How to Source Double Corrugated Box Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for double corrugated box

The global market for double corrugated boxes is expanding rapidly, driven by the increasing demand for robust packaging solutions that can withstand the rigors of international shipping and storage. B2B buyers often face challenges in sourcing these boxes due to varying quality standards, material specifications, and the complexities of supplier vetting across different regions. This guide is designed to navigate these challenges, offering a comprehensive overview of the types and applications of double corrugated boxes, as well as critical insights into cost structures and sourcing strategies.

Within these pages, international buyers from Africa, South America, the Middle East, and Europe—particularly in markets like Germany and Nigeria—will find valuable information tailored to their unique needs. We will explore the various styles of double wall boxes, their suitability for fragile items, and the environmental benefits of choosing recycled options. Additionally, the guide will address essential considerations for evaluating suppliers, ensuring compliance with international shipping regulations, and understanding the cost implications of different box specifications.

By empowering buyers with actionable insights and clear guidelines, this resource aims to facilitate informed purchasing decisions that enhance operational efficiency and product safety. Whether you are a seasoned procurement professional or new to the packaging sector, this guide will serve as your go-to reference for navigating the complexities of the double corrugated box market.

Understanding double corrugated box Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Heavy Duty Double Wall Box | Extra corrugation for maximum strength; ECT rating 48 | Shipping fragile or heavy items | Pros: Exceptional protection; ideal for heavy loads. Cons: Higher cost compared to standard boxes. |

| Eco-Friendly Double Wall Box | Made from recycled materials; sustainable options | Eco-conscious shipping and storage | Pros: Reduces carbon footprint; good for brand image. Cons: May have limited availability. |

| Customizable Double Wall Box | Options for branding and specific dimensions | Tailored packaging solutions | Pros: Enhances brand visibility; meets specific needs. Cons: Longer lead times for production. |

| Standard Double Wall Box | Available in various sizes; good balance of strength | General shipping and storage needs | Pros: Versatile; cost-effective for bulk purchasing. Cons: May lack the strength for extremely heavy items. |

| Wardrobe Double Wall Box | Designed with a hanging bar; tall and sturdy | Moving and storing clothing and textiles | Pros: Convenient for clothing transport; prevents wrinkling. Cons: Takes up more space during storage. |

What Are the Characteristics of Heavy Duty Double Wall Boxes?

Heavy Duty Double Wall Boxes are characterized by their robust construction, featuring an additional layer of corrugation that provides superior strength. With an Edge Crush Test (ECT) rating of 48, these boxes are ideal for shipping fragile or heavy items, making them a go-to choice for B2B companies dealing with valuable products. Buyers should consider the higher cost associated with these boxes, which is justified by the level of protection they offer during transit.

How Do Eco-Friendly Double Wall Boxes Benefit Businesses?

Eco-Friendly Double Wall Boxes are crafted from recycled materials, appealing to businesses focused on sustainability. These boxes not only meet shipping needs but also enhance a company’s eco-conscious image, which can be a significant selling point in today’s market. While they contribute positively to environmental goals, buyers should be aware that availability can sometimes be limited, potentially affecting supply chain efficiency.

What Makes Customizable Double Wall Boxes a Smart Choice?

Customizable Double Wall Boxes allow businesses to tailor packaging to specific dimensions and branding needs, enhancing product presentation. This flexibility is particularly beneficial for companies looking to differentiate themselves in a competitive market. However, buyers should factor in longer lead times for custom orders, which could impact project timelines and inventory management.

Why Are Standard Double Wall Boxes Versatile for B2B Use?

Standard Double Wall Boxes come in a variety of sizes and offer a good balance of strength and cost-effectiveness, making them suitable for a wide range of shipping and storage applications. Their versatility makes them a popular choice for bulk purchasing, allowing businesses to streamline their logistics. However, these boxes may not provide sufficient protection for extremely heavy items, which could lead to damage during transit.

What Are the Advantages of Wardrobe Double Wall Boxes?

Wardrobe Double Wall Boxes are specifically designed for transporting clothing and textiles, featuring a hanging bar that keeps garments wrinkle-free. This design is particularly advantageous for moving companies and retailers. While they offer significant convenience, buyers should consider the additional space they occupy, both during transport and storage, which may not be ideal for all businesses.

Key Industrial Applications of double corrugated box

| Industry/Sector | Specific Application of double corrugated box | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| E-commerce | Shipping of fragile electronics and high-value items | Enhanced protection during transit reduces damages, leading to lower return rates. | Ensure ECT ratings meet transport standards and consider eco-friendly options. |

| Food and Beverage | Packaging for bulk food products and beverages | Maintains product integrity and freshness, crucial for customer satisfaction. | Compliance with food safety standards and moisture resistance. |

| Pharmaceuticals | Secure transport of sensitive medical supplies | Guarantees product safety, minimizing liability and ensuring compliance with regulations. | Look for tamper-evident features and temperature control capabilities. |

| Furniture and Home Goods | Moving and storage of heavy furniture items | Provides structural integrity, reducing the risk of damage during transport. | Consider custom sizes and strength ratings for specific items. |

| Automotive Parts | Packaging for heavy automotive components | Protects valuable parts from damage, ensuring timely delivery and customer satisfaction. | Evaluate weight capacity and stackability for efficient shipping. |

How Are Double Corrugated Boxes Used in E-commerce Shipping?

