How to Source Directory Of Manufacturers Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for directory of manufacturers

In today’s interconnected global economy, sourcing reliable manufacturers can be a daunting challenge for international B2B buyers. Whether you are searching for advanced components for automotive production or durable materials for construction projects, identifying trustworthy suppliers is crucial for maintaining operational efficiency and competitiveness. This comprehensive guide to directories of manufacturers will navigate you through the vast landscape of sourcing, highlighting various types of manufacturing capabilities, applications, and supplier vetting processes.

You will learn how to assess costs effectively and select manufacturers that align with your specific needs, whether you are based in Africa, South America, the Middle East, or Europe. With detailed insights into the latest trends and technologies, this guide empowers you to make informed purchasing decisions, ensuring you connect with the right suppliers who can meet your quality and budget requirements.

By leveraging the information presented in this guide, you can streamline your procurement process, mitigate risks associated with sourcing from unfamiliar markets, and foster strategic partnerships that drive business growth. Prepare to enhance your sourcing strategy and gain a competitive edge by discovering the best practices in navigating the global market for manufacturers.

Understanding directory of manufacturers Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Online Manufacturer Directories | Comprehensive databases with filtering options, user reviews, and direct quotes | Sourcing components, OEM partnerships, market research | Pros: Wide selection, easy access, user-friendly. Cons: Quality varies, potential for outdated information. |

| Industry-Specific Directories | Focused on niche markets, offering tailored supplier lists and industry insights | Specialized procurement, targeted sourcing | Pros: Relevant suppliers, deeper industry knowledge. Cons: Limited options, may lack broader market insights. |

| Trade Association Directories | Listings from recognized industry bodies, often with certification details | Networking, compliance verification | Pros: Credibility, access to vetted suppliers. Cons: May be less comprehensive, fees for membership may apply. |

| Local and Regional Directories | Emphasis on geographically relevant suppliers, often with local support options | Regional sourcing, community partnerships | Pros: Localized service, easier logistics. Cons: Limited to certain areas, may lack global reach. |

| Custom Manufacturing Platforms | Platforms that facilitate bespoke manufacturing services, often with advanced tech capabilities | Custom parts production, prototyping | Pros: Tailored solutions, innovative technologies. Cons: Higher costs, longer lead times. |

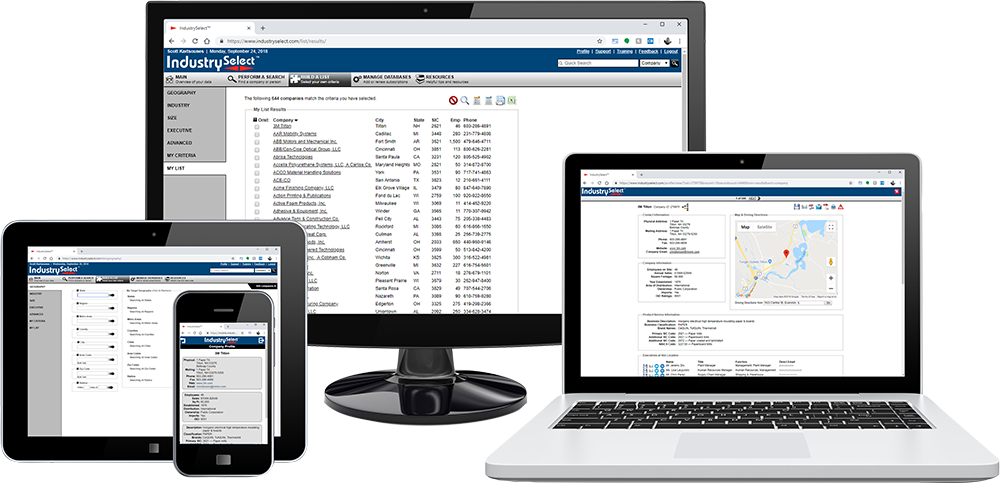

What Are the Characteristics of Online Manufacturer Directories?

Online manufacturer directories serve as vast databases that allow businesses to search for suppliers across various industries. They typically feature filtering options based on capabilities, certifications, and geographical location, enabling buyers to find the most suitable manufacturers quickly. This type of directory is particularly useful for sourcing components or establishing OEM partnerships. However, the quality of listings can vary, and users may encounter outdated information, necessitating due diligence.

How Do Industry-Specific Directories Cater to Niche Markets?

Industry-specific directories focus on particular sectors, providing curated lists of suppliers relevant to that field. These directories often include valuable industry insights and trends, making them indispensable for businesses engaged in specialized procurement. They enable buyers to connect with suppliers who understand their unique needs, enhancing the efficiency of the sourcing process. However, the limited scope may mean fewer options compared to broader directories.

Why Are Trade Association Directories Considered Reliable?

Directories maintained by trade associations offer listings of suppliers that meet certain industry standards and certifications. This adds a layer of credibility, as buyers can trust that these manufacturers adhere to specific quality and compliance requirements. These directories are invaluable for networking and verifying compliance, particularly in regulated industries. However, they may not provide the extensive range of suppliers found in larger directories, and accessing some resources may require membership fees.

Illustrative image related to directory of manufacturers

What Benefits Do Local and Regional Directories Provide?

Local and regional directories highlight suppliers within specific geographic areas, facilitating easier logistics and communication. They are ideal for businesses looking to establish community partnerships or support local economies. The localized nature of these directories can lead to quicker turnaround times and personalized service. However, their limitations in terms of global reach may restrict options for businesses seeking international suppliers.

How Do Custom Manufacturing Platforms Enhance the Sourcing Process?

Custom manufacturing platforms connect buyers with manufacturers capable of producing bespoke parts tailored to unique specifications. These platforms often utilize advanced technologies like 3D printing and CNC machining, allowing for innovative solutions and rapid prototyping. While they provide tailored services that can meet specific requirements, buyers should be prepared for potentially higher costs and longer lead times compared to standard manufacturing processes.

