How to Source Fractional Motor Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for fractional motor

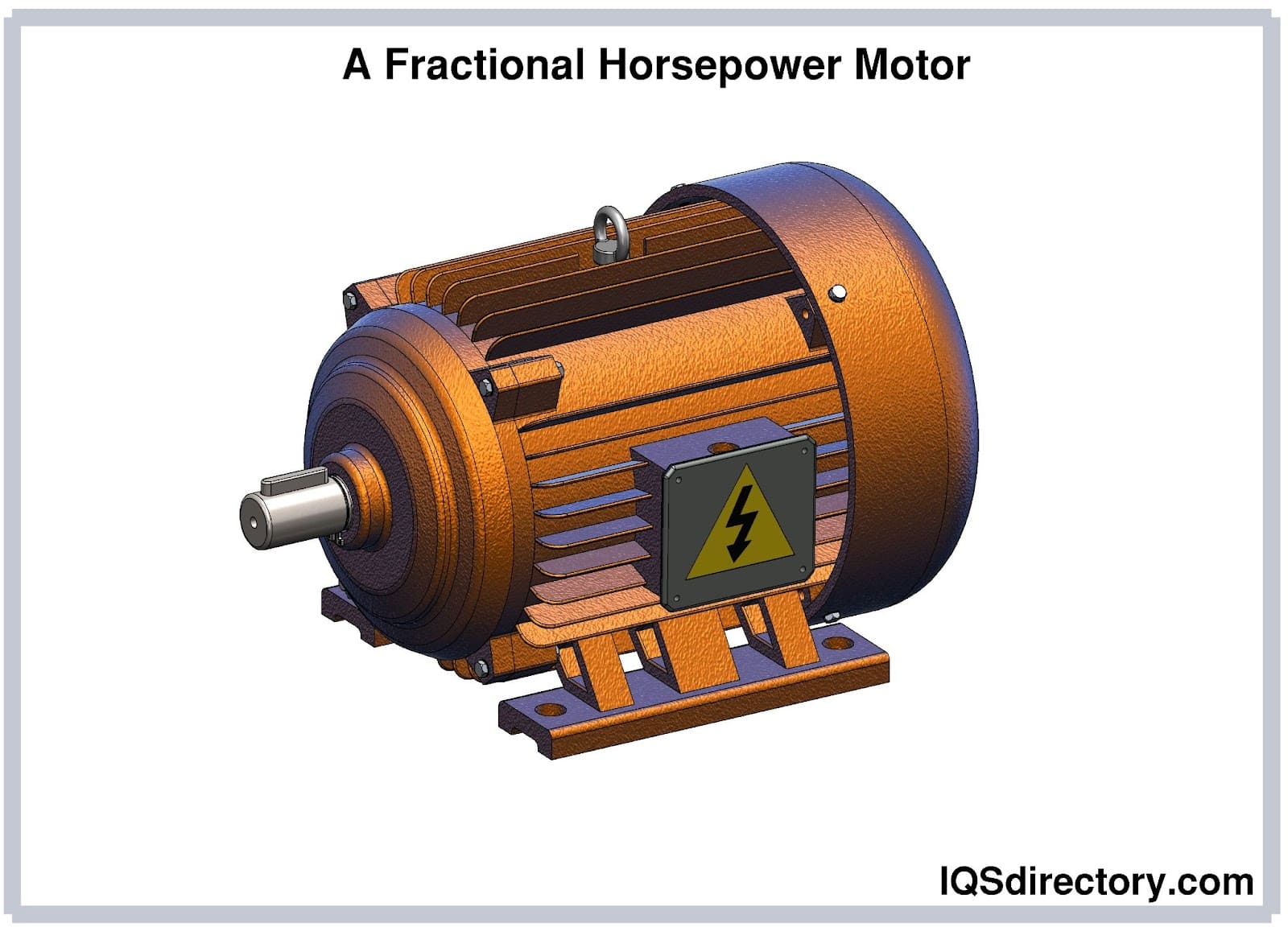

Navigating the global market for fractional motors can be a daunting task for international B2B buyers, particularly those hailing from diverse regions like Africa, South America, the Middle East, and Europe. With the increasing demand for efficient, compact power solutions, sourcing the right fractional motor—those delivering less than one horsepower—requires a strategic approach. This guide is designed to demystify the complexities of fractional motors, covering essential aspects such as types, applications, supplier vetting, and cost considerations.

Understanding the nuances of fractional motors is crucial for businesses aiming to enhance their operational efficiency. These motors are pivotal in a myriad of applications, from industrial automation and automotive systems to medical devices and consumer electronics. By providing insights into the various designs, including permanent magnet and wound field options, this guide empowers buyers to make informed decisions that align with their specific needs.

Moreover, we will explore best practices for evaluating suppliers, ensuring that you partner with reliable manufacturers capable of delivering quality products that meet international standards. With actionable insights and expert recommendations, this guide equips B2B buyers with the tools necessary to navigate the competitive landscape of fractional motors, ultimately facilitating successful procurement strategies that drive business growth in today’s dynamic market.

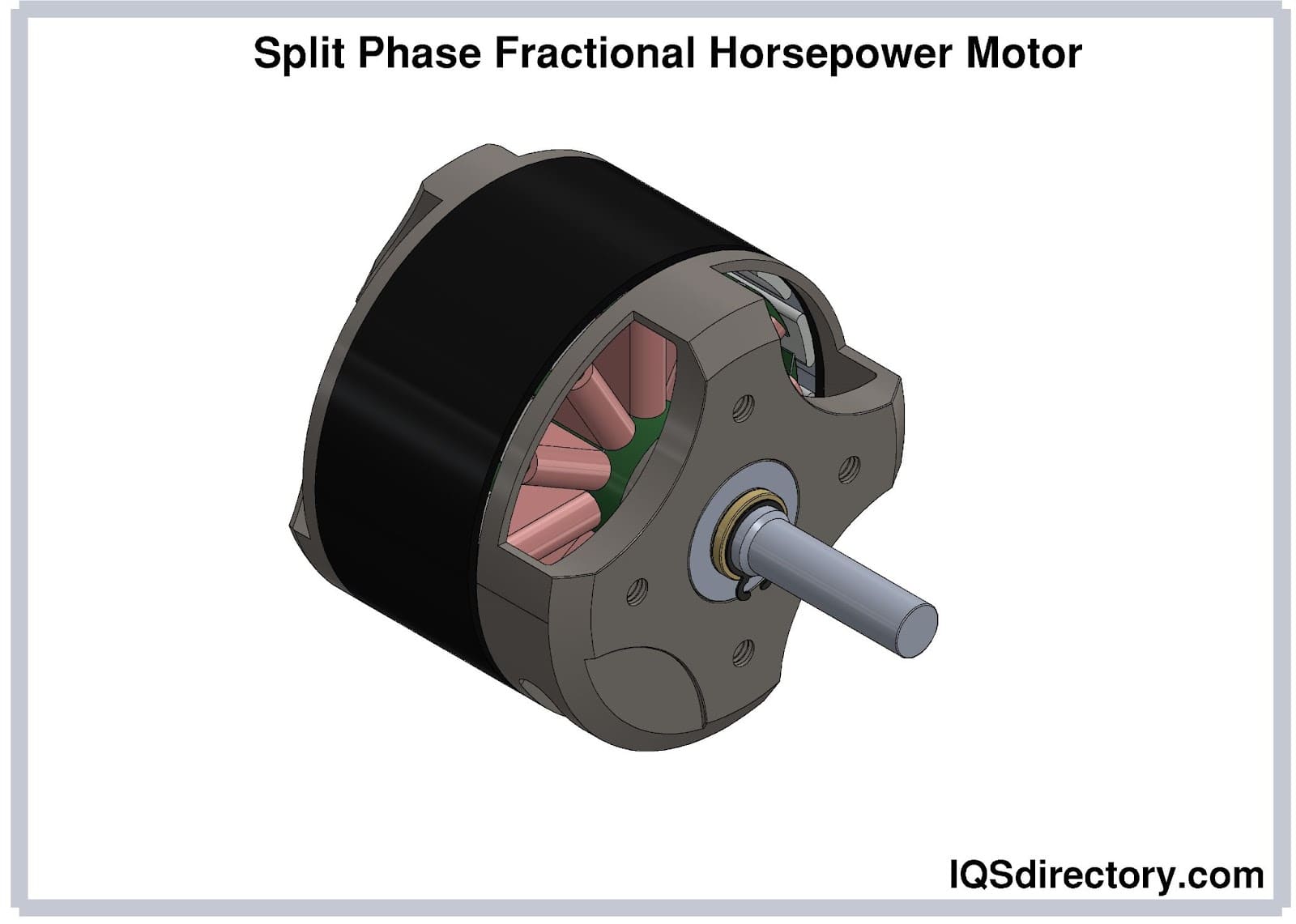

Understanding fractional motor Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Permanent Magnet Motors | High efficiency, compact size, and low maintenance | Robotics, HVAC systems, medical devices | Pros: Energy-efficient, quiet operation. Cons: Limited torque at high speeds. |

