How to Source Forklift Truck Parts Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for forklift truck parts

In the competitive landscape of material handling, sourcing high-quality forklift truck parts is a critical challenge for international B2B buyers. With the increasing demand for efficient operations, businesses from Africa, South America, the Middle East, and Europe, including countries like Brazil and Germany, are constantly seeking reliable suppliers that can meet their specific needs. This guide serves as a comprehensive resource, covering various types of forklift parts, their applications, and essential factors to consider when vetting suppliers.

Understanding the intricacies of the global market for forklift parts is vital for maintaining operational efficiency and ensuring the safety of equipment and personnel. Buyers will gain insights into the range of available parts—from hydraulic components to electrical systems—and learn about the importance of sourcing OEM versus aftermarket parts. Additionally, this guide delves into cost considerations, helping businesses make informed decisions that align with their budget and operational requirements.

By leveraging the information provided, B2B buyers can navigate the complexities of the forklift parts market with confidence. This guide empowers them to build strategic partnerships with suppliers that not only meet their immediate needs but also support long-term operational success. With a focus on quality, reliability, and efficiency, we aim to enhance your procurement strategy in the ever-evolving landscape of material handling equipment.

Understanding forklift truck parts Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Electric Truck Components | Battery packs, electric motors, controllers | Warehousing, manufacturing, retail | Pros: Eco-friendly, lower operating costs. Cons: Higher initial investment. |

| Forks and Attachment Parts | Various fork lengths, widths, and attachments | Material handling, construction | Pros: Versatile for different loads. Cons: Requires careful selection for compatibility. |

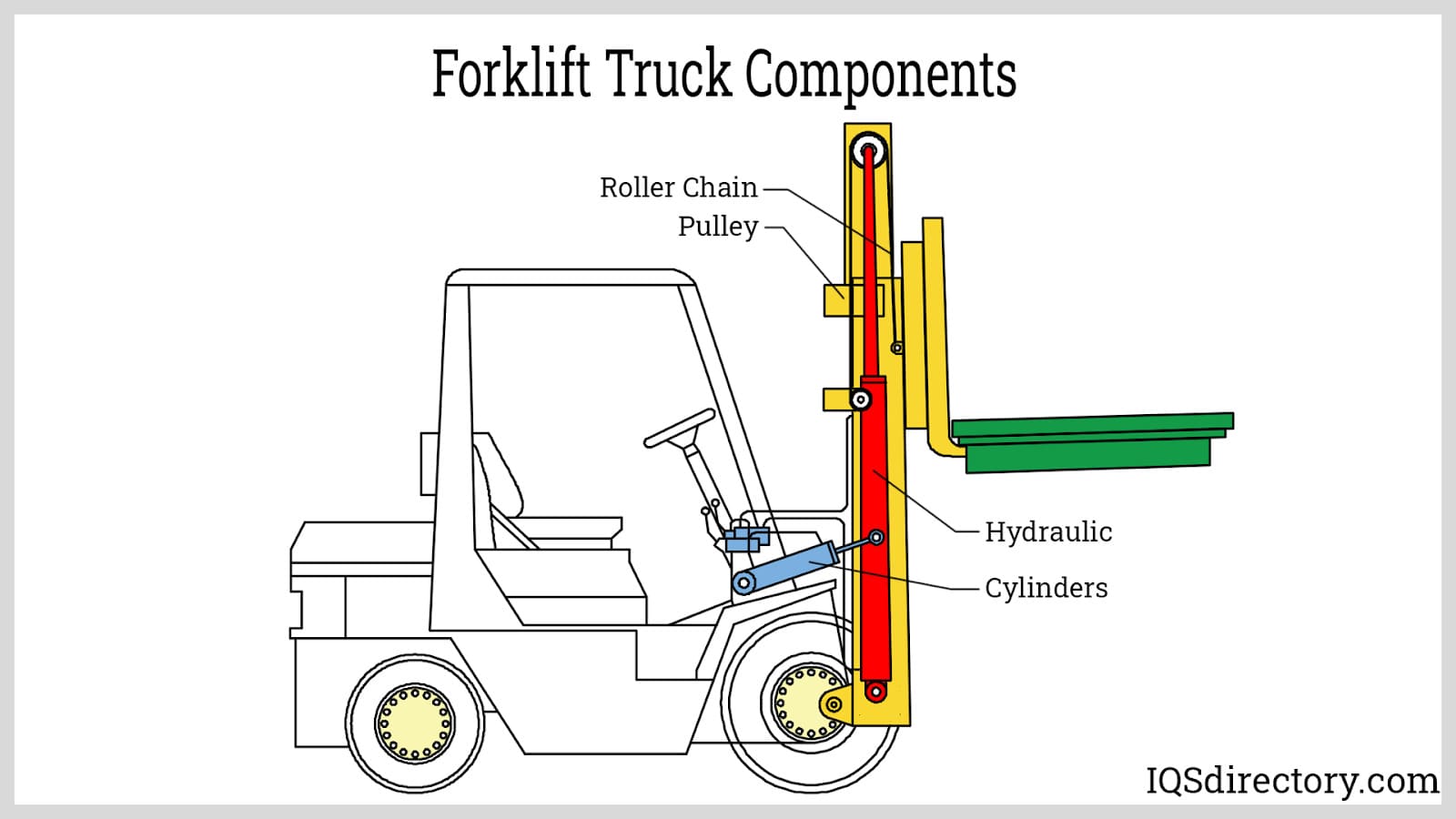

| Hydraulic Components | Cylinders, pumps, hoses, and valves | Heavy lifting, industrial applications | Pros: Essential for power and precision. Cons: Can be costly to replace. |

| Internal Combustion (IC) Components | Engines, fuel systems, exhaust systems | Outdoor applications, construction sites | Pros: High power output, durability. Cons: Higher emissions and maintenance needs. |

| Wheels and Tires | Solid, pneumatic, and polyurethane options | All types of forklifts | Pros: Essential for stability and safety. Cons: Different types may affect performance. |

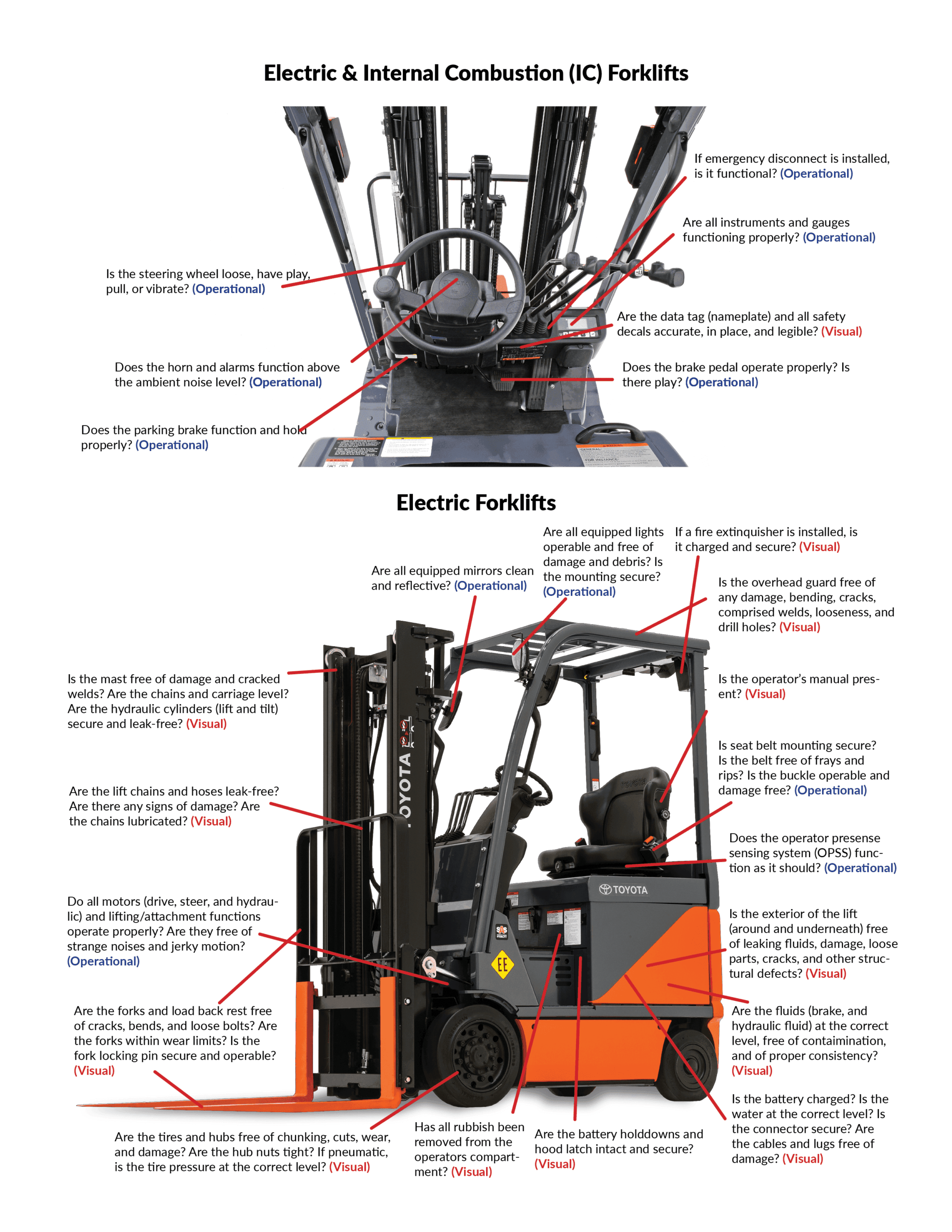

What are Electric Truck Components and Their Importance for B2B Buyers?

