How to Source Emi Wire Shielding Sleeve Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for emi wire shielding sleeve

In an increasingly interconnected world, sourcing reliable EMI wire shielding sleeves is critical for businesses aiming to protect their electronic devices from electromagnetic interference. The challenge lies not only in identifying high-quality products but also in navigating a global market filled with diverse suppliers and varying standards. This comprehensive guide provides B2B buyers with essential insights into the different types of EMI shielding solutions, their applications across various industries, and strategies for vetting suppliers.

From military-grade shielding wraps to flexible heat shrink tubing, understanding the nuances of each product can significantly impact performance and compliance with international standards. This guide delves into the key considerations for selecting the right shielding solution, including cost analysis and material specifications, ensuring buyers can make informed purchasing decisions.

By addressing the specific needs of international B2B buyers from regions such as Africa, South America, the Middle East, and Europe—including countries like Saudi Arabia and Vietnam—this resource empowers stakeholders to confidently navigate the complexities of sourcing EMI wire shielding sleeves. With actionable insights and expert recommendations, businesses can enhance their operational efficiency and secure their electronic assets against potential interference, ultimately leading to improved product reliability and customer satisfaction.

Understanding emi wire shielding sleeve Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Braided EMI Shielding Sleeve | Made from interwoven conductive materials, providing flexibility. | Aerospace, Automotive, Telecommunications | Pros: Lightweight, good abrasion resistance. Cons: May require careful installation. |

| Heat Shrink EMI Shielding Tubing | Shrinks upon heat application, creating a tight seal. | Electronics, Medical Devices | Pros: Excellent environmental protection. Cons: Limited reusability. |

| EMI Shielding Wrap | Flexible wrap-around design, easy to apply over existing cables. | Industrial Equipment, Military Applications | Pros: Versatile and adaptable. Cons: May not provide as much protection as solid sleeves. |

| EMI Shielding Tape | Adhesive-backed tape for quick fixes and temporary applications. | Repair Work, Prototyping | Pros: Easy to use, cost-effective. Cons: Less durable over time. |

| Expandable Braided Shielding | Adjustable diameter, suitable for various cable sizes. | Data Centers, High-Speed Communication | Pros: Customizable fit, good EMI protection. Cons: Can be bulkier than other options. |