In the e-commerce sector, double corrugated boxes are vital for shipping fragile electronics and high-value items. They provide enhanced protection against impacts and vibrations during transit, which is crucial for minimizing damages and reducing return rates. Buyers in this sector should focus on boxes with adequate Edge Crush Test (ECT) ratings to ensure they can withstand the rigors of transportation, especially in regions with varying logistics capabilities. Eco-friendly options are increasingly preferred to align with sustainability goals.

What Role Do Double Corrugated Boxes Play in Food and Beverage Packaging?

Double corrugated boxes are widely used in the food and beverage industry for packaging bulk products. They help maintain the integrity and freshness of goods, which is essential for customer satisfaction and brand reputation. B2B buyers need to ensure compliance with food safety regulations, including moisture resistance and the ability to withstand temperature fluctuations. Sourcing from suppliers who provide certified materials can help mitigate risks associated with food packaging.

How Are Double Corrugated Boxes Essential for Pharmaceuticals?

In the pharmaceutical sector, double corrugated boxes are critical for the secure transport of sensitive medical supplies. They provide robust protection, ensuring that products remain intact and compliant with stringent regulations. This minimizes liability for companies and enhances patient safety. Buyers should prioritize boxes with tamper-evident features and temperature control capabilities to ensure that products are delivered safely and securely, particularly in regions with challenging logistics.

Why Are Double Corrugated Boxes Important for Moving Furniture and Home Goods?

For the furniture and home goods industry, double corrugated boxes are essential for moving and storing heavy items. Their structural integrity protects against damage during transport, which is crucial for maintaining customer satisfaction and minimizing losses. Buyers should consider custom sizes and strength ratings tailored to specific items to ensure that the boxes meet their unique needs. Efficient sourcing can also help manage costs and streamline logistics.

How Do Double Corrugated Boxes Support the Automotive Parts Industry?

In the automotive parts industry, double corrugated boxes are used for packaging heavy components, protecting them from damage during transit. This is vital for ensuring timely delivery and maintaining customer satisfaction, as delays or damages can lead to significant financial losses. Buyers should evaluate the weight capacity and stackability of these boxes to optimize shipping efficiency and reduce costs, particularly in international markets where logistics may vary significantly.

3 Common User Pain Points for ‘double corrugated box’ & Their Solutions

Scenario 1: Struggling with Fragile Item Protection During Shipping

The Problem: A common challenge faced by B2B buyers is ensuring the safe transport of fragile items. When shipping delicate products like glassware, electronics, or custom components, the risk of damage during transit can be significant. Buyers often find that standard packaging solutions do not provide adequate cushioning and protection, leading to costly returns and damaged goods that can tarnish their brand reputation.

The Solution: To effectively protect fragile items, opt for double corrugated boxes designed specifically for heavy-duty use. When sourcing these boxes, look for those with a high Edge Crush Test (ECT) rating, ideally above 44, to ensure they can withstand the rigors of shipping without collapsing. Additionally, utilize protective materials such as bubble wrap or packing peanuts inside the box to further absorb shocks. It’s also advisable to fill any empty spaces within the box to prevent items from shifting during transit. Establishing a relationship with a reliable supplier who can provide custom-sized double wall boxes will allow for a snug fit, offering enhanced protection for your products.

Scenario 2: Difficulty in Managing Inventory and Storage

The Problem: B2B buyers often grapple with space constraints in their warehouses, making it challenging to store large quantities of double corrugated boxes. When boxes are bulky or not easily stackable, they can consume valuable floor space, leading to inefficiencies in inventory management and increased operational costs.

The Solution: To address storage issues, consider sourcing double corrugated boxes that are designed for flat shipping and storage. Many suppliers offer boxes that ship flat, allowing you to maximize space when they are not in use. Additionally, choose boxes with a modular design that can be easily stacked without compromising stability. Implementing a systematic inventory management system can also help you track box usage and reorder levels, ensuring you have adequate stock without overcommitting storage space. Regularly review your inventory turnover rate to align box purchases with actual demand, minimizing excess storage.

Scenario 3: Navigating Compliance and Sustainability Requirements

The Problem: As global shipping regulations become more stringent, B2B buyers face increasing pressure to comply with sustainability initiatives. Many businesses are looking for environmentally friendly packaging solutions, yet they worry that switching to sustainable materials may compromise the strength and reliability of their packaging, especially for heavy or fragile items.

The Solution: When sourcing double corrugated boxes, prioritize those made from recycled materials or certified sustainable sources. Many manufacturers now produce eco-friendly double wall boxes that do not sacrifice strength for sustainability. Look for products that have been tested for performance, such as those with ECT ratings suitable for heavy-duty use. Additionally, communicate with suppliers about their sustainability practices, including sourcing, production methods, and end-of-life recycling options. This proactive approach not only helps meet compliance requirements but can also enhance your brand’s image as a responsible business, appealing to environmentally conscious customers.

