How to Source Deburring Machine Methods Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for deburring machine methods

In the fast-paced world of manufacturing, sourcing effective deburring machine methods is crucial for maintaining quality and efficiency in production. As industries across Africa, South America, the Middle East, and Europe strive for operational excellence, the challenge of choosing the right deburring solution becomes increasingly complex. With numerous options available—from manual techniques to advanced automated systems—deciding which method best suits your specific needs can feel overwhelming. This guide aims to demystify the various deburring methods, detailing their applications, benefits, and limitations, allowing you to make informed purchasing decisions.

Throughout this comprehensive resource, we will explore the different types of deburring processes, including manual, thermal, electrochemical, and mechanical methods. You will gain insights into how each approach can be tailored to meet your production requirements, enhance part quality, and reduce operational costs. Additionally, we will provide guidance on supplier vetting, helping you identify reputable manufacturers that align with your business goals.

By equipping international B2B buyers with actionable information, this guide empowers you to navigate the global market confidently, ensuring that you select the most suitable deburring machine methods for your operations. Whether you are in Vietnam, Saudi Arabia, or beyond, our expert insights will support your quest for reliability and precision in metalworking.

Understanding deburring machine methods Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Deburring | Utilizes handheld tools for localized burr removal | Small batch production, prototypes | Pros: Low cost, flexibility. Cons: Time-consuming, inconsistent quality. |

| Thermal Deburring | Uses heat and shockwaves to vaporize burrs | High-volume production, complex parts | Pros: Fast, effective on intricate designs. Cons: Limited to specific materials, safety concerns with gases. |

| Cryogenic Deburring | Employs liquid nitrogen to embrittle and remove burrs | Aerospace, automotive components | Pros: Precise, effective for delicate parts. Cons: High operational costs, specialized equipment needed. |

| Electrochemical Deburring | Relies on electrolysis for targeted burr removal | High-precision industries | Pros: Extremely accurate, suitable for hard metals. Cons: Environmental concerns, requires chemical handling. |

| Mechanical Deburring | Automated systems for general grinding and burr removal | Mass production, varied materials | Pros: Scalable, consistent quality, efficient. Cons: Higher initial investment, requires maintenance. |

What Are the Characteristics of Manual Deburring and Its Suitability for B2B Buyers?

Manual deburring is one of the most accessible methods, utilizing simple handheld tools to remove burrs from workpieces. This method is particularly suitable for small batch production or prototype runs, where flexibility and cost-effectiveness are paramount. However, it can be labor-intensive and time-consuming, making it less ideal for high-volume manufacturing. B2B buyers should consider the trade-off between initial costs and the potential impact on operational productivity when evaluating this method.

How Does Thermal Deburring Work and Where Is It Best Applied?

Thermal deburring employs a rapid heat process to vaporize burrs, making it particularly effective for complex geometries and hard-to-reach areas. This method is best suited for high-volume production environments, such as automotive and aerospace industries, where precision is crucial. While it offers quick processing times, buyers should be aware of its limitations, including material compatibility and potential safety hazards associated with the gases produced during the process.

What Are the Advantages of Cryogenic Deburring for Precision Applications?

Cryogenic deburring utilizes liquid nitrogen to embrittle burrs before removal, making it an excellent choice for delicate components in industries such as aerospace and automotive. This method allows for precise burr removal without damaging the workpiece. However, the high operational costs and specialized equipment required may deter some buyers. Companies should assess the value of precision against the investment needed to implement cryogenic deburring effectively.

What Makes Electrochemical Deburring a Unique Choice for High-Precision Industries?

Electrochemical deburring leverages electrolysis to precisely remove burrs from metal components, making it a go-to method for high-precision industries like aerospace and medical device manufacturing. Its ability to target specific areas without affecting the overall part integrity is a significant advantage. However, the environmental implications and the need for chemical handling can complicate its use. B2B buyers must weigh the benefits of accuracy against regulatory compliance and operational considerations.

Why Is Mechanical Deburring Often Preferred for Mass Production?

Mechanical deburring automates the burr removal process, making it suitable for mass production across various materials. It offers scalability and consistent quality, which are critical for manufacturers focused on efficiency. While the initial investment can be higher than manual methods, the long-term savings in labor and time often justify the costs. Buyers should evaluate their production needs, the types of materials processed, and the potential for automation when considering mechanical deburring solutions.

Key Industrial Applications of deburring machine methods

| Industry/Sector | Specific Application of deburring machine methods | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Edge finishing of engine components | Enhances part reliability, reduces friction and wear | Consider machine compatibility with various metal types |

| Aerospace | Deburring of critical flight components | Ensures safety and compliance with strict industry standards | Evaluate precision requirements and certifications needed |

| Electronics | Deburring of circuit boards and connectors | Improves electrical connections and reduces failure rates | Focus on machinery that accommodates small and delicate parts |

| Medical Devices | Deburring of surgical instruments | Ensures patient safety and compliance with health regulations | Assess sterilization capabilities and material compatibility |

| Construction Machinery | Deburring of structural steel components | Increases durability and reduces maintenance costs | Look for machines that can handle large and heavy components |

How is Deburring Machine Methods Used in the Automotive Industry?

In the automotive sector, deburring machine methods are crucial for edge finishing on engine components, such as crankshafts and cylinder heads. These methods eliminate sharp edges that can lead to friction and wear, enhancing the overall reliability of the parts. For international buyers, especially in regions like South America and Europe, sourcing machines that can effectively handle various metal types and ensure consistent quality is vital to maintain production efficiency and reduce costs.

What Role Does Deburring Play in Aerospace Applications?

Deburring is essential in aerospace for processing critical flight components, such as turbine blades and landing gear. The precision required in this industry is paramount, as any imperfection can compromise safety and performance. Buyers from the Middle East and Africa should prioritize machines that meet stringent industry standards and certifications, ensuring they can produce components that withstand rigorous testing and regulatory scrutiny.

