How to Source Fuel Pump Diaphragm Material Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for fuel pump diaphragm material

In today’s competitive landscape, sourcing fuel pump diaphragm material poses significant challenges for international B2B buyers, particularly those operating in regions such as Africa, South America, the Middle East, and Europe. The diverse applications of diaphragm materials—ranging from automotive to industrial pumps—demand a deep understanding of material properties, performance standards, and regional compliance requirements. This guide is designed to provide a comprehensive overview of the various types of fuel pump diaphragm materials, including elastomers like nitrile and Viton, and their suitability for different operational environments.

Throughout this guide, we will explore critical factors influencing procurement decisions, such as supplier vetting processes, cost considerations, and the importance of material certification for international standards. By delving into the nuances of diaphragm material selection, buyers will be equipped to make informed choices that enhance operational efficiency and reliability.

Furthermore, we will highlight best practices for evaluating suppliers, ensuring that your sourcing strategy aligns with both quality and budgetary constraints. With insights tailored for B2B decision-makers in key markets, this guide empowers you to navigate the complexities of the fuel pump diaphragm material landscape confidently, ultimately driving better purchasing outcomes for your organization.

Understanding fuel pump diaphragm material Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Nitrile Rubber (NBR) | Excellent fuel resistance, good elasticity | Automotive, industrial machinery, small engines | Pros: Cost-effective, good durability. Cons: Limited temperature range. |

| Fluoroelastomer (FKM) | High chemical resistance, withstands extreme temperatures | Aerospace, chemical processing, automotive | Pros: Superior performance, long lifespan. Cons: Higher cost, less availability. |

| Ethylene Propylene Diene Monomer (EPDM) | Good weather resistance, ozone resistant | HVAC systems, automotive, outdoor applications | Pros: Excellent durability, cost-efficient. Cons: Moderate fuel resistance. |

| PTFE (Teflon) | Non-stick surface, excellent chemical resistance | Food processing, pharmaceuticals, high-purity applications | Pros: High temperature tolerance, inert properties. Cons: Fragile, can be expensive. |

| Composite Diaphragm | Combination of elastomers with fabric reinforcement | Industrial pumps, water treatment, oil & gas | Pros: Enhanced strength, customizable. Cons: Complexity in sourcing, potential higher costs. |

What Are the Characteristics of Nitrile Rubber (NBR) Diaphragms?

Nitrile rubber, commonly referred to as NBR, is a widely utilized material for fuel pump diaphragms due to its excellent resistance to various fuels and oils. It offers good elasticity and is relatively cost-effective, making it a popular choice for automotive applications and industrial machinery. Buyers should consider the temperature range of NBR, as it is not suitable for extreme heat environments, which may limit its application in certain high-performance settings.

How Does Fluoroelastomer (FKM) Compare to Other Materials?

Fluoroelastomer, or FKM, is known for its outstanding chemical resistance and ability to withstand high temperatures, making it ideal for demanding environments such as aerospace and chemical processing. While it provides a longer lifespan than many alternatives, the higher cost and limited availability can be a barrier for some buyers. Companies looking for durability and performance in harsh conditions should prioritize FKM despite the investment.

Why Choose Ethylene Propylene Diene Monomer (EPDM) for Your Applications?

EPDM is valued for its exceptional weather resistance and durability, particularly in outdoor applications and HVAC systems. While it offers moderate fuel resistance, it is still a cost-efficient option for many automotive applications. Buyers should evaluate the specific environmental conditions and chemical exposures their diaphragms will face, as EPDM may not perform as well in aggressive fuel environments.

What Are the Advantages of Using PTFE Diaphragms?

PTFE, commonly known as Teflon, is recognized for its non-stick properties and remarkable chemical resistance, making it suitable for high-purity applications in food processing and pharmaceuticals. Its ability to endure high temperatures is another significant advantage. However, PTFE diaphragms can be fragile and are often more expensive than other materials, which may limit their use in less critical applications.

How Do Composite Diaphragms Enhance Performance?

Composite diaphragms combine elastomers with fabric reinforcement, offering enhanced strength and flexibility. These diaphragms are particularly beneficial in industrial pumps and oil & gas applications where durability is crucial. While they can be customized to meet specific requirements, the complexity in sourcing and potentially higher costs may deter some buyers. Companies should weigh the performance benefits against the investment needed for composite materials.

Key Industrial Applications of fuel pump diaphragm material

| Industry/Sector | Specific Application of fuel pump diaphragm material | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Fuel pump systems in vehicles | Ensures reliable fuel delivery and engine performance | Material compatibility with various fuel types; durability under extreme conditions |

| Oil & Gas | Diaphragm pumps for fluid transfer | Enhances efficiency in transporting hydrocarbons | Resistance to corrosive substances; compliance with safety standards |

| Agriculture | Fuel pumps in agricultural machinery | Supports efficient operation of farming equipment | Availability of custom sizes; resistance to environmental factors |

| Marine | Fuel systems in boats and ships | Maintains performance in harsh marine conditions | Lightweight materials; ability to withstand saltwater exposure |

| Industrial Equipment Manufacturing | Pumps in hydraulic systems | Improves operational reliability and safety | Certifications for industrial applications; ability to handle high pressures |

How is Fuel Pump Diaphragm Material Used in the Automotive Industry?

In the automotive sector, fuel pump diaphragm materials are crucial for ensuring the effective delivery of fuel to the engine. These diaphragms must withstand various fuel compositions, including those with ethanol blends, without degrading. Buyers should prioritize materials like nitrile rubber (NBR) or fluorocarbon (FKM) due to their superior chemical resistance and durability. Furthermore, sourcing from reputable manufacturers who can provide quality certifications is essential to ensure compliance with automotive standards, especially for international buyers in regions like Europe and the Middle East.

What Role Does Fuel Pump Diaphragm Material Play in the Oil & Gas Industry?

Fuel pump diaphragm materials are vital in the oil and gas industry, particularly in diaphragm pumps used for transferring various fluids, including crude oil and refined products. These materials must offer resistance to corrosive environments and maintain functionality under high pressures. Buyers should consider sourcing materials that meet industry safety standards and have proven reliability in extreme conditions. Additionally, suppliers who can provide detailed specifications and certifications will be invaluable to international buyers operating in regions like Africa and South America.

How is Fuel Pump Diaphragm Material Beneficial in Agriculture?

In agriculture, fuel pump diaphragm materials are used in fuel systems of tractors and other machinery to ensure efficient operation. The materials must withstand exposure to various environmental conditions, such as moisture and dust, which can affect performance. Buyers should look for materials that offer durability and flexibility, allowing for reliable operation over extended periods. Custom sizing options from manufacturers can also be a significant advantage for agricultural equipment tailored to specific needs.

Why is Fuel Pump Diaphragm Material Important for Marine Applications?

Marine applications require fuel pump diaphragm materials that can endure harsh conditions, including saltwater exposure and varying temperatures. Diaphragms in boats and ships must maintain performance reliability to prevent fuel leaks and ensure engine efficiency. Buyers should prioritize lightweight materials that do not compromise strength and durability. Sourcing from manufacturers with marine certifications will also help ensure compliance with international maritime safety standards, particularly for businesses operating in regions like Saudi Arabia.

How Does Fuel Pump Diaphragm Material Enhance Industrial Equipment Manufacturing?

In industrial equipment manufacturing, fuel pump diaphragm materials are integral to hydraulic systems, where they ensure the safe and efficient transfer of fluids. The reliability of these diaphragms directly impacts operational efficiency and safety. Buyers should focus on sourcing materials that have been tested for high-pressure applications and possess the necessary industry certifications. Collaborating with suppliers who can offer tailored solutions and extensive testing data will be beneficial for international buyers looking to optimize their operations.

3 Common User Pain Points for ‘fuel pump diaphragm material’ & Their Solutions

Scenario 1: Sourcing Durable Diaphragm Materials for Harsh Environments

The Problem: B2B buyers in industries such as oil and gas, agriculture, or automotive often face challenges in sourcing diaphragm materials that can withstand extreme temperatures, chemical exposure, and fluctuating pressures. In regions like Saudi Arabia or Nigeria, where environmental conditions can be severe, the risk of diaphragm failure increases. This can lead to costly downtime, compromised equipment performance, and safety hazards for workers.

