How to Source Double Plating Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for double plating

In the rapidly evolving landscape of orthopedic solutions, sourcing reliable double plating systems presents a significant challenge for international B2B buyers. As the demand for advanced fracture fixation techniques grows, understanding the intricacies of double plating—particularly in regions such as Africa, South America, the Middle East, and Europe—becomes crucial. This guide aims to demystify the complexities surrounding double plating, addressing various applications and the types of plates available, while also offering insights into supplier vetting processes and cost considerations.

Double plating is particularly advantageous in scenarios involving complex fracture patterns and conditions such as osteoporosis, where enhanced stability is paramount. By providing a comprehensive overview, this guide empowers buyers to make informed purchasing decisions that align with their specific needs and the expectations of their healthcare markets. From understanding the biomechanical principles of double plating to evaluating the latest innovations in implant technology, this resource equips B2B professionals with the knowledge necessary to navigate the global market effectively.

Furthermore, the guide emphasizes best practices for supplier selection, ensuring that buyers can identify reputable manufacturers who meet stringent quality standards. With this information at hand, stakeholders can confidently engage in the procurement process, ultimately improving patient outcomes through superior fixation solutions.

Understanding double plating Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lateral and Medial Plating | Uses both lateral and medial plates for stability | Complex fracture fixation in trauma cases | Pros: Enhanced stability; Cons: More invasive, longer recovery. |

| Bridging Double Plating | Focuses on bridging fixation across fracture sites | Metaphyseal comminution treatment | Pros: Reduces load on fracture; Cons: Requires precise contouring. |

| Locking Plate Systems | Incorporates locking screws for secure fixation | Osteoporotic fractures or high-load scenarios | Pros: Greater fixation strength; Cons: Higher cost, complex installation. |

| Malleable Template Plating | Utilizes customizable plates for anatomical fit | Tailored solutions for irregular fractures | Pros: Improved fit and stability; Cons: Longer preparation time. |

| Intramedullary Support | Combines plates with intramedullary devices | Severe fractures or revision surgeries | Pros: Additional support; Cons: Increased complexity in surgery. |

What are the Characteristics and Suitability of Lateral and Medial Plating?

Lateral and medial plating involves the application of both lateral and medial plates to enhance fixation in complex fractures. This method is particularly suitable for cases with multfragmentary patterns or where osteoporosis is present. Buyers should consider the surgical experience required for this dual approach, as it demands proficiency in both lateral and medial fixation techniques. The additional stability offered by this method can significantly improve patient outcomes, making it a preferred choice for high-risk fractures.

How Does Bridging Double Plating Work?

Bridging double plating is designed to provide stability across the fracture site by using plates that span the affected area. This technique is especially effective for metaphyseal comminution, where traditional fixation methods may fail. B2B buyers should assess the specific needs of their patient population, as this method is beneficial for those with high loads on the fracture site. However, the requirement for precise contouring and the potential for increased surgical time should be factored into purchasing decisions.

What are the Advantages of Locking Plate Systems?

Locking plate systems utilize screws that lock into the plate, providing a robust fixation mechanism ideal for osteoporotic bones or high-load scenarios. These systems are increasingly popular in B2B markets due to their reliability and strength. Buyers must weigh the higher costs associated with these systems against the potential for improved patient outcomes. Additionally, the complexity of installation may necessitate advanced training for surgical staff.

Why Choose Malleable Template Plating?

Malleable template plating allows for customization of plates to fit the unique anatomical structures of patients. This adaptability is crucial for achieving optimal stability in irregular fractures. B2B buyers should consider the time investment required for preparation and contouring, as this method can extend surgical duration. However, the enhanced fit and stability it provides can lead to better recovery outcomes and patient satisfaction.

What is the Role of Intramedullary Support in Double Plating?

Intramedullary support complements double plating by providing additional structural integrity to the fixation. This approach is particularly useful in severe fractures or revision surgeries where traditional plating may not suffice. Buyers should evaluate the complexity and potential complications associated with this method, as it requires a higher level of surgical expertise. The added support can significantly enhance healing and functional recovery, making it a valuable option for challenging cases.

Key Industrial Applications of double plating

| Industry/Sector | Specific Application of double plating | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Orthopedic Surgery | Fixation of complex fractures in distal femur | Enhanced stability in cases of multifragmentary fractures, reducing the risk of implant failure. | Sourcing high-quality locking plates and experienced surgical teams. |

| Construction | Reinforcement of structural elements in civil engineering | Increased load-bearing capacity and safety in infrastructure projects. | Availability of custom plate designs and compliance with local regulations. |

| Aerospace | Repair of aircraft components under high-stress conditions | Ensures structural integrity and safety in critical aerospace applications. | Certification of materials and adherence to aerospace standards. |

| Automotive | Repair of chassis and suspension systems | Improved durability and performance in high-load automotive applications. | Sourcing lightweight yet strong materials for optimal performance. |

| Oil & Gas | Structural support for drilling rigs and pipelines | Enhanced safety and reliability in challenging operational environments. | Compliance with industry safety standards and availability of corrosion-resistant materials. |

How is double plating utilized in orthopedic surgery, and what challenges does it address for international buyers?

In orthopedic surgery, double plating is employed primarily for the fixation of complex fractures, particularly in the distal femur. This technique provides superior biomechanical stability compared to single plating, especially in cases involving multifragmentary fractures or patients with osteoporosis. International buyers, particularly from regions like Africa and South America, must consider the availability of high-quality locking plates and the expertise of surgical teams, as these factors significantly influence patient outcomes and recovery rates.

