How to Source Film 1K Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for film 1k

In the competitive landscape of international trade, sourcing high-quality film 1k can pose significant challenges for B2B buyers, especially those operating across diverse markets in Africa, South America, the Middle East, and Europe. The intricacies of navigating global suppliers, understanding product specifications, and ensuring compliance with regional standards can complicate purchasing decisions. This guide aims to demystify the complexities surrounding film 1k, providing actionable insights for businesses looking to make informed and strategic procurement choices.

Within this comprehensive resource, you will find detailed information on various types of film 1k, their diverse applications across industries, and best practices for supplier vetting. We will delve into critical factors affecting cost, helping you identify budget-friendly options without compromising on quality. Additionally, the guide will outline market trends and regional considerations, enabling you to align your sourcing strategies with current demands.

By equipping you with essential knowledge and practical tools, this guide empowers B2B buyers to confidently navigate the global market for film 1k. Whether you are in Vietnam, Brazil, or beyond, the insights provided here will facilitate smarter purchasing decisions, ultimately driving your business’s success in a competitive environment.

Understanding film 1k Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Film 1K | Basic resolution, suitable for general use | Marketing materials, presentations | Pros: Cost-effective; Cons: Limited detail |

| High-Definition Film 1K | Enhanced clarity and color accuracy | High-quality video production, advertising | Pros: Superior quality; Cons: Higher cost |

| Specialty Film 1K | Tailored for specific industries (e.g., medical, architectural) | Niche markets, specialized projects | Pros: Targeted solutions; Cons: Limited availability |

| Eco-Friendly Film 1K | Made from sustainable materials | Green marketing, environmentally-conscious brands | Pros: Brand alignment with sustainability; Cons: Potentially higher prices |

| Interactive Film 1K | Incorporates interactive elements | Training, education, and promotional content | Pros: Engaging user experience; Cons: Complex production process |

What Are the Characteristics of Standard Film 1K and Its Suitability for B2B Buyers?

Standard Film 1K is characterized by its basic resolution, making it a versatile choice for general applications. This type of film is commonly used in marketing materials and presentations where high detail is not critical. B2B buyers seeking cost-effective solutions will find this option appealing, especially for projects with tight budgets. However, it’s essential to consider that while it serves well for basic needs, it lacks the detail required for high-end applications.

How Does High-Definition Film 1K Enhance Quality for Professional Use?

High-Definition Film 1K offers enhanced clarity and color accuracy, making it ideal for high-quality video production and advertising. This type of film is particularly suitable for businesses aiming to create visually striking content that captures audience attention. While it comes at a higher cost than standard options, the investment is justified for B2B buyers focused on premium branding and messaging. The superior quality can significantly enhance viewer engagement and perception of the brand.

What Unique Benefits Do Specialty Film 1K Variants Provide for Niche Markets?

Specialty Film 1K is designed for specific industries, such as medical or architectural sectors, providing tailored solutions that meet unique requirements. This type of film is particularly useful in niche markets where standard films may not suffice. B2B buyers in these sectors should consider the benefits of specialized features, such as enhanced detail or compliance with industry standards. However, availability may be limited, and buyers should ensure they have access to reliable suppliers for these tailored products.

Why Should Eco-Friendly Film 1K Be Considered by Sustainability-Focused Brands?

Eco-Friendly Film 1K is produced from sustainable materials, aligning with the growing trend towards environmentally-conscious business practices. This type of film is ideal for green marketing initiatives and brands that wish to showcase their commitment to sustainability. While it may come at a premium price, the potential for enhanced brand loyalty and customer engagement can offset the initial costs. B2B buyers should evaluate their target market’s values and the potential for eco-friendly branding.

What Are the Advantages and Challenges of Using Interactive Film 1K in Training and Promotion?

Interactive Film 1K incorporates engaging elements that enhance user experience, making it a powerful tool for training, education, and promotional content. This type of film can significantly improve viewer retention and engagement, which is vital for effective communication in B2B settings. However, the production process can be more complex and costly, requiring careful planning and execution. Buyers should weigh the benefits of increased interactivity against the investment needed for production to ensure it aligns with their business objectives.

Key Industrial Applications of film 1k

| Industry/Sector | Specific Application of film 1k | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Packaging | Food and Beverage Packaging | Extends shelf life, enhances product safety | Compliance with food safety regulations, material durability |