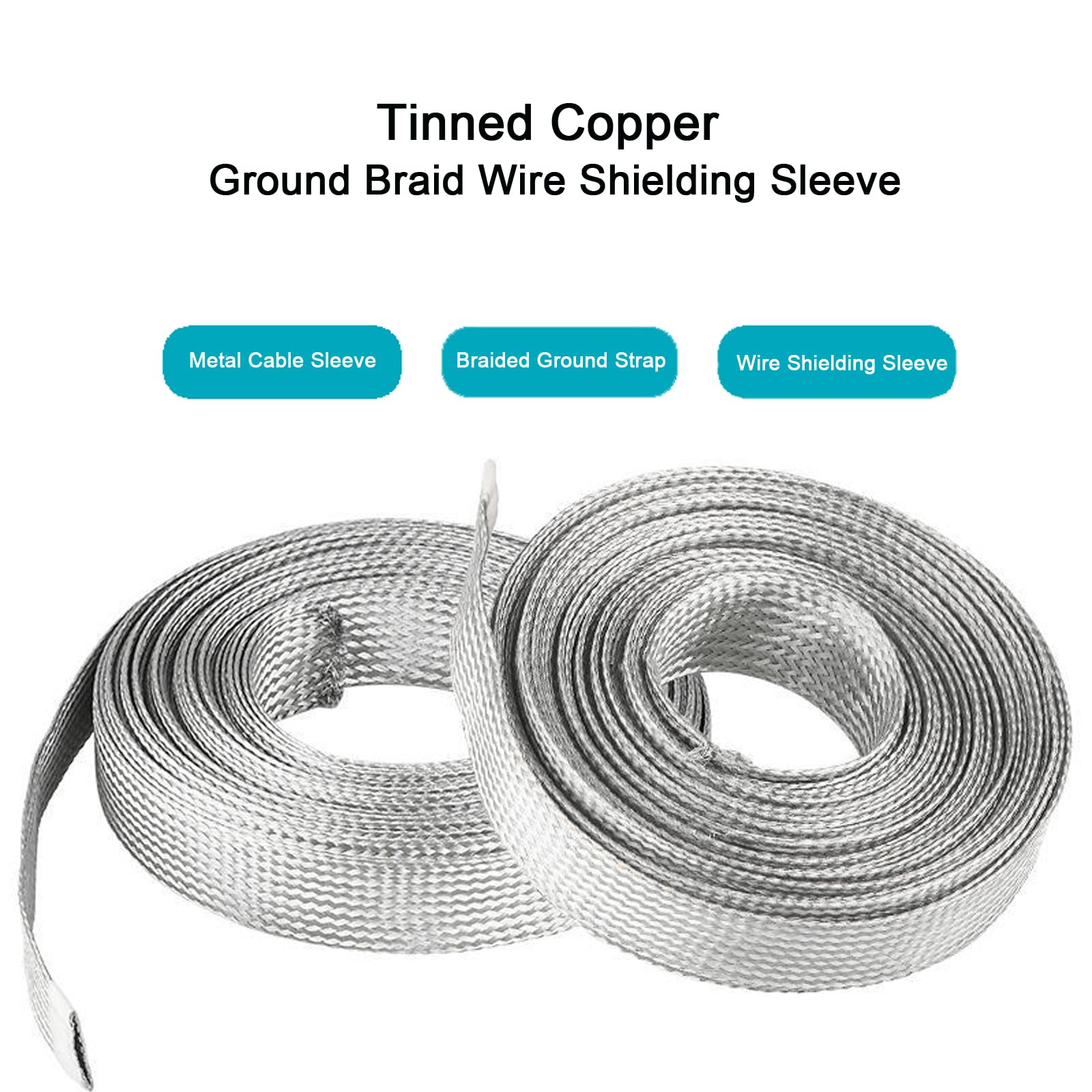

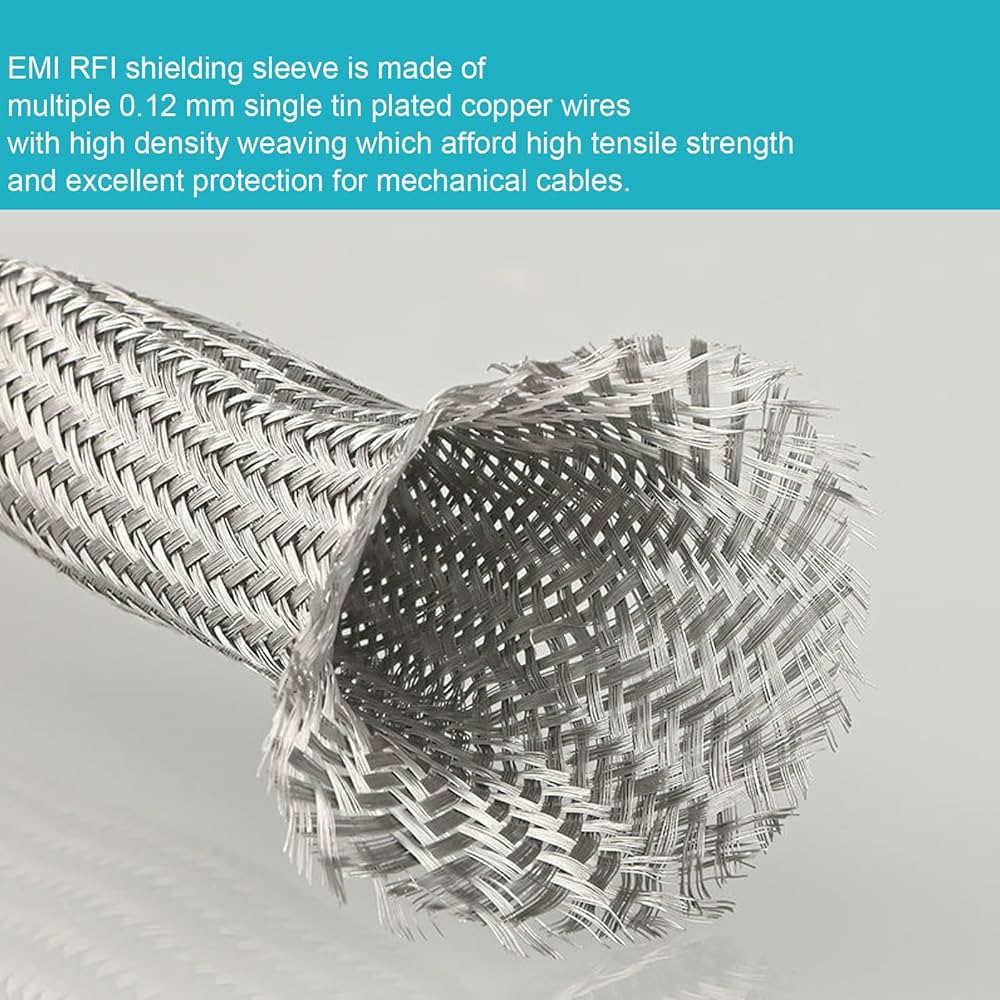

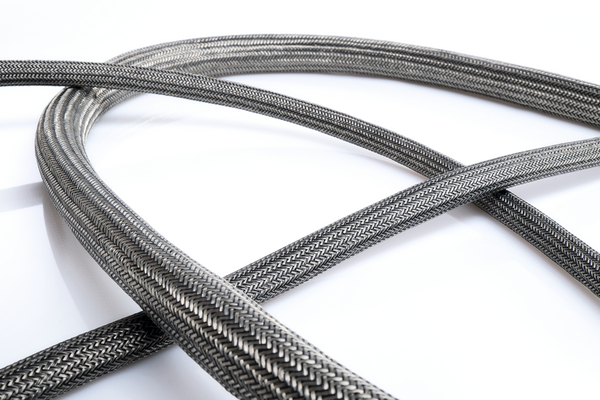

What are the Characteristics of Braided EMI Shielding Sleeves?

Braided EMI shielding sleeves are constructed from interwoven conductive materials, typically metallic fibers. This design provides flexibility, making them suitable for dynamic applications like aerospace and automotive sectors where movement and vibration are common. Buyers should consider the weight and abrasion resistance of these sleeves, as they offer substantial protection without adding significant bulk to the wire harness.

How Does Heat Shrink EMI Shielding Tubing Work?

Heat shrink EMI shielding tubing is designed to shrink when heat is applied, forming a tight seal around the cables. This type is particularly advantageous in electronics and medical devices, where environmental protection is critical. Buyers should evaluate the temperature resistance and shrink ratio when purchasing, as these factors will influence the tubing’s performance in specific applications.

Why Choose EMI Shielding Wrap?

EMI shielding wrap provides a flexible solution that can be easily applied around existing cables, making it ideal for industrial equipment and military applications. Its adaptability allows for quick installation, but buyers should be aware that while it offers decent protection, it may not match the effectiveness of solid sleeves in high-interference environments.

What are the Benefits of Using EMI Shielding Tape?

EMI shielding tape is an adhesive-backed solution suitable for quick fixes or temporary applications. It is particularly useful in repair work and prototyping. While it is easy to apply and cost-effective, buyers should consider its long-term durability, as it may degrade faster than more permanent solutions like sleeves or wraps.

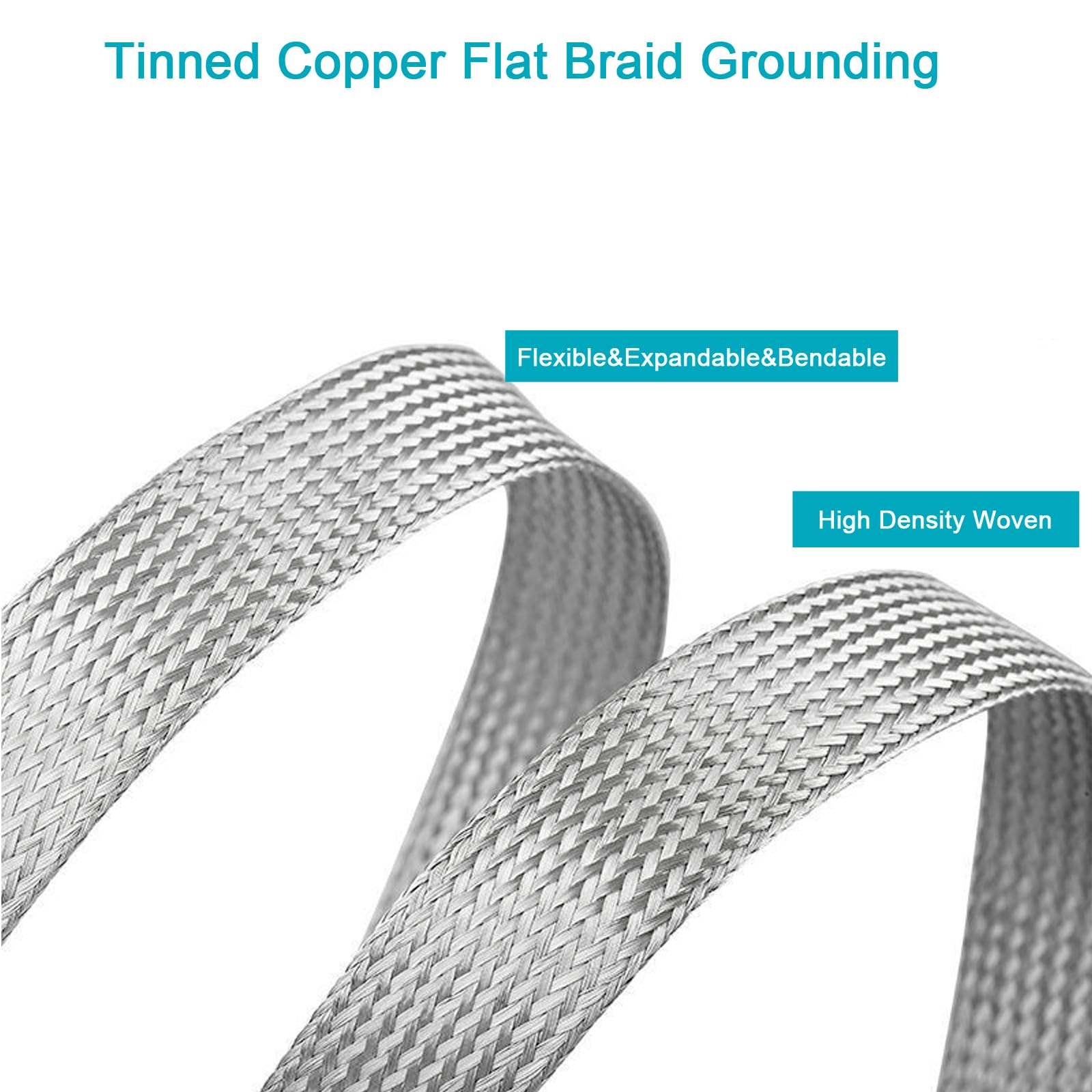

How Does Expandable Braided Shielding Enhance Cable Management?

Expandable braided shielding allows for adjustable diameters, accommodating various cable sizes while providing essential EMI protection. Commonly used in data centers and high-speed communication environments, this type is customizable, which can be a significant advantage for businesses with diverse wiring needs. However, its bulkiness compared to other options may be a drawback in space-constrained installations.

Key Industrial Applications of emi wire shielding sleeve

| Industry/Sector | Specific Application of emi wire shielding sleeve | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace and Defense | Protection of avionics wiring and communication systems | Ensures reliable performance in high-stakes environments, reducing failure risk | Certification for aerospace applications, compliance with military standards |

| Automotive | Shielding for electronic control units (ECUs) and sensors | Enhances vehicle reliability and safety, meeting stringent industry regulations | Compatibility with various vehicle models, temperature tolerance |

| Telecommunications | EMI protection for data cables and wireless equipment | Improves signal integrity and reduces data loss, enhancing user experience | Adaptability to diverse cable types, flexibility in installation |

| Industrial Automation | Shielding for robotic systems and machinery controls | Increases operational efficiency by minimizing interference | Durability under harsh conditions, ease of installation |

| Medical Devices | Protection for sensitive diagnostic and monitoring equipment | Ensures accurate readings and patient safety, adhering to health regulations | Biocompatibility, compliance with medical device standards |

How Are EMI Wire Shielding Sleeves Used in Aerospace and Defense?