What role does double plating play in the construction industry, and what are the key considerations for sourcing?

In the construction sector, double plating is used to reinforce structural elements, enhancing the load-bearing capacity of beams and columns. This technique is particularly valuable in seismic zones or areas subject to extreme weather conditions, where safety is paramount. When sourcing double plating solutions, businesses must prioritize the availability of custom plate designs that meet local building codes and regulations, ensuring compliance and safety in construction projects across Europe and the Middle East.

How does double plating benefit the aerospace industry, and what sourcing challenges may arise?

In the aerospace industry, double plating is crucial for repairing aircraft components that experience high-stress conditions. This method ensures structural integrity and safety, which are critical in aviation. Buyers in this sector must be vigilant about sourcing certified materials that adhere to stringent aerospace standards, as any compromise in quality can lead to catastrophic failures and significant financial losses.

In what ways does double plating enhance automotive applications, and what should buyers consider when sourcing?

Double plating is utilized in automotive applications for the repair of chassis and suspension systems, where it improves durability and performance under high load. This is especially important for vehicles designed for off-road use or heavy-duty applications. Buyers should consider sourcing lightweight yet strong materials to optimize vehicle performance while ensuring that the components meet industry safety standards and regulations, particularly in regions with stringent automotive requirements.

What advantages does double plating offer in the oil and gas sector, and what are the key sourcing factors?

In the oil and gas industry, double plating provides structural support for drilling rigs and pipelines, enhancing safety and reliability in challenging operational environments. This technique is essential for preventing failures that could lead to costly shutdowns or environmental disasters. When sourcing double plating solutions, businesses must focus on materials that are not only strong but also resistant to corrosion, as the harsh environments in which they operate demand high durability and compliance with industry safety standards.

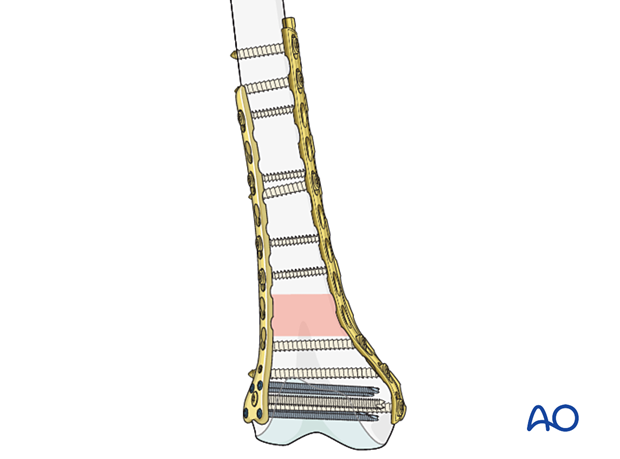

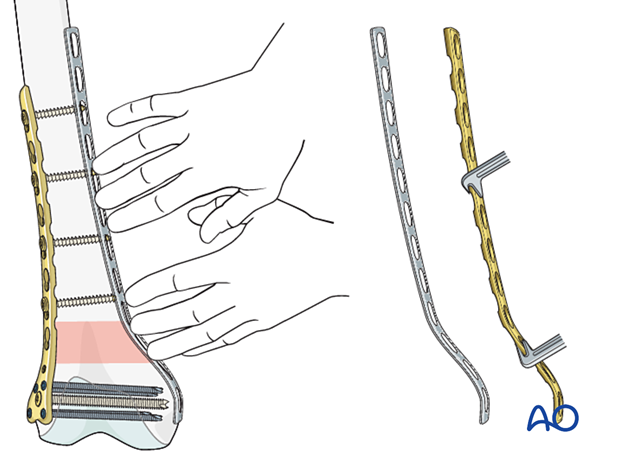

Illustrative image related to double plating

3 Common User Pain Points for ‘double plating’ & Their Solutions

Scenario 1: Difficulty in Selecting the Right Plate for Double Plating Procedures

The Problem: One of the most common challenges faced by B2B buyers in the orthopedic sector is the selection of the appropriate plate for double plating procedures. With various options available, such as locking compression plates (LCP) and less familiar surgeon-contoured plates, making the right choice can be daunting. This decision is critical as improper plate selection can lead to inadequate stabilization of fractures, prolonged healing times, or even surgical complications. Furthermore, the unique anatomical considerations of each case can complicate matters, especially in regions with limited access to specific implants.

The Solution: To overcome this challenge, it is essential to establish a systematic approach to plate selection. Begin by conducting a thorough assessment of the fracture characteristics, including the type of fracture, bone quality, and patient-specific factors such as age and activity level. Collaborate closely with orthopedic surgeons to understand their preferences and experiences with different plate systems. Consider sourcing plates that offer a range of locking and non-locking screw options, allowing for versatility in fixation. Additionally, investing in a malleable template can aid in contouring plates to fit the specific anatomy of the patient, ensuring optimal stabilization. Building relationships with suppliers who can provide reliable technical support and training on new products can also enhance the decision-making process.