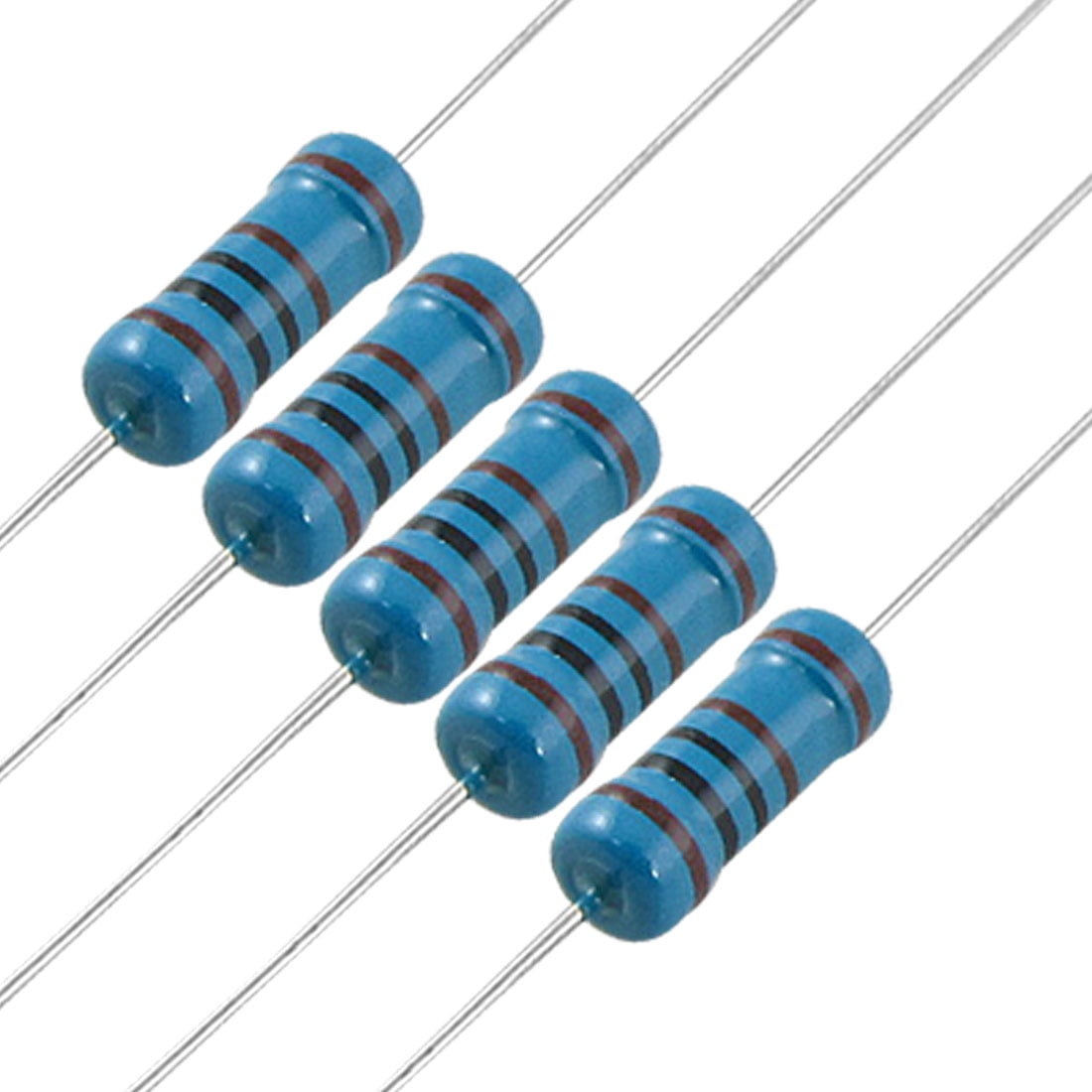

| Electronics | Flexible Printed Circuits (FPC) | Lightweight, space-saving design for devices | Electrical conductivity, thermal stability, customization |

| Automotive | Interior and Exterior Vehicle Components | Improved aesthetics, weather resistance | UV stability, adhesion properties, compatibility with materials |

| Construction | Protective Films for Surfaces | Reduces damage during transport and installation | Adhesive strength, ease of removal, surface compatibility |

| Healthcare | Medical Device Packaging | Ensures sterility, protects against contamination | Biocompatibility, regulatory certifications, barrier properties |

How is film 1k used in the packaging industry, and what benefits does it offer?

In the packaging sector, film 1k is primarily utilized for food and beverage packaging, where it serves to extend shelf life and enhance product safety. By providing a barrier against moisture, oxygen, and contaminants, film 1k ensures that products remain fresh and safe for consumption. For international buyers, especially in regions like Africa and South America, sourcing film 1k requires a focus on compliance with local food safety regulations and the material’s durability to withstand varying climatic conditions.

What role does film 1k play in the electronics industry?

Within the electronics industry, film 1k is crucial for creating flexible printed circuits (FPC). Its lightweight and space-saving attributes make it ideal for modern electronic devices, where compact design is essential. Buyers from Europe and the Middle East should prioritize sourcing film 1k with excellent electrical conductivity and thermal stability, ensuring that it meets the specific performance requirements of advanced electronic applications.

How is film 1k enhancing the automotive sector?

In the automotive industry, film 1k is applied in both interior and exterior vehicle components. It improves aesthetics while providing weather resistance, which is vital for maintaining the longevity and appearance of vehicles. B2B buyers should consider the UV stability and adhesion properties of film 1k when sourcing materials, as these factors significantly influence the durability and performance of automotive applications.

What advantages does film 1k provide in construction?

Film 1k is commonly used as protective films for surfaces in the construction industry. It helps reduce damage during transport and installation of various materials, thereby minimizing costly repairs and replacements. Buyers should focus on the adhesive strength and ease of removal when sourcing film 1k for construction applications, as these characteristics can greatly impact the efficiency of their projects.

How does film 1k contribute to the healthcare sector?

In healthcare, film 1k is essential for medical device packaging, where it ensures sterility and protects against contamination. This application is critical for maintaining the integrity of medical products. International buyers, particularly in regions with stringent health regulations, should ensure that the film 1k sourced is biocompatible and meets all necessary regulatory certifications to guarantee safety and effectiveness in medical applications.

3 Common User Pain Points for ‘film 1k’ & Their Solutions

Scenario 1: Navigating Supply Chain Disruptions in Film 1k Procurement

The Problem:

B2B buyers, particularly in regions like Africa and South America, often face significant supply chain disruptions when sourcing film 1k. Factors such as political instability, limited local suppliers, and logistical challenges can lead to inconsistent product availability. This unpredictability not only delays projects but can also result in increased costs as businesses scramble to meet deadlines, ultimately impacting their operational efficiency and client satisfaction.