Key Industrial Applications of directory of manufacturers

| Industry/Sector | Specific Application of directory of manufacturers | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Sourcing parts for vehicle assembly and components | Ensures access to high-quality, certified parts to meet safety standards | Consider certifications, lead times, and geographical proximity |

| Aerospace | Finding suppliers for precision components and assemblies | Reduces risk of supply chain disruptions and ensures compliance with aviation regulations | Evaluate supplier reliability, certifications, and past performance |

| Consumer Electronics | Sourcing electronic components and assembly services | Enables faster product development and reduces time to market | Assess component compatibility, supplier capacity, and delivery timelines |

| Industrial Equipment | Identifying manufacturers for machinery and tools | Enhances operational efficiency and reduces downtime through reliable sourcing | Focus on equipment specifications, warranty terms, and maintenance support |

| Medical Devices | Sourcing compliant materials and manufacturing services | Ensures product safety and regulatory compliance in a highly regulated industry | Verify ISO certifications, quality control processes, and material traceability |

How Can Automotive Manufacturers Benefit from a Directory of Manufacturers?

In the automotive sector, a directory of manufacturers is invaluable for sourcing parts required for vehicle assembly, such as engines, transmissions, and electronic systems. International buyers, especially from regions like Africa and South America, often face challenges in finding certified suppliers who meet stringent safety and quality standards. By leveraging a manufacturer directory, these buyers can connect with verified suppliers, ensuring they obtain high-quality parts while reducing the risk of delays in production. Key considerations include checking for necessary certifications, understanding lead times, and evaluating geographical proximity to minimize shipping costs.

What Advantages Do Aerospace Companies Gain from Manufacturer Directories?

Aerospace companies require precision components that must adhere to strict regulatory standards. Using a directory of manufacturers, these businesses can identify suppliers specializing in aerospace-grade materials and components, such as turbine blades and avionics systems. This resource mitigates the risk of supply chain disruptions by connecting buyers with reliable manufacturers who have proven track records. International buyers must consider factors such as supplier reliability, relevant certifications, and historical performance to ensure compliance with aviation regulations and maintain operational integrity.

How Do Consumer Electronics Firms Utilize Manufacturer Directories?

In the fast-paced consumer electronics industry, time-to-market is crucial. A directory of manufacturers facilitates the sourcing of essential electronic components and assembly services, allowing firms to streamline product development processes. This is particularly beneficial for international buyers in emerging markets, who may struggle to find suppliers capable of meeting their specific requirements. When using such directories, companies should prioritize evaluating component compatibility, the manufacturing capacity of suppliers, and adherence to delivery timelines to ensure efficient production cycles.

Illustrative image related to directory of manufacturers

Why Are Directories Essential for Sourcing Industrial Equipment?

Industrial equipment manufacturers rely on directories to identify suppliers of machinery and tools that enhance operational efficiency. By sourcing through these platforms, companies can reduce downtime by ensuring they procure reliable equipment. For international buyers, especially from developing regions, the ability to access a wide range of manufacturers can significantly impact production capabilities. Key sourcing considerations include understanding equipment specifications, warranty terms, and the availability of maintenance support, which are vital for sustaining long-term operations.

How Do Medical Device Manufacturers Benefit from Using Directories?

In the medical device sector, compliance with safety regulations is paramount. A directory of manufacturers helps companies source compliant materials and manufacturing services, ensuring their products meet industry standards. For international buyers, particularly those in regions with strict regulatory environments, finding suppliers who can provide ISO-certified products is essential. Buyers should verify quality control processes, material traceability, and supplier certifications to ensure the safety and efficacy of their medical devices in the global market.

3 Common User Pain Points for ‘directory of manufacturers’ & Their Solutions

Scenario 1: Difficulty in Finding Specialized Manufacturers

The Problem: B2B buyers often struggle to locate manufacturers that offer highly specialized services or products tailored to their unique needs. For instance, a company in the aerospace sector might require specific components that adhere to stringent safety and regulatory standards. Searching through a generic directory can lead to frustration, as many manufacturers listed may not have the necessary certifications or capabilities, resulting in wasted time and resources.

The Solution: To effectively utilize a directory of manufacturers, buyers should start by defining their specific requirements in detail, including technical specifications, certifications, and production capacities. Instead of browsing randomly, use advanced filtering options available in directories to narrow down the search based on industry, product type, and manufacturer capabilities. Additionally, buyers should take advantage of request-for-quote (RFQ) features to directly inquire about the manufacturers’ experience with specialized products. Engaging in this focused approach can help connect buyers with the right suppliers who meet their precise needs efficiently.

Scenario 2: Concerns About Manufacturer Reliability and Quality

The Problem: Many buyers worry about the reliability and quality of manufacturers listed in directories. With the global supply chain being susceptible to disruptions, it’s critical for B2B buyers to ensure that their chosen manufacturers can deliver consistently high-quality products on time. A lack of transparent reviews or ratings can leave buyers feeling uncertain about whom to trust.

Illustrative image related to directory of manufacturers

The Solution: To mitigate these concerns, buyers should leverage directories that provide verified reviews and ratings of manufacturers. Look for directories that feature user-generated feedback and case studies that illustrate the manufacturer’s performance and reliability. Additionally, conducting background checks on potential suppliers is crucial. This may include asking for references from previous clients, reviewing their quality control processes, and even requesting samples of previous work. By combining the insights gained from directory resources with proactive due diligence, buyers can make informed decisions that enhance their supply chain reliability.

Scenario 3: Navigating Language and Cultural Barriers

The Problem: International B2B buyers often face language and cultural barriers when sourcing manufacturers from different regions, such as Africa or South America. Miscommunications can lead to misunderstandings about product specifications, delivery timelines, and pricing, potentially jeopardizing the success of the procurement process.

