How to Source Drive Gear Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for drive gear

In today’s competitive landscape, sourcing high-quality drive gear components can be a daunting task for international B2B buyers, especially in regions like Africa, South America, the Middle East, and Europe. With a plethora of options available, understanding the nuances of various gear types—such as spur, helical, and worm gears—along with their specific applications, is essential for making informed purchasing decisions. This guide aims to demystify the drive gear market by providing comprehensive insights into the different types of drive gears, their applications across industries, and strategies for effectively vetting suppliers.

Navigating the complexities of sourcing drive gears requires a clear understanding of not just the products themselves, but also the market dynamics, cost considerations, and quality standards that influence procurement. By exploring topics such as supplier reliability, pricing structures, and industry trends, this guide empowers B2B buyers to streamline their purchasing processes. It addresses key challenges, including how to select the right gear for specific applications and how to negotiate favorable terms with suppliers.

With actionable insights and expert recommendations, this guide serves as a valuable resource for businesses looking to enhance their operational efficiency and drive growth through informed sourcing of drive gear solutions. Whether you are in Saudi Arabia, Nigeria, or any other market, this comprehensive guide will equip you with the knowledge needed to make strategic purchasing decisions that align with your business objectives.

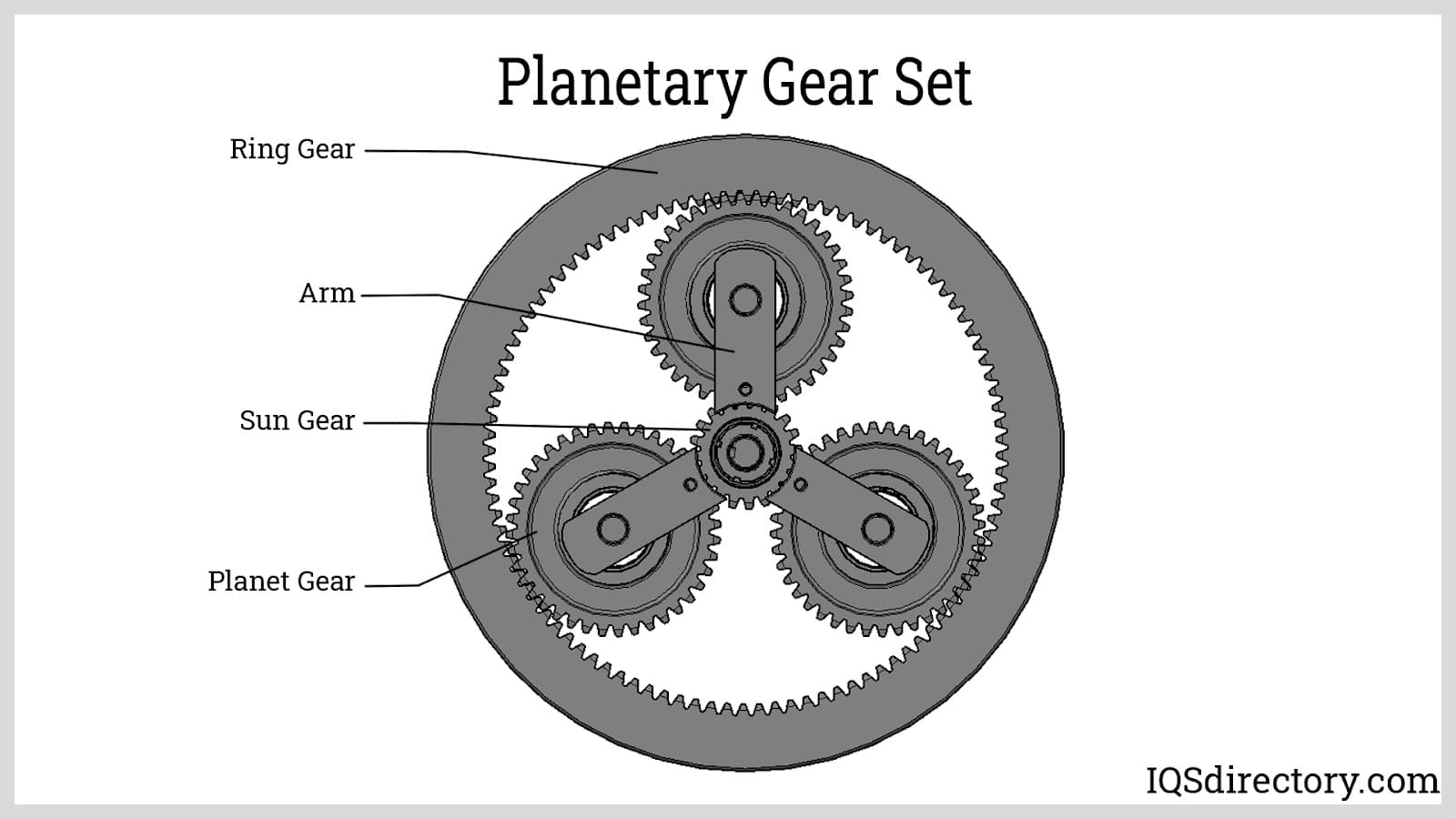

Understanding drive gear Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Spur Gears | Straight teeth, parallel shafts | Industrial machinery, conveyor systems | Pros: Simple design, high efficiency. Cons: Noisy operation, limited load capacity. |

| Helical Gears | Angled teeth, smooth engagement | Automotive transmissions, robotics | Pros: Quieter operation, higher load capacity. Cons: More complex design, higher cost. |

| Worm Gears | Screw-like design, high torque transmission | Lifting equipment, machinery with limited space | Pros: Compact size, significant speed reduction. Cons: Lower efficiency, potential for overheating. |

| Bevel Gears | Cone-shaped, allows for non-parallel shafts | Power tools, automotive differentials | Pros: Versatile angle adjustments, high efficiency. Cons: More complex installation, potential alignment issues. |

| Rack and Pinion | Converts rotational motion to linear motion | Steering systems, linear actuators | Pros: Direct control over linear movement, simplicity. Cons: Limited speed reduction capabilities. |

What are the Characteristics of Spur Gears and Their Suitability for B2B Buyers?

Spur gears are one of the most straightforward types of drive gears, characterized by their straight teeth and parallel shafts. They are predominantly used in industrial machinery and conveyor systems due to their simple design and high efficiency in transmitting power. For B2B buyers, these gears are ideal for applications requiring reliable performance at moderate speeds. However, buyers should consider that spur gears can be noisy during operation and may have limitations in terms of load capacity, making them less suitable for high-torque applications.

How Do Helical Gears Stand Out in Terms of Performance?