The Solution:

To mitigate these supply chain issues, it is essential for buyers to establish strong relationships with multiple suppliers, both local and international. Diversifying the supplier base reduces dependency on a single source and enhances reliability. Additionally, implementing a robust inventory management system can help track stock levels and predict shortages. Buyers should also consider collaborating with logistics partners who specialize in international shipping to streamline the procurement process. By investing in supply chain resilience, companies can ensure a steady supply of film 1k, keeping projects on schedule and within budget.

Illustrative image related to film 1k

Scenario 2: Understanding Technical Specifications and Compatibility Issues

The Problem:

A common challenge for B2B buyers is navigating the complex technical specifications of film 1k products. Different manufacturers may use varying terminologies, and not all film 1k is compatible with every type of equipment or application. This confusion can lead to costly purchasing mistakes, project delays, and dissatisfaction among stakeholders who expect high-quality outcomes.

The Solution:

To address compatibility issues, buyers should prioritize thorough research and engagement with manufacturers to understand the nuances of film 1k specifications. Investing time in product training or attending industry workshops can provide insights into the technical aspects of different films. Additionally, creating a checklist of essential specifications—such as thickness, adhesive properties, and application methods—can help streamline the decision-making process. Buyers should also consider consulting with technical experts or engineers who can provide guidance on the best film 1k solutions tailored to their specific applications.

Scenario 3: Balancing Cost with Quality in Film 1k Purchases

The Problem:

In competitive markets, B2B buyers often grapple with the challenge of balancing cost and quality when purchasing film 1k. While it may be tempting to opt for the cheapest options to cut costs, doing so can compromise the quality of the final product. This dilemma is particularly pronounced in industries where the integrity of the film is critical to project success, leading to potential rework and lost revenue.

The Solution:

To strike an optimal balance between cost and quality, buyers should adopt a value-based purchasing strategy. This involves conducting a total cost of ownership analysis that considers not just the purchase price but also the long-term performance, durability, and potential for defects. Engaging in trials or pilot projects with different film 1k options can also provide practical insights into performance without a significant financial commitment. Finally, fostering open discussions with suppliers about the importance of quality can lead to better pricing structures that do not sacrifice performance. By focusing on value rather than just price, businesses can make informed decisions that enhance their product offerings and maintain customer satisfaction.

Strategic Material Selection Guide for film 1k

When selecting materials for film 1k applications, it is essential to consider a variety of factors, including performance properties, cost implications, and regional compliance requirements. Below is an analysis of four common materials used in film 1k, focusing on their key properties, advantages, disadvantages, and their impact on application suitability.

What are the Key Properties of Polyethylene Terephthalate (PET) for Film 1k?

Polyethylene Terephthalate (PET) is widely recognized for its excellent mechanical properties, including high tensile strength and resistance to impact. It also exhibits good thermal stability with a temperature rating up to 120°C, making it suitable for various applications. PET is resistant to moisture and many chemicals, though it may not perform well against strong acids and bases.

Pros and Cons: PET is relatively low-cost and easy to manufacture, which makes it a popular choice for many applications. However, its susceptibility to UV degradation can limit its use in outdoor environments without additional treatments.

Impact on Application: PET is compatible with a wide range of media, including food products, making it a preferred choice in the packaging industry. However, international buyers should ensure compliance with food safety standards, such as those set by the FDA or EFSA.

