How to Source Crucible And Tongs Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for crucible and tongs

In the competitive landscape of manufacturing and metalworking, sourcing the right crucible and tongs can present a significant challenge for international B2B buyers. Whether you are melting precious metals in Germany or working with alloys in Saudi Arabia, the quality and suitability of your crucible and tongs directly impact operational efficiency and safety. This comprehensive guide addresses the complexities of selecting the right crucible and tongs by exploring various types, applications, and critical factors for supplier vetting.

From understanding the nuances between ceramic and graphite crucibles to evaluating different tong designs for specific melting processes, this guide empowers buyers with the insights needed to make informed purchasing decisions. We delve into cost considerations, providing a clear overview of pricing structures across different regions, including Africa, South America, and the Middle East.

By the end of this guide, you will be equipped with the knowledge to navigate the global market effectively, ensuring that your sourcing strategy aligns with industry standards and your operational requirements. Whether you’re a seasoned buyer or venturing into this niche for the first time, the insights presented here will help streamline your procurement process, minimize risks, and enhance your overall productivity in metalworking and foundry operations.

Understanding crucible and tongs Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Clay Graphite Crucibles | High thermal conductivity, lightweight, suitable for high temps. | Metal melting, jewelry production, foundries | Pros: Excellent heat retention; Cons: Fragile, can crack under thermal shock. |

| Ceramic Crucibles | Durable, resistant to thermal shock, non-reactive. | Laboratory experiments, metal casting | Pros: High chemical resistance; Cons: Heavier than graphite. |