| Wound Field Motors | Adjustable speed, robust design | Packaging machinery, conveyors | Pros: High torque, versatile applications. Cons: Bulkier, may require more maintenance. |

| Universal Motors | Operate on AC and DC, cost-effective | Automotive systems, consumer electronics | Pros: Versatile, reliable performance. Cons: Lower efficiency compared to specialized motors. |

| Gear Motors | Integrated gear reduction for higher torque | Industrial automation, conveyor systems | Pros: Enhanced torque output, compact design. Cons: More complex, potential for gear wear. |

| Brushless DC Motors | High efficiency, low noise, longer lifespan | Electric vehicles, drones, HVAC applications | Pros: Minimal maintenance, precise control. Cons: Higher initial cost, requires specialized controllers. |

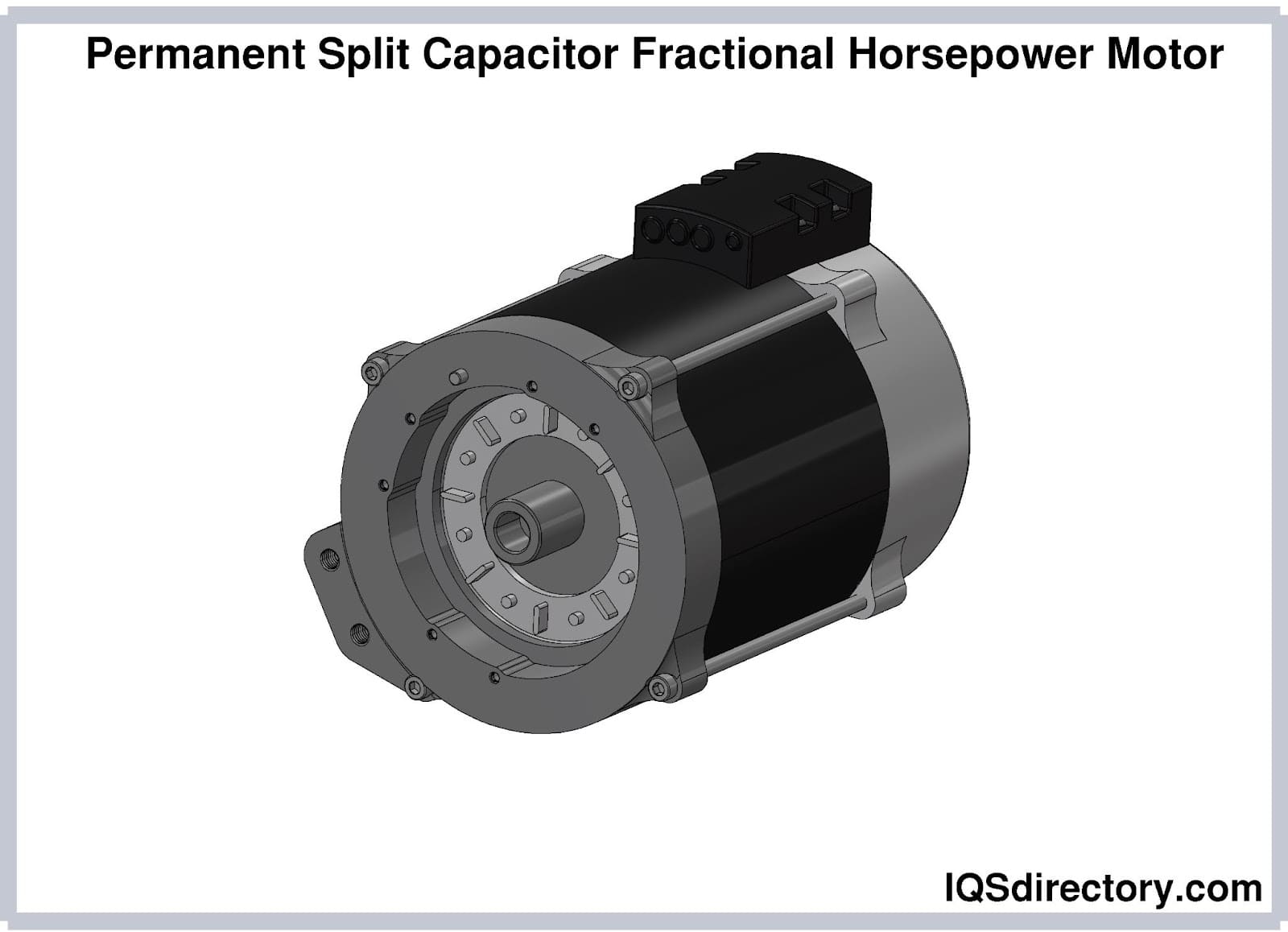

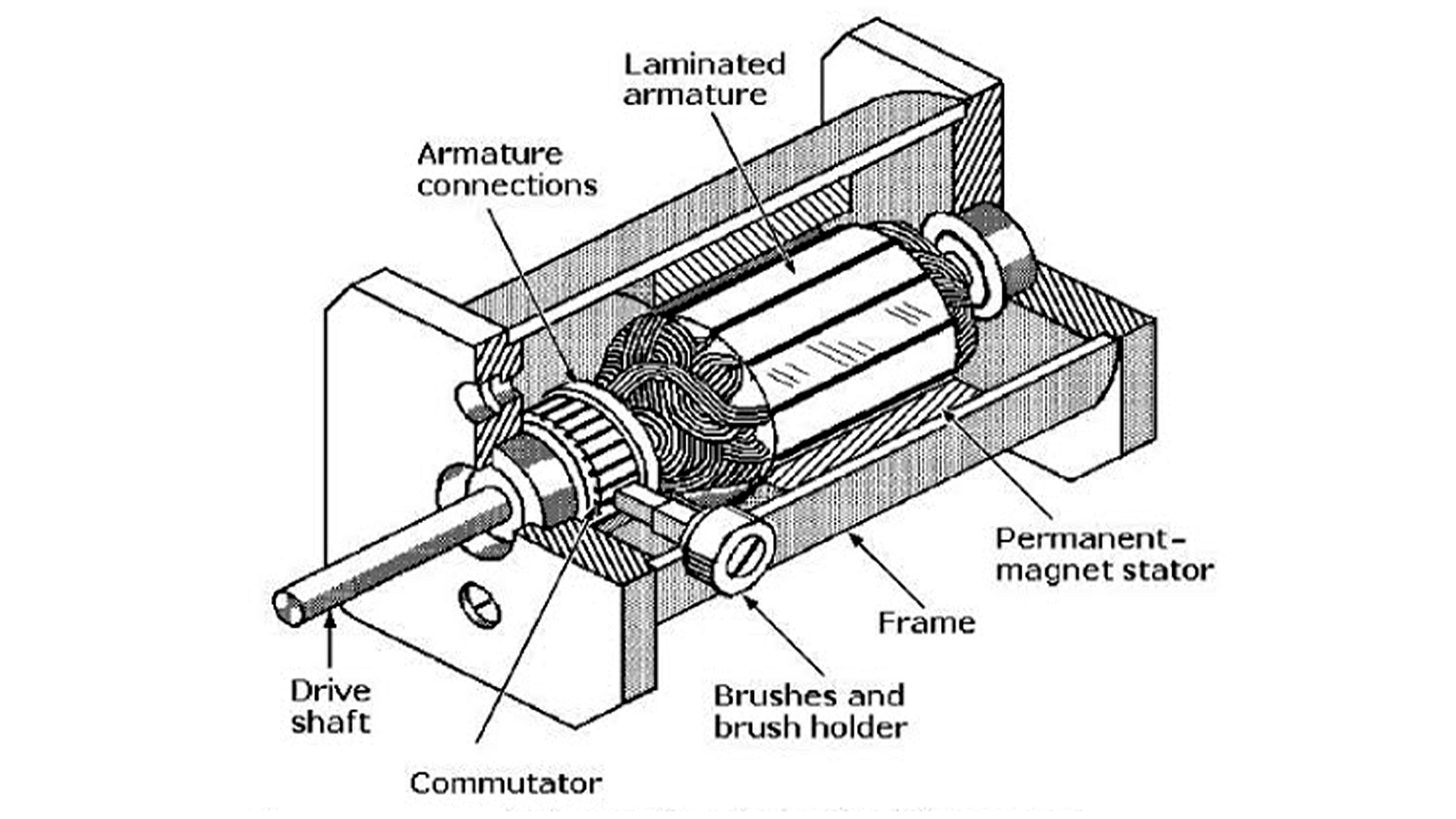

What are the Characteristics of Permanent Magnet Motors?

Permanent magnet motors are known for their compact size and high efficiency. They utilize permanent magnets to generate a magnetic field, resulting in lower energy consumption and reduced maintenance needs. These motors are particularly suitable for applications requiring consistent performance with minimal noise, such as in HVAC systems and medical devices. When purchasing, buyers should consider the motor’s power rating, efficiency class, and compatibility with existing systems to ensure optimal performance.

How Do Wound Field Motors Differ from Other Types?

Wound field motors feature a design that allows for adjustable speed operation, making them versatile for various applications like packaging machinery and conveyors. Their robust construction provides high torque, which is beneficial for heavy-duty tasks. However, they can be bulkier than other fractional motors and may require more maintenance. Buyers should evaluate their specific application needs, including load requirements and environmental conditions, to determine the best fit.

What Makes Universal Motors a Popular Choice?

Universal motors are unique in their ability to operate on both AC and DC power, making them highly versatile and cost-effective for various applications, including automotive systems and consumer electronics. They are compact and provide reliable performance but can be less efficient than specialized motors. B2B buyers should assess the operational environment and load demands to choose the right universal motor, balancing cost and efficiency.

In What Scenarios are Gear Motors the Best Option?

Gear motors combine a motor with a gearbox, providing enhanced torque output for applications such as industrial automation and conveyor systems. Their compact design makes them ideal for situations where space is limited, but they can be more complex and susceptible to gear wear over time. Buyers should consider the required torque and speed for their application while ensuring that the gear motor’s design meets their operational requirements.

Why Choose Brushless DC Motors for Advanced Applications?

Brushless DC motors are recognized for their high efficiency, low noise, and longer lifespan compared to traditional motors. They are ideal for high-tech applications such as electric vehicles and drones, where precision control is crucial. However, they often come with a higher initial cost and require specialized controllers. When purchasing, B2B buyers should weigh the long-term benefits of reduced maintenance and energy efficiency against the upfront investment to determine the best option for their needs.

Key Industrial Applications of fractional motor

| Industry/Sector | Specific Application of Fractional Motor | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Industrial Automation | Conveyor Systems | Enhances operational efficiency and reduces downtime | Reliability, torque specifications, and speed control |

| Automotive | Power Windows and HVAC Systems | Improves user comfort and system reliability | Compact design, energy efficiency, and noise levels |

| Medical Devices | Infusion Pumps and Dental Equipment | Ensures precision and patient safety | Regulatory compliance, low power consumption, and durability |

| HVAC | Fans and Compressors | Optimizes energy usage and air quality | Energy efficiency ratings, load capacity, and size constraints |

| Consumer Appliances | Washing Machines and Kitchen Mixers | Increases consumer satisfaction through performance | Noise levels, size, and ease of integration |

How Are Fractional Motors Used in Industrial Automation?