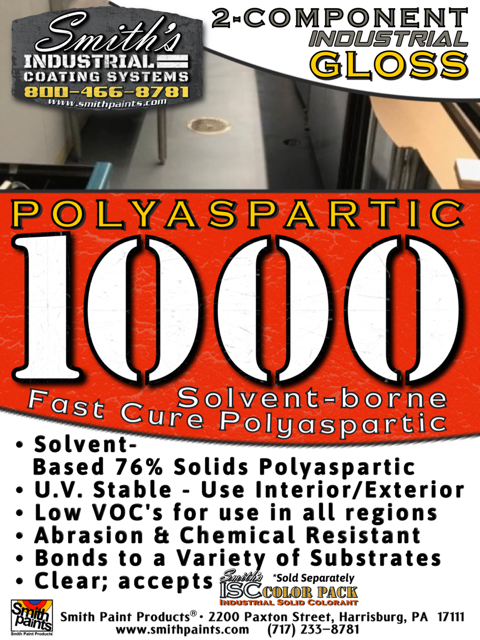

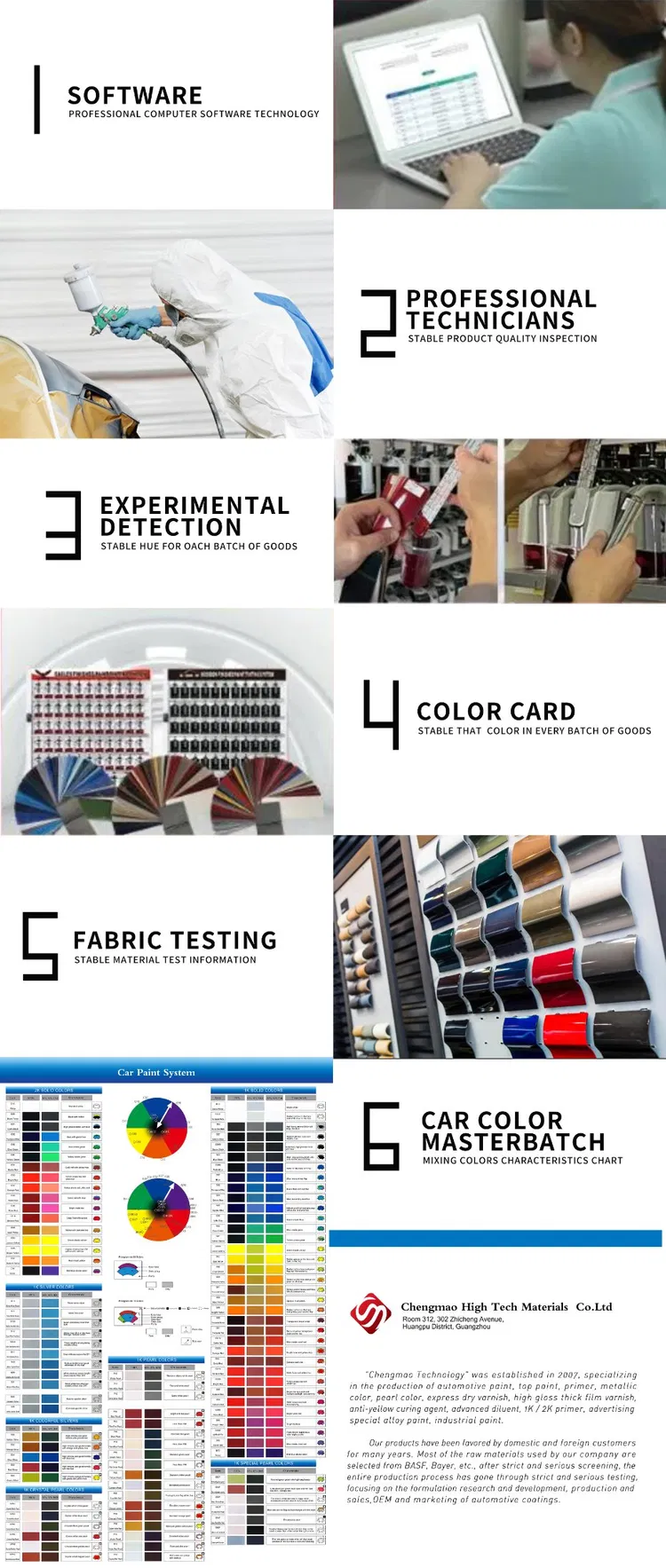

Illustrative image related to film 1k

How Does Polypropylene (PP) Compare in Performance for Film 1k?

Polypropylene is another prevalent material for film 1k applications, known for its excellent chemical resistance and low density. It can withstand temperatures up to 100°C and is particularly resistant to many solvents, acids, and bases.

Pros and Cons: The lightweight nature of PP makes it cost-effective for shipping and handling. However, its lower tensile strength compared to PET can be a drawback in applications requiring high durability.

Impact on Application: PP is suitable for applications where chemical exposure is significant, such as in the automotive and industrial sectors. Buyers in regions like Africa and South America should consider local regulations regarding chemical resistance and safety.

Illustrative image related to film 1k

What Advantages Does Polyvinyl Chloride (PVC) Offer for Film 1k Applications?

Polyvinyl Chloride (PVC) is known for its durability and versatility. It can withstand temperatures up to 60°C and offers excellent resistance to environmental factors, including moisture and UV light. PVC is also flame-retardant, which can be a critical factor in certain applications.

Pros and Cons: The primary advantage of PVC is its cost-effectiveness and ease of processing. However, the environmental impact of PVC production and disposal is a growing concern, which may affect its acceptance in certain markets.

Impact on Application: PVC is commonly used in construction and electrical applications. B2B buyers should be aware of compliance with international standards such as ASTM D638 and local regulations regarding the use of PVC in construction.

Illustrative image related to film 1k

What are the Key Properties of Polyamide (Nylon) for Film 1k?

Polyamide, commonly referred to as nylon, offers exceptional strength and abrasion resistance, making it suitable for high-performance applications. It can tolerate temperatures up to 120°C and exhibits good chemical resistance, though it is sensitive to strong acids and bases.

Pros and Cons: The high durability and flexibility of nylon make it ideal for applications requiring resilience. However, its higher cost and more complex manufacturing processes can be limiting factors for some buyers.

Impact on Application: Nylon is often used in automotive and industrial applications where strength and flexibility are paramount. International buyers should consider the specific chemical compatibility of nylon with their intended media and ensure compliance with relevant standards.

Summary Table of Material Selection for Film 1k

| Material | Typical Use Case for film 1k | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene Terephthalate (PET) | Food packaging, general applications | High tensile strength and moisture resistance | Susceptible to UV degradation | Low |

| Polypropylene (PP) | Automotive, industrial applications | Excellent chemical resistance | Lower tensile strength than PET | Low |

| Polyvinyl Chloride (PVC) | Construction, electrical applications | Cost-effective and durable | Environmental concerns in production | Low |

| Polyamide (Nylon) | Automotive, high-performance applications | Exceptional strength and flexibility | Higher cost and manufacturing complexity | High |

This strategic material selection guide provides B2B buyers with critical insights into the properties and applications of various materials for film 1k. Understanding these factors will enable informed decision-making tailored to specific regional and industry needs.

In-depth Look: Manufacturing Processes and Quality Assurance for film 1k

What Are the Main Stages in the Manufacturing Process of Film 1k?

The manufacturing process for Film 1k involves several critical stages that ensure the final product meets industry standards and customer expectations.

Illustrative image related to film 1k

Material Preparation

The first stage begins with material preparation, where raw materials such as polymers and additives are selected based on the desired film characteristics. During this phase, suppliers typically conduct quality checks on incoming materials to ensure compliance with specifications. This is crucial, as the quality of raw materials directly impacts the film’s performance.

Forming Techniques: How Is Film 1k Created?

Once the materials are prepared, the next step is forming. This involves several techniques, including extrusion, casting, and blow molding, depending on the specific requirements of Film 1k.

- Extrusion: This is the most common method, where the raw materials are melted and forced through a die to create a continuous film. The thickness and width can be precisely controlled, making it suitable for various applications.