The Solution: To mitigate these risks, buyers should focus on sourcing high-performance materials specifically designed for harsh environments. Nitrile rubber (NBR) and fluorocarbon elastomers (FKM) are excellent choices due to their resistance to fuels and extreme temperatures. When selecting suppliers, prioritize those who offer comprehensive testing data and certifications, ensuring their products meet industry standards. Collaborating with material experts can also help in customizing diaphragm designs that fit unique operational conditions, thereby enhancing reliability.

Scenario 2: Ensuring Compatibility with Modern Fuel Blends

The Problem: The introduction of biofuels and ethanol-blended fuels has complicated the selection of diaphragm materials. Traditional materials may degrade quickly when exposed to these modern fuel blends, leading to leaks and failures. Buyers in regions like South America, where biofuels are prevalent, must ensure that the diaphragm materials they choose are compatible with these fuels to avoid operational disruptions.

The Solution: Buyers should invest in materials specifically formulated to resist the effects of biofuels. Viton (FKM) and EPDM rubber are known for their excellent compatibility with ethanol and biodiesel. It is crucial to request compatibility data from suppliers, including long-term exposure tests to these fuel types. Additionally, engaging in proactive maintenance schedules can help identify potential issues before they escalate, ensuring that the chosen materials maintain their integrity over time.

Scenario 3: Cost Management in Diaphragm Procurement

The Problem: Cost considerations can be a significant pain point for B2B buyers, especially when facing budget constraints while needing high-quality diaphragm materials. Buyers may feel pressured to opt for cheaper alternatives, risking quality and performance. This dilemma is particularly acute in developing markets where cost sensitivity is high, yet reliability cannot be compromised.

The Solution: A strategic approach to procurement can alleviate this challenge. Buyers should consider total cost of ownership (TCO) rather than just initial purchase price. This includes factoring in potential savings from reduced downtime, maintenance, and replacement costs. Establishing long-term relationships with reliable suppliers can also lead to negotiated pricing and volume discounts. Furthermore, exploring bulk purchasing options or co-op buying with other companies can enhance purchasing power, ensuring access to high-quality diaphragm materials without exceeding budget constraints.

By addressing these common pain points with tailored solutions, B2B buyers can enhance operational efficiency, ensure safety, and maintain competitive advantage in their respective markets.

Strategic Material Selection Guide for fuel pump diaphragm material

What Are the Key Properties of Nitrile Rubber for Fuel Pump Diaphragms?

Nitrile rubber, also known as NBR or Buna-N, is a widely used material for fuel pump diaphragms due to its excellent resistance to fuel and oil. It typically operates effectively at temperatures ranging from -40°C to 100°C and can withstand moderate pressures. The material is known for its good tensile strength and flexibility, making it suitable for dynamic applications. However, it is essential to note that Nitrile rubber may degrade when exposed to certain chemicals, such as ozone and some solvents.

Pros: Nitrile rubber is relatively inexpensive, readily available, and easy to manufacture. Its flexibility allows for effective sealing in various applications, making it a popular choice for many fuel pump designs.

Cons: While it performs well with petroleum-based fuels, its resistance to biofuels and high-temperature applications is limited. Additionally, the lifespan of Nitrile diaphragms can be shorter in harsh environments.

How Does Viton Compare as a Material for Fuel Pump Diaphragms?

Viton, or FKM, is a fluoropolymer known for its exceptional chemical resistance and high-temperature capabilities, typically functioning effectively between -20°C and 200°C. This material is ideal for applications involving aggressive fuels, including ethanol-blended fuels and biodiesel. Viton diaphragms can endure higher pressures and provide excellent sealing performance.

Pros: The primary advantage of Viton is its durability and resistance to a wide range of chemicals, making it suitable for demanding applications. Its longevity can result in lower replacement costs over time.