In industrial automation, fractional motors are integral to conveyor systems, driving the movement of goods and materials efficiently. Their compact size and adaptability allow for seamless integration into existing machinery, ensuring minimal disruption during upgrades. Businesses benefit from reduced downtime and increased throughput, as these motors provide reliable performance under varying load conditions. International buyers must consider sourcing motors with the appropriate torque and speed control features to meet specific operational demands.

What Role Do Fractional Motors Play in the Automotive Sector?

In the automotive industry, fractional motors power essential components such as power windows, seat adjustments, and HVAC systems. Their small size and efficiency enhance vehicle functionality while contributing to user comfort and safety. For international buyers, selecting motors that meet specific voltage requirements and environmental standards is crucial. Additionally, understanding the expected lifespan and maintenance needs of these motors can help ensure long-term reliability in automotive applications.

How Are Fractional Motors Essential in Medical Devices?

Fractional motors are critical in medical devices, including infusion pumps and dental equipment, where precision and reliability are paramount. These motors facilitate accurate dosing and operation of medical machinery, thereby improving patient outcomes. Buyers in the medical sector must prioritize motors that comply with stringent regulatory standards and offer low power consumption. Durability and quiet operation are also significant considerations, ensuring that devices function effectively in sensitive healthcare environments.

Why Are Fractional Motors Important in HVAC Systems?

In HVAC applications, fractional motors are used to power fans and compressors, playing a vital role in maintaining air quality and temperature control. Their energy efficiency helps reduce operational costs, making them an attractive option for businesses looking to optimize their HVAC systems. International buyers should focus on sourcing motors that can handle varying load capacities and have favorable energy efficiency ratings. Additionally, size and noise levels are essential factors that influence the choice of motors in HVAC installations.

How Do Fractional Motors Enhance Consumer Appliances?

Fractional motors are widely utilized in consumer appliances like washing machines and kitchen mixers, where they provide reliable and efficient operation. Their compact design allows for space-saving solutions in home devices, while low noise output enhances user experience. For B2B buyers in the consumer goods sector, factors such as ease of integration, performance specifications, and reliability are crucial. Ensuring that sourced motors meet consumer expectations for quality and durability can significantly impact market success.

3 Common User Pain Points for ‘fractional motor’ & Their Solutions

Scenario 1: Inconsistent Performance in Machinery Applications

The Problem: B2B buyers often face challenges with fractional motors that lead to inconsistent performance in machinery applications. For instance, a manufacturing company may notice that the motors powering their conveyors or packaging equipment are unable to maintain a constant speed under varying loads. This inconsistency can cause bottlenecks in production, leading to delayed deliveries and increased operational costs. Moreover, fluctuating speeds can result in product defects, impacting quality control and customer satisfaction.

The Solution: To address this issue, buyers should prioritize the selection of fractional motors with adjustable speed control capabilities. Implementing a closed-loop control system that includes a tachometer can help maintain consistent speed across different loads. When sourcing fractional motors, look for models specifically designed for variable speed applications, ensuring they are compatible with the existing control systems in place. Additionally, consider conducting load testing to determine the most suitable motor specifications for the application. Regular maintenance checks can also be instituted to monitor performance and preemptively identify potential issues.

Illustrative image related to fractional motor

Scenario 2: High Energy Consumption and Costs

The Problem: Many businesses are increasingly concerned about their operational costs, particularly those associated with energy consumption. B2B buyers in sectors such as HVAC, automotive, or medical devices may find that their fractional motors are drawing more power than expected, leading to inflated electricity bills. This can be exacerbated by outdated motor designs that lack energy efficiency features, ultimately reducing profit margins and competitiveness in the market.