- Casting: This method involves pouring the melted material into molds, allowing it to solidify into sheets. It is often used for thicker films that require specific surface properties.

- Blow Molding: This technique is primarily used for creating hollow film structures and is less common for standard Film 1k applications.

Assembly and Finishing: What Comes Next?

After the film is formed, it undergoes assembly and finishing processes. This includes cutting the film into specified dimensions, applying coatings, and adding any necessary features such as printing or laminating. Finishing processes are crucial for enhancing the film’s durability and aesthetic appeal, making it more suitable for various end-user applications.

How Is Quality Assurance Integrated Throughout the Manufacturing Process?

Quality assurance (QA) is an integral part of the manufacturing process for Film 1k, ensuring that the product meets both international standards and specific customer requirements.

What International Standards Should B2B Buyers Be Aware Of?

B2B buyers should familiarize themselves with relevant international standards that govern the manufacturing of Film 1k. Notably, ISO 9001 is a widely recognized standard for quality management systems. Compliance with ISO 9001 indicates that the manufacturer has established processes to ensure consistent quality and continuous improvement.

Illustrative image related to film 1k

In addition to ISO standards, industry-specific certifications like CE marking for European markets or API standards for specific applications can provide further assurance of product quality. These certifications often require rigorous testing and validation processes, adding another layer of credibility.

What Are the Key Quality Control Checkpoints?

Quality control (QC) checkpoints are strategically placed throughout the manufacturing process to monitor product quality at various stages. These checkpoints typically include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to verify that they meet specified standards. Suppliers should provide test reports or certificates of conformity for verification.

-

In-Process Quality Control (IPQC): During production, continuous monitoring occurs to ensure that processes remain within established parameters. This can include real-time measurements of thickness, clarity, and other critical properties.

-

Final Quality Control (FQC): After production, a final inspection is conducted to ensure that the finished product meets all specifications before it is shipped to customers. This may include visual inspections and performance tests.

What Common Testing Methods Are Used for Film 1k?

Various testing methods are employed to ensure the quality and performance of Film 1k. Common tests include:

- Mechanical Testing: Evaluates properties such as tensile strength, elongation, and tear resistance to ensure the film can withstand its intended application.

- Thermal Testing: Determines how the film behaves under different temperature conditions, which is critical for applications involving heat exposure.

- Chemical Resistance Testing: Assesses how well the film holds up against various chemicals, which is particularly important for industrial applications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability and compliance with standards.

Illustrative image related to film 1k

What Steps Can Buyers Take?

-

Conduct Supplier Audits: Regular audits can help assess the effectiveness of a supplier’s quality management system. This includes reviewing documentation, observing processes, and inspecting facilities.

-

Request Quality Reports: Suppliers should provide detailed QC reports that outline testing results and compliance with relevant standards. This transparency helps buyers make informed decisions.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and product quality. This can be particularly beneficial for buyers from regions with varying standards.

What Are the Quality Control and Certification Nuances for International Buyers?

When sourcing Film 1k from international suppliers, particularly from regions like Africa, South America, the Middle East, and Europe, buyers should be aware of certain nuances:

-

Regulatory Compliance: Different regions may have specific regulations governing the use of certain materials or manufacturing processes. Understanding these regulations is crucial to avoid non-compliance issues.

-

Cultural Differences: Communication and business practices may vary across regions. Establishing clear expectations and maintaining open lines of communication can help mitigate misunderstandings related to quality standards.

-

Logistics and Supply Chain: International shipping can introduce additional variables affecting quality, such as temperature fluctuations and handling practices. Buyers should discuss logistics with suppliers to ensure that quality is maintained throughout the supply chain.

Conclusion

The manufacturing processes and quality assurance measures for Film 1k are essential for ensuring product reliability and performance. By understanding the key stages of manufacturing, relevant international standards, and effective quality control measures, B2B buyers can make informed decisions when sourcing Film 1k. Engaging with suppliers transparently and proactively verifying their QC processes can lead to successful partnerships and high-quality products that meet market demands.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘film 1k’

In this sourcing guide, we aim to provide B2B buyers with a practical checklist for procuring ‘film 1k’, ensuring that your purchasing decisions are informed and strategic. This step-by-step approach will help streamline the sourcing process, mitigate risks, and enhance the quality of your procurement.

Illustrative image related to film 1k

Step 1: Define Your Technical Specifications

Before initiating the sourcing process, clearly outline the technical specifications of ‘film 1k’ that meet your project requirements. This may include dimensions, thickness, material properties, and performance characteristics. A well-defined specification helps suppliers understand your needs and reduces the likelihood of discrepancies later in the process.

Step 2: Conduct Market Research

Research the current market landscape for ‘film 1k’, focusing on suppliers from key regions such as Africa, South America, the Middle East, and Europe. Analyze market trends, pricing, and availability to identify potential suppliers. Understanding the market will enable you to make informed decisions and negotiate better terms.

Step 3: Evaluate Potential Suppliers

Before committing to a supplier, conduct a thorough evaluation. Request company profiles, product samples, and references from previous clients, particularly those in your industry or region. Pay attention to factors such as supplier reputation, production capacity, and reliability, as these can significantly impact your procurement process.

Step 4: Verify Supplier Certifications

Ensure that potential suppliers possess relevant industry certifications and quality assurance standards. This could include ISO certifications or compliance with specific regional regulations. Verifying certifications not only ensures product quality but also mitigates risks associated with non-compliance.

Step 5: Request Quotes and Compare Offers

Once you’ve shortlisted potential suppliers, request detailed quotes that outline pricing, payment terms, lead times, and shipping options. Compare these offers carefully, taking into account not only the cost but also the value added by each supplier, such as customer service and after-sales support.