The Solution: To navigate these challenges, buyers should utilize directories that offer multilingual support or localized services. This can include directories that provide translation tools or connect buyers with suppliers who have multilingual staff. Furthermore, it is beneficial to establish clear communication protocols upfront, such as using visual aids, detailed specifications, and standardized documentation. In addition, utilizing video conferencing tools can help bridge the gap by allowing for real-time discussions, ensuring that both parties have a mutual understanding of expectations. By taking these steps, buyers can foster better relationships with manufacturers, leading to smoother transactions and successful partnerships.

Strategic Material Selection Guide for directory of manufacturers

When selecting materials for manufacturing, understanding the properties, advantages, and limitations of each material is crucial for ensuring product performance and compliance with industry standards. This guide analyzes four common materials used in manufacturing, focusing on their characteristics, applications, and considerations for international B2B buyers.

Illustrative image related to directory of manufacturers

What Are the Key Properties of Aluminum in Manufacturing?

Aluminum is a lightweight metal known for its excellent corrosion resistance and high strength-to-weight ratio. It typically has a temperature rating of up to 600°C and can withstand moderate pressures, making it suitable for various applications, including automotive and aerospace components. Its non-toxic nature and recyclability further enhance its appeal.

Pros and Cons: Aluminum’s durability and resistance to rust make it a popular choice; however, it can be more expensive than other metals like steel. The manufacturing complexity can also be higher due to the need for specialized equipment for processes such as extrusion and anodizing.

Impact on Application: Aluminum is compatible with various media, including water and chemicals, making it suitable for both structural and aesthetic applications. Its lightweight nature contributes to energy savings in transportation.

Considerations for International Buyers: Compliance with standards such as ASTM and ISO is essential. Buyers from regions like Africa and South America should ensure that suppliers can meet local regulations regarding aluminum grades.

How Does Stainless Steel Compare in Terms of Performance?

Stainless steel is renowned for its exceptional corrosion resistance, high tensile strength, and ability to withstand extreme temperatures (up to 1,500°C). It is commonly used in food processing, medical equipment, and construction.

Pros and Cons: The key advantage of stainless steel is its durability and long lifespan, making it a cost-effective option in the long run. However, it can be more expensive upfront than other materials, and its weight may be a disadvantage in applications where weight reduction is critical.

Impact on Application: Stainless steel is compatible with a wide range of media, including acidic and alkaline substances, making it ideal for harsh environments. Its aesthetic appeal also makes it popular in consumer products.

Illustrative image related to directory of manufacturers

Considerations for International Buyers: Buyers should be aware of the various grades of stainless steel and their specific applications. Compliance with international standards such as DIN and JIS is crucial for ensuring quality and performance.

What Are the Benefits of Using Polypropylene in Manufacturing?

Polypropylene (PP) is a thermoplastic polymer known for its chemical resistance, lightweight nature, and flexibility. It can withstand temperatures up to 100°C, making it suitable for various applications, including packaging and automotive parts.

Pros and Cons: The primary advantage of polypropylene is its low cost and ease of manufacturing, allowing for efficient production processes like injection molding. However, it has a lower temperature resistance compared to metals, which may limit its use in high-heat applications.

Impact on Application: Polypropylene is compatible with many chemicals, making it ideal for containers and automotive components. Its lightweight nature contributes to reduced shipping costs.

Illustrative image related to directory of manufacturers

Considerations for International Buyers: Buyers should ensure compliance with local and international standards for plastic materials. Understanding the recycling regulations in their respective regions is also vital for sustainability considerations.

Why Is Copper Important in Electrical Applications?

Copper is a highly conductive metal, making it essential for electrical applications. It has a temperature rating of up to 200°C and excellent corrosion resistance, which is crucial in electrical wiring and components.

Pros and Cons: The key advantage of copper is its superior conductivity, which allows for efficient energy transfer. However, it is relatively expensive compared to aluminum and can be prone to corrosion if not properly treated.

Impact on Application: Copper is ideal for electrical applications, including wiring, motors, and connectors, due to its excellent conductivity and resistance to oxidation.

Considerations for International Buyers: Buyers should verify compliance with electrical standards and regulations in their countries. Understanding the supply chain for copper, especially in regions with limited access, is also essential.

| Material | Typical Use Case for directory of manufacturers | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Automotive parts, aerospace components | Lightweight and corrosion-resistant | Higher manufacturing complexity | Medium |

| Stainless Steel | Food processing equipment, medical devices | Exceptional durability | Higher upfront cost | High |

| Polypropylene | Packaging, automotive parts | Low cost and easy to manufacture | Limited temperature resistance | Low |

| Copper | Electrical wiring and components | Superior conductivity | Expensive compared to aluminum | High |

In-depth Look: Manufacturing Processes and Quality Assurance for directory of manufacturers

What Are the Main Stages of Manufacturing Processes in B2B Production?

Manufacturing processes can be broadly divided into several key stages: material preparation, forming, assembly, and finishing. Each of these stages plays a critical role in ensuring that the final product meets the required specifications and quality standards.

Material Preparation

This initial stage involves the selection and preparation of raw materials. The choice of materials can significantly impact the overall quality and performance of the final product. For instance, metals may need to be treated or alloyed to enhance their properties, while plastics may require specific additives to achieve desired characteristics. Buyers should ensure that suppliers use high-grade materials and that they can provide documentation regarding material certifications.

Forming

The forming stage encompasses various techniques used to shape materials into desired forms. Common methods include:

- Casting: Pouring molten material into molds to create specific shapes.

- Machining: Removing material through processes such as CNC machining, turning, and milling to achieve precise dimensions.