Electric truck components, including battery packs, electric motors, and controllers, are critical for the operation of electric forklifts. These components are favored in environments where emissions are a concern, such as warehouses and retail spaces. When purchasing electric components, B2B buyers should consider the total cost of ownership, including maintenance and energy savings, alongside the initial investment which can be higher than traditional options.

How Do Forks and Attachment Parts Enhance Forklift Versatility?

Forks and attachment parts come in various lengths and widths, allowing businesses to customize their forklifts for specific material handling tasks. This versatility is particularly valuable in sectors such as construction and logistics, where different load types are common. Buyers should evaluate compatibility with existing equipment and the specific applications they intend to serve, ensuring they select the right attachments for efficiency and safety.

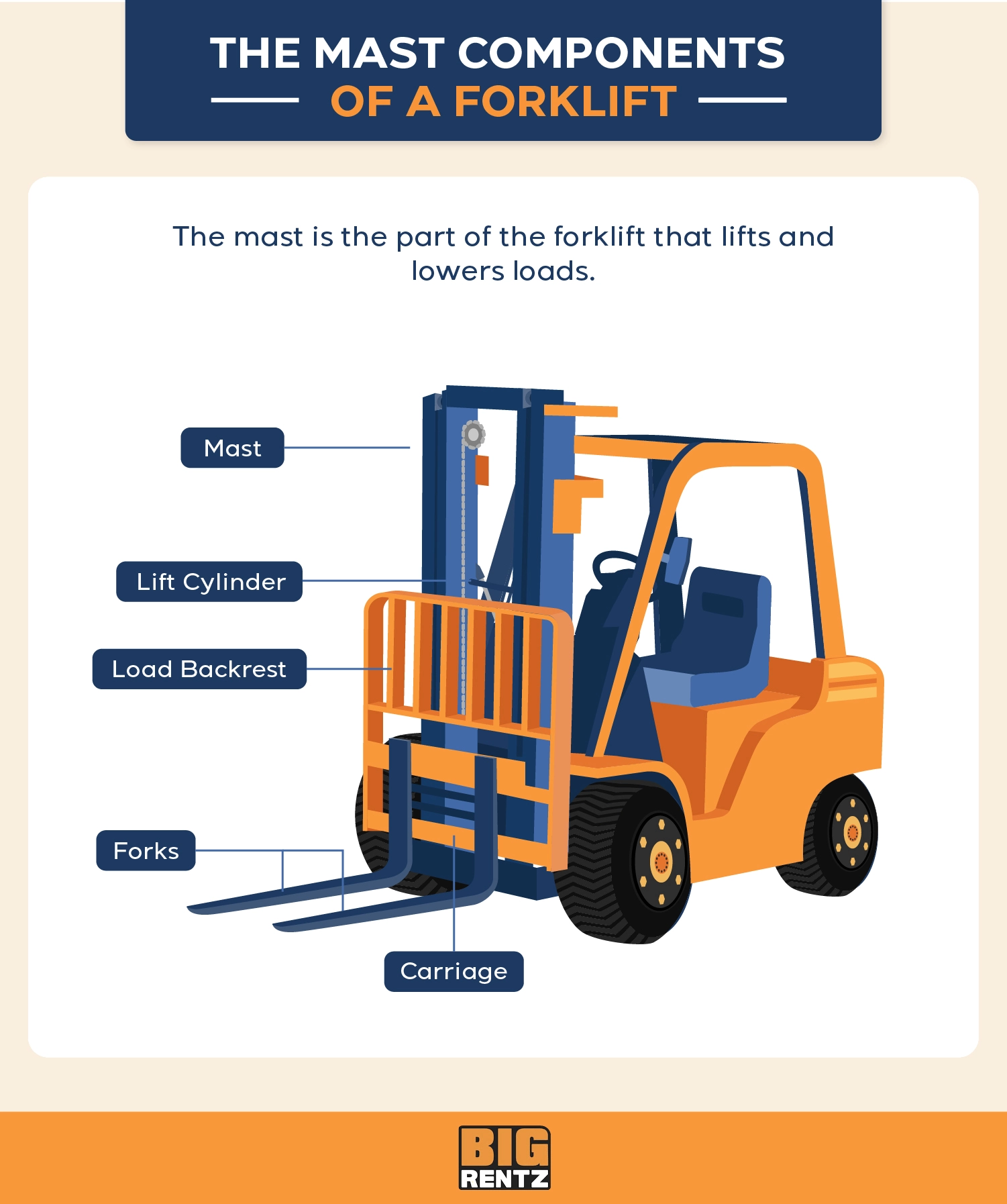

Why are Hydraulic Components Essential in Forklift Operations?

Hydraulic components like cylinders, pumps, and hoses are vital for the lifting and lowering functions of forklifts. They provide the necessary power and precision for heavy lifting in industrial applications. When sourcing hydraulic parts, B2B buyers should focus on quality and reliability, as the costs for replacements can be significant. Understanding the specific hydraulic requirements of their equipment will aid in making informed purchasing decisions.

What Should B2B Buyers Know About Internal Combustion (IC) Components?

Internal combustion components, such as engines and fuel systems, are primarily used in forklifts operating in outdoor environments or heavy-duty applications. These components offer high power output and durability, making them suitable for construction sites and warehouses with extensive material handling needs. However, buyers must consider the higher emissions and maintenance requirements associated with IC forklifts, balancing performance needs with environmental regulations.

How Do Wheels and Tires Impact Forklift Performance?

Wheels and tires play a crucial role in the stability and safety of forklifts. Options vary from solid to pneumatic and polyurethane, each suited for different applications and surfaces. B2B buyers should assess the operating environment and load types when selecting wheels and tires, as the wrong choice can affect performance and safety. Understanding the implications of different tire types will ensure optimal forklift operation and longevity.

Key Industrial Applications of forklift truck parts

| Industry/Sector | Specific Application of forklift truck parts | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Replacement of hydraulic components for forklifts | Ensures operational efficiency and safety in lifting operations | Quality assurance and compatibility with existing machinery |

| Warehousing & Logistics | Forklift tire replacements for better traction | Reduces downtime and enhances load handling capabilities | Availability of OEM vs. aftermarket options |

| Construction | Forklift forks for material handling | Increases productivity by enabling safe and efficient lifting of heavy materials | Compliance with safety standards and load capacity ratings |

| Agriculture | Heavy-duty forklift parts for farm equipment | Optimizes the handling of bulk materials, improving workflow | Durability and weather resistance of parts |

| Retail and Distribution | Electric forklift battery components | Enhances energy efficiency and reduces operational costs | Fast delivery options to minimize downtime |

How Are Forklift Truck Parts Used in Manufacturing?

In manufacturing, forklift truck parts, particularly hydraulic components, play a critical role in maintaining the functionality of lifting equipment. These parts are essential for the smooth operation of forklifts that handle heavy materials on production lines. A failure in hydraulic systems can lead to significant downtime, impacting productivity and safety. Buyers in this sector should prioritize sourcing high-quality, compatible parts that meet rigorous industry standards to ensure reliability and efficiency.

What Role Do Forklift Parts Play in Warehousing & Logistics?

In the warehousing and logistics sector, forklift tire replacements are vital for maintaining optimal traction and stability. Worn-out tires can drastically affect a forklift’s performance, leading to slower operations and potential accidents. To mitigate these risks, businesses must consider sourcing both OEM and aftermarket options that offer durability and cost-effectiveness. Timely availability of these parts is crucial to minimize downtime and ensure continuous operations.