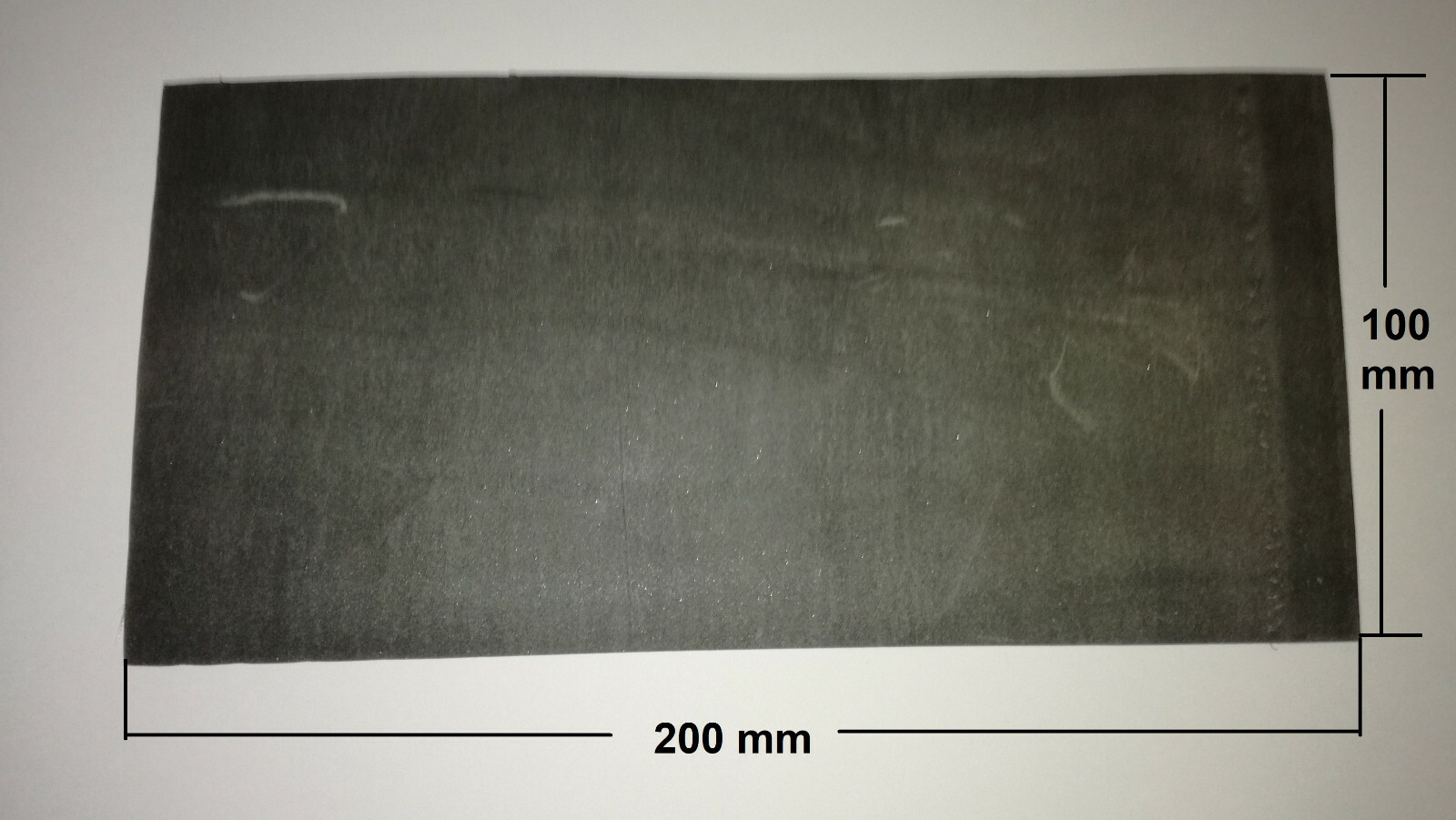

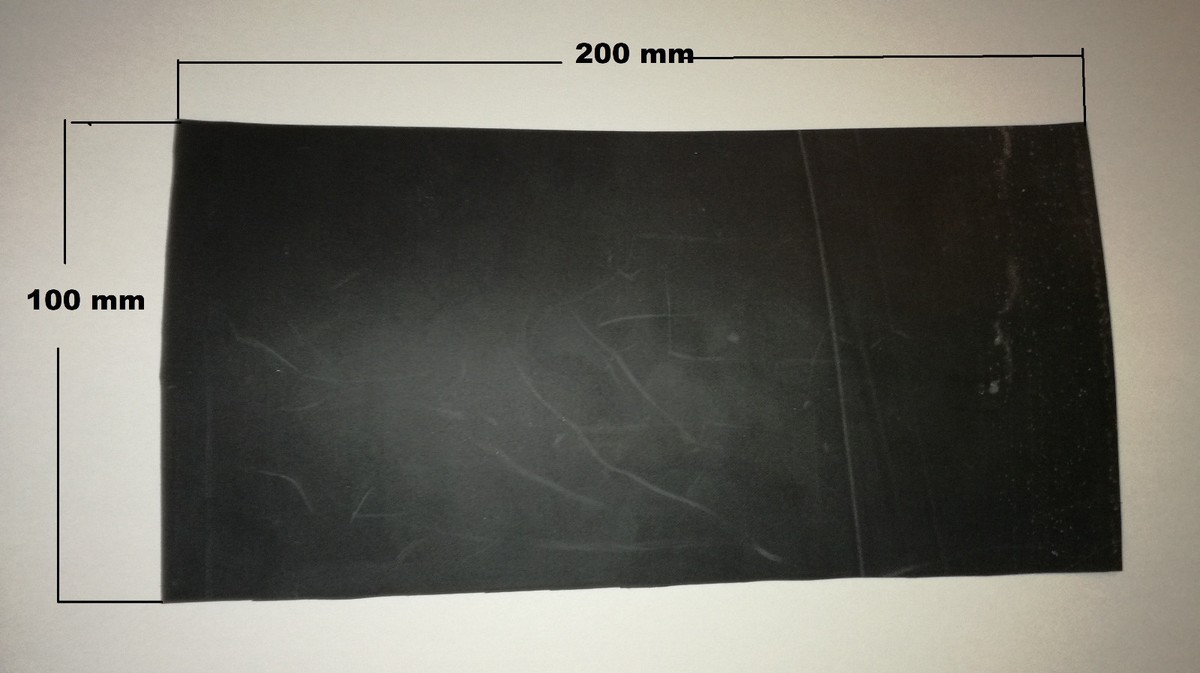

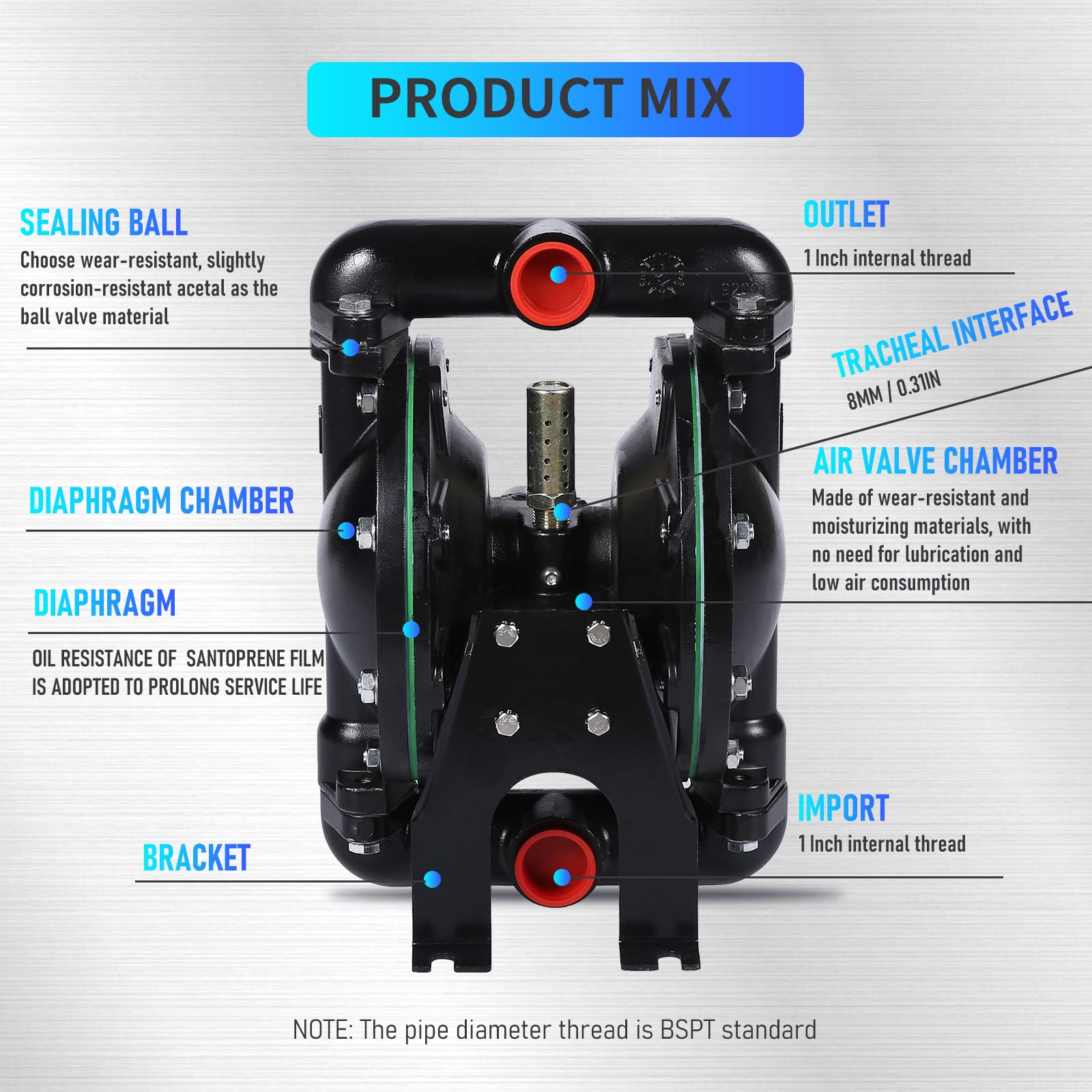

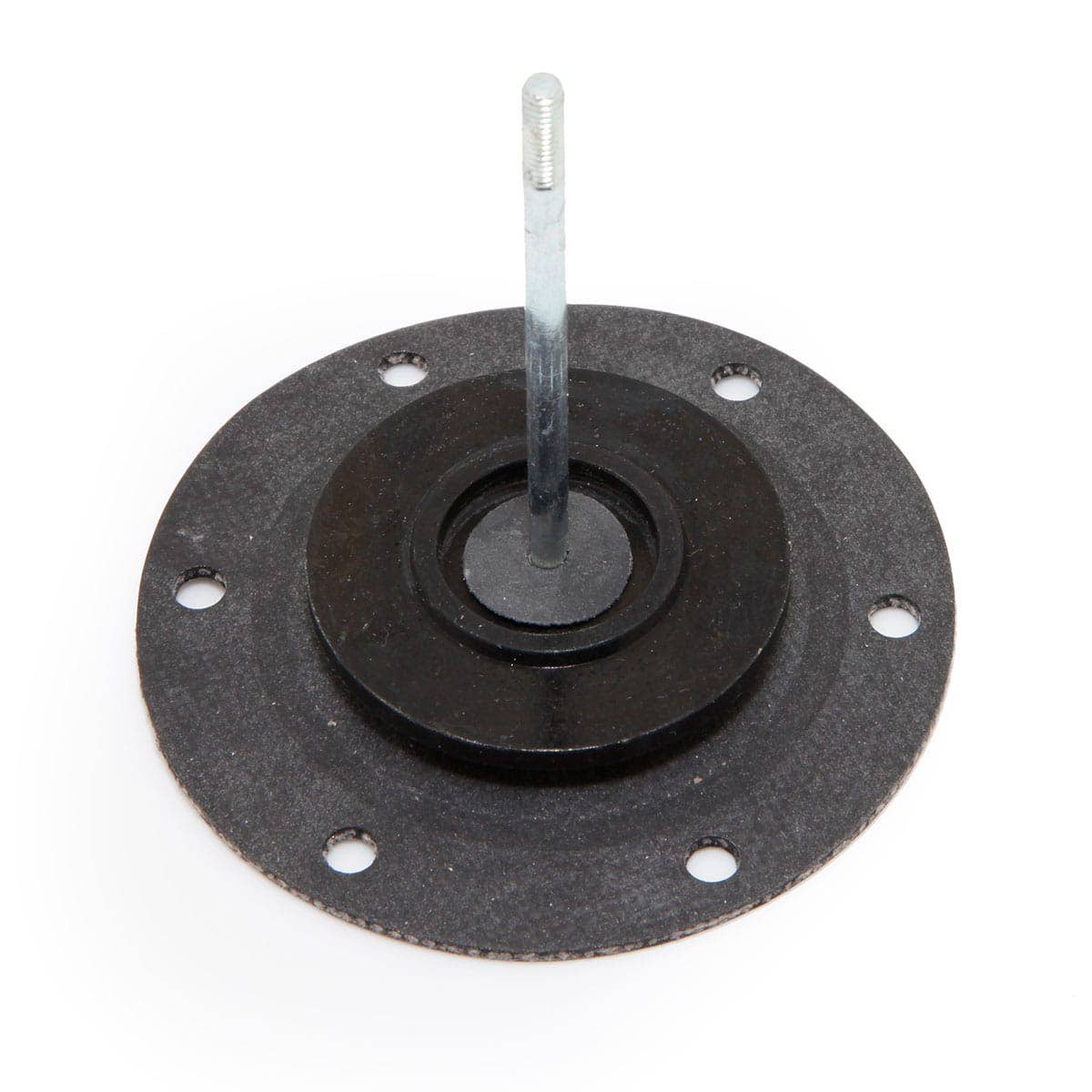

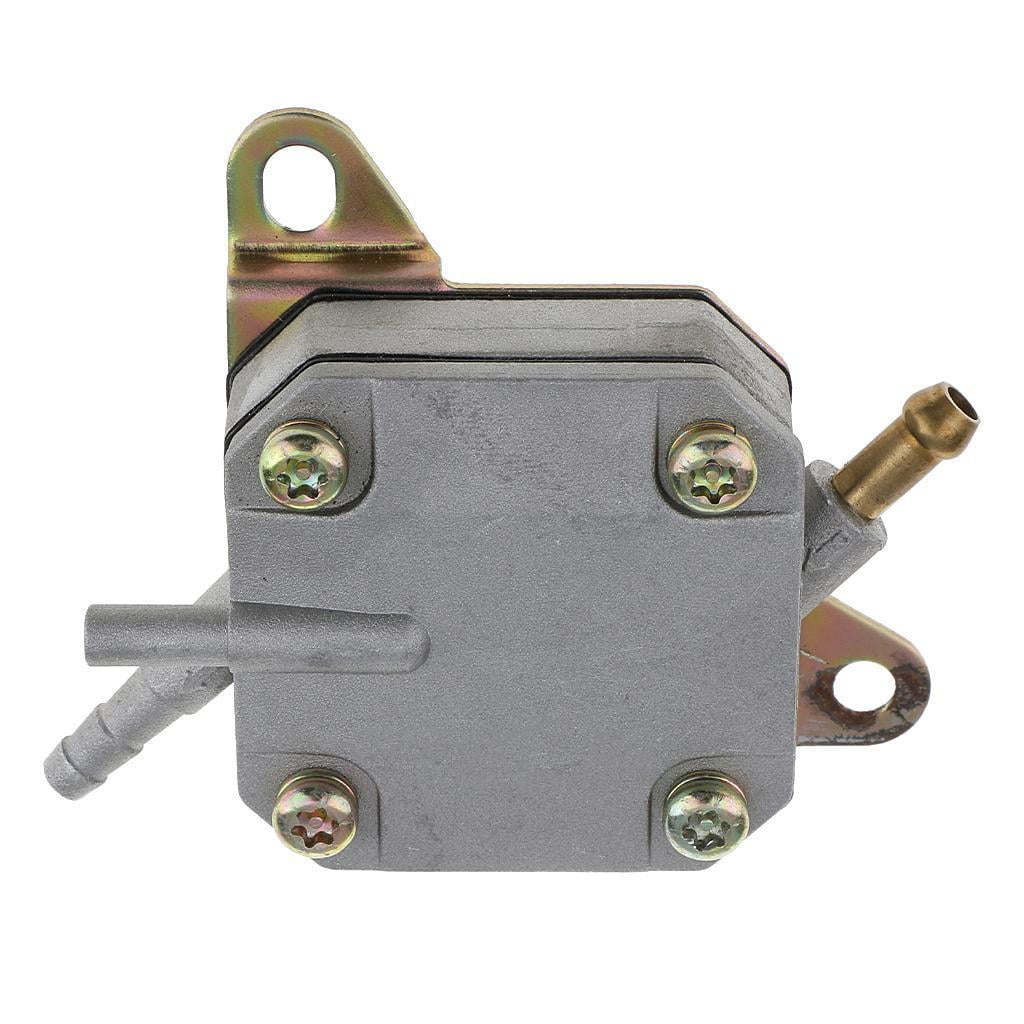

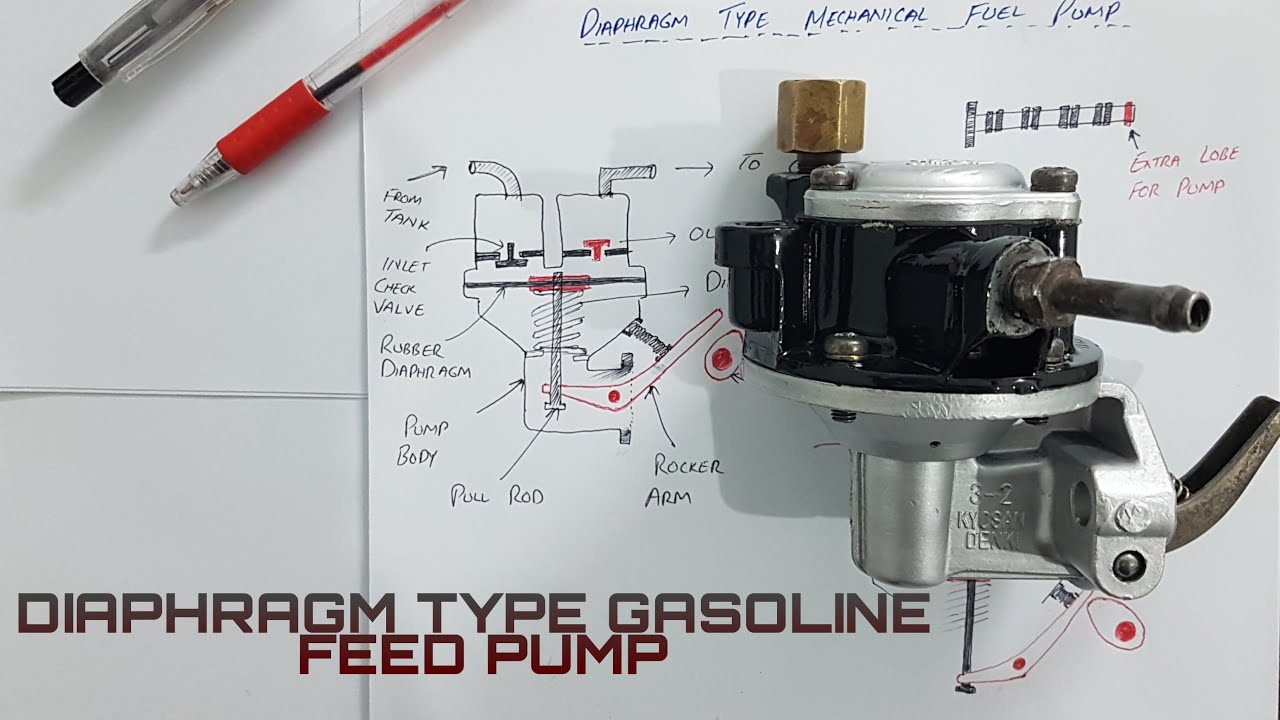

Illustrative image related to fuel pump diaphragm material

Cons: Viton is significantly more expensive than Nitrile rubber and may require more complex manufacturing processes. This can lead to higher initial costs for B2B buyers, particularly in price-sensitive markets.

