How to Source Filter Specialists Inc Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for filter specialists inc

In today’s competitive landscape, sourcing high-quality filtration systems is a pressing challenge for international B2B buyers, particularly those in industries such as food and beverage, pharmaceuticals, and petrochemicals. Filter Specialists Inc. stands out as a trusted provider, offering a diverse range of filtration solutions tailored to meet the specific needs of various sectors. This guide aims to empower buyers by providing in-depth insights into the types of filtration systems available, their applications, and the critical factors to consider when selecting a supplier.

Navigating the complexities of the global market can be daunting, especially for businesses in Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Brazil. This comprehensive resource will delve into the nuances of filtration technologies, outline effective supplier vetting strategies, and explore cost considerations that impact purchasing decisions. By equipping buyers with the knowledge necessary to make informed choices, this guide ensures that you can confidently select the right filtration solutions to enhance operational efficiency and product quality.

As you explore the following sections, you will find actionable insights designed to streamline your procurement process, minimize risks, and foster successful partnerships with filter specialists like Filter Specialists Inc. Embrace the opportunity to enhance your filtration systems and elevate your business to new heights.

Understanding filter specialists inc Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

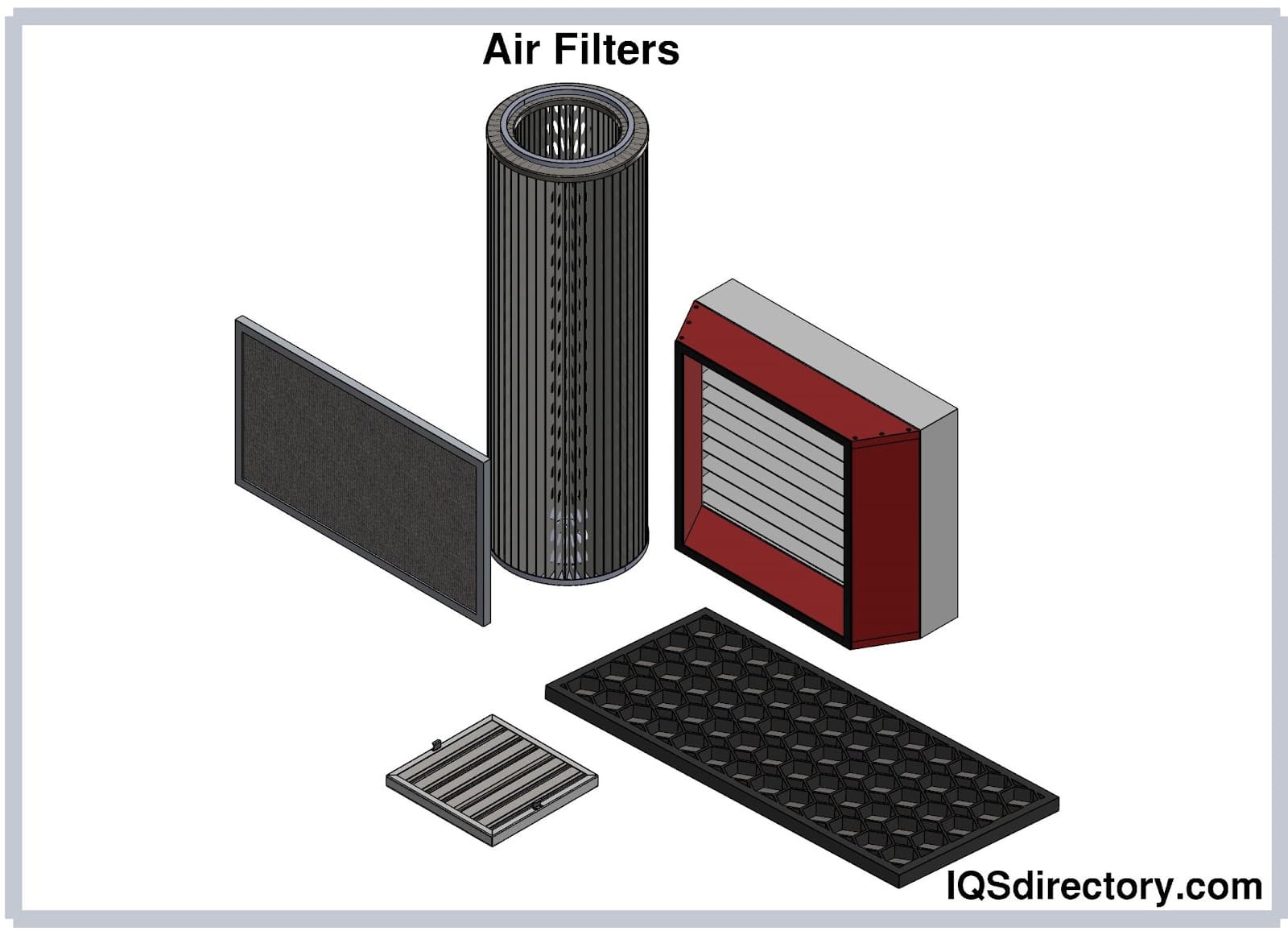

| Air Filters | Designed to capture airborne particles and pollutants | Manufacturing, HVAC, Pharmaceuticals | Pros: Enhances air quality, protects equipment; Cons: Requires regular maintenance and replacement. |

