How to Source Door Handle Parts Names Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for door handle parts names

In the dynamic landscape of global trade, sourcing door handle parts names can pose significant challenges for international B2B buyers, especially those operating in diverse markets like Africa, South America, the Middle East, and Europe. The complexity arises from the myriad of components available, each serving specific functions in security, aesthetics, and functionality. This comprehensive guide aims to demystify the world of door handle parts by categorizing the various types, discussing their applications, and providing insights into supplier vetting processes and pricing strategies.

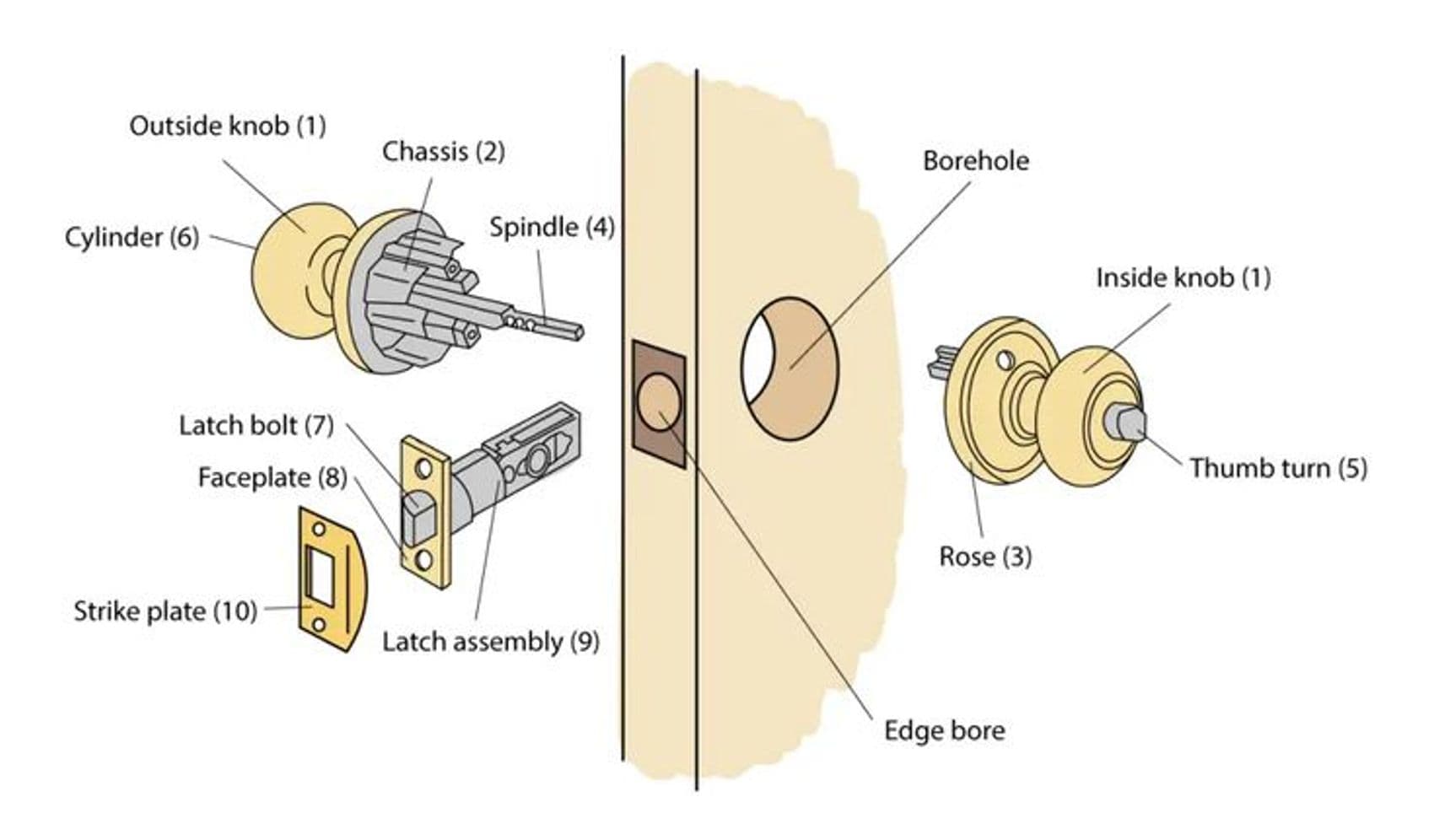

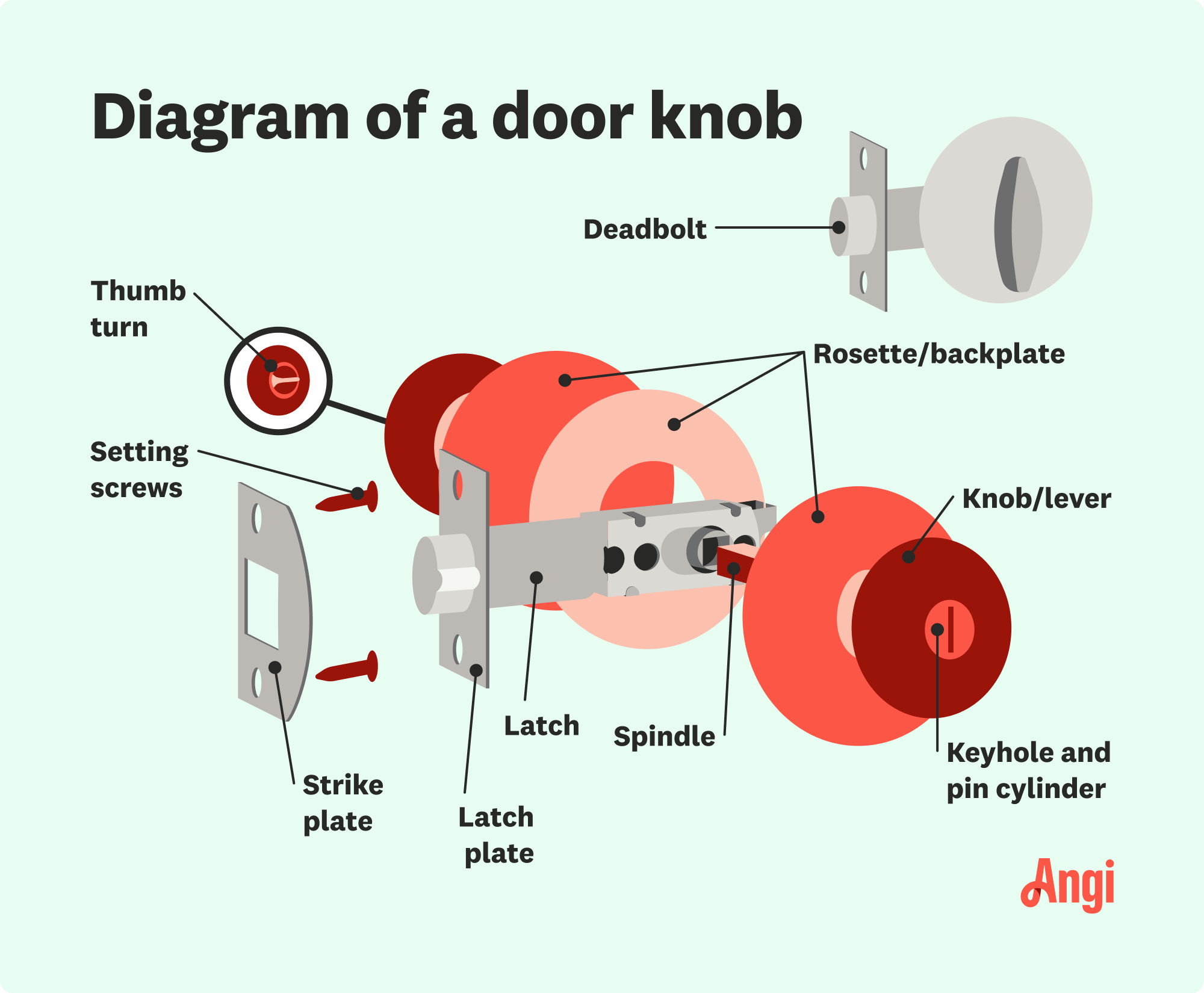

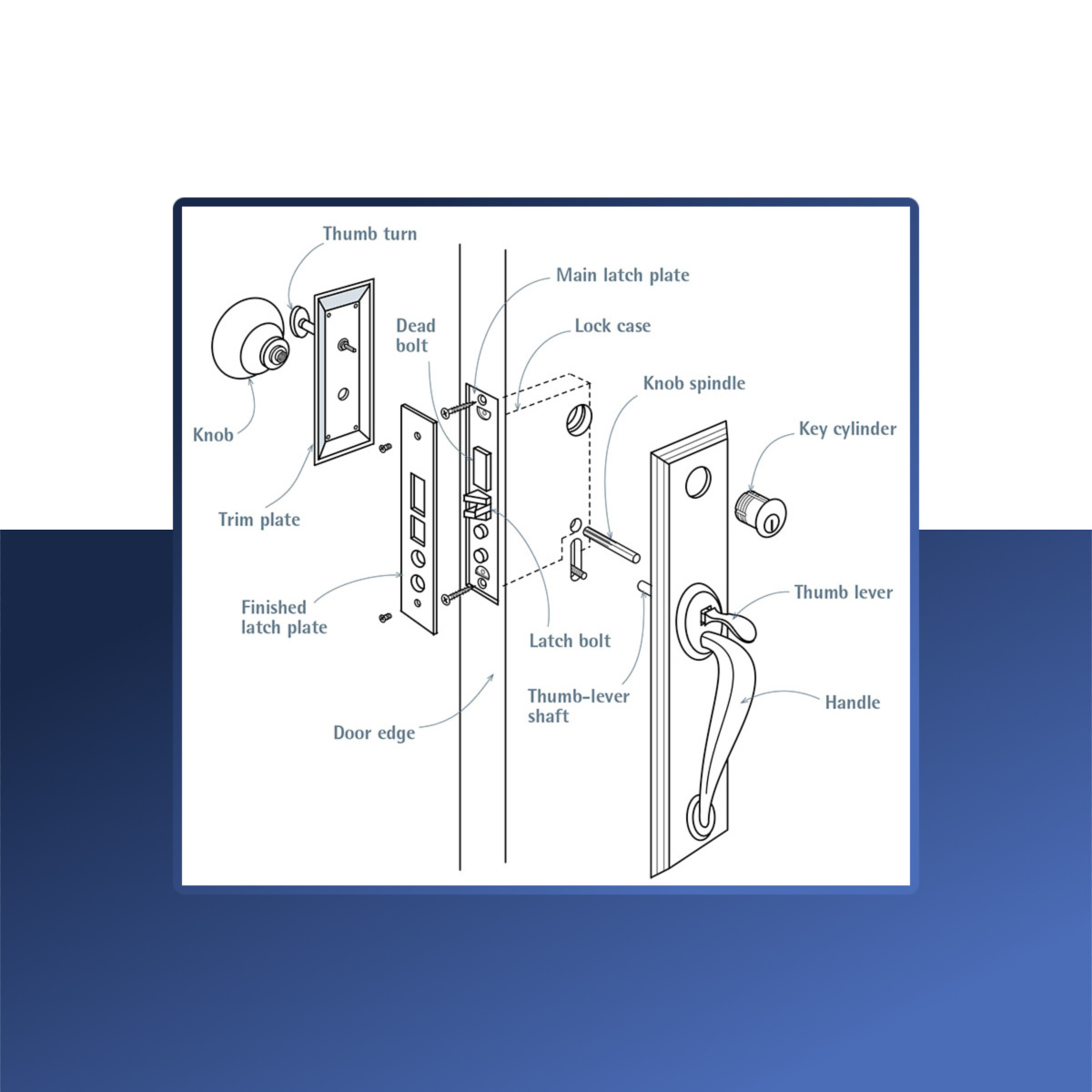

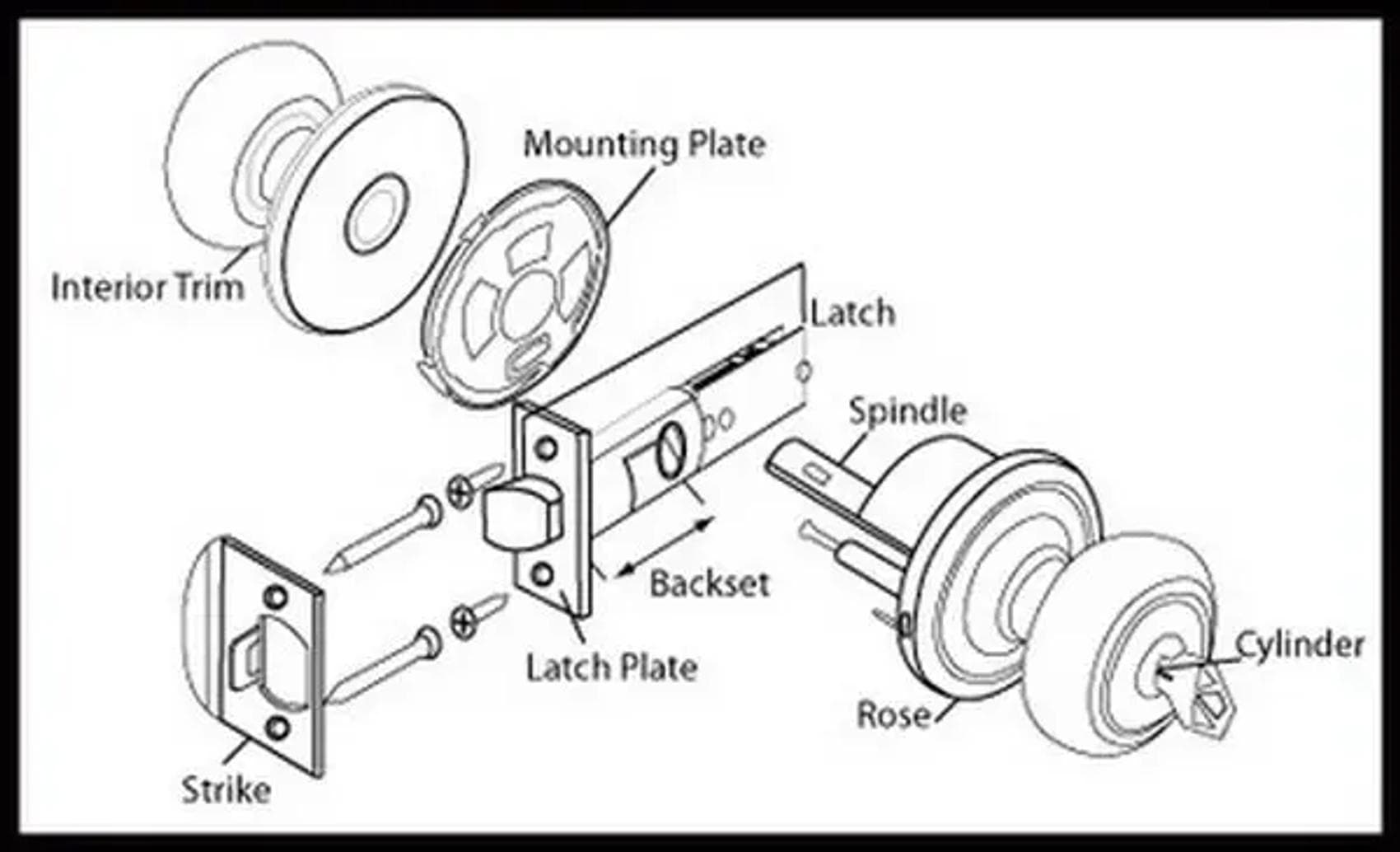

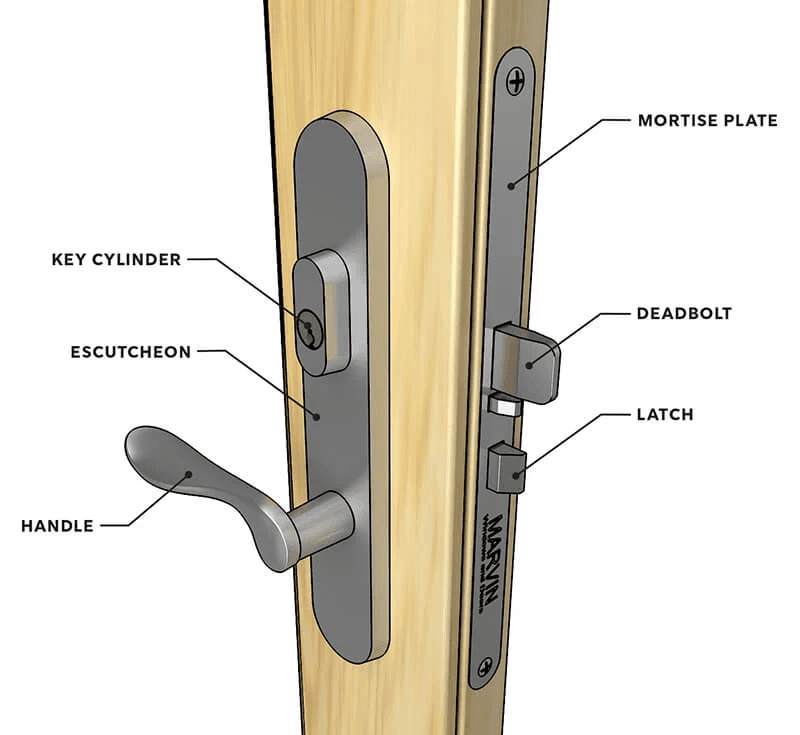

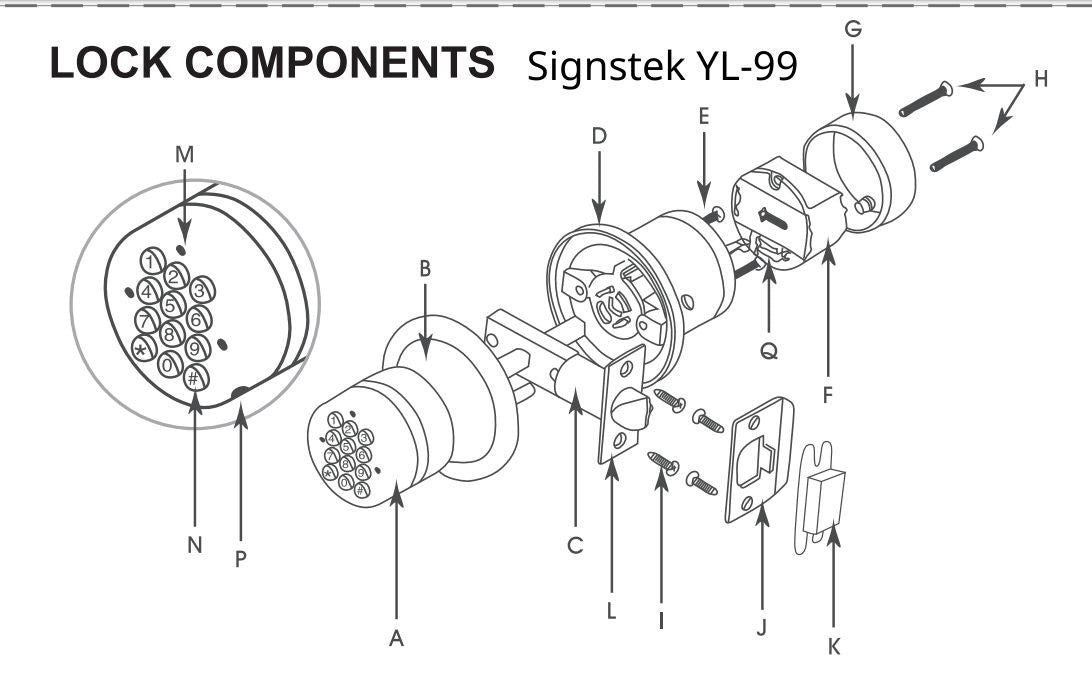

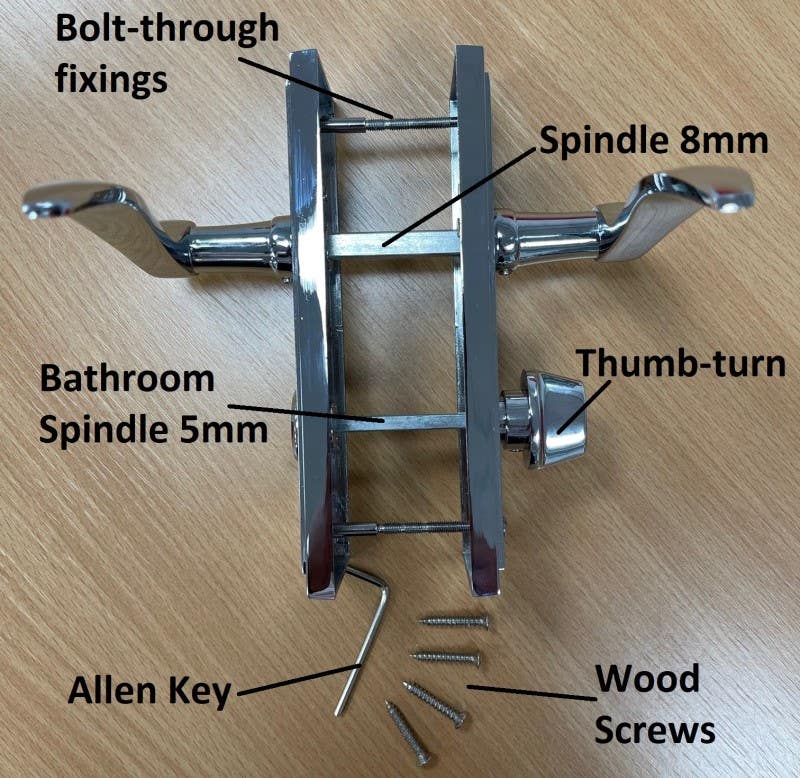

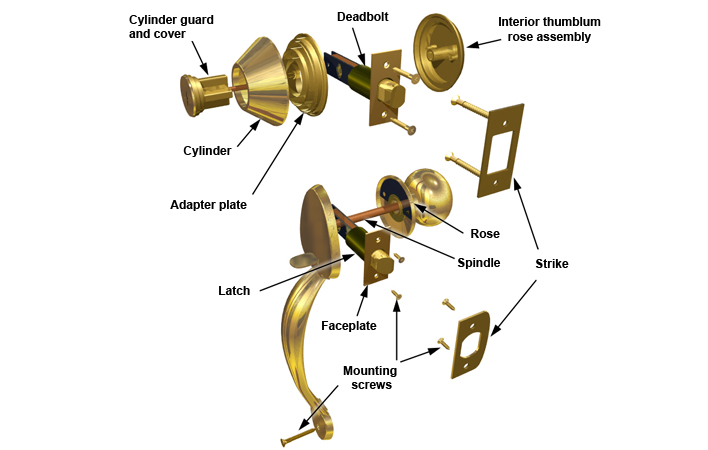