What Role Does Ethylene Propylene Diene Monomer (EPDM) Play in Fuel Pump Diaphragms?

EPDM is a synthetic rubber that offers excellent weather and ozone resistance, making it suitable for outdoor applications. It typically operates effectively at temperatures ranging from -50°C to 150°C. While it is not as resistant to petroleum-based fuels as Nitrile or Viton, EPDM can handle certain alcohols and is often used in applications where environmental exposure is a concern.

Pros: EPDM is cost-effective, has good aging resistance, and is environmentally friendly. Its versatility allows it to be used in various sealing applications beyond fuel pumps.

Illustrative image related to fuel pump diaphragm material

Cons: Its chemical resistance to hydrocarbons is limited, which may lead to premature failure in certain fuel applications. This limitation makes it less suitable for traditional fuel systems compared to Nitrile or Viton.

What Are the Advantages of Using PTFE in Fuel Pump Diaphragms?

Polytetrafluoroethylene (PTFE) is renowned for its non-stick properties and exceptional chemical resistance. It can operate effectively in a temperature range from -200°C to 260°C, making it suitable for extreme environments. PTFE is particularly useful in applications where chemical compatibility is critical.

Pros: The primary advantage of PTFE is its outstanding chemical resistance, making it ideal for harsh fuel mixtures. Its high-temperature tolerance also allows it to maintain performance under extreme conditions.

Cons: PTFE is more expensive than other materials and can be challenging to manufacture due to its rigidity. Its installation may require specialized techniques, which can increase overall costs for B2B buyers.

Summary Table of Fuel Pump Diaphragm Materials

| Material | Typical Use Case for fuel pump diaphragm material | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nitrile Rubber (NBR) | General fuel pumps using petroleum-based fuels | Cost-effective and flexible | Limited resistance to biofuels | Low |

| Viton (FKM) | High-performance fuel pumps with aggressive fuels | Excellent chemical resistance and durability | Higher cost and complex manufacturing | High |

| EPDM | Outdoor applications and certain alcohol blends | Good weather resistance and cost-effective | Limited resistance to hydrocarbons | Medium |

| PTFE | Extreme environments with harsh chemicals | Outstanding chemical resistance and high-temperature tolerance | Expensive and challenging to manufacture | High |

This strategic material selection guide provides insights into the various materials used for fuel pump diaphragms, helping international B2B buyers make informed decisions based on performance, cost, and application requirements.

Illustrative image related to fuel pump diaphragm material

In-depth Look: Manufacturing Processes and Quality Assurance for fuel pump diaphragm material

What Are the Key Stages in the Manufacturing Process of Fuel Pump Diaphragm Material?

The manufacturing of fuel pump diaphragm material involves several critical stages to ensure that the final product meets rigorous performance and safety standards.

Material Preparation

The first step in the manufacturing process is material preparation, where raw materials are selected based on their chemical resistance and mechanical properties. Common materials include Nitrile Rubber (NBR), Fluoroelastomers (FKM), and Ethylene Propylene Diene Monomer (EPDM). Each material possesses unique attributes, such as flexibility, temperature resistance, and compatibility with various fuels, which are crucial for the diaphragm’s functionality.

Once the materials are selected, they undergo a thorough quality check to confirm that they meet the necessary specifications. This may involve testing for tensile strength, elongation, and hardness. The raw materials are then processed into sheets or rolls of the required thickness, ready for the next stage.

Forming Processes: How Are Diaphragms Shaped?

The forming stage is where the raw material is transformed into the desired diaphragm shape. There are several techniques employed in this phase, including:

-

Die Cutting: This method involves using a die to cut the diaphragm from a sheet of material. It is efficient for producing large quantities of uniform diaphragms and is often used when the diaphragm shape is relatively simple.

-

Molding: In cases where complex shapes are required, molding techniques such as compression or injection molding may be used. These methods allow for intricate designs and can include features like reinforcement materials for added durability.

-

Hydroforming: This advanced technique uses high-pressure fluid to shape the material, creating flexible and robust diaphragms. Hydroforming is particularly beneficial for creating convoluted or rolling diaphragms that require specific curvature.

Each of these forming processes must be carefully controlled to ensure dimensional accuracy and performance consistency.

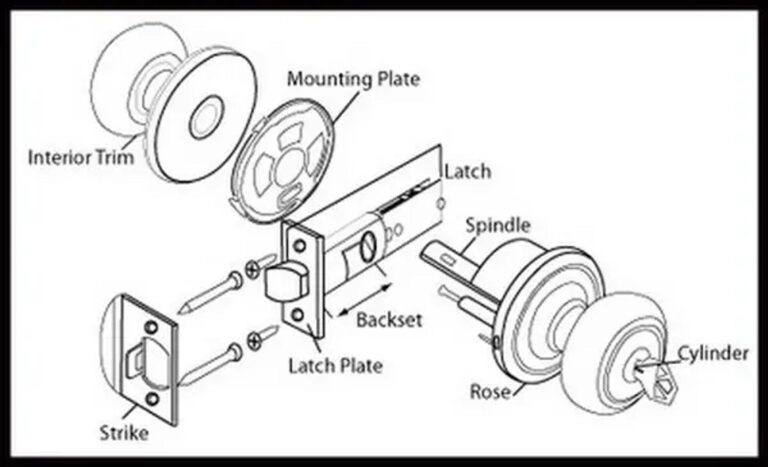

Assembly: How Are Components Integrated?

Following the forming process, diaphragms may require assembly with other components, such as support frames or sealing elements. This stage often involves techniques like bonding or welding, depending on the design requirements.

For example, some diaphragms are reinforced with fabric layers to enhance strength and prevent tearing. Proper alignment and bonding are crucial in this phase to ensure that the diaphragm can withstand operational stresses without failure.

What Quality Control Measures Are Essential for Fuel Pump Diaphragm Manufacturing?

Quality control (QC) is paramount in the manufacturing of fuel pump diaphragms, given their critical role in fuel systems. Adhering to international standards and industry-specific regulations ensures that the products are reliable and safe for use.

What International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 provide a framework for quality management systems, ensuring that manufacturers maintain consistent quality in their processes. Additionally, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for petroleum products are vital for compliance.

Illustrative image related to fuel pump diaphragm material

These certifications not only enhance the credibility of the manufacturer but also assure B2B buyers of the quality and safety of the diaphragms.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control checkpoints should be integrated at various stages of the manufacturing process:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet the required specifications. Tests may include chemical analysis and physical property assessments.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular checks should be conducted to monitor the quality of the production. This includes dimensional checks and performance tests to ensure that any variations are addressed in real time.

-

Final Quality Control (FQC): Once the diaphragms are fully assembled, they undergo final inspection and testing. This may include leak testing, pressure testing, and compatibility testing with various fuels to verify that they meet performance standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly in regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential to mitigate risks.

What Steps Can Be Taken to Ensure Supplier Compliance?

-

Supplier Audits: Conducting thorough audits of potential suppliers can provide insights into their manufacturing processes and quality control systems. Look for evidence of compliance with international standards and industry-specific certifications.

-

Quality Assurance Reports: Request detailed quality assurance reports that outline the testing methods used, the frequency of inspections, and the results of past quality control checks.

-

Third-Party Inspections: Engaging third-party inspectors can provide an unbiased assessment of the supplier’s quality control practices. These inspectors can conduct on-site evaluations and testing to ensure compliance with required standards.

-

Certification Verification: Check the validity of any certifications the supplier claims to hold. This can typically be done through the issuing bodies and is crucial for ensuring that the supplier meets the necessary quality benchmarks.

What Are the Quality Control Nuances for International B2B Buyers?

For buyers in diverse markets, understanding local regulations and industry standards is crucial. Quality control processes may differ significantly across regions. For instance, in Europe, compliance with CE marking is mandatory, while in the Middle East, local standards may apply depending on the country.

Buyers should also consider the potential for variations in material quality based on regional availability. Engaging with suppliers who have a proven track record of international compliance can mitigate risks associated with quality inconsistencies.