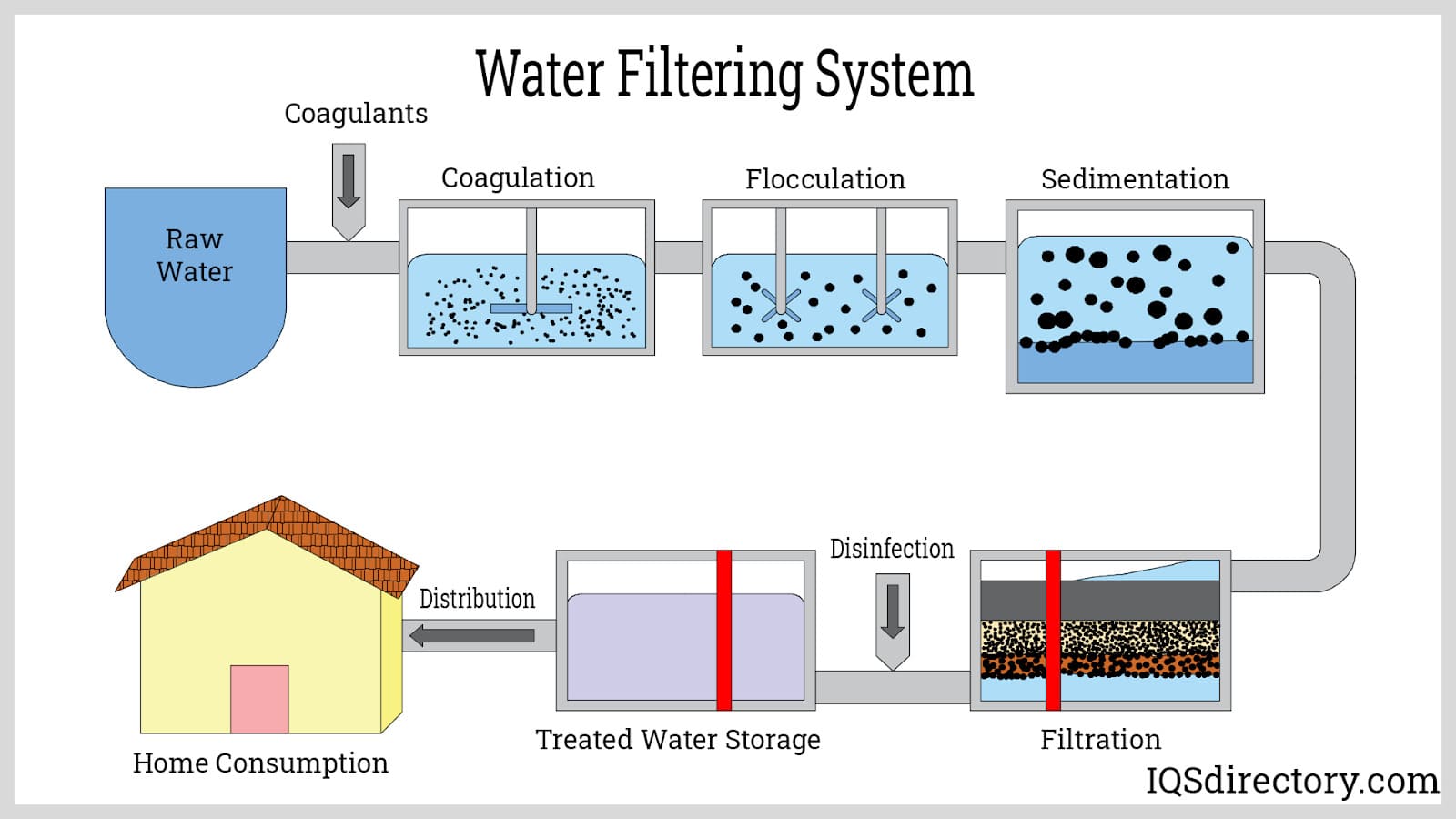

| Water Filters | Removes impurities from water sources | Food & Beverage, Water Treatment | Pros: Ensures safe drinking water, customizable; Cons: Initial installation costs may be high. |

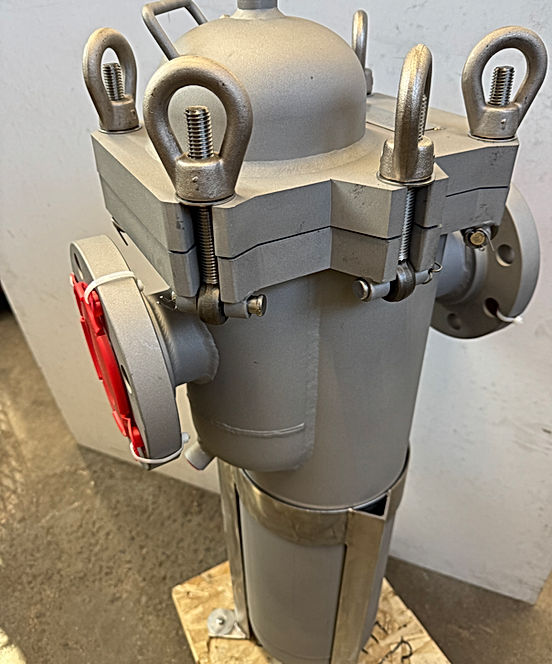

| Oil Filters | Specialized for removing contaminants from oils and lubricants | Automotive, Marine, Industrial | Pros: Extends machinery lifespan, improves efficiency; Cons: May require specific types for different applications. |

| Gas Filters | Removes impurities from gas streams | Energy, Petrochemical, HVAC | Pros: Ensures gas quality, protects equipment; Cons: Can be costly depending on gas type and application. |

| Industrial Fluid Filters | Designed for various industrial fluids like hydraulic and coolant | Manufacturing, Aerospace, Automotive | Pros: Protects machinery, enhances operational efficiency; Cons: Complex systems may require expert installation and maintenance. |

What Are the Characteristics and Suitability of Air Filters for B2B Buyers?

Air filters are essential in various industrial settings, specifically designed to capture airborne particles, allergens, and pollutants. They are crucial for maintaining clean air quality in manufacturing facilities, HVAC systems, and pharmaceutical environments. B2B buyers should consider the filter’s efficiency rating, maintenance requirements, and compatibility with existing systems. Regular maintenance is necessary to ensure optimal performance, making it essential to factor in ongoing costs alongside initial purchase prices.

How Do Water Filters Ensure Safety in B2B Applications?

Water filters are designed to remove contaminants from water sources, ensuring the safety and quality of water in food and beverage production, as well as in municipal water treatment facilities. These filters can be customized to meet specific needs based on the source and type of contaminants present. When purchasing, buyers should evaluate the filter’s capacity, maintenance needs, and regulatory compliance. While initial installation may involve significant costs, the long-term benefits of providing clean water often outweigh these expenses.

Why Are Oil Filters Critical for Machinery Longevity?

Oil filters play a vital role in removing contaminants from oils and lubricants used in various machinery, including automotive and industrial applications. By ensuring clean oil circulation, these filters enhance the efficiency and longevity of equipment. B2B buyers should assess the filter’s compatibility with specific machinery types and the environment in which they will be used. While oil filters can be more expensive, the reduction in machinery wear and tear can lead to substantial cost savings over time.