Helical gears feature teeth that are angled, allowing for smoother engagement compared to spur gears. This design results in quieter operation and greater load capacity, making them suitable for automotive transmissions and robotics. For B2B buyers, the choice of helical gears may translate into reduced noise levels and improved durability in high-load scenarios. However, the complexity of their design and higher costs may be a consideration for budget-sensitive projects.

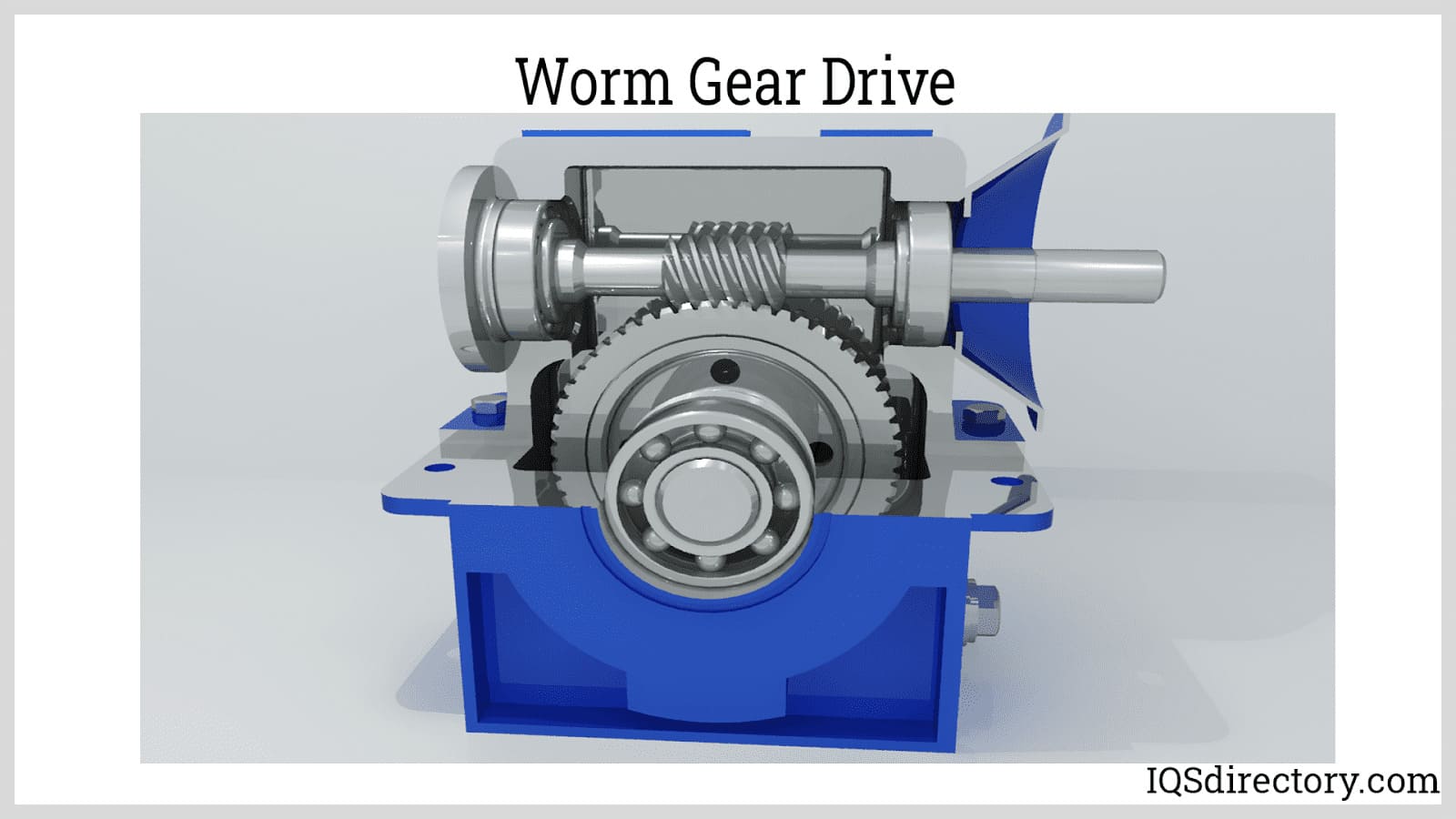

Why Are Worm Gears Preferred for Space-Constrained Applications?

Worm gears utilize a screw-like design that excels in providing high torque transmission and significant speed reduction, making them particularly useful in lifting equipment and machinery where space is limited. B2B buyers often appreciate the compact size and the unique ability of worm gears to maintain position without back-driving. Nevertheless, the lower efficiency and potential for overheating in heavy-duty applications are crucial factors to assess before purchasing.

与drive gear相关的说明性图片

What Advantages Do Bevel Gears Offer for Angle Adjustments?

Bevel gears are distinguished by their cone shape, which allows for the transmission of power between non-parallel shafts. This makes them a popular choice for power tools and automotive differentials. The versatility in angle adjustments and high efficiency are significant advantages for B2B applications. However, buyers should be aware of the complexities involved in installation and the potential for alignment issues, which could affect performance and maintenance costs.

In What Scenarios Are Rack and Pinion Systems Most Effective?

Rack and pinion systems are designed to convert rotational motion into linear movement, making them essential in steering systems and linear actuators. Their simplicity and direct control over movement make them appealing for B2B applications requiring precision. However, buyers should consider the limited speed reduction capabilities, which may not suit all operational needs. Understanding the specific application requirements will help buyers make informed decisions regarding the suitability of rack and pinion systems.

Key Industrial Applications of drive gear

| Industry/Sector | Specific Application of drive gear | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Conveyor Systems | Enhanced efficiency in material handling | Durability, compatibility with existing systems |

| Automotive | Transmission Systems | Improved power transmission and vehicle performance | Precision engineering, compliance with automotive standards |

| Mining and Heavy Machinery | Gear Reduction in Excavators and Drilling Equipment | Increased torque and operational reliability | Load capacity, environmental resistance |

| Agriculture | Drive Mechanisms in Tractors and Harvesters | Optimized field operations and reduced downtime | Adaptability to different terrains, maintenance support |

| Renewable Energy | Gear Systems in Wind Turbines | Enhanced energy conversion efficiency | Material quality, resistance to wear and tear |

How is Drive Gear Used in Manufacturing Conveyor Systems?

In the manufacturing sector, drive gears are integral to conveyor systems, which transport materials between production stages. These systems require gears that can handle high loads and provide precise speed control to ensure seamless operations. The implementation of drive gears reduces the risk of material jams and downtime, thereby enhancing overall productivity. Buyers need to prioritize sourcing durable materials and compatibility with existing machinery to ensure smooth integration.

What Role Does Drive Gear Play in Automotive Transmission Systems?