Scenario 2: Challenges in Training Surgical Teams on Double Plating Techniques

The Problem: B2B buyers often struggle with the effective training of surgical teams on the complexities of double plating techniques. Given the intricacies involved, including appropriate patient positioning, incision techniques, and fixation strategies, insufficient training can lead to surgical errors and suboptimal outcomes. This is particularly concerning in regions where access to advanced surgical education and resources is limited, making it crucial for medical facilities to ensure that their teams are well-prepared.

The Solution: To address this training gap, organizations should prioritize comprehensive educational programs that combine theoretical knowledge with hands-on practice. Partnering with reputable orthopedic training institutions or industry experts can provide valuable insights and techniques that are specific to double plating. Consider organizing workshops or simulation training sessions where surgical teams can practice the double plating technique on cadaver models or simulators. This practical approach will not only boost the confidence of the surgical staff but also enhance their understanding of the biomechanical principles underlying double plating. Additionally, ongoing education should be encouraged, with refresher courses scheduled regularly to keep the team updated on the latest advancements in double plating techniques.

Scenario 3: Postoperative Complications and Rehabilitation Concerns

The Problem: After a double plating procedure, B2B buyers often face significant concerns regarding postoperative complications and the rehabilitation process. Issues such as delayed healing, infection, or implant-related symptoms can arise, potentially leading to increased costs and extended recovery times. Additionally, ensuring effective rehabilitation protocols that promote optimal recovery while safeguarding against further injury can be a complex undertaking, especially in diverse patient populations.

Illustrative image related to double plating

The Solution: To mitigate postoperative complications, implementing a structured follow-up protocol is crucial. This should include regular assessments to monitor wound healing and implant integrity. Encourage the use of advanced imaging techniques to evaluate the healing process, allowing for timely interventions if complications arise. Furthermore, collaborating with physical therapists to develop individualized rehabilitation plans tailored to each patient’s needs is essential. These plans should emphasize progressive mobilization and strengthening exercises while taking into account the specific demands of the double plating procedure. Providing patients with educational materials on self-care and rehabilitation expectations can also enhance their compliance and engagement in the recovery process, ultimately leading to improved outcomes.

Strategic Material Selection Guide for double plating

What Are the Key Properties of Common Materials Used in Double Plating?

When selecting materials for double plating in orthopedic applications, several options stand out due to their unique properties and performance characteristics. Here, we analyze four common materials: Stainless Steel, Titanium, Cobalt-Chromium Alloy, and Polyether Ether Ketone (PEEK).

1. Stainless Steel

Key Properties: Stainless steel is known for its excellent mechanical properties, including high tensile strength and good ductility. It typically has a temperature rating up to 800°C and exhibits good corrosion resistance, particularly in saline environments.

Pros & Cons: The primary advantage of stainless steel is its durability and cost-effectiveness, making it a popular choice in orthopedic implants. However, it is heavier than other materials and may not be suitable for all patients, especially those with allergies to nickel, which is often present in stainless steel alloys.

Impact on Application: Stainless steel is compatible with various media, including saline and blood, making it suitable for surgical environments. However, its weight can be a drawback in applications where minimizing mass is crucial.

Considerations for International Buyers: Compliance with standards such as ASTM F138 and ISO 5832-1 is essential. Buyers from regions with stringent regulations, like Europe, should ensure that their suppliers meet these standards.

Illustrative image related to double plating

2. Titanium

Key Properties: Titanium is lightweight yet incredibly strong, with a temperature rating exceeding 600°C. It is highly resistant to corrosion, particularly in bodily fluids, and has excellent biocompatibility.

Pros & Cons: The main advantage of titanium is its strength-to-weight ratio, making it ideal for applications requiring minimal mass. However, titanium can be more expensive than stainless steel and may require specialized manufacturing processes, increasing overall costs.

Impact on Application: Titanium’s biocompatibility makes it suitable for long-term implantation in the human body. Its low density is beneficial in reducing overall implant weight, which is crucial for patient comfort and mobility.

Considerations for International Buyers: Buyers should look for compliance with ASTM F136 and ISO 5832-2 standards. In regions like the Middle East, where quality assurance is critical, sourcing from reputable manufacturers is vital.

3. Cobalt-Chromium Alloy

Key Properties: Cobalt-chromium alloys are known for their exceptional wear resistance and strength, with temperature ratings that can exceed 1000°C. They also exhibit excellent corrosion resistance.

Pros & Cons: The key advantage of cobalt-chromium is its durability, making it suitable for high-load applications. However, it is more expensive than both stainless steel and titanium and can be more challenging to machine.

Impact on Application: This material is particularly effective in load-bearing applications, such as joint replacements. Its high wear resistance makes it ideal for implants subjected to significant mechanical stress.

Considerations for International Buyers: Compliance with ASTM F75 and ISO 5832-4 is crucial. Buyers in South America and Africa should ensure that their suppliers can provide certifications that meet these standards.

4. Polyether Ether Ketone (PEEK)

Key Properties: PEEK is a high-performance polymer known for its excellent mechanical properties and thermal stability, with a temperature rating of up to 260°C. It is also biocompatible and has good wear resistance.

Illustrative image related to double plating

Pros & Cons: The primary advantage of PEEK is its lightweight nature and flexibility, which can reduce stress shielding in bone. However, it is less durable than metal options and may not be suitable for high-load applications.

Impact on Application: PEEK is particularly advantageous in applications where flexibility and reduced weight are essential. It is compatible with various biological environments but may not withstand extreme mechanical loads.