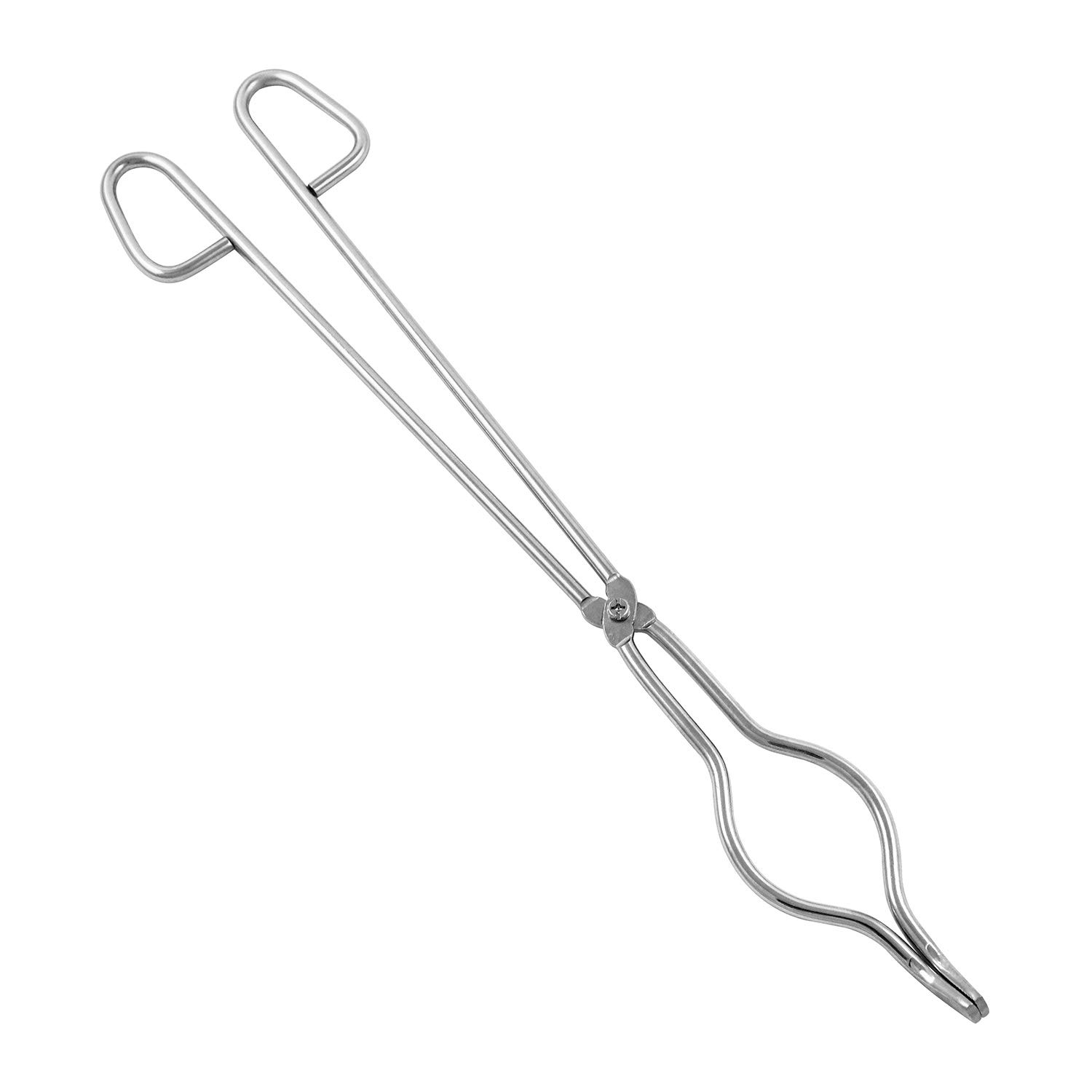

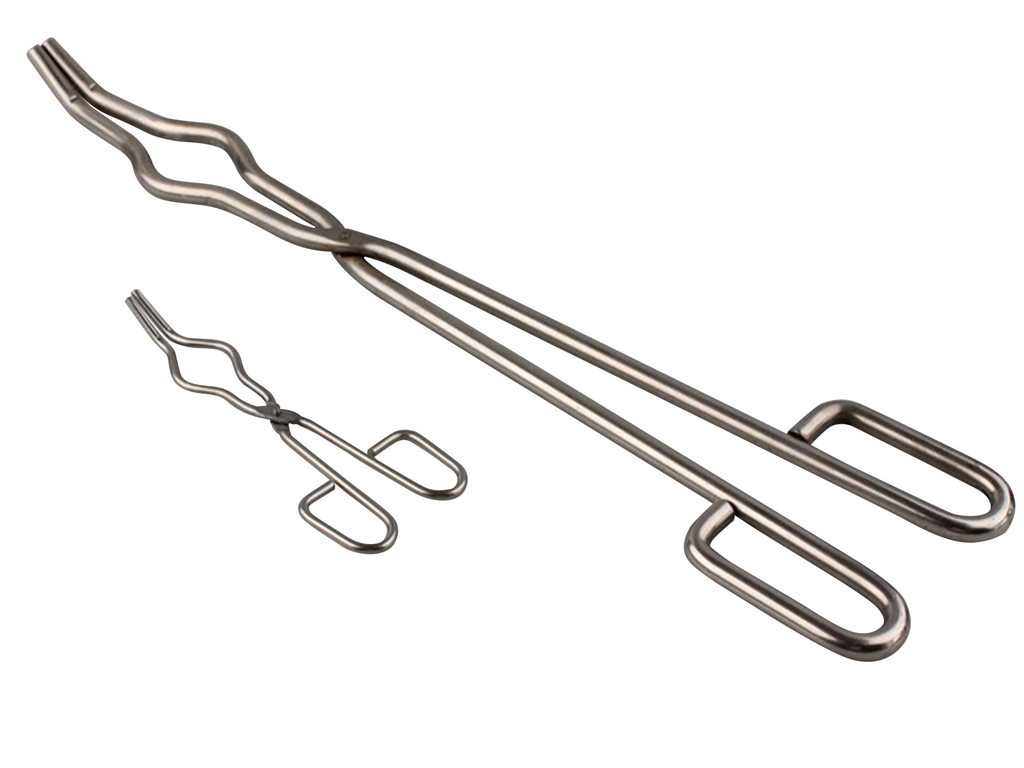

| Stainless Steel Tongs | Corrosion-resistant, sturdy, often adjustable. | Metalworking, foundries, laboratory settings | Pros: Durable, easy to clean; Cons: Heavier than other materials. |