The Solution: To combat high energy consumption, buyers should consider investing in energy-efficient fractional motors that comply with standards such as NEMA Premium or IEC energy efficiency classifications. When evaluating options, buyers should examine the motor’s efficiency ratings, particularly under typical operational loads. Furthermore, integrating variable frequency drives (VFDs) can optimize the motor’s performance by adjusting the frequency and voltage supplied to the motor, thus significantly reducing energy use during low-demand periods. Regular monitoring of energy consumption patterns can also help identify areas for improvement and validate the effectiveness of the implemented solutions.

Scenario 3: Limited Technical Support and Resources

The Problem: B2B buyers may encounter challenges when sourcing fractional motors due to limited technical support and resources from suppliers. This is particularly true for businesses in emerging markets in regions like Africa or South America, where access to expertise may be limited. Buyers might struggle to find reliable information on installation, maintenance, and troubleshooting, leading to prolonged downtime and increased reliance on external contractors, which adds to costs.

The Solution: To alleviate this pain point, buyers should seek suppliers who offer comprehensive technical support and resources as part of their service package. This includes access to installation guides, maintenance manuals, and responsive customer service teams that can provide real-time assistance. Establishing a partnership with manufacturers that have a proven track record in your industry can also be beneficial. Some suppliers may offer training programs or workshops to empower in-house staff with the knowledge needed to handle common issues. Finally, leveraging online platforms for knowledge sharing and community forums can help buyers connect with other users and industry experts for additional insights and support.

Strategic Material Selection Guide for fractional motor

What Are the Key Materials Used in Fractional Motors?

When selecting materials for fractional motors, it’s essential to consider their properties, advantages, disadvantages, and how they align with specific applications. The right material can significantly impact the motor’s performance, durability, and suitability for various environments. Below, we analyze four common materials used in fractional motors.

1. Steel

Key Properties:

Steel is known for its high tensile strength and durability, making it suitable for components that experience significant mechanical stress. It can withstand high temperatures and has good magnetic properties, which are critical for motor efficiency.

Pros & Cons:

The advantages of steel include its robustness and cost-effectiveness, as it is widely available and relatively inexpensive. However, it is prone to corrosion if not treated or coated, which can lead to failure in humid or corrosive environments. Manufacturing complexity can also increase with the need for additional coatings or treatments.

Impact on Application:

Steel is ideal for applications requiring strength, such as in industrial machinery or automotive systems. However, in environments with high humidity or exposure to chemicals, the risk of corrosion must be managed.

Considerations for International Buyers:

International buyers should ensure compliance with standards such as ASTM A36 for structural steel or DIN 10130 for cold-rolled steel. In regions like Europe and the Middle East, corrosion-resistant coatings may be a requirement.

2. Aluminum

Key Properties:

Aluminum is lightweight, corrosion-resistant, and has good thermal conductivity. It can operate effectively in a range of temperatures and is non-magnetic, which can be beneficial in specific motor designs.

Pros & Cons:

The primary advantage of aluminum is its low weight, which can enhance the efficiency of fractional motors. However, it is generally less durable than steel and can be more expensive. Manufacturing processes for aluminum can also be more complex, requiring specialized techniques.

Impact on Application:

Aluminum is particularly suitable for applications in consumer electronics and HVAC systems, where weight reduction is crucial. Its corrosion resistance makes it a good choice for environments with high moisture levels.

Considerations for International Buyers:

Buyers in regions like South America and Europe should be aware of standards such as ASTM B221 for aluminum extrusions. Additionally, the availability of aluminum may vary by region, influencing lead times and costs.

3. Copper

Key Properties:

Copper is an excellent conductor of electricity and has good thermal conductivity. It is also resistant to corrosion, particularly in dry environments, making it a popular choice for windings and electrical connections in motors.

Pros & Cons:

The key advantage of copper is its superior electrical conductivity, which enhances motor efficiency. However, copper is relatively expensive compared to aluminum and steel, and its weight can be a disadvantage in applications where lightweight components are preferred.