Considerations for International Buyers: Buyers should ensure compliance with ISO 10993 for biocompatibility. In regions like Europe, where regulatory compliance is stringent, sourcing from certified manufacturers is crucial.

Illustrative image related to double plating

Summary Table of Material Selection for Double Plating

| Material | Typical Use Case for double plating | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | General orthopedic implants | Cost-effective and durable | Heavier, potential nickel allergy | Medium |

| Titanium | Long-term implants in orthopedic surgery | Lightweight and highly biocompatible | Higher cost, specialized processing | High |

| Cobalt-Chromium Alloy | High-load orthopedic applications | Exceptional wear resistance | Expensive, difficult to machine | High |

| Polyether Ether Ketone (PEEK) | Flexible implants, reducing stress | Lightweight and flexible | Less durable for high loads | Medium |

This guide provides a comprehensive overview of material options for double plating, empowering international buyers to make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for double plating

What are the Key Manufacturing Processes for Double Plating?

The manufacturing of double plating systems involves several critical stages that ensure the final product meets the stringent requirements of medical applications, particularly in orthopedic trauma. Understanding these processes can help B2B buyers make informed decisions when selecting suppliers.

How is Material Prepared for Double Plating?

The first step in the manufacturing process is material selection, typically involving high-grade stainless steel or titanium, known for their strength, corrosion resistance, and biocompatibility. The selected materials undergo rigorous quality checks to ensure they meet international standards.

Once the materials are verified, they are cut and shaped into the required dimensions using precision machining techniques. This includes processes like CNC machining, which allows for high accuracy in creating complex geometries essential for anatomical fitting.

What Forming Techniques are Utilized in Double Plating?

After material preparation, the next stage is forming, which involves several techniques to achieve the desired plate shape. Common methods include:

Illustrative image related to double plating

-

Stamping and Forging: These techniques are used to create strong and lightweight plates. Stamping allows for high-volume production with precise shapes, while forging enhances material properties through deformation, improving strength and fatigue resistance.

-

Bending and Contouring: For plates that require specific anatomical fitting, especially on the medial side, a malleable template is often employed. This ensures that the plate contours accurately to the bone structure, which is crucial for effective stabilization.

How is Assembly Conducted for Double Plating Systems?

The assembly stage focuses on integrating various components, including the plates and screws. Precision is vital at this stage to ensure that all parts fit together seamlessly.

-

Joining Techniques: Techniques such as welding or the use of locking mechanisms are employed to ensure robust connections. The integration of locking screws, which provide additional stability, is also a critical aspect of assembly.

-

Quality Assurance During Assembly: Each assembly step is subjected to quality checks to verify that tolerances are maintained and that components are correctly aligned.

What Finishing Processes are Important for Double Plating?

Finishing processes enhance the durability and biocompatibility of the double plating systems. Key finishing techniques include:

-

Surface Treatment: This often involves anodizing or passivation to improve corrosion resistance and reduce friction. These treatments help in minimizing the risk of implant failure due to wear and tear.

-

Polishing: A fine polish is applied to ensure that the plates have a smooth surface, which is essential for reducing tissue irritation during implantation.

-

Sterilization: The final step before packaging involves sterilizing the products to ensure they are safe for surgical use. Methods such as ethylene oxide gas or gamma radiation are commonly used.

What Quality Control Measures are Essential for Double Plating?

Quality control (QC) is paramount in the manufacturing of double plating systems, especially given the high stakes involved in medical applications.

Illustrative image related to double plating

Which International Standards Should B2B Buyers Consider?

B2B buyers should look for manufacturers that comply with international quality standards, such as:

-

ISO 9001: This standard outlines the requirements for a quality management system (QMS) and is crucial for ensuring consistent quality in production.

-

ISO 13485: Specifically for medical devices, this standard emphasizes the importance of a QMS that demonstrates the ability to provide medical devices that consistently meet customer and regulatory requirements.

-

CE Marking: In Europe, CE marking indicates that the product meets all safety and health requirements.

What are the Key QC Checkpoints in Manufacturing?

Quality control checkpoints are integrated throughout the manufacturing process, including:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specified standards.

-

In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process helps identify defects early, allowing for immediate corrective actions.

-

Final Quality Control (FQC): A thorough inspection is conducted on the finished products to verify that they meet all specifications and standards before packaging.

What Testing Methods Are Commonly Used for Double Plating?

B2B buyers should be aware of the various testing methods employed to ensure product quality:

-

Mechanical Testing: This includes tensile strength and fatigue testing to ensure that the plates can withstand the stresses they will encounter in use.

-

Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or X-ray inspection are used to detect internal defects without damaging the product.

-

Biocompatibility Testing: To ensure safety, materials undergo biocompatibility tests to assess their interaction with biological systems.

How Can B2B Buyers Verify Supplier Quality Control?

To ensure that suppliers maintain high-quality standards, B2B buyers can take several proactive steps:

-

Supplier Audits: Conducting audits of manufacturing facilities helps verify compliance with quality standards and operational processes.

-

Reviewing Quality Reports: Suppliers should provide detailed quality reports, including results from IQC, IPQC, and FQC stages, to assure buyers of their commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes and product integrity.

What Are the Nuances of Quality Control for International B2B Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding local regulatory requirements and ensuring compliance can be complex. Buyers should:

-

Understand Regional Regulations: Different regions may have specific regulations regarding medical device manufacturing and quality assurance. Familiarity with these regulations is crucial for successful procurement.