How Are Forklift Parts Utilized on Construction Sites?

Construction sites often require specialized forklift forks designed for heavy-duty material handling. These forks enable workers to efficiently lift and transport construction materials, thus enhancing overall productivity. Sourcing considerations include ensuring that the forks meet safety standards and are rated for the specific loads they will carry. Companies must also consider the availability of parts to prevent project delays due to equipment failure.

Why Are Forklift Parts Important in Agriculture?

In the agricultural sector, heavy-duty forklift parts are essential for handling bulk materials such as grains and fertilizers. The durability and weather resistance of these parts ensure they can withstand harsh environmental conditions while maintaining operational efficiency. Buyers should focus on sourcing parts that are specifically designed for agricultural applications, as this can significantly improve workflow and productivity on farms.

How Do Forklift Parts Impact Retail and Distribution?

In retail and distribution, electric forklift battery components are crucial for ensuring energy efficiency and reducing operational costs. High-quality batteries lead to longer operational periods and fewer interruptions due to charging. When sourcing these components, businesses should consider fast delivery options to minimize downtime and maintain inventory flow. Prioritizing reliable suppliers with a proven track record can enhance operational efficiency in this competitive sector.

3 Common User Pain Points for ‘forklift truck parts’ & Their Solutions

Scenario 1: Delays in Receiving Essential Forklift Parts

The Problem: In industries where forklifts are integral to operations, delays in receiving critical parts can lead to significant downtime. A B2B buyer may order a hydraulic component for their forklift, only to find out that the supplier cannot deliver for several days or even weeks. This situation not only disrupts the workflow but can also result in financial losses and decreased productivity. Additionally, for buyers operating in remote locations or regions with limited suppliers, the challenge of timely delivery is exacerbated, leading to further frustration.

The Solution: To mitigate delays, B2B buyers should partner with suppliers that have a robust logistics network and promise expedited shipping options. It is essential to assess suppliers based on their inventory levels and shipping capabilities. For instance, choosing a supplier that stocks a wide range of parts and guarantees same-day shipping can significantly reduce waiting times. Buyers should also consider establishing a consignment inventory system where critical parts are kept on-site, enabling immediate access when needed. This proactive approach ensures that essential parts are always available, minimizing disruptions to operations and enhancing overall efficiency.

Illustrative image related to forklift truck parts

Scenario 2: Difficulty Sourcing Quality Replacement Parts

The Problem: Many B2B buyers encounter the challenge of sourcing quality replacement parts for various makes and models of forklifts. With countless manufacturers and models in circulation, finding compatible parts can be a daunting task. Buyers may face the risk of purchasing low-quality or counterfeit parts that do not meet safety standards or operational requirements, leading to further complications down the line. This situation not only jeopardizes equipment performance but can also pose safety risks for operators.

The Solution: To successfully navigate this challenge, buyers should prioritize sourcing parts from established and reputable suppliers that offer OEM (Original Equipment Manufacturer) components. Conducting thorough research on suppliers, checking their certifications, and reading customer reviews can provide insights into their reliability. It is also beneficial to work with suppliers that offer a comprehensive catalog featuring parts for multiple brands and models, thereby simplifying the search process. Additionally, buyers should establish relationships with suppliers who provide technical support and advice on compatibility, ensuring that they acquire the right parts for their specific forklift models.

Scenario 3: Managing Costs of Forklift Parts and Maintenance

The Problem: The cost of forklift parts and maintenance can be a significant concern for B2B buyers, particularly in industries where operational budgets are tight. Unexpected repairs or the need for urgent parts replacement can strain financial resources, leading to difficult decisions about maintaining equipment versus purchasing new machinery. Buyers often struggle to find a balance between acquiring high-quality parts and managing overall costs effectively.

The Solution: To manage costs effectively, buyers should consider implementing a planned maintenance program that focuses on regular inspections and timely replacements. This strategy can help identify potential issues before they escalate into costly repairs. Additionally, exploring options for remanufactured parts can provide high-quality alternatives at a lower price point without compromising on performance. Establishing long-term relationships with suppliers may also lead to bulk purchasing discounts or loyalty rewards. Finally, keeping track of inventory levels and usage patterns can assist in forecasting future parts needs, allowing buyers to budget more effectively and avoid sudden financial burdens.

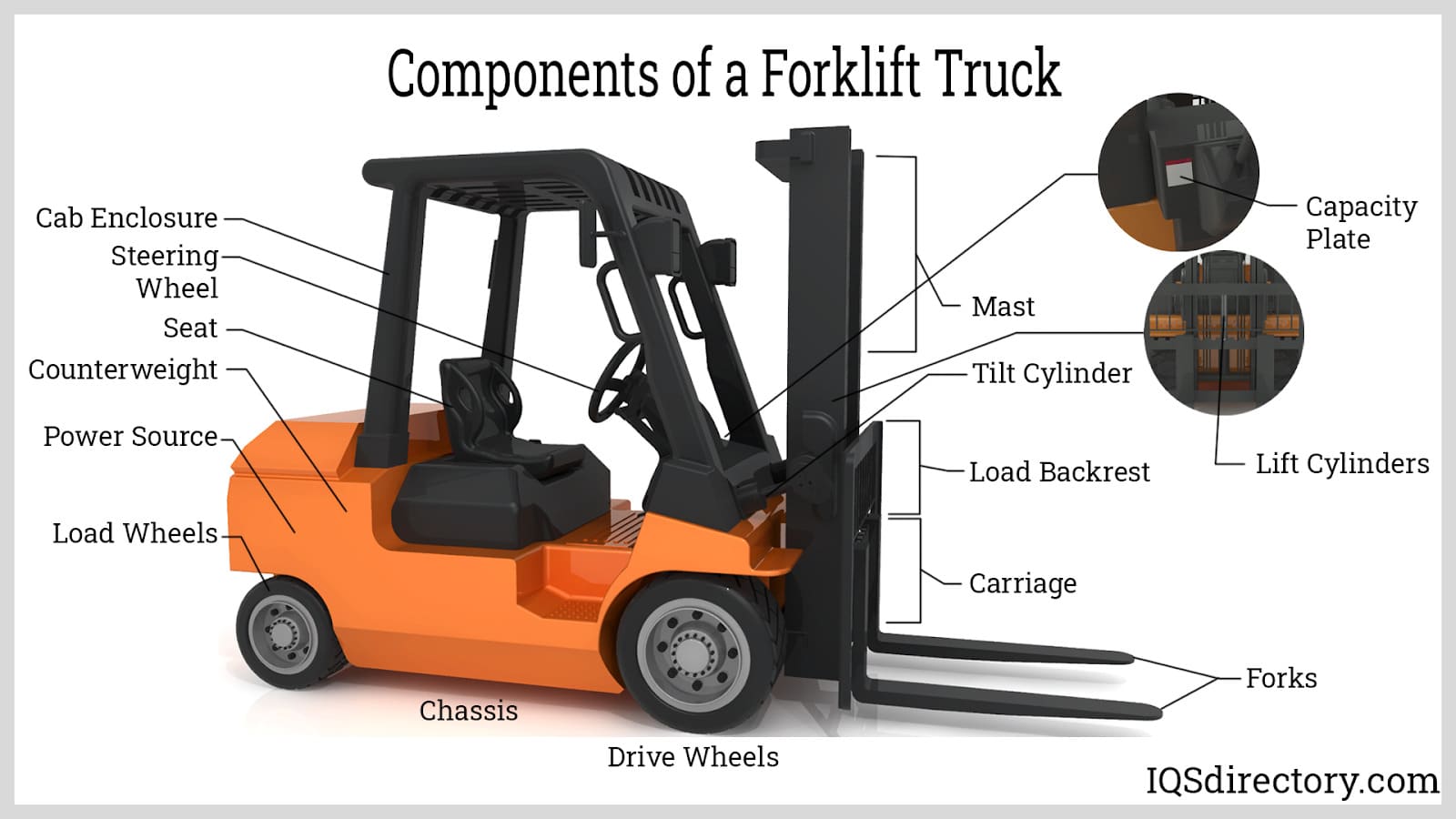

Illustrative image related to forklift truck parts

Strategic Material Selection Guide for forklift truck parts

What Are the Key Materials Used in Forklift Truck Parts?

When selecting materials for forklift truck parts, several factors influence the decision-making process for international B2B buyers. The choice of material directly impacts performance, durability, and cost-effectiveness. Below is an analysis of four common materials used in forklift truck components, focusing on their properties, advantages, disadvantages, and considerations for buyers in diverse markets.

How Does Steel Perform as a Material for Forklift Parts?