In the aerospace and defense sector, EMI wire shielding sleeves are crucial for protecting avionics wiring and communication systems from electromagnetic interference. These sleeves maintain signal integrity in environments where reliability is paramount. Buyers in this sector must ensure that products meet specific certifications and military standards, as the failure of electronic systems can lead to catastrophic outcomes.

What Role Do EMI Wire Shielding Sleeves Play in the Automotive Industry?

In the automotive industry, EMI shielding sleeves are used to protect electronic control units (ECUs) and sensors from external electromagnetic interference. This is essential for maintaining vehicle reliability and safety, especially with the rise of electric and hybrid vehicles that rely heavily on electronic systems. B2B buyers should consider sourcing sleeves that are compatible with various vehicle models and can withstand high temperatures and vibrations typical in automotive applications.

How Do Telecommunications Benefit from EMI Wire Shielding Sleeves?

Telecommunications companies utilize EMI shielding sleeves to protect data cables and wireless equipment from interference that can degrade signal quality. By enhancing signal integrity and minimizing data loss, these sleeves improve overall user experience. Buyers should prioritize sourcing options that are adaptable to different cable types and ensure flexibility during installation, particularly in dynamic environments where equipment may frequently change.

Illustrative image related to emi wire shielding sleeve

In What Ways Do Industrial Automation Applications Use EMI Wire Shielding Sleeves?

In industrial automation, EMI wire shielding sleeves are essential for shielding robotic systems and machinery controls from interference. This protection increases operational efficiency by minimizing disruptions caused by electromagnetic fields. Buyers in this sector should focus on sourcing sleeves that demonstrate durability under harsh conditions and offer ease of installation to facilitate rapid deployment in automated environments.

Why Are EMI Wire Shielding Sleeves Important for Medical Devices?

For medical devices, EMI shielding sleeves protect sensitive diagnostic and monitoring equipment from electromagnetic interference, ensuring accurate readings and patient safety. Compliance with health regulations is critical in this industry, making it essential for B2B buyers to source sleeves that are biocompatible and meet stringent medical device standards. This guarantees that the equipment performs reliably without compromising patient health.

3 Common User Pain Points for ’emi wire shielding sleeve’ & Their Solutions

Scenario 1: Ensuring Effective EMI Protection in Harsh Environments

The Problem:

B2B buyers, especially those in sectors such as military, aerospace, and automotive, often face significant challenges when sourcing EMI wire shielding sleeves capable of withstanding extreme environmental conditions. High temperatures, humidity, and exposure to chemicals can degrade the performance of shielding materials, leading to potential failures in critical systems. Buyers may worry about the reliability of their chosen materials, fearing that inadequate shielding will result in increased electromagnetic interference, jeopardizing the integrity of sensitive equipment.

Illustrative image related to emi wire shielding sleeve

The Solution:

To ensure effective EMI protection in harsh environments, it’s crucial to select EMI wire shielding sleeves specifically designed for high-performance applications. Buyers should look for materials that offer both thermal and chemical resistance, such as PTFE or specialized heat-shrink tubing with built-in shielding properties. When sourcing, inquire about certifications and performance metrics relevant to your application, including temperature tolerance and resistance to environmental factors. Additionally, consider collaborating with manufacturers who can provide customization options to match your specific requirements. This tailored approach not only enhances protection but also extends the lifespan of your equipment.

Scenario 2: Navigating Complex Compliance Standards

The Problem:

International B2B buyers often grapple with complex compliance standards regarding electromagnetic compatibility (EMC) in their respective markets. Different regions, such as Europe or North America, may have stringent regulations that require specific EMI shielding measures. Non-compliance can lead to costly fines, product recalls, or even legal repercussions. As buyers attempt to navigate these regulations, they may find it challenging to source EMI wire shielding sleeves that meet the necessary criteria.

The Solution:

To effectively navigate compliance standards, buyers should prioritize sourcing EMI wire shielding sleeves from manufacturers with a proven track record in meeting international standards. Request detailed documentation that showcases compliance with relevant regulations, such as ISO, IEC, or specific military standards. It’s advisable to engage with suppliers who offer guidance and support on regulatory requirements, ensuring that the selected shielding materials are not only effective but also compliant. Additionally, maintaining open communication with local regulatory bodies can provide valuable insights and updates on changing compliance landscapes, allowing buyers to stay ahead of requirements.

Scenario 3: Balancing Cost and Quality

The Problem:

Cost management is a significant concern for B2B buyers, particularly in competitive markets where price sensitivity is high. Buyers may feel pressured to opt for lower-cost EMI wire shielding sleeves, which could compromise quality and performance. This dilemma often leads to a trade-off between affordability and the need for reliable, high-quality materials that ensure effective EMI protection.

The Solution:

To strike a balance between cost and quality, buyers should conduct a thorough cost-benefit analysis before making procurement decisions. Investing in higher-quality EMI wire shielding sleeves may lead to long-term savings by reducing maintenance costs and improving system reliability. When evaluating options, consider the total cost of ownership rather than just the upfront purchase price. Engage with suppliers who offer a range of products at different price points, and don’t hesitate to ask for samples to test performance in your specific application. Building strong relationships with reliable manufacturers can also lead to favorable pricing and terms, allowing for a sustainable procurement strategy that meets both budgetary and quality requirements.

Strategic Material Selection Guide for emi wire shielding sleeve

What are the Key Materials for EMI Wire Shielding Sleeves?

When selecting materials for EMI wire shielding sleeves, understanding the properties and applications of various options is crucial for international B2B buyers. Here, we analyze four common materials used in EMI shielding, focusing on their performance characteristics, advantages, disadvantages, and considerations for buyers in diverse markets.

How Does Aluminum Shielding Perform in EMI Applications?

Aluminum is a widely used material for EMI shielding due to its excellent conductivity and lightweight properties. It typically offers a good balance of shielding effectiveness and cost. Aluminum shielding can withstand moderate temperatures, making it suitable for various applications, including automotive and aerospace.

Pros: Aluminum is cost-effective and easy to work with, allowing for simpler manufacturing processes. Its lightweight nature reduces the overall weight of the cable assemblies, which is particularly beneficial in applications where weight is a critical factor.

Illustrative image related to emi wire shielding sleeve

Cons: While aluminum has decent corrosion resistance, it may not perform well in highly corrosive environments unless treated. Additionally, its mechanical strength is lower compared to some other materials, which may limit its use in high-stress applications.

Impact on Application: Aluminum shielding is effective in blocking a wide range of electromagnetic frequencies, making it suitable for precision machines and military equipment. However, it may not be the best choice for applications exposed to harsh environmental conditions.