Illustrative image related to filter specialists inc

What Are the Key Features of Gas Filters in Industrial Applications?

Gas filters are designed to remove impurities from gas streams, which is particularly important in energy and petrochemical industries. They help ensure the quality of gases like natural gas and propane, protecting downstream equipment from damage. When selecting gas filters, buyers must consider the type of gas, the level of filtration required, and the filter’s capacity. Although gas filters can be costly, they are crucial for maintaining operational efficiency and safety in industrial applications.

How Do Industrial Fluid Filters Enhance Operational Efficiency?

Industrial fluid filters are tailored to remove contaminants from various fluids, including hydraulic fluids and coolants used in manufacturing and aerospace applications. These filters help protect machinery from damage, thereby enhancing overall operational efficiency. B2B buyers should evaluate the filter’s design, filtration capacity, and maintenance requirements. While complex systems might necessitate expert installation and ongoing maintenance, the investment is justified by the improved reliability and performance of industrial operations.

Key Industrial Applications of filter specialists inc

| Industry/Sector | Specific Application of filter specialists inc | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Filtration of water and liquids in processing | Ensures product safety and compliance with health standards | Quality certifications, custom designs, and maintenance support |

| Pharmaceuticals | Air and liquid filtration for cleanroom environments | Guarantees contamination-free products and processes | Regulatory compliance, HEPA filter efficiency, and reliability |

| Petrochemicals | Oil and gas filtration systems | Enhances operational efficiency and equipment lifespan | Material compatibility, pressure ratings, and emergency support |

| Water Treatment | Filtration systems for municipal and industrial water | Promotes safe drinking water and environmental compliance | Filtration capacity, local regulations, and installation services |

| Manufacturing | Industrial fluid filters for machinery | Reduces downtime and maintenance costs | Customization options, technical support, and service agreements |

How Does Filter Specialists Inc. Benefit the Food and Beverage Industry?

In the food and beverage sector, Filter Specialists Inc. provides filtration systems that are essential for ensuring the purity of water and other liquids during processing. These systems effectively remove impurities, pathogens, and contaminants, which is crucial for meeting stringent health and safety regulations. International buyers, particularly from regions such as Africa and South America, should consider the specific requirements of local regulations and quality certifications when sourcing these solutions. Additionally, the ability to customize filtration systems can enhance operational efficiency and product quality.

What Role Does Filtration Play in the Pharmaceutical Sector?

In pharmaceutical manufacturing, maintaining a contamination-free environment is vital. Filter Specialists Inc. offers advanced air and liquid filtration systems designed for cleanroom environments. These systems ensure that air quality meets the high standards required for drug production, thereby safeguarding the efficacy and safety of pharmaceutical products. For international buyers, it’s important to focus on HEPA filter efficiency and compliance with global regulatory standards to ensure that their operations remain competitive and compliant.

How Are Filtration Systems Used in the Petrochemical Industry?

In the petrochemical industry, Filter Specialists Inc. provides robust oil and gas filtration systems that play a critical role in enhancing operational efficiency. By removing contaminants from oil and gas streams, these systems help prolong the lifespan of machinery and reduce maintenance costs. Buyers in this sector, especially from the Middle East, should prioritize sourcing filters that are compatible with specific fluid characteristics and that can withstand high-pressure environments. Additionally, having access to emergency support can be a significant advantage in maintaining continuous operations.

Illustrative image related to filter specialists inc

What Are the Benefits of Filtration in Water Treatment?

Water treatment facilities rely heavily on filtration systems to ensure safe drinking water and compliance with environmental regulations. Filter Specialists Inc. supplies filtration solutions that effectively remove sediments, bacteria, and chemical contaminants from various water sources. For international B2B buyers, particularly in developing regions, understanding local regulations and the filtration capacity needed for municipal applications is crucial. Additionally, buyers should consider the availability of installation and maintenance services to ensure the longevity and reliability of their filtration systems.

How Does Filtration Improve Manufacturing Processes?

In the manufacturing sector, Filter Specialists Inc. provides industrial fluid filters designed to maintain the quality of lubricants and other fluids used in machinery. These filters help reduce downtime and lower maintenance costs by preventing contamination that can lead to equipment failure. Buyers should seek customization options that fit their specific operational needs and ensure technical support is available for installation and troubleshooting. This focus on tailored solutions can significantly enhance productivity and operational efficiency in manufacturing environments.

3 Common User Pain Points for ‘filter specialists inc’ & Their Solutions

Scenario 1: Inconsistent Filtration Quality Impacting Production

The Problem:

B2B buyers in industries such as food and beverage or pharmaceuticals often face significant challenges with inconsistent filtration quality. This inconsistency can lead to contamination of products, resulting in costly recalls, regulatory fines, and damage to brand reputation. For instance, a beverage manufacturer might experience variable filter performance, where some batches meet quality standards while others do not. This unpredictability can stem from the use of subpar filters or inadequate maintenance practices, leaving buyers feeling frustrated and uncertain about their filtration systems’ reliability.

The Solution:

To address this issue, buyers should conduct a thorough assessment of their current filtration systems and identify specific needs based on the type of materials being filtered. Engaging with Filter Specialists Inc. can provide tailored filtration solutions that ensure consistent quality. Buyers should consider requesting a comprehensive consultation where Filter Specialists can evaluate existing setups and recommend custom-designed filters that match the operational requirements. Additionally, implementing a proactive maintenance schedule, supported by Filter Specialists’ installation and servicing capabilities, will enhance the longevity and effectiveness of the filtration systems, ensuring that every batch meets the required quality standards.

Scenario 2: High Operational Costs Due to Inefficient Filtration Systems

The Problem:

Many businesses struggle with high operational costs linked to inefficient filtration systems. For instance, an industrial plant may find that their current filters require frequent replacements or cleaning, leading to unplanned downtime and increased labor costs. Moreover, poor filtration can lead to equipment damage, further inflating maintenance expenses. This situation is particularly concerning for businesses operating in competitive markets where profit margins are tight, and every dollar counts.