Strategic Material Selection Guide for double corrugated box

When selecting materials for double corrugated boxes, it is essential to consider various factors that impact their performance, cost, and suitability for specific applications. Below, we analyze four common materials used in the manufacturing of double corrugated boxes, focusing on their properties, advantages, disadvantages, and considerations for international B2B buyers.

What Are the Key Properties of Paperboard in Double Corrugated Boxes?

Paperboard is the most common material used for double corrugated boxes, known for its lightweight and strong structure. It typically features a fluted layer sandwiched between two liners, providing excellent stacking strength and durability. Paperboard can withstand varying temperatures and pressures, making it suitable for a range of products.

Pros:

– Cost-effective and readily available.

– Eco-friendly, being recyclable and made from renewable resources.

– Good printability for branding and product information.

Cons:

– Vulnerable to moisture and humidity, which can compromise structural integrity.

– Limited strength under extreme conditions compared to synthetic materials.

How Does Plastic Compare as a Material for Double Corrugated Boxes?

Plastic, particularly polyethylene and polypropylene, is another option for double corrugated boxes. These materials are engineered for enhanced durability and resistance to moisture, chemicals, and physical stress.

Pros:

– High resistance to moisture, making them suitable for products sensitive to humidity.

– Superior durability and longevity compared to paperboard.

– Lightweight, reducing shipping costs.

Cons:

– Higher production costs due to complex manufacturing processes.

– Less environmentally friendly unless recycled materials are used.

What Are the Advantages of Using Recycled Materials in Double Corrugated Boxes?

Recycled materials, often sourced from post-consumer waste, are increasingly used in double corrugated boxes. This approach not only reduces waste but also meets the growing demand for sustainable packaging solutions.

Pros:

– Environmentally friendly, appealing to eco-conscious consumers.

– Can be produced at a lower cost compared to virgin materials.

– Meets compliance standards for sustainability in many regions.

Cons:

– Potential variability in quality and strength depending on the source of recycled materials.

– May require additional processing to ensure performance standards are met.

What Considerations Should International B2B Buyers Keep in Mind?

When sourcing double corrugated boxes, international buyers from regions like Africa, South America, the Middle East, and Europe should consider compliance with local and international standards such as ASTM, DIN, and JIS. Understanding regional preferences for material sustainability and performance characteristics is crucial. For instance, European markets may prioritize eco-friendly options, while buyers in the Middle East may focus on moisture resistance due to climate conditions.

In addition, logistical considerations, such as shipping costs and material weight, can significantly affect overall expenses. Buyers should also evaluate the supplier’s ability to meet demand fluctuations and provide consistent quality.

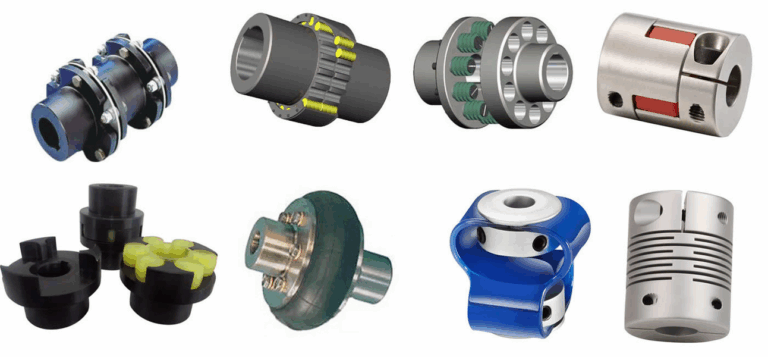

Illustrative image related to double corrugated box

Summary Table of Material Selection for Double Corrugated Boxes

| Material | Typical Use Case for double corrugated box | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Paperboard | General shipping and storage | Cost-effective and recyclable | Vulnerable to moisture | Low |

| Plastic | Heavy-duty shipping and moisture-sensitive products | High durability and moisture resistance | Higher production costs | High |

| Recycled Materials | Sustainable packaging solutions | Environmentally friendly | Variability in quality | Medium |

| Composite Materials | Industrial applications requiring high strength | Excellent strength and durability | Complex manufacturing processes | High |

This guide provides a comprehensive overview of the strategic material selection for double corrugated boxes, enabling B2B buyers to make informed decisions based on their specific needs and market conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for double corrugated box

What Are the Key Stages in the Manufacturing Process of Double Corrugated Boxes?

The manufacturing of double corrugated boxes involves several critical stages that ensure the final product meets the required specifications for strength, durability, and usability. Each stage is essential for delivering a product that can withstand the rigors of transportation and storage.

-

Material Preparation: The primary materials used in manufacturing double corrugated boxes are kraft paper and recycled paper. The process begins with sourcing high-quality paper from reputable suppliers. The paper is tested for moisture content, thickness, and strength. Once approved, the paper is cut into sheets of predetermined sizes, suitable for forming the corrugated structure.

-

Forming the Corrugated Structure: The prepared sheets undergo a process called corrugation, where they are passed through a corrugating machine. This machine creates a wavy middle layer (the fluting) sandwiched between two flat layers. The combination of these layers results in a double-wall structure, enhancing the box’s strength. The fluting can vary in size and type, depending on the box’s intended use.