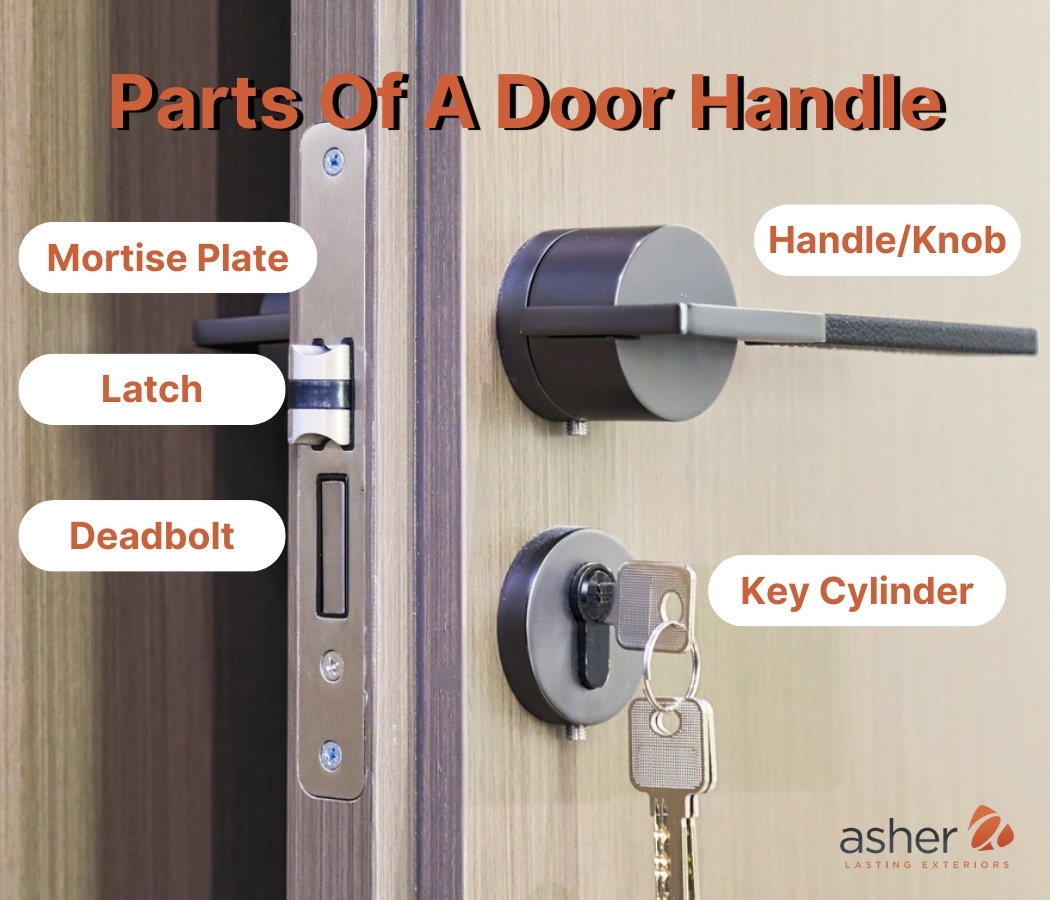

By navigating through this guide, B2B buyers will gain a holistic understanding of essential components such as knobs, levers, latches, and deadbolts, along with key terminology that is critical for effective communication with suppliers. Furthermore, the guide emphasizes the importance of selecting the right materials and designs that align with regional standards and consumer preferences, ensuring that procurement decisions are not only informed but also strategically advantageous.