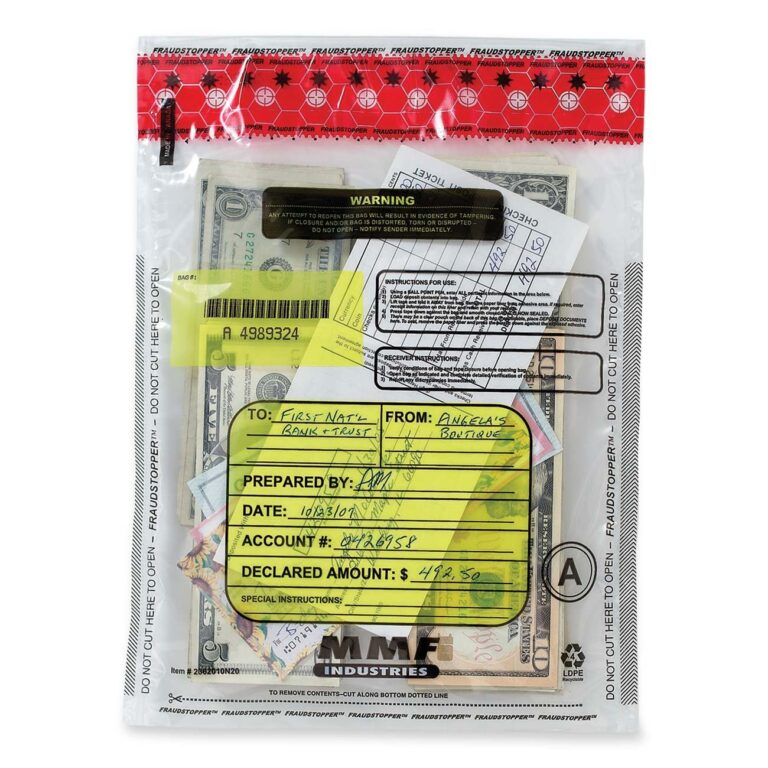

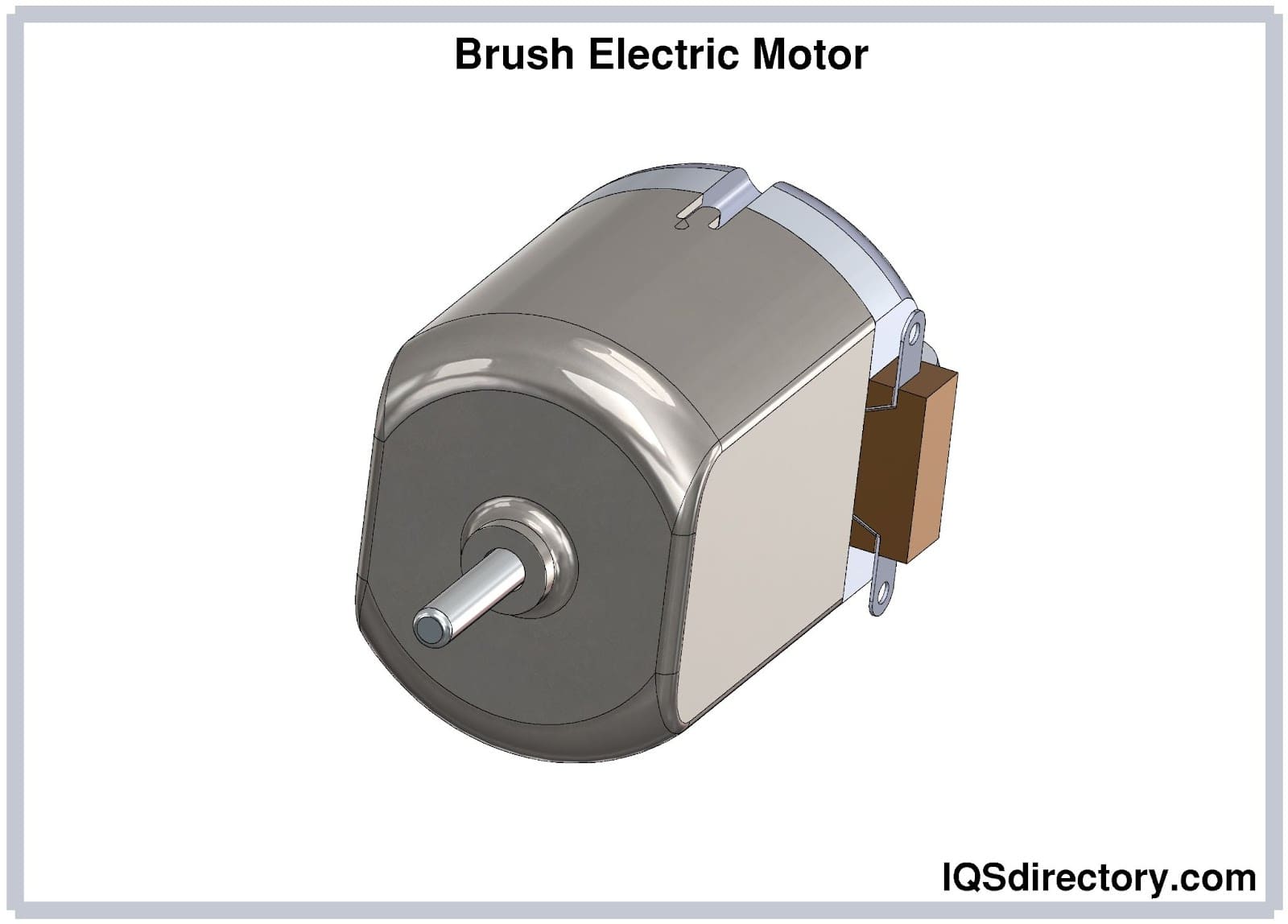

Illustrative image related to fractional motor

Impact on Application:

Copper is essential for electrical components in fractional motors, ensuring efficient power transfer in applications like automotive systems and industrial machinery. However, its weight may limit its use in lightweight designs.

Considerations for International Buyers:

Compliance with standards such as ASTM B170 for copper wire is crucial. Buyers should also consider regional pricing fluctuations, especially in markets like Europe and the Middle East, where copper prices can be volatile.

4. Plastic Composites

Key Properties:

Plastic composites are lightweight, corrosion-resistant, and can be engineered for specific thermal and electrical properties. They are versatile and can be molded into complex shapes.

Pros & Cons:

The advantages of plastic composites include their lightweight nature and resistance to corrosion, making them suitable for various applications. However, they may not withstand high temperatures as well as metals and can have lower mechanical strength.

Impact on Application:

Plastic composites are ideal for applications in consumer electronics and medical devices, where weight and corrosion resistance are critical. However, they may not be suitable for high-stress mechanical components.

Illustrative image related to fractional motor

Considerations for International Buyers:

Buyers should ensure compliance with relevant standards such as ASTM D638 for tensile properties of plastics. In regions like Africa and South America, availability and cost can vary significantly.

Summary Table of Material Selection for Fractional Motors

| Material | Typical Use Case for fractional motor | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Industrial machinery, automotive systems | High strength and durability | Prone to corrosion | Low |

| Aluminum | Consumer electronics, HVAC systems | Lightweight and corrosion-resistant | Less durable than steel | Medium |

| Copper | Electrical components in motors | Superior electrical conductivity | Higher cost and weight | High |

| Plastic Composites | Medical devices, consumer electronics | Lightweight and corrosion-resistant | Lower mechanical strength | Medium |

This material selection guide provides a comprehensive overview of common materials used in fractional motors, helping international B2B buyers make informed decisions that align with their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for fractional motor

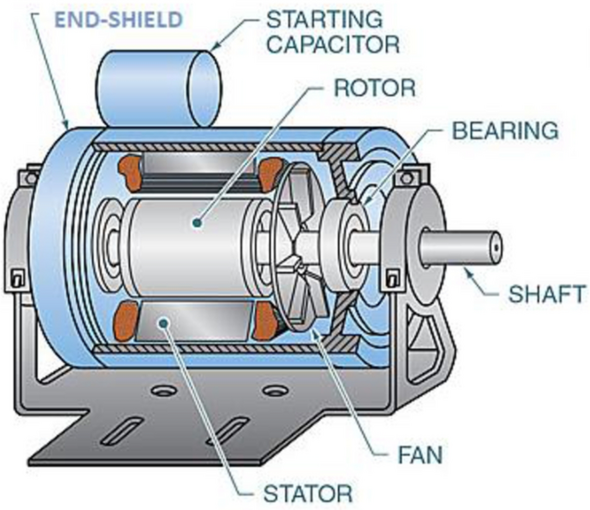

What Are the Main Stages of Manufacturing Fractional Motors?

The manufacturing process of fractional motors is a complex procedure that involves several key stages, each critical for ensuring that the final product meets performance and quality standards.

1. Material Preparation

The journey begins with the selection and preparation of raw materials. Common materials include copper for windings, various grades of steel for the motor frame, and specialized plastics for insulation. Suppliers must ensure that all materials comply with relevant international standards, such as ISO 9001 for quality management systems. Material testing is often performed to verify electrical and mechanical properties before moving to the next stage.

2. Forming and Machining

Once materials are prepared, the next phase involves forming and machining. This includes processes such as stamping, machining, and molding. Stamping is used to create the motor’s stator and rotor components, while precision machining ensures that all parts fit together accurately. Advanced techniques like CNC (Computer Numerical Control) machining are employed to enhance precision and reduce waste, thus contributing to overall efficiency.

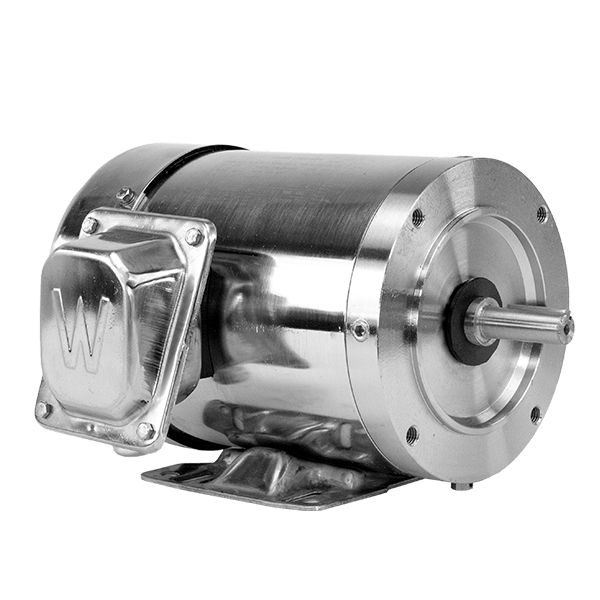

Illustrative image related to fractional motor

3. Assembly

The assembly stage is where the individual components come together. This typically involves several sub-processes, including winding the coils, attaching the rotor to the stator, and securing the motor housing. In this phase, automated assembly lines are often utilized to improve speed and reduce human error. Moreover, skilled technicians oversee the assembly to ensure that each motor is constructed according to specifications.

4. Finishing Processes

After assembly, fractional motors undergo finishing processes that may include painting, coating, and the application of labels. These steps not only enhance the aesthetic appeal of the motors but also provide essential protective layers against environmental factors. Quality checks are conducted at this stage to ensure that the finishing meets industry standards.

How Is Quality Assurance Implemented in Fractional Motor Manufacturing?

Quality assurance (QA) is a critical aspect of fractional motor production, ensuring that each motor meets stringent performance and reliability standards.

What Are the Relevant International Standards for Fractional Motors?

Manufacturers of fractional motors often adhere to various international and industry-specific standards. ISO 9001 is the most recognized quality management standard, ensuring that processes meet customer and regulatory requirements. In addition, compliance with CE marking indicates that the product meets European safety, health, and environmental protection standards. Other standards, such as API for pumps and motors used in oil and gas applications, may also apply depending on the motor’s intended use.

What Are the Key QC Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established at various stages of the manufacturing process to identify defects early. These checkpoints typically include:

-

Incoming Quality Control (IQC): This involves the inspection of raw materials and components before they enter the production line. Suppliers must provide certificates of conformity to verify that materials meet required specifications.