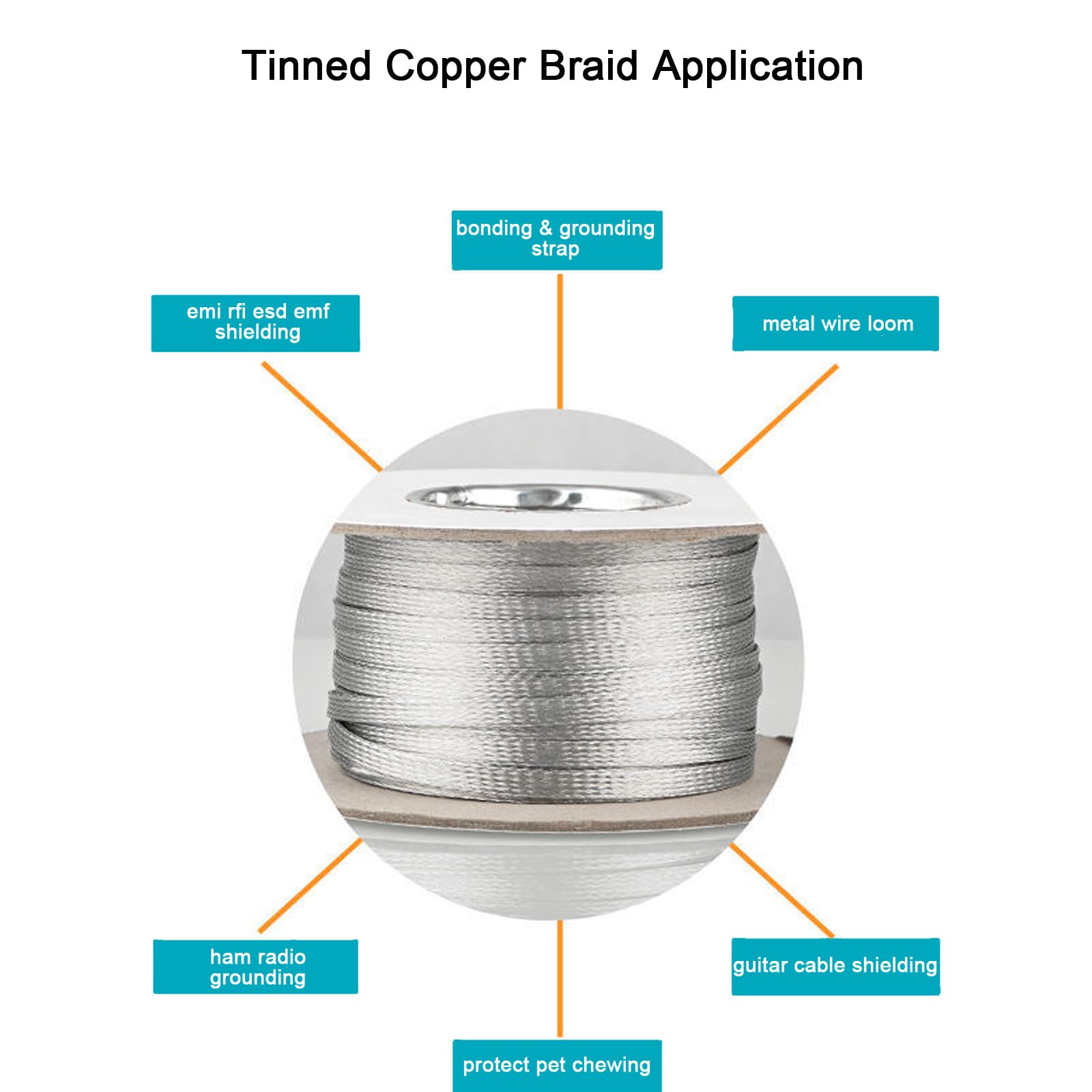

What Advantages Do Braided Copper Sleeves Offer for EMI Shielding?

Copper, known for its superior electrical conductivity, is another popular choice for EMI shielding sleeves. Braided copper sleeves provide excellent flexibility and can conform to various shapes, making them ideal for complex wiring harnesses.

Illustrative image related to emi wire shielding sleeve

Pros: The high conductivity of copper ensures effective EMI shielding, and its durability offers long-term reliability. Copper also provides good thermal conductivity, which can be advantageous in applications where heat dissipation is necessary.

Cons: Copper is generally more expensive than aluminum and may require additional treatments to prevent corrosion, particularly in humid or saline environments. The manufacturing process can also be more complex due to the need for precise braiding techniques.

Impact on Application: Braided copper sleeves are particularly effective in high-frequency applications, such as telecommunications and aerospace. Buyers should consider the cost versus performance trade-offs when selecting copper shielding for their projects.

How Do Non-Metallic Materials Compare in EMI Shielding?

Non-metallic materials, such as PTFE and nylon, are increasingly used for EMI shielding due to their lightweight and flexible nature. These materials can be engineered to provide specific shielding properties while also offering additional benefits like chemical resistance.

Illustrative image related to emi wire shielding sleeve

Pros: Non-metallic EMI shielding materials are often more resistant to corrosion and chemicals than their metallic counterparts. They can also be manufactured in various colors and sizes, allowing for customization to meet specific application needs.

Cons: While they can provide adequate shielding, non-metallic materials may not match the shielding effectiveness of metals, particularly at lower frequencies. Their cost can also be higher depending on the type of polymer used.

Impact on Application: Non-metallic sleeves are suitable for applications where flexibility and resistance to harsh chemicals are critical, such as in the automotive and medical sectors. Buyers should assess the specific EMI requirements of their applications to determine the suitability of non-metallic options.

What is the Role of Hybrid Materials in EMI Shielding Solutions?

Hybrid materials, which combine metallic and non-metallic elements, are becoming popular for EMI shielding. These materials can leverage the advantages of both types, offering enhanced performance in various applications.

Pros: Hybrid materials can provide excellent shielding while maintaining flexibility and lightweight characteristics. They can also be tailored to meet specific environmental requirements, such as temperature extremes or exposure to chemicals.

Illustrative image related to emi wire shielding sleeve

Cons: The complexity of manufacturing hybrid materials can lead to higher costs. Additionally, the performance may vary significantly depending on the specific formulation used, necessitating thorough testing.

Impact on Application: Hybrid shielding solutions are particularly beneficial in industries requiring high-performance standards, such as aerospace and defense. Buyers should ensure compliance with international standards and regulations when selecting hybrid materials.

Summary of Material Selection for EMI Wire Shielding Sleeves

| Material | Typical Use Case for EMI Wire Shielding Sleeve | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive, aerospace | Cost-effective and lightweight | Moderate corrosion resistance | Low |

| Braided Copper | Telecommunications, aerospace | Superior conductivity and durability | Higher cost and complex manufacturing | High |

| Non-Metallic | Automotive, medical | Corrosion-resistant and customizable | Lower shielding effectiveness at low frequencies | Medium |

| Hybrid | Aerospace, defense | Enhanced performance and flexibility | Higher cost and variable performance | High |

This guide provides essential insights for B2B buyers looking to make informed decisions about EMI wire shielding sleeves, considering material properties, application suitability, and regional compliance standards.

Illustrative image related to emi wire shielding sleeve

In-depth Look: Manufacturing Processes and Quality Assurance for emi wire shielding sleeve

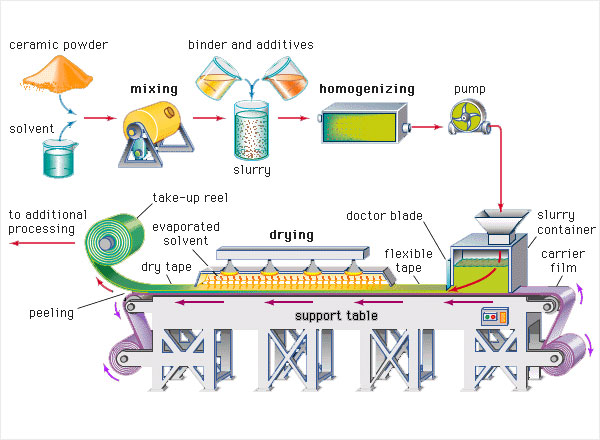

What Are the Main Stages of Manufacturing EMI Wire Shielding Sleeves?

The manufacturing of EMI wire shielding sleeves involves several key stages that ensure the final product meets stringent performance standards. The process typically includes material preparation, forming, assembly, and finishing.

How Is Material Prepared for EMI Wire Shielding Sleeves?

Material preparation is the first step in the manufacturing process. It involves selecting appropriate materials that provide the necessary electromagnetic shielding properties. Common materials include copper, aluminum, and various polymers that can enhance conductivity and flexibility. Advanced techniques such as alloying or surface treatments may be employed to improve the material’s shielding effectiveness and durability.

Once the materials are sourced, they undergo rigorous inspections to ensure they meet predefined specifications. This includes checking for impurities, dimensional accuracy, and mechanical properties. Suppliers often rely on certified material testing labs to validate the quality and suitability of the materials before proceeding to the next stage.

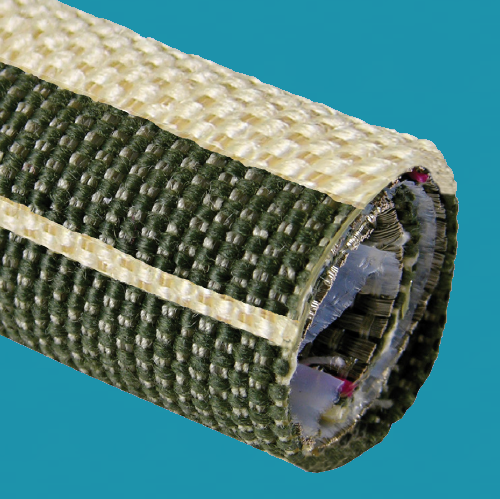

What Techniques Are Used in Forming EMI Wire Shielding Sleeves?

Forming is the next critical stage, where the prepared materials are shaped into sleeves. Techniques such as extrusion, weaving, and braiding are commonly used.