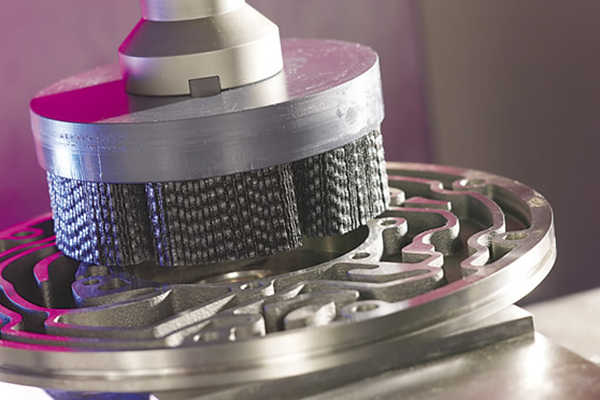

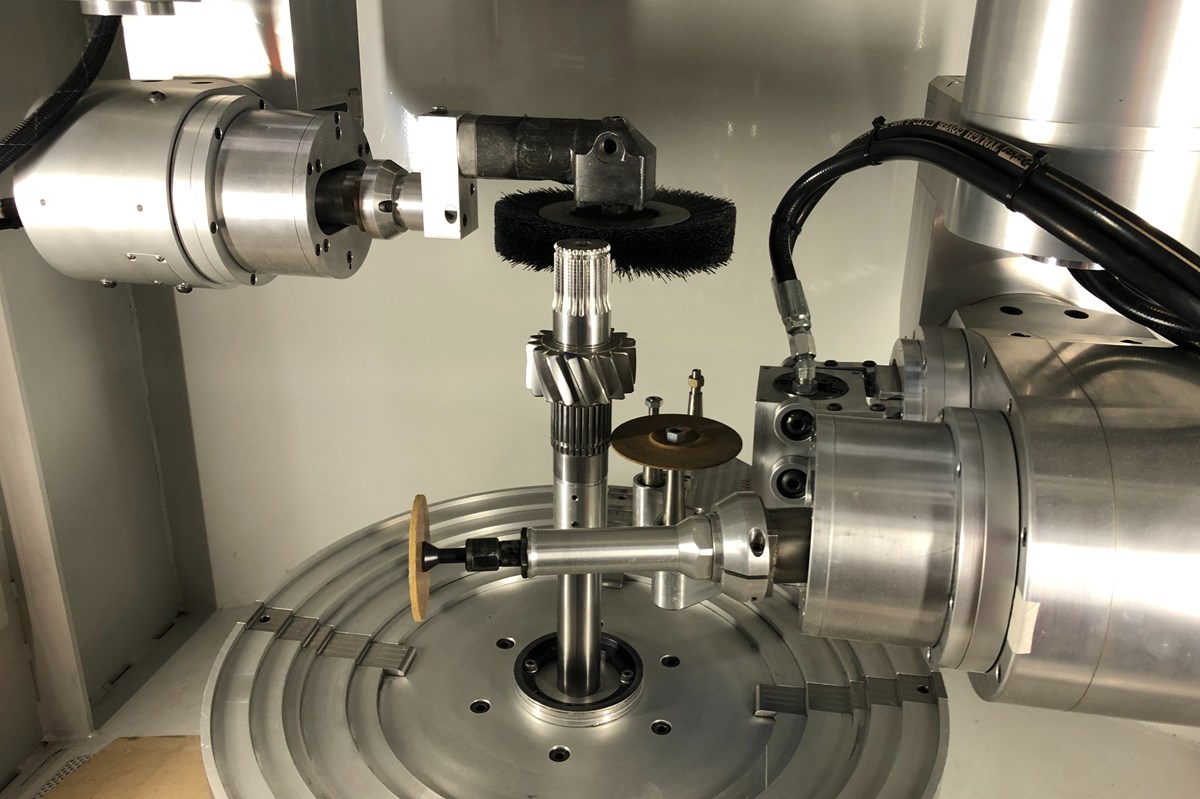

Illustrative image related to deburring machine methods

How is Deburring Used in Electronics Manufacturing?

In electronics, deburring methods are applied to circuit boards and connectors to remove any burrs that could impair electrical connections. This process is vital for reducing failure rates in electronic devices, which can lead to costly recalls and repairs. Buyers, particularly from emerging markets, should seek machinery capable of handling small, delicate parts while maintaining high throughput to meet increasing demand.

Why is Deburring Critical for Medical Devices?

Deburring is a critical process for manufacturing surgical instruments, where sharp edges can pose risks to patient safety. Ensuring that all instruments are free of burrs is essential for compliance with health regulations. Buyers in the medical sector, especially in regions with stringent compliance requirements, should look for deburring solutions that incorporate sterilization capabilities and can work with biocompatible materials.

How Does Deburring Enhance Construction Machinery Durability?

In the construction machinery sector, deburring methods are employed to finish structural steel components, enhancing their durability and reducing maintenance costs. By removing burrs, manufacturers can ensure that these parts fit together smoothly, minimizing wear over time. For international buyers, especially in Africa and South America, sourcing robust deburring machines that can handle large and heavy components is crucial for maintaining operational efficiency and product longevity.

3 Common User Pain Points for ‘deburring machine methods’ & Their Solutions

Scenario 1: Inconsistent Quality of Deburring Results

The Problem: B2B buyers often encounter challenges with achieving consistent quality in deburring results, particularly when using manual or semi-automated methods. For instance, a manufacturer may experience varying surface finishes on parts processed through manual deburring, leading to increased rejection rates and customer complaints. This inconsistency can stem from operator skill levels, variations in tool wear, or lack of standardized processes. As a result, companies face increased costs due to rework, scrap, and missed deadlines.

The Solution: To mitigate these issues, buyers should consider investing in advanced mechanical deburring machines that offer automated processes with built-in quality control features. Look for machines that utilize programmable settings to ensure uniform pressure and speed across all parts. Additionally, sourcing equipment that allows for easy integration with existing workflows can enhance overall productivity. By implementing a standardized deburring process through automation, companies can achieve consistent quality, reduce labor dependency, and ultimately improve throughput.

Scenario 2: High Operational Costs Due to Inefficient Methods

The Problem: Many businesses struggle with high operational costs associated with traditional deburring methods, such as manual scraping or brushing. The time-consuming nature of these methods often leads to labor inefficiencies and increased overtime costs. Moreover, the risk of injuries from repetitive motions can further inflate operational expenses, as companies may incur costs related to worker compensation and downtime.

The Solution: To address these challenges, companies should evaluate the total cost of ownership (TCO) when selecting a deburring method. Transitioning to automated or mechanical deburring systems can significantly reduce labor costs and improve safety. Buyers should conduct a thorough cost-benefit analysis, considering both the upfront investment and long-term savings from reduced labor, minimized injuries, and improved part quality. Opting for machines that can handle multiple processes—such as deburring, edge rounding, and surface finishing—can further streamline operations and decrease overall costs.

