl-Coated Wire | Residential fencing, landscaping | Excellent weather resistance | Prone to chipping | Medium |

This detailed analysis provides B2B buyers with critical insights into the material selection process for galvanized wire mesh, ensuring informed decision-making aligned with their specific application needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for galvanized wire mesh

What Are the Key Stages in the Manufacturing Process of Galvanized Wire Mesh?

The manufacturing process of galvanized wire mesh involves several critical stages that ensure the final product meets quality standards and functional requirements. Understanding these stages is essential for B2B buyers looking to procure reliable galvanized wire mesh.

Material Preparation: Selecting the Right Raw Materials

The first step in the manufacturing process is selecting high-quality raw materials. Typically, low-carbon steel wire is used due to its excellent tensile strength and malleability. The wire is sourced from reputable suppliers, ensuring it meets industry standards. Before manufacturing begins, the wire undergoes a thorough inspection to eliminate any defects or inconsistencies.

Forming: Wire Mesh Creation Techniques

Once the materials are prepared, the wire is formed into mesh through various techniques, including welding or weaving.

Illustrative image related to galvanized wire mesh

-

Welding: In this method, wires are crossed and welded at the intersections, creating a sturdy and uniform mesh. This technique is particularly effective for producing welded wire mesh, which is commonly used in fencing and construction.

-

Weaving: For woven wire mesh, the wires are interlaced to form a flexible structure. This method allows for a variety of mesh sizes and patterns, catering to different applications.

Both techniques ensure that the wire mesh retains its strength while providing the necessary flexibility for installation.

Assembly: Structuring the Final Product

The assembly stage involves cutting the formed wire mesh to specified dimensions. At this stage, additional processes such as bending, shaping, or coating may also occur, depending on the intended application. For instance, some products may require additional features like PVC coating for enhanced corrosion resistance.

Finishing: Ensuring Durability and Aesthetics

The final stage of manufacturing is finishing, where the galvanized wire mesh is treated to enhance its durability and aesthetic appeal. The galvanization process involves coating the wire with a layer of zinc to prevent rust and corrosion. There are two primary methods for galvanization:

Illustrative image related to galvanized wire mesh

-

Hot-Dip Galvanizing: The wire is submerged in molten zinc, providing a thicker and more robust coating.

-

Electro-Galvanizing: A thinner layer of zinc is applied through an electrochemical process, suitable for applications requiring a more delicate finish.

The choice of galvanization method affects the wire mesh’s longevity, corrosion resistance, and overall performance.

How Is Quality Assurance Implemented in Galvanized Wire Mesh Manufacturing?

Quality assurance is crucial in the production of galvanized wire mesh to meet international standards and customer expectations. Various processes and checkpoints are implemented throughout the manufacturing cycle.

What International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 are essential for ensuring consistent quality in manufacturing processes. These standards outline the requirements for a quality management system, emphasizing customer satisfaction and continuous improvement. Additionally, industry-specific certifications like CE (Conformité Européenne) and API (American Petroleum Institute) are vital for certain applications, particularly in construction and oil and gas sectors.

What Are the Key Quality Control Checkpoints?

Quality control is integrated into the manufacturing process through several checkpoints:

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to ensure they meet specified standards. Any non-conforming materials are rejected to prevent defects in the final product.

-

In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to monitor adherence to specifications and quality standards. This step helps identify and rectify issues early in the process.

-

Final Quality Control (FQC): After the production process, the finished galvanized wire mesh undergoes thorough testing and inspection. This may include checking dimensions, mesh integrity, and the quality of the galvanization.

What Testing Methods Are Commonly Used?

Several testing methods are employed to ensure the quality of galvanized wire mesh, including:

-

Tensile Strength Testing: Measures the maximum amount of tensile stress that the wire can withstand before failure, ensuring it meets required strength specifications.

-

Corrosion Resistance Testing: Evaluates the effectiveness of the galvanization process by exposing samples to corrosive environments and measuring the rate of deterioration.

-

Mesh Integrity Testing: Assesses the overall integrity of the mesh structure, ensuring there are no weak points or defects.