Drive gears are crucial in automotive transmission systems, where they facilitate the transfer of power from the engine to the wheels. By optimizing gear ratios, these components enhance vehicle acceleration and fuel efficiency. International buyers in this sector must consider precision engineering and adherence to automotive standards to ensure reliability and safety in their vehicles. Sourcing gears that meet specific performance criteria can significantly impact vehicle performance.

How Do Drive Gears Enhance Mining and Heavy Machinery Operations?

In the mining sector, drive gears are essential for gear reduction in heavy machinery like excavators and drilling equipment. They provide the necessary torque to move heavy loads, which is vital for operational efficiency in challenging environments. Buyers in this industry should focus on sourcing gears that can withstand harsh conditions, including dust and moisture. Ensuring that the gears have high load capacities is critical for maintaining operational reliability.

What is the Importance of Drive Mechanisms in Agricultural Equipment?

Drive gears are used in tractors and harvesters to facilitate various functions, such as steering and propulsion. These mechanisms enhance the efficiency of agricultural operations by ensuring optimal power delivery and reducing the likelihood of equipment failure. Buyers from agricultural sectors should consider the adaptability of drive gears to different terrains and their maintenance support options. Selecting the right gears can lead to significant reductions in downtime and operational costs.

How Do Drive Gears Contribute to Renewable Energy Solutions?

In the renewable energy sector, particularly in wind turbines, drive gears play a pivotal role in converting wind energy into mechanical energy. They enable the efficient transmission of power generated by the turbine blades to the generator. Buyers in this industry need to focus on sourcing high-quality materials that resist wear and tear, as well as gears designed for high efficiency. This ensures that turbines operate effectively, maximizing energy conversion and minimizing maintenance costs.

3 Common User Pain Points for ‘drive gear’ & Their Solutions

Scenario 1: Challenges in Sourcing High-Quality Drive Gears

The Problem:

B2B buyers often face the challenge of sourcing high-quality drive gears that meet specific operational requirements. In regions with diverse industrial needs, such as Africa and South America, the availability of suitable suppliers may be limited. Buyers may encounter issues such as inconsistent quality, delayed deliveries, and lack of customization options. These challenges not only affect production timelines but can also lead to significant financial losses due to equipment downtime or suboptimal performance.

The Solution:

To effectively source high-quality drive gears, buyers should start by establishing clear specifications based on their machinery requirements, including load capacity, speed ratios, and material durability. Engaging with multiple suppliers through platforms such as industry trade shows or online marketplaces can provide insights into the best options available. It’s essential to request samples and conduct thorough quality checks before making bulk purchases. Additionally, forming partnerships with manufacturers who offer customization can ensure that the drive gears are tailored to specific applications, thus enhancing operational efficiency.

Scenario 2: Understanding Gear Ratios for Optimal Performance

The Problem:

Many buyers struggle with understanding gear ratios and their impact on machine performance. Miscalculating the appropriate gear ratio can lead to insufficient torque or excessive speed, causing machinery to underperform or even fail. This issue is particularly pronounced in industries that rely on precise mechanical operations, such as automotive or manufacturing, where even minor miscalculations can result in costly errors and safety hazards.

The Solution:

To mitigate this risk, it is crucial for buyers to invest time in understanding the fundamentals of gear ratios. Utilizing online calculators or consulting with gear specialists can help in determining the right ratio for specific applications. Additionally, creating a standardized guide for internal teams can streamline the selection process. It’s beneficial to use simulation software to visualize how different gear configurations affect performance before finalizing the order. Regular training sessions for staff on gear mechanics can also enhance their ability to make informed decisions regarding drive gear selection.

Scenario 3: Maintenance Challenges Leading to Gear Failures

The Problem:

Another significant pain point for B2B buyers is the maintenance of drive gears, which can often be overlooked. Inadequate maintenance practices can lead to premature wear and tear, resulting in unexpected breakdowns. This is especially critical in high-demand industries where machinery operates continuously. Buyers may find themselves facing operational delays, increased repair costs, and the risk of damaging adjacent components due to gear failure.

The Solution:

Implementing a robust maintenance schedule is essential for prolonging the lifespan of drive gears. Buyers should develop a comprehensive maintenance checklist that includes regular inspections, lubrication of moving parts, and timely replacement of worn components. Utilizing predictive maintenance technologies, such as vibration analysis or temperature monitoring, can provide early warnings of potential issues, allowing for proactive interventions. Furthermore, training maintenance staff on the intricacies of gear operation and maintenance best practices can foster a culture of care that enhances equipment reliability and performance.

By addressing these pain points proactively, B2B buyers can ensure that their operations run smoothly, enhancing productivity and reducing overall costs associated with drive gear management.

Strategic Material Selection Guide for drive gear

What Are the Common Materials Used for Drive Gears?

When selecting materials for drive gears, it is crucial to consider various factors such as mechanical properties, cost, and application-specific requirements. Here, we analyze four common materials used in the manufacturing of drive gears: steel, aluminum, plastic, and cast iron.

How Does Steel Perform as a Material for Drive Gears?

Steel is one of the most widely used materials for drive gears due to its excellent mechanical properties. It offers high tensile strength and durability, making it suitable for high-load applications. Steel gears can withstand elevated temperatures and pressures, which is essential in heavy machinery and automotive applications. However, steel is susceptible to corrosion unless treated or coated, which can increase manufacturing complexity and costs.

Pros: High strength, excellent wear resistance, and good thermal stability.

Cons: Heavier than alternative materials, potential for corrosion, and higher manufacturing costs due to heat treatment processes.

In applications where high torque and durability are required, such as in automotive and industrial machinery, steel gears are often the preferred choice. International buyers should consider compliance with standards like ASTM A36 or JIS G3101 for structural steel.

What Are the Advantages of Using Aluminum for Drive Gears?

Aluminum is increasingly being used for drive gears, especially in lightweight applications. It has a lower density than steel, which contributes to reduced overall weight, making it ideal for applications where weight savings are critical, such as in aerospace and automotive industries. Aluminum also offers good corrosion resistance, which can be beneficial in humid or corrosive environments.

与drive gear相关的说明性图片

Pros: Lightweight, good corrosion resistance, and ease of machining.

Cons: Lower strength compared to steel, limited high-temperature performance, and potential for deformation under heavy loads.

Aluminum gears are suitable for applications where weight reduction is essential, but they may not be ideal for high-torque environments. Buyers from regions like Europe and the Middle East should ensure compliance with aluminum standards such as EN AW-6061.

How Do Plastics Compare for Drive Gear Applications?