In conclusion, understanding the manufacturing processes and quality assurance measures for fuel pump diaphragm materials is vital for B2B buyers. By focusing on the key stages of production and implementing rigorous quality control practices, buyers can ensure they procure reliable and high-performance products suitable for their applications.

Illustrative image related to fuel pump diaphragm material

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fuel pump diaphragm material’

To assist B2B buyers in effectively procuring fuel pump diaphragm materials, this guide provides a structured checklist designed to streamline the sourcing process. Each step is crucial for ensuring that the materials meet the required performance standards while aligning with business needs.

Step 1: Define Your Technical Specifications

Before starting the procurement process, clearly outline your technical requirements for the fuel pump diaphragm. Consider factors such as material type, thickness, flexibility, and resistance to specific fuels. Documenting these specifications ensures that you only evaluate products that meet your operational needs.

- Material Types: Common options include Nitrile (NBR), Viton (FKM), and EPDM, each with varying chemical resistances.

- Performance Requirements: Determine the environmental conditions and operational pressures the diaphragm will face.

Step 2: Research Potential Suppliers

Once you have your specifications, begin researching potential suppliers. Look for manufacturers with a proven track record in producing high-quality diaphragm materials. Online platforms, trade shows, and industry publications can be valuable resources.

- Supplier Reputation: Check reviews and testimonials from other businesses in your industry.

- Product Range: Ensure the supplier offers a variety of materials that can meet your specific needs.

Step 3: Evaluate Supplier Certifications

Certification is critical in ensuring that the materials you procure comply with industry standards and regulations. Verify that potential suppliers hold relevant certifications, such as ISO 9001 for quality management and any specific certifications for fuel-related applications.

- Compliance Standards: Look for certifications that align with your industry’s requirements, such as FDA or NSF for food-related applications.

- Sustainability Practices: Consider suppliers that demonstrate commitment to sustainable practices, which can enhance your corporate responsibility image.

Step 4: Request Material Samples

Before making a bulk purchase, request samples of the materials you are considering. This allows you to assess their quality and suitability for your applications. Evaluate the samples under real-world conditions to ensure they meet your performance expectations.

Illustrative image related to fuel pump diaphragm material

- Testing Conditions: Conduct tests that mimic the actual operating environment of the fuel pump.

- Durability Assessments: Check for resistance to fuel types and environmental factors like temperature and humidity.

Step 5: Negotiate Pricing and Terms

Once you have selected a supplier, engage in negotiations regarding pricing, delivery times, and payment terms. Establish a clear agreement that includes all aspects of the purchase to avoid misunderstandings later.

- Bulk Discounts: Inquire about price breaks for larger orders, which can significantly reduce costs.

- Delivery Schedules: Ensure that the supplier can meet your timelines to avoid disruptions in your operations.

Step 6: Establish Quality Control Processes

After procurement, implement quality control measures to ensure that the diaphragm materials consistently meet your specifications. This could involve setting up regular audits or inspections of incoming materials.

- Inspection Protocols: Develop a checklist for assessing the quality of received materials.

- Feedback Loop: Create a system for providing feedback to suppliers based on performance and quality issues.

Step 7: Build Long-term Relationships with Suppliers

Fostering strong relationships with your suppliers can lead to better pricing, priority service, and access to new products. Keep communication lines open and collaborate on future projects to enhance mutual benefits.

Illustrative image related to fuel pump diaphragm material

- Regular Check-ins: Schedule periodic meetings to discuss performance and potential improvements.

- Partnership Opportunities: Explore opportunities for joint development initiatives that can lead to innovative solutions for your business.

By following these steps, B2B buyers can effectively navigate the complexities of sourcing fuel pump diaphragm materials, ensuring that they meet both operational and quality standards.

Comprehensive Cost and Pricing Analysis for fuel pump diaphragm material Sourcing

What Are the Key Cost Components in Fuel Pump Diaphragm Material Sourcing?

When sourcing fuel pump diaphragm materials, understanding the cost structure is essential for informed decision-making. The primary cost components include:

-

Materials: The choice of material significantly impacts the price. Common materials such as Nitrile (NBR), Viton (FKM), and rubber composites vary in cost based on their properties and performance characteristics. For instance, specialized elastomers designed for high-temperature or chemical resistance may command a premium.

-

Labor: Labor costs encompass the workforce involved in the manufacturing process. Skilled labor is required for the production of high-quality diaphragms, particularly those needing precision engineering and customization.

-

Manufacturing Overhead: This includes indirect costs related to production facilities, utilities, and equipment maintenance. Efficient manufacturing processes can help minimize overhead, affecting overall pricing.

-

Tooling: Custom tooling for specific diaphragm designs can be a significant initial investment. However, for larger orders, this cost can be amortized over a greater number of units, potentially reducing the per-unit cost.

-

Quality Control (QC): Ensuring the reliability and durability of diaphragm materials requires rigorous quality control processes. These processes can add to the overall cost but are crucial for compliance with industry standards.

-

Logistics: Transportation and storage costs must also be considered. Shipping costs can vary significantly based on the distance, shipping method, and any customs duties applicable to international shipments.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and ensure profitability. This margin can vary based on market conditions and supplier competition.

How Do Price Influencers Affect Fuel Pump Diaphragm Material Costs?

Several factors can influence the pricing of fuel pump diaphragm materials:

-

Volume/MOQ: Suppliers often offer better pricing for larger orders. Understanding Minimum Order Quantities (MOQ) can help buyers negotiate favorable terms.

-

Specifications and Customization: Custom-designed diaphragms tailored to specific applications may incur additional costs. Buyers should weigh the benefits of customization against the potential price increase.

-

Materials and Quality Certifications: High-performance materials with certifications for safety and compliance (e.g., FDA, NSF) can significantly affect pricing. Buyers should consider the long-term benefits of investing in certified materials.

-

Supplier Factors: Supplier reputation, experience, and reliability can influence pricing. Established suppliers may charge a premium for their assurance of quality and service.

-

Incoterms: The terms of shipping and delivery can impact the overall cost. Understanding Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can help buyers anticipate additional expenses.

What Are the Best Practices for Negotiating Fuel Pump Diaphragm Material Prices?

To achieve cost-efficiency in sourcing fuel pump diaphragm materials, buyers should consider the following strategies:

Illustrative image related to fuel pump diaphragm material

-

Conduct Market Research: Understanding current market trends and competitor pricing can provide leverage during negotiations. Buyers should gather quotes from multiple suppliers to identify competitive pricing.

-

Total Cost of Ownership: Evaluate the long-term costs associated with diaphragm materials, including maintenance and replacement costs. Cheaper options may lead to higher expenses over time due to lower durability or performance.

-

Negotiate Payment Terms: Flexible payment terms can improve cash flow for buyers. Discussing options such as staggered payments or discounts for early payments can be beneficial.

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing and service. Regular communication and collaboration can help in negotiating favorable terms.

-

Be Aware of Pricing Nuances: For international buyers, factors such as currency fluctuations, import tariffs, and regional demand can impact pricing. Staying informed about these elements can aid in making strategic sourcing decisions.

Conclusion

Understanding the comprehensive cost and pricing analysis for fuel pump diaphragm material sourcing is crucial for B2B buyers. By dissecting the cost components, recognizing price influencers, and employing effective negotiation strategies, businesses can optimize their procurement processes, ensuring they receive quality materials at competitive prices. As the market continues to evolve, keeping abreast of industry standards and supplier dynamics will further enhance sourcing efficiency.