How Can B2B Buyers Verify Supplier Quality Control Processes?

B2B buyers must take proactive steps to verify the quality control processes of their suppliers. Here are some effective strategies:

Conducting Supplier Audits

Regular audits of suppliers can provide insights into their quality control processes, manufacturing practices, and compliance with international standards. Buyers should develop a checklist based on relevant standards and industry best practices to ensure a thorough evaluation.

Illustrative image related to galvanized wire mesh

Requesting Quality Assurance Reports

Buyers should request detailed quality assurance reports that outline the results of inspections, testing, and certifications. These documents provide transparency and help buyers assess the reliability of the supplier’s quality control measures.

Utilizing Third-Party Inspections

Engaging third-party inspection services can add an extra layer of assurance. These independent entities can conduct audits and testing to verify that the supplier adheres to quality standards and that the products meet specified requirements.

What Are the Unique Quality Control Considerations for International Buyers?

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, may face unique challenges in ensuring quality control. Factors such as varying regulatory standards, supply chain complexities, and differences in manufacturing practices can impact the procurement process.

Understanding Regional Standards

Buyers should familiarize themselves with regional standards and regulations that may differ from international norms. This knowledge is crucial for ensuring compliance and avoiding potential pitfalls.

Establishing Clear Communication

Effective communication with suppliers is vital for clarifying quality expectations and addressing any issues that may arise during production. Establishing a clear line of communication can facilitate a smoother procurement process and help build long-term partnerships.

By understanding the manufacturing processes and quality assurance practices for galvanized wire mesh, B2B buyers can make informed decisions that enhance their procurement strategies and ensure they receive high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘galvanized wire mesh’

Introduction

Sourcing galvanized wire mesh requires a systematic approach to ensure that you acquire the right product for your specific needs. This guide provides a step-by-step checklist tailored for international B2B buyers, particularly those from diverse regions such as Africa, South America, the Middle East, and Europe. By following these steps, you can make informed decisions that align with your technical specifications and business requirements.

1. Define Your Technical Specifications

Clearly articulate your requirements for galvanized wire mesh. Consider factors such as mesh size, wire diameter, and intended application.

– Mesh Size: Determine the specific opening dimensions (e.g., 4×4, 10×10) needed for your project.

– Wire Diameter: Specify the gauge of the wire to ensure strength and durability.

2. Research Material Types and Coatings

Understand the different types of galvanized wire mesh available and the coatings that enhance their performance.

– Material Options: Common materials include carbon steel and stainless steel. Identify which material best suits your environment, especially if corrosion resistance is a priority.

– Coatings: Consider additional coatings like PVC for enhanced weather resistance, which can extend the lifespan of your wire mesh in harsh conditions.

3. Evaluate Potential Suppliers

Before committing to a supplier, conduct thorough evaluations to ensure reliability and quality.

– Supplier Profiles: Request comprehensive company profiles that detail their manufacturing processes and product offerings.

– References: Seek testimonials or case studies from other businesses in similar sectors to gauge supplier credibility.

4. Request Samples for Testing

Obtaining samples is crucial for assessing product quality and suitability for your specific application.

– Testing Samples: Ensure that the samples meet your defined specifications and perform adequately under expected conditions.

– Quality Assurance: Look for any signs of defects or inconsistencies in the mesh that could affect performance.

5. Verify Compliance with Industry Standards

Ensure that the galvanized wire mesh complies with relevant industry standards and regulations.

– Certification Checks: Verify if the supplier holds certifications like ISO or ASTM that indicate adherence to quality standards.

– Local Regulations: Be aware of any regional compliance requirements, particularly if you are importing the product.

6. Negotiate Terms and Pricing

Once you’ve identified a suitable supplier, negotiate pricing and terms to ensure a favorable deal.

– Bulk Pricing: Inquire about discounts for larger orders, which can significantly reduce your overall costs.

– Payment Terms: Discuss payment options and terms to establish a clear understanding before finalizing the purchase.