- Extrusion involves forcing molten material through a die to create a continuous sleeve of uniform cross-section. This method is particularly effective for polymer-based sleeves.

- Weaving and braiding are techniques used primarily for metallic shielding. They provide excellent flexibility and strength while allowing for intricate designs that enhance shielding effectiveness. For example, Glenair’s lightweight braided sleeving combines microfilament materials for optimal conductivity and EMI protection.

During the forming stage, manufacturers often incorporate features such as heat resistance and abrasion protection, which are critical for applications in harsh environments, such as military and aerospace settings.

Illustrative image related to emi wire shielding sleeve

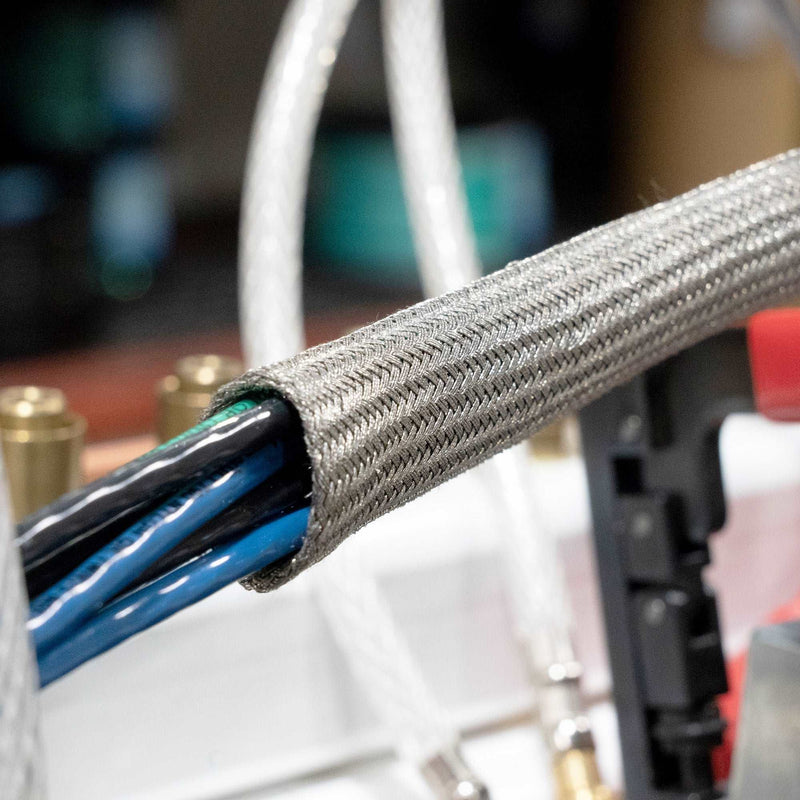

How Are EMI Wire Shielding Sleeves Assembled?

Assembly is where components are combined to create the final EMI shielding sleeve. This stage may involve several sub-processes, including cutting, sealing, and integrating additional features like connectors or fasteners.

For instance, sleeves may be cut to specific lengths and then subjected to heat treatment or other processes to ensure they retain their shape and performance characteristics. Assembly must be performed with precision to avoid any gaps or defects that could compromise shielding effectiveness.

Quality control checkpoints are established throughout this stage to ensure that every assembly meets design specifications. This includes visual inspections and functional tests to verify the integrity of the assembly.

What Finishing Processes Are Used for EMI Wire Shielding Sleeves?

Finishing processes enhance the sleeve’s performance and aesthetic appeal. This stage may involve surface treatments, such as coating or plating, to improve corrosion resistance and conductivity.

Common finishing techniques include anodizing for aluminum sleeves and plating for copper sleeves, which can provide additional protection against environmental factors. Packaging also falls under this stage, ensuring that products are delivered in a manner that maintains their quality and readiness for use.

What Quality Control Measures Are Essential for EMI Wire Shielding Sleeves?

Quality assurance is critical in the production of EMI wire shielding sleeves, as these components must consistently perform under demanding conditions. Adhering to international standards such as ISO 9001 ensures that manufacturers maintain a systematic approach to quality management.

Which International Standards Are Relevant for EMI Wire Shielding Sleeves?

ISO 9001 is a widely recognized standard that focuses on quality management systems. Compliance with this standard indicates that a manufacturer has established processes for quality assurance, including regular audits and continuous improvement initiatives.

In addition to ISO 9001, industry-specific standards may apply, such as CE marking for products sold within the European Union, which demonstrates conformity with health, safety, and environmental protection standards. Other standards, like API (American Petroleum Institute) specifications, may be relevant for applications in oil and gas, ensuring that the products meet specific performance criteria.

Illustrative image related to emi wire shielding sleeve

What Are the Key QC Checkpoints During the Manufacturing Process?

Quality control checkpoints are established throughout the manufacturing process to catch defects early. These typically include:

- Incoming Quality Control (IQC): Verification of raw materials and components before they enter the production line.

- In-Process Quality Control (IPQC): Ongoing assessments during the manufacturing stages to ensure compliance with specifications.

- Final Quality Control (FQC): Comprehensive testing and inspection of finished products to validate performance and safety before shipment.

These checkpoints utilize various testing methods, including dimensional checks, conductivity tests, and environmental simulations to ensure the sleeves perform under expected conditions.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers looking to source EMI wire shielding sleeves should implement several strategies to verify the quality control practices of potential suppliers.

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is a fundamental practice. This involves visiting the manufacturing facility to review processes, quality control systems, and compliance with relevant standards. Auditors should focus on the supplier’s documentation, training programs, and internal audit results to gauge the effectiveness of their quality management system.

Illustrative image related to emi wire shielding sleeve

How Can B2B Buyers Use Reports and Certifications?

Buyers should request quality reports and certifications from suppliers. These documents should detail compliance with international and industry-specific standards, as well as results from third-party testing labs. Certifications such as ISO 9001, CE marking, and others relevant to the specific application provide assurance of the supplier’s commitment to quality.

What Role Do Third-Party Inspections Play in Quality Assurance?

Engaging third-party inspection services can further enhance confidence in supplier quality. These services provide an unbiased assessment of manufacturing practices and product quality, ensuring that the products meet the required specifications before shipment.

Conclusion: What Should B2B Buyers Consider in Quality Assurance for EMI Wire Shielding Sleeves?

For B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the manufacturing processes and quality assurance practices for EMI wire shielding sleeves is crucial. By focusing on material selection, manufacturing techniques, and robust quality control measures, buyers can ensure they source products that meet their operational needs and comply with international standards. Engaging in thorough supplier evaluations, audits, and verification of quality documentation will help in making informed purchasing decisions, ultimately leading to successful partnerships and high-quality outcomes.

Practical Sourcing Guide: A Step-by-Step Checklist for ’emi wire shielding sleeve’

When sourcing EMI wire shielding sleeves, it is essential to follow a systematic approach to ensure that you select the right product and supplier for your needs. This guide provides a step-by-step checklist to assist international B2B buyers in making informed decisions throughout the procurement process.

Step 1: Define Your Technical Specifications

Before reaching out to suppliers, establish clear technical specifications for the EMI shielding sleeves you require. Consider factors such as the frequency range, shielding effectiveness, environmental conditions, and mechanical properties like flexibility and abrasion resistance. Specifying these details upfront will help you filter out unsuitable products and focus on options that meet your operational requirements.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers specializing in EMI wire shielding sleeves. Look for manufacturers with a strong reputation and extensive experience in the industry. Key factors to evaluate include:

– Product Range: Ensure they offer a variety of shielding solutions that match your specifications.

– Geographical Reach: Verify if they can serve your location efficiently, especially if you are sourcing from regions like Africa or South America.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with international standards. Check for certifications like ISO 9001 for quality management and any specific industry standards relevant to EMI shielding. This step is critical to ensure that the products meet safety and performance benchmarks, reducing the risk of future issues.

Step 4: Request Samples for Testing

Always request samples before making a bulk purchase. Testing samples allows you to evaluate the quality, performance, and compatibility of the shielding sleeves with your existing systems. Ensure that the samples are representative of the actual product you intend to purchase and conduct tests under conditions similar to your operational environment.

Step 5: Assess Pricing and Terms of Service

Compare pricing from multiple suppliers to ensure you are getting a competitive rate. However, do not base your decision solely on price; consider the overall value, including quality, delivery times, and after-sales support. Clarify payment terms, lead times, and return policies to avoid any surprises after placing your order.