-

In-Process Quality Control (IPQC): At this stage, random samples are taken during the manufacturing process to monitor for deviations from standards. This can involve testing for electrical resistance, mechanical integrity, and dimensional accuracy.

-

Final Quality Control (FQC): Once the motors are fully assembled, they undergo comprehensive testing to ensure they function as intended. This may include performance tests under load, thermal testing, and noise level assessments.

What Common Testing Methods Are Used for Fractional Motors?

Testing is an integral part of the quality assurance process for fractional motors. Common testing methods include:

-

Electrical Testing: This involves checking insulation resistance, winding resistance, and power factor. These tests are crucial for ensuring that the motor operates efficiently and safely.

-

Performance Testing: Motors are subjected to operational tests to evaluate speed, torque, and efficiency under load conditions. This helps verify that the motor meets its design specifications.

-

Environmental Testing: Motors may also undergo tests simulating real-world conditions, such as temperature extremes and humidity, to ensure reliability in diverse environments.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, especially those operating in Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is essential for ensuring product reliability.

What Audits and Reports Should Buyers Request?

Buyers should request detailed quality assurance reports, including results from IQC, IPQC, and FQC stages. Additionally, conducting regular audits of suppliers can provide insights into their manufacturing processes and adherence to quality standards. Third-party audits can also offer an unbiased assessment of a supplier’s capabilities.

How Do QC and Certification Nuances Affect International Trade?

When engaging with international suppliers, it is crucial to understand the nuances of QC and certification processes. Different regions may have varying standards and regulatory requirements. For instance, a motor certified in Europe may require additional testing to meet standards in the Middle East or Africa. Buyers should ensure that their suppliers can provide all necessary certifications and documentation relevant to their specific market.

Conclusion

The manufacturing processes and quality assurance practices for fractional motors are intricate and vital for ensuring product reliability and performance. By understanding these processes, B2B buyers can make informed decisions when selecting suppliers, ultimately leading to successful partnerships and enhanced operational efficiency. A thorough approach to verifying quality control not only safeguards investments but also fosters trust and collaboration in international markets.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘fractional motor’

To assist international B2B buyers in procuring fractional motors effectively, this checklist outlines essential steps to ensure you select the right product and supplier for your specific needs. Fractional motors are critical components across various industries, and making informed decisions can significantly impact operational efficiency and costs.

Illustrative image related to fractional motor

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, it’s vital to establish clear technical specifications for the fractional motors you require. Determine factors such as power rating (typically below one horsepower), frame size, voltage requirements, and intended applications. This clarity will help you communicate effectively with suppliers and ensure that the motors meet your operational needs.

Step 2: Research and Identify Potential Suppliers

Compile a list of manufacturers and suppliers known for producing high-quality fractional motors. Focus on companies with a solid reputation in your industry and geographic region. Utilize online directories, industry forums, and trade shows to gather information on potential partners. Look for suppliers with experience in your specific application area, such as HVAC, automotive, or medical devices.

Step 3: Evaluate Supplier Certifications and Compliance

Verify that potential suppliers comply with relevant industry standards and regulations. This may include certifications like ISO 9001 for quality management or CE marking for compliance with European safety standards. Ensuring that suppliers adhere to these standards can mitigate risks associated with product quality and reliability.

Step 4: Assess Product Quality and Performance

Request samples or detailed product specifications from shortlisted suppliers to evaluate the quality of their fractional motors. Consider key performance indicators such as efficiency, durability, and noise levels. If possible, conduct performance tests to ensure the motors meet your operational expectations and standards.

Step 5: Request Quotes and Compare Pricing

Once you have a clear understanding of your requirements and have shortlisted suppliers, request detailed quotations. Ensure that the quotes include all relevant costs, such as shipping, taxes, and any applicable tariffs. Comparing pricing alongside the quality and specifications will help you make an informed decision that balances cost and performance.

Illustrative image related to fractional motor

Step 6: Check References and Customer Feedback

Before finalizing your supplier choice, seek references from other companies that have previously purchased fractional motors from the suppliers you are considering. Customer feedback can provide valuable insights into the reliability, service, and support of potential partners. Pay attention to reviews from businesses in similar industries or regions to gauge compatibility.

Step 7: Finalize Terms and Establish Communication

After selecting a supplier, ensure that all terms, including payment schedules, delivery timelines, and warranty conditions, are clearly defined in the contract. Establish a communication plan to maintain ongoing dialogue throughout the procurement process. This proactive approach can help address any issues that arise promptly and strengthen your relationship with the supplier.

By following this structured checklist, B2B buyers can streamline the sourcing process for fractional motors, ensuring that they select the right products and suppliers to meet their operational needs effectively.

Comprehensive Cost and Pricing Analysis for fractional motor Sourcing

What Are the Key Cost Components in Fractional Motor Sourcing?

Understanding the cost structure of fractional motors is essential for B2B buyers aiming to optimize their procurement strategies. The primary cost components include:

-

Materials: The cost of raw materials like copper, aluminum, and various composites used in motor construction significantly influences the overall price. High-quality materials enhance performance but may raise costs.

-

Labor: Labor costs, including wages for skilled technicians and assembly workers, contribute to the manufacturing price. Regions with higher labor costs may see increased prices, impacting sourcing decisions.

-

Manufacturing Overhead: This includes utilities, facility costs, and administrative expenses associated with production. Efficient manufacturing processes can reduce these overheads, translating to more competitive pricing.

-

Tooling: Custom tooling for specific motor designs can incur substantial upfront costs. Buyers requiring specialized motors should factor these costs into their pricing considerations.

-

Quality Control (QC): Rigorous QC processes are vital for ensuring product reliability, especially in critical applications. Enhanced QC measures can increase costs but are essential for maintaining standards.

-

Logistics: Transportation and shipping expenses vary significantly based on the destination. Incoterms (International Commercial Terms) also play a crucial role in determining who bears these costs.

-

Margin: Suppliers typically add a profit margin to cover their operational costs and ensure sustainability. This margin can vary based on market conditions and competition.

How Do Price Influencers Affect Fractional Motor Sourcing?

Several factors can influence the price of fractional motors, which buyers should consider:

-

Volume/MOQ: Purchasing in larger quantities often leads to lower unit prices due to economies of scale. Buyers should assess their needs carefully to negotiate favorable terms.

-

Specifications and Customization: Custom motors with specific requirements can incur additional costs. Buyers should be clear about their specifications to avoid unexpected pricing changes.

-

Material Quality and Certifications: Higher quality materials and compliance with industry standards or certifications can impact pricing. Buyers should weigh the benefits of quality against their budget constraints.

-

Supplier Factors: Supplier reputation, reliability, and location can affect pricing. Established suppliers may charge a premium but can offer better service and quality assurance.

-

Incoterms: Understanding the implications of different Incoterms (e.g., FOB, CIF) is crucial for international buyers. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can affect overall costs.

What Are the Best Buyer Tips for Cost-Efficient Sourcing?

To maximize value when sourcing fractional motors, consider the following strategies:

-

Negotiation: Engage suppliers in open discussions about pricing, especially for bulk orders. Leverage competitive quotes to negotiate better terms.

-

Cost-Efficiency Analysis: Conduct a Total Cost of Ownership (TCO) analysis, factoring in not just the purchase price but also maintenance, energy consumption, and lifespan. This approach helps identify the most cost-effective options over time.

-

Pricing Nuances for International Buyers: Understand the impact of currency fluctuations, import tariffs, and regional market conditions on pricing. Buyers from Africa, South America, the Middle East, and Europe should also consider local supplier partnerships to mitigate risks associated with international logistics.

-

Request Detailed Quotations: Ask suppliers for breakdowns of costs, including materials, labor, and logistics. This transparency can help identify areas for potential savings.

Disclaimer on Indicative Prices

Pricing for fractional motors can vary widely based on the factors mentioned above. It is advisable for buyers to seek multiple quotes and conduct thorough market research to ensure they receive competitive pricing tailored to their specific needs.