| Hinge-Style Tongs | Designed for secure gripping, allows for precise control. | Foundries, metal casting, jewelry making | Pros: Enhanced control; Cons: May require two hands for larger crucibles. |

| Adjustable Fly-Nut Tongs | Versatile, accommodates various crucible sizes, easy to operate. | Metal casting, jewelry, glasswork | Pros: Adjustable for different sizes; Cons: Less sturdy for very heavy crucibles. |

What Are Clay Graphite Crucibles and Their Applications?

Clay graphite crucibles are favored for their high thermal conductivity and lightweight nature, making them ideal for applications in metal melting and jewelry production. Their ability to withstand high temperatures allows for efficient melting of various metals. However, buyers should consider their fragility, as they can crack under sudden thermal changes. When sourcing these crucibles, ensure that the supplier provides a range of sizes to accommodate different melting needs.

How Do Ceramic Crucibles Stand Out?

Ceramic crucibles are well-known for their durability and resistance to thermal shock, making them a popular choice in laboratories and metal casting applications. Their non-reactive nature ensures that they do not contaminate the materials being melted. While they are heavier than their graphite counterparts, their longevity and chemical resistance make them a worthwhile investment. Buyers should assess the specific thermal requirements of their processes to choose the right ceramic crucible.

What Are the Advantages of Using Stainless Steel Tongs?

Stainless steel tongs are widely used in foundries and laboratory settings due to their corrosion resistance and sturdy construction. These tongs are often adjustable, allowing for flexibility when handling various crucible sizes. While they are easy to clean, their weight can be a drawback for some users, especially when handling larger crucibles. Buyers should consider the balance between durability and ease of use when selecting stainless steel tongs for their operations.

Why Choose Hinge-Style Tongs?

Hinge-style tongs are designed to provide a secure grip and allow for precise control when handling crucibles, making them ideal for foundries and jewelry making. Their design typically requires two hands for larger crucibles, which can be a consideration for operations that prioritize efficiency. Buyers should evaluate their specific handling needs and the size of the crucibles they work with to determine if hinge-style tongs are the best fit for their processes.

What Makes Adjustable Fly-Nut Tongs a Versatile Option?

Adjustable fly-nut tongs are versatile tools that can accommodate various crucible sizes, making them suitable for metal casting, jewelry, and glasswork. Their ease of operation is a significant advantage, especially in fast-paced environments. However, they may not provide the same level of sturdiness for extremely heavy crucibles. When purchasing, it’s crucial for buyers to assess the range of sizes they will be working with to ensure they select the right tongs for their applications.

Key Industrial Applications of crucible and tongs

| Industry/Sector | Specific Application of crucible and tongs | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Metal Foundry | Melting and pouring of metals | Enhanced safety and efficiency in handling molten metals | Compliance with safety standards; material durability |

| Jewelry Manufacturing | Melting precious metals for casting | Precision in metal melting and pouring | Size compatibility; temperature resistance; ergonomic design |

| Laboratory Research | Heating and melting materials in scientific experiments | High accuracy and repeatability in experiments | Material quality; heat resistance; size specifications |

| Recyclable Materials | Processing scrap metals and alloys | Cost-effective recycling processes | Tongs designed for various crucible shapes; lifting capacity |

| Automotive Manufacturing | Melting and pouring of alloys for component production | Improved production efficiency and quality assurance | Compatibility with specific crucible types; safety features |