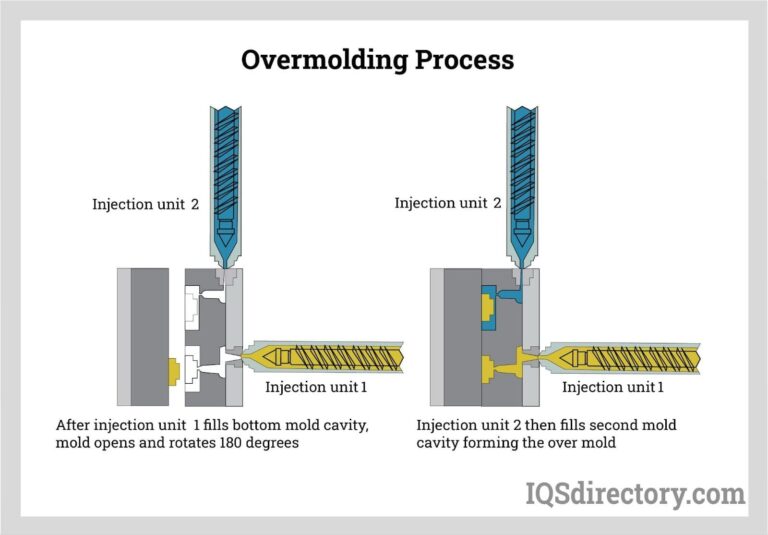

- Molding: Techniques like injection molding, blow molding, and rotational molding are widely used for plastics.

- Additive Manufacturing: Technologies such as 3D printing, which allow for complex geometries and rapid prototyping.

Understanding the forming techniques employed by a manufacturer can help B2B buyers assess the potential quality and suitability of the products for their specific applications.

Illustrative image related to directory of manufacturers

Assembly

In this stage, individual components are put together to create the final product. This may involve mechanical fastening, welding, or adhesive bonding. The assembly process is critical, as it can affect the structural integrity and functionality of the product. Buyers should inquire about the assembly techniques used and whether the manufacturer adheres to industry best practices.

Finishing

Finishing processes enhance the aesthetic and functional properties of the product. This stage may include surface treatments such as painting, plating, or polishing. Finishing is essential for improving durability, corrosion resistance, and overall appearance. B2B buyers should evaluate the finishing capabilities of manufacturers to ensure that the products meet their visual and functional requirements.

How Do Quality Assurance Processes Ensure Manufacturing Excellence?

Quality assurance (QA) is an integral part of the manufacturing process, ensuring that products meet specified standards and regulations. In international trade, adherence to quality standards is particularly vital due to varying regional requirements.

Illustrative image related to directory of manufacturers

What Are the Relevant International and Industry-Specific Standards?

Manufacturers often comply with international standards such as ISO 9001, which outlines the criteria for a quality management system. This certification ensures that organizations consistently provide products that meet customer and regulatory requirements. Additionally, industry-specific certifications, such as CE marking for products sold in the European Economic Area or API standards for the oil and gas industry, may be required.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are critical for identifying defects and ensuring compliance throughout the manufacturing process. Common QC checkpoints include:

- Incoming Quality Control (IQC): Inspecting raw materials upon arrival to verify their compliance with specifications.

- In-Process Quality Control (IPQC): Monitoring production processes at various stages to catch defects early.

- Final Quality Control (FQC): Conducting thorough inspections and tests on finished products before shipment.

These checkpoints help maintain product quality and can significantly reduce the likelihood of defects reaching the customer.

What Common Testing Methods Are Used in Quality Assurance?

Various testing methods are employed to evaluate the quality of products. These methods can include:

Illustrative image related to directory of manufacturers

- Dimensional Inspection: Verifying that products meet specified dimensions using tools such as calipers and gauges.

- Material Testing: Assessing mechanical properties, such as tensile strength and hardness, through standardized tests.

- Functional Testing: Ensuring that the product performs as intended under specific conditions.

- Environmental Testing: Evaluating the product’s resistance to environmental factors, such as temperature and humidity.

Understanding the testing methods used by manufacturers can provide B2B buyers with confidence in the reliability and performance of their products.

How Can B2B Buyers Verify Supplier Quality Control Practices?

B2B buyers can take several steps to verify the quality control practices of potential suppliers:

-

Conduct Audits: Regular audits of suppliers can provide insight into their manufacturing processes and quality assurance protocols. Buyers should consider scheduling on-site visits to assess the facilities and practices firsthand.

-

Request Quality Reports: Suppliers should be able to provide documentation of their quality control processes, including inspection reports and test results. This transparency can help build trust between buyers and suppliers.

-

Utilize Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control processes. These inspections can be particularly valuable for international buyers unfamiliar with local practices.

What Are the Quality Control Nuances for International B2B Buyers?

For B2B buyers operating in diverse markets, understanding the nuances of quality control is essential. Different regions may have varying standards and regulations, which can affect product compliance. Buyers should be aware of:

-

Regional Compliance Requirements: Familiarize themselves with local regulations and standards that may apply to their products, such as safety standards or environmental regulations.

-

Cultural Differences in Quality Perception: Recognize that expectations regarding quality may differ across cultures. Clear communication about quality requirements can help bridge these gaps.

-

Logistical Considerations: International shipping can introduce additional risks, such as damage during transit. Buyers should work with suppliers who have robust packaging and shipping practices to mitigate these risks.

By understanding the manufacturing processes and quality assurance practices, B2B buyers can make informed decisions and establish successful partnerships with manufacturers across the globe.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘directory of manufacturers’

This practical sourcing guide is designed to assist international B2B buyers in effectively navigating directories of manufacturers. By following this step-by-step checklist, buyers can streamline their procurement process and ensure they select the best suppliers for their specific needs.

Step 1: Define Your Technical Specifications

Clearly articulating your technical specifications is essential for narrowing down potential manufacturers. This includes detailing the materials, dimensions, tolerances, and any other specific requirements pertinent to your product. A well-defined specification helps manufacturers understand your needs and ensures that you receive accurate quotations.