Steel is one of the most widely used materials in forklift truck parts due to its excellent strength and durability. It typically has a high temperature and pressure rating, making it suitable for heavy-duty applications. Steel components can withstand significant wear and tear, which is crucial in environments where forklifts operate continuously.

Pros: Steel is relatively inexpensive and widely available, making it a cost-effective choice for many manufacturers. Its high strength-to-weight ratio allows for the production of robust parts without excessive weight.

Cons: However, steel is prone to corrosion if not properly treated. This can be a significant drawback in humid or corrosive environments, which are common in regions like Africa and South America.

Impact on Application: Steel is often used for structural components, such as frames and forks, where strength is paramount. Buyers must consider the environmental conditions in their region and whether additional coatings or treatments are necessary to prevent rust.

What Role Does Aluminum Play in Forklift Truck Parts?

Aluminum is increasingly popular in forklift truck parts, particularly for components that require a lightweight material. It has a good strength-to-weight ratio and offers excellent corrosion resistance, making it suitable for various applications.

Pros: The lightweight nature of aluminum contributes to improved fuel efficiency and ease of handling. It is also resistant to rust, which is beneficial in humid climates.

Cons: The primary limitation of aluminum is its higher cost compared to steel. Additionally, while aluminum is strong, it may not be suitable for high-stress applications without proper engineering.

Illustrative image related to forklift truck parts

Impact on Application: Aluminum is often used in components like frames and panels where weight savings are critical. Buyers should be aware of the specific strength requirements of their applications to ensure aluminum is a suitable choice.

How Do Plastics Enhance Forklift Truck Parts?

Plastics, particularly engineering plastics like nylon and polycarbonate, are used in various forklift truck parts, especially for non-structural components. These materials offer excellent resistance to chemicals and wear.

Pros: Plastics are lightweight, corrosion-resistant, and can be molded into complex shapes, providing design flexibility. They are also less expensive than metals.

Cons: The main disadvantage is that plastics may not withstand high temperatures or heavy loads as well as metals. This limits their use in high-stress applications.

Impact on Application: Plastics are often utilized for covers, guards, and non-load-bearing components. Buyers should consider the operational environment and the specific mechanical requirements of the parts being replaced.

Illustrative image related to forklift truck parts

What Are the Benefits of Using Rubber in Forklift Parts?

Rubber is commonly used in forklift truck parts, particularly for tires, seals, and vibration dampening components. Its elasticity and resilience make it an excellent choice for applications requiring shock absorption.

Pros: Rubber provides excellent traction and shock absorption, which enhances safety and performance. It is also resistant to many chemicals, making it suitable for various operating environments.

Cons: However, rubber can degrade over time due to exposure to UV light and extreme temperatures, which may necessitate more frequent replacements.

Impact on Application: Rubber is critical for tires and seals, where performance and safety are paramount. Buyers should consider the specific operating conditions, such as terrain and climate, when selecting rubber components.

Summary Table of Material Selection for Forklift Truck Parts

| Material | Typical Use Case for forklift truck parts | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Structural components (frames, forks) | High strength and durability | Prone to corrosion | Low |

| Aluminum | Lightweight structural components | Excellent corrosion resistance | Higher cost than steel | Med |

| Plastics | Non-structural components (covers, guards) | Lightweight and design flexibility | Limited high-stress applications | Low |

| Rubber | Tires and seals | Excellent traction and shock absorption | Degrades over time | Med |

This guide provides a comprehensive overview of materials used in forklift truck parts, allowing international B2B buyers to make informed decisions based on their specific operational needs and environmental conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for forklift truck parts

What Are the Key Stages in the Manufacturing Process of Forklift Truck Parts?

The manufacturing process for forklift truck parts involves several critical stages, each designed to ensure the final product meets stringent quality and performance standards. Understanding these stages is vital for B2B buyers, especially those sourcing parts internationally.

1. Material Preparation: What Materials Are Typically Used?

The manufacturing process begins with material preparation. Common materials for forklift parts include high-strength steel, aluminum, and various polymers. These materials are selected based on their mechanical properties, which must withstand the rigors of heavy lifting and transport.

-

Material Selection: High-strength steel is often used for structural components like frames and forks due to its durability and load-bearing capacity. Aluminum is preferred for parts requiring lightweight properties, while polymers are utilized for components like seals and gaskets.

-

Material Testing: Before proceeding, raw materials undergo rigorous testing to confirm they meet specified standards for tensile strength, ductility, and fatigue resistance.

2. Forming: How Are Forklift Parts Shaped?

Once materials are prepared, the next step is forming. This involves various techniques to shape the materials into desired configurations.

Illustrative image related to forklift truck parts

-

Processes Used: Common forming techniques include stamping, forging, casting, and machining. Stamping is frequently used for flat components like brackets, while forging is ideal for parts requiring high strength, such as axles and gears.

-

Precision Engineering: Advanced CNC (Computer Numerical Control) machines are employed to ensure precision in cutting and shaping, reducing waste and enhancing consistency across batches.

3. Assembly: What Happens During Assembly?

After forming, parts are assembled. This stage integrates individual components into a complete unit.

-

Assembly Techniques: Techniques such as welding, bolting, and riveting are commonly used. For example, welding is crucial for joining structural components, while bolting allows for easier disassembly during maintenance.

-

Automated Systems: Many manufacturers employ automated assembly lines to enhance efficiency and reduce human error, ensuring that parts are assembled consistently.

4. Finishing: What Finishing Processes Are Applied?

The final stage is finishing, which enhances both the aesthetics and functionality of the parts.

-

Finishing Techniques: Techniques such as painting, powder coating, and anodizing are used to protect against corrosion and wear. These processes also improve the appearance of parts, which can be an important factor for end-users.

-

Quality Control: Finishing processes are closely monitored to ensure that coatings meet thickness and adhesion standards, which are critical for the longevity of the parts.

How Is Quality Assurance Ensured in Forklift Part Manufacturing?

Quality assurance (QA) is a crucial component of the manufacturing process for forklift truck parts. Various international and industry-specific standards guide manufacturers in establishing effective QA protocols.

What International Standards Apply to Forklift Parts?

International standards such as ISO 9001 provide a framework for quality management systems. This standard emphasizes a process-based approach, helping organizations ensure that they consistently meet customer and regulatory requirements.

-

ISO 9001 Certification: Manufacturers seeking ISO 9001 certification undergo rigorous audits by accredited organizations. This certification is a strong indicator of a company’s commitment to quality.

-

Industry-Specific Standards: Additional standards like CE marking (European Conformity) and API (American Petroleum Institute) standards are critical for ensuring safety and reliability in specific markets. These standards are particularly important for international buyers, as compliance can vary by region.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are integrated throughout the manufacturing process to catch defects early and ensure product integrity.

-

Incoming Quality Control (IQC): This initial stage involves inspecting raw materials and components before they enter the production line. Any non-conforming materials are rejected or reworked.

-

In-Process Quality Control (IPQC): During manufacturing, inspections occur at various stages to monitor processes and ensure adherence to specifications. Statistical process control (SPC) techniques may be employed to track and analyze production data.

-

Final Quality Control (FQC): After assembly, the final product undergoes rigorous testing, including functional tests, dimensional checks, and performance evaluations. This stage is critical to ensure that each part meets the required specifications before shipping.

What Common Testing Methods Are Used for Forklift Parts?

Several testing methods are employed to verify the quality and performance of forklift parts.

-

Destructive Testing: This includes tensile tests, impact tests, and fatigue tests, which evaluate how materials perform under extreme conditions. While these methods destroy the sample, they provide invaluable data on material properties.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing, magnetic particle inspection, and radiography allow for the evaluation of materials without causing damage. NDT is particularly useful for detecting internal defects in welded joints or castings.

-

Performance Testing: Forklift components undergo functional tests to ensure they operate correctly under load. For instance, hydraulic parts may be tested for pressure tolerance and leak resistance.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to ensure that their suppliers maintain high-quality standards.

What Should Buyers Look for in Supplier Audits and Reports?

-

Supplier Audits: Regular audits of suppliers provide insight into their quality management processes. Buyers should request audit reports, focusing on compliance with ISO and other relevant standards.

-

Quality Reports: Suppliers should be willing to share quality reports detailing defect rates, testing results, and corrective actions taken. This transparency is essential for building trust.

What Role Do Third-Party Inspections Play?

Engaging third-party inspection services can provide an unbiased assessment of a supplier’s quality control processes.

-

Independent Verification: Third-party inspectors can evaluate manufacturing practices, conduct material testing, and verify compliance with international standards. This additional layer of scrutiny is particularly valuable for buyers in regions where local regulations may differ.