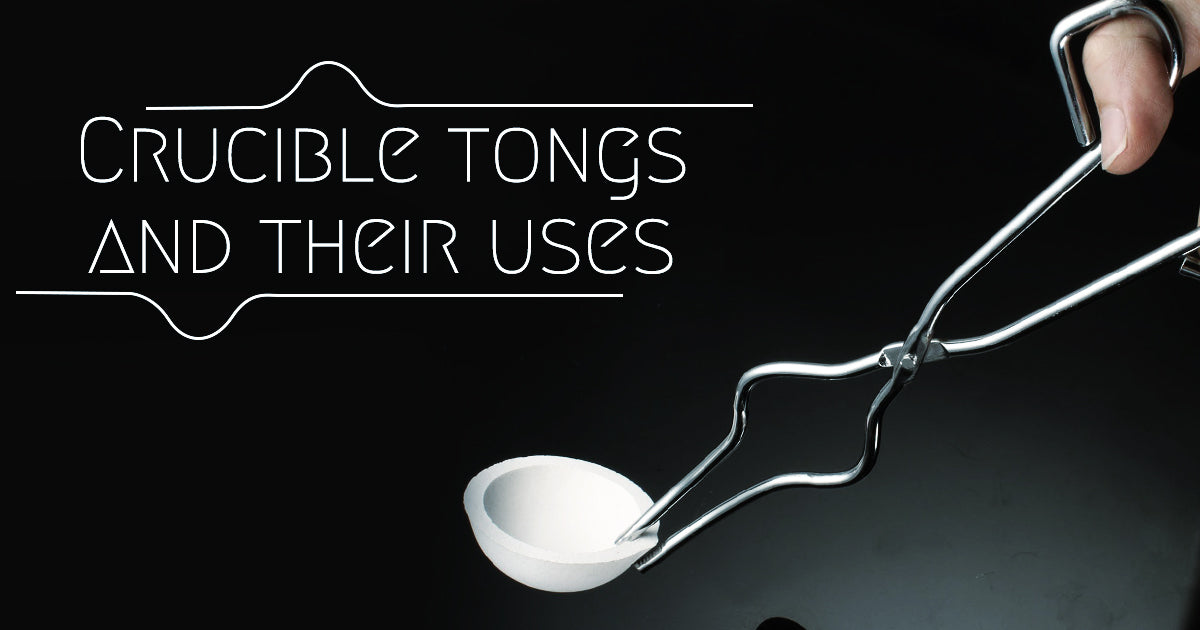

How Are Crucible and Tongs Used in the Metal Foundry Sector?

In metal foundries, crucibles are essential for melting various metals before casting. Tongs facilitate the safe handling and pouring of molten metal, significantly reducing the risk of accidents. Foundries require tongs that are compatible with specific crucible sizes and shapes, ensuring that they can safely lift and pour without compromising the integrity of the crucible. Buyers must consider the durability and heat resistance of the tongs, as well as compliance with industry safety regulations.

What Role Do Crucible and Tongs Play in Jewelry Manufacturing?

In jewelry manufacturing, crucibles are used to melt precious metals like gold and silver. The accurate pouring of these metals into molds is crucial for producing high-quality jewelry pieces. Tongs designed for delicate handling provide the necessary control during this process. Buyers in this sector should prioritize tongs that offer precision, temperature resistance, and compatibility with various crucible sizes to enhance their production capabilities.

How Are Crucible and Tongs Utilized in Laboratory Research?

Laboratories often use crucibles for heating and melting materials during experiments. The ability to control temperature and handle materials safely is essential for obtaining reliable results. Tongs designed for laboratory use must be made from materials that withstand high temperatures and provide ergonomic handling. International buyers need to focus on sourcing products that meet specific laboratory standards and ensure accurate experimental outcomes.

Why Are Crucible and Tongs Important in Recycling Industries?

In the recycling sector, crucibles are utilized for melting down scrap metals and alloys to be repurposed. Tongs are critical for safely maneuvering heavy crucibles filled with molten materials, improving operational efficiency. Buyers should consider tongs that can accommodate various crucible shapes and sizes, ensuring compatibility with the specific materials being processed. The focus on cost-effective solutions is vital for maximizing profitability in this industry.

How Do Crucible and Tongs Enhance Automotive Manufacturing?