Step 2: Conduct Market Research

Before diving into manufacturer directories, take the time to conduct thorough market research. Identify key players in your industry, understand current trends, and determine the geographical strengths of different manufacturers. This foundational knowledge will guide your search and help you focus on suppliers that align with your business goals.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for:

– Certifications: Ensure suppliers hold relevant industry certifications that demonstrate compliance with international standards.

– Experience: Assess their experience with similar products to gauge their capability.

Step 4: Check Supplier Capabilities and Services

Investigate the manufacturing capabilities of potential suppliers. This includes understanding their production processes, technology, and equipment. Ensure they can meet your specific needs by looking for:

– Diverse Manufacturing Processes: Suppliers should offer processes like CNC machining, injection molding, or 3D printing, depending on your requirements.

– Quality Assurance Practices: Confirm that they have robust quality control measures in place to maintain product standards.

Step 5: Request Quotes and Compare Pricing

Once you have shortlisted potential suppliers, request detailed quotes. Compare not only the prices but also the terms of service, lead times, and payment options. A comprehensive comparison will help you make an informed decision based on cost-effectiveness and supplier reliability.

Illustrative image related to directory of manufacturers

Step 6: Verify Supplier Reputation and Reliability

Research the reputation of your shortlisted suppliers through online reviews, industry forums, and feedback from past clients. A supplier’s reputation can significantly impact your procurement process. Look for:

– Customer Testimonials: Positive feedback can indicate a supplier’s reliability and quality.

– Industry Presence: Suppliers with a strong industry presence are often more trustworthy.

Step 7: Establish Communication and Relationship Management

Effective communication is crucial for successful supplier relationships. Ensure that the supplier is responsive and willing to engage in ongoing dialogue about your needs. Establishing a good rapport can facilitate smoother transactions and better problem resolution in the future.

By following these steps, international B2B buyers can effectively utilize directories of manufacturers to find reliable partners that meet their specific procurement needs. This structured approach not only saves time but also enhances the quality of supplier selection.

Comprehensive Cost and Pricing Analysis for directory of manufacturers Sourcing

What are the Key Cost Components in Sourcing from a Directory of Manufacturers?

Understanding the cost structure associated with sourcing from a directory of manufacturers is crucial for B2B buyers. The primary components include:

-

Materials: The quality and type of raw materials significantly influence costs. Specialty materials or those with limited availability tend to be more expensive. Additionally, fluctuations in global commodity prices can impact material costs unpredictably.

-

Labor: Labor costs vary by region and manufacturing process. For instance, countries with lower labor costs may provide a competitive advantage but may also raise concerns regarding quality and compliance with international labor standards.

-

Manufacturing Overhead: This encompasses all indirect costs associated with production, including utilities, depreciation, and facility maintenance. Efficient production processes can minimize overhead, thus reducing overall costs.

-

Tooling: Custom tooling can be a significant upfront investment, especially for specialized parts. This cost must be factored into the total pricing, particularly for low-volume production runs.

-

Quality Control (QC): Robust QC processes ensure that products meet specified standards, but they come with associated costs. Buyers should assess the level of QC implemented by manufacturers to align with their quality expectations.

-

Logistics: Shipping, handling, and insurance costs can add significantly to the total cost of ownership. International logistics may involve customs duties and tariffs that vary by region, impacting overall pricing.

-

Margin: Manufacturers typically build a profit margin into their pricing, which can vary widely based on competition, product type, and market demand.

How Do Price Influencers Affect Sourcing Decisions?

Several factors can influence pricing in the B2B manufacturing sector, particularly for international buyers:

Illustrative image related to directory of manufacturers

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs due to economies of scale. Conversely, smaller orders may attract higher prices, making it essential for buyers to negotiate MOQs that align with their needs.

-

Specifications and Customization: Customized products tend to incur higher costs than standard offerings. Buyers should clearly define their specifications to avoid unexpected charges.

-

Materials and Quality Certifications: The choice of materials impacts both cost and quality. Moreover, products with industry-standard certifications may command a premium price due to the assurance of quality and compliance.

-

Supplier Factors: The reputation and reliability of suppliers can also influence pricing. Established manufacturers with a track record of delivering quality products might charge more, but they can also reduce risk.

-

Incoterms: Understanding Incoterms is essential for international transactions. These terms dictate the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs, which can significantly affect overall costs.

What Are Effective Buyer Tips for Sourcing from Manufacturer Directories?

For international B2B buyers, especially those from Africa, South America, the Middle East, and Europe, effective sourcing strategies can lead to substantial cost savings:

-

Negotiation: Always approach negotiations with a clear understanding of your budget and the market rates for similar products. Leverage competing quotes to negotiate better terms.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO) rather than just the initial price. This includes ongoing costs such as maintenance, logistics, and potential downtime due to quality issues.

-

Pricing Nuances: Be aware of the pricing nuances that may arise from currency fluctuations, import taxes, and shipping delays. These factors can significantly impact the final cost of products sourced internationally.

-

Research and Due Diligence: Utilize directories effectively by researching manufacturers thoroughly. Review their capabilities, customer feedback, and compliance with industry standards to make informed decisions.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and service. Regular communication and collaboration can also foster trust and reliability.

By understanding these cost components, price influencers, and effective sourcing strategies, B2B buyers can navigate the complexities of sourcing from manufacturer directories more effectively. Always remember that indicative prices should be treated as a starting point for negotiations, as actual costs can vary based on numerous factors.

Alternatives Analysis: Comparing directory of manufacturers With Other Solutions

Understanding the Alternatives to Manufacturer Directories

When sourcing manufacturers, B2B buyers have several options beyond traditional directories. While directories of manufacturers provide a comprehensive database of suppliers, other solutions can offer different advantages based on specific business needs. This analysis compares directories of manufacturers to two viable alternatives: Supplier Relationship Management (SRM) software and online marketplaces.