With a focus on empowering buyers to make confident purchasing decisions, this resource serves as a valuable tool for those looking to optimize their supply chain and enhance product offerings. Whether you’re a distributor in Brazil seeking high-quality hardware or a contractor in Saudi Arabia aiming to meet client demands, this guide equips you with the knowledge needed to thrive in the competitive market for door handle parts.

Understanding door handle parts names Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Lever Handle | Longer design, ergonomic grip, available in various finishes | Commercial buildings, residential properties | Pros: Easy to operate, stylish options. Cons: May require more space for installation. |

| Knob | Round shape, compact design, various materials | Residential homes, office doors | Pros: Space-efficient, diverse styles. Cons: Can be harder to grip for some users. |

| Deadbolt | Enhanced security, available in single and double cylinder types | External doors, high-security applications | Pros: High security, durable. Cons: More complex installation, may require extra keys. |

| Dummy Knob/Lever | Non-functional, decorative, mounted directly to the door | Closets, pantry doors | Pros: Aesthetic appeal, easy to install. Cons: No locking mechanism, limited functionality. |

| Privacy Lock | Mechanism for privacy, typically with a push or turn feature | Bathrooms, bedrooms | Pros: Good for privacy, simple locking. Cons: Not suitable for external doors, limited security. |

What Are the Key Characteristics of Lever Handles in B2B Applications?

Lever handles are characterized by their elongated design, which allows for easier operation compared to traditional knobs. They are available in various finishes and styles, making them suitable for a wide range of environments, from corporate offices to upscale residential properties. When purchasing lever handles, B2B buyers should consider the door swing direction and the space available for installation. Lever handles are particularly advantageous in commercial settings where accessibility is a priority.

How Do Knobs Differ and What Are Their Applications?

Knobs are typically round and compact, making them ideal for spaces where aesthetics and space are critical. Commonly used in residential homes and office doors, they come in various materials such as brass, zinc die cast, and plastic. When sourcing knobs, B2B buyers should evaluate the ease of use for all potential users, including those with limited hand strength. While knobs can be stylish, they may not provide the same level of ease of operation as lever handles.

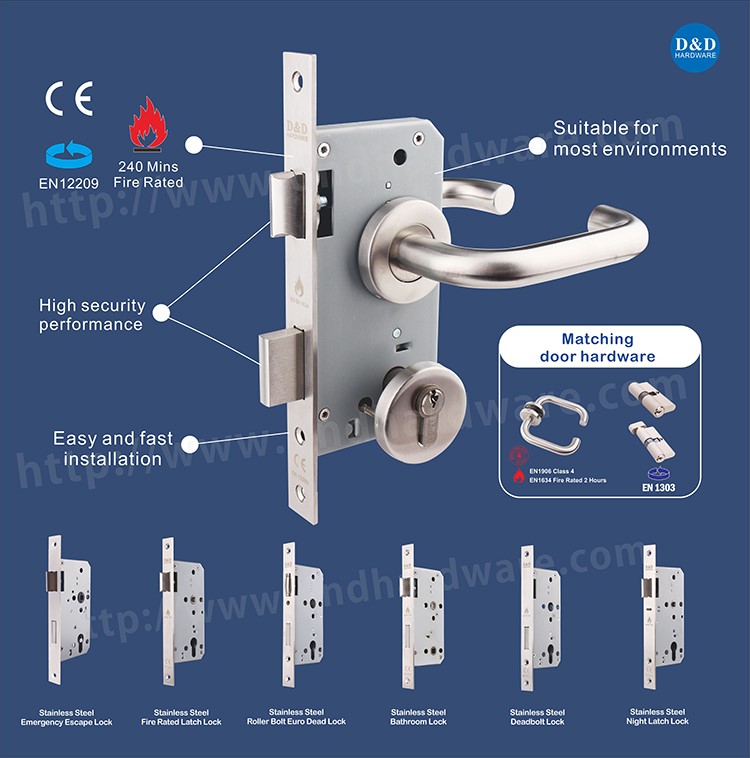

Why Choose Deadbolts for High-Security Needs?

Deadbolts are vital for enhancing door security, especially in external applications. They come in single and double cylinder configurations, allowing for various locking options depending on security needs. B2B buyers should prioritize deadbolts for doors requiring high security, such as those in commercial buildings or high-risk residential areas. While they offer robust protection, buyers must also consider the complexity of installation and the need for additional keys.

What Role Do Dummy Knobs and Levers Play in Design?

Dummy knobs and levers serve primarily a decorative function, often mounted on doors that do not require a locking mechanism, such as closets or pantry doors. They are easy to install and can significantly enhance the aesthetic appeal of a space. B2B buyers should recognize that while dummy knobs provide visual consistency, they lack functionality and are not suited for applications requiring security or privacy.

How Do Privacy Locks Function in Residential Settings?

Privacy locks are designed for spaces where confidentiality is essential, such as bathrooms and bedrooms. They typically feature a simple locking mechanism activated by a push button or turn knob. B2B buyers should consider privacy locks for residential projects, balancing the need for privacy with ease of access in emergencies. However, it is crucial to note that privacy locks are not suitable for external doors where higher security measures are required.

Illustrative image related to door handle parts names

Key Industrial Applications of door handle parts names

| Industry/Sector | Specific Application of door handle parts names | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Installation of door hardware in commercial buildings | Enhances security and functionality of entrances | Compliance with local building codes and standards |

| Hospitality | Use of durable and stylish door handles in hotels | Improves guest experience and aesthetic appeal | Sourcing materials that withstand high traffic and wear |

| Residential Development | Custom door handle solutions for new homes | Adds value and personalization to properties | Variety in styles and finishes to meet diverse consumer preferences |

| Retail | Implementation of access control systems with door handles | Increases security for merchandise and staff | Compatibility with existing security systems and ease of installation |

| Healthcare | Installation of sanitary door handles in clinics | Promotes hygiene and safety for patients | Compliance with health regulations and ease of cleaning |

How are door handle parts names utilized in the construction industry?

In the construction sector, door handle parts are essential for the installation of door hardware in both residential and commercial buildings. They ensure secure access and enhance the functionality of entrances. For international buyers, particularly in regions like Africa and the Middle East, it is crucial to source products that comply with local building codes and standards to avoid legal issues and ensure safety. Additionally, durability is paramount, as these components must withstand heavy usage in commercial settings.

What role do door handle parts play in the hospitality industry?

In the hospitality industry, door handle parts are used extensively in hotels and resorts, where both functionality and aesthetics are vital. High-quality door handles not only improve the guest experience by providing ease of access but also contribute to the overall aesthetic appeal of the property. Buyers in this sector should prioritize sourcing materials that can withstand high traffic and wear, ensuring longevity and reducing replacement costs. Consideration for design trends that resonate with target demographics can also enhance brand image.

How are door handle parts names important for residential development?

In residential development, custom door handle solutions allow builders to add unique features to new homes, enhancing their market appeal. These components can significantly increase the value of properties by offering personalization options that cater to diverse consumer preferences. For international buyers, especially in regions like South America and Europe, it is important to source a wide variety of styles and finishes that align with regional design trends and cultural preferences, ensuring that the product meets local market demands.

What benefits do door handle parts provide to the retail sector?

In the retail sector, door handle parts are integral to implementing access control systems that enhance security for merchandise and staff. These components can deter theft and unauthorized access while ensuring a smooth customer experience. For businesses in regions like Brazil and the Middle East, compatibility with existing security systems is essential. Buyers should also consider ease of installation and maintenance, as minimizing downtime during upgrades can lead to significant cost savings.