Plastic gears are often employed in low-load applications due to their lightweight and low-cost characteristics. They offer excellent corrosion resistance and can operate silently, making them suitable for consumer products and electronic devices. However, plastics typically have lower mechanical strength and are not suitable for high-temperature environments.

Pros: Low cost, lightweight, and good corrosion resistance.

Cons: Limited load-bearing capacity, lower thermal stability, and potential for wear under high friction.

Plastic gears are ideal for applications like small motors and consumer electronics. B2B buyers should consider industry standards such as ISO 1043 for plastic materials to ensure compatibility with specific applications.

What Role Does Cast Iron Play in Drive Gear Manufacturing?

Cast iron is another material used for drive gears, particularly in heavy machinery. It has excellent wear resistance and can absorb vibrations effectively, which is beneficial in reducing noise in mechanical systems. However, cast iron is brittle and can fracture under excessive stress, limiting its use in high-torque applications.

Pros: Good wear resistance, vibration dampening properties, and cost-effective for large components.

Cons: Brittle nature, heavier than alternatives, and limited flexibility in design.

Cast iron gears are often found in industrial applications where durability is prioritized over weight. Buyers should be aware of relevant standards like ASTM A48 for gray cast iron to ensure quality and performance.

Summary Table of Material Selection for Drive Gears

| Material | Typical Use Case for drive gear | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive, industrial machinery | High strength and durability | Susceptible to corrosion | High |

| Aluminum | Aerospace, automotive applications | Lightweight and corrosion-resistant | Lower strength than steel | Medium |

| Plastic | Consumer electronics, small motors | Low cost and lightweight | Limited load-bearing capacity | Low |

| Cast Iron | Heavy machinery | Good wear resistance and cost-effective | Brittle and heavy | Medium |

This strategic material selection guide provides B2B buyers with insights into the strengths and weaknesses of different materials for drive gears, helping them make informed decisions that align with their specific application needs and regional standards.

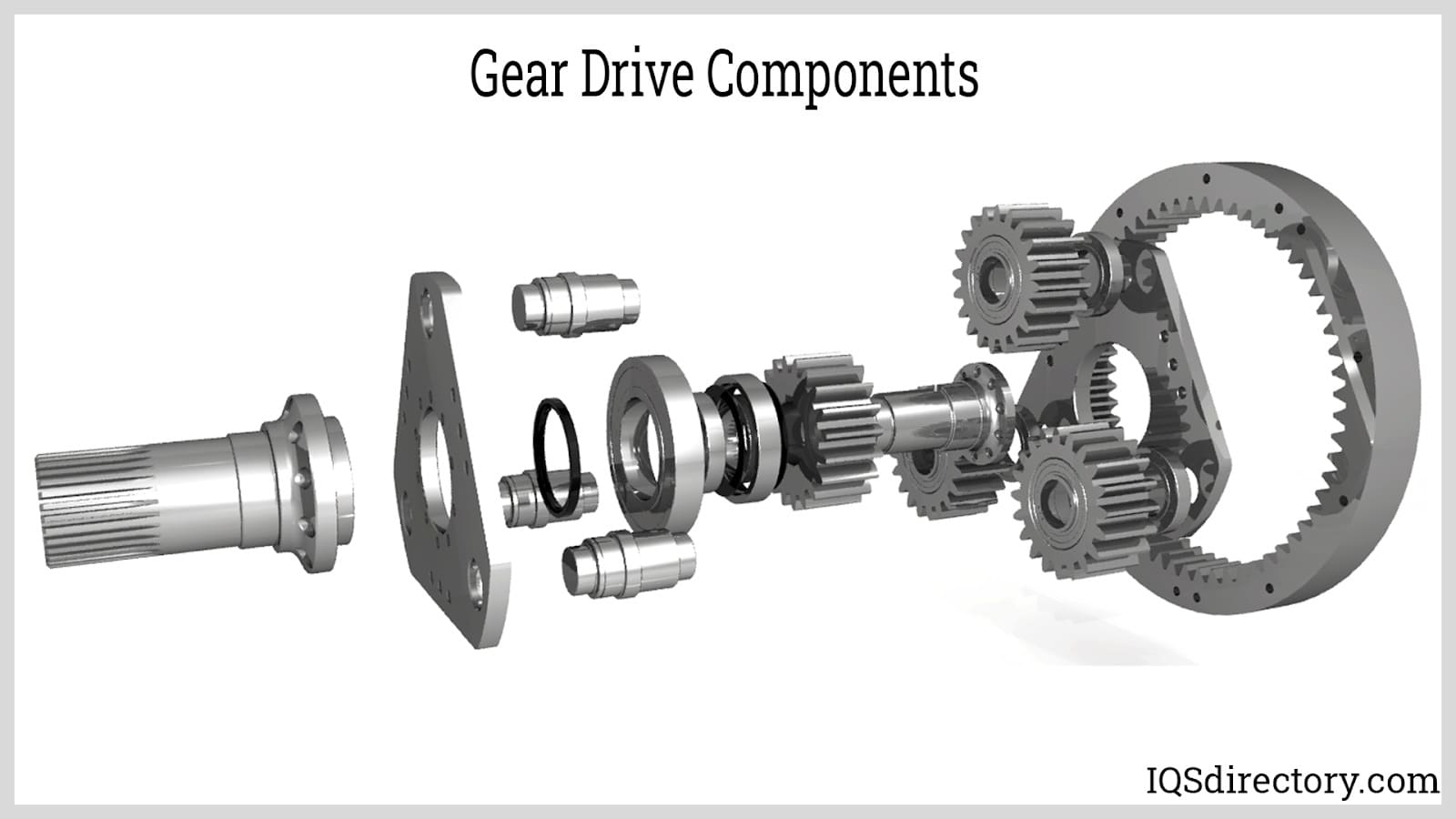

In-depth Look: Manufacturing Processes and Quality Assurance for drive gear

What Are the Main Stages in the Manufacturing Process for Drive Gears?

The manufacturing of drive gears involves several critical stages, each integral to ensuring the final product meets stringent quality and performance standards. The primary stages are material preparation, forming, assembly, and finishing.

Material Preparation

The first step in manufacturing drive gears is the careful selection and preparation of raw materials. Common materials include carbon steel, alloy steel, and sometimes specialized materials like plastic or composites for specific applications. The selection depends on the gear’s intended use, load requirements, and environmental conditions. The material is typically sourced from reputable suppliers to ensure quality.

Once the raw materials are selected, they undergo processes such as cutting and heat treatment to enhance their mechanical properties. For example, heat treatment processes like quenching and tempering can significantly improve the hardness and durability of the steel.

How Are Drive Gears Formed?