Scenario 3: Difficulty in Choosing the Right Deburring Method for Diverse Applications

The Problem: B2B buyers often face the dilemma of selecting the most appropriate deburring method for a variety of materials and product designs. Different metals and complex geometries may require specific deburring techniques, and the wrong choice can lead to subpar results or even damage to the workpieces. This uncertainty can cause delays in production and affect customer satisfaction.

Illustrative image related to deburring machine methods

The Solution: To navigate this complexity, companies should invest time in understanding the specific requirements of their parts and materials. It’s advisable to partner with deburring technology providers who can offer comprehensive consultations. They can help assess the unique characteristics of the workpieces and recommend tailored solutions, whether it’s thermal, cryogenic, or electrochemical deburring. Additionally, conducting trials with different methods can provide valuable insights into which process yields the best results for specific applications. By leveraging expert advice and conducting thorough testing, companies can confidently select the most effective deburring method, ensuring high-quality outcomes and customer satisfaction.

Strategic Material Selection Guide for deburring machine methods

What Are the Key Properties of Common Materials Used in Deburring Machine Methods?

When selecting materials for deburring processes, understanding the properties and characteristics of common materials is essential for ensuring optimal performance and efficiency. Below, we analyze four common materials used in deburring applications: Aluminum, Stainless Steel, Carbon Steel, and Brass.

How Does Aluminum Perform in Deburring Applications?

Aluminum is widely used in various industries due to its lightweight nature and excellent corrosion resistance. Its temperature rating allows it to withstand moderate thermal conditions, making it suitable for many manufacturing processes.

Pros: Aluminum is relatively inexpensive and easy to machine, which reduces manufacturing complexity. It can be deburred effectively using both manual and automated methods, and its low density allows for faster processing times.

Cons: However, aluminum can be prone to scratching and may require careful handling during deburring. Additionally, its softness can lead to burrs that are more challenging to remove without affecting the surface finish.

Impact on Application: Aluminum is compatible with various deburring media, including abrasive brushes and cryogenic processes. However, care must be taken to select the right method to avoid damaging the material.

Considerations for International Buyers: Buyers in regions like Africa and South America should ensure compliance with local standards such as ASTM for aluminum grades. Understanding the local market’s preference for aluminum versus other materials can also influence purchasing decisions.

What Advantages Does Stainless Steel Offer for Deburring?

Stainless steel is renowned for its strength and corrosion resistance, making it a popular choice in industries such as food processing and medical equipment. Its high-temperature rating allows it to perform well in demanding environments.

Pros: The durability of stainless steel means that it requires less frequent replacement, leading to long-term cost savings. It also offers excellent surface finishes post-deburring, enhancing the overall product quality.

Cons: The higher cost of stainless steel compared to other materials can be a barrier for some businesses. Additionally, its toughness can make deburring more challenging, requiring more advanced machinery.

Impact on Application: Stainless steel can be effectively deburred using mechanical and electrochemical methods, but the choice of method may depend on the specific grade of stainless steel being used.

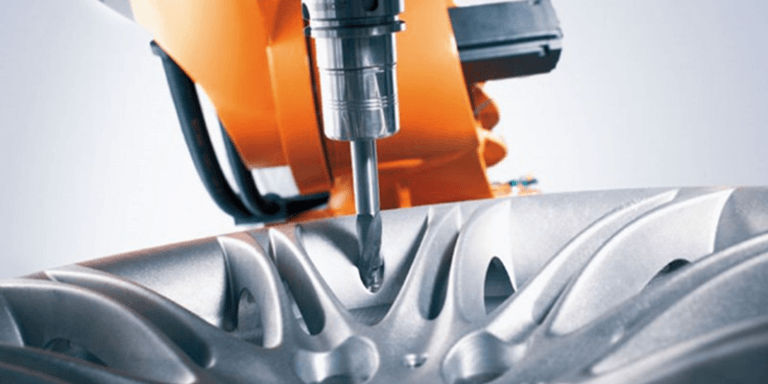

Illustrative image related to deburring machine methods

Considerations for International Buyers: Compliance with international standards such as ISO and ASTM is crucial, especially in regulated industries. Buyers should also be aware of the specific grades of stainless steel that are preferred in their local markets.

How Does Carbon Steel Compare in Deburring Processes?

Carbon steel is a versatile material that is widely used in construction and manufacturing due to its strength and affordability. It has a moderate temperature rating and can be treated for enhanced corrosion resistance.

Pros: Carbon steel is cost-effective and can be easily machined, making it a popular choice for high-volume production. Its strength allows for the creation of durable components.

Cons: On the downside, carbon steel is more susceptible to rust and corrosion, which can complicate the deburring process. Additionally, it may require protective coatings post-deburring to maintain its integrity.

Impact on Application: Carbon steel can be deburred using a variety of methods, including mechanical and thermal processes. However, the presence of rust may require additional steps in the deburring process.

Considerations for International Buyers: Buyers should consider the local availability of carbon steel and its compliance with regional standards. Understanding the implications of corrosion in specific environments is also essential.

What Role Does Brass Play in Deburring Applications?

Brass, an alloy of copper and zinc, is commonly used in applications requiring good corrosion resistance and machinability. It has a moderate temperature rating and is often used in plumbing and electrical applications.

Pros: Brass is easy to machine and can achieve excellent surface finishes, making it suitable for decorative applications. Its resistance to corrosion is a significant advantage in humid environments.

Cons: However, brass can be more expensive than carbon steel and may require specialized deburring techniques to avoid damaging the surface finish.

Impact on Application: Brass is compatible with various deburring methods, including manual and mechanical processes. Care must be taken to select the right abrasives to avoid scratching.

Considerations for International Buyers: Buyers should be aware of the specific brass alloys that comply with local standards, such as JIS in Japan or DIN in Europe. Understanding the local demand for brass products can also influence purchasing decisions.

Summary Table of Material Selection for Deburring

| Material | Typical Use Case for deburring machine methods | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components, automotive parts | Lightweight and corrosion-resistant | Prone to scratching | Low |

| Stainless Steel | Medical devices, food processing equipment | High strength and excellent finish | Higher cost and tougher to deburr | High |

| Carbon Steel | Construction materials, heavy machinery | Cost-effective and durable | Susceptible to rust | Low |

| Brass | Plumbing fixtures, electrical components | Excellent machinability and finish | More expensive and requires care | Medium |

This analysis provides B2B buyers with actionable insights into material selection for deburring processes, ensuring they can make informed decisions that align with their operational needs and regional compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for deburring machine methods

What Are the Main Stages of Manufacturing Processes for Deburring Machine Methods?