-

Assembly: After forming, the corrugated sheets are glued together to create the double wall. This is typically done using a specialized adhesive that ensures a strong bond. The glued sheets are then cut into the desired dimensions and folded into box shapes. Automated machines often assist in this process to enhance efficiency and precision.

-

Finishing: The final stage involves adding any necessary features such as printing, die-cutting, or additional protective coatings. Printing can include branding, handling instructions, or barcodes, which are crucial for logistics. The boxes are then tested for quality before being packaged for shipment.

How Is Quality Assurance Implemented in Double Corrugated Box Manufacturing?

Quality assurance (QA) is integral to the manufacturing process of double corrugated boxes, ensuring that every product meets international standards and customer expectations. Here are the key aspects of QA relevant to this industry.

-

International Standards Compliance: Manufacturers often adhere to ISO 9001 standards, which focus on quality management systems. This ensures that the production processes are consistent and that the final products meet customer requirements. Additionally, certifications such as CE (Conformité Européenne) or API (American Petroleum Institute) can be relevant for specific applications.

-

Quality Control Checkpoints: Quality control (QC) is divided into several checkpoints throughout the manufacturing process:

– Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet the required specifications.

– In-Process Quality Control (IPQC): During production, various checks are performed at critical stages to monitor parameters such as adhesive application, sheet alignment, and corrugation quality.

– Final Quality Control (FQC): The finished boxes undergo rigorous testing for structural integrity, including edge crush tests (ECT) and burst tests. These tests ensure that the boxes can withstand stacking and handling stresses. -

Common Testing Methods for Double Corrugated Boxes: Testing methods for quality assurance include:

– Edge Crush Test (ECT): Measures the box’s ability to withstand vertical pressure.

– Burst Test: Assesses the box’s resistance to bursting under pressure.

– Compression Test: Evaluates how much weight a stack of boxes can hold without collapsing.

– Moisture Content Testing: Ensures that the paper used in manufacturing does not exceed optimal moisture levels, which could affect strength.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control processes of suppliers is crucial. Here are actionable steps buyers can take:

-

Supplier Audits: Conducting audits of potential suppliers allows buyers to assess manufacturing practices, equipment, and adherence to quality standards. This can be done through on-site visits or third-party audit services.

-

Requesting Quality Reports: Buyers should request detailed quality reports from suppliers, including results from testing methods like ECT and burst tests. These reports provide insights into the supplier’s commitment to quality.

-

Third-Party Inspections: Engaging third-party inspection agencies can provide unbiased assessments of the manufacturing processes and quality of the products. These agencies can offer additional credibility and assurance that the products meet required standards.

-

Understanding QC Certification Nuances: Buyers should familiarize themselves with the specific certifications relevant to their region and industry. For instance, European buyers might prioritize CE certification, while buyers in the Middle East may look for local compliance standards.

What Are the Benefits of Adhering to Quality Assurance Practices in Double Corrugated Box Manufacturing?

Implementing rigorous quality assurance practices in the manufacturing of double corrugated boxes yields several benefits:

-

Enhanced Product Reliability: Adhering to quality standards ensures that boxes maintain structural integrity during shipping and storage, reducing the risk of product damage.

-

Increased Customer Satisfaction: Reliable packaging contributes to a positive customer experience, leading to repeat business and improved brand loyalty.

-

Cost Efficiency: By minimizing defects and ensuring that only high-quality products reach the market, manufacturers can reduce waste and lower costs associated with returns or replacements.

-

Regulatory Compliance: Meeting international quality standards helps manufacturers stay compliant with regulations, facilitating smoother trade across borders.

By understanding the manufacturing processes and quality assurance practices involved in double corrugated box production, B2B buyers can make informed decisions, ensuring they partner with suppliers that meet their needs for quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘double corrugated box’

Introduction

This sourcing guide is designed to assist B2B buyers in procuring double corrugated boxes effectively. Given the diverse needs across various industries, understanding the nuances of double wall boxes will help ensure you select the best options for your shipping and storage requirements. This checklist outlines essential steps for a successful procurement process.

Step 1: Define Your Technical Specifications

Establishing your technical specifications is the first critical step in sourcing double corrugated boxes. Consider the dimensions, weight capacity, and edge crush test (ECT) rating that suits your products. For instance, if you plan to ship heavy or fragile items, opt for boxes with a higher ECT rating, such as 48 or 44, to ensure durability during transit.

- Consider product dimensions: Measure the items you need to package to determine the appropriate box size.

- Assess weight requirements: Ensure the boxes can handle the weight of your products without risk of damage.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in double corrugated boxes. Look for companies with a strong reputation and positive reviews from international buyers. This step is crucial to ensure reliability and quality in your procurement process.

- Evaluate supplier history: Focus on suppliers with a proven track record in your target regions, such as Africa or Europe.

- Check for product range: Ensure the supplier offers various sizes and specifications that meet your needs.

Step 3: Evaluate Supplier Certifications

Before finalizing a supplier, verify their certifications and compliance with international quality standards. This step is essential to ensure that the boxes meet safety and environmental regulations, particularly if you are shipping across borders.

- Request certifications: Ask for ISO certifications or other relevant quality assurances.

- Inquire about sustainability practices: Suppliers using recycled materials may align better with your company’s environmental goals.