The Solution:

Buyers should analyze the total cost of ownership of their filtration systems rather than just the initial purchase price. By partnering with Filter Specialists Inc., businesses can benefit from expert recommendations on high-efficiency filters that offer longer service life and lower energy consumption. Implementing advanced filtration technologies, such as HEPA filters or custom industrial fluid filters, can drastically reduce operational costs over time. Additionally, engaging in filter testing services offered by Filter Specialists can validate the performance of existing filters and inform decisions on upgrades, ensuring the most cost-effective solutions are in place.

Scenario 3: Regulatory Compliance Challenges with Filtration Systems

The Problem:

In regulated industries like pharmaceuticals and food processing, failing to comply with stringent filtration standards can have severe repercussions. Buyers often face challenges in understanding and implementing the necessary filtration technologies to meet local and international regulations. For example, a pharmaceutical manufacturer may be unaware that their current filtration solution does not meet new regulatory guidelines, risking not only financial penalties but also jeopardizing their product’s market availability.

The Solution:

To navigate the complexities of regulatory compliance, B2B buyers should leverage the expertise of Filter Specialists Inc. by initiating discussions on compliance requirements specific to their industry. Buyers should ensure that their filtration solutions are designed to meet these regulations from the outset. Filter Specialists can assist in selecting the right filters and systems that comply with health and safety standards. Moreover, utilizing their technical support for filter testing and documentation can provide the necessary assurance that filtration systems meet the required benchmarks. Engaging in regular audits and updates with Filter Specialists will also keep buyers informed of any changes in regulations, ensuring ongoing compliance and peace of mind.

Strategic Material Selection Guide for filter specialists inc

What Are the Key Materials Used in Filtration Systems by Filter Specialists Inc.?

Filter Specialists Inc. utilizes a variety of materials in their filtration systems, each with unique properties that cater to different applications. Understanding these materials is crucial for international B2B buyers seeking effective filtration solutions.

How Do Stainless Steel Filters Perform in Industrial Applications?

Stainless steel is a popular choice for filtration systems due to its excellent corrosion resistance and high-temperature tolerance. It can withstand harsh environments, making it ideal for industries such as petrochemicals and pharmaceuticals. The key properties include a temperature rating of up to 800°F (427°C) and high pressure ratings, often exceeding 150 psi.

Pros: Stainless steel is durable, easy to clean, and resistant to rust and corrosion, which enhances the longevity of the filtration system.

Cons: However, it is relatively expensive compared to other materials, and its manufacturing can be complex, potentially leading to longer lead times.

For international buyers, especially in regions like the Middle East where high temperatures and corrosive environments are common, stainless steel filters are often compliant with ASTM standards, ensuring reliability.

What Advantages Do Polypropylene Filters Offer for Water Filtration?

Polypropylene is widely used for water filtration applications due to its excellent chemical resistance and lightweight nature. It can handle temperatures up to 180°F (82°C) and provides a good barrier against a range of contaminants.

Pros: The material is cost-effective and easy to manufacture, allowing for rapid production of custom filters.

Cons: However, polypropylene may not be suitable for high-temperature applications or where exposure to certain solvents is expected.

International buyers, particularly from South America where water quality is a significant concern, find polypropylene filters appealing due to their compliance with local health and safety standards.

Why Are Activated Carbon Filters Essential for Air Quality Management?

Activated carbon is essential for air filtration systems, especially in applications requiring the removal of volatile organic compounds (VOCs) and odors. It operates effectively at room temperature and can handle moderate pressure conditions.

Pros: Activated carbon filters are highly effective at trapping impurities, providing superior air quality.

Cons: They have a limited lifespan and may require frequent replacement, which can increase long-term costs.

In regions like Europe, where environmental regulations are stringent, activated carbon filters often meet compliance standards such as DIN EN 779, making them a preferred choice for industrial air quality management.

What Role Does Glass Fiber Play in High-Efficiency Filtration?

Glass fiber is utilized in high-efficiency particulate air (HEPA) filters due to its ability to capture very small particles, including allergens and bacteria. It can operate effectively at temperatures up to 500°F (260°C) and under high pressure.

Illustrative image related to filter specialists inc

Pros: Glass fiber filters offer high filtration efficiency and durability, making them suitable for critical applications in healthcare and cleanroom environments.

Cons: The manufacturing process can be more complex, which may lead to higher costs compared to synthetic alternatives.

For international buyers, particularly in the healthcare sector in regions like Africa, glass fiber filters align with compliance standards such as ISO 14644, ensuring they meet necessary air quality requirements.

Summary Table of Material Properties

| Material | Typical Use Case for filter specialists inc | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Petrochemical filtration | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Polypropylene | Water filtration | Cost-effective and lightweight | Limited high-temperature suitability | Low |

| Activated Carbon | Air quality management | Superior impurity trapping | Short lifespan requiring frequent replacement | Medium |

| Glass Fiber | HEPA filtration in healthcare | High filtration efficiency | More complex manufacturing process | High |

This strategic material selection guide provides essential insights for international B2B buyers, enabling informed decisions when sourcing filtration solutions from Filter Specialists Inc.

Illustrative image related to filter specialists inc

In-depth Look: Manufacturing Processes and Quality Assurance for filter specialists inc

What Are the Key Stages in the Manufacturing Process at Filter Specialists Inc.?

Filter Specialists Inc. employs a comprehensive manufacturing process that ensures the production of high-quality filtration systems. This process can be broken down into several main stages: material preparation, forming, assembly, and finishing.

How Is Material Prepared for Filtration Systems?

The first stage of manufacturing begins with the careful selection and preparation of materials. Filter Specialists Inc. sources high-quality materials such as stainless steel, polypropylene, and specialized filter media that meet industry standards. These materials undergo rigorous inspection to confirm their integrity and suitability for filtration applications. By utilizing advanced material preparation techniques, the company ensures that only the best components are used in the production process.

What Techniques Are Used in Forming Filtration Products?

Once the materials are ready, they move to the forming stage. This involves various techniques, including cutting, welding, and molding, tailored to the specific requirements of each filtration product. For instance, the company may use precision cutting to create filter bags and advanced welding techniques to assemble metal frames for air and liquid filters. The choice of forming technique is critical as it directly impacts the performance and durability of the filtration systems.

How Are Filtration Systems Assembled?