-

Certifications and Compliance: Buyers should seek suppliers that possess relevant certifications, as these indicate a commitment to quality and reliability.

What Are the Quality Control Nuances for International B2B Buyers?

For international B2B buyers, understanding the nuances of quality control is critical, especially when sourcing from different regions.

-

Regulatory Differences: Different countries may have varying regulations regarding safety and quality standards. Buyers should familiarize themselves with local compliance requirements in their target markets.

-

Cultural Considerations: Cultural differences can impact communication and expectations regarding quality. Building strong relationships with suppliers and understanding their operational practices can lead to better outcomes.

-

Logistics and Supply Chain: Quality assurance extends beyond manufacturing to include logistics. Buyers should assess how parts are stored and transported, as improper handling can compromise quality.

Conclusion

Understanding the manufacturing processes and quality assurance measures for forklift truck parts is essential for B2B buyers seeking reliable suppliers. By familiarizing themselves with the stages of production, relevant standards, and quality control methods, buyers can make informed decisions that ensure the longevity and safety of their material handling equipment.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘forklift truck parts’

Introduction

Sourcing forklift truck parts can be a complex process, particularly for international B2B buyers. This guide provides a step-by-step checklist to streamline your procurement efforts, ensuring you acquire high-quality parts efficiently while minimizing downtime. By following these actionable steps, you can make informed purchasing decisions that enhance the operational efficiency of your material handling equipment.

Illustrative image related to forklift truck parts

Step 1: Define Your Technical Specifications

Understanding the specific requirements for your forklift truck parts is essential. Identify the make and model of your equipment, as well as the type of parts needed, such as hydraulic components, electrical parts, or tires. This clarity will help you communicate effectively with suppliers and ensure compatibility with your existing machinery.

Step 2: Research Potential Suppliers

Take the time to research suppliers that specialize in forklift truck parts. Look for companies with a solid reputation in the industry, as well as those that offer a wide range of parts for various makes and models. Utilize online reviews, industry forums, and recommendations from peers to gather insights on potential partners.

Step 3: Evaluate Supplier Certifications

Before finalizing your choice, verify the certifications and quality standards of potential suppliers. Check for ISO certifications or other industry-specific credentials that demonstrate compliance with international quality norms. This step is crucial to ensure that you are sourcing parts that meet safety and performance standards.

Step 4: Request Samples or Product Specifications

Once you narrow down your list of suppliers, request samples or detailed product specifications. This will allow you to assess the quality of the parts and ensure they meet your operational needs. Pay attention to material quality, dimensions, and any warranties offered, as these factors can significantly impact your equipment’s performance.

Step 5: Understand Pricing and Payment Terms

Discuss pricing structures and payment terms with your shortlisted suppliers. Inquire about bulk purchase discounts, shipping costs, and any additional fees that may apply. Understanding the total cost of ownership is vital for budgeting and can help you negotiate better terms.

Step 6: Review Delivery Times and Logistics

Evaluate the delivery times and logistics capabilities of your chosen suppliers. Confirm their ability to provide timely shipments, especially if you operate in regions with specific logistical challenges. A supplier that guarantees quick turnaround times can significantly reduce downtime and enhance operational efficiency.

Step 7: Establish a Communication Plan

Develop a clear communication plan with your supplier to ensure ongoing support and collaboration. Establish points of contact for order tracking, technical support, and any potential issues that may arise. Effective communication will facilitate a smoother procurement process and foster a long-term partnership.

Illustrative image related to forklift truck parts

By adhering to this practical sourcing checklist, you can enhance your procurement strategy for forklift truck parts, ensuring that you invest in quality components that keep your operations running smoothly.

Comprehensive Cost and Pricing Analysis for forklift truck parts Sourcing

What Are the Key Cost Components in Forklift Truck Parts Sourcing?

Understanding the cost structure of forklift truck parts is essential for effective sourcing. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margins.

-

Materials: The choice of materials significantly influences the overall cost. High-quality, durable materials may incur higher initial costs but can reduce the frequency of replacements, ultimately saving money in the long run.

-

Labor: Labor costs vary by region and the complexity of the manufacturing process. Skilled labor may be required for precision parts, impacting the overall pricing.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, rent, and equipment maintenance. Efficient manufacturing processes can help minimize these costs.

-

Tooling: Initial tooling costs can be substantial, especially for custom parts. However, these costs can be amortized over larger production runs, making it crucial to consider volume when negotiating.

-

Quality Control: Investing in quality control processes ensures that parts meet required specifications and certifications. This can prevent costly returns and replacements, making it an essential aspect of the cost structure.

-

Logistics: Transportation and handling costs should not be overlooked. These can vary based on the distance to the buyer, shipping methods, and whether the parts are delivered in bulk or as single units.

-

Margin: Suppliers will typically add a margin to cover their operational costs and profit. Understanding the average margin in your specific market can aid in negotiating better prices.

How Do Price Influencers Affect Forklift Truck Parts Costs?

Several factors can influence the pricing of forklift truck parts, making it essential for buyers to grasp these nuances.

-

Volume/MOQ (Minimum Order Quantity): Larger orders often qualify for discounts due to economies of scale. Buyers should assess their needs and negotiate for favorable terms when purchasing in bulk.

-

Specifications and Customization: Customized parts or those with specific specifications usually come at a premium. Buyers should weigh the necessity of customization against potential cost savings from standard parts.

-

Material Quality and Certifications: Parts that meet international quality standards or possess certifications will typically be priced higher. Buyers in regions like Europe may prioritize certified parts for compliance reasons.

-

Supplier Factors: The reputation and reliability of suppliers can significantly impact pricing. Established suppliers with a history of quality may charge more, but the assurance of quality and timely delivery can justify the expense.

-

Incoterms: Understanding shipping terms is crucial for international buyers. Incoterms define responsibilities for shipping, insurance, and tariffs, affecting the total cost of procurement.

What Are Effective Buyer Tips for Forklift Truck Parts Sourcing?

When sourcing forklift truck parts, especially for international transactions, buyers can adopt several strategies to enhance cost-efficiency.

-

Negotiate: Don’t hesitate to negotiate pricing, especially for larger orders. Suppliers often have room for discounts, particularly if they value long-term relationships.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes maintenance, downtime, and replacement costs. Higher-quality parts may have a higher initial cost but offer savings over time.

-

Understand Pricing Nuances: Be aware of regional pricing variations. For example, parts sourced from Europe may come with different cost structures than those from South America or Africa, influenced by local labor and material costs.

-

Research and Compare Suppliers: Utilize online platforms to compare prices and quality. Establishing relationships with multiple suppliers can provide leverage in negotiations and ensure access to diverse parts.

-

Account for Shipping Costs: Factor in logistics and shipping costs when evaluating total pricing. Depending on the Incoterms, these costs can significantly alter the final price.

Disclaimer: Prices for forklift truck parts can fluctuate based on market conditions, supply chain factors, and specific buyer-supplier agreements. Always request current pricing from suppliers to ensure accurate budgeting.

Illustrative image related to forklift truck parts

Alternatives Analysis: Comparing forklift truck parts With Other Solutions

Understanding Alternative Solutions to Forklift Truck Parts

In the realm of material handling, the efficiency and reliability of equipment are paramount. Forklift truck parts play a crucial role in maintaining operational effectiveness. However, various alternative solutions exist that can either supplement or replace traditional forklift parts, offering businesses different pathways to achieve their material handling goals. This analysis explores these alternatives, providing insight into their viability for B2B buyers.

| Comparison Aspect | Forklift Truck Parts | Alternative 1: Automated Guided Vehicles (AGVs) | Alternative 2: Forklift Rentals |

|---|---|---|---|

| Performance | High durability and reliability with proper maintenance | High efficiency in moving goods with minimal human intervention | Varies based on rental terms and equipment condition |

| Cost | Initial investment + maintenance costs | Higher upfront investment; potential cost savings in labor | Lower short-term costs; potential long-term expenses |

| Ease of Implementation | Requires skilled technicians for maintenance | Complex implementation requiring infrastructure changes | Simple setup; however, may require training for operators |

| Maintenance | Regular maintenance required for longevity | Minimal maintenance; software updates needed | Maintenance handled by rental company |

| Best Use Case | Long-term operations needing consistent performance | Warehouses with high throughput and repetitive tasks | Short-term needs or fluctuating workloads |

What Are the Pros and Cons of Automated Guided Vehicles (AGVs)?