How do door handle parts contribute to healthcare facilities?

In healthcare settings, the use of sanitary door handles is crucial for promoting hygiene and safety. These handles are designed to minimize contact and are often made from materials that are easy to clean and disinfect. For international buyers, especially in regions with strict health regulations, sourcing door handle parts that comply with these standards is essential. Additionally, features such as anti-microbial finishes can enhance patient safety, making them a valuable consideration in procurement decisions.

3 Common User Pain Points for ‘door handle parts names’ & Their Solutions

Scenario 1: Navigating Complex Door Handle Specifications

The Problem: B2B buyers often encounter difficulties when trying to understand the multitude of specifications associated with door handle parts. Terms like “backset,” “bore hole,” and “cross bore” can be confusing, especially when buyers are unfamiliar with the technical jargon. This lack of clarity may lead to incorrect orders, resulting in delays and increased costs. For instance, an importer in Brazil might order the wrong type of latch, causing disruptions in their supply chain and dissatisfaction among their clients.

The Solution: To mitigate this issue, B2B buyers should invest time in familiarizing themselves with standard door hardware terminology and specifications. Engaging with educational resources, such as detailed product guides or webinars provided by manufacturers, can enhance understanding. Additionally, creating a checklist of required specifications before placing an order can streamline the procurement process. Buyers should also seek suppliers who offer comprehensive product descriptions, including images and installation guides, to ensure they select the correct components. Utilizing digital tools like online configurators can further assist in visualizing how different parts fit together, reducing the likelihood of errors in ordering.

Illustrative image related to door handle parts names

Scenario 2: Dealing with Inconsistent Quality Across Suppliers

The Problem: Quality inconsistency is a pervasive issue in the door hardware industry, particularly when sourcing from various international suppliers. A contractor in Saudi Arabia may experience frustration when different batches of door handles arrive with varying finishes or dimensions, compromising project timelines and customer satisfaction. This inconsistency not only affects aesthetic appeal but can also raise safety concerns, especially in commercial applications where durability is crucial.

The Solution: To ensure consistent quality, B2B buyers should establish long-term relationships with a select group of reputable suppliers known for their reliability. Conducting thorough supplier audits and requiring samples before bulk orders can help assess quality standards. Additionally, buyers can implement a quality control checklist that includes specific criteria for each door handle part, such as material specifications, finish, and compliance with local standards. Regular communication with suppliers about quality expectations and potential issues can foster a collaborative approach to quality assurance. Utilizing third-party inspection services before shipment can also provide an added layer of security.

Scenario 3: Simplifying the Replacement Process for Door Handle Parts

The Problem: Many B2B buyers face challenges when trying to replace outdated or damaged door handle parts. Often, buyers may not know the exact part names or specifications required, leading to prolonged downtimes and increased operational costs. For instance, a facility manager in Europe may struggle to find a compatible latch for an older door model, resulting in delays in securing entry points and potential security risks.

The Solution: To streamline the replacement process, buyers should maintain a detailed inventory of door handle parts currently in use, including images and specifications. This inventory can serve as a quick reference for ordering replacements. Moreover, partnering with suppliers who offer a comprehensive replacement guide based on the door types can significantly ease the procurement process. Encouraging suppliers to provide a searchable database of parts can empower buyers to quickly identify the necessary components. Finally, training staff on basic door hardware terminology and replacement procedures can enhance efficiency and reduce downtime, ultimately improving overall operational performance.

Strategic Material Selection Guide for door handle parts names

What are the Key Properties of Common Materials Used in Door Handle Parts?

When selecting materials for door handle components, it is essential to consider their key properties that influence product performance. Common materials include brass, stainless steel, zinc die-cast, and plastic. Each material has distinct characteristics that can affect durability, cost, and suitability for specific applications.

How Does Brass Perform as a Material for Door Handle Parts?

Brass is a traditional choice for door handles due to its excellent corrosion resistance and aesthetic appeal. It typically has a temperature rating suitable for indoor and outdoor environments, making it versatile. The main advantage of brass is its durability; it can withstand significant wear and tear, which is crucial for high-traffic areas. However, brass can be more expensive than other materials, and its manufacturing process can be complex, leading to higher costs.

Illustrative image related to door handle parts names

For international buyers, especially in regions like Europe and the Middle East, brass door handles often comply with standards such as EN 1906, ensuring quality and safety. In contrast, buyers from Africa and South America should consider local availability and pricing fluctuations.

What Are the Benefits of Stainless Steel in Door Handle Manufacturing?

Stainless steel is another popular material for door handle parts, known for its exceptional strength and corrosion resistance. It is ideal for environments exposed to moisture or harsh weather conditions, making it suitable for outdoor applications. Stainless steel handles are also easy to clean and maintain, which is a significant advantage in commercial settings.

The downside of stainless steel is its relatively high cost compared to other materials like zinc die-cast. Additionally, the manufacturing process can be more energy-intensive, which may impact the overall cost. Buyers from regions like Brazil and Saudi Arabia should ensure that the stainless steel used meets local standards, such as ASTM A240 for corrosion resistance.

Illustrative image related to door handle parts names

Why Choose Zinc Die-Cast for Door Handle Components?

Zinc die-cast is a cost-effective option for door handle parts, offering good strength and durability. It is particularly suitable for decorative elements due to its ability to be molded into intricate designs. The manufacturing process is less complex than that of brass or stainless steel, resulting in lower production costs.

However, zinc die-cast is less corrosion-resistant than brass or stainless steel, making it less suitable for outdoor applications unless properly coated. For international buyers, especially in humid climates, it is crucial to consider the potential for corrosion and to ensure that the products meet relevant standards, such as ISO 9001 for quality management.

What Role Does Plastic Play in Door Handle Applications?

Plastic is increasingly used in door handle manufacturing due to its lightweight nature and versatility. It can be molded into various shapes and colors, making it an attractive option for residential applications. Plastic handles are also resistant to corrosion and can be produced at a lower cost than metal alternatives.

On the downside, plastic may not offer the same level of durability as metals, particularly in high-traffic areas. Additionally, it may not be suitable for applications requiring a high-end aesthetic. Buyers in regions like Africa and South America should consider the environmental impact of plastic and whether it aligns with their sustainability goals.

Summary Table of Material Selection for Door Handle Parts

| Material | Typical Use Case for door handle parts names | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Brass | High-end residential and commercial handles | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Stainless Steel | Outdoor and commercial applications | Exceptional strength and durability | Higher cost and energy-intensive | High |

| Zinc Die-Cast | Decorative residential handles | Cost-effective and intricate designs | Less corrosion resistance | Medium |

| Plastic | Lightweight residential applications | Lightweight and versatile | Lower durability in high traffic | Low |

This strategic material selection guide provides valuable insights for international B2B buyers, enabling informed decisions based on specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for door handle parts names

What Are the Main Stages of Manufacturing Door Handle Parts?

Manufacturing door handle parts is a meticulous process that involves several key stages: material preparation, forming, assembly, and finishing. Each of these stages is critical in ensuring the final product meets the required specifications for quality, durability, and aesthetics.

How Is Material Prepared for Door Handle Manufacturing?

The manufacturing process begins with material preparation, which typically involves selecting the right metals such as brass, stainless steel, or zinc die-cast. The choice of material significantly impacts the final product’s strength, corrosion resistance, and overall appearance. Once the materials are selected, they undergo several treatments to enhance their properties. This may include processes like annealing to improve ductility and hardness or surface treatments to prevent oxidation.

What Forming Techniques Are Used in Door Handle Production?

After material preparation, the forming stage follows, which can involve various techniques such as casting, forging, or machining.

- Casting is often used for more complex shapes, allowing for intricate designs that would be difficult to achieve through other methods.

- Forging enhances the material’s strength through deformation, making it ideal for high-stress components like levers.

- Machining is employed for precision parts, where exact dimensions and tolerances are critical. Techniques such as CNC machining ensure high accuracy in producing components like knobs and latches.

Each of these forming techniques has its advantages and is chosen based on the specific requirements of the door handle parts being produced.

Illustrative image related to door handle parts names

How Are Door Handle Parts Assembled?

Once the individual components are formed, the assembly process begins. This stage involves fitting together various parts, such as knobs, levers, latches, and rosettes. Assembly can be done manually or through automated processes, depending on the scale of production. Quality control during assembly is vital; any misalignment or improper fitting can lead to functional issues.

For door handle systems that require locking mechanisms, such as deadbolts, additional care is taken to ensure that all components work seamlessly together. This may involve testing the movement of the latch and key mechanism to ensure smooth operation.