7. Plan for Logistics and Delivery

Finally, consider the logistics involved in transporting the galvanized wire mesh to your location.

– Shipping Options: Evaluate different shipping methods to determine the most efficient and cost-effective option.

– Delivery Timeline: Establish a timeline for delivery to align with your project schedules, ensuring that the mesh arrives when needed.

By following this comprehensive checklist, B2B buyers can confidently navigate the procurement process for galvanized wire mesh, ensuring they make informed choices that meet their operational needs.

Comprehensive Cost and Pricing Analysis for galvanized wire mesh Sourcing

What Are the Key Cost Components in Sourcing Galvanized Wire Mesh?

When sourcing galvanized wire mesh, it’s essential to understand the various cost components that contribute to the overall price. The primary elements include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and the supplier’s margin.

-

Materials: The cost of raw materials, such as galvanized steel, significantly influences pricing. Variations in steel prices due to market fluctuations can impact overall costs. Additionally, the choice between standard and specialty materials (like PVC-coated options) will also affect pricing.

-

Labor: Labor costs encompass the expenses related to manufacturing, including skilled and unskilled workers involved in production. The labor market conditions in the supplier’s region can lead to substantial cost variations.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and equipment maintenance. Efficient production processes can help minimize these overheads, thereby reducing overall pricing.

-

Tooling: Initial setup costs for production tooling can be significant, especially for customized mesh specifications. These costs are often amortized over larger production runs, meaning higher volume orders can yield lower per-unit costs.

-

Quality Control: Ensuring product quality through rigorous QC processes adds to the cost structure. Certifications and compliance with international standards can also drive up costs, but they are critical for meeting buyer specifications, particularly for international transactions.

-

Logistics: Transporting galvanized wire mesh involves various logistics costs, which can vary significantly based on distance, shipping methods, and Incoterms. Understanding these costs is vital for buyers to assess total expenses accurately.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary based on the supplier’s business model, market positioning, and perceived product value.

How Do Price Influencers Affect the Cost of Galvanized Wire Mesh?

Several factors can influence the pricing of galvanized wire mesh, particularly for international buyers:

-

Volume and Minimum Order Quantity (MOQ): Purchasing in larger volumes often leads to discounts. Suppliers may offer better pricing for orders that meet or exceed their MOQ, allowing buyers to optimize their procurement costs.

-

Specifications and Customization: Customized products, such as unique mesh sizes or additional coatings, generally come with higher costs. Buyers should weigh the benefits of customization against the additional expenses.

-

Material Quality and Certifications: Higher quality materials and certifications that ensure compliance with international standards can raise prices. However, investing in quality can lead to long-term savings through reduced maintenance and replacement costs.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their services due to trust and quality assurance, while newer entrants might offer lower prices to gain market share.

-

Incoterms: Understanding Incoterms is crucial for international shipping. Different terms can affect the cost structure significantly, particularly in terms of who bears the shipping and insurance costs.

What Are the Best Negotiation Tips for International Buyers of Galvanized Wire Mesh?

B2B buyers should adopt strategic approaches to negotiate effectively and achieve cost efficiency:

-

Understand Total Cost of Ownership (TCO): Consider all cost components, including shipping, tariffs, and potential quality issues, rather than just the purchase price. A lower upfront cost may lead to higher TCO if the product requires frequent replacements.

-

Build Relationships with Suppliers: Establishing long-term relationships with suppliers can lead to better pricing and terms. Suppliers may be more willing to negotiate with buyers they trust and see as long-term partners.

-

Leverage Competitive Quotes: Gathering multiple quotes from different suppliers can create leverage in negotiations. It also provides insight into the market price, helping buyers to negotiate better terms.

-

Be Clear on Specifications: Clearly communicate your requirements and specifications to avoid misunderstandings. This clarity can prevent unnecessary costs related to revisions and quality control.

-

Monitor Market Trends: Keeping an eye on market trends related to steel prices and demand for galvanized wire mesh can provide insights for timing purchases effectively.