-

Establish Clear Communication: Maintaining open lines of communication with suppliers can help clarify quality expectations and address any issues promptly.

-

Consider Local Certification Bodies: Engaging with local certification bodies can provide additional assurance of product quality and compliance with regional standards.

By understanding these manufacturing processes and quality assurance protocols, B2B buyers can make more informed decisions when sourcing double plating systems, ensuring they partner with suppliers that uphold the highest standards in quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘double plating’

To assist B2B buyers in effectively procuring double plating solutions, this practical sourcing guide outlines essential steps to ensure that the selected products meet your operational and clinical needs. Double plating is vital for enhancing biomechanical stability in complex fracture treatments, making the choice of materials and suppliers crucial for successful outcomes.

Step 1: Define Your Technical Specifications

Establish clear technical specifications based on the specific requirements of your operations. Consider factors such as the types of fractures you are addressing, patient demographics, and any unique anatomical considerations. This clarity will aid in aligning your needs with the capabilities of potential suppliers.

- Material Requirements: Identify the required materials, such as titanium or stainless steel, that ensure durability and compatibility with surgical protocols.

- Plate Contouring Needs: Specify if you need pre-contoured plates or if custom contouring will be necessary, particularly for the medial side.

Step 2: Research Supplier Experience and Expertise

Investigate potential suppliers to gauge their experience in manufacturing double plating systems. A supplier with a robust background in orthopedic solutions will likely provide higher quality products and support.

- Industry Reputation: Look for suppliers with a proven track record in the orthopedic field, particularly those who have worked with similar fracture types.

- Case Studies and References: Request case studies that demonstrate the effectiveness of their products in clinical settings.

Step 3: Evaluate Potential Suppliers

Before making a commitment, conduct a thorough evaluation of the suppliers you are considering. This step is essential to mitigate risks associated with product quality and supplier reliability.

- Supplier Certifications: Ensure suppliers have relevant certifications, such as ISO or CE marking, which indicate adherence to international quality standards.

- Customer Feedback: Seek testimonials or feedback from other B2B buyers in your region or industry to gain insights into their experiences.

Step 4: Assess Product Quality and Compliance

Quality assurance is critical when sourcing double plating systems. Verify that the products meet both your technical specifications and regulatory requirements.

- Material Testing: Inquire about the material testing processes employed by the supplier to ensure that their products can withstand the required biomechanical loads.

- Regulatory Compliance: Confirm that the products comply with local and international regulations governing medical devices.

Step 5: Request Samples and Conduct Trials

Whenever possible, request samples of the double plating systems for evaluation. This practical step allows you to assess the product firsthand and determine its suitability for your applications.

Illustrative image related to double plating

- Trial Procedures: Consider conducting trials on cadaver models or in controlled settings to evaluate the performance of the plates in real-world scenarios.

- Feedback from Surgical Teams: Involve your surgical teams in the evaluation process to gather their insights on the usability and effectiveness of the products.

Step 6: Negotiate Terms and Conditions

Once you have identified a suitable supplier, enter into negotiations to establish favorable terms and conditions. This step is crucial for ensuring a mutually beneficial partnership.

- Pricing and Payment Terms: Discuss pricing structures, payment terms, and bulk order discounts to ensure cost-effectiveness.

- Warranty and Support: Clarify warranty conditions and the level of after-sales support provided, which can be critical for ongoing product performance.

Step 7: Establish a Relationship for Future Needs

Finally, build a long-term relationship with your chosen supplier. A strong partnership can lead to better support, product updates, and collaboration on future projects.

- Regular Communication: Maintain open lines of communication to discuss any emerging needs or issues that may arise.

- Feedback Mechanism: Establish a system for providing feedback on product performance, which can help the supplier improve their offerings over time.

By following these steps, B2B buyers can make informed decisions when sourcing double plating solutions, ensuring that they meet both clinical and operational requirements effectively.

Comprehensive Cost and Pricing Analysis for double plating Sourcing

What Are the Key Cost Components in Double Plating Sourcing?

When sourcing double plating systems, several cost components significantly influence the total expenditure. The primary components include:

Illustrative image related to double plating

-

Materials: The choice of materials is paramount, with high-grade stainless steel or titanium commonly used for their strength and biocompatibility. Specialty coatings for corrosion resistance can also add to material costs.

-

Labor: Skilled labor is essential for manufacturing and assembling the double plating systems. Labor costs will vary depending on the region and the complexity of the surgical instruments or implants being produced.

-

Manufacturing Overhead: This includes indirect costs such as utilities, rent, and equipment depreciation. Efficient production processes can help minimize overhead costs.

-

Tooling: The initial investment in tooling can be substantial, especially for custom or specialized plates. Reusable molds and jigs can offset costs over time, but the initial outlay should be considered.

-

Quality Control (QC): Rigorous quality assurance processes are crucial for medical devices, adding to costs. Certifications like ISO 13485 can enhance product value but also increase expenses.

-

Logistics: Transportation costs, especially for international shipping, can vary significantly based on distance, shipping method, and customs fees. Understanding Incoterms is essential for budgeting logistics accurately.

-

Margin: Suppliers will add a profit margin to cover their risks and costs. This margin can fluctuate based on market demand, competition, and the supplier’s positioning.

How Do Price Influencers Affect Double Plating Costs?