Step 4: Request Samples

Always request samples before making bulk orders. This allows you to assess the box quality firsthand and verify that it meets your specifications. Inspect the boxes for construction, durability, and overall performance.

- Conduct stress tests: Check how the boxes perform under load to ensure they can withstand shipping conditions.

- Evaluate usability: Consider how easy the boxes are to assemble and seal, which can impact packing efficiency.

Step 5: Compare Pricing and Terms

Once you have narrowed down your options, compare pricing structures and payment terms. Pricing can vary significantly based on factors such as order volume and supplier location, so it’s vital to analyze the total cost of ownership.

- Look for bulk discounts: Many suppliers offer price breaks for larger orders, which can significantly reduce your costs.

- Examine shipping costs: Factor in shipping fees to ensure that your total expenditure aligns with your budget.

Step 6: Confirm Delivery and Lead Times

Understanding delivery timelines is crucial for maintaining your supply chain efficiency. Confirm with the supplier about lead times and shipping methods to ensure your orders arrive on schedule.

- Discuss production timelines: Ensure the supplier can meet your deadlines, especially during peak seasons.

- Evaluate shipping options: Consider faster shipping methods if you need urgent deliveries, keeping in mind the associated costs.

Step 7: Establish a Long-Term Relationship

Once you have successfully sourced your double corrugated boxes, focus on building a long-term relationship with your supplier. This can lead to better pricing, priority service, and improved communication over time.

- Communicate regularly: Keep an open line of communication to address any issues or changes in your requirements.

- Provide feedback: Sharing your experience can help the supplier improve their offerings and service.

By following these steps, B2B buyers can ensure a smooth and effective sourcing process for double corrugated boxes, ultimately supporting their business needs.

Comprehensive Cost and Pricing Analysis for double corrugated box Sourcing

When sourcing double corrugated boxes, understanding the cost structure and pricing dynamics is crucial for international B2B buyers. This section delves into the components that influence costs, the factors affecting pricing, and provides practical tips for effective negotiation.

What Are the Key Cost Components of Double Corrugated Boxes?

The cost of double corrugated boxes is comprised of several components:

-

Materials: The primary material is high-quality corrugated cardboard, which varies in thickness and strength. The choice between virgin or recycled materials can significantly influence costs, with recycled options typically being more economical.

-

Labor: Labor costs encompass the workforce involved in manufacturing, quality control (QC), and packaging. Regions with lower labor costs can provide significant savings, but it’s essential to balance this with quality considerations.

-

Manufacturing Overhead: This includes expenses related to factory operations, such as utilities and equipment maintenance. Efficient manufacturing processes can reduce overhead, thereby lowering overall costs.

-

Tooling: Custom tooling for specific box sizes or designs can add to initial costs. This is particularly relevant for bespoke solutions, where one-time setup costs must be amortized over the production volume.

-

Quality Control: Ensuring the boxes meet industry standards and buyer specifications requires investment in quality assurance processes. This can involve testing for durability, weight capacity, and compliance with international shipping regulations.

-

Logistics: Shipping costs vary significantly based on destination, volume, and Incoterms. Buyers should consider both inbound logistics (raw materials) and outbound logistics (finished products) when evaluating total costs.

-

Margin: Suppliers typically add a markup to cover their operational costs and profit margin. Understanding standard margins in your target market can help in negotiations.

How Do Price Influencers Impact Sourcing Decisions?

Several factors can influence the pricing of double corrugated boxes:

-

Volume/MOQ: Minimum order quantities (MOQ) can significantly affect pricing. Larger orders often result in lower per-unit costs due to economies of scale.

-

Specifications and Customization: Custom sizes, printing, or special features (like moisture resistance) can increase costs. Standard sizes and designs typically yield better pricing.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., FSC certified for sustainable sourcing) can add to the cost but may be necessary for specific markets or customer requirements.

-

Supplier Factors: The reputation and reliability of the supplier can impact pricing. Established suppliers may charge more due to their track record of quality and service.

-

Incoterms: Understanding Incoterms is critical for international buyers. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect overall costs and risk allocation.

What Are Effective Buyer Tips for Cost-Efficiency?

To maximize value when sourcing double corrugated boxes, consider the following tips:

-

Negotiate Wisely: Leverage your order size and long-term partnership potential to negotiate better pricing. Be transparent about your needs and explore flexible payment terms.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial prices, assess the TCO, which includes shipping, storage, and potential waste costs. Higher-quality boxes may reduce damage during transit, offering long-term savings.

-

Understand Pricing Nuances for International Buyers: Currency fluctuations and local taxes can impact pricing. Always factor in these elements when assessing costs, particularly in regions like Africa and South America where economic conditions may vary.

-

Research Market Trends: Staying informed about market trends and material costs can provide leverage in negotiations. Suppliers may be more willing to offer discounts during periods of lower demand.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better terms and priority service. Regular communication and feedback can foster trust and collaboration.

Conclusion

Sourcing double corrugated boxes involves a multifaceted understanding of cost structures, pricing influencers, and effective negotiation strategies. By considering these elements, international B2B buyers can make informed decisions that optimize their supply chain and enhance profitability. Always remember that prices can fluctuate, so it’s prudent to approach sourcing with a long-term strategy in mind.