The assembly stage is where individual components come together to create the final product. Filter Specialists Inc. employs skilled technicians who meticulously assemble each filtration system, ensuring that all parts fit together perfectly. This stage also includes integrating any necessary automation or monitoring systems, which can enhance the operational efficiency of the filters. By focusing on precision and attention to detail during assembly, the company minimizes the risk of defects and maximizes performance.

What Finishing Processes Are Implemented to Ensure Quality?

The finishing stage involves several processes designed to enhance the aesthetic and functional qualities of the filtration systems. This can include surface treatments, coatings, and final inspections. For example, filters may undergo a corrosion-resistant coating process to extend their lifespan, especially in harsh environments. Final inspections at this stage are crucial to ensure that every product meets the company’s stringent quality standards before it is shipped to clients.

Illustrative image related to filter specialists inc

What Quality Assurance Practices Does Filter Specialists Inc. Implement?

Quality assurance (QA) is an integral part of Filter Specialists Inc.’s operations, ensuring that every filtration system meets both internal and international standards. The company adheres to ISO 9001, a widely recognized standard for quality management systems, which ensures consistent quality in products and services.

Which International and Industry-Specific Standards Are Followed?

In addition to ISO 9001, Filter Specialists Inc. complies with various industry-specific standards such as CE marking for European markets and API standards for oil and gas applications. These certifications demonstrate the company’s commitment to safety, reliability, and performance in its filtration products. For B2B buyers, especially those in international markets like Africa, South America, the Middle East, and Europe, understanding these standards is crucial for ensuring product compliance and reliability.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Filter Specialists Inc. incorporates multiple quality control (QC) checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Materials are inspected upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing stages to catch any defects early. This includes checking dimensions, tolerances, and assembly accuracy.

- Final Quality Control (FQC): After assembly, each filtration system undergoes a comprehensive inspection to ensure it meets all performance specifications and quality standards.

By implementing these checkpoints, the company can maintain high-quality output and reduce the likelihood of defects.

What Common Testing Methods Are Used to Validate Filter Performance?

To validate the performance of its filtration systems, Filter Specialists Inc. employs a variety of testing methods. These may include:

- Flow Rate Testing: Ensuring that the filter operates efficiently under specified conditions.

- Particle Retention Testing: Measuring the filter’s ability to capture contaminants.

- Pressure Drop Testing: Assessing the filter’s resistance to airflow or fluid flow, which indicates efficiency and performance.

These tests are critical for ensuring that products meet client specifications and industry standards.

How Can B2B Buyers Verify the Quality Control of Filter Specialists Inc.?

For international B2B buyers, particularly those from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential. Here are several methods to ensure the reliability of Filter Specialists Inc.:

What Steps Can Be Taken to Conduct Supplier Audits?

Buyers can conduct supplier audits to evaluate the manufacturing processes and quality control measures in place. This can include site visits to observe the production environment, review documentation related to quality assurance practices, and discuss processes with the management team.

Illustrative image related to filter specialists inc

How Can Buyers Access Quality Reports and Certifications?

Buyers should request quality assurance reports and certifications from Filter Specialists Inc. These documents provide insight into compliance with international standards and demonstrate the company’s commitment to quality. Regular updates on quality metrics can also be beneficial.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can offer an additional layer of assurance. These independent organizations can perform audits and testing to validate the claims made by Filter Specialists Inc. regarding product quality and performance. This is particularly important for buyers in competitive markets, where quality can be a differentiating factor.

What Are the Unique Quality Control Considerations for International Buyers?

International buyers must also consider specific nuances related to quality control. For instance, understanding local regulations and standards can impact the acceptance of products in different regions. Furthermore, language barriers and differences in business practices can affect communication regarding quality assurance. Establishing clear expectations and maintaining open lines of communication with Filter Specialists Inc. can help mitigate these challenges.

By understanding the manufacturing processes and quality assurance practices at Filter Specialists Inc., B2B buyers can make informed decisions and establish reliable partnerships that enhance their operations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘filter specialists inc’

Introduction

This practical sourcing guide is designed to assist B2B buyers in navigating the procurement process for filtration systems from Filter Specialists Inc. By following this step-by-step checklist, buyers can ensure they make informed decisions that align with their operational needs, regulatory requirements, and quality standards.

Illustrative image related to filter specialists inc

Step 1: Define Your Technical Specifications

Clearly outlining your filtration needs is crucial before reaching out to suppliers. Consider factors such as the type of contaminants you need to filter, the volume of liquid or air to be processed, and the environmental conditions in which the filters will operate. This will help ensure that you select a system that meets your specific performance requirements.

Step 2: Research Filter Specialists Inc. Offerings

Take the time to explore the range of products and services offered by Filter Specialists Inc. This includes air filters, water filters, oil filters, and industrial fluid filters. Understanding their product capabilities will enable you to identify the right solutions for your industry, whether it’s pharmaceuticals, food and beverage, or petrochemicals.

Step 3: Evaluate Potential Suppliers

Before making a commitment, it’s essential to thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. Look for suppliers that demonstrate a strong track record of reliability and quality to ensure you’re partnering with a reputable provider.

Step 4: Request Customization Options

Engage with Filter Specialists Inc. to discuss any customization needs for your filtration systems. Many industries have unique requirements, and customized filters can significantly enhance performance and efficiency. Inquire about their ability to tailor solutions to your specifications and the associated costs and timelines.

Step 5: Check Certifications and Compliance

Verify that the filtration systems comply with relevant industry standards and certifications. This is particularly important for sectors like pharmaceuticals and food and beverage, where regulatory compliance is critical. Certifications can also be an indicator of product quality and reliability.

Step 6: Assess After-Sales Support and Services

Inquire about the after-sales support and maintenance services offered by Filter Specialists Inc. A reliable supplier should provide installation, maintenance, and emergency support services. Understanding these offerings will help you gauge the overall partnership value and ensure your systems operate optimally throughout their lifecycle.

Step 7: Request a Quote and Compare Offers

Finally, request a detailed quote from Filter Specialists Inc. and compare it with other suppliers. Pay attention to pricing, delivery timelines, and terms of service. A thorough comparison will not only help you understand the market value but also empower you to negotiate better terms based on your findings.

By following this checklist, B2B buyers can effectively source filtration solutions from Filter Specialists Inc., ensuring that their procurement decisions are strategic and well-informed.