Alternatives Analysis: Comparing fractional motor With Other Solutions

In the evolving landscape of industrial machinery and automation, businesses often seek alternatives to fractional motors to meet their specific operational needs. Understanding the advantages and limitations of these alternatives is essential for B2B buyers aiming to optimize performance, cost-effectiveness, and maintenance requirements.

| Comparison Aspect | Fractional Motor | Servo Motor | Stepper Motor |

|---|---|---|---|

| Performance | Reliable for low-power applications; high efficiency | Excellent for precise control; fast response | Good for precise positioning; moderate speed |

| Cost | Generally lower initial investment | Higher upfront costs | Moderate costs, depending on complexity |

| Ease of Implementation | Simple integration in existing systems | Requires more complex setup and tuning | Easier to implement for basic applications |

| Maintenance | Low maintenance needs; durable | Moderate maintenance; requires calibration | Low maintenance but may require periodic checks |

| Best Use Case | Ideal for conveyors, pumps, and small machinery | Best for robotics, CNC machines, and applications needing high precision | Suitable for 3D printers, scanners, and simple automation tasks |

What are the Advantages and Disadvantages of Servo Motors Compared to Fractional Motors?

Servo motors offer superior performance, particularly in applications requiring precise control over speed and position. They excel in environments such as robotics and CNC machinery, where accuracy is paramount. However, the complexity of installation and calibration can deter some businesses, especially those with simpler operational needs. Additionally, servo motors typically carry a higher initial cost, which may not be justifiable for all applications.

How do Stepper Motors Compare to Fractional Motors in Terms of Functionality?

Stepper motors provide reliable precision for applications such as 3D printing and basic automation. They operate by dividing a full rotation into equal steps, allowing for accurate positioning without the need for feedback systems. While they are generally easier to implement than servo motors, stepper motors may not achieve the same speeds and torque as fractional motors in high-demand situations. They also tend to have lower power efficiency, which can lead to higher operational costs over time.

Conclusion: How Should B2B Buyers Choose Between Fractional Motors and Alternatives?

Choosing the right motor solution hinges on specific operational requirements and constraints. B2B buyers should evaluate the performance needs of their applications, considering factors such as precision, speed, and power consumption. Additionally, the total cost of ownership, including initial investment and maintenance, plays a crucial role in decision-making. By carefully assessing these elements against the capabilities of fractional motors and their alternatives, businesses can select the most suitable solution that aligns with their operational goals and budgetary constraints.

Illustrative image related to fractional motor

Essential Technical Properties and Trade Terminology for fractional motor

What Are the Key Technical Properties of Fractional Motors?

Understanding the essential technical specifications of fractional motors is crucial for B2B buyers to make informed purchasing decisions. Here are some of the most critical properties:

1. Power Rating (Horsepower)

Fractional motors are defined by their power output, typically measured in horsepower (HP). Motors with a rating of less than one HP are considered fractional horsepower (FHP) motors. This specification is essential for buyers to ensure the motor can handle the required load in applications such as conveyors, pumps, and fans. Matching the power rating with application demands helps prevent overloading and potential motor failure.

2. Frame Size

The frame size of a fractional motor is a standardized measurement that determines the motor’s physical dimensions and mounting compatibility. Common frame sizes include 42, 48, and 56. Selecting the correct frame size is vital for installation, as it ensures that the motor fits within the designated space and aligns with existing machinery. This factor is especially important for OEMs looking to integrate motors into their products.

3. Voltage and Current Ratings

Fractional motors can operate on various voltage levels, commonly including 90V and 180V for DC motors. The current rating, measured in amperes (A), indicates the amount of electrical current the motor requires to function efficiently. Understanding these ratings is critical for buyers to ensure compatibility with their electrical systems and to avoid issues such as overheating or underperformance.

4. Efficiency Class

Efficiency ratings (e.g., IE1, IE2, IE3) measure how effectively a motor converts electrical energy into mechanical energy. Higher efficiency ratings indicate lower energy consumption and operational costs. For businesses focused on sustainability and cost-effectiveness, selecting a motor with a high efficiency class is essential for reducing long-term expenses and minimizing environmental impact.

5. Speed Control Capabilities

Fractional motors often feature adjustable speed options, which allow for precise control over their operation. This capability is particularly beneficial in applications requiring variable speed, such as mixers and conveyors. Buyers should consider whether they need constant torque or variable speed capabilities, as this will influence motor selection and associated control systems.

Illustrative image related to fractional motor

What Common Trade Terms Should B2B Buyers Know When Purchasing Fractional Motors?

Navigating the procurement process for fractional motors involves understanding specific trade terminology. Here are some key terms that are frequently encountered:

1. OEM (Original Equipment Manufacturer)

An OEM is a company that produces components that are used in another company’s end products. For fractional motors, an OEM may integrate these motors into larger systems or machinery. Understanding OEM relationships can help buyers identify reliable suppliers and partners for their manufacturing needs.

2. MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units that a supplier is willing to sell in a single order. This term is crucial for B2B buyers as it affects inventory management and overall procurement costs. Buyers should clarify the MOQ with suppliers to align their purchasing strategy with production requirements.

3. RFQ (Request for Quotation)

An RFQ is a document that potential buyers use to solicit price quotes from suppliers. It typically includes specifications, quantities, and delivery requirements. Issuing an RFQ allows buyers to compare prices and terms from different suppliers, ensuring they make cost-effective purchasing decisions.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers regarding the delivery of goods. They specify who bears the costs and risks at various stages of transportation. Understanding Incoterms is essential for international B2B transactions, as it helps clarify shipping responsibilities and can impact overall project costs.

Illustrative image related to fractional motor

5. NEMA Standards (National Electrical Manufacturers Association)

NEMA standards provide guidelines for the design and performance of electrical equipment, including fractional motors. Compliance with these standards ensures that motors are reliable, safe, and compatible with industry practices. Buyers should look for NEMA-compliant motors to ensure quality and performance consistency.

By understanding these technical properties and trade terms, B2B buyers can make more informed decisions regarding fractional motors, leading to enhanced operational efficiency and reduced costs in their applications.

Navigating Market Dynamics and Sourcing Trends in the fractional motor Sector

What Are the Current Market Dynamics and Key Trends in the Fractional Motor Sector?

The fractional motor sector is witnessing a transformative phase, driven by advancements in technology and changing market demands. Globally, the increasing need for energy-efficient solutions across industries such as manufacturing, automotive, and healthcare is propelling the demand for fractional horsepower (FHP) motors. In regions like Africa, South America, the Middle East, and Europe, international B2B buyers are particularly focused on sourcing motors that combine reliability with compact design and low power consumption.

Emerging trends indicate a shift towards automation and digitalization, where FHP motors play a crucial role in enhancing operational efficiency. Technologies like IoT and Industry 4.0 are influencing sourcing decisions, as businesses seek motors that can integrate seamlessly with smart systems and provide real-time data analytics. Moreover, there’s a growing emphasis on customization, with buyers looking for motors tailored to specific applications, such as packaging machinery or HVAC systems.

Illustrative image related to fractional motor

Additionally, sustainability is becoming a pivotal concern. Manufacturers are increasingly adopting eco-friendly practices and materials, prompting buyers to consider the environmental footprint of their sourcing decisions. Understanding these dynamics is essential for international buyers who aim to remain competitive and align with global standards.

How Are Sustainability and Ethical Sourcing Reshaping the Fractional Motor Market?

The environmental impact of manufacturing processes is a crucial consideration for today’s B2B buyers. The fractional motor sector is increasingly prioritizing sustainability, with manufacturers exploring innovative materials and methods to reduce emissions and waste. Companies are now more inclined to source motors that utilize energy-efficient designs and sustainable materials, responding to both regulatory pressures and market expectations.

Ethical sourcing is gaining traction as well, with buyers demanding transparency in supply chains. Ensuring that materials are sourced responsibly and that labor practices are ethical not only mitigates risks but also enhances brand reputation. Certifications such as ISO 14001 for environmental management and the use of recyclable materials are becoming essential criteria in the sourcing process.