Illustrative image related to emi wire shielding sleeve

Step 6: Review Customer Support and Communication

Effective communication is vital in any business relationship. Assess the supplier’s responsiveness and willingness to provide support during the sourcing process. A reliable supplier should be available to answer questions, provide technical assistance, and address concerns throughout the procurement journey.

Step 7: Finalize Your Purchase Agreement

Once you have selected a supplier, ensure that all terms and conditions are clearly outlined in a purchase agreement. This should include product specifications, pricing, delivery schedules, and warranty details. A well-documented agreement protects both parties and fosters a professional relationship moving forward.

Following this checklist will help you navigate the complexities of sourcing EMI wire shielding sleeves, ensuring that you make informed decisions that align with your business needs.

Comprehensive Cost and Pricing Analysis for emi wire shielding sleeve Sourcing

What Are the Key Cost Components in Sourcing EMI Wire Shielding Sleeves?

When sourcing EMI wire shielding sleeves, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The choice of materials significantly impacts pricing. Common materials used in EMI shielding include copper, aluminum, and specialized composites. High-performance options like stainless steel or advanced thermoplastics can drive costs higher due to their superior shielding capabilities and durability.

-

Labor: Labor costs encompass not only the direct wages of production staff but also the expertise required for specialized manufacturing processes. Skilled labor may be needed for intricate assembly or quality assurance, particularly for custom solutions.

-

Manufacturing Overhead: This includes costs related to utilities, facility maintenance, and administrative expenses. Efficient manufacturing processes can help reduce overhead, thereby influencing the overall pricing of the shielding sleeves.

-

Tooling: Initial tooling costs can be significant, especially for custom products. Custom molds and specialized machinery require upfront investment, which can be amortized over larger production runs, making high-volume orders more cost-effective.

-

Quality Control (QC): Ensuring that the EMI shielding sleeves meet international standards involves rigorous testing and inspection processes. The costs associated with QC should be factored into the overall pricing, especially for applications in sectors such as aerospace and military, where compliance is critical.

-

Logistics: Shipping and handling costs can vary widely based on the destination, weight, and dimensions of the shipments. International buyers should consider the total logistics costs, including customs duties and tariffs, which can significantly affect the final price.

-

Margin: Suppliers typically include a margin in their pricing to cover risks and generate profit. Understanding the market dynamics and competition can help buyers negotiate better margins.

How Do Volume and Customization Affect Pricing for EMI Shielding Sleeves?

Pricing for EMI shielding sleeves can be heavily influenced by order volume and customization:

-

Volume/MOQ: Suppliers often have minimum order quantities (MOQs) that can lead to volume discounts. Bulk purchasing can significantly reduce the per-unit cost, making it an attractive option for businesses with ongoing needs.

-

Specifications and Customization: Custom designs that meet specific application requirements can incur additional costs. Buyers should be clear about their specifications upfront to avoid unexpected charges during production. Customization may also lengthen lead times, impacting the overall supply chain efficiency.

What Buyer Tips Can Help Optimize Costs in Sourcing EMI Shielding Sleeves?

To achieve cost-efficiency and maximize value, buyers should consider the following strategies:

-

Negotiation: Engage in open discussions with suppliers about pricing. Understanding the supplier’s cost structure can empower buyers to negotiate better terms, especially when leveraging bulk purchasing power or long-term contracts.

-

Total Cost of Ownership (TCO): Evaluate the TCO, which includes not just the purchase price but also installation, maintenance, and potential downtime costs. A lower initial price may lead to higher long-term costs if the product requires more frequent replacements or lacks durability.

-

Pricing Nuances for International Buyers: For buyers in regions like Africa, South America, and the Middle East, it is essential to be aware of currency fluctuations, import regulations, and local market conditions that can affect pricing. Utilizing Incoterms effectively can also help clarify shipping responsibilities and costs.

Are There Pricing Variations Based on Supplier Factors?

Yes, various supplier factors can lead to pricing variations:

-

Quality and Certifications: Suppliers that offer products with recognized certifications (e.g., ISO, military standards) may charge a premium. However, these certifications can justify higher prices due to enhanced reliability and compliance.

-

Supplier Reputation: Established suppliers with a strong track record may command higher prices due to perceived quality and reliability. Conversely, newer or less-known suppliers might offer lower prices but could involve greater risk.

-

Incoterms: The choice of Incoterms can influence cost structures, as they define the responsibilities of buyers and sellers in shipping and logistics. Understanding these terms can help buyers avoid hidden costs related to transportation and customs.

Disclaimer on Indicative Prices

It is important to note that prices for EMI wire shielding sleeves can vary widely based on the factors mentioned above. The prices provided by suppliers are often indicative and should be confirmed through direct communication to account for specific requirements and market conditions.

Alternatives Analysis: Comparing emi wire shielding sleeve With Other Solutions

Understanding Alternatives to EMI Wire Shielding Sleeves

When addressing electromagnetic interference (EMI) in various applications, businesses often look for effective shielding solutions. While EMI wire shielding sleeves are a popular choice, there are several alternative products that can also mitigate EMI effects. Each alternative comes with its own set of benefits and drawbacks, making it essential for buyers to carefully evaluate their specific needs and circumstances.

Comparison Table of EMI Shielding Solutions

| Comparison Aspect | EMI Wire Shielding Sleeve | Braided Cable Shielding | EMI Shielding Tape |

|---|---|---|---|

| Performance | High effectiveness against EMI; flexible and durable | Excellent EMI/RFI protection; abrasion resistance | Good for quick fixes; moderate EMI protection |

| Cost | Moderate to high depending on material | Varies; often higher due to complex manufacturing | Generally low-cost solution |

| Ease of Implementation | Requires careful installation | More complex; may need professional installation | Easy to apply; no special tools required |

| Maintenance | Low; generally durable | Low, but may need inspection over time | Low; replaced as needed |

| Best Use Case | Aerospace, automotive, military applications | Harsh environments with mechanical stress | Temporary repairs or light EMI applications |

An In-Depth Look at Alternative Solutions

What are the Advantages and Disadvantages of Braided Cable Shielding?

Braided cable shielding provides superior protection against electromagnetic and radio frequency interference (EMI/RFI). This solution features interwoven conductive materials that create a barrier, effectively grounding electromagnetic fields. While the performance is generally excellent, the cost can be higher due to the complexity of manufacturing. Installation can also be more challenging, often requiring specialized knowledge or tools, making it less suitable for quick or DIY applications.

How Does EMI Shielding Tape Compare as an Alternative?

EMI shielding tape serves as a quick and effective solution for addressing EMI concerns. Its ease of application allows for repairs and installations without the need for specialized tools or skills. However, while it is a cost-effective option, the performance may not match that of sleeves or braided solutions, particularly in high-stress or critical environments. It is best used for temporary fixes or in applications where EMI exposure is minimal.

Choosing the Right EMI Shielding Solution for Your Needs

Selecting the most suitable EMI shielding solution hinges on several factors, including the specific application requirements, budget constraints, and installation capabilities. For industries such as aerospace or military, where performance and durability are paramount, EMI wire shielding sleeves or braided cable shielding may be the best choices. Conversely, for less critical applications or temporary fixes, EMI shielding tape could be a practical option.

By carefully considering these factors, B2B buyers can make informed decisions that align with their operational needs and financial resources, ensuring optimal protection against electromagnetic interference.

Illustrative image related to emi wire shielding sleeve

Essential Technical Properties and Trade Terminology for emi wire shielding sleeve

What Are the Key Technical Properties of EMI Wire Shielding Sleeves?