Several factors can influence the pricing structure for double plating systems:

-

Volume/MOQ: Larger orders typically qualify for discounts. Minimum order quantities (MOQ) can affect pricing and are often negotiable depending on the supplier’s capacity.

-

Specifications and Customization: Custom designs and specific material requirements can increase costs. Buyers should balance the need for customization against potential price increases.

-

Materials and Quality Certifications: Higher-quality materials and certifications add to the cost but are crucial for ensuring reliability in surgical applications. Buyers should evaluate whether the added cost aligns with their quality requirements.

-

Supplier Factors: Supplier reputation, reliability, and historical performance can affect pricing. Long-term relationships with suppliers may yield better pricing and terms.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) can significantly impact the total cost. Buyers should fully understand their responsibilities regarding shipping, insurance, and tariffs.

What Tips Can Help Buyers Achieve Cost Efficiency in Double Plating Sourcing?

To navigate the complexities of double plating sourcing and optimize costs, buyers can consider the following strategies:

-

Effective Negotiation: Leverage volume purchases and long-term contracts to negotiate better pricing. Establishing a collaborative relationship with suppliers can lead to favorable terms.

-

Total Cost of Ownership (TCO): Assess the TCO rather than just the purchase price. Consider factors such as maintenance, repair, and potential downtime, which can significantly affect overall expenditures.

-

Understanding Pricing Nuances: International buyers should be aware of currency fluctuations, tariffs, and import regulations that can affect pricing. Engaging with local agents or consultants can provide valuable insights.

-

Supplier Diversification: Avoid reliance on a single supplier. Diversifying sources can enhance competition and provide leverage during negotiations, potentially lowering costs.

-

Focus on Quality: While it may be tempting to choose lower-cost options, prioritizing quality can prevent costly complications down the line, such as device failures or the need for replacements.

Conclusion: Navigating Double Plating Costs

In summary, understanding the comprehensive cost structure and the various price influencers in double plating sourcing is crucial for international B2B buyers. By focusing on strategic negotiation, evaluating the total cost of ownership, and staying informed about pricing nuances, buyers can make informed decisions that align with their operational needs and budget constraints. Always remember that indicative prices may vary based on market conditions and specific sourcing requirements.

Alternatives Analysis: Comparing double plating With Other Solutions

Understanding Alternative Solutions to Double Plating

When addressing complex fractures, particularly in the context of orthopedic trauma, various fixation methods can be employed to enhance stability and promote healing. Double plating is one such method, but it is crucial for B2B buyers, especially in international markets like Africa, South America, the Middle East, and Europe, to consider alternative solutions that may align better with specific clinical needs, cost constraints, or operational capabilities.

Comparison Table

| Comparison Aspect | Double Plating | Intramedullary Nailing | External Fixation |

|---|---|---|---|

| Performance | High stability for complex fractures; ideal for osteoporotic patients. | Excellent for diaphyseal fractures; maintains alignment well. | Good for external stabilization; allows for soft tissue management. |

| Cost | Higher initial costs due to materials and complexity. | Moderate; costs vary by nail type and locking mechanisms. | Generally lower; fewer implants required, but variable based on complexity. |

| Ease of Implementation | Requires advanced surgical skills and experience; involves multiple incisions. | Generally easier to implement with a single incision; less demanding than double plating. | Can be applied in a variety of settings; less invasive but requires careful management. |

| Maintenance | Requires follow-up for implant removal and monitoring; potential complications from hardware. | Minimal maintenance; often removed after healing unless complications arise. | Requires regular monitoring; risks of pin site infections. |

| Best Use Case | Ideal for multifragmentary and unstable fractures, particularly in older patients with osteoporosis. | Best for long bone fractures, especially in younger, active patients. | Suitable for temporary stabilization of fractures, particularly in polytrauma cases. |

Detailed Breakdown of Alternatives

Intramedullary Nailing

Intramedullary nailing involves inserting a rod into the medullary canal of the bone. This method is particularly effective for diaphyseal fractures and offers excellent alignment while minimizing soft tissue disruption. The ease of implementation is a significant advantage, as it typically requires only a single incision. However, its performance may not match double plating in cases of complex fractures or those involving significant comminution. Additionally, while costs are moderate, the initial investment in quality nails can vary.

External Fixation

External fixation is a technique that stabilizes fractures through pins or screws placed outside the body, connected by a rigid frame. This method is advantageous for managing open fractures or when soft tissue integrity is compromised. Its low initial costs and minimal invasiveness make it appealing; however, it does require vigilant monitoring for complications such as pin site infections. External fixation is often seen as a temporary solution and may not provide the same level of biomechanical stability as double plating or intramedullary nailing for complex fractures.

How Should B2B Buyers Choose the Right Solution?

Selecting the appropriate fracture fixation method involves a careful assessment of clinical needs, patient demographics, and economic considerations. B2B buyers should evaluate the specific types of fractures they encounter and the associated patient profiles. For instance, double plating may be the preferred choice for complex, unstable fractures in older patients, while intramedullary nailing might be better suited for younger, active individuals with diaphyseal fractures. External fixation serves as a reliable temporary measure in cases with significant soft tissue compromise. Ultimately, the decision should align with both clinical efficacy and cost-effectiveness, ensuring optimal patient outcomes and resource utilization.

Essential Technical Properties and Trade Terminology for double plating

What Are the Key Technical Properties of Double Plating?