Disclaimer on Indicative Prices

Prices for galvanized wire mesh can vary significantly based on the factors discussed above. It is advisable for buyers to conduct thorough market research and obtain updated quotes directly from suppliers to ensure accurate pricing for their specific needs.

Alternatives Analysis: Comparing galvanized wire mesh With Other Solutions

Introduction: Exploring Alternatives to Galvanized Wire Mesh

In the realm of industrial and construction applications, galvanized wire mesh is a popular choice due to its durability and versatility. However, it is essential for B2B buyers to explore alternative solutions that may offer different benefits or meet specific project requirements. This analysis will compare galvanized wire mesh with welded wire fencing and plastic mesh, highlighting their respective strengths and weaknesses to help buyers make informed decisions.

Comparison Table

| Comparison Aspect | Galvanized Wire Mesh | Welded Wire Fencing | Plastic Mesh |

|---|---|---|---|

| Performance | High tensile strength; corrosion-resistant | Strong and durable; suitable for security | Lightweight; flexible but less strong |

| Cost | Moderate to high | Moderate; varies by gauge | Generally low |

| Ease of Implementation | Easy to cut and install; requires basic tools | Requires skilled labor for installation | Very easy; often DIY-friendly |

| Maintenance | Low maintenance; can last for years | Low maintenance; weather-resistant | Moderate; can degrade under UV exposure |

| Best Use Case | Industrial applications, fencing, and architectural designs | Agricultural fencing, security barriers | Garden fencing, temporary enclosures |

Detailed Breakdown of Alternatives

Welded Wire Fencing

Welded wire fencing is a robust alternative that consists of wires welded at intersections, providing a strong and stable structure. This type of fencing is often used in agricultural settings and for security purposes due to its durability. One of the significant advantages of welded wire fencing is its strength, which can deter larger animals or intruders. However, it can be more expensive than galvanized wire mesh, depending on the gauge and height needed. Installation may also require professional assistance, which could increase the overall cost and time.

Plastic Mesh

Plastic mesh offers a lightweight and cost-effective solution for various applications. It is typically made from high-density polyethylene, making it resistant to corrosion and decay. The primary benefits of plastic mesh include its ease of installation and versatility for temporary or low-security fencing needs, such as garden enclosures or plant support structures. However, plastic mesh generally lacks the tensile strength of galvanized wire mesh and welded wire fencing, making it less suitable for high-security or heavy-duty applications. Additionally, prolonged exposure to UV rays can lead to degradation, necessitating more frequent replacements.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate mesh solution for your project, consider the specific requirements such as strength, durability, cost, and installation complexity. Galvanized wire mesh excels in industrial and architectural applications due to its corrosion resistance and long lifespan. In contrast, welded wire fencing is ideal for security and agricultural needs, while plastic mesh is best suited for lightweight, temporary applications. By evaluating these factors and aligning them with your project goals, you can make a well-informed decision that meets your operational needs and budget constraints.

Essential Technical Properties and Trade Terminology for galvanized wire mesh

What Are the Key Technical Properties of Galvanized Wire Mesh?

Understanding the essential technical properties of galvanized wire mesh is crucial for B2B buyers, particularly when selecting materials for construction, industrial applications, or custom projects. Here are the critical specifications you should consider:

-

Material Grade:

Galvanized wire mesh is typically made from carbon steel that has been coated with zinc for corrosion resistance. The material grade indicates the tensile strength and durability of the wire, which can significantly affect the performance of the mesh in various applications. Higher grades provide better strength and longevity, making them suitable for heavy-duty uses. -

Wire Diameter:

The diameter of the wire used in the mesh directly influences its strength and application suitability. Common diameters range from 0.025 inches to 0.105 inches. Thicker wires offer higher tensile strength and resistance to bending and deformation, which is essential for structural applications or environments with heavy loads. -

Mesh Count:

This specification refers to the number of openings per linear inch in both directions of the mesh. Higher mesh counts (e.g., 10 x 10) indicate smaller openings, making the mesh suitable for applications that require filtration or containment of small particles. Conversely, lower mesh counts are ideal for applications needing larger openings for visibility or airflow. -