What Finishing Processes Are Applied to Door Handle Parts?

Finishing processes provide the final touches to door handle parts, enhancing their appearance and protecting them from environmental factors. Common finishing techniques include:

- Plating: Applying a thin layer of metal (like chrome or nickel) to enhance corrosion resistance and provide an appealing finish.

- Powder Coating: A dry powder is applied and then cured under heat, creating a durable and decorative finish that resists scratching and fading.

- Polishing: This process is essential for achieving a high-gloss finish, especially for decorative brass or stainless steel components.

These finishing processes not only improve aesthetics but also ensure that the door handles are suitable for various environments, from residential to industrial.

How Is Quality Assurance Implemented in Door Handle Manufacturing?

Quality assurance (QA) is a crucial aspect of the manufacturing process, ensuring that products meet international and industry-specific standards. For B2B buyers, understanding these quality control measures is essential for making informed purchasing decisions.

Illustrative image related to door handle parts names

What Are the Relevant International Standards for Door Handle Parts?

In the door hardware industry, compliance with international standards such as ISO 9001 is critical. This standard specifies requirements for a quality management system, emphasizing customer satisfaction and continuous improvement. Additionally, products may need to adhere to specific regulations depending on the market, such as CE marking in Europe, which indicates conformity with health, safety, and environmental protection standards.

What Quality Control Checkpoints Are Commonly Used?

Quality control typically involves several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): At this stage, raw materials are inspected upon arrival to ensure they meet specified standards.

- In-Process Quality Control (IPQC): During production, regular checks are conducted to monitor processes and identify any deviations from quality standards.

- Final Quality Control (FQC): After assembly and finishing, a comprehensive inspection is performed to ensure that all components function correctly and meet aesthetic standards.

These checkpoints are essential for minimizing defects and ensuring that the final products meet customer specifications.

What Common Testing Methods Are Utilized for Door Handle Parts?

Testing methods vary based on the product’s intended use, but common practices include:

- Mechanical Testing: Assessing the strength and durability of components through tensile tests or fatigue tests.

- Corrosion Testing: Simulating environmental conditions to evaluate the resistance of finishes and materials to corrosion.

- Functional Testing: Ensuring that locking mechanisms and moving parts operate smoothly and securely.

These tests help manufacturers identify potential weaknesses and improve product reliability.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, verifying supplier quality control is crucial for ensuring product reliability and compliance with standards. Here are some strategies:

What Should Buyers Look for in Supplier Audits and Reports?

Buyers should request detailed audits and quality control reports from suppliers. These documents should outline the supplier’s quality management system, compliance with international standards, and results from recent quality inspections and tests. A reputable supplier should be transparent about their processes and willing to share relevant certifications.

How Important Is Third-Party Inspection in Quality Assurance?

Engaging third-party inspection services can provide an additional layer of assurance. These independent entities can perform audits and product inspections, ensuring that the manufacturing processes align with stated standards and specifications. This is particularly valuable for buyers who may not have the resources to conduct on-site inspections themselves.

What Are the Quality Control Nuances for Different Regions?

Buyers must also be aware of regional quality control nuances. For example, products exported to Europe must comply with CE marking, while those in the Middle East may require adherence to local standards. Understanding these regional requirements can help buyers avoid compliance issues and ensure that products meet local regulations.

By thoroughly understanding the manufacturing processes and quality assurance protocols involved in door handle parts production, B2B buyers can make informed decisions, ensuring that they source reliable and high-quality products for their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘door handle parts names’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure door handle parts. Understanding the various components and ensuring that they meet your specific needs is crucial for quality and functionality. This checklist will help streamline your procurement process, ensuring that you secure the right parts from reliable suppliers.

1. Identify Your Requirements

Begin by clearly defining the types of door handle parts you need. Different projects may require specific components such as knobs, levers, or deadbolts. Understanding your requirements ensures that you source the correct parts, which can significantly reduce delays and potential returns.

- Consider the Application: Are these parts for residential, commercial, or industrial doors?

- Specify Material Needs: Different materials (e.g., brass, stainless steel) have varying durability and aesthetic qualities.

2. Define Your Technical Specifications

Establishing the technical specifications is essential for compatibility with existing door systems. This includes measurements such as backset, bore hole diameter, and cross bore size.

- Standard Measurements: Familiarize yourself with industry standards; for instance, a typical bore hole is 2 1/8 inches.

- Customization Needs: Determine if you require custom sizes or features to accommodate specific door designs.

3. Research Potential Suppliers

Identify and evaluate potential suppliers who can provide the door handle parts you need. Look for suppliers with a proven track record in the industry.

- Supplier Reputation: Check reviews and ratings from other B2B buyers, especially in your region (e.g., Africa, South America).

- Product Range: Ensure they offer a comprehensive range of door handle parts to meet all your needs.

4. Verify Supplier Certifications

Before making a commitment, it’s crucial to verify that your suppliers have the necessary certifications. This ensures that the products meet safety and quality standards.

- ISO Certifications: Look for suppliers with ISO 9001 certification, which indicates a commitment to quality management.

- Regional Compliance: Ensure they comply with local regulations and standards relevant to your market.

5. Request Samples

Always request samples of the door handle parts before placing a bulk order. This step allows you to evaluate the quality and functionality of the components firsthand.

Illustrative image related to door handle parts names

- Quality Assessment: Inspect the materials and construction quality to ensure they meet your specifications.

- Fit Testing: Check compatibility with your existing door systems to avoid costly mistakes.

6. Negotiate Terms and Conditions

Once you’ve selected a supplier, engage in negotiations to establish favorable terms and conditions. This includes pricing, delivery timelines, and payment terms.

- Volume Discounts: Inquire about discounts for larger orders, which can significantly reduce costs.

- Shipping and Handling: Clarify shipping costs and delivery schedules to align with your project timelines.

7. Establish a Quality Control Process

Implement a quality control process to monitor the received door handle parts. This ensures that they meet your standards and specifications.

- Inspection Protocols: Create a checklist for inspecting parts upon arrival to catch any discrepancies early.

- Feedback Mechanism: Establish a system for providing feedback to suppliers, which can enhance future transactions.

By following these steps, B2B buyers can effectively navigate the procurement of door handle parts, ensuring they receive high-quality components that meet their project requirements.

Comprehensive Cost and Pricing Analysis for door handle parts names Sourcing

What Are the Key Cost Components in Sourcing Door Handle Parts?

Understanding the cost structure for sourcing door handle parts is crucial for international B2B buyers. The primary cost components include:

Illustrative image related to door handle parts names

-

Materials: The type of materials used significantly impacts the overall cost. Common materials for door handles include brass, stainless steel, and zinc die-cast. Higher-quality materials often come with a higher price tag but may offer better durability and aesthetics.

-

Labor: Labor costs can vary based on the region and the complexity of the manufacturing process. Skilled labor may demand higher wages, especially in countries with strict labor laws or high living costs.

-

Manufacturing Overhead: This includes costs related to production facilities, utilities, and indirect labor. Efficient manufacturing processes can reduce overhead costs, making it essential for suppliers to optimize their operations.

-

Tooling: The initial investment in tooling for specialized parts can be significant. Custom designs or unique specifications may require custom tooling, affecting the overall pricing.

-

Quality Control (QC): Implementing rigorous quality control processes ensures that products meet required standards, but it also adds to the cost. Buyers should assess how much emphasis suppliers place on QC as it can impact long-term reliability.

-

Logistics: Transportation costs can vary widely, influenced by distance, mode of transport, and shipping regulations. International buyers must consider these logistics costs when calculating total expenditure.

-

Margin: Supplier margins will fluctuate based on market demand and competition. Understanding the typical markup in the industry can help buyers negotiate better terms.

How Do Price Influencers Affect Sourcing Costs for Door Handle Parts?

Several factors can influence the pricing of door handle parts:

-

Volume/MOQ (Minimum Order Quantity): Larger orders usually lead to lower per-unit costs. Negotiating favorable terms for bulk purchases can significantly reduce the overall expenditure.

-

Specifications and Customization: Custom designs or specialized features may increase costs. Buyers should weigh the benefits of customization against the additional costs incurred.

-

Materials: The choice of materials directly affects pricing. High-end finishes and durable materials can elevate costs, making it essential to balance quality with budget constraints.

-

Quality and Certifications: Certifications such as ISO or other industry-specific standards can add to the cost but often assure buyers of quality and compliance. Understanding the importance of these certifications can aid in decision-making.

-

Supplier Factors: The supplier’s reputation, production capabilities, and location can impact pricing. Established suppliers may command higher prices due to their reliability and quality assurance.