Buyers should consider partnering with manufacturers who are committed to sustainability and can provide verifiable certifications. This focus not only aligns with corporate social responsibility goals but also meets the growing consumer demand for greener products, ultimately leading to more sustainable business practices.

What Is the Historical Context of Fractional Motors and Its Relevance to Today’s B2B Buyers?

The evolution of fractional motors is closely linked to the advancement of electric power and automation. Nikola Tesla’s invention of the induction motor in 1888 laid the groundwork for the development of fractional horsepower motors. While initial applications were limited, the widespread adoption of electric utilities in the early 20th century saw a surge in the use of FHP motors, particularly in household appliances.

By the mid-20th century, the demand for compact and efficient motors skyrocketed, leading to innovations that enhanced performance and reliability. Today, fractional motors are integral to various sectors, from manufacturing to healthcare, underscoring their versatility and importance in modern applications.

Understanding the historical context of fractional motors enables B2B buyers to appreciate the technological advancements that have shaped the current market. This knowledge can inform sourcing strategies, helping buyers select products that not only meet current needs but also anticipate future trends in efficiency and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of fractional motor

-

How do I choose the right fractional motor for my application?

Choosing the right fractional motor involves assessing your specific application requirements, including power needs, speed control, and environmental conditions. Start by defining the load and duty cycle, as well as the voltage and current specifications. Consider the motor type—AC or DC—and whether you need features like adjustable speed or integrated tachometers. Additionally, evaluate the physical size constraints and mounting options. Collaborating with suppliers who understand your industry can also provide valuable insights into the best options for your operational needs. -

What is the best fractional motor for industrial automation?

The best fractional motor for industrial automation typically depends on the specific machinery and application. Permanent magnet DC motors are often preferred due to their efficiency and compact design, making them suitable for conveyor systems and robotic applications. Look for motors that offer precise speed control and durability, particularly those rated for continuous duty in harsh environments. Working with established suppliers can help you identify motors that meet your automation requirements while ensuring compliance with international standards. -

What are the key factors to consider when vetting fractional motor suppliers?

When vetting suppliers for fractional motors, consider their industry reputation, experience, and product quality. Request certifications and compliance with international standards, especially if you’re operating in regulated markets. Evaluate their manufacturing capabilities, including the ability to customize motors according to your specifications. Additionally, assess their customer service, lead times, and after-sales support. A supplier with a strong track record in your region can also help navigate local regulations and logistics effectively. -

What customization options are available for fractional motors?

Customization options for fractional motors can include variations in power ratings, voltage specifications, frame sizes, and mounting configurations. Suppliers may also offer modifications such as integrated encoders, specific speed ranges, and tailored insulation for different environmental conditions. Discussing your specific application with potential suppliers can help identify the best customization options available. Ensure that the supplier can meet both performance criteria and design requirements to optimize integration into your existing systems. -

What is the minimum order quantity (MOQ) for fractional motors?

Minimum order quantities for fractional motors can vary significantly among suppliers. Typically, MOQs may range from a few units for smaller manufacturers to larger quantities for established brands. It’s essential to communicate your needs with potential suppliers, as some may offer flexibility based on your specific project requirements or offer sample orders. Understanding the MOQ is crucial for budgeting and planning, especially when sourcing for larger projects or new product lines. -

What payment terms should I expect when purchasing fractional motors internationally?

Payment terms for international purchases of fractional motors can vary widely. Common practices include advance payment, net 30 or net 60 terms, or a letter of credit, especially for larger orders. Always clarify payment conditions before finalizing the agreement, including any potential currency exchange considerations. Establishing trust with your supplier can lead to more favorable terms, so consider building a long-term relationship to negotiate better payment options in the future. -

How can I ensure quality assurance (QA) for fractional motors?

To ensure quality assurance for fractional motors, request detailed product specifications and certification documents from your suppliers. Conducting pre-shipment inspections can help verify compliance with your standards and specifications. Additionally, consider suppliers who offer warranties or guarantees on their products, as this indicates confidence in their manufacturing processes. Collaborating with third-party quality assurance firms can also provide an extra layer of scrutiny, especially when dealing with international suppliers. -

What logistics considerations should I keep in mind when sourcing fractional motors?

Logistics play a crucial role in sourcing fractional motors, particularly for international shipments. Consider factors such as shipping methods, customs regulations, and import duties specific to your country. Work with suppliers who have experience in international trade to ensure compliance with all legal requirements. Additionally, factor in lead times and potential delays in shipping, especially during peak seasons. Effective communication with your supplier regarding logistics can help streamline the process and mitigate risks associated with international procurement.

Top 5 Fractional Motor Manufacturers & Suppliers List

1. Baldor – Fractional HP DC Motors

Domain: baldor.com

Registered: 1995 (30 years)

Introduction: Fractional HP DC motors with both wound field and permanent magnet designs. Wound field designs available up to 3 HP, permanent magnet designs up to 5 HP. Designed for adjustable speed operation from SCR controls. Applications include conveyors, extruders, packaging equipment, mixers, winders, printing presses, and metering pumps. Most designs allow for tachometer addition for closed loop applicat…

2. Fractional Horsepower Motors – FHP Solutions

Domain: fractionalhorsepowermotors.com

Registered: 2000 (25 years)

Introduction: Fractional horsepower motors (FHP motors) are small electric motors with a power rating of less than one horsepower (746 watts). They are categorized by frame size and power output, typically used in industrial automation, automotive systems, medical devices, HVAC equipment, and consumer electronics. Applications include driving pumps, fans, conveyors, power windows, infusion pumps, and household …

3. Groschopp – Fractional Horsepower Motors

Domain: groschopp.com

Registered: 1995 (30 years)

Introduction: Fractional horsepower motors are defined as motors with a power rating of less than one horsepower (746 Watts). Groschopp specializes in mid- to large-sized fractional horsepower AC motors and small- to mid-sized DC and BLDC motors. The HP ranges for Groschopp’s motors are as follows: AC – 1/20 – 1 hp, DC – 1/100 – ½ hp, Brushless – 1/35 – ½ hp, Universal – ¼ – 2 ½ hp. Groschopp’s Universal motors…

4. IQS Directory – Fractional Horsepower Motors

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Fractional horsepower motors operate using AC or DC and provide less than one horsepower (peak power capacity of 746 watts). They are ideal for compact electronic devices and simple consumer products, with applications in robotics, HVAC systems, medical devices, and household appliances. Types include: 1. Brush Series Motors – Simple speed control, used in power tools and appliances. 2. Brushless …

5. ABB – Fractional HP DC Motors

Domain: new.abb.com

Registered: 1990 (35 years)

Introduction: Fractional HP DC Motors include both wound field and permanent magnet designs. Wound field designs are available up to 3 HP, while permanent magnet designs are available up to 5 HP. They are designed for adjustable speed operation from SCR controls. Common applications include conveyors, extruders, packaging equipment, mixers, winders, printing presses, and metering pumps. Most designs allow for t…

Strategic Sourcing Conclusion and Outlook for fractional motor

In the evolving landscape of fractional motors, strategic sourcing emerges as a pivotal approach for international B2B buyers. Understanding the specific applications and advantages of fractional horsepower motors—ranging from industrial automation to consumer appliances—can significantly enhance operational efficiency and reduce costs. By leveraging reliable suppliers, businesses can secure high-quality motors that meet their precise needs, ensuring sustainable performance across various sectors.

As markets in Africa, South America, the Middle East, and Europe continue to expand, the demand for energy-efficient and compact motor solutions will only grow. Buyers should prioritize partnerships with manufacturers who emphasize innovation and quality, as these relationships can lead to shared expertise and improved product offerings.

Illustrative image related to fractional motor

Looking ahead, the integration of fractional motors into emerging technologies and sustainable applications presents exciting opportunities for growth and innovation. By investing in strategic sourcing now, companies can position themselves at the forefront of this dynamic industry, unlocking new potentials and driving competitive advantage. Engage with your suppliers today to explore tailored solutions that align with your business goals and operational demands.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.