Comprehensive Cost and Pricing Analysis for filter specialists inc Sourcing

What Are the Key Cost Components in Sourcing Filtration Solutions from Filter Specialists Inc.?

When sourcing filtration systems from Filter Specialists Inc., understanding the cost structure is essential for making informed purchasing decisions. The primary cost components include:

-

Materials: The quality of materials used in filtration systems significantly influences cost. High-grade materials such as stainless steel and specialized filter media may have a higher upfront cost but can enhance durability and performance.

-

Labor: Labor costs encompass the workforce involved in manufacturing, assembling, and testing filtration systems. Skilled labor may be required for custom solutions, leading to variations in labor costs based on complexity.

-

Manufacturing Overhead: This includes indirect costs associated with production, such as facility maintenance, utilities, and equipment depreciation. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: Custom filtration solutions often require specialized tooling, which can add to the initial investment. However, the costs can be amortized over larger production runs.

-

Quality Control (QC): Rigorous QC processes ensure that products meet specified standards, affecting overall costs. Investing in quality assurance can prevent costly recalls or rework.

-

Logistics: Shipping and handling costs can vary depending on destination, freight method, and Incoterms. International shipments may incur additional tariffs or duties, impacting the total landed cost.

-

Margin: The profit margin for Filter Specialists Inc. will depend on market conditions and competition. Understanding the pricing strategy can help buyers negotiate better deals.

How Do Price Influencers Affect Filtration System Costs?

Several factors influence the pricing of filtration systems from Filter Specialists Inc., including:

-

Volume/MOQ: Purchasing in larger quantities often results in discounts. Understanding the minimum order quantity (MOQ) can help buyers optimize their purchasing strategy.

-

Specifications and Customization: Custom-designed filters tailored to specific needs typically come at a premium. Buyers should weigh the benefits of customization against standard solutions.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, FDA) can increase costs but ensure compliance and reliability. Buyers should assess their industry requirements when considering certifications.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a track record of quality and service may command higher prices but offer peace of mind.

-

Incoterms: The chosen Incoterms can influence shipping costs and responsibilities. Understanding these terms can help buyers calculate total costs more accurately.

What Are the Best Practices for Negotiating Prices in International B2B Filtration Purchases?

International buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, should consider the following tips to negotiate effectively:

-

Understand Total Cost of Ownership (TCO): Evaluate not only the purchase price but also installation, maintenance, and operational costs over the lifecycle of the filtration system. This holistic view can justify a higher initial investment if it leads to lower operational costs.

-

Leverage Volume Discounts: If feasible, consolidate orders to meet or exceed MOQs to take advantage of bulk pricing. This approach can lead to significant savings.

-

Be Transparent About Needs: Clearly communicate specific requirements and constraints. This transparency can foster trust and facilitate tailored offers from suppliers.

-

Factor in Logistics and Duties: When negotiating prices, consider the implications of shipping and customs duties. Understanding the total landed cost can provide leverage in discussions.

-

Build Long-Term Relationships: Establishing a good rapport with suppliers can lead to better pricing and terms over time. Long-term partnerships can result in enhanced service and preferential pricing.

Disclaimer on Pricing Information

Prices can vary widely based on numerous factors, including market fluctuations, specific project requirements, and geographic location. The figures discussed herein are indicative and should be verified with Filter Specialists Inc. for accurate quotes tailored to your specific needs.

Alternatives Analysis: Comparing filter specialists inc With Other Solutions

Understanding Alternative Filtration Solutions for B2B Buyers

When considering filtration systems, B2B buyers often seek alternatives that can meet their specific requirements while optimizing performance and cost. Filter Specialists Inc. offers a robust range of filtration solutions; however, evaluating alternatives can provide insights into different technologies and methodologies that may better suit unique business needs. Below, we compare Filter Specialists Inc. with two viable alternatives: Cartridge Filtration Systems and Reverse Osmosis Systems.

| Comparison Aspect | Filter Specialists Inc. | Cartridge Filtration Systems | Reverse Osmosis Systems |

|---|---|---|---|

| Performance | High-quality filtration for various industries | Effective for particulate removal | Excellent for dissolved solids removal |

| Cost | Moderate initial investment | Generally lower upfront costs | Higher initial setup and maintenance costs |

| Ease of Implementation | Requires professional installation and setup | Easier installation; often DIY-friendly | Complex installation requiring professionals |

| Maintenance | Regular maintenance needed; professional support available | Low maintenance; frequent cartridge replacement | Regular maintenance and monitoring needed |

| Best Use Case | Versatile applications across multiple industries | Ideal for water and air filtration | Best for applications requiring high purity water |

What Are the Pros and Cons of Cartridge Filtration Systems?

Cartridge filtration systems are a popular choice for many businesses due to their effectiveness in removing particulate matter from liquids and air. They are relatively low-cost and easy to install, making them accessible for smaller operations or those with limited technical expertise. However, they require regular cartridge replacement, which can accumulate costs over time. Additionally, while effective for particulate removal, they may not address dissolved solids or chemical contaminants, limiting their application scope.

What Makes Reverse Osmosis Systems a Viable Alternative?

Reverse osmosis (RO) systems are renowned for their ability to remove dissolved solids, making them ideal for applications requiring high-purity water, such as pharmaceuticals and food production. They are highly effective in removing a wide range of contaminants, including salts and minerals. However, the initial setup and maintenance costs can be significant, and they typically require professional installation. Additionally, RO systems may produce wastewater, which can be a drawback for some operations focused on sustainability.

Conclusion: How to Choose the Right Filtration Solution

Selecting the right filtration solution requires a clear understanding of your specific business needs and operational challenges. B2B buyers should evaluate the performance requirements, budget constraints, and maintenance capabilities of each solution. Filter Specialists Inc. offers a comprehensive array of filtration systems tailored to various industries, but alternatives like cartridge filtration and reverse osmosis systems may provide better alignment with certain operational needs. By assessing the pros and cons of each option, businesses can make informed decisions that enhance their filtration processes and overall operational efficiency.

Essential Technical Properties and Trade Terminology for filter specialists inc

What Are the Key Technical Properties of Filtration Systems?