Step 6: Assess Logistics and Supply Chain Capabilities

Consider the logistics involved in sourcing ‘film 1k’ from your selected suppliers. Evaluate their supply chain capabilities, including shipping methods, delivery times, and customs handling. A reliable logistics plan is crucial for ensuring timely delivery and minimizing disruptions in your production schedule.

Step 7: Finalize Contracts and Terms of Agreement

After selecting a supplier, negotiate and finalize contracts that clearly outline terms of agreement, including pricing, delivery schedules, and quality assurance measures. Ensure that both parties understand their responsibilities and that there are clauses addressing potential disputes or breaches of contract.

By following this checklist, B2B buyers can effectively navigate the sourcing process for ‘film 1k’, ensuring a successful procurement experience that meets their operational needs and business goals.

Illustrative image related to film 1k

Comprehensive Cost and Pricing Analysis for film 1k Sourcing

What Are the Key Cost Components in Film 1k Sourcing?

When analyzing the costs associated with sourcing Film 1k, it’s crucial to break down the various cost components. The primary elements include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margin.

Materials are often the largest portion of the cost structure, as the quality and type of raw materials used can significantly influence the final price. For Film 1k, high-quality polymers and additives are essential for ensuring durability and performance, which may come at a premium.

Labor costs vary by region and can be influenced by local wage standards. In developing markets such as parts of Africa and South America, labor costs might be lower, but skill levels and training can affect productivity.

Illustrative image related to film 1k

Manufacturing overhead encompasses indirect costs such as utilities, facility maintenance, and administrative expenses. This can differ widely depending on the location of the manufacturing facility, as some regions may have more favorable conditions or government incentives.

Tooling is another significant cost, particularly for customized Film 1k solutions. Initial investments in molds and machinery can be substantial, but these costs can be amortized over larger production runs, making higher volume orders more cost-effective.

Quality Control (QC) is essential to ensure that the Film 1k meets industry standards and customer specifications. The costs associated with QC processes can vary, but investing in robust QC can save costs in the long run by reducing returns and ensuring customer satisfaction.

Logistics costs, including shipping and handling, can fluctuate based on distance, mode of transport, and the chosen Incoterms. For international buyers, understanding the logistics landscape in their region is key to managing costs effectively.

Lastly, margin is the profit that suppliers add to their costs. This can vary based on market dynamics, competition, and the perceived value of the product.

How Do Price Influencers Impact Film 1k Sourcing?

Several factors can influence the pricing of Film 1k, making it essential for buyers to understand these variables. Volume and Minimum Order Quantity (MOQ) play a critical role; suppliers often offer better pricing for larger orders. This can be advantageous for businesses that can forecast their needs accurately.

Specifications and customization also affect pricing. Custom Film 1k solutions tailored to specific applications may incur additional costs due to the complexity of production and the need for specialized materials.

The quality of materials used significantly impacts the final price. Higher-grade materials generally lead to better performance and longer-lasting products, which can justify a higher upfront cost.

Supplier factors, such as the supplier’s reputation, experience, and location, can influence price. A well-established supplier with a track record of quality may command higher prices, but they often provide assurance of reliability and performance.

Understanding Incoterms is crucial for international buyers, as these terms dictate the responsibilities of buyers and sellers in shipping and delivery. Choosing the right Incoterm can help mitigate unexpected costs.

What Are the Best Buyer Tips for Cost-Efficient Film 1k Sourcing?

For B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe, negotiating effectively can lead to significant savings. Establishing long-term relationships with suppliers may also yield better pricing over time.

Consider the Total Cost of Ownership (TCO) rather than just the purchase price. This includes factors such as logistics, maintenance, and potential wastage. A lower upfront cost might lead to higher TCO if quality is compromised.

Buyers should be aware of pricing nuances in their specific regions. For instance, tariffs, taxes, and local market conditions can impact the overall cost. Understanding these dynamics can lead to more informed purchasing decisions.

Lastly, always request indicative prices as a starting point for negotiations. Prices can fluctuate based on market conditions, so having a clear understanding of the factors influencing price can aid in securing the best deal possible.

Alternatives Analysis: Comparing film 1k With Other Solutions

Understanding Alternatives for Film 1K

In the competitive landscape of film solutions, it’s crucial for B2B buyers to evaluate various options to determine which best meets their operational needs. Film 1K has established itself as a reliable choice, but understanding how it stacks up against alternative solutions can inform better purchasing decisions. This analysis will compare Film 1K with two viable alternatives: Digital Imaging and Traditional Film.

Comparison Table

| Comparison Aspect | Film 1K | Digital Imaging | Traditional Film |

|---|---|---|---|

| Performance | High fidelity, excellent color accuracy | Good resolution, but can vary based on equipment | High resolution, but subject to degradation over time |

| Cost | Moderate initial investment, long-term savings | Higher upfront costs for equipment | Low initial cost, but ongoing film purchase and processing fees |

| Ease of Implementation | Requires trained personnel for optimal use | User-friendly with software integration | Labor-intensive setup and processing |

| Maintenance | Low maintenance, minimal upkeep | Regular software updates needed | Requires film storage and development |

| Best Use Case | Commercial projects needing durability and longevity | Quick turnaround projects needing flexibility | Artistic projects valuing traditional aesthetics |

What Are the Pros and Cons of Digital Imaging?

Digital Imaging technology has gained traction for its ability to deliver high-quality images with rapid turnaround times. Its user-friendly interfaces and integration with various software tools make it accessible for teams without extensive training. However, the initial investment in high-end digital cameras and editing software can be substantial. Additionally, while digital imaging provides flexibility, the quality can vary significantly based on the equipment used, which may not always meet the high standards set by Film 1K.