The manufacturing process for deburring machines involves several critical stages that ensure the final product meets quality and operational standards. These stages include material preparation, forming, assembly, and finishing, each playing a vital role in producing effective deburring solutions.

Illustrative image related to deburring machine methods

How Is Material Prepared for Deburring Machines?

Material preparation is the foundational step in the manufacturing process. It involves selecting the right type of metal or other materials based on the intended application and the specific deburring method to be used. Factors such as hardness, thickness, and type of burrs present are assessed to determine the most appropriate deburring technique.

During this stage, raw materials are often subjected to initial machining processes like cutting, grinding, or drilling. It’s crucial to ensure that the materials are free from contaminants and defects, as these can adversely affect the deburring process. Quality checks at this stage may include visual inspections and basic dimensional measurements to confirm adherence to specifications.

What Techniques Are Used During the Forming Stage?

The forming stage encompasses various machining operations where the material is shaped into its final form. This stage typically employs techniques such as CNC machining, laser cutting, and water jet cutting. Each of these methods can produce burrs that require subsequent deburring.

Illustrative image related to deburring machine methods

The choice of forming technique affects not only the type and size of the burrs created but also the efficiency of the deburring process. For example, CNC machining may produce finer burrs that require more delicate handling compared to laser cutting, which might leave larger burrs. Understanding the relationship between forming methods and burr types is essential for selecting the most effective deburring solution.

How Is Assembly Conducted in Deburring Machine Manufacturing?

The assembly stage is where the individual components of deburring machines are brought together. This process may involve integrating various systems, such as automated feeds, brush configurations, or thermal deburring chambers, depending on the machine type. Precision is critical here; components must be aligned correctly to ensure that the deburring process is both efficient and effective.

Quality assurance during assembly includes functional testing of each component and the overall machine. This may involve simulating the deburring process to ensure that all parts work together seamlessly and that the machine can handle the specified workload without malfunctioning.

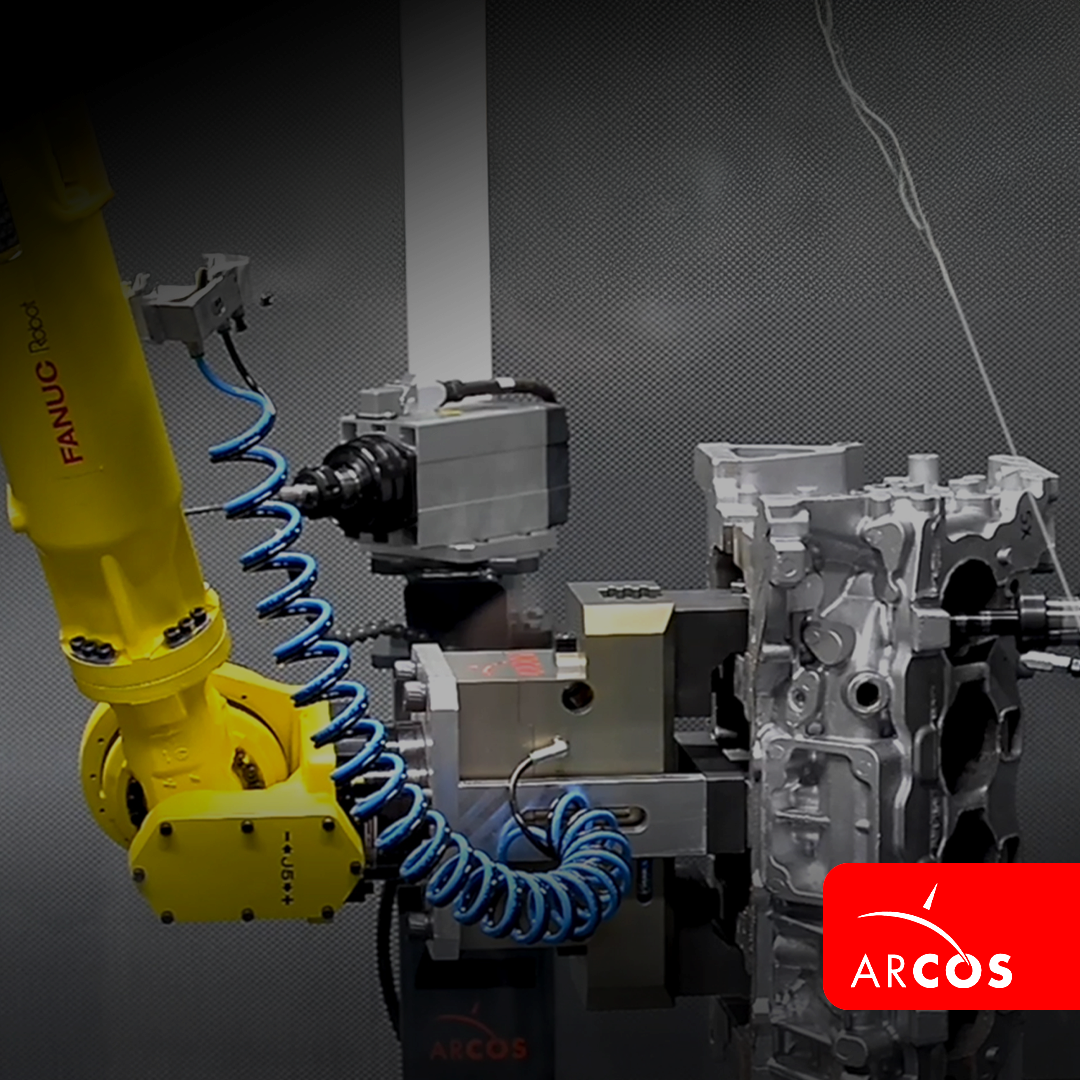

Illustrative image related to deburring machine methods

What Finishing Techniques Are Applied to Deburring Machines?

Finishing techniques are the final touchpoints in the manufacturing process. They include polishing, painting, and coating, which are essential for protecting the machine and enhancing its aesthetic appeal. The finishing process also serves to ensure that any sharp edges are smoothed out, which is particularly important for user safety.

Moreover, finishing can impact the machine’s performance by influencing how burrs are removed. For example, a well-finished surface can facilitate easier cleaning and maintenance, leading to prolonged machine life and consistent performance.

What Quality Assurance Standards Should B2B Buyers Consider?

Quality assurance (QA) is a critical aspect of manufacturing deburring machines, particularly for international B2B buyers. Understanding the relevant standards and checkpoints can help ensure that the products meet both safety and performance criteria.