1. Material Grade

The material grade of filters is crucial in determining their durability and effectiveness. Common materials include stainless steel, polypropylene, and fiberglass. Each material has its unique resistance to chemicals, temperature, and pressure, which impacts its suitability for specific applications. For instance, stainless steel is preferred in high-temperature and corrosive environments, while polypropylene is often used for water filtration due to its chemical resistance. Understanding material grades helps buyers select the right filter for their operational needs, ensuring longevity and reliability.

2. Filtration Efficiency

Filtration efficiency, often expressed as a percentage, indicates the filter’s ability to remove particles of specific sizes from a fluid stream. This specification is vital for industries like pharmaceuticals and food and beverage, where product purity is non-negotiable. High-efficiency filters, such as HEPA filters, can capture particles down to 0.3 microns, making them essential in environments requiring strict air quality standards. Buyers must assess their filtration efficiency needs based on the contaminants present in their processes.

3. Flow Rate

Flow rate refers to the volume of fluid that can pass through a filter within a given time frame, typically measured in gallons per minute (GPM) or liters per second (L/s). This property is essential for ensuring that filtration systems can handle the operational demands of a facility without bottlenecks. A mismatch between flow rate and operational requirements can lead to inefficiencies or equipment failure. Buyers should evaluate their processes to determine the necessary flow rate before selecting a filtration system.

4. Tolerance Levels

Tolerance levels indicate the permissible variation in the dimensions of the filter components, which is critical for ensuring a proper fit and function within filtration systems. Tight tolerances are particularly important in high-precision applications, such as aerospace and medical industries, where even minor deviations can lead to significant performance issues. Buyers should be aware of tolerance requirements to avoid compatibility problems and ensure optimal filtration performance.

5. Operating Pressure and Temperature

Filters must be rated for specific operating pressures and temperatures to function effectively in their intended environments. Overlooking these specifications can lead to filter failure, resulting in costly downtime and repairs. Buyers need to consider the operational conditions of their applications when selecting filters, ensuring that they can withstand the anticipated pressures and temperatures without compromising performance.

What Are Common Trade Terms Relevant to Filter Specialists Inc.?

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the filtration industry, OEM filters are designed to meet specific standards set by equipment manufacturers, ensuring compatibility and reliability. Understanding OEM specifications is crucial for buyers looking to maintain equipment performance.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is particularly relevant in B2B transactions, as it affects purchasing decisions and inventory management. Buyers should inquire about MOQs to ensure that their procurement aligns with their operational needs and budget constraints.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to solicit price quotations for specific products or services. It outlines the buyer’s requirements, allowing suppliers to provide competitive pricing. For B2B buyers, submitting an RFQ can streamline the procurement process and ensure they receive the best possible offers for filtration systems.

Illustrative image related to filter specialists inc

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in global trade. They clarify who is responsible for shipping, insurance, and tariffs, which is particularly important for international buyers in regions like Africa and South America. Familiarity with Incoterms helps buyers mitigate risks and understand their obligations in cross-border transactions.

5. Service Level Agreement (SLA)

An SLA is a contract that outlines the expected level of service between a service provider and a client. In the context of filtration systems, it may include performance metrics, response times for maintenance, and support services. Understanding SLAs is essential for buyers to ensure they receive the necessary support and reliability from their filtration systems.

These technical properties and trade terms are vital for B2B buyers in making informed decisions when sourcing filtration solutions from Filter Specialists Inc. By understanding these aspects, buyers can optimize their filtration processes and enhance operational efficiency.

Illustrative image related to filter specialists inc

Navigating Market Dynamics and Sourcing Trends in the filter specialists inc Sector

What Are the Key Market Dynamics and Trends in the Filter Specialists Inc Sector?

The filtration industry is experiencing significant growth driven by increasing regulatory standards and rising demand for high-quality filtration solutions across various sectors, including food and beverage, pharmaceuticals, and petrochemicals. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly looking for reliable partners who can provide customized filtration systems that meet their specific operational needs. As environmental concerns rise, there’s a marked shift towards filtration solutions that not only enhance product purity but also minimize waste and energy consumption.

Emerging technologies, such as IoT-enabled filtration systems and advanced materials, are reshaping sourcing strategies. Buyers are leveraging data analytics to optimize the performance of filtration systems and enhance predictive maintenance capabilities. This trend towards digitalization is vital for international buyers who seek to improve operational efficiency and reduce downtime. Furthermore, the rise of e-commerce platforms is facilitating easier access to a broader range of products and suppliers, empowering buyers to make informed decisions based on comparative analyses.

How Can Sustainability and Ethical Sourcing Impact B2B Relationships in the Filtration Sector?

Sustainability is becoming a critical factor for B2B buyers in the filtration industry. Companies are increasingly aware of their environmental footprint and are seeking filtration solutions that reduce waste and promote resource conservation. This shift is prompting suppliers like Filter Specialists Inc. to adopt environmentally friendly practices, such as using recyclable materials and minimizing the use of harmful chemicals in their products.

Ethical sourcing is also gaining traction, as buyers demand transparency in supply chains. This includes understanding the sourcing of materials and ensuring that suppliers adhere to ethical labor practices. Certifications such as ISO 14001 (Environmental Management) and other ‘green’ certifications are becoming essential for suppliers aiming to establish credibility in the market. International buyers are particularly focused on suppliers who can demonstrate compliance with these standards, as it not only reflects a commitment to sustainability but also enhances brand reputation and consumer trust.

Illustrative image related to filter specialists inc

What Is the Historical Context of Filter Specialists Inc in the B2B Market?

Founded in 1995, Filter Specialists Inc. has evolved into a key player in the filtration market by focusing on high-quality products and exceptional customer service. Over the years, the company has expanded its offerings to include a wide range of filtration systems tailored to various industries. Their commitment to innovation and customer-centric solutions has positioned them as a trusted partner for international B2B buyers. As the industry continues to evolve, Filter Specialists Inc. remains dedicated to adapting its strategies to meet the changing needs of the global market, ensuring that they stay ahead in an increasingly competitive landscape.

Frequently Asked Questions (FAQs) for B2B Buyers of filter specialists inc

1. How do I select the right filtration system for my industry?

Choosing the right filtration system depends on the specific needs of your industry and application. Start by assessing the type of contaminants you need to remove—whether they are solid particles, bacteria, or chemical impurities. For instance, food and beverage industries may require high-grade water filters, while petrochemical operations might need robust oil filters. Collaborate with Filter Specialists Inc. to understand their range of products, including custom solutions, ensuring you select a system that meets your operational standards and compliance requirements.