Alternatives Analysis: Comparing double corrugated box With Other Solutions

In the competitive landscape of packaging solutions, businesses often seek alternatives to double corrugated boxes for their shipping and storage needs. While double corrugated boxes are renowned for their durability and protection, it’s essential to explore other viable options that may offer unique advantages. This analysis presents a comparative overview of double corrugated boxes against two prominent alternatives: plastic packaging and wooden crates.

| Comparison Aspect | Double Corrugated Box | Plastic Packaging | Wooden Crates |

|---|---|---|---|

| Performance | High strength, crush-resistant, ECT ratings up to 48 | Water-resistant, good for lightweight items | Very durable, can support heavy loads |

| Cost | Moderate, typically $2-$5 per box | Generally lower cost, varies by type | Higher initial investment due to materials |

| Ease of Implementation | Readily available, easy to assemble | Lightweight, can be pre-formed | Requires assembly and may need tools |

| Maintenance | Minimal, recyclable and biodegradable | Can be reused, but environmental concerns | Durable, but may require repair |

| Best Use Case | Ideal for fragile or heavy items, long-distance shipping | Best for lightweight, non-fragile products | Suitable for heavy machinery or bulk items |

What are the Advantages and Disadvantages of Plastic Packaging Compared to Double Corrugated Boxes?

Plastic packaging is a popular alternative that offers several benefits, including water resistance and lightweight properties, making it ideal for products that may be exposed to moisture. However, while its cost is generally lower, it often lacks the strength required for heavier items and can have negative environmental implications, especially in terms of recyclability. Additionally, plastic packaging may not provide the same level of protection for fragile items as double corrugated boxes.

How Do Wooden Crates Stack Up Against Double Corrugated Boxes?

Wooden crates are another robust alternative, providing exceptional durability and strength, making them suitable for heavy machinery and bulk items. They can be customized to fit specific product dimensions and can withstand rough handling during transit. However, the initial cost of wooden crates is generally higher, and they require more effort to assemble and maintain. While they offer excellent protection, their weight can be a disadvantage for shipping logistics.

How Should B2B Buyers Choose the Right Packaging Solution?

When selecting the right packaging solution, B2B buyers should consider several factors, including the nature of the products being shipped, the weight and fragility of those items, and environmental concerns. Double corrugated boxes are ideal for companies needing reliable protection for fragile goods during transport, while plastic packaging can be a cost-effective choice for lighter items. For heavy-duty needs, wooden crates provide unmatched strength but come at a higher price point. Ultimately, the choice should align with the specific logistical requirements and sustainability goals of the business. By evaluating these alternatives based on performance, cost, ease of implementation, and maintenance, buyers can make informed decisions that best suit their operational needs.

Essential Technical Properties and Trade Terminology for double corrugated box

What Are the Key Technical Properties of Double Corrugated Boxes?

Double corrugated boxes are designed to offer superior strength and protection, making them ideal for shipping and storing fragile or heavy items. Here are some critical specifications to consider:

-

Material Grade: Double corrugated boxes are made from two layers of fluted paper sandwiched between three sheets of linerboard. This construction enhances durability and makes the boxes suitable for heavy or fragile items. The material grade typically reflects the box’s weight capacity and resistance to compression and puncture.

-

Edge Crush Test (ECT) Rating: The ECT rating measures the box’s ability to withstand vertical pressure. A higher ECT indicates greater strength; for example, a box with an ECT rating of 48 can handle heavier loads without collapsing. Understanding ECT ratings is essential for B2B buyers to ensure that the packaging meets their specific shipping needs.

-

Box Dimensions and Tolerances: Box size is critical for optimizing shipping and storage. Dimensions should be specified in length, width, and height, with tolerances indicating acceptable variations. Proper sizing prevents damage during transit and maximizes storage efficiency, which can lead to cost savings.

-

Weight Capacity: This specification indicates the maximum weight a box can safely hold. Double corrugated boxes often have a recommended weight capacity ranging from 80 lbs to over 275 lbs, depending on their construction. Knowing the weight capacity helps businesses select the right box for their products, ensuring safe transport.

-

Recyclability: Sustainability is increasingly important in B2B transactions. Double corrugated boxes are often made from recycled materials, making them an eco-friendly choice. Companies can enhance their sustainability credentials by opting for recyclable packaging, appealing to environmentally conscious customers.

Which Trade Terminology Should B2B Buyers Understand?

Understanding industry jargon is crucial for effective communication and negotiation. Here are several key terms related to double corrugated boxes:

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce components or products that are used in another company’s end product. In the packaging industry, an OEM might create custom double corrugated boxes tailored to a client’s specifications.

-

MOQ (Minimum Order Quantity): MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is essential for B2B buyers as it can impact inventory levels and cash flow. Buyers should negotiate MOQs based on their specific needs and storage capabilities.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. B2B buyers use RFQs to compare prices and terms from different manufacturers, which is vital for budgeting and procurement processes.

-

Incoterms (International Commercial Terms): These are predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping responsibilities, risk transfer, and cost allocation.

-

Freight Class: This term categorizes goods for shipping based on characteristics like density, value, and stowability. Understanding freight class is important for calculating shipping costs accurately, especially when dealing with heavy or bulky items packed in double corrugated boxes.