What Are the Strengths and Weaknesses of Traditional Film?

Traditional Film remains a choice for projects where artistic expression is paramount. Its ability to capture organic textures and colors can give a unique character to visual storytelling. The low initial cost of purchasing film stock may seem attractive, but the long-term expenses associated with development and processing can accumulate quickly. Moreover, traditional film requires careful handling and storage to prevent degradation, which can pose logistical challenges for businesses aiming for efficiency and durability.

How to Choose the Right Solution for Your Needs

Selecting the right solution involves assessing your specific business requirements, budget constraints, and desired outcomes. Film 1K offers a balanced approach with high performance and low maintenance, making it ideal for commercial applications that require longevity. Digital Imaging is suited for projects that prioritize speed and flexibility, while Traditional Film appeals to those looking for a classic aesthetic. Ultimately, the decision should align with your project goals, operational capabilities, and the importance of cost efficiency in the long run.

By carefully weighing these alternatives, B2B buyers can make informed decisions that enhance their project outcomes and overall business success.

Essential Technical Properties and Trade Terminology for film 1k

What Are the Key Technical Properties of Film 1k?

Understanding the technical specifications of Film 1k is crucial for B2B buyers who need to ensure product compatibility and performance. Here are some essential properties to consider:

Illustrative image related to film 1k

1. Material Grade

Film 1k is typically made from various polymers, such as PET (Polyethylene Terephthalate) or PP (Polypropylene). The material grade affects durability, flexibility, and resistance to environmental factors. Selecting the appropriate grade is vital for applications ranging from packaging to industrial uses, as it influences overall product quality and lifecycle.

2. Thickness

The thickness of Film 1k is measured in microns and can significantly affect its mechanical properties, including strength and flexibility. Thicker films generally offer greater durability, while thinner films may provide advantages in cost and weight. For B2B buyers, understanding the thickness specifications helps in selecting the right film for specific applications, ensuring optimal performance and cost-efficiency.

3. Tolerance

Tolerance refers to the allowable variation in film thickness and width. A tighter tolerance indicates higher precision in manufacturing, which is essential for applications requiring exact specifications, such as in electronics or medical packaging. Buyers must consider tolerance levels to avoid issues in production that could lead to increased waste or product failure.

4. Barrier Properties

Barrier properties determine how well the film can protect contents from external factors such as moisture, oxygen, and UV light. These properties are critical in food packaging and pharmaceuticals, where product integrity is paramount. B2B buyers should evaluate barrier performance to ensure that the Film 1k meets the requirements of their specific application, thereby prolonging shelf life and maintaining quality.

5. Surface Treatment

Surface treatments, such as corona treatment or coating, enhance the film’s adhesion properties and printability. This is particularly important for brands looking to improve packaging aesthetics or functionality. Understanding the surface treatment options allows buyers to select films that align with their branding and technical requirements.

Illustrative image related to film 1k

What Trade Terminology Should B2B Buyers Know for Film 1k?

Familiarity with industry jargon is essential for navigating contracts and negotiations effectively. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of Film 1k, an OEM may provide custom films tailored to specific industry needs. B2B buyers should consider OEM options for specialized applications to ensure they receive products that meet their unique specifications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For Film 1k, MOQs can vary significantly based on the supplier and the complexity of the order. Understanding MOQ is crucial for buyers, as it directly impacts inventory management and overall project costs.

3. RFQ (Request for Quotation)

An RFQ is a document that solicits pricing and terms from suppliers for specific products. B2B buyers should use RFQs to compare suppliers effectively and negotiate better terms for Film 1k purchases, ensuring they make informed decisions that align with budget constraints.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international rules that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers, as they dictate who is responsible for shipping, insurance, and tariffs, which can significantly impact the overall cost of Film 1k procurement.

5. Lead Time

Lead time refers to the amount of time from placing an order to receiving the product. In the context of Film 1k, lead times can vary based on production schedules and shipping logistics. Buyers should consider lead times in their planning to avoid production delays and ensure timely delivery of materials.

By grasping these essential technical properties and industry terminology, B2B buyers can make informed decisions that enhance their procurement strategies for Film 1k, ultimately leading to improved operational efficiency and cost-effectiveness.

Navigating Market Dynamics and Sourcing Trends in the film 1k Sector

What Are the Key Market Dynamics and Trends Affecting the Film 1k Sector?

The film 1k sector is currently experiencing transformative shifts driven by globalization, technological advancements, and evolving consumer preferences. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe engage in this dynamic market, understanding these drivers is crucial. The demand for high-quality, versatile film products has surged, propelled by industries ranging from packaging to construction. Notably, the integration of digital technologies in sourcing processes, such as e-procurement platforms and blockchain for supply chain transparency, is reshaping how businesses interact and transact.

Emerging trends indicate a growing preference for customized solutions tailored to specific industry needs, which can enhance operational efficiencies and reduce waste. Additionally, the rise of regional manufacturing hubs, particularly in Southeast Asia and South America, is creating new opportunities for cost-effective sourcing. International buyers should remain attentive to these shifts, as they can influence pricing strategies and supply chain logistics.

How Is Sustainability Shaping Sourcing Decisions in the Film 1k Sector?

Sustainability and ethical sourcing have become paramount in the film 1k sector, reflecting a broader global commitment to environmental stewardship. The production of film products can have significant environmental impacts, including pollution and resource depletion. As a result, B2B buyers are increasingly prioritizing suppliers who demonstrate a commitment to sustainable practices. This includes sourcing raw materials from responsible producers and minimizing carbon footprints throughout the supply chain.