Comparison Table

| Comparison Aspect | Directory Of Manufacturers | Supplier Relationship Management (SRM) Software | Online Marketplaces |

|---|---|---|---|

| Performance | High; extensive database of verified suppliers | Medium; relies on user input and data quality | High; dynamic listings with real-time updates |

| Cost | Typically low or free access | Moderate to high; subscription or licensing fees | Variable; often free to access, but transaction fees apply |

| Ease of Implementation | Easy; straightforward search features | Moderate; requires training and integration | Easy; user-friendly interfaces for quick transactions |

| Maintenance | Low; minimal upkeep required | High; ongoing updates and management needed | Low; platforms manage listings and transactions |

| Best Use Case | Comprehensive sourcing for diverse needs | Managing ongoing supplier relationships and performance | Quick transactions and immediate sourcing |

What Are the Benefits and Drawbacks of Supplier Relationship Management (SRM) Software?

Supplier Relationship Management (SRM) software focuses on managing interactions with suppliers to maximize value from those relationships. One of the main advantages of SRM is its ability to centralize supplier information and performance metrics, allowing for informed decision-making. However, it typically requires a higher initial investment and ongoing maintenance, which may not be suitable for smaller businesses or those with less complex supplier networks. Additionally, the effectiveness of SRM heavily depends on accurate data entry and user engagement, which can be a challenge.

How Do Online Marketplaces Compare to Directories of Manufacturers?

Online marketplaces, such as Alibaba or Amazon Business, provide a platform for buyers to find suppliers and purchase products directly. One significant benefit of these platforms is the ability to view real-time inventory and pricing, making it easier for buyers to make swift purchasing decisions. However, while they offer convenience, the quality and reliability of suppliers can vary widely, as many are not vetted to the same extent as those listed in dedicated directories. This variance can lead to risks in product quality and supply chain reliability.

Illustrative image related to directory of manufacturers

Conclusion: Which Solution is Right for Your B2B Sourcing Needs?

Choosing the right sourcing solution depends on your specific business requirements and operational context. If your priority is comprehensive data on a wide range of manufacturers, a directory may be the best fit. For businesses that prioritize ongoing supplier relationships and performance management, SRM software might be more appropriate. Conversely, for immediate procurement needs and real-time pricing, online marketplaces can offer the speed and flexibility required. Ultimately, assessing the unique needs of your business, including budget constraints, supplier management capabilities, and sourcing goals, will guide you in selecting the most effective solution for your manufacturing sourcing strategy.

Essential Technical Properties and Trade Terminology for directory of manufacturers

What Are the Essential Technical Properties in a Manufacturer Directory?

Understanding the critical technical properties of manufacturing processes is vital for B2B buyers to make informed purchasing decisions. Here are some key specifications that every buyer should consider:

Material Grade

Material grade refers to the classification of materials based on their properties and performance characteristics. Common grades include stainless steel, aluminum, and various plastics. Knowing the material grade is essential as it directly impacts product durability, strength, and suitability for specific applications. Buyers should ensure that the manufacturers provide detailed material specifications to avoid compatibility issues in their projects.

Tolerance

Tolerance defines the allowable deviation from a specified dimension in manufacturing. It is crucial for ensuring that parts fit together correctly in assemblies. For instance, tighter tolerances are often required in precision engineering applications. Understanding tolerances helps buyers gauge the precision capabilities of a manufacturer and ensures that the final product meets quality and performance standards.

Surface Finish

Surface finish describes the texture and quality of a surface after manufacturing. Common finishes include polished, anodized, or painted. The choice of surface finish can affect not only the aesthetic appeal but also the performance characteristics, such as corrosion resistance and friction properties. Buyers should specify their surface finish requirements to manufacturers to ensure the final product meets their operational needs.

Illustrative image related to directory of manufacturers

Load Capacity

Load capacity refers to the maximum weight or force a product can safely support. This property is especially important in structural applications, such as machinery and equipment. Knowing the load capacity ensures that buyers select the right components for their specific applications, preventing failures and enhancing safety.

Dimensional Accuracy

Dimensional accuracy indicates how closely a manufactured part matches its intended design specifications. It is measured in terms of tolerances and is crucial for ensuring that parts fit together seamlessly in an assembly. Buyers should assess a manufacturer’s capability to achieve the required dimensional accuracy, as it can significantly impact product performance and reliability.

What Are Common Trade Terms in the Manufacturing Industry?

Familiarity with industry jargon can greatly enhance communication between buyers and manufacturers. Here are some essential trade terms to know:

OEM (Original Equipment Manufacturer)

An OEM is a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is critical for buyers looking for specific components or seeking to integrate parts into their products. It helps in identifying reliable suppliers who can deliver quality components that meet industry standards.

Illustrative image related to directory of manufacturers

MOQ (Minimum Order Quantity)

MOQ refers to the minimum number of units that a manufacturer is willing to produce or sell. This term is crucial for buyers as it affects inventory management and cost-effectiveness. Understanding MOQs allows buyers to plan their purchases effectively, ensuring they do not overstock or understock essential components.

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and availability for specific products or services. It is a critical tool for buyers to compare costs and capabilities among different manufacturers. A well-structured RFQ can streamline the procurement process and help in securing favorable terms.

Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in shipping goods. They clarify who is responsible for transportation costs, insurance, and risk during shipping. Understanding Incoterms is essential for buyers engaged in international trade, as they can significantly impact total landed costs.

Lead Time

Lead time is the period required from the initiation of an order until its completion. It encompasses manufacturing, assembly, and shipping times. For B2B buyers, understanding lead times is crucial for planning and ensuring timely delivery of products, particularly in industries where time-sensitive projects are commonplace.

By grasping these technical properties and industry terms, B2B buyers can better navigate the manufacturing landscape, fostering more effective partnerships and ensuring successful procurement strategies.

Navigating Market Dynamics and Sourcing Trends in the directory of manufacturers Sector

What Are the Key Trends Shaping the Directory of Manufacturers Sector?