Which International Standards Are Relevant for Deburring Machine Quality?

International standards such as ISO 9001 provide a framework for quality management systems that ensure consistent product quality and customer satisfaction. ISO 9001 focuses on process efficiency, continuous improvement, and customer feedback, making it an essential certification for manufacturers looking to expand into global markets.

Additionally, industry-specific certifications like CE marking in Europe and API certification in the oil and gas sector further validate compliance with stringent safety and quality regulations. These certifications assure buyers that the machines meet specific industry requirements and are safe for use.

What Are the Key QC Checkpoints in Deburring Machine Manufacturing?

Quality control checkpoints are vital in the manufacturing process to ensure that every stage meets established standards. The main QC checkpoints typically include:

-

Incoming Quality Control (IQC): This involves inspecting raw materials before they enter the production line. It ensures that materials meet predefined specifications and quality standards.

-

In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is essential to catch defects early. This may involve periodic inspections and testing of components and assemblies.

-

Final Quality Control (FQC): Before the machines are shipped, a final inspection is conducted to verify that all specifications are met. This includes functional testing and performance evaluations.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers should take proactive steps to verify the quality control processes of their suppliers. Here are some effective strategies:

-

Conduct Audits: Regular audits of suppliers can provide insights into their quality management practices and adherence to international standards. This includes reviewing their QA documentation and visiting manufacturing facilities if possible.

-

Request Quality Reports: Suppliers should be able to provide detailed quality reports that outline their testing methods, results, and any corrective actions taken in response to defects.

-

Engage Third-Party Inspectors: Utilizing independent third-party inspection services can offer an unbiased assessment of the supplier’s quality control processes and the final product’s conformity to specifications.

What Common Testing Methods Are Used in Deburring Machine Quality Assurance?

Testing methods play a significant role in ensuring that deburring machines operate efficiently and safely. Common testing methods include:

Illustrative image related to deburring machine methods

-

Dimensional Inspection: Ensures that the machine components meet specified dimensions and tolerances.

-

Functional Testing: Verifies that the deburring machine operates as intended under normal working conditions.

-

Performance Testing: Measures the effectiveness of the deburring process, ensuring that burrs are adequately removed without damaging the workpiece.

What Are the QC and Certification Nuances for International B2B Buyers?

International buyers, especially from regions like Africa, South America, the Middle East, and Europe, should be aware of the nuances in quality control and certification:

-

Regional Compliance: Different regions may have specific regulations regarding machinery safety and performance. Understanding local compliance requirements is crucial for successful market entry.

-

Cultural Considerations: Different cultures may have varying expectations regarding quality and service. Engaging with local representatives or partners can provide insights into these nuances.

-

Logistics and Shipping: Quality assurance does not end with manufacturing. Ensuring that the machines are properly packaged and shipped to prevent damage during transit is equally important.

By understanding these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions and select deburring machines that align with their operational needs and quality expectations.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘deburring machine methods’

To assist international B2B buyers in selecting the right deburring machine methods, this guide provides a structured checklist to streamline the sourcing process. By following these steps, buyers can ensure they procure the most suitable solutions for their operational needs.

Step 1: Define Your Technical Specifications

Before engaging suppliers, clearly outline your technical requirements for deburring machines. Consider factors such as the types of materials you’ll be working with, the size and shape of the parts, and the specific burrs to be removed. This initial step is crucial as it sets the foundation for effective communication with suppliers and helps in identifying machines that can meet your needs.

Illustrative image related to deburring machine methods

Step 2: Assess Production Volume and Frequency

Evaluate how many pieces you need to process and the frequency of these jobs. High-volume production may necessitate automated solutions, while lower volumes could be effectively managed with manual methods. Understanding your production needs helps in selecting a deburring method that balances efficiency and cost-effectiveness.

Step 3: Evaluate Potential Suppliers

Conduct thorough due diligence on potential suppliers. Request detailed company profiles, case studies, and references from other businesses in your industry or region. Look for suppliers with a proven track record in deburring technologies and those who offer after-sales support, as this can be critical for ongoing operations.

Step 4: Compare Costs and ROI

Analyze the costs associated with different deburring methods, including upfront investment and long-term operating expenses. Calculate the potential return on investment (ROI) by considering factors such as reduced labor costs, improved part quality, and decreased scrap rates. This financial analysis will help justify your purchasing decision and ensure sustainability.

Illustrative image related to deburring machine methods

Step 5: Verify Compliance and Certifications

Ensure that the machines and suppliers comply with international safety and quality standards. Request documentation for relevant certifications, such as ISO or CE markings, which can indicate the quality and reliability of the equipment. Compliance not only ensures safety but also minimizes the risk of costly liabilities in the future.

Step 6: Consider Environmental Impact

Evaluate the environmental implications of your chosen deburring method. Some processes may utilize harmful chemicals or generate excessive waste. Opt for suppliers that prioritize sustainability and offer eco-friendly deburring solutions, which can enhance your brand reputation and meet regulatory requirements.

Step 7: Request Demonstrations and Trials

Before finalizing a purchase, request demonstrations or trials of the deburring machines. Observing the machine in action can provide insights into its efficiency, ease of use, and overall performance. This hands-on experience is invaluable in ensuring that the equipment meets your expectations and operational demands.

By following this checklist, B2B buyers can make informed decisions when sourcing deburring machine methods, ultimately leading to improved operational efficiency and product quality.

Comprehensive Cost and Pricing Analysis for deburring machine methods Sourcing

What Are the Key Cost Components in Deburring Machine Methods?

When sourcing deburring machine methods, understanding the cost structure is critical for making informed purchasing decisions. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margins.

Illustrative image related to deburring machine methods

-

Materials: The choice of materials directly influences the price. High-quality abrasives, cutting tools, and machine components may incur higher initial costs but can enhance durability and efficiency, leading to lower long-term expenses.

-

Labor: Labor costs vary significantly based on location and the complexity of the deburring method. Automated systems typically require less direct labor, while manual deburring processes may need skilled operators, impacting overall costs.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, rent, and equipment depreciation. Efficient manufacturing processes can reduce overhead, thus lowering the total price of deburring methods.

-

Tooling: The initial investment in tooling can be substantial, particularly for specialized or custom deburring solutions. This is an important consideration for international buyers, as tooling costs may vary by region.

-

Quality Control (QC): Implementing robust QC measures ensures product consistency and reduces the risk of defects. While this adds to upfront costs, it can save money by minimizing rework and scrap rates.