Illustrative image related to film 1k

Buyers should seek partners that hold recognized green certifications, such as ISO 14001 or FSC (Forest Stewardship Council) certification, which indicate adherence to environmental management standards. Utilizing biodegradable or recyclable materials in film production not only meets consumer demand for eco-friendly products but also enhances brand reputation in a competitive marketplace. By aligning sourcing strategies with sustainability goals, businesses can differentiate themselves and appeal to a growing segment of environmentally conscious consumers.

How Has the Film 1k Sector Evolved Over Time?

The film 1k sector has seen significant evolution over the past few decades, transitioning from traditional manufacturing processes to advanced, technology-driven production methods. Initially dominated by basic plastic films, the sector has expanded to include a diverse range of products with enhanced functionality, such as barrier films for food packaging and specialized films for industrial applications.

The globalization of supply chains has further transformed the landscape, enabling international collaboration and innovation. As markets in regions like Africa and South America continue to develop, the film 1k sector is poised for continued growth, driven by advancements in materials science and increased demand for versatile film applications. Understanding this evolution is crucial for B2B buyers aiming to make informed sourcing decisions that align with market trends and future opportunities.

Illustrative image related to film 1k

Frequently Asked Questions (FAQs) for B2B Buyers of film 1k

-

How do I ensure the quality of film 1k from suppliers?

To ensure the quality of film 1k, start by vetting suppliers through their certifications and industry standards compliance, such as ISO certifications. Request samples before placing bulk orders to assess material quality. Additionally, consider third-party quality assurance inspections to verify that the film meets your specifications. Establish clear quality criteria in your purchase agreement, and maintain open communication with your supplier regarding production processes and potential issues. -

What factors should I consider when choosing a supplier for film 1k?

When selecting a supplier for film 1k, assess their production capacity, lead times, and reliability. Investigate their experience in the industry and reputation by reading reviews and testimonials. Additionally, consider their ability to customize products according to your specific needs and the flexibility of their minimum order quantities (MOQs). It’s also vital to evaluate their logistics capabilities and after-sales support, particularly for international shipments. -

What is the ideal minimum order quantity (MOQ) for film 1k?

The ideal MOQ for film 1k can vary significantly between suppliers, typically ranging from a few hundred to several thousand units. If you’re a smaller business, look for suppliers that offer flexible MOQs or are willing to negotiate terms. Keep in mind that larger orders may yield better pricing, but ensure that you can manage inventory effectively to avoid excess stock. Discuss your requirements upfront to find a suitable arrangement. -

What payment terms are commonly used in international trade for film 1k?

Payment terms in international trade can vary widely, but common arrangements include letters of credit, advance payments, or net payment terms (e.g., net 30 or net 60). Negotiating favorable terms that ensure security for both parties is essential. Consider using escrow services for larger transactions to mitigate risks. Always clarify payment methods accepted by the supplier, as some may prefer wire transfers, while others may accept credit cards or online payment platforms. -

How can I customize film 1k to meet my specific needs?

Customization options for film 1k often include variations in thickness, size, color, and finish. Start by clearly defining your requirements and discussing them with potential suppliers. Many manufacturers are open to creating bespoke products, but it’s important to understand any implications on pricing, lead times, and MOQs. Request prototypes or samples of customized products to ensure they align with your expectations before committing to a larger order. -

What logistics considerations should I keep in mind when sourcing film 1k internationally?

When sourcing film 1k internationally, consider shipping methods, delivery timelines, and customs regulations. Evaluate the supplier’s experience with international logistics to ensure timely delivery. Factor in potential tariffs and duties that could affect overall costs, and ensure that the supplier provides necessary documentation for customs clearance. Collaborate with a reliable freight forwarder to navigate logistics challenges and optimize shipping efficiency. -

What should I know about the certifications for film 1k?

Certifications for film 1k can vary by region and application but may include ISO, CE, and RoHS compliance. These certifications indicate adherence to quality and safety standards, which is critical for ensuring the film’s performance in its intended application. Request documentation from your supplier to verify these certifications and ensure they align with your market’s regulatory requirements. Being informed about the certifications can also enhance your credibility with your customers. -

How can I handle disputes or issues with my film 1k supplier?

To effectively handle disputes with your film 1k supplier, establish clear communication channels and maintain a professional tone when addressing issues. Refer to your contract for guidance on dispute resolution procedures, which may include mediation or arbitration clauses. Document all correspondence related to the dispute for future reference. If necessary, involve a legal expert to navigate complex issues, but aim to resolve conflicts amicably to maintain a long-term business relationship.

A Look at Film 1K Manufacturers & Suppliers

We are currently compiling a detailed list of top film 1k suppliers. Please check back later.

Strategic Sourcing Conclusion and Outlook for film 1k

Strategic sourcing for film 1k offers significant advantages to international B2B buyers, particularly in dynamic markets across Africa, South America, the Middle East, and Europe. By prioritizing supplier relationships and leveraging global networks, businesses can ensure consistent quality, competitive pricing, and innovative solutions tailored to their specific needs. The insights gathered throughout this guide underscore the necessity of a strategic approach to sourcing, emphasizing the importance of due diligence, market analysis, and adaptability in an ever-evolving landscape.

Investing in strategic sourcing not only mitigates risks associated with supply chain disruptions but also fosters long-term partnerships that can drive growth and sustainability. As buyers engage with suppliers, they should prioritize transparency and collaboration to enhance value and streamline operations.

Looking ahead, the film 1k market presents opportunities for those willing to adapt and innovate. As demand evolves, staying informed about industry trends and emerging technologies will be crucial for maintaining a competitive edge. Now is the time for international buyers to take proactive steps in optimizing their sourcing strategies, ensuring they are well-positioned to capitalize on future growth and advancements in the film industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.