In summary, understanding the essential technical properties and trade terminology related to double corrugated boxes enables B2B buyers to make informed decisions, ensuring that their packaging solutions meet their operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the double corrugated box Sector

What Are the Current Market Dynamics and Key Trends Impacting Double Corrugated Box Sourcing?

The global double corrugated box market is experiencing robust growth, driven by the increasing demand for packaging solutions across various industries, including e-commerce, food and beverage, and consumer goods. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek reliable packaging solutions, several key trends have emerged.

First, the rise of e-commerce has significantly influenced the packaging landscape. Businesses are looking for durable and lightweight options that can withstand the rigors of shipping while ensuring product integrity. This has led to an increased demand for double corrugated boxes, which provide superior protection and stacking strength compared to single-wall alternatives.

Additionally, advancements in technology are reshaping sourcing strategies. Automation in manufacturing and supply chain processes is enhancing efficiency and reducing lead times. International buyers are increasingly leveraging digital platforms for procurement, allowing for greater transparency and competitive pricing.

Furthermore, the shift towards sustainability is becoming a crucial market dynamic. As environmental regulations tighten and consumers demand eco-friendly solutions, B2B buyers are actively seeking suppliers who can provide sustainable packaging options. This trend not only reflects a growing awareness of environmental impacts but also aligns with corporate social responsibility initiatives.

How Are Sustainability and Ethical Sourcing Shaping the Double Corrugated Box Industry?

The importance of sustainability and ethical sourcing is paramount in the double corrugated box sector. The environmental impact of packaging materials has come under scrutiny, prompting businesses to adopt more sustainable practices. Double corrugated boxes, often made from recycled materials, present an excellent opportunity for companies to reduce their carbon footprint.

B2B buyers are increasingly prioritizing suppliers who can demonstrate a commitment to sustainable practices. Certifications such as Forest Stewardship Council (FSC) and Sustainable Forestry Initiative (SFI) are becoming essential benchmarks for ethical sourcing. These certifications assure buyers that the materials used in manufacturing double corrugated boxes are sourced responsibly and contribute to the preservation of forests.

Moreover, the use of eco-friendly inks and adhesives in the production of double corrugated boxes is gaining traction. Buyers from regions like Europe are particularly sensitive to these factors due to stringent regulations and consumer expectations for sustainable packaging. By opting for environmentally friendly options, businesses not only comply with regulations but also enhance their brand image and appeal to environmentally-conscious consumers.

What Is the Brief Evolution of the Double Corrugated Box Market?

The evolution of the double corrugated box market can be traced back to the early 20th century when corrugated cardboard was first introduced as a packaging solution. Initially used for shipping fragile items, the design and functionality of corrugated boxes have significantly advanced over the decades.

In the latter half of the 20th century, the introduction of double-wall construction provided enhanced strength and durability, making these boxes a preferred choice for heavy and fragile goods. The growth of the e-commerce sector in the 21st century further accelerated the demand for double corrugated boxes, as businesses sought reliable packaging solutions for shipping products directly to consumers.

Today, the market is characterized by continuous innovation in materials and manufacturing processes, driven by technological advancements and changing consumer preferences. As sustainability becomes a central theme in packaging, the double corrugated box sector is poised to adapt and thrive, offering businesses the durability they require while meeting their environmental responsibilities.

Frequently Asked Questions (FAQs) for B2B Buyers of double corrugated box

-

How do I choose the right double corrugated box for my products?

When selecting the appropriate double corrugated box, consider the weight and fragility of your items. Look for boxes with a suitable Edge Crush Test (ECT) rating, which indicates their strength. For heavier or fragile products, opt for boxes with higher ECT ratings (e.g., 44 or 48). Additionally, evaluate the dimensions to ensure a snug fit, minimizing movement during transit. Supplier catalogs often provide detailed specifications, allowing you to compare and select based on your specific needs. -

What factors should I consider when sourcing double corrugated boxes internationally?

Key factors include the supplier’s reliability, production capabilities, and compliance with international shipping regulations. Research potential suppliers by checking reviews and certifications. Assess their ability to meet your quality standards and delivery timelines. It’s also crucial to understand local customs regulations in your region to avoid delays and additional costs. Establishing clear communication with your supplier can facilitate smoother transactions and mitigate risks. -

What are the minimum order quantities (MOQs) for double corrugated boxes?

MOQs vary significantly between suppliers and can range from as low as 50 boxes to several hundred. Factors influencing MOQs include box size, customization options, and production capacity. When negotiating with suppliers, discuss your specific needs and seek flexibility, especially if you are testing new products or entering a market with low demand. Some suppliers may offer lower MOQs for standard sizes or bulk discounts for larger orders. -

Can I customize double corrugated boxes for branding purposes?

Yes, many suppliers offer customization options, including printing your logo, brand colors, or specific designs on the boxes. Customization can enhance brand visibility and create a professional presentation for your products. When discussing customization, inquire about minimum quantities, lead times, and additional costs. Ensure that the supplier can provide samples before placing a large order to verify quality and design accuracy. -

What payment terms are typically offered by suppliers of double corrugated boxes?