In automotive manufacturing, crucibles are used for melting alloys essential for producing components like engine parts. Tongs facilitate the safe handling of these materials, improving production efficiency and ensuring quality control. Buyers must ensure that the tongs are compatible with specific crucible types and have features that enhance safety, such as locking mechanisms and sturdy construction. This attention to detail can significantly impact the overall production process and product quality.

3 Common User Pain Points for ‘crucible and tongs’ & Their Solutions

Scenario 1: Ensuring Proper Fit Between Crucibles and Tongs

The Problem: One of the most common challenges faced by B2B buyers is the mismatch between crucibles and tongs. This issue often arises when purchasing tongs that do not fit the specific dimensions or shape of the crucibles used in their operations. A poor fit can lead to accidents, such as dropping a crucible filled with molten metal, which poses significant safety risks and can result in costly damages. Furthermore, a lack of understanding regarding the required specifications can lead to wasted time and resources in the procurement process.

The Solution: To overcome this problem, it is crucial to thoroughly document and specify the dimensions of both the crucibles and tongs before making a purchase. Buyers should consult with manufacturers to obtain detailed specifications for their products, ensuring compatibility. It may also be beneficial to request samples or product demonstrations to verify that the tongs properly grip the crucible’s lip without compromising safety. Additionally, consider investing in adjustable or customizable tongs that can accommodate various crucible shapes, reducing the need for multiple purchases.

Scenario 2: Addressing Temperature Limitations of Tongs

The Problem: Another significant pain point is the temperature limitations of crucible tongs. Many standard tongs are not designed to withstand the extreme temperatures encountered when melting metals, especially in high-temperature environments. This can lead to the tongs warping or failing during use, resulting in accidents and interruptions in production. Buyers may also struggle to identify which tongs are suitable for their specific melting applications, leading to suboptimal performance and safety hazards.

The Solution: To mitigate this issue, buyers should prioritize sourcing tongs that are specifically engineered to handle high temperatures. Look for products made from materials such as carbon steel or nickel-plated steel, which can withstand high heat without losing integrity. Additionally, reviewing the product specifications for maximum temperature ratings can aid in selecting the right tongs for the intended application. Engaging with suppliers who provide technical support and can recommend appropriate products based on specific melting requirements will enhance safety and efficiency in operations.

Scenario 3: Managing Inventory and Cost Efficiency

The Problem: B2B buyers often face challenges related to inventory management and cost efficiency when procuring crucibles and tongs. The need for multiple sizes and types of tongs can lead to excessive inventory costs, while insufficient stock can result in production delays. Furthermore, buyers might struggle to find a balance between quality and price, often sacrificing one for the other, which can impact overall operational efficiency and profitability.

The Solution: A strategic approach to inventory management can alleviate these concerns. Start by analyzing usage patterns and identifying the most frequently used crucible and tong combinations within your operations. This analysis can help in determining which products to keep in stock. Additionally, consider forming partnerships with suppliers who offer bulk purchasing options or loyalty programs, which can lead to cost savings. Investing in high-quality, durable tongs may have a higher upfront cost but can lead to lower replacement rates and increased safety, thus enhancing long-term cost efficiency. Regular reviews of inventory levels and supplier performance can also ensure that procurement processes remain efficient and aligned with operational needs.

Strategic Material Selection Guide for crucible and tongs

What are the Key Properties of Common Materials Used in Crucibles and Tongs?

When selecting materials for crucibles and tongs, it is essential to consider their performance characteristics, particularly in high-temperature applications. The most commonly used materials include clay graphite, stainless steel, nickel-plated steel, and cast iron. Each material has unique properties that affect its suitability for various applications.

How Does Clay Graphite Perform in High-Temperature Applications?

Clay graphite is a popular choice for crucibles due to its excellent thermal conductivity and high-temperature resistance, typically rated up to 1600°C. Its ability to withstand thermal shock makes it ideal for melting metals and alloys. However, while clay graphite is durable, it can be prone to wear and cracking under mechanical stress.