AGVs represent a modern solution for material handling, automating the transport of goods across facilities. These vehicles can enhance efficiency, particularly in environments that demand high throughput. The primary advantage of AGVs is their ability to reduce labor costs and human error while operating continuously without breaks. However, the initial investment can be significant, and the implementation may require substantial changes to existing infrastructure, making it less viable for smaller operations or those with limited budgets.

What Are the Benefits and Drawbacks of Forklift Rentals?

Forklift rentals offer flexibility and lower initial costs, making them an attractive option for businesses that experience fluctuating demand. This solution allows companies to access high-quality equipment without the burden of long-term ownership costs. The rental companies typically handle maintenance, ensuring that equipment is operational when needed. However, reliance on rentals can become costly over time, especially for businesses requiring consistent access to forklifts. Additionally, the quality and availability of rental equipment can vary, potentially impacting operational efficiency.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the appropriate solution for material handling requires a thorough understanding of your specific operational needs, budget constraints, and long-term goals. For businesses engaged in heavy lifting and frequent use of forklifts, investing in high-quality forklift parts may be the best option for ensuring reliability and performance. Conversely, companies looking for flexibility or facing seasonal demand fluctuations might find forklift rentals more suitable. For facilities aiming to innovate and automate processes, AGVs could offer significant long-term advantages, despite their higher upfront costs.

By carefully analyzing these options, B2B buyers can make informed decisions that align with their operational strategies and financial capabilities, ultimately enhancing their material handling efficiency and effectiveness.

Essential Technical Properties and Trade Terminology for forklift truck parts

What Are the Key Technical Properties of Forklift Truck Parts?

When sourcing forklift truck parts, understanding critical specifications is essential for making informed purchasing decisions. Here are some key technical properties to consider:

Material Grade

The material grade of forklift parts significantly affects durability and performance. Common materials include high-strength steel for forks and aluminum for lighter components. Higher-grade materials typically offer enhanced resistance to wear, corrosion, and fatigue. For B2B buyers, selecting parts with appropriate material grades ensures reliability and longevity, reducing downtime and maintenance costs.

Tolerance

Tolerance refers to the permissible limit of variation in a part’s dimensions. Precision in manufacturing is crucial, especially for components like hydraulic cylinders and gears, where even minor discrepancies can lead to operational failures. In a B2B context, understanding tolerance levels helps buyers ensure compatibility with existing machinery, minimizing installation issues and operational disruptions.

Load Capacity

Load capacity indicates the maximum weight a forklift part can handle safely. This specification is critical for components such as forks and lifting mechanisms. B2B buyers must match the load capacity of parts with their operational requirements to ensure safety and compliance with regulatory standards. Overloading components can lead to accidents and costly damage.

Lifespan and Warranty

The expected lifespan of forklift parts is a vital consideration. Many suppliers provide warranties that indicate the durability of their products. A longer lifespan often correlates with higher quality and lower total cost of ownership. For B2B buyers, evaluating warranty terms can provide insights into the manufacturer’s confidence in their products and help mitigate risks.

Performance Ratings

Performance ratings encompass various metrics, such as efficiency, response time, and energy consumption for electric components. These ratings are crucial for optimizing the operational efficiency of forklift fleets. B2B buyers should seek parts with favorable performance ratings to enhance productivity and reduce operating costs.

What Are Common Trade Terms in the Forklift Parts Industry?

Familiarity with industry jargon can significantly streamline communication and purchasing processes. Here are some common trade terms relevant to forklift parts:

OEM (Original Equipment Manufacturer)

OEM parts are components made by the original manufacturer of the forklift. These parts are typically considered the gold standard for quality and compatibility. B2B buyers should weigh the benefits of OEM parts against potential cost savings from aftermarket options, ensuring that they meet operational standards and warranty requirements.

MOQ (Minimum Order Quantity)

MOQ refers to the smallest number of units a supplier will sell in a single order. Understanding MOQ is crucial for B2B buyers to manage inventory levels and cash flow effectively. Suppliers with flexible MOQs can help businesses scale their purchases according to specific needs, thereby optimizing procurement strategies.

RFQ (Request for Quotation)

An RFQ is a formal process in which a buyer requests pricing and terms from suppliers for specific parts. This process is essential for B2B buyers to compare costs and assess supplier capabilities. A well-structured RFQ can lead to better deals and improved supplier relationships.

Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is vital for B2B buyers engaged in international trade, as they help clarify risks and costs associated with transportation and delivery.

Lead Time

Lead time refers to the period between placing an order and receiving the parts. In the context of forklift parts, shorter lead times can significantly affect operational efficiency. B2B buyers should consider suppliers with reliable lead times to minimize downtime and ensure that equipment is always operational.

Illustrative image related to forklift truck parts

By grasping these essential technical properties and trade terms, B2B buyers can navigate the forklift parts market more effectively, ensuring that their procurement strategies align with operational needs and budgetary constraints.

Navigating Market Dynamics and Sourcing Trends in the forklift truck parts Sector

What Are the Key Trends Shaping the Forklift Truck Parts Market?

The global forklift truck parts market is experiencing dynamic shifts influenced by several factors. One of the primary drivers is the rapid advancement of technology, particularly in automation and IoT integration. These technologies enable real-time monitoring and predictive maintenance of forklift fleets, reducing downtime and improving operational efficiency. For international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, this means sourcing parts that are compatible with these advanced systems is crucial.

Moreover, the demand for high-quality, durable parts is surging as businesses seek to extend the lifespan of their equipment. Buyers are increasingly prioritizing suppliers with extensive inventories that can deliver parts quickly, often within 24 to 48 hours. This trend is particularly evident among European buyers, where same-day shipping has become a competitive standard. In contrast, emerging markets may face challenges related to logistics and supply chain infrastructure, making reliable sourcing partners essential.

Sustainability is another emerging trend affecting the forklift parts sector. With growing awareness of environmental issues, businesses are gravitating towards suppliers who offer eco-friendly components and remanufactured parts. This shift not only helps in minimizing waste but also aligns with corporate social responsibility goals. Consequently, B2B buyers are encouraged to consider suppliers that demonstrate a commitment to sustainable practices, which can also enhance their brand reputation.

How Is Sustainability and Ethical Sourcing Influencing B2B Purchasing Decisions?

The importance of sustainability in the forklift parts sector cannot be overstated. As environmental regulations tighten globally, businesses are increasingly held accountable for their sourcing decisions. Buyers are now looking for suppliers who prioritize ethical sourcing practices, ensuring that materials are obtained responsibly and with minimal environmental impact. This trend is particularly significant for B2B buyers in regions where environmental laws are becoming more stringent.

Illustrative image related to forklift truck parts

One effective way to gauge a supplier’s commitment to sustainability is by checking for certifications such as ISO 14001, which focuses on effective environmental management systems. Additionally, the use of recycled materials in manufacturing forklift parts is gaining traction. Suppliers that provide remanufactured components not only offer cost-effective solutions but also contribute to reducing waste in landfills.

Furthermore, transparency in the supply chain is becoming a critical factor for buyers. Companies that can provide detailed information about their sourcing practices and the environmental impact of their products are more likely to gain the trust of B2B clients. This trend emphasizes the need for suppliers to be proactive in communicating their sustainability efforts, which can differentiate them in a competitive marketplace.

How Has the Forklift Parts Sector Evolved Over Time?

The forklift parts industry has undergone significant evolution over the past few decades, driven by technological advancements and changing market demands. Initially focused on basic mechanical components, the sector has expanded to include sophisticated electronic parts and IoT-enabled devices. This transition reflects the broader movement towards automation in material handling and logistics.

Historically, the industry relied heavily on OEM parts, but the rise of aftermarket parts has provided buyers with more options, often at lower prices. This diversification has enabled businesses to balance cost-effectiveness with quality, particularly in regions where budgets may be constrained. Additionally, as businesses increasingly prioritize uptime and operational efficiency, the focus on rapid delivery and extensive inventories has become a hallmark of leading suppliers.

Overall, the evolution of the forklift parts sector underscores the importance of adaptability and innovation. B2B buyers are encouraged to partner with suppliers who not only understand these shifts but also anticipate future trends, ensuring they are well-equipped to meet their operational needs.

Frequently Asked Questions (FAQs) for B2B Buyers of forklift truck parts

-

How do I choose the right forklift truck parts for my equipment?

Choosing the right forklift truck parts begins with identifying your specific model and its requirements. Consult the equipment manual to understand the necessary specifications. Consider sourcing parts from reputable suppliers who provide OEM (Original Equipment Manufacturer) parts for guaranteed compatibility and quality. Additionally, inquire about aftermarket options that may offer cost savings while still meeting safety and performance standards. Always verify the supplier’s expertise and customer support to ensure you can get assistance if needed. -

What are the advantages of using OEM versus aftermarket forklift parts?