The next stage is forming, which involves shaping the prepared material into gear components. This can be achieved through various methods, including:

与drive gear相关的说明性图片

- Machining: Precision cutting processes such as turning, milling, and grinding are commonly used to achieve the required dimensions and surface finishes.

- Forging: This method involves shaping the material using compressive forces, which can improve the material’s strength.

- Casting: In some cases, gears may be cast using molds, particularly for complex shapes or large sizes.

Each method has its advantages and is selected based on factors like cost, volume, and the specific characteristics required in the final product.

What Is Involved in the Assembly of Drive Gears?

After forming, the various components of the drive gear are assembled. This stage may involve:

- Interference fitting: Components are pressed together to ensure a tight fit.

- Welding or brazing: For certain designs, parts may need to be welded or brazed for added strength.

- Quality checks: During assembly, components are checked for compatibility and alignment to prevent operational issues.

This stage is crucial, as any misalignment can lead to increased wear, noise, and ultimately, gear failure.

How Does Finishing Impact Drive Gear Quality?

Finishing processes are essential to enhance the performance and lifespan of drive gears. Common finishing techniques include:

- Surface hardening: Methods like carburizing or nitriding increase surface hardness while maintaining core toughness.

- Coating: Applying protective coatings can prevent corrosion and reduce friction, enhancing the gear’s operational life.

- Polishing: This improves the surface finish, reducing wear and noise during operation.

Finishing not only improves the aesthetics of the gear but also contributes significantly to its functionality and durability.

What Quality Assurance Standards Are Relevant for Drive Gears?

Quality assurance in the manufacturing of drive gears is paramount, particularly for B2B buyers in international markets. Understanding relevant standards and quality control processes is essential for ensuring product reliability.

Which International Standards Should B2B Buyers Consider?

International standards such as ISO 9001 provide a framework for quality management systems and are widely recognized across various industries. Compliance with these standards ensures that manufacturers have established processes to consistently deliver high-quality products.

Additionally, industry-specific certifications like CE (Conformité Européenne) for products sold in Europe and API (American Petroleum Institute) standards for gears used in the oil and gas sector are critical. These certifications demonstrate adherence to safety, health, and environmental protection standards.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is integrated throughout the manufacturing process and typically involves several checkpoints:

- Incoming Quality Control (IQC): This involves inspecting raw materials upon arrival to ensure they meet specified standards before production begins.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process allows for immediate correction of any deviations from standards.

- Final Quality Control (FQC): Before products are shipped, they undergo final inspections to verify that they meet all specifications and performance criteria.

These checkpoints are crucial for identifying defects early and ensuring that only high-quality products reach the market.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, verifying a supplier’s quality control practices is essential to mitigate risks associated with product quality. Here are several strategies:

What Should Buyers Look for in Supplier Audits and Reports?

- Supplier Audits: Conducting audits helps assess a supplier’s adherence to quality management systems and production processes. This can be done through on-site visits or third-party assessments.

- Quality Reports: Requesting detailed quality reports, including testing results and compliance certifications, can provide insights into a supplier’s quality assurance processes.

Why Are Third-Party Inspections Important?

Third-party inspections offer an unbiased evaluation of the supplier’s quality control practices. Engaging independent inspectors can provide assurance that products meet required specifications and standards before shipment.

What Nuances Should International Buyers Be Aware of Regarding Quality Control?

When sourcing drive gears from international suppliers, particularly from regions like Africa, South America, and the Middle East, buyers should consider:

- Cultural Differences: Understanding regional practices and communication styles can improve negotiation and collaboration.

- Regulatory Compliance: Different countries may have varying regulations regarding manufacturing and product standards. Familiarity with these requirements is essential to ensure compliance and avoid legal issues.

- Logistical Challenges: Factors such as shipping times, customs regulations, and local infrastructure can impact the reliability of supply chains. Establishing clear communication and contingency plans is vital.

Conclusion

The manufacturing processes and quality assurance for drive gears are intricate, demanding careful attention to detail at every stage. For B2B buyers, understanding these processes and the relevant quality standards can significantly influence the reliability and performance of the products they procure. By prioritizing suppliers with robust quality control practices and certifications, businesses can ensure they receive high-quality drive gears that meet their operational needs.

与drive gear相关的说明性图片

Practical Sourcing Guide: A Step-by-Step Checklist for ‘drive gear’

Introduction

This sourcing guide provides a comprehensive checklist for B2B buyers seeking to procure drive gears. Understanding the nuances of drive gear selection is crucial for ensuring optimal performance in various applications, from automotive to industrial machinery. By following this checklist, buyers can make informed decisions that align with their technical requirements and operational goals.

1. Define Your Technical Specifications

Establishing clear technical specifications is the foundation of an effective sourcing process. Consider factors such as gear type (e.g., spur, helical, worm), material, size, and load capacity. This step ensures that the gears you select will meet the demands of your specific application, preventing costly mistakes down the line.

2. Research Market Suppliers

Thoroughly research potential suppliers to identify those with a strong reputation and reliable product offerings. Focus on suppliers that specialize in drive gears and have experience in your industry. Look for online reviews, ratings, and testimonials to gauge their reliability and service quality.

3. Evaluate Potential Suppliers

Before making a commitment, vet suppliers rigorously. Request detailed company profiles, product catalogs, and case studies that showcase their expertise and past projects. Seek references from buyers in similar industries or regions to understand the supplier’s reliability and customer service.

4. Verify Supplier Certifications

Ensure that suppliers hold relevant industry certifications and adhere to quality standards such as ISO 9001. Certifications indicate a supplier’s commitment to quality control and operational excellence. This is particularly important in regions with varying regulatory standards, such as Africa and the Middle East.

5. Request Samples and Test Products

Before finalizing your order, request samples of the drive gears to evaluate their quality and performance. Testing samples allows you to assess compatibility with your existing systems and verify that they meet your specifications. Consider conducting trials in real-world conditions if possible.

6. Assess Pricing and Total Cost of Ownership

While price is an important factor, consider the total cost of ownership, which includes installation, maintenance, and potential downtime costs. Compare quotes from multiple suppliers to ensure you are getting the best value. Look for suppliers that offer warranties or service agreements as part of their pricing.

7. Negotiate Terms and Finalize Contracts

Once you have selected a supplier, negotiate terms that protect your interests, including pricing, delivery timelines, and payment terms. Clear contracts should outline responsibilities, warranties, and penalties for non-compliance. Ensure both parties understand and agree to the terms to avoid misunderstandings later.

By following this checklist, B2B buyers can navigate the complexities of sourcing drive gears effectively, ensuring they select the right products for their operational needs while building strong supplier relationships.

Comprehensive Cost and Pricing Analysis for drive gear Sourcing

What Are the Key Cost Components in Drive Gear Manufacturing?