Opening Size:

The width of each opening in the mesh is critical for determining what can pass through. This property is often expressed in inches and should be aligned with the specific needs of your project. For example, larger openings are favorable for fencing or safety barriers, while smaller openings are better for screens or filters. -

Construction Type:

Galvanized wire mesh can be welded or woven, affecting its overall strength and flexibility. Welded mesh is generally more robust and suitable for heavy-duty applications, while woven mesh provides greater flexibility and is often used in lighter applications, such as garden fencing or decorative purposes. -

Coating Type:

The type of galvanization can vary; it can be hot-dip or electro-galvanized. Hot-dip galvanization provides a thicker coating and superior corrosion resistance, making it ideal for outdoor and harsh environments. Understanding the coating type can help you select the right mesh for longevity in specific climatic conditions.

What Are Common Trade Terms Used in the Galvanized Wire Mesh Industry?

Familiarity with industry terminology can significantly streamline the purchasing process and enhance communication between buyers and suppliers. Here are some essential trade terms:

-

OEM (Original Equipment Manufacturer):

This term refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is vital for ensuring quality and consistency in the materials you source. -

MOQ (Minimum Order Quantity):

This is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ helps in budgeting and planning inventory levels, especially when dealing with large-scale projects. -

RFQ (Request for Quotation):

An RFQ is a document sent to suppliers to request pricing and terms for specific products. It is essential for obtaining competitive bids and ensuring that you are making informed purchasing decisions. -

Incoterms (International Commercial Terms):

These are a set of predefined commercial terms published by the International Chamber of Commerce (ICC) related to international trade. Understanding Incoterms is crucial for clarifying the responsibilities of buyers and sellers concerning shipping, insurance, and tariffs. -

Lead Time:

This term refers to the amount of time it takes for an order to be processed and delivered. Knowing the lead time is essential for project planning, especially if specific deadlines must be met. -

Certification Standards:

These are quality benchmarks that products must meet to be sold in certain markets. Familiarity with relevant certification standards can help ensure that the galvanized wire mesh meets local regulations and quality expectations.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions, ensuring that the galvanized wire mesh they purchase meets their specific needs and industry standards.

Navigating Market Dynamics and Sourcing Trends in the galvanized wire mesh Sector

What Are the Current Market Dynamics and Key Trends in the Galvanized Wire Mesh Sector?

The galvanized wire mesh market is experiencing significant growth, driven by increasing demand across various sectors, including construction, agriculture, and industrial applications. This trend is particularly pronounced in emerging markets in Africa, South America, the Middle East, and Europe. B2B buyers are increasingly seeking versatile products that can serve multiple applications, from fencing and security solutions to architectural designs and plant screens. The shift towards lightweight and easy-to-install materials has led manufacturers to innovate, offering a wide range of mesh sizes, wire diameters, and coatings, such as PVC for enhanced corrosion resistance.

Technological advancements are also shaping the sourcing landscape. Digital platforms and e-commerce solutions are streamlining procurement processes, making it easier for international buyers to access suppliers and compare products. The rise of Industry 4.0 is enabling manufacturers to optimize production processes and improve product quality, further enhancing competitiveness in the global market. Additionally, the trend towards customization is gaining traction, with buyers looking for tailored solutions that meet specific project requirements.

Illustrative image related to galvanized wire mesh

How Can Sustainability and Ethical Sourcing Impact B2B Purchases of Galvanized Wire Mesh?

Sustainability is becoming a pivotal factor in B2B purchasing decisions, with increasing emphasis on environmentally friendly practices and materials. The production of galvanized wire mesh can have environmental impacts, particularly related to the galvanization process, which may involve the use of toxic chemicals. Therefore, buyers are urged to consider suppliers that prioritize sustainable practices and offer products with minimal ecological footprints.

Moreover, ethical sourcing is gaining importance among international buyers. Companies are increasingly scrutinizing their supply chains to ensure they adhere to ethical labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and other green certifications can serve as indicators of a supplier’s commitment to sustainability. By choosing suppliers who demonstrate transparency in their sourcing and manufacturing processes, B2B buyers can enhance their brand reputation while contributing to a more sustainable future.