OEM parts are specifically designed for your forklift model, ensuring perfect compatibility and adherence to manufacturer specifications. They often come with warranties and are tested for quality, which can provide peace of mind. On the other hand, aftermarket parts may offer cost advantages and greater availability. However, their quality can vary significantly, so it’s essential to source them from reputable suppliers who provide quality guarantees. Ultimately, the choice depends on your budget, urgency, and the operational demands of your equipment. -

What should I consider when vetting a supplier for forklift parts?

When vetting a supplier for forklift parts, assess their experience and reputation in the industry. Look for suppliers with a robust inventory, especially for the makes and models relevant to your operations. Evaluate their customer service, including response times and support availability in your preferred language. Additionally, check for quality certifications, warranty policies, and the ability to provide documentation for parts. Testimonials and reviews from other businesses can also help gauge their reliability and service quality. -

What is the minimum order quantity (MOQ) for forklift parts?

Minimum order quantities (MOQ) for forklift parts can vary significantly based on the supplier and the type of parts. Some suppliers may have a low MOQ for standard parts, while others might require larger quantities for specialized items or OEM parts. It is advisable to communicate directly with potential suppliers to understand their MOQ policies. For B2B buyers, negotiating MOQs can sometimes lead to better pricing and terms, especially if you are committing to a long-term partnership. -

What are common payment terms when purchasing forklift parts internationally?

Payment terms for international purchases of forklift parts can differ widely among suppliers. Common arrangements include payment in advance, net 30/60/90 days after delivery, or a letter of credit, especially for larger transactions. Ensure that the payment method aligns with your cash flow capabilities and risk tolerance. Discussing and agreeing on payment terms upfront can prevent misunderstandings and help establish a trustworthy relationship with your supplier. -

How can I ensure quality assurance for the forklift parts I purchase?

To ensure quality assurance for forklift parts, choose suppliers who conduct rigorous quality checks and offer warranties on their products. Request certifications that demonstrate compliance with international standards. Reviewing product specifications and testing results can also provide insights into the quality of the parts. Additionally, establishing a relationship with your supplier can facilitate ongoing communication about quality expectations and prompt resolutions for any issues that arise. -

What logistics considerations should I keep in mind when sourcing forklift parts internationally?

Logistics is crucial when sourcing forklift parts internationally. Consider the shipping options and lead times for delivery to your location. Understand the customs regulations and duties applicable to your imports to avoid unexpected costs and delays. Collaborating with suppliers who offer reliable shipping and tracking services can streamline the process. Additionally, evaluate the supplier’s capacity to handle urgent requests and their policies on returns or exchanges in case of issues with parts. -

Can I customize forklift parts to fit my specific needs?

Yes, many suppliers offer customization options for forklift parts to meet specific operational requirements. Customization may involve modifying existing parts or manufacturing new ones based on your specifications. It is essential to communicate your needs clearly and provide detailed requirements to your supplier. Be aware that custom orders may have longer lead times and potentially higher costs, so plan accordingly. Always confirm the supplier’s capabilities and past experience with custom solutions to ensure successful outcomes.

Top 8 Forklift Truck Parts Manufacturers & Suppliers List

1. Crown – Forklift Parts & Accessories

Domain: shop.crown.com

Registered: 1998 (27 years)

Introduction: Forklift Parts And Accessories include a variety of components such as Hydraulic Components, Fork Attachments, Electric Truck Components, Wheels and Tires, and Internal Combustion (IC) Truck Components. Popular products listed are: Ball Bearing (2.047 in. O.D., 0.984 in. I.D.) priced at $3.62, Shoulder Bearing (2.047 in. O.D., 0.984 in. I.D.) priced at $6.45, Crown Channel Slide Lube (10.5 oz.) pr…

2. Helmar Parts – Forklift Parts & Accessories

Domain: helmarparts.com

Registered: 1998 (27 years)

Introduction: Key product details include: 1. Forklift Parts & Accessories: Various categories such as Electrical & Ignition, Engine & Cooling, Hydraulics & Lifting, Brakes & Drivetrain, Transmission, Bearings, Wiring/Cables, Safety & Accessories, and more. 2. Featured Products: – IGNITION SWITCH (KEYLESS) – $21.84 – HEADLAMP (12-80V LED) – $15.00 (originally $26.40) – POWER STEERING CYLINDER – $605.00 – CARBUR…

3. TVH – Forklift Parts & Accessories

Domain: tvh.com

Registered: 1997 (28 years)

Introduction: Forklift parts and accessories suitable for any make or model. Over 50 years of technical expertise in material handling equipment. 49,500,000 known references for all major makes and models. 95% of orders shipped the same day and delivered within 24 hours in Europe and 48 hours worldwide. Database of 44,000,000 known references and 930,000 parts in stock, making TVH the biggest supplier of forkli…

4. Equipment Depot – OEM & Aftermarket Parts

Domain: eqdepot.com

Registered: 1998 (27 years)

Introduction: Equipment Depot offers a vast inventory of over $22 million in genuine OEM and aftermarket parts for various equipment including forklifts, scissor lifts, and boom lifts. They provide same and next-day shipping, and all parts are guaranteed for 6 months. The parts inventory includes replacement parts, maintenance parts, forklift tires, batteries, and chargers. Equipment Depot serves all major bran…

5. Cat® – Genuine Lift Truck Parts & Service

Domain: catlifttruck.com

Registered: 1999 (26 years)

Introduction: Genuine Cat® lift truck parts and service include a wide range of products such as counterbalance forklift trucks, warehouse equipment, and EQ line products. Key product categories include:

– Counterbalance Forklift Trucks: Electric Powered (1.4-12.0 tonnes), Diesel Powered (2.0-10.0 tonnes), LP Gas Powered (1.5-5.5 tonnes)

– Warehouse Equipment: Hand Pallet Trucks (2.5 tonnes), Power Pallet Tru…

6. Raymond – Limit Switch, Cylinder Kit, Hydraulic Pump

Domain: intellaparts.com

Registered: 2021 (4 years)

Introduction: Aftermarket forklift parts and accessories for brands including Hyster, Yale, Toyota, Clark, Crown, Caterpillar, JLG, Upright, and Terex. New products include: 1) Raymond 1-150-356-001 Limit Switch, 2) Raymond 828-900-096/102 Cylinder Kit, 3) Raymond 500-486/200 Hydraulic Pump, 4) Raymond 1035902-001 Grab Rail Switch Assembly, 5) Raymond 950-BLU-GRD Blue Guardian, 6) Raymond 114-009-649/005 Cable …

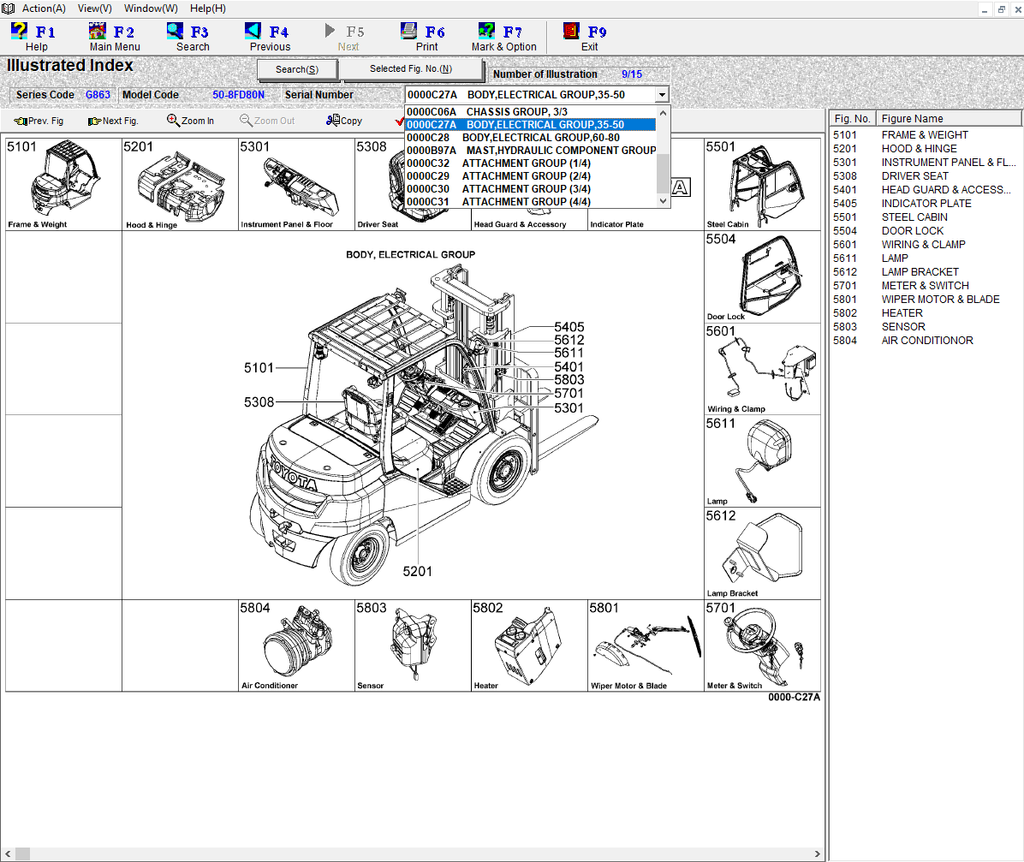

7. Toyota – Genuine Forklift Parts

Domain: toyotaforklift.com

Registered: 1996 (29 years)