When sourcing drive gears, understanding the cost structure is essential for effective budgeting and decision-making. The primary cost components include:

-

Materials: The choice of materials significantly impacts the overall cost. Common materials for drive gears include carbon steel, stainless steel, and plastic. The cost of raw materials can vary based on global market trends, availability, and quality specifications.

-

Labor: Labor costs encompass the wages paid to skilled workers involved in the manufacturing process. Skilled machinists and engineers typically demand higher salaries, particularly in regions with a high cost of living or where specialized skills are required.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities, equipment maintenance, and facility costs. Efficient manufacturing processes can help minimize overhead costs.

-

Tooling: The costs associated with the design and creation of molds and tools necessary for production are significant, especially for custom gears. These upfront investments can be substantial but are amortized over the production run.

-

Quality Control (QC): Ensuring that drive gears meet the required specifications is critical, especially in industries where performance is paramount. QC processes incur costs related to inspections, testing, and compliance with international standards.

-

Logistics: Transportation costs can fluctuate based on the distance from the manufacturer to the buyer, mode of transport, and current fuel prices. Efficient logistics planning can mitigate costs.

-

Margin: Suppliers typically add a profit margin to cover their risks and costs, which can vary widely depending on the market conditions and competition.

How Do Price Influencers Affect Drive Gear Sourcing?

Several factors can influence the pricing of drive gears, including:

-

Volume/MOQ: Purchasing in larger quantities often leads to discounts, as suppliers benefit from economies of scale. Understanding the minimum order quantities (MOQ) can help buyers negotiate better prices.

-

Specifications and Customization: Customized drive gears that meet specific operational needs generally come at a premium. Buyers should clearly define their specifications to avoid unnecessary costs.

-

Materials and Quality Certifications: The type of material used and the presence of quality certifications (such as ISO) can significantly affect pricing. High-quality materials and certifications typically lead to higher prices but can result in better performance and longevity.

-

Supplier Factors: Different suppliers may have varying pricing structures based on their operational efficiencies, location, and market positioning. Establishing relationships with multiple suppliers can enhance negotiating power.

-

Incoterms: Understanding the implications of Incoterms is crucial for international buyers. The chosen terms affect shipping costs, risk, and responsibilities for both the buyer and seller, which can influence the final price.

What Tips Can Help Buyers Negotiate Better Prices for Drive Gears?

For international B2B buyers, particularly those from regions like Africa, South America, the Middle East, and Europe, several strategies can enhance negotiation outcomes:

-

Conduct Market Research: Knowledge of current market conditions and competitor pricing can provide leverage during negotiations. Understanding local and global pricing trends can guide buyers in making informed offers.

-

Evaluate Total Cost of Ownership (TCO): Rather than focusing solely on the purchase price, consider the TCO, which includes maintenance, operational efficiency, and longevity of the drive gears. This perspective can justify higher upfront costs for better quality products.

-

Negotiate Payment Terms: Favorable payment terms can alleviate cash flow pressures. Consider negotiating for extended payment periods or installment payments, especially for larger orders.

-

Engage in Long-Term Relationships: Building long-term relationships with suppliers can lead to better pricing and terms over time. Suppliers may offer loyalty discounts or be more flexible in negotiations with established customers.

-

Understand Regional Pricing Nuances: Be aware of regional economic factors that may affect pricing, such as tariffs, taxes, and currency fluctuations. This knowledge can aid in calculating the true cost of sourcing from various suppliers.

By leveraging these insights, B2B buyers can make more informed decisions when sourcing drive gears, ensuring that they achieve both cost-effectiveness and quality in their procurement processes.

Alternatives Analysis: Comparing drive gear With Other Solutions

Introduction to Alternatives in Drive Systems

In the realm of mechanical systems, drive gears play a crucial role in transmitting motion and power. However, various alternatives exist that can achieve similar objectives, each with distinct advantages and disadvantages. Understanding these alternatives can empower B2B buyers to make informed decisions based on their specific operational needs, budget constraints, and desired performance outcomes.

Comparison Table

| Comparison Aspect | Drive Gear | Chain Drive | Belt Drive |

|---|---|---|---|

| Performance | High torque transmission; effective for precise speed ratios | Good for high torque; less precise than gears | Moderate torque; better for variable speed applications |

| Cost | Moderate initial investment; longevity can reduce long-term costs | Generally lower upfront costs but higher maintenance | Lower initial costs; replacement frequency can increase total cost |

| Ease of Implementation | Requires precise alignment; installation can be complex | Easier to install; requires less precision | Simple installation; can be adjusted easily |

| Maintenance | Low maintenance with proper lubrication | Moderate maintenance; lubrication and tension adjustments needed | Regular replacements needed; tension monitoring required |

| Best Use Case | Heavy machinery, automotive, robotics where precision is critical | Motorcycles, bicycles, and machinery requiring high torque | Conveyor systems, fans, and applications needing flexibility |

Detailed Breakdown of Alternatives

Chain Drive

Chain drives utilize a series of interconnected links to transmit power between sprockets. They are particularly advantageous in applications requiring high torque, such as motorcycles and some industrial machinery. The main benefits of chain drives include their cost-effectiveness and ease of installation. However, they may require regular maintenance, including lubrication and tension adjustments, to ensure optimal performance. While they offer good torque transmission, chain drives may not provide the precision that gear systems deliver, making them less suitable for applications demanding exact speed ratios.

Belt Drive

Belt drives consist of flexible belts that transmit power between pulleys. They are often used in applications like conveyor systems and fans, where flexibility and variable speed are essential. The initial costs are typically lower than gear systems, and they are easier to install and adjust. However, belt drives can wear out more quickly and require frequent replacements, which may lead to higher long-term costs. Additionally, they can transmit less torque compared to chain or gear drives, making them less ideal for heavy-duty applications.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate drive system, B2B buyers should consider the specific requirements of their applications, including torque needs, precision, installation complexity, and maintenance capabilities. Drive gears excel in scenarios demanding high precision and torque, making them ideal for heavy machinery and robotics. Conversely, chain and belt drives offer cost-effective and flexible alternatives that may be better suited for less demanding applications. Ultimately, understanding the distinct characteristics of each solution will enable buyers to make choices aligned with their operational goals and budgetary constraints.

Essential Technical Properties and Trade Terminology for drive gear

What Are the Key Technical Properties of Drive Gear?