-

Incoterms: The shipping terms (Incoterms) agreed upon can influence total costs. Buyers must understand the implications of terms like FOB (Free on Board) and CIF (Cost, Insurance, and Freight) on their overall expenditure.

What Buyer Tips Can Help in Negotiating Costs for Door Handle Parts?

B2B buyers can adopt several strategies to negotiate better pricing and ensure cost efficiency:

-

Negotiate Effectively: Establishing a good rapport with suppliers can open avenues for negotiation. Discussing volume discounts or long-term partnerships can lead to more favorable pricing.

-

Evaluate Total Cost of Ownership (TCO): Instead of focusing solely on the purchase price, consider the TCO, which includes maintenance, durability, and potential replacement costs. This broader view can influence purchasing decisions.

-

Understand Pricing Nuances for International Buyers: Different regions may have varying pricing standards influenced by local economies, tariffs, and import regulations. Buyers from Africa, South America, the Middle East, and Europe should conduct thorough market research to understand these nuances.

-

Request Quotes from Multiple Suppliers: Gathering quotes from various suppliers allows for better comparison and negotiation leverage. Be transparent about your needs to receive the most accurate pricing.

-

Stay Informed About Market Trends: Keeping abreast of industry trends, material costs, and supplier innovations can provide valuable insights for making informed purchasing decisions.

Disclaimer

The pricing information provided in this analysis is indicative and can fluctuate based on market conditions, supplier negotiations, and specific buyer requirements. Always consult with suppliers for the most accurate and current pricing structures.

Alternatives Analysis: Comparing door handle parts names With Other Solutions

Exploring Alternatives to Traditional Door Handle Parts Names

In the realm of door hardware, understanding the various components and their terminologies is essential for effective communication and procurement. However, as the industry evolves, alternative solutions and technologies are emerging that can enhance or even replace traditional door handle parts. This section will compare conventional door handle parts names with two viable alternatives: smart locking systems and electronic access control solutions.

Comparison Table

| Comparison Aspect | Door Handle Parts Names | Smart Locking Systems | Electronic Access Control Solutions |

|---|---|---|---|

| Performance | Reliable mechanical function with physical keys or knobs. | Offers keyless entry, remote access, and activity logs. | Provides controlled access to multiple users, often managed centrally. |

| Cost | Generally lower initial cost, varying by material and design. | Higher upfront investment; potential long-term savings on key management. | Higher installation and maintenance costs, but scalable for larger operations. |

| Ease of Implementation | Simple installation for most standard doors. | May require professional installation depending on complexity. | Often needs professional installation and integration with existing systems. |

| Maintenance | Minimal; primarily cleaning and occasional lubrication. | Requires software updates and battery replacements. | Requires ongoing management and potential software updates; may need technical support. |

| Best Use Case | Residential and commercial properties where traditional access is preferred. | Ideal for tech-savvy users or properties requiring flexible access management. | Best suited for large facilities, corporate offices, and high-security environments. |

Detailed Breakdown of Alternatives

1. Smart Locking Systems

Smart locking systems are revolutionizing door access by providing keyless entry through mobile apps, biometric scans, or keypad codes. The primary advantage is the convenience and flexibility they offer; users can grant access remotely and monitor entry logs, which is particularly beneficial for rental properties or shared spaces. However, the initial investment can be significant, and ongoing maintenance involves keeping software updated and batteries charged. This option is ideal for tech-savvy users looking to enhance security and convenience without relying solely on traditional keys.

2. Electronic Access Control Solutions

Electronic access control systems go a step further by integrating access management into a centralized software platform. These systems allow for multi-user management, where access can be granted or revoked in real-time, making them suitable for larger organizations. The primary benefits include enhanced security and administrative control over who enters specific areas. However, the complexity of installation and the higher costs associated with these systems can be a drawback for smaller businesses. This solution is best for enterprises that require strict access control and the ability to manage numerous users efficiently.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate door hardware solution, B2B buyers must consider their specific requirements, including budget constraints, the level of security needed, and the desired convenience of access. Traditional door handle parts names may suffice for straightforward applications, while smart locks and electronic access control solutions offer advanced features that cater to modern security challenges. Ultimately, the decision should align with the operational needs of the business, the technological readiness of the users, and the potential for future scalability. Prioritizing these factors will ensure that the chosen solution effectively meets both current and future demands.

Essential Technical Properties and Trade Terminology for door handle parts names

What Are the Key Technical Properties of Door Handle Parts?

Understanding the technical specifications of door handle components is crucial for B2B buyers, especially when sourcing products for international markets. Here are some essential properties to consider:

-

Material Grade

– The material used in door handle parts can significantly impact durability and performance. Common materials include stainless steel, brass, and zinc die-cast. Stainless steel is preferred for its corrosion resistance and strength, making it ideal for exterior applications. Buyers must assess the material grade to ensure it meets their quality and durability standards. -

Tolerance Levels

– Tolerance refers to the allowable deviation in dimensions during manufacturing. Tight tolerances ensure that parts fit together correctly and function smoothly. For instance, door handles must fit precisely into their respective locks and latches. When sourcing, buyers should confirm that the manufacturer can meet specified tolerances to prevent assembly issues and ensure long-term reliability. -

Finish Type

– The finish of door handle parts affects both aesthetics and functionality. Common finishes include polished, brushed, or coated options that enhance appearance and resist wear. A suitable finish can prevent corrosion, tarnishing, and scratching, essential for maintaining the product’s look and longevity, particularly in high-traffic areas. -

Load Capacity

– This property indicates the maximum weight a door handle can support without failure. It is particularly important for commercial applications where handles may be subject to frequent and heavy use. Buyers should verify load capacity specifications to ensure safety and reliability, especially in public buildings or facilities. -

Security Features

– Many door handle components incorporate advanced security features, such as anti-pick cylinders and reinforced materials. Understanding these features is vital for buyers concerned with safety and theft prevention. When sourcing for markets with higher security needs, such as commercial or governmental applications, buyers should prioritize products with robust security features.

What Trade Terminology Should B2B Buyers Know?

Familiarity with industry terminology can streamline the sourcing process and facilitate better communication with suppliers. Here are key terms that B2B buyers should be aware of:

-

OEM (Original Equipment Manufacturer)

– An OEM refers to a company that produces parts and equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers seeking specific quality standards and compatibility with existing products. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest number of units that a supplier is willing to sell. This term is significant for buyers to understand their purchasing constraints and negotiate better terms. Knowing the MOQ helps in planning inventory and managing cash flow. -

RFQ (Request for Quotation)

– An RFQ is a document sent to suppliers to solicit price quotes for specific products or services. It is a critical step in the procurement process, allowing buyers to compare costs and make informed purchasing decisions. A well-structured RFQ can result in better pricing and terms. -

Incoterms (International Commercial Terms)

– Incoterms are a set of international rules that define the responsibilities of sellers and buyers in shipping goods. Familiarity with these terms is essential for international buyers to understand shipping costs, insurance, and risk during transit. -

Lead Time

– Lead time refers to the time taken from placing an order to receiving it. For B2B buyers, understanding lead times is crucial for inventory management and project planning. Longer lead times may affect production schedules, so buyers should factor this into their procurement strategies. -

Certification Standards

– Certification standards, such as ISO or ANSI, indicate that products meet specific quality and safety benchmarks. Buyers should look for these certifications to ensure they are sourcing reliable and compliant products, especially when operating in regulated markets.

By grasping these technical properties and trade terminologies, B2B buyers can make more informed decisions when sourcing door handle parts, ensuring they meet quality, functionality, and regulatory standards while optimizing their supply chain.

Navigating Market Dynamics and Sourcing Trends in the door handle parts names Sector

What Are the Key Market Dynamics and Trends Influencing Door Handle Parts Names?

The global market for door handle parts is shaped by several significant drivers that influence B2B sourcing strategies. Key trends include the increasing demand for customized solutions, driven by the rise of smart home technologies and the integration of IoT (Internet of Things) in building security. International buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly looking for innovative designs that not only serve functional purposes but also enhance aesthetic appeal. Additionally, the push for energy-efficient and sustainable building practices is leading to a surge in demand for door hardware that meets these criteria.

Emerging B2B technologies are also transforming the sourcing landscape. E-commerce platforms are becoming essential for international buyers, providing access to a wider range of products and suppliers. This trend is particularly pronounced in regions such as Brazil and Saudi Arabia, where local manufacturers are expanding their offerings to compete with international brands. Moreover, data analytics and AI are being employed to predict market needs, optimize inventory, and enhance customer experiences, making the procurement process more efficient.