What is the Historical Context of the Galvanized Wire Mesh Market?

The use of wire mesh dates back to ancient times, with early forms being utilized for various purposes, including construction and security. However, the galvanized wire mesh we know today emerged in the mid-20th century, following advancements in galvanization techniques that improved durability and corrosion resistance. Initially popularized in agricultural applications, galvanized wire mesh has since expanded its reach into diverse sectors, including construction, architecture, and landscaping. This evolution reflects broader trends in material science and manufacturing processes, enabling the development of more versatile and durable products that meet the growing demands of global markets.

As the market continues to evolve, international B2B buyers must stay informed about emerging trends and practices to ensure they make strategic sourcing decisions that align with their business objectives and sustainability goals.

Frequently Asked Questions (FAQs) for B2B Buyers of galvanized wire mesh

-

How do I choose the right galvanized wire mesh for my project?

Selecting the appropriate galvanized wire mesh involves understanding the specific requirements of your application. Consider factors such as the mesh size, wire gauge, and type of galvanization (hot-dip or electro-galvanized). Assess the environmental conditions—like humidity and exposure to chemicals—to determine the level of corrosion resistance needed. Additionally, if aesthetics are important, explore various patterns and coatings available. It’s advisable to consult with suppliers to ensure the chosen mesh meets your project’s technical specifications and durability standards. -

What is the best gauge of galvanized wire mesh for fencing?

The best gauge for galvanized wire mesh fencing typically ranges from 12 to 16, with 14 being the most commonly used. A lower gauge number indicates a thicker wire, offering greater strength and durability, which is crucial for security applications. However, if weight and ease of installation are priorities, a higher gauge may suffice. Always consider the specific requirements of your environment and the intended use of the fence, as these will influence the best gauge choice. -

What are the minimum order quantities (MOQs) for galvanized wire mesh?

Minimum order quantities for galvanized wire mesh can vary significantly by supplier and region. Generally, MOQs can range from 100 square meters to several tons, depending on the product type and supplier capabilities. For international buyers, it’s essential to clarify MOQs during the negotiation phase, as larger orders may provide opportunities for bulk discounts. If your needs are below the MOQ, inquire about possible alternatives, such as combining orders with other buyers or selecting a different product line. -

How do I verify the credibility of a galvanized wire mesh supplier?

To verify a supplier’s credibility, conduct thorough due diligence. Start by checking their business licenses and certifications, which should comply with international standards. Look for reviews and testimonials from previous clients, and consider requesting samples of their products. Additionally, assess their production capabilities and quality assurance processes. Engaging with industry-specific forums or trade shows can also provide insights into the supplier’s reputation and reliability. -

What payment terms should I expect when purchasing galvanized wire mesh?

Payment terms can vary widely among suppliers and depend on factors such as order size and buyer-supplier relationships. Common terms include full payment upfront, a deposit with the balance due upon shipment, or net 30/60/90 days after delivery. It’s crucial to negotiate these terms clearly before finalizing the contract. For international transactions, consider using secure payment methods such as letters of credit or escrow services to mitigate risks. -

How can I ensure the quality of galvanized wire mesh products?

Ensuring quality in galvanized wire mesh products involves selecting suppliers with robust quality control measures. Request documentation of their quality assurance processes, including certifications (e.g., ISO). Inspect product samples for consistency in wire gauge, mesh size, and galvanization quality. Additionally, consider third-party inspections, especially for large orders, to verify compliance with your specifications before shipping. Establishing a quality agreement with the supplier can also help ensure adherence to your standards. -

What logistics considerations should I take into account when importing galvanized wire mesh?

When importing galvanized wire mesh, logistics considerations include shipping methods, customs clearance, and lead times. Choose a reliable freight forwarder familiar with regulations in both the exporting and importing countries. Understand the costs associated with shipping, including duties and taxes. Also, factor in the timeline for production and delivery, ensuring that your project schedule aligns with the expected arrival of materials. Proper documentation is essential to avoid delays during customs inspections. -

Can galvanized wire mesh be customized for specific applications?