Understanding the technical specifications of drive gears is crucial for making informed purchasing decisions. Here are several critical properties that B2B buyers should consider:

-

Material Grade

Drive gears can be manufactured from various materials, including steel, aluminum, and plastic. The choice of material affects durability, strength, and resistance to wear and corrosion. For instance, steel gears offer high tensile strength suitable for heavy-duty applications, while plastic gears may be favored for lighter loads and reduced noise levels. Selecting the right material is essential to match the operational demands of your machinery. -

Tooth Profile

The design of the gear teeth, including their shape and size, influences the gear’s efficiency and performance. Common profiles include spur, helical, bevel, and worm gears. Each design has unique advantages; for example, helical gears provide smoother engagement and quieter operation compared to spur gears. Understanding tooth profiles helps buyers select gears that optimize performance and reduce wear. -

Tolerance and Precision

Tolerance refers to the allowable deviation in the dimensions of the gear. High precision in manufacturing ensures that gears mesh smoothly, reducing friction and increasing efficiency. For applications requiring high-speed operations or heavy loads, tighter tolerances are critical. Buyers must evaluate the required precision based on their operational needs to avoid premature gear failure. -

Load Capacity

The load capacity of a drive gear indicates the maximum load it can handle without failure. This specification is vital for applications in automotive, industrial machinery, and other heavy-duty environments. Understanding the load requirements of your application helps in selecting gears that can withstand operational stresses, thereby ensuring longevity and reliability. -

Surface Treatment

Surface treatments, such as hardening, coating, or polishing, enhance the durability and performance of drive gears. These treatments can improve wear resistance, reduce friction, and prevent corrosion. Buyers should consider the environmental conditions in which the gears will operate to choose appropriate surface treatments that prolong gear life.

What Are Common Trade Terms in the Drive Gear Industry?

Familiarity with industry terminology can streamline communication and negotiations in B2B transactions. Here are several essential trade terms related to drive gears:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the context of drive gears, knowing whether a supplier is an OEM can indicate the reliability and quality of the components being sourced. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for budgeting and inventory management, especially for businesses looking to optimize their supply chain. -

RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to solicit price quotes for specific products or services. It allows buyers to compare costs and terms from multiple suppliers, ensuring they make informed purchasing decisions. -

Incoterms (International Commercial Terms)

Incoterms are predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps buyers understand shipping responsibilities, risks, and costs associated with their purchases. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. Knowing the lead time is critical for planning production schedules and managing inventory effectively. -

Gear Ratio

Gear ratio is the ratio of the number of teeth on two meshing gears. It is a fundamental concept that determines how torque and speed are transmitted between gears. Understanding gear ratios is vital for selecting the right gear combination for specific applications, ensuring optimal performance and efficiency.

By comprehending these technical properties and trade terms, B2B buyers can navigate the drive gear market more effectively, ensuring they select the right components for their machinery and operational needs.

Navigating Market Dynamics and Sourcing Trends in the drive gear Sector

What Are the Current Market Dynamics and Key Trends Affecting the Drive Gear Sector?

The drive gear sector is experiencing robust growth, driven by increasing demand across various industries, including automotive, aerospace, and manufacturing. Key market drivers include the rising need for efficient power transmission systems and the growing trend towards automation and robotics in manufacturing processes. This shift is particularly significant in emerging markets in Africa and South America, where infrastructure development is rapidly expanding. In the Middle East, the push for modernization in various sectors, including oil and gas, is further propelling the demand for advanced drive gear solutions.

Emerging B2B technology trends are reshaping sourcing strategies in the drive gear market. Digitalization and Industry 4.0 are facilitating real-time supply chain management, allowing buyers to make data-driven decisions. The integration of AI and machine learning in production processes is improving gear design and manufacturing efficiency, leading to enhanced product quality and reduced lead times. Furthermore, the adoption of e-commerce platforms is simplifying the procurement process for international buyers, enabling them to access a broader range of suppliers and products from around the globe.

Market dynamics are also influenced by geopolitical factors and trade policies. Buyers in regions like Europe and the Middle East must navigate tariffs and trade agreements that can impact sourcing costs. Consequently, international buyers should focus on building strong relationships with suppliers and exploring local sourcing options to mitigate risks associated with global supply chain disruptions.

How Is Sustainability and Ethical Sourcing Influencing the Drive Gear Market?

Sustainability has become a critical concern for B2B buyers in the drive gear sector. Companies are increasingly recognizing the environmental impact of their operations and are seeking to minimize their carbon footprint through sustainable practices. This includes the responsible sourcing of raw materials and the adoption of energy-efficient manufacturing processes. Buyers are encouraged to prioritize suppliers who demonstrate a commitment to sustainability, as this can enhance their brand reputation and meet the growing consumer demand for environmentally friendly products.

Ethical sourcing is equally important in today’s market landscape. Buyers should consider suppliers who adhere to fair labor practices and maintain transparency in their supply chains. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety can serve as indicators of a supplier’s commitment to ethical practices. Additionally, the use of recycled materials and the implementation of circular economy principles are becoming increasingly relevant in the drive gear sector, allowing buyers to contribute to a more sustainable future.

What Is the Historical Context of the Drive Gear Industry?

The drive gear industry has evolved significantly over the past century, paralleling advancements in technology and manufacturing processes. Initially, drive gears were primarily made from steel, focusing on durability and strength. However, with the advent of new materials and manufacturing techniques, including computer-aided design (CAD) and precision machining, the industry has seen a shift towards more complex gear designs that optimize performance and efficiency.

This evolution has been driven by the increasing demands of modern machinery and vehicles, which require higher torque and speed capabilities. Innovations such as helical and bevel gears have expanded the functional applications of drive gears, making them essential components in various industries. As technology continues to advance, the drive gear sector is poised for further innovation, offering exciting opportunities for B2B buyers to explore cutting-edge solutions that meet their operational needs.

Frequently Asked Questions (FAQs) for B2B Buyers of drive gear

-

How do I solve compatibility issues with drive gears in my machinery?

Compatibility issues often arise from differences in gear specifications such as size, tooth count, and material. To resolve these, first, ensure that the driving gear’s specifications match those of the driven gear. Review the gear ratio needed for your application, as this affects performance. If necessary, consult with suppliers for alternative options or custom solutions. Additionally, consider conducting a thorough testing phase to verify compatibility before full-scale implementation. -

What is the best type of drive gear for high-torque applications?

For high-torque applications, helical gears are typically recommended due to their ability to handle greater loads and provide smoother operation compared to spur gears. Helical gears feature angled teeth that engage gradually, reducing noise and wear. It’s also crucial to consider the material and heat treatment of the gears to enhance durability and performance. Always consult with gear manufacturers to determine the optimal specifications for your specific application. -

How can I ensure the quality of drive gears from international suppliers?