Introduction: Genuine Toyota Forklift Parts & Accessories, Toyota Genuine Parts, Toyota Starlift Parts, high quality and durability, authorized Toyota Forklift Dealer, industry-leading two-year parts warranty, support from over 65 dealerships, 3,500+ Toyota Certified Technicians, guaranteed 4-hour emergency response time, designed for Toyota Forklifts, essential for maintaining safety and performance.

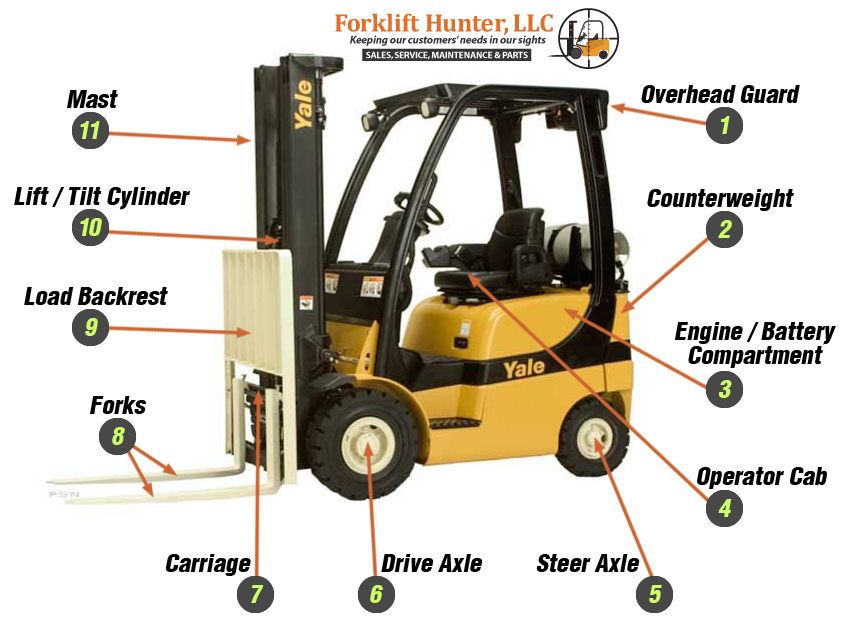

8. Logisnext Americas – Forklift Mast & Cylinder Solutions

Domain: logisnextamericas.com

Registered: 2020 (5 years)

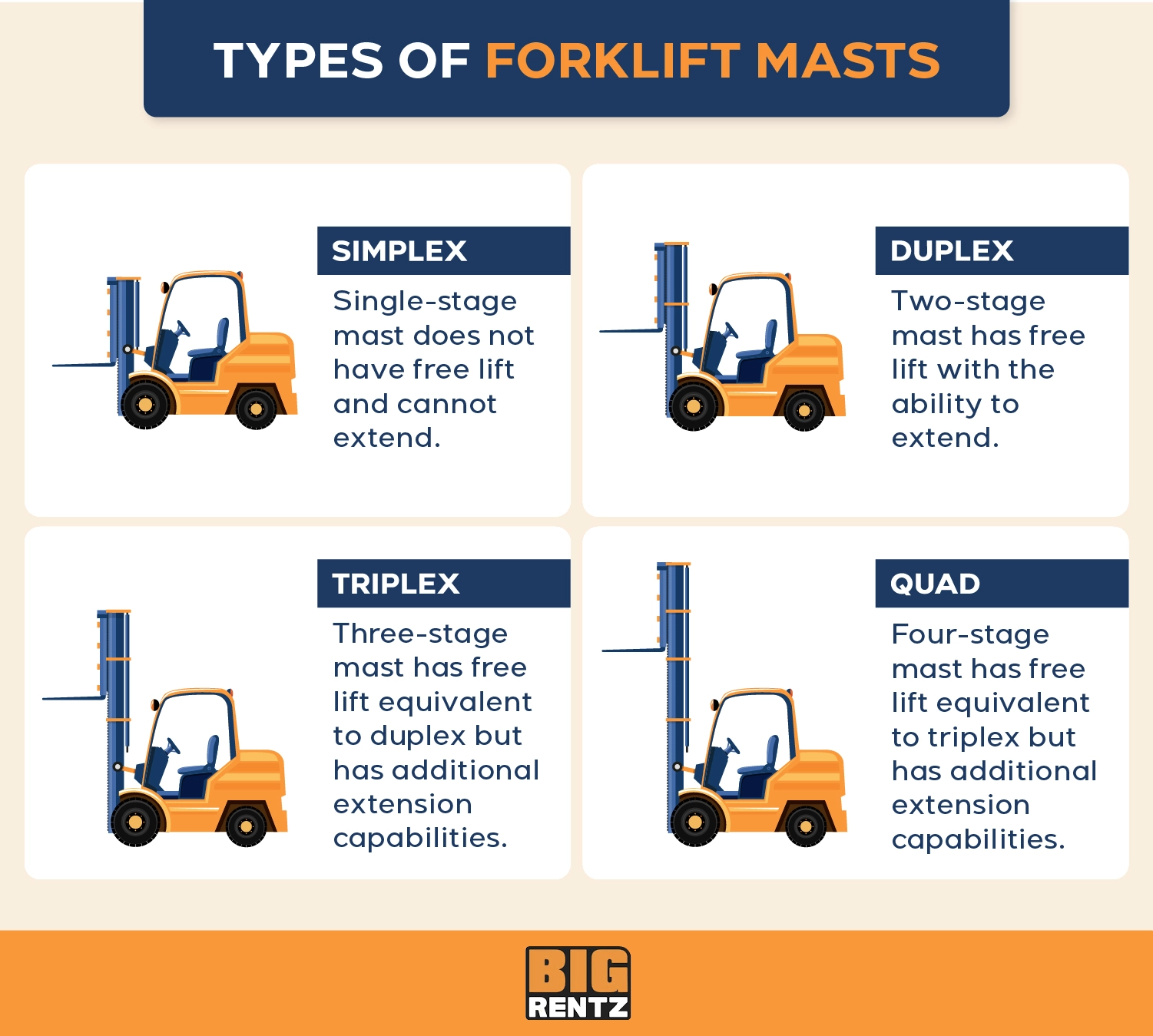

Introduction: Mast: Vertical support for raising/lowering loads; types include Duplex (2 stages), Triplex (3 stages), Quad (4 sections). Lift Cylinder: Powers vertical movement of the mast, generally hydraulically powered. Tilt Cylinder: Controls tilt movement of the carriage and forks. Forklift Carriage Assembly: Platform for mounting objects, includes forks and load backrest. Forks: Used to lift and transport…

Strategic Sourcing Conclusion and Outlook for forklift truck parts

In navigating the complex landscape of forklift truck parts, strategic sourcing emerges as a pivotal factor for international B2B buyers. By prioritizing high-quality components and reliable suppliers, businesses can significantly enhance operational efficiency and minimize downtime. The importance of sourcing genuine OEM and aftermarket parts cannot be overstated, as these choices directly impact the longevity and safety of equipment.

Moreover, leveraging suppliers with extensive inventories and rapid delivery capabilities—like those with same-day shipping options—ensures that companies can maintain their equipment without prolonged interruptions. As businesses expand across Africa, South America, the Middle East, and Europe, establishing robust relationships with trusted parts suppliers becomes essential.

Looking ahead, the demand for forklift truck parts is poised to grow alongside global supply chain advancements. Buyers are encouraged to explore partnerships that not only meet immediate needs but also align with long-term operational goals. By investing in strategic sourcing today, you can secure a competitive advantage that propels your business forward in an increasingly dynamic market. Embrace the future of material handling by optimizing your parts procurement strategy now.

Illustrative image related to forklift truck parts

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to forklift truck parts