When considering EMI wire shielding sleeves, understanding their critical specifications is essential for ensuring optimal performance in various applications. Here are some vital technical properties:

-

Material Grade

The material used in EMI shielding sleeves can significantly impact their effectiveness. Common materials include aluminum, copper, and various non-metallic composites. Each offers unique properties; for instance, aluminum provides excellent conductivity and is lightweight, while copper offers superior shielding effectiveness. Selecting the appropriate material based on the specific electromagnetic interference (EMI) environment is crucial for ensuring compliance with electromagnetic compatibility (EMC) standards. -

Shielding Effectiveness

Measured in decibels (dB), shielding effectiveness quantifies how well a sleeve blocks EMI. Higher dB values indicate better performance. For B2B buyers, understanding this metric is essential, as it directly correlates to the sleeve’s ability to protect sensitive electronics and maintain signal integrity in high-frequency applications. -

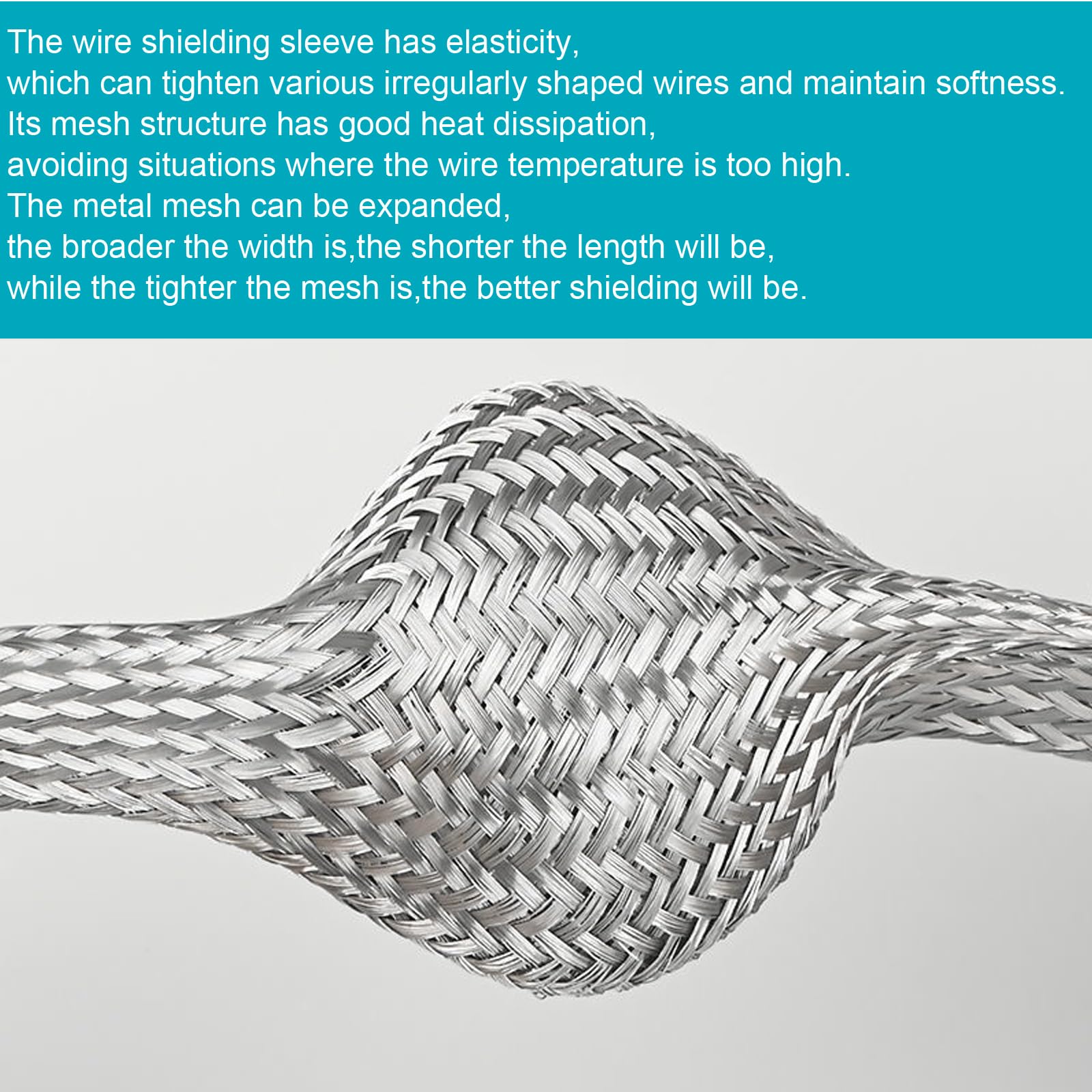

Flexibility and Expandability

EMI shielding sleeves come in various designs, including braided and tubular forms. Their flexibility and expandability are important for installation in tight spaces or around complex cable configurations. This adaptability can reduce installation time and costs, making it a key consideration for buyers looking for efficient solutions. -

Temperature Resistance

Different applications may expose shielding sleeves to varying temperature ranges. Buyers should look for sleeves that can withstand the specific thermal conditions of their environments, whether high-temperature applications in automotive settings or lower temperatures in consumer electronics. This property ensures long-term reliability and performance. -

Abrasion and Cut Resistance

EMI shielding sleeves must also provide protection against physical damage. Materials that offer high abrasion and cut resistance are vital in environments where cables may be subject to wear and tear. For B2B buyers, this specification can influence product lifespan and reduce maintenance costs.

Which Trade Terminology Should B2B Buyers Understand for EMI Wire Shielding Sleeves?

Familiarity with industry-specific jargon can enhance communication and negotiation with suppliers. Here are some common terms related to EMI wire shielding sleeves:

-

OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding this term helps buyers identify suppliers who can provide specialized shielding solutions tailored to specific applications. -

MOQ (Minimum Order Quantity)

MOQ is the minimum number of units that a supplier is willing to sell. For B2B buyers, knowing the MOQ helps in budgeting and inventory planning. This term is crucial when negotiating purchase agreements, especially for smaller businesses that may not require large quantities. -

RFQ (Request for Quotation)

An RFQ is a document that solicits price quotations from suppliers for specific products or services. When purchasing EMI shielding sleeves, submitting an RFQ can help buyers compare prices and terms, ensuring they receive competitive offers from multiple vendors. -

Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers in the shipping process. Understanding these terms helps B2B buyers manage risks related to shipping and logistics, ensuring clarity on who bears costs and responsibilities during transit. -

EMC (Electromagnetic Compatibility)

EMC is the ability of electronic devices to operate without interfering with each other and to withstand interference from external sources. This concept is fundamental when selecting EMI shielding sleeves, as compliance with EMC standards is often required in regulated industries.

By grasping these technical properties and trade terminologies, B2B buyers can make informed decisions when sourcing EMI wire shielding sleeves, ensuring they select the right products to meet their operational needs.

Illustrative image related to emi wire shielding sleeve

Navigating Market Dynamics and Sourcing Trends in the emi wire shielding sleeve Sector

Global drivers in the EMI wire shielding sleeve market are increasingly influenced by the rapid growth of technology sectors, including telecommunications, automotive, and aerospace industries. The rising demand for electronic devices with enhanced performance and reliability has necessitated advanced electromagnetic interference (EMI) solutions. This growth is particularly evident in regions like Africa, South America, the Middle East, and Europe, where industries are modernizing and adopting stricter electromagnetic compatibility (EMC) standards. The increasing complexity of electronic systems is pushing manufacturers to invest in innovative shielding solutions that can meet these demands.

Current trends highlight a shift towards integrating advanced materials and technologies in EMI shielding products. For instance, the use of lightweight, flexible materials, such as braided cable shielding and expandable sleeves, is gaining traction due to their superior performance and ease of installation. Furthermore, the adoption of custom solutions tailored to specific applications, such as military and aerospace, is becoming more prevalent. B2B buyers should also pay attention to the growing role of automation and digitalization in sourcing processes, which streamline procurement and enhance supply chain visibility.

Emerging markets in Africa and South America are experiencing significant growth, driven by increased foreign investments and infrastructure development. Buyers in these regions should be aware of the local regulatory frameworks governing EMC, as compliance will be critical for successful market entry. Additionally, understanding regional manufacturing capabilities and potential partnerships will be essential for sourcing high-quality EMI shielding solutions.

How is Sustainability Influencing the Sourcing of EMI Wire Shielding Sleeves?

The environmental impact of manufacturing processes and materials used in EMI wire shielding sleeves is becoming a focal point for B2B buyers. There is a growing demand for sustainable products that minimize ecological footprints, prompting manufacturers to explore eco-friendly materials and production methods. Sustainable sourcing not only addresses environmental concerns but also enhances brand reputation and meets the expectations of increasingly environmentally-conscious customers.