Yes, galvanized wire mesh can often be customized to meet specific application needs. Many suppliers offer options for varying mesh sizes, wire gauges, and coatings. Customization can also include specific dimensions or patterns tailored to unique projects, such as architectural designs or industrial applications. When requesting customization, provide detailed specifications and consult with the supplier to ensure feasibility and cost implications. This approach can enhance the functionality and effectiveness of the mesh in your intended application.

Top 4 Galvanized Wire Mesh Manufacturers & Suppliers List

1. Nixalite – Galvanized Wire Mesh

Domain: nixalite.com

Registered: 1996 (29 years)

Introduction: Galvanized Wire Mesh from Nixalite offers full rolls in multiple sizes, ideal for keeping out nuisance animals and birds. The welded wire mesh can be cut to fit and molded into shapes for installation over, under, or around various objects and openings. Key specifications include: 4ft x 100ft roll (400 square feet) and 4ft x 50ft roll (200 square feet) with 1/2″ square mesh made of 19 gauge steel,…

2. Darby Wire Mesh – Galvanized Wire Mesh

Domain: darbywiremesh.com

Registered: 2007 (18 years)

Introduction: Galvanized Wire Mesh is a protective zinc-coated steel mesh used to prevent rusting. It is categorized based on its manufacturing process: galvanized before woven or welded, and galvanized after woven or welded. Common applications include fencing, caging, enclosures, agricultural use, window guards, construction projects, and high-security applications. Available opening sizes range from 4″ x 4″ …

3. Siddal & Hilton – Wire Mesh 1 x 1 8 GA HDG

Domain: fenceweb.com

Registered: 2013 (12 years)

Introduction: {“Product Name”: “Wire Mesh | 1″ x 1″ | 8 GA | Hot Dip Galvanized”, “SKU”: “Wire Mesh 1×1 8 GA HDG”, “Price”: “$312.00”, “Mesh Opening”: “1” x 1″”, “Wire Diameter”: “8 GA (3.9 mm)”, “Material”: “Hot Dip Galvanized steel”, “Manufacturer”: “Siddal & Hilton”, “Delivery Options”: “Delivery from stock, In-house production, Nationwide delivery”}

4. Banker Wire – Pre-Galvanized Wire Solutions

Domain: bankerwire.com

Registered: 1997 (28 years)

Introduction: Banker Wire offers two types of Pre-Galvanized wire: “Regular coating” and trademarked “Galfan”. Pre-galvanized wire has a zinc coating applied before mesh manufacturing, while hot-dipped galvanizing (Galfan) occurs after, providing a thicker protective layer. Regular coating pre-galv wire is carbon steel with a thin zinc layer, offering improved corrosion resistance and is suitable for powder-coa…

Strategic Sourcing Conclusion and Outlook for galvanized wire mesh

How Can Strategic Sourcing Enhance Your Procurement of Galvanized Wire Mesh?

In conclusion, the strategic sourcing of galvanized wire mesh presents a multitude of opportunities for international B2B buyers. By prioritizing quality and supplier reliability, businesses can ensure they are investing in products that meet their operational needs while also enhancing project durability. The versatility of galvanized wire mesh, suitable for applications ranging from construction to agriculture, underscores its importance in various sectors.

Understanding the specifications—such as mesh size, wire diameter, and coating options—empowers buyers to make informed decisions that align with their project requirements. Additionally, leveraging local suppliers can significantly reduce lead times and shipping costs, particularly for buyers in Africa, South America, the Middle East, and Europe.

Looking ahead, the demand for galvanized wire mesh is expected to rise, driven by infrastructure development and increased agricultural activities. By proactively engaging with suppliers and exploring innovative sourcing strategies, businesses can position themselves for success in this evolving market. Now is the time to evaluate your sourcing strategies and invest in high-quality galvanized wire mesh that supports your long-term goals.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.