-

Logistics: Transportation and import/export duties significantly affect pricing for international buyers. Understanding Incoterms can help buyers anticipate logistics costs more accurately.

-

Margin: Suppliers typically include a profit margin in their pricing. This margin can vary based on market conditions, competition, and the supplier’s position within the supply chain.

How Do Price Influencers Affect Deburring Machine Costs?

Several factors can influence the pricing of deburring machine methods:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often benefit from economies of scale, leading to reduced per-unit costs. Buyers should negotiate MOQs to optimize their purchasing strategy.

-

Specifications and Customization: Custom solutions tailored to specific applications may incur additional costs. Buyers must weigh the benefits of customization against the price to ensure alignment with operational needs.

-

Materials and Quality Certifications: Higher quality materials and certifications (e.g., ISO) can increase costs but also enhance product reliability and compliance with industry standards, which is particularly crucial for buyers in regulated sectors.

-

Supplier Factors: The supplier’s reputation, location, and capacity to deliver can impact pricing. Establishing strong relationships with suppliers can facilitate better pricing and service.

-

Incoterms and Shipping Considerations: Understanding terms like FOB (Free on Board) or CIF (Cost, Insurance, Freight) can help buyers manage costs effectively. Buyers should also consider the implications of shipping times and potential tariffs when sourcing internationally.

What Buyer Tips Can Enhance Cost-Efficiency in Deburring Machine Sourcing?

To maximize value when sourcing deburring machine methods, buyers should consider the following strategies:

-

Negotiate Terms: Engage suppliers in discussions about pricing, payment terms, and warranties. Strong negotiation can lead to better terms and reduced overall costs.

-

Evaluate Total Cost of Ownership (TCO): Beyond initial purchase price, assess the TCO, which includes maintenance, operational efficiency, and potential downtime costs. This holistic view aids in making more informed decisions.

-

Stay Informed on Market Trends: Understanding market dynamics can provide leverage during negotiations. Regularly review industry reports and pricing forecasts to anticipate fluctuations.

-

Consider Regional Suppliers: For international buyers, sourcing from local suppliers can reduce shipping costs and lead times, enhancing overall cost-effectiveness.

-

Assess Long-Term Needs: Consider future production requirements and scalability when selecting deburring methods. Investing in flexible, scalable solutions can yield significant savings over time.

Conclusion

Navigating the costs and pricing of deburring machine methods requires a strategic approach, particularly for international B2B buyers. By understanding the cost components, price influencers, and implementing effective purchasing strategies, businesses can optimize their sourcing decisions, ensuring they achieve the best value for their investment.

Alternatives Analysis: Comparing deburring machine methods With Other Solutions

Introduction: Exploring Alternatives in Deburring Solutions

In the realm of manufacturing and metalworking, deburring is a critical process aimed at enhancing the quality and safety of machined parts. While deburring machine methods are widely used for their efficiency and scalability, it’s essential for B2B buyers to explore alternative solutions that may better suit their specific operational needs. This analysis compares deburring machine methods with manual deburring techniques and chemical deburring processes, providing insights into their respective strengths and weaknesses.

Comparison Table

| Comparison Aspect | Deburring Machine Methods | Manual Deburring Techniques | Chemical Deburring Processes |

|---|---|---|---|

| Performance | High throughput and consistency; automated systems ensure uniform quality. | Variable performance; dependent on operator skill and can lead to inconsistencies. | Effective for intricate designs; can achieve high precision but may be slower. |

| Cost | Higher initial investment; cost-effective in high-volume production. | Low initial cost; labor-intensive, leading to higher long-term costs. | Moderate cost; requires investment in chemicals and safety measures. |

| Ease of Implementation | Requires training and setup; integration with existing systems can be complex. | Simple to implement; no special training needed for basic tasks. | Complex setup; requires specialized knowledge and handling of hazardous materials. |

| Maintenance | Regular maintenance needed; automated systems can reduce downtime. | Minimal maintenance; tools need periodic replacement. | Maintenance of chemical handling systems and safety equipment required. |

| Best Use Case | Ideal for high-volume production and complex geometries. | Suitable for low-volume tasks and quick fixes. | Best for intricate parts or materials that are challenging to deburr mechanically. |

Detailed Breakdown of Alternatives

Manual Deburring Techniques: Are They Worth the Effort?

Manual deburring involves using handheld tools such as files, sanders, or brushes to remove burrs. The primary advantage of this method is its low cost and simplicity, making it accessible for small operations or low-volume tasks. However, the quality of the results can vary significantly based on the operator’s skill, leading to potential inconsistencies in the finished product. Additionally, this method can be time-consuming and may not meet the demands of high-speed production environments, making it less viable for larger manufacturers.

Chemical Deburring Processes: Precision at a Cost

Chemical deburring utilizes specific chemicals to dissolve burrs from parts, particularly effective for complex shapes and delicate materials. This method offers high precision and is particularly useful for intricate components where mechanical methods may struggle. However, it requires careful handling of hazardous materials, strict safety protocols, and potentially high ongoing costs for chemicals and waste disposal. The complexity of implementation can also be a barrier for companies without the necessary expertise in chemical handling.

Illustrative image related to deburring machine methods

Conclusion: How to Choose the Right Deburring Solution for Your Needs

When selecting a deburring solution, B2B buyers must consider their production volume, part complexity, and budget constraints. Deburring machine methods generally provide the best performance and consistency for high-volume applications, while manual techniques may be suitable for smaller operations or less critical tasks. Chemical deburring processes can offer precision for specialized parts but come with safety and cost considerations. By evaluating these factors, buyers can make informed decisions that align with their operational goals and ensure the quality of their products.

Essential Technical Properties and Trade Terminology for deburring machine methods

What Are the Key Technical Properties in Deburring Machine Methods?

Understanding the technical properties of deburring machine methods is essential for B2B buyers aiming for optimal performance and cost-effectiveness in manufacturing. Here are some critical specifications to consider:

1. Material Grade

The material grade of the deburring machine is crucial as it determines durability and resistance to wear. High-grade materials such as stainless steel or specialized alloys can withstand harsh operational conditions and ensure longevity. For B2B buyers, investing in machines made from superior material grades can minimize maintenance costs and downtime.

2. Tolerance Levels

Tolerance refers to the permissible limit of variation in a physical dimension. In deburring, maintaining tight tolerances is vital for ensuring that parts fit together properly and function effectively. For manufacturers, understanding tolerance requirements helps in selecting the right deburring process and machine, ultimately influencing product quality and customer satisfaction.