Alternatives Analysis: Comparing fuel pump diaphragm material With Other Solutions

Introduction

When selecting the ideal solution for fuel pumping applications, it’s essential for B2B buyers to consider various alternatives to traditional fuel pump diaphragm materials. Each option presents distinct advantages and drawbacks that can significantly impact performance, cost, and longevity. This analysis will provide a comparative overview of traditional fuel pump diaphragm materials against alternative solutions, enabling buyers to make informed decisions based on their specific operational needs.

| Comparison Aspect | Fuel Pump Diaphragm Material | Alternative 1: Nitrile Rubber | Alternative 2: PTFE (Teflon) |

|---|---|---|---|

| Performance | High flexibility and durability; suitable for various fuels | Moderate flexibility; good chemical resistance | Excellent chemical resistance; low friction |

| Cost | Moderate to high, depending on material quality | Lower cost, widely available | Higher cost due to manufacturing complexity |

| Ease of Implementation | Standardized sizes available, may require customization | Easy to cut and shape; readily available | Requires specialized fabrication techniques |

| Maintenance | Requires periodic inspection; long lifespan with proper care | Moderate; can degrade over time with certain fuels | Minimal maintenance; highly durable |

| Best Use Case | Ideal for standard fuel systems in varied industries | Suitable for general-purpose applications | Best for chemical and high-temperature environments |

Detailed Breakdown

What are the Advantages and Disadvantages of Nitrile Rubber as an Alternative?

Nitrile rubber, commonly used in various industrial applications, offers a cost-effective alternative to traditional fuel pump diaphragm materials. Its moderate flexibility allows for effective sealing under pressure, making it a viable option for many fuel applications. However, nitrile’s chemical resistance can vary based on the specific formulation, and it may degrade when exposed to certain fuel types, particularly those containing high levels of ethanol. For users seeking a budget-friendly option with decent performance, nitrile rubber can be a sound choice, but it’s crucial to assess compatibility with the specific fuel being used.

How Does PTFE (Teflon) Compare to Traditional Fuel Pump Diaphragm Materials?

PTFE, known for its exceptional chemical resistance and low friction properties, is another alternative for fuel pump applications. Its durability makes it an excellent choice for environments where aggressive chemicals are present, as well as high-temperature scenarios. However, PTFE is typically more expensive than traditional diaphragm materials and may require specialized fabrication due to its unique characteristics. While it offers minimal maintenance requirements, the higher initial investment and potential challenges in sourcing custom parts can be a drawback for some B2B buyers.

Conclusion

Choosing the right diaphragm material or alternative solution for fuel pumping applications depends on specific operational needs, including performance requirements, budget constraints, and maintenance capabilities. Buyers should carefully evaluate the pros and cons of traditional fuel pump diaphragm materials versus alternatives like nitrile rubber and PTFE. By assessing factors such as cost, ease of implementation, and best-use cases, B2B buyers can make informed decisions that align with their operational goals and ensure long-lasting performance in their fuel systems.

Essential Technical Properties and Trade Terminology for fuel pump diaphragm material

What Are the Key Technical Properties of Fuel Pump Diaphragm Material?

Understanding the technical specifications of fuel pump diaphragm materials is essential for B2B buyers to ensure optimal performance and longevity of their fuel systems. Below are critical properties to consider:

1. Material Grade

Material grade refers to the specific composition and quality of the material used in manufacturing the diaphragm. Common grades include Nitrile Rubber (NBR), Ethylene Propylene Diene Monomer (EPDM), and Fluoroelastomer (FKM). Each material offers different levels of fuel resistance, temperature tolerance, and durability. Selecting the appropriate grade ensures that the diaphragm can withstand the specific fuels and environmental conditions it will encounter, thus enhancing reliability and reducing maintenance costs.

2. Tolerance

Tolerance indicates the allowable deviation from specified dimensions during the manufacturing process. It is crucial for ensuring a proper fit within fuel pump assemblies. A tighter tolerance can lead to better sealing and efficiency, while a looser tolerance may result in leaks or premature wear. Understanding tolerance levels helps buyers select diaphragms that will function effectively in their applications, minimizing operational disruptions.

3. Thickness

The thickness of the diaphragm material plays a vital role in its performance. Thicker diaphragms generally provide greater durability and resistance to wear, while thinner materials may offer improved flexibility. It is essential for buyers to balance thickness with the specific demands of their application to achieve optimal performance without compromising on reliability.

4. Temperature Resistance

Temperature resistance specifies the range of temperatures a diaphragm can withstand without losing its mechanical properties. Different applications may expose diaphragms to varying thermal conditions, and selecting a material with the appropriate temperature resistance is crucial for preventing failures. This property is especially important in regions with extreme climates, such as parts of Africa and the Middle East.

5. Chemical Compatibility

Chemical compatibility refers to the diaphragm’s ability to resist degradation when exposed to various fuels and chemicals. Buyers must consider the specific fuel types they will be using, as some materials can swell, harden, or break down when in contact with certain chemicals. Ensuring chemical compatibility is vital for extending the lifespan of the diaphragm and maintaining system integrity.

6. Reinforcement

Reinforcement involves embedding materials, such as fabric or mesh, within the diaphragm to enhance its strength and longevity. This property is particularly important in high-pressure applications where increased durability is required. Buyers should evaluate whether reinforced diaphragms are necessary for their specific applications to ensure optimal performance.

What Are Common Trade Terms in the Fuel Pump Diaphragm Market?

Familiarity with industry jargon is essential for effective communication and negotiation in the B2B marketplace. Here are some common trade terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts that are used in another company’s end product. Understanding OEM specifications is crucial when sourcing diaphragm materials, as these components must meet specific quality and performance standards defined by the original manufacturer.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for buyers as it affects inventory management and cash flow. Understanding MOQ helps in planning purchases and can influence negotiations with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products or services. It is a critical step in the procurement process, enabling buyers to gather competitive pricing and assess supplier capabilities.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers regarding the delivery of goods. Familiarity with these terms can help buyers avoid misunderstandings about shipping costs, insurance, and liability during transportation.

5. Lead Time

Lead time is the amount of time it takes from placing an order to receiving the product. Understanding lead times is essential for supply chain planning and inventory management, especially in regions where delays may be common due to logistical challenges.

6. Certification

Certification refers to the verification that products meet specific industry standards or regulations. Certifications can include quality assurance, environmental compliance, and safety standards. Buyers should prioritize sourcing diaphragm materials that have the necessary certifications to ensure compliance and reliability in their applications.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that enhance the performance and reliability of their fuel pump systems.

Navigating Market Dynamics and Sourcing Trends in the fuel pump diaphragm material Sector

What Are the Current Market Dynamics and Key Trends in Fuel Pump Diaphragm Material Sourcing?

The fuel pump diaphragm material sector is experiencing notable shifts driven by several global factors. Increased demand for fuel efficiency and stringent environmental regulations are pushing manufacturers to seek advanced materials that can withstand harsh conditions and fuel compositions, including biofuels and ethanol blends. In regions like Africa and South America, rapid urbanization and a growing automotive sector are leading to heightened demand for fuel pumps, thus influencing sourcing strategies.

Emerging technologies such as 3D printing and advanced composite materials are revolutionizing the manufacturing processes, allowing for custom solutions that cater to specific performance requirements. B2B buyers are increasingly leveraging digital platforms for procurement, allowing them to access a broader range of suppliers and materials. This digital shift is particularly evident in Europe and the Middle East, where e-commerce and online marketplaces are becoming essential for sourcing components. As buyers seek to optimize costs and enhance supply chain resilience, partnerships with local suppliers are gaining importance, particularly in regions with logistical challenges.

Illustrative image related to fuel pump diaphragm material

How Does Sustainability and Ethical Sourcing Impact the Fuel Pump Diaphragm Material Market?

The environmental impact of manufacturing processes is a critical concern for today’s B2B buyers. The fuel pump diaphragm material sector is responding to this challenge by prioritizing sustainability and ethical sourcing. Companies are increasingly adopting materials that meet green certifications, such as those compliant with FDA, NSF, and other international standards, ensuring that products are safe and environmentally friendly.

The use of recycled and bio-based materials is on the rise, as manufacturers recognize the importance of reducing their carbon footprint. For instance, elastomers like Nitrile (NBR) and Fluoroelastomers (FKM) are being produced with eco-friendly practices, enhancing their appeal to environmentally conscious buyers. Furthermore, establishing transparent supply chains is vital; buyers are encouraged to engage with suppliers who prioritize ethical practices, such as fair labor conditions and responsible sourcing of raw materials. This focus not only enhances brand reputation but also aligns with the growing consumer preference for sustainable products.

What Is the Historical Context of Fuel Pump Diaphragm Material Development?