How Is Sustainability and Ethical Sourcing Affecting the Door Handle Parts Names Sector?

Sustainability and ethical sourcing are increasingly becoming focal points in the door handle parts industry. The environmental impact of manufacturing processes, including resource extraction and waste generation, is prompting buyers to seek suppliers that prioritize eco-friendly practices. Sustainable materials, such as recycled metals and responsibly sourced wood, are gaining traction, reflecting a broader trend toward green construction practices.

For international buyers, particularly those in regions with stringent environmental regulations, understanding the importance of certifications such as LEED (Leadership in Energy and Environmental Design) and FSC (Forest Stewardship Council) can significantly influence sourcing decisions. These certifications not only validate the sustainability of products but also enhance the reputation of businesses that prioritize ethical supply chains. As consumers increasingly demand transparency regarding the origins and environmental impacts of their purchases, B2B buyers must adapt by partnering with suppliers who align with these values.

How Has the Door Handle Parts Names Sector Evolved Over Time?

The evolution of door handle parts can be traced back to the early days of architectural hardware, where functionality was the primary concern. Over time, as construction techniques and materials advanced, so too did the complexity and design of door hardware. The introduction of new materials, such as brass and stainless steel, enhanced durability and aesthetics, making door handles a key element of interior design.

In recent decades, the rise of technology has further transformed the sector, with smart locks and electronic door hardware becoming increasingly common. This shift not only reflects changing consumer preferences but also highlights the need for B2B buyers to stay abreast of technological advancements in the market. As global markets continue to integrate advanced solutions, understanding the historical context of door handle parts will enable buyers to make informed sourcing decisions that cater to modern demands.

Illustrative image related to door handle parts names

Frequently Asked Questions (FAQs) for B2B Buyers of door handle parts names

-

How do I solve issues with door handle parts compatibility?

To solve compatibility issues with door handle parts, first, ensure you know the standard door preparation specifications, such as bore hole and cross bore dimensions. Measure the backset, which is the distance from the edge of the door to the center of the bore hole. Communicate these specifications to suppliers to confirm that the parts you are ordering will fit your existing doors. Additionally, inquire if the supplier offers adjustable components that can accommodate variations in door preparation. -

What is the best door handle for high-security applications?

For high-security applications, a deadbolt paired with a keyed entry door handle is recommended. Deadbolts provide an additional layer of security, as they extend deep into the door frame. Look for models that are ANSI Grade 1 certified, which indicates superior strength and durability. Ensure that the handle and deadbolt have matching keyways to simplify key management and enhance security. -

What customization options are available for door handle parts?

Customization options for door handle parts often include finishes, materials, and specific dimensions. Many manufacturers allow you to choose from a variety of finishes, such as polished brass, brushed nickel, or matte black, to match your project’s aesthetic. Additionally, you can specify unique sizes or shapes for components like rosettes and levers. Always discuss your customization needs with potential suppliers to confirm their capabilities and lead times. -

What are the typical minimum order quantities (MOQ) for door handle parts?

Minimum order quantities (MOQ) for door handle parts can vary significantly between suppliers and regions. Generally, MOQs can range from 50 to several hundred units, depending on the item and the supplier’s production capabilities. When sourcing internationally, consider negotiating MOQs, especially if you are a smaller buyer or testing new products. Establish clear communication about your needs to find a supplier willing to accommodate your order size. -

What payment terms should I expect when sourcing door handle parts internationally?

Payment terms for international orders can vary based on the supplier and the buyer’s relationship. Common terms include upfront payment, a deposit with the balance due before shipping, or net 30/60/90 days after delivery. It is crucial to discuss and negotiate payment terms upfront to avoid misunderstandings. Additionally, consider using secure payment methods, such as letters of credit, to protect your financial interests. -

How can I ensure quality assurance for door handle parts sourced internationally?

To ensure quality assurance, request samples before placing a bulk order. Conduct inspections during production and upon arrival to verify that products meet your specifications and standards. Many suppliers offer third-party quality assurance services that can perform inspections on your behalf. Additionally, establish a clear return policy in case any products do not meet your quality expectations. -

What logistics considerations should I keep in mind when importing door handle parts?

When importing door handle parts, consider shipping methods, lead times, and customs regulations. Choose between air freight for faster delivery or sea freight for cost-effective options, depending on your timeline. Be aware of customs duties and taxes applicable in your country, and ensure that all documentation is in order to avoid delays. Partnering with a freight forwarder can simplify the logistics process and help manage these aspects effectively. -

How do I vet suppliers for door handle parts in international markets?

To vet suppliers, start by checking their business licenses and certifications to ensure legitimacy. Look for reviews and testimonials from other buyers, and consider requesting references from previous clients. Assess their production capabilities and quality control processes through factory visits or virtual audits. Finally, consider starting with a small order to evaluate the supplier’s reliability and product quality before committing to larger orders.

Top 6 Door Handle Parts Names Manufacturers & Suppliers List

1. Direct Door Hardware – Premium Door Knobs & Levers

Domain: directdoorhardware.com

Registered: 2003 (22 years)

Introduction: Door Hardware Terms: Door Knobs (Modern, Crystal, Thick Doors, 5″ Backset), Lever Handles (Modern, Rustic, Keyless, Thick Doors, 5″ Backset), Deadbolts (Single Cylinder, Double Cylinder, Keyless, Single Sided, Indicator), Handlesets (Thick Doors, Mortise, Keyless), Door Hinges (3 1/2″, 4″, 4 1/2″, Spring, Ball Bearing, Specialty), Door Accessories (Address Plaques, Ball Catches, Door Stops, Flush …

2. DND Hardware – Key Product

Domain: dndhardware.com

Registered: 2008 (17 years)

Introduction: Key Product Details: 1. Exterior Handle: Used for opening and closing outside doors, often part of a handleset, can be made from wood, metal, plastic, or glass. 2. Interior Handle: Designed for comfort and style, used in rooms like bedrooms and offices, not for security. 3. Spindle: Connects both handles and moves the latch bolt when the handle is turned. 4. Latch Mechanism: Keeps the door shut, f…

3. Homebuilders Hardware – Doorknob Components Guide

Domain: homebuildershardware.com

Registered: 2005 (20 years)

Introduction: A Guide to Doorknob Parts and Names includes details about the following components: 1. Handles or Knob Set: Exterior and interior handles or knobs used to open and close the door. 2. Locking and Latch Mechanisms: Mechanisms that allow the door to be locked and opened. 3. Strike Plate: Installed on the doorframe, it provides a secure place for the latch bolt. 4. Faceplate: Surrounds the latch mech…

4. Pinterest – Key Door Knob Parts Guide

Domain: pinterest.com

Registered: 2009 (16 years)

Introduction: Complete guide on 12 key Door Knob/lock Parts: Names & Diagram, covers names, functions, and diagrams, improves house safety & security.

5. DoorCloser – Fast Delivery & Easy Returns

Domain: doorcloser.com

Registered: 1998 (27 years)

Introduction: This company, DoorCloser – Fast Delivery & Easy Returns, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

6. Angi – Door Hardware

Domain: angi.com

Registered: 1996 (29 years)

Introduction: 1. Knob or Lever: The main interface for opening the door, available in various designs and materials. 2. Keyhole and Pin Cylinder: Mechanism for key-operated locks, with pins that correspond to a specific key pattern. 3. Rosette or Backplate: Covers the hole in the door, stabilizes the knob, and provides a clean look. 4. Spindle: Metal rod connecting knobs to the latch, allowing for door operatio…

Strategic Sourcing Conclusion and Outlook for door handle parts names

In the competitive landscape of door hardware, strategic sourcing is essential for international B2B buyers seeking quality and reliability. Understanding the various door handle parts, from knobs to deadbolts, allows buyers to make informed decisions that enhance product offerings. By sourcing from reputable suppliers, businesses can ensure they meet regional standards and customer expectations while optimizing costs.

The growing demand for high-quality door hardware across Africa, South America, the Middle East, and Europe presents significant opportunities for suppliers and buyers alike. Buyers should leverage local insights and supplier capabilities to navigate the complexities of international procurement effectively.

Looking ahead, the door hardware market is poised for innovation, driven by advancements in technology and design. International buyers are encouraged to explore partnerships that prioritize sustainability and efficiency, aligning with global trends. By staying informed and proactive in sourcing strategies, businesses can not only enhance their product lines but also build lasting relationships with suppliers that foster growth and resilience in an evolving market. Embrace the future of door handle parts sourcing—secure your supply chain today for tomorrow’s success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to door handle parts names

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.