When considering double plating for orthopedic applications, several critical specifications must be understood to ensure optimal performance and patient outcomes. Here are the essential technical properties:

-

Material Grade

The material used in double plating is typically titanium or stainless steel. Titanium is preferred for its strength-to-weight ratio and corrosion resistance, while stainless steel offers high tensile strength and is cost-effective. Choosing the right material is crucial as it directly influences the implant’s durability and biocompatibility. -

Plate Thickness

The thickness of the plates can vary based on the fracture type and patient needs. Thicker plates provide greater stability, especially in cases with multifragmentary fractures or osteoporosis. Understanding the required thickness helps in selecting an appropriate plate that meets biomechanical demands. -

Screw Compatibility and Design

Double plating often utilizes locking screws that create a fixed-angle construct, enhancing stability. The design of screws, such as bicortical versus unicortical, affects the fixation strength. Proper screw selection is vital for ensuring that the plates remain securely attached to the bone throughout the healing process. -

Plate Contouring

The ability to contour plates to fit the specific anatomy of the patient is essential. Customization improves contact between the plate and bone, reducing the risk of movement and enhancing healing. This property is particularly important in complex fractures where standard plates may not provide adequate support. -

Load-Bearing Capacity

The load-bearing capacity of double plating systems is critical, especially in patients with high activity levels or those who may be at risk for implant failure due to excessive loads. This capacity should be evaluated in relation to patient factors, including weight and activity level, to ensure appropriate material and design choices are made. -

Corrosion Resistance

Given that implants are subject to bodily fluids, corrosion resistance is a key property. Materials should be selected based on their ability to withstand these conditions over time without degrading, which can lead to implant failure.

What Are Common Trade Terms Related to Double Plating?

Understanding industry-specific terminology can facilitate smoother transactions and communications. Here are several common trade terms in the context of double plating:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are marketed under another company’s brand. In the context of double plating, OEMs may produce the plates and screws used in surgical procedures. Knowing the OEM helps ensure quality and reliability in medical devices. -

MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. For buyers in the medical field, understanding MOQ can assist in planning inventory and managing costs effectively, ensuring that necessary materials are always on hand without overcommitting financially. -

RFQ (Request for Quotation)

An RFQ is a document used to solicit price proposals from suppliers. For B2B buyers of double plating materials, an RFQ can help compare prices and terms from different manufacturers, enabling informed purchasing decisions. -

Incoterms (International Commercial Terms)

These are standardized trade terms used in international sales contracts to define the responsibilities of buyers and sellers. Familiarity with Incoterms is crucial for international buyers to understand shipping costs, risks, and logistics associated with acquiring double plating systems. -

Lead Time

Lead time refers to the time taken from placing an order to delivery. For surgical supplies, understanding lead times is essential for ensuring that materials are available when needed, particularly in urgent medical situations. -

Regulatory Compliance

This term encompasses the standards and regulations that medical devices must meet to be approved for use in specific markets. Awareness of regulatory compliance is vital for B2B buyers to ensure that the double plating systems they source meet local health and safety standards.

By grasping these technical properties and trade terminologies, international B2B buyers can make more informed decisions when sourcing double plating systems, ultimately leading to better patient outcomes and operational efficiency.

Illustrative image related to double plating

Navigating Market Dynamics and Sourcing Trends in the double plating Sector

What Are the Current Market Dynamics and Key Trends in the Double Plating Sector?

The global double plating market is experiencing notable growth, driven by increasing orthopedic procedures, particularly in trauma care and joint reconstruction. As populations in regions like Africa, South America, the Middle East, and Europe age, the demand for orthopedic solutions rises. Surgeons are increasingly opting for double plating techniques due to their enhanced biomechanical stability, especially in complex fractures and patients with osteoporosis. This trend is further supported by advancements in materials and technology, including the development of locking plates that improve fixation and reduce the risk of implant failure.

Emerging B2B technology trends are reshaping sourcing strategies. Digital platforms and online marketplaces are becoming pivotal for international buyers, enabling them to access a wider range of products and suppliers. Additionally, the integration of artificial intelligence in supply chain management is streamlining procurement processes, allowing for better inventory management and demand forecasting. Buyers from diverse regions are increasingly seeking suppliers who can offer rapid delivery and customization options, emphasizing the need for agile supply chains that can respond to fluctuating market demands.

Moreover, the rise of telemedicine and virtual consultations is influencing purchasing decisions, as healthcare providers seek to optimize patient outcomes while minimizing in-person visits. This shift is encouraging suppliers to invest in educational content and virtual training to assist buyers in understanding the latest double plating techniques and products.

How Are Sustainability and Ethical Sourcing Impacting the Double Plating Industry?

Sustainability and ethical sourcing are becoming critical considerations for B2B buyers in the double plating sector. The environmental impact of medical implants, including the carbon footprint associated with manufacturing and transportation, is prompting buyers to prioritize suppliers committed to sustainable practices. This includes the use of recycled materials in the production of double plating systems and the implementation of energy-efficient manufacturing processes.

The importance of ethical supply chains cannot be overstated. Buyers are increasingly scrutinizing their suppliers for compliance with ethical labor practices and environmental regulations. Certifications such as ISO 14001 for environmental management and ISO 45001 for occupational health and safety are becoming essential for suppliers aiming to build trust with international buyers.