The landscape of the directory of manufacturers is continually evolving, driven by several global factors. One significant driver is the increasing demand for local sourcing, particularly in emerging markets in Africa and South America, as companies seek to reduce lead times and transportation costs. This trend is further enhanced by political and economic shifts that encourage local production and consumption. Additionally, the digital transformation of supply chains, facilitated by technologies such as artificial intelligence and machine learning, is reshaping how buyers interact with manufacturers. These technologies allow for more efficient supplier discovery, better demand forecasting, and streamlined communication, creating a more agile marketplace.

Emerging B2B tech trends include the rise of platforms that provide not just directories but also integrated solutions for procurement, such as real-time data analytics and automated quote requests. For international buyers, particularly in regions like the Middle East and Europe, the ability to filter suppliers by certifications, capabilities, and geographical proximity is becoming increasingly important. This capability not only enhances supplier selection but also mitigates risks associated with geopolitical instability and supply chain disruptions.

How Are Sustainability and Ethical Sourcing Influencing B2B Manufacturing?

Sustainability has become a cornerstone of modern B2B practices, with an emphasis on ethical sourcing gaining traction in the directory of manufacturers sector. International buyers are increasingly aware of the environmental impact of their sourcing decisions, leading to a growing preference for manufacturers that prioritize sustainable practices. This includes the adoption of green certifications and the use of eco-friendly materials, which are now critical factors in the supplier selection process.

Illustrative image related to directory of manufacturers

The importance of ethical supply chains cannot be overstated. Buyers are not only looking for cost-effective solutions but are also demanding transparency regarding labor practices and environmental stewardship. Manufacturers that can demonstrate compliance with international standards and certifications, such as ISO 14001 for environmental management or Fair Trade certifications, will have a competitive edge. This shift towards sustainable and ethical sourcing is not merely a trend but a fundamental change in how businesses operate, as buyers increasingly align their purchasing decisions with their corporate social responsibility goals.

How Has the Directory of Manufacturers Evolved Over Time?

The directory of manufacturers has undergone significant evolution since its inception. Initially, these directories served as simple listings, primarily in print format, offering limited information about manufacturers and their products. However, with the advent of the internet and digital technology, these directories transformed into comprehensive online platforms that provide extensive details about suppliers, including capabilities, certifications, and customer reviews.

Today, directories are not just about listing manufacturers but also about facilitating connections and enhancing the purchasing experience for B2B buyers. They have become vital tools in the sourcing process, allowing businesses to conduct extensive research and make informed decisions. The integration of advanced search functionalities and real-time data analytics has further enhanced their utility, making them indispensable resources for international buyers navigating complex global supply chains. This evolution reflects the growing sophistication of the manufacturing sector and the increasing demands placed upon suppliers to deliver value beyond just products.

Illustrative image related to directory of manufacturers

Frequently Asked Questions (FAQs) for B2B Buyers of directory of manufacturers

-

How do I find reliable manufacturers in a directory?

To find reliable manufacturers, start by using established directories that have verified listings, such as ThomasNet or MFG.com. Look for manufacturers that have positive reviews, certifications, and a solid portfolio showcasing their capabilities. Utilize filters to narrow down your search by industry, location, and specific manufacturing processes. Request quotes and ask for references to ensure the manufacturer meets your quality and service expectations. -

What is the best directory of manufacturers for international sourcing?

The best directory for international sourcing often depends on your specific needs. For diverse product categories and global reach, ThomasNet and IQS Directory are excellent choices. If you require specialized manufacturing processes, MFG.com provides focused search capabilities. Research the directory’s user interface, search functionalities, and customer support to determine which one aligns with your sourcing strategy. -

How do I vet manufacturers from a directory?

Vetting manufacturers requires thorough research. Begin by reviewing their company profile, looking for certifications, industry experience, and customer testimonials. Schedule direct communication to discuss your specific needs and gauge their responsiveness. Additionally, ask for samples or case studies of previous work to evaluate their capabilities and quality standards. Consider visiting the manufacturer’s facility if feasible, or use third-party auditing services for a comprehensive assessment. -

What customization options should I expect from manufacturers?

Most manufacturers offer varying degrees of customization, including material selection, design modifications, and tailored production processes. When sourcing, clearly communicate your requirements and inquire about their ability to accommodate them. Some manufacturers may have minimum order quantities (MOQs) for customized products, so ensure you understand their policies and capabilities before committing. -

What are the typical minimum order quantities (MOQs) for manufacturers?

MOQs can vary significantly depending on the manufacturer and the type of product. Some manufacturers may allow small batches for prototyping, while others may require larger orders to justify production costs. It’s essential to discuss MOQs upfront to align your purchasing strategy with the manufacturer’s requirements. This can also influence your negotiation on pricing and payment terms. -

What payment terms are common when working with manufacturers?

Payment terms can differ based on the manufacturer’s policies and your negotiation. Common arrangements include upfront deposits (usually 30-50%), payment upon delivery, or net terms (e.g., net 30 or net 60 days). International transactions may involve additional considerations such as currency exchange and payment methods (e.g., wire transfers, letters of credit). Always clarify payment terms before placing an order to avoid misunderstandings. -

How can I ensure quality assurance (QA) when sourcing from manufacturers?

To ensure quality assurance, establish clear quality standards and specifications before production begins. Discuss QA processes with the manufacturer, including inspections at various stages of production. Consider implementing third-party quality audits or inspections, especially for international sourcing. Additionally, request documentation of quality certifications (e.g., ISO) to confirm the manufacturer’s commitment to quality management. -

What logistics considerations should I keep in mind when sourcing internationally?

Logistics plays a crucial role in international sourcing. Consider shipping methods, lead times, and customs regulations that may affect delivery. Discuss with the manufacturer who will handle logistics and whether they offer freight services. Evaluate costs associated with shipping, tariffs, and insurance to budget accurately. Finally, ensure that you have a reliable logistics partner to manage the supply chain and mitigate risks associated with international shipping.