Ethical supply chains are essential in this context, as buyers seek transparency and accountability from their suppliers. Certifications such as ISO 14001 and materials labeled as “green” or “eco-friendly” can serve as indicators of responsible sourcing practices. Additionally, the use of recyclable or biodegradable materials in the production of EMI shielding sleeves can significantly reduce waste and environmental degradation.

As the global market shifts towards sustainability, B2B buyers should prioritize suppliers that demonstrate a commitment to ethical practices and sustainable innovation. This focus can lead to long-term partnerships that not only fulfill current needs but also align with future environmental goals.

What is the Historical Context of EMI Wire Shielding Technology?

The evolution of EMI wire shielding technology dates back several decades, emerging alongside the rapid advancement of electronic devices. Initially, shielding solutions were rudimentary, primarily focused on providing basic protection against electromagnetic interference. As technology progressed, the complexity and sophistication of electronic systems increased, necessitating more effective shielding solutions.

In the early days, materials such as copper and aluminum were predominantly used for shielding applications. However, the introduction of advanced materials, such as braided composites and non-metallic options, has revolutionized the market. These innovations have led to the development of lightweight, flexible, and high-performance EMI shielding sleeves that cater to diverse industries.

Illustrative image related to emi wire shielding sleeve

Today, the EMI wire shielding sleeve market is characterized by continuous innovation and adaptation to meet the demands of modern electronic applications. As B2B buyers navigate this dynamic landscape, understanding the historical context can provide valuable insights into current trends and future developments in shielding technology.

Frequently Asked Questions (FAQs) for B2B Buyers of emi wire shielding sleeve

-

1. How do I solve electromagnetic interference (EMI) issues in my equipment?

To effectively solve EMI issues, start by identifying the source of interference in your equipment. Use EMI wire shielding sleeves to protect cables and sensitive components. Choose sleeves made from materials specifically designed to block or divert electromagnetic fields, such as braided metallic or non-metallic options. Ensure proper installation to maximize effectiveness, and consider consulting with a specialist for tailored solutions that meet your specific application requirements. -

2. What is the best EMI wire shielding sleeve for automotive applications?

For automotive applications, the best EMI wire shielding sleeves are those that offer high flexibility, durability, and resistance to environmental factors. Look for options made from lightweight materials like braided stainless steel or composite thermoplastics that can withstand high temperatures and vibrations. Ensure that the chosen sleeves provide adequate grounding capabilities to minimize interference. It’s also advisable to select sleeves that comply with automotive industry standards for safety and performance. -

3. What customization options are available for EMI wire shielding sleeves?

Many suppliers offer customization options for EMI wire shielding sleeves, including variations in size, color, and material composition. You can also request specific lengths or pre-cut sizes to fit your application. Some manufacturers may provide custom printing or labeling for branding purposes. Before placing an order, discuss your requirements with the supplier to ensure they can meet your specifications and deliver the desired functionality. -

4. What are the minimum order quantities (MOQs) for EMI wire shielding sleeves?

Minimum order quantities (MOQs) for EMI wire shielding sleeves can vary widely depending on the supplier and the specific product. Generally, MOQs may range from a few hundred units for standard items to several thousand for customized solutions. It’s essential to inquire directly with suppliers about their MOQ policies, as some may offer flexibility for first-time buyers or smaller businesses looking to test products before committing to larger orders. -

5. What payment terms should I expect when purchasing EMI wire shielding sleeves internationally?

Payment terms for international purchases of EMI wire shielding sleeves often vary by supplier and region. Common options include upfront payments, partial payments with delivery, or letters of credit for larger orders. Always clarify payment terms before finalizing the order to avoid misunderstandings. It’s advisable to use secure payment methods that offer buyer protection, especially for significant investments, to mitigate financial risks. -

6. How can I vet suppliers for EMI wire shielding sleeves?

To vet suppliers effectively, start by researching their reputation within the industry. Look for reviews, testimonials, and case studies from previous clients. Verify their certifications and compliance with international quality standards. Request samples to assess the quality of their products. Additionally, consider their responsiveness, customer service, and willingness to provide references. Engaging in direct communication can also help gauge their reliability and expertise. -

7. What quality assurance (QA) measures should I expect from suppliers?

Reputable suppliers of EMI wire shielding sleeves should have robust quality assurance (QA) measures in place. Expect them to conduct rigorous testing on their products for performance against EMI, durability, and compliance with industry standards. Inquire about their QA processes, including certifications such as ISO 9001, and whether they offer warranties or guarantees on their products. A transparent QA process reflects a supplier’s commitment to quality and customer satisfaction. -

8. What logistics considerations should I keep in mind for international shipping of EMI wire shielding sleeves?

When considering logistics for international shipping, factor in shipping costs, delivery times, and customs regulations in your country. Choose a supplier that provides clear shipping options and can assist with documentation for smooth customs clearance. It’s beneficial to use freight forwarders familiar with your region’s regulations. Additionally, consider the supplier’s ability to track shipments and their policy on handling delays or damaged goods during transit.

Top 5 Emi Wire Shielding Sleeve Manufacturers & Suppliers List

1. Zippertubing – EMI Shielding Solutions

Domain: zippertubing.com

Registered: 1996 (29 years)

Introduction: EMI Shielding Solutions from Zippertubing include a variety of high-performance products designed to protect electronics from electromagnetic interference. Key offerings include: 1. Z-3250-Tape – EMI Shielding Tape 2. Shrink-N-Shield® (2:1) – EMI Shielded Heat Shrink Tubing 3. Z-Shield® (Al) – EMI Shielding Wrap 4. Z-Shield® (3250) – EMI Shielding Wrap 5. Zip-Shield® (VNH) – Military Grade Cable S…

2. McMaster – EMI-RFI Shielding Sleeving

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – EMI-RFI Shielding Sleeving, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Glenair – EMI/RFI Cable Shielding Solutions

Domain: glenair.com

Registered: 1995 (30 years)

Introduction: EMI / RFI Braided Cable Shielding, Tubular Expandable Braided Cable Sleeving, Ground Straps; Lightweight Metallic and Non-Metallic Cable Shielding; Protects cables from electrostatic and electromagnetic interference; Interwoven conductive wire acts as a ground-path barrier; Provides abrasion and cut protection; Suitable for environments like aircraft; ArmorLite braided shielding made from ultra-li…

4. Holland Shielding – EMI Shielding Cables & Entries

Domain: hollandshielding.com

Registered: 1998 (27 years)

Introduction: EMI shielding cables & entries include various products designed for electromagnetic interference (EMI) and radio frequency interference (RFI) shielding. Key products include: 1. Wrapshield (4730) – Knitted wire mesh for EMI/RFI cable shielding. 2. Ready-made cableshielding sleeve (4700S) – Available in Amucor or conductive fabric, providing high shielding performance. 3. Flexible cable shield (47…

5. AB Thermal – EMI RFI Shielding Split Sleeve

Domain: abthermal.com

Registered: 2010 (15 years)

Introduction: EMI RFI shielding nickel copper fabric split sleeve with adhesive closure for EMI/RFI/EMF protection; wire and cable shielding; made of nickel-copper coated polyester fabric; continuous exposure temperature: 302°F / 150°C; lightweight and flexible; easily cut to length; provides high attenuation to frequencies; includes internal tinned copper braid for drain/earthing connection at either or both e…

Strategic Sourcing Conclusion and Outlook for emi wire shielding sleeve

In today’s highly competitive and technologically advanced marketplace, the strategic sourcing of EMI wire shielding sleeves is paramount for ensuring product reliability and compliance across various industries. As electromagnetic interference (EMI) continues to pose significant challenges, particularly in sectors such as telecommunications, automotive, and military applications, investing in high-quality shielding solutions can enhance the performance and lifespan of electronic systems.

B2B buyers should prioritize suppliers that offer a diverse range of EMI shielding products, including flexible, expandable sleeves and robust materials that cater to specific environmental conditions. Furthermore, considering factors such as scalability, customization, and sustainability in sourcing decisions will not only streamline procurement processes but also align with global standards and practices.

Looking ahead, international buyers from regions like Africa, South America, the Middle East, and Europe are encouraged to embrace innovative solutions and foster partnerships with reputable manufacturers. By doing so, they can enhance their operational capabilities, mitigate risks associated with EMI, and remain at the forefront of technological advancements. Engage with suppliers today to explore tailored EMI shielding solutions that meet your unique business needs and drive your success in an ever-evolving market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to emi wire shielding sleeve

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.