To ensure quality, start by vetting potential suppliers thoroughly. Look for certifications such as ISO 9001, which indicates adherence to quality management standards. Request samples and conduct performance tests under your specific operational conditions. Additionally, inquire about their manufacturing processes and quality assurance protocols. Establishing clear communication with suppliers about your quality expectations can also help mitigate risks. -

What factors should I consider when customizing drive gears?

When customizing drive gears, consider the application requirements, including load capacity, speed, and environmental conditions. Material selection is critical; options like steel, aluminum, or plastic can significantly affect performance. Also, focus on gear tooth design and surface finish to optimize efficiency and reduce wear. Lastly, ensure that you provide detailed specifications to your supplier to avoid miscommunication and ensure the final product meets your needs. -

What is the typical minimum order quantity (MOQ) for drive gears?

Minimum order quantities for drive gears can vary significantly by supplier and the complexity of the gear design. Standard gears may have an MOQ of 100-500 units, while custom gears could require a higher MOQ due to the setup costs involved. It’s advisable to discuss your needs directly with suppliers, as some may offer flexibility based on your specific requirements or potential for ongoing business. -

What payment terms should I expect when sourcing drive gears internationally?

Payment terms can differ widely among suppliers, but common practices include upfront payments, letters of credit, or net 30-60 days after delivery. Be sure to clarify payment terms before finalizing agreements to avoid misunderstandings. Additionally, consider using secure payment methods that offer buyer protection, especially for larger orders. Negotiating favorable terms can also help in managing cash flow effectively. -

What logistics considerations should I keep in mind when importing drive gears?

When importing drive gears, factor in shipping methods, customs duties, and import regulations specific to your country. Choose a reliable freight forwarder who can navigate international shipping complexities and provide guidance on documentation required for customs clearance. Additionally, consider lead times for production and shipping, as these can impact your project timelines. Clear communication with suppliers regarding logistics can ensure smoother transactions. -

How do I handle warranty claims for defective drive gears?

To handle warranty claims effectively, first, ensure you understand the warranty policy provided by the supplier. Document any defects thoroughly with photographs and detailed descriptions of the issues encountered. Contact the supplier promptly, providing all necessary documentation to support your claim. Maintain a record of all communications for reference. If resolution is not satisfactory, consider discussing the issue with relevant industry bodies or seeking legal counsel if necessary.

Top 7 Drive Gear Manufacturers & Suppliers List

1. KHK Gears – Driving Gear Solutions

Domain: khkgears.net

Registered: 2015 (10 years)

Introduction: Driving gear is the gear that transmits rotational motion from a motor or device through the drive shaft. It can function as a reduction device if it has fewer teeth than the driven gear, or as an increaser device if it has more teeth. For example, with a driving gear having 30 teeth and a driven gear with 60 teeth, the speed transmission ratio is 2, resulting in the driven gear rotating at 200 rp…

2. VW – DriverGear Collection Summer 2025

Domain: drivergear.vw.com

Registered: 1994 (31 years)

Introduction: VW DriverGear Collection Summer 2025 features apparel including tees, shorts, caps, bags, and coolers. Highlights include the Throwback Cali collection, New Classics, and bold Streetwear. The 2025 U.S. Soccer Pre-Match Top and Soccer Collection focuses on designs for active movement. Offers include 20% off the first order for new subscribers.

3. Drive Gear – Essential Component

Domain: my-summer-car.fandom.com

Registered: 1996 (29 years)

Introduction: {“name”: “Drive Gear”, “release_date”: “Pre-public release”, “bolts”: “7x6mm”, “damageable”: “No”, “source”: “Garage at home”, “description”: “The drive gear (Pääakseli) is a car part that connects the gearbox to the clutch. If not installed or bolted properly, the clutch will not work.”}

4. Koike – DRIVE GEAR, A/P

Domain: koike.com

Registered: 1996 (29 years)

Introduction: {“product_name”: “DRIVE GEAR, A/P”, “SKU”: “ZS31333”, “UPC”: “”, “MSRP”: “$112.80”, “current_stock”: 1, “reviews”: {“rating”: “No reviews yet”, “review_count”: 0}}

5. Good Vibes Racing – Premium Gear Drives

Domain: goodvibesracing.com

Registered: 1999 (26 years)

Introduction: Gear Drives: USA made premium Gear Drives ideal for blown alcohol and nitrous applications, as well as high lift & high compression engines. Product breakdown includes:

– Billet CHEVY Gear Drives

– Billet HEMI Gear Drives

– Milodon Gear Drives

– Internal bearing Support 331-392 HEMI Cam Covers

– Crank & Cam Gears

– Quick-Release Fuel Pump Clamp

– Billet Pump Extensions

– Crank Seal…

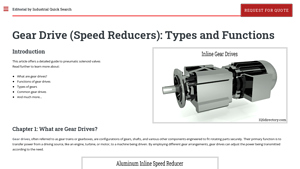

6. IQS Directory – Gear Drives

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Gear drives, also known as gear trains or gearboxes, are mechanical systems designed to transfer power from a driving source to a driven machine. They can adjust the power transmitted by altering the rotational speed of the output shaft, functioning as speed reducers that increase torque while decreasing speed. Key components include gears made from alloyed steel, shafts, keys, couplings, bearings…

7. Gunite – 3 Gear Drive

Domain: gunitesupply.com

Registered: 2000 (25 years)

Introduction: {“product_name”: “3” Gear Drive”, “part_number”: “705790”, “price”: “$262.00/EA”, “availability”: “In Stock”, “used_on”: “C-10 SL”, “warehouse_stock”: {“G2”: 33, “G3”: 2}}

Strategic Sourcing Conclusion and Outlook for drive gear

How Can Strategic Sourcing Enhance Your Drive Gear Procurement?

In today’s competitive landscape, strategic sourcing is pivotal for optimizing the procurement of drive gears. Understanding the intricacies of gear types—such as spur, helical, and worm gears—enables buyers to select the most suitable components for their applications, ultimately enhancing operational efficiency. By leveraging strategic sourcing, companies can not only reduce costs but also ensure quality and reliability in their supply chain, which is crucial for maintaining production schedules and minimizing downtime.

与drive gear相关的说明性图片

Moreover, as global markets evolve, particularly in regions like Africa, South America, the Middle East, and Europe, there is an increasing demand for high-performance drive gear solutions. Buyers are encouraged to forge partnerships with reputable manufacturers and suppliers who demonstrate technological prowess and commitment to innovation. This collaboration can lead to customized solutions that meet specific industry needs.

Looking ahead, the future of drive gear sourcing is bright, with advancements in materials and manufacturing technologies promising improved performance and durability. Now is the time for international B2B buyers to take proactive steps in enhancing their sourcing strategies, ensuring they remain at the forefront of industry developments. Embrace strategic sourcing today to secure a competitive edge in tomorrow’s marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.