Top 4 Directory Of Manufacturers Manufacturers & Suppliers List

1. MFG.com – Comprehensive Manufacturing Solutions

Domain: mfg.com

Registered: 1991 (34 years)

Introduction: Manufacturing Services: 3D Printing, CNC Machining, Engineering and Design Services, Injection Molding, Sheet Metal Fabrication, Stamping. 3D Printing Capabilities: Direct Metal Laser Sintering (DMLS), Fused Deposition Modeling (FDM), HP Multi-Jet Fusion (MJF), Selective Laser Sintering (SLS), Stereolithography (SLA). Other Manufacturing Processes: Blow Molding, Compression Molding, Die Casting, E…

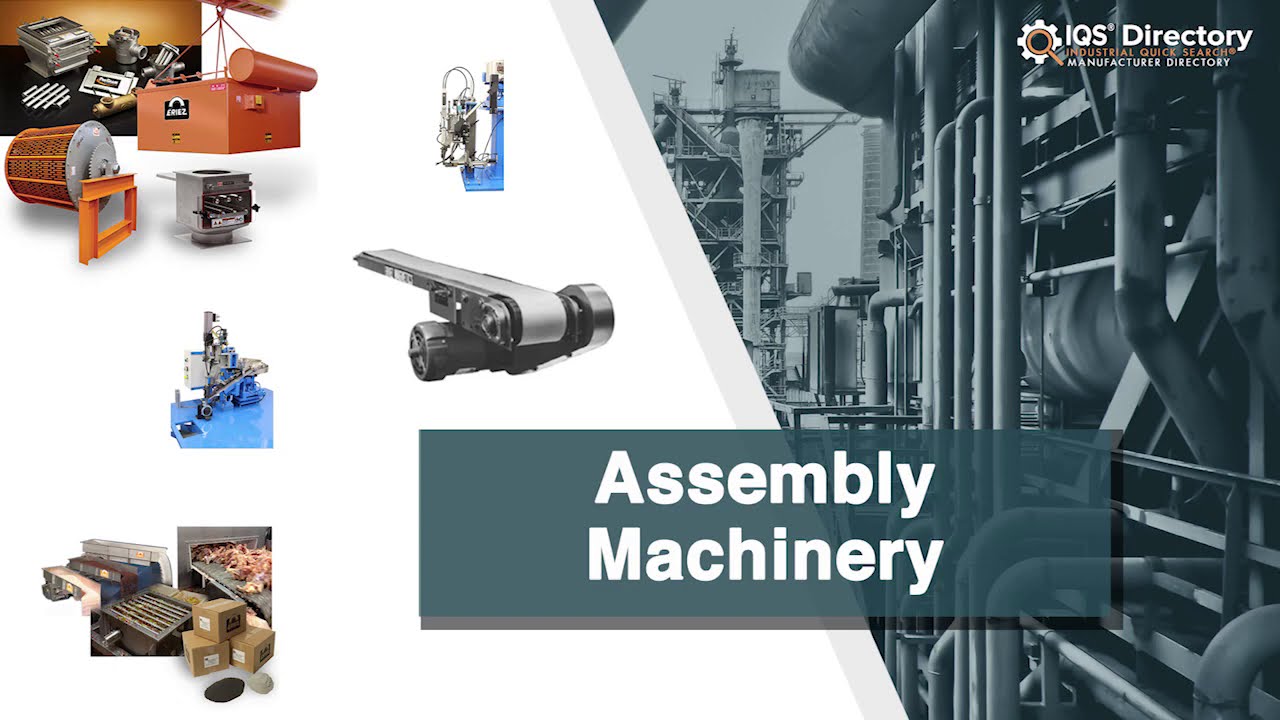

2. IQS Directory – OEM Manufacturing Solutions

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: OEM Manufacturers, OEM Manufacturing Companies, Manufacturing Site Categories, 55 Gallon Drums, Automation Equipment, Automated Guided Vehicles, Air Pollution Control, Aluminum Extrusions, Balers, Blowers, Blow Molding, Boilers, Brushes, Cardboard Tubes, Carrying Cases, Ceramic Machining, Chillers, Clean Rooms, Conveyors, Corrugated Boxes, Crane Manufacturers, Deburring Equipment, Die Castings, Di…

3. Brass – Supplier Directories

Domain: brass.libguides.com

Registered: 2007 (18 years)

Introduction: Directories of Suppliers & Manufacturers: 1. ThomasNet – A leading source of suppliers, equipment, raw materials, and manufacturing services. 2. Logistics Network – An internet gateway to business logistics, providing tools for professionals and a free answer-back service. 3. Logistics World – A transportation and logistics directory that also provides news and tools to assist with logistics. 4. M…

4. MNI – Comprehensive Manufacturer Directory

Domain: mni.net

Registered: 1996 (29 years)

Introduction: This company, MNI – Comprehensive Manufacturer Directory, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for directory of manufacturers

In today’s dynamic global marketplace, strategic sourcing remains a cornerstone for international B2B buyers seeking to optimize their supply chains and enhance competitive advantage. By leveraging comprehensive directories of manufacturers, businesses can identify and engage with suppliers that possess the specific capabilities needed for their operations—whether it be advanced machining, injection molding, or innovative 3D printing technologies.

The diverse range of manufacturers available through these directories enables buyers from Africa, South America, the Middle East, and Europe to source quality products while fostering long-term partnerships. This strategic approach not only mitigates risks associated with supply disruptions but also promotes cost savings and innovation within supply chains.

Looking ahead, as industries continue to evolve with technological advancements and sustainability initiatives, the value of informed sourcing decisions will only increase. Buyers are encouraged to explore the vast resources available in manufacturer directories, ensuring they stay ahead of market trends and meet the demands of their customers. Take action today—begin your journey towards strategic sourcing excellence and unlock new opportunities for growth and collaboration.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.