The evolution of fuel pump diaphragm materials reflects the ongoing advancements in materials science and engineering. Initially, simple rubber compounds dominated the market, which were limited in their resistance to various fuels and environmental conditions. Over the decades, the introduction of synthetic materials, such as Nitrile and Viton, marked significant improvements in performance, allowing diaphragms to withstand more aggressive fuel compositions and environmental factors.

Illustrative image related to fuel pump diaphragm material

As the automotive industry evolved, so did the demand for higher efficiency and reliability, prompting manufacturers to innovate further. The development of composite diaphragms, which incorporate fabric reinforcement for added durability, represents a significant leap forward. Today, the market is characterized by a diverse array of high-performance materials tailored to meet specific application requirements, reflecting both technological advancements and changing regulatory landscapes. This historical context underscores the importance of ongoing research and development in maintaining competitive advantages in the fuel pump diaphragm material sector.

Frequently Asked Questions (FAQs) for B2B Buyers of fuel pump diaphragm material

-

How do I solve sourcing issues for fuel pump diaphragm materials?

To address sourcing challenges for fuel pump diaphragm materials, start by identifying reliable suppliers with a proven track record in your region. Utilize platforms like Alibaba or industry-specific directories to connect with manufacturers. Engage in direct communication to clarify specifications, material types (like NBR or Viton), and certifications. Additionally, consider attending trade shows or industry expos to meet suppliers face-to-face, which can enhance trust and facilitate negotiations. -

What is the best material for fuel pump diaphragms?

The best material for fuel pump diaphragms largely depends on the application and the type of fuel being handled. Nitrile rubber (NBR) is commonly preferred for its excellent resistance to fuels and oils, while Viton offers superior chemical resistance and durability in extreme conditions. For specialized applications, consider reinforced materials to enhance longevity. Always assess compatibility with the fuel type to prevent premature failure. -

What are the minimum order quantities (MOQs) for fuel pump diaphragm materials?

Minimum order quantities for fuel pump diaphragm materials can vary significantly based on the supplier and material type. Many manufacturers set MOQs ranging from 100 to 1,000 units to ensure cost-effectiveness. It’s advisable to discuss your specific needs with suppliers, as they may offer flexibility for first-time buyers or smaller businesses. Always clarify MOQs early in negotiations to align expectations. -

What payment terms should I expect when sourcing internationally?

Payment terms for international transactions can differ based on the supplier’s policies and the buyer’s negotiation. Common options include letters of credit, advance payment, or net terms (e.g., net 30 or net 60 days). For first-time orders, suppliers may require partial upfront payments. It’s crucial to establish clear payment terms in the contract to avoid misunderstandings and ensure a smooth transaction. -

How can I ensure quality assurance in fuel pump diaphragm materials?

To ensure quality assurance, request samples from potential suppliers before placing bulk orders. Look for suppliers who provide certifications for their materials, such as ISO or ASTM standards. Establish a quality control process that includes inspections upon receipt and periodic checks during production. Collaborating with suppliers that have in-house testing facilities can also enhance confidence in the quality of the diaphragm materials. -

What logistics considerations should I keep in mind when importing fuel pump diaphragm materials?

When importing fuel pump diaphragm materials, consider shipping methods, customs clearance procedures, and lead times. Air freight is faster but more expensive, while sea freight is cost-effective for larger shipments. Ensure that the supplier provides all necessary documentation for customs, including invoices and certificates of origin. Familiarize yourself with local import regulations to avoid delays and additional costs. -

How do I evaluate suppliers for fuel pump diaphragm materials?

Evaluating suppliers involves assessing their experience, reputation, and product quality. Research online reviews, request references, and check their compliance with industry standards. It’s beneficial to visit the supplier’s facility if possible or engage in video calls to gauge their operations. Consider suppliers who offer flexibility in customization and responsiveness to your specific needs, as this can indicate a commitment to customer satisfaction. -

What customization options are available for fuel pump diaphragm materials?

Many suppliers offer customization options for fuel pump diaphragm materials, including variations in size, thickness, and material composition. Discuss your specific requirements with potential suppliers, including any unique environmental or operational conditions the diaphragms must withstand. Custom designs may also be available for specialized applications, ensuring that the diaphragms meet performance standards for your particular use case.

Top 5 Fuel Pump Diaphragm Material Manufacturers & Suppliers List

1. B BOAT AND OUTBOARD – Nitrile Nylon Diaphragm Fuel Pump

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“Product Name”:”Nitrile Nylon Diaphragm Fuel Pump Material”,”Compatible Fluids”:”Petrol, Diesel, Oil, Solvents”,”Thickness”:”0.5mm”,”Condition”:”New”,”Seller”:”B BOAT AND OUTBOARD”,”Price”:”GBP 6.59 (approx US $8.93)”,”Shipping Cost”:”GBP 9.85 (approx US $13.35)”,”Shipping Method”:”Royal Mail International Tracked”,”Location”:”Nelson, United Kingdom”,”Delivery Estimate”:”Between Sat, Sep 27 and M…

2. Diaphragm Fuel Pump – Durable Rubber Materials

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Diaphragm fuel pump, compatible rubber materials: Nitrile, Viton, Kalrez. Avoid EPDM/EPR due to swelling. Durometer ratings: Viton commonly available at 75A, Buna available in 40A, 50A, or 65A. Need for durability and gasoline compatibility.

3. PSG Dover – Diaphragm Materials and Designs

Domain: psgdover.com

Registered: 2011 (14 years)

Introduction: Diaphragm Materials: Thermoplastic Elastomers (TPE), Polytetrafluoroethylene Elastomers (PTFE), Rubber Elastomers. Diaphragm Designs: Chem-Fuse IPD, Pure-Fuse IPD, EZ-Install Diaphragm, Full-Stroke PTFE Diaphragm, Reduced-Stroke PTFE Diaphragm, Ultra-Flex™ Diaphragm, Traditional AODD Diaphragm.

4. The Rubber Company – Ultra-Thin Nitrile Coated Nylon

Domain: therubbercompany.com

Registered: 2013 (12 years)

Introduction: {‘item_code’: ‘RC0328-CO’, ‘key_features’: [‘High quality material’, ‘Ultra-thin form factor’, ‘Excellent mineral oil resistance’, ‘Excellent resistance against petroleum’, ‘Highly durable material’, ‘Strong & flexible’, ‘Easy to cut to size’], ‘product_description’: ‘Our thin nitrile coated nylon diaphragm sheeting is a high-quality material that combines excellent resistance with durable physica…

5. Rubber Tools – Fuel Pump Diaphragms

Domain: rubber-tools.com

Registered: 2022 (3 years)

Introduction: Fuel pump diaphragms are critical components in fuel systems, made from various rubber materials such as EPDM, Viton, and Nitrile rubber.

Key Technical Features:

– EPDM: Temperature Range -40°C to 120°C, Moderate Chemical Resistance, Good Durability, Low Cost.

– Viton: Temperature Range -20°C to 200°C, Excellent Chemical Resistance, Excellent Durability, High Cost.

– Nitrile: Temperature Range -…

Strategic Sourcing Conclusion and Outlook for fuel pump diaphragm material

In the complex landscape of fuel pump diaphragm materials, strategic sourcing emerges as a critical factor for international B2B buyers. By understanding the diverse material options—such as nitrile rubber, Viton, and reinforced elastomers—businesses can make informed decisions that enhance durability, performance, and cost-effectiveness. Key insights reveal that sourcing materials from reputable suppliers ensures compliance with international standards and mitigates risks associated with low-quality alternatives.

For buyers in Africa, South America, the Middle East, and Europe, establishing relationships with manufacturers who offer tailored solutions can lead to significant operational efficiencies. Collaborating with experts who provide comprehensive testing and validation services is essential for ensuring that the diaphragms meet specific application requirements.

As the demand for high-performance fuel pump diaphragms continues to grow, now is the time for businesses to reevaluate their sourcing strategies. Embrace innovation and leverage advanced materials to stay competitive in the marketplace. By prioritizing quality and reliability, companies can secure a sustainable future in fuel pump technology. Take action today—connect with leading suppliers and explore the possibilities of enhancing your product offerings through strategic sourcing.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.