For international buyers, particularly from regions with stringent quality standards like Germany, it is crucial to ensure that the clay graphite crucibles meet relevant ASTM or DIN specifications. Additionally, the cost of clay graphite crucibles can be moderate to high, depending on the quality and manufacturer.

What Advantages Does Stainless Steel Offer for Tongs and Crucibles?

Stainless steel is often used for tongs due to its corrosion resistance and strength. It can withstand temperatures up to 800°C, making it suitable for various applications, including handling molten metals. The durability of stainless steel tongs means they require less frequent replacement, which can be a cost-saving factor in the long run.

However, stainless steel can be more expensive than other materials and may not be suitable for all crucible types due to its weight and thermal conductivity properties. For B2B buyers in regions like Saudi Arabia, where high humidity can lead to corrosion, selecting high-grade stainless steel is advisable to ensure longevity.

Why is Nickel-Plated Steel a Viable Option for Crucible Tongs?

Nickel-plated steel combines the strength of steel with enhanced corrosion resistance, making it a suitable choice for crucible tongs. Typically, nickel-plated tongs can handle temperatures up to 1000°C and are designed for gripping crucibles securely. The nickel plating also provides a smoother surface, reducing the risk of metal contamination.

The primary disadvantage of nickel-plated steel is that it may wear off over time, especially in high-frequency use scenarios. For buyers in South America, where budget constraints are often a concern, nickel-plated options can be a cost-effective alternative to stainless steel without compromising too much on performance.

What Role Does Cast Iron Play in the Manufacturing of Crucibles?

Cast iron is another material used in crucibles, particularly for melting ferrous metals. It can withstand high temperatures and is generally less expensive than other materials. However, cast iron is more brittle and can crack under thermal shock, making it less suitable for applications requiring rapid temperature changes.

For international buyers, particularly in Africa, understanding local manufacturing capabilities and material availability is crucial. Cast iron crucibles must comply with local safety and quality standards, which can vary significantly across regions.

Summary Table of Material Selection for Crucibles and Tongs

| Material | Typical Use Case for crucible and tongs | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Clay Graphite | Melting non-ferrous metals | Excellent thermal conductivity | Prone to wear and cracking | Medium to High |

| Stainless Steel | Handling molten metals | Corrosion-resistant and durable | Higher cost and weight | Medium to High |

| Nickel-Plated Steel | Tongs for various crucibles | Enhanced corrosion resistance | Plating may wear off | Low to Medium |

| Cast Iron | Melting ferrous metals | Cost-effective | Brittle and prone to cracking | Low |

By understanding the properties, advantages, and limitations of these materials, B2B buyers can make informed decisions that align with their operational needs and compliance requirements in their respective regions.

In-depth Look: Manufacturing Processes and Quality Assurance for crucible and tongs

What Are the Main Stages in the Manufacturing Process of Crucibles and Tongs?

The manufacturing of crucibles and tongs involves several critical stages that ensure product quality and reliability. The key stages include material preparation, forming, assembly, and finishing.

How Is Material Prepared for Crucibles and Tongs?

The first stage, material preparation, begins with selecting high-quality raw materials. For crucibles, materials such as clay, graphite, and ceramics are common due to their high melting points and thermal shock resistance. Tongs are typically made from durable metals like nickel-plated steel or carbon steel, which provide the necessary strength and heat resistance.

Once the materials are sourced, they undergo rigorous testing to ensure they meet specific mechanical and thermal properties. This might include tensile strength tests and thermal conductivity evaluations. Only materials that pass these evaluations proceed to the next stage.

What Forming Techniques Are Used in Manufacturing Crucibles and Tongs?

The forming stage involves shaping the prepared materials into their final forms. For crucibles, this often involves processes such as casting or pressing. For instance, clay and graphite crucibles may be pressed into molds, ensuring they maintain their shape and structural integrity during use.

Tongs are typically manufactured through processes like forging or stamping, where metal sheets are shaped into the desired configuration. Advanced techniques, such as computer numerical control (CNC) machining, may also be employed to achieve precise dimensions and specifications.