Additionally, the trend toward ‘green’ materials is gaining traction. Innovations in biocompatible and biodegradable materials are being explored to minimize environmental impact while ensuring patient safety. Suppliers who can demonstrate their commitment to sustainability through transparent practices and certifications will have a competitive advantage in attracting conscientious buyers.

What Is the Evolution of Double Plating Techniques in the B2B Context?

The evolution of double plating techniques has been significant in response to the increasing complexity of fractures and the varying needs of patients. Initially developed as a solution for simple fractures, the technique has advanced to address multifragmentary fractures and those in osteoporotic bones, where conventional plating may fail.

Over the years, improvements in plate design, such as locking mechanisms and contoured plates, have enhanced the stability and effectiveness of double plating. This evolution has not only improved patient outcomes but also influenced purchasing trends, with B2B buyers increasingly seeking advanced, reliable solutions from reputable manufacturers.

As the market continues to mature, the emphasis on innovation and quality in double plating will remain paramount, ensuring that suppliers who invest in research and development will play a crucial role in shaping future trends in this vital sector.

Frequently Asked Questions (FAQs) for B2B Buyers of double plating

-

How do I solve issues related to the quality of double plating?

To address quality concerns when sourcing double plating, it’s crucial to perform thorough supplier vetting. Look for manufacturers with relevant certifications such as ISO 13485 for medical devices. Request samples to assess material quality and craftsmanship. Additionally, inquire about their quality assurance processes, including testing methods and compliance with international standards. Establishing a quality control agreement can also ensure that the products meet your specific requirements consistently. -

What is the best material for double plating in orthopedic applications?

The best materials for double plating in orthopedic applications are typically titanium and stainless steel. Titanium offers excellent biocompatibility and corrosion resistance, making it suitable for implants that remain in the body. Stainless steel, while slightly less biocompatible, is often favored for its strength and cost-effectiveness. When choosing materials, consider factors such as the specific medical application, patient demographics, and long-term performance requirements. -

What customization options are available for double plating?

Customization options for double plating can include specific plate sizes, shapes, and screw configurations tailored to individual patient needs. Many manufacturers offer surgeon-contoured plates to ensure optimal fit and stability. It’s essential to communicate your requirements clearly during the design phase and confirm the manufacturer’s ability to accommodate these customizations. Lead times for customized products can vary, so plan accordingly. -

What are the minimum order quantities (MOQs) for double plating products?

Minimum order quantities (MOQs) for double plating can vary widely among suppliers. Some manufacturers may require a MOQ of 50 units, while others might allow smaller orders, especially for custom designs. It’s advisable to discuss your specific needs with potential suppliers to understand their policies and find a partner that can accommodate your order size without compromising on quality or lead times. -

What payment terms should I expect when sourcing double plating internationally?

Payment terms for international sourcing of double plating typically range from 30% upfront and 70% upon delivery to full payment in advance. Some suppliers may offer net 30 or net 60 terms, depending on your relationship and order size. Always clarify the payment terms before finalizing contracts and consider using secure payment methods such as letters of credit or escrow services to protect your investment. -

How can I ensure timely delivery of double plating products?

To ensure timely delivery of double plating products, establish clear timelines with your supplier at the outset. Discuss production lead times, shipping methods, and potential customs delays that could affect delivery. It’s also wise to keep open lines of communication throughout the production process. Consider working with suppliers who have a proven track record of meeting deadlines and who can provide real-time tracking of shipments. -

What logistics considerations should I keep in mind when importing double plating?

When importing double plating, consider logistics aspects such as shipping methods, customs regulations, and duty fees. Choose a reliable freight forwarder familiar with medical device imports to navigate the complexities of international shipping. Ensure that all documentation, including invoices and certificates of conformity, is accurate and complete to avoid customs delays. Additionally, be aware of the import regulations specific to your country or region. -

What should I look for in a supplier of double plating?

When selecting a supplier for double plating, prioritize those with a strong reputation for quality and reliability. Check for industry certifications and compliance with relevant standards. Evaluate their experience in producing orthopedic implants and their ability to offer customization. Request references from previous clients and assess their customer service responsiveness. A good supplier will also provide transparent communication and support throughout the sourcing process.

A Look at Double Plating Manufacturers & Suppliers

Could not verify enough suppliers for double plating to create a list at this time.

Strategic Sourcing Conclusion and Outlook for double plating

In summary, strategic sourcing for double plating presents a critical opportunity for international B2B buyers aiming to enhance their orthopedic offerings. The double plating technique provides superior biomechanical stability, particularly in complex fracture scenarios and cases involving osteoporosis, making it a vital consideration for suppliers in diverse markets. By prioritizing reliable and high-quality materials, buyers can ensure optimal outcomes in surgical procedures, ultimately improving patient care and satisfaction.

As the demand for advanced orthopedic solutions continues to rise across Africa, South America, the Middle East, and Europe, leveraging strategic sourcing practices will be instrumental. Establishing strong partnerships with manufacturers who specialize in double plating systems can lead to competitive advantages, including cost savings and access to innovative technologies.

Looking ahead, B2B buyers are encouraged to stay informed about the latest advancements in double plating techniques and implant materials. Investing in quality and performance not only enhances surgical outcomes but also solidifies your position in the global market. Collaborate with trusted suppliers to secure the best options for your needs and drive your business forward in this evolving landscape.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to double plating