2. What are the available customization options for filtration products?

Filter Specialists Inc. offers extensive customization options to meet diverse industrial needs. This includes tailored filter sizes, materials, and designs based on your specific applications. Whether you require specialized air filters for cleanroom environments or unique bag filters for specific liquids, their engineering team can assist in developing a solution that aligns with your operational parameters. Engage in discussions with their experts to explore how your unique requirements can be integrated into the filtration design.

Illustrative image related to filter specialists inc

3. What are the minimum order quantities (MOQs) for filter systems?

Minimum order quantities (MOQs) can vary depending on the specific filter product and customization requirements. Typically, bulk orders may qualify for reduced pricing or special terms. It is advisable to consult with Filter Specialists Inc. directly to understand the MOQs for your desired products, ensuring you can plan your procurement strategy effectively while accommodating your budget and inventory needs.

4. How does Filter Specialists Inc. ensure quality assurance in their products?

Quality assurance at Filter Specialists Inc. is maintained through rigorous testing and compliance with industry standards. Each filtration product undergoes extensive quality checks to ensure it meets performance criteria and durability. They also provide filter testing services, allowing you to verify that the filters are suitable for your application. Collaborating with their team can help you understand the specific quality measures in place and how they align with your operational requirements.

5. What payment terms does Filter Specialists Inc. offer for international buyers?

Filter Specialists Inc. offers flexible payment terms for international buyers, which may include options like wire transfers, letters of credit, or payment upon delivery. The specific terms can vary based on the order size, frequency, and the buyer’s creditworthiness. It is essential to discuss payment terms upfront during the negotiation phase to ensure clarity and alignment with your financial processes.

Illustrative image related to filter specialists inc

6. What logistics and shipping options are available for international orders?

For international orders, Filter Specialists Inc. collaborates with various logistics partners to provide efficient shipping solutions. Options may include air freight for urgent shipments or ocean freight for bulk orders. The choice of logistics will depend on factors such as cost, urgency, and destination. Engage with their logistics team to determine the most suitable shipping method that aligns with your delivery timelines and budget.

7. How does Filter Specialists Inc. support clients after the sale?

Post-sale support is a key component of Filter Specialists Inc.’s service offerings. They provide installation, maintenance, and emergency repair services to ensure your filtration systems operate efficiently. Their technical support team is available to assist with troubleshooting and product inquiries, helping you maximize the lifespan and performance of your filtration systems. Building a long-term partnership with them can enhance your operational reliability.

8. What industries can benefit from Filter Specialists Inc.’s filtration solutions?

Filter Specialists Inc. caters to a wide range of industries, including food and beverage, pharmaceuticals, petrochemicals, water treatment, and more. Each sector has distinct filtration needs, from ensuring product purity in food processing to maintaining equipment efficiency in manufacturing. By understanding the specific requirements of your industry, you can leverage their expertise to implement effective filtration solutions that enhance product quality and operational efficiency.

Top 5 Filter Specialists Inc Manufacturers & Suppliers List

1. Pall – FSI Filters

Domain: pall.com

Registered: 1995 (30 years)

Introduction: FSI Filters are designed for critical applications in various industries, providing high-performance filtration solutions. They ensure the removal of contaminants from liquids and gases, enhancing process efficiency and product quality. The filters are engineered for durability and reliability, suitable for both upstream and downstream processes. Key features include a wide range of filter media o…

2. Pall Corp. – Filtration Products

Domain: machinerylubrication.com

Registered: 2001 (24 years)

Introduction: Pall Corp. has acquired Filter Specialists Inc. (FSI), a supplier of filtration products based in Michigan City, Ind. FSI’s product offerings include well-known Polyweld, Polymicro, and BOS filter bags, as well as an extensive line of steel and plastic filter vessels. FSI operates primarily in the industrial paint, chemical, petrochemical, oil and gas, and food and beverage markets.

3. Filter Specialists Inc. – Liquid Filters

Domain: liquid-filters.net

Registered: 2002 (23 years)

Introduction: Filter Specialists Inc. (FSI) is a manufacturer of liquid filters established in 1972, known for its innovative designs and patented products. Key products include: Bag Filters, Biodiesel Filters, Cartridge Filters, Chemical Filters, Filter Media, Gas Filters, Hydraulic Filters, Industrial Water Filters, Liquid Filtration Systems, Reverse Osmosis Water Filters, Strainers, and Wet Dry Filters. FSI …

4. FSI – Innovative Liquid Filtration Solutions

Domain: sg.linkedin.com

Registered: 2002 (23 years)

Introduction: This company, FSI – Innovative Liquid Filtration Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

5. Filter Specialists Inc. – Liquid Filtration Products

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Filter Specialists Inc. manufactures liquid filtration products including filter vessels, filter bags, and filter cartridges. Established in 1972, the company is known for its patented designs that enhance efficiency and reduce costs. Products are made in a silicone-free environment.

Strategic Sourcing Conclusion and Outlook for filter specialists inc

How Can Strategic Sourcing Enhance Your Filtration Solutions?

In today’s competitive global market, strategic sourcing from Filter Specialists Inc. offers significant advantages for businesses seeking high-quality filtration systems. With a diverse product range—including air, water, oil, and gas filters—companies can customize solutions to meet specific operational needs, ensuring compliance with industry standards and enhancing product quality.

Illustrative image related to filter specialists inc

The commitment of Filter Specialists Inc. to exceptional customer service and tailored support strengthens their position as a reliable partner. Their services, including installation, maintenance, and technical support, are vital for optimizing filtration processes and prolonging system lifespan. By prioritizing these aspects, businesses can achieve operational efficiency and reduce costs associated with downtime.

Looking forward, international B2B buyers, especially those in Africa, South America, the Middle East, and Europe, are encouraged to leverage the expertise and innovation that Filter Specialists Inc. provides. Engaging with their team can unlock tailored filtration solutions that not only meet current needs but also anticipate future challenges. Embrace strategic sourcing today to enhance your operational resilience and drive sustainable growth.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.