3. Throughput Capacity

Throughput capacity indicates the number of parts that can be processed in a given time frame. Machines with higher throughput capacities can significantly boost production rates, making them more appealing for high-volume operations. B2B buyers should assess their production needs to choose a deburring machine that aligns with their throughput requirements, thereby optimizing efficiency.

4. Energy Consumption

The energy consumption of deburring machines impacts operational costs. Machines designed for energy efficiency can lead to significant savings over time, especially in large-scale manufacturing. Buyers should evaluate energy ratings and operational costs when selecting machines, as this can affect the overall return on investment.

5. Automation Level

The level of automation in deburring machines varies widely, from manual to fully automated systems. Automated machines often provide consistent quality and reduce labor costs. B2B buyers must consider their workforce capabilities and production demands to determine the right level of automation for their operations.

6. Surface Finish Quality

The surface finish quality achieved by a deburring machine is a key performance metric. Different methods yield varying surface finishes, which can affect the aesthetic and functional properties of the final product. Understanding the required surface finish for specific applications is essential for B2B buyers to ensure compliance with industry standards and customer expectations.

What Are Common Trade Terms in Deburring Machine Procurement?

Navigating the procurement landscape for deburring machines involves familiarizing oneself with industry jargon. Here are some common terms that B2B buyers should know:

Illustrative image related to deburring machine methods

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking for reliable suppliers and quality assurance in parts and machines.

2. MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of products a supplier is willing to sell. This term is significant for buyers as it affects inventory management and initial investment. Ensuring that MOQ aligns with production needs can help avoid excess stock or missed opportunities.

3. RFQ (Request for Quotation)

An RFQ is a formal process where buyers request price quotations from suppliers for specific products or services. For B2B buyers, crafting a detailed RFQ can facilitate better pricing and terms, ensuring a competitive procurement process.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined international trade terms that clarify the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms helps buyers understand shipping costs and responsibilities, reducing the risk of disputes during international transactions.

5. TCO (Total Cost of Ownership)

TCO encompasses the total expenses associated with acquiring and operating a machine over its lifecycle. This includes purchase price, maintenance, energy consumption, and disposal costs. Understanding TCO enables B2B buyers to make informed decisions based on long-term value rather than just upfront costs.

6. Lead Time

Lead time refers to the time taken from placing an order to receiving the product. For B2B buyers, understanding lead times is essential for planning production schedules and ensuring timely delivery to customers, thereby maintaining a competitive edge in the market.

By comprehending these technical properties and trade terms, international B2B buyers can make informed decisions that enhance operational efficiency and product quality in deburring processes.

Illustrative image related to deburring machine methods

Navigating Market Dynamics and Sourcing Trends in the deburring machine methods Sector

Market Overview & Key Trends: What Drives the Deburring Machine Methods Market?

The global deburring machine methods market is experiencing significant growth, driven by the increasing demand for precision-engineered components across various sectors, including automotive, aerospace, and electronics. As manufacturers emphasize quality and efficiency, automation and advanced technology are becoming vital for maintaining competitive advantage. International B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, are increasingly seeking automated deburring solutions that enhance productivity and ensure consistent quality.

Key trends shaping the market include the rise of smart manufacturing technologies, such as IoT-enabled machines that allow real-time monitoring and data analytics to optimize deburring processes. Additionally, the shift toward Industry 4.0 is encouraging companies to adopt integrated systems that streamline operations from machining to finishing. Emerging markets, especially in Africa and South America, are witnessing increased investment in manufacturing infrastructure, prompting a higher demand for efficient deburring methods.

Moreover, sustainability is becoming a paramount consideration. Buyers are now more focused on sourcing deburring machines that not only meet production needs but also align with environmental standards. Companies that can offer energy-efficient, low-waste solutions will likely capture a larger share of the market as B2B buyers prioritize sustainable practices.

Sustainability & Ethical Sourcing in B2B: How Does It Impact Deburring Machine Methods?

Sustainability has become a critical focus for B2B buyers in the deburring machine methods sector. The environmental impact of manufacturing processes, including deburring, is under scrutiny, with companies seeking ways to minimize their carbon footprint. As a result, ethical sourcing and sustainability certifications are increasingly influencing purchasing decisions.

Buyers are looking for suppliers that provide eco-friendly materials and technologies, such as water-based lubricants, energy-efficient machines, and recyclable components. Additionally, companies that can demonstrate compliance with international environmental standards, such as ISO 14001, are likely to gain a competitive edge.

The importance of ethical supply chains cannot be overstated; buyers are increasingly aware of the social and environmental implications of their sourcing decisions. This awareness drives them to select suppliers committed to ethical practices, including fair labor conditions and reduced environmental impact. As a result, suppliers that prioritize sustainability and transparency in their operations are better positioned to meet the evolving demands of B2B buyers across the globe.

Brief Evolution/History: How Have Deburring Methods Developed Over Time?

The evolution of deburring methods has been marked by technological advancements and changing industrial needs. Traditionally, manual deburring techniques dominated the landscape, with labor-intensive processes relying on handheld tools. However, as manufacturing became more complex and the demand for precision increased, automated solutions gained traction.

In the late 20th century, the introduction of mechanical and thermal deburring technologies revolutionized the industry, allowing for faster and more consistent results. With the rise of digital manufacturing and automation in the 21st century, deburring machines have become more sophisticated, incorporating smart technologies and IoT capabilities. This evolution reflects a broader trend towards automation in manufacturing, where efficiency and quality are paramount. Today, the focus is not only on speed and effectiveness but also on sustainability and ethical sourcing, shaping the future of deburring machine methods in the global market.

Frequently Asked Questions (FAQs) for B2B Buyers of deburring machine methods

-

How do I choose the right deburring method for my manufacturing needs?

Choosing the right deburring method involves assessing your specific requirements, such as production volume, part complexity, and desired surface finish. Evaluate factors like cost per piece, speed of operation, and the potential impact on overall workflow. For high-volume production, automated methods like mechanical deburring may be ideal, while manual methods might suffice for lower volumes or intricate parts. Also, consider the material type and the burr characteristics, as these can dictate the most effective deburring technique. -

What is the best deburring method for intricate metal parts?

For intricate metal parts, electrochemical deburring is often the best choice. This method allows for precise removal of burrs from complex geometries without damaging the underlying material. Another effective option is cryogenic deburring, which embrittles burrs using liquid nitrogen, making them easier to remove. Both methods can achieve high-quality finishes while ensuring that the overall integrity of the part is maintained, which is crucial in industries requiring tight tolerances. -

What are the key factors to consider when vetting deburring machine suppliers?