Payment terms can vary widely based on the supplier’s policies and your negotiating power. Common terms include upfront payment, partial payment before production, and the balance upon delivery. Some suppliers may offer credit terms, especially for repeat customers. It’s essential to clarify payment methods (e.g., bank transfers, letters of credit) and any applicable fees to avoid surprises during the transaction process. -

How do I ensure the quality of double corrugated boxes before shipment?

Implement a quality assurance (QA) process by requesting product samples before placing a bulk order. Inspect samples for strength, durability, and compliance with specifications. Additionally, consider conducting factory audits to assess production processes and standards. Collaborating with third-party quality inspectors can also provide an objective assessment of the boxes’ quality prior to shipment, reducing the risk of receiving subpar products. -

What logistics considerations should I keep in mind when importing double corrugated boxes?

Logistics considerations include shipping methods, lead times, and customs clearance processes. Choose a reliable freight forwarder experienced in handling packaging materials. Understand the shipping costs involved, including duties and taxes, to accurately budget your expenses. Additionally, ensure that your supplier provides necessary documentation for customs, such as certificates of origin and compliance, to facilitate a smooth import process. -

What are the environmental impacts of using double corrugated boxes, and are there eco-friendly options?

Double corrugated boxes are often made from recycled materials, making them a more sustainable packaging choice. Many suppliers offer eco-friendly options that use 100% recycled content or biodegradable materials. When sourcing, inquire about the environmental certifications of the boxes, such as FSC (Forest Stewardship Council) certification. By choosing eco-friendly packaging, you not only reduce your environmental footprint but also appeal to environmentally conscious customers.

Top 4 Double Corrugated Box Manufacturers & Suppliers List

1. The Boxery – Heavy Duty Double Wall Boxes

Domain: theboxery.com

Registered: 2010 (15 years)

Introduction: Heavy Duty Double Wall Boxes, ideal for fragile or heavy items, made from over 80% recycled materials, ECT 48 strength, ships flat for storage savings, available in various sizes including 6x6x6”, 8x8x8”, 12x12x12”, 18x18x18”, and larger options up to 48x40x36”. Most items sold in bundles of 10 or 15 boxes. Made in USA, eco-friendly.

2. Packaging Price – Heavy-Duty Corrugated Boxes

Domain: packagingprice.com

Registered: 1999 (26 years)

Introduction: Corrugated Heavy-Duty Boxes – Double Wall; Free shipping on qualified orders of $299 or more; Categories include Heavy Duty Double Wall, Triple Wall, Stock Boxes, Shipping Boxes, Moving Boxes, Single Wall Boxes, Flat Boxes, Long Boxes, Multi-Depth Boxes, Side Loading Boxes, Tall Boxes, Telescoping Boxes.

3. U-Haul – Double Wall Boxes

Domain: uhaul.com

Registered: 1995 (30 years)

Introduction: Double Wall Boxes from U-Haul include the following options: 1. Dish Barrel® Box – Heavy-Duty Dish Packing Box – Dimensions: 18” x 18” x 28” – Price: $8.10 2. Extra-Large Heavy-Duty Double Wall Moving & Shipping Box – Dimensions: 24” x 18” x 24” – Price: $7.95 3. Large Heavy-Duty Double Wall Moving & Shipping Box – Dimensions: 18” x 18” x 24” – Price: $5.95 4. Medium Heavy-Duty Double Wall Moving …

4. Benchmark – Double-Walled Boxes

Domain: benchmarkinc.com

Registered: 2002 (23 years)

Introduction: Double-Walled Boxes from Benchmark provide extra protection for shipping. They are made of 48 ECT Kraft Corrugated material and are available in various sizes. Each box is sold in bundles, with different pricing tiers based on the quantity purchased. The sizes include: 6x6x6 (15/BDL, 675/Bale), 8x8x8 (15/BDL, 300/Bale), 9x9x6 1/2 (25/BDL, 300/Bale), 9x9x9 (15/BDL, 300/Bale), 9x9x13 (25/BDL, 300/Ba…

Strategic Sourcing Conclusion and Outlook for double corrugated box

In today’s competitive landscape, strategic sourcing of double corrugated boxes is essential for businesses aiming to enhance operational efficiency and ensure product safety during transportation. By leveraging the benefits of double wall construction, companies can protect fragile and heavy items, reduce damage rates, and ultimately lower costs associated with returns and replacements. The eco-friendly nature of these boxes, often made from recycled materials, aligns with the growing demand for sustainable packaging solutions, appealing to environmentally-conscious consumers and businesses alike.

International B2B buyers from regions such as Africa, South America, the Middle East, and Europe should prioritize partnerships with reliable suppliers who can offer customized solutions tailored to their specific needs. Engaging with manufacturers that provide robust product testing, such as edge crush test (ECT) ratings, guarantees that your packaging meets industry standards and can withstand the rigors of global shipping.

Looking ahead, the market for double corrugated boxes is poised for growth, driven by increasing demand for e-commerce and logistical efficiency. Now is the time to invest in strategic sourcing initiatives that not only enhance your supply chain resilience but also position your business for future success. Embrace the opportunity to optimize your packaging solutions and drive sustainable growth in your operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to double corrugated box

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.