When vetting suppliers for deburring machines, consider their experience in your specific industry, customer reviews, and the variety of machines they offer. Evaluate their after-sales support, including maintenance and training services, as well as their ability to customize machines for your specific needs. Additionally, inquire about their compliance with international quality standards and certifications, as this can impact the reliability of their products. -

How can I determine the minimum order quantity (MOQ) for deburring machines?

The MOQ for deburring machines can vary based on the supplier and the complexity of the machine. Typically, manufacturers set MOQs to ensure cost-effectiveness in production. It’s essential to communicate your specific needs, including potential future orders, to negotiate favorable terms. If you are a smaller buyer, consider discussing options for lower MOQs or exploring used equipment as a viable alternative. -

What payment terms should I expect when purchasing deburring machines internationally?

Payment terms can vary widely among suppliers, often influenced by the region and the buyer’s creditworthiness. Common terms include payment upfront, a deposit followed by the balance on delivery, or net payment terms (e.g., net 30 or net 60 days). It is advisable to discuss and negotiate these terms upfront, ensuring clarity on any additional costs such as shipping, taxes, and duties, to avoid surprises later in the transaction. -

What quality assurance (QA) processes should I look for in deburring machine suppliers?

Look for suppliers that implement rigorous quality assurance processes, including regular inspections and testing of machines before shipment. Certifications such as ISO 9001 can indicate a commitment to quality management. Additionally, inquire about their warranty policies and how they handle defective machines. A reliable supplier should have a clear QA protocol that assures you of the machine’s performance and longevity. -

How do logistics and shipping impact the purchasing of deburring machines?

Logistics and shipping are critical factors in the procurement of deburring machines, particularly for international buyers. Consider the supplier’s shipping options, delivery times, and costs associated with transporting heavy machinery. It’s also essential to understand customs regulations and potential import duties in your country. Collaborating with a supplier that has experience in international shipping can help streamline the process and mitigate delays. -

What are the advantages of investing in automated deburring solutions?

Investing in automated deburring solutions offers numerous advantages, including increased efficiency, consistency, and quality of output. Automation minimizes human error, reduces labor costs, and can significantly enhance production speed, making it ideal for high-volume operations. Additionally, automated machines can handle complex geometries and various materials, providing flexibility for manufacturers. This investment can lead to long-term cost savings and improved product quality, ultimately enhancing competitiveness in the market.

Top 6 Deburring Machine Methods Manufacturers & Suppliers List

1. James Engineering – MAX System

Domain: james-engineering.com

Registered: 2001 (24 years)

Introduction: The MAX System from James Engineering is a high precision deburring and chamfering machine that features a multi-tooling capability customizable to specific company needs. It includes an 11-axis overhead gantry system for reaching any angle and can deburr, chamfer, radius, wash, and brush parts concurrently. The system is designed for parts and gears of any size and complexity, utilizing Focused D…

2. Heule Werkzeug AG – Key Deburring Tools

Domain: heule.com

Registered: 1996 (29 years)

Introduction: Heule Werkzeug AG offers various deburring tools and methods suitable for serial production in industries such as automotive, aircraft, and fluid power. Key products include: COFA, DL2, X-BORES, SNAP, DEFA, GH-K, BSF SOLO, VEX DCC Module Line. The deburring methods include thermal deburring (TEM), electrochemical deburring (ECM), high-pressure waterjet deburring (HDW), blasting with granulates, br…

3. Universal Grinding – Mechanical Deburring Solutions

Domain: universalgrinding.com

Registered: 1996 (29 years)

Introduction: Mechanical deburring employs cutting, grinding, milling, or brushing tools to remove burrs through direct contact. It is ideal for heavy or strong burrs that are difficult to remove with other methods. Mechanical deburring is faster, more accurate, and repeatable compared to hand deburring, which is time-consuming and varies based on the operator. Although more expensive than hand deburring, it is…

4. Timesavers – Deburring Machines

Domain: timesaversint.com

Registered: 2000 (25 years)

Introduction: Timesavers offers a range of high-quality deburring machines designed to automate the deburring process for metal workpieces. These machines utilize abrasive belts of varying grain sizes to effectively remove burrs created during machining operations such as punching, drilling, milling, cutting, and turning. The machines can handle different types of metals, including aluminum, stainless steel, ti…

5. Benchmark Abrasives – Quality Abrasive Tools

Domain: benchmarkabrasives.com

Registered: 2009 (16 years)

Introduction: Backing Pad, Blade, Buffing Compound, Buffing Wheels, Carbide Burr, Cartridge Roll, Change Disc, Chop Saw Wheel, Convolute Wheel, Cut-off Wheel, Fiber Disc, Flap Disc, Flap Wheel, Gift Card, Grinding Cup Wheel, Grinding Wheel, Hand Pads, Hole Saw, Hook & Loop Disc, Mandrel, Non-Woven Abrasives, Nylon Wire Product, PSA Disc, Recip Blade, Shop Roll, Spiral Band, Steel Brush, Stud Cutter, Surface Con…

6. IQS Directory – Deburring Solutions

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Deburring is a secondary machining process that removes raised edges and excess material (burrs) from primary machining tasks. Burrs can occur due to shearing, bending, cutting, piercing, and compressing, especially in soft and malleable materials. Deburring machines use mechanical, electrochemical, and thermal methods to eliminate imperfections. Deburring is crucial for product quality, preventin…

Strategic Sourcing Conclusion and Outlook for deburring machine methods

In conclusion, selecting the right deburring method is crucial for enhancing operational efficiency and product quality. B2B buyers must carefully evaluate various deburring techniques—ranging from manual and thermal methods to advanced mechanical solutions—based on factors such as production volume, part complexity, and quality standards. The strategic sourcing of deburring machines not only ensures the removal of imperfections but also mitigates risks associated with poor quality, such as increased operational costs and customer dissatisfaction.

Investing in automated deburring solutions can significantly reduce labor costs and processing time while maintaining consistent quality. As manufacturers across Africa, South America, the Middle East, and Europe seek to optimize their production processes, embracing innovative deburring technologies will be key to staying competitive in the global market.

Looking ahead, international B2B buyers are encouraged to engage with suppliers who offer tailored deburring solutions that align with their specific needs. By prioritizing strategic sourcing, businesses can enhance their operational capabilities, drive efficiency, and ensure the long-term reliability of their products. Explore your options today and elevate your manufacturing processes to meet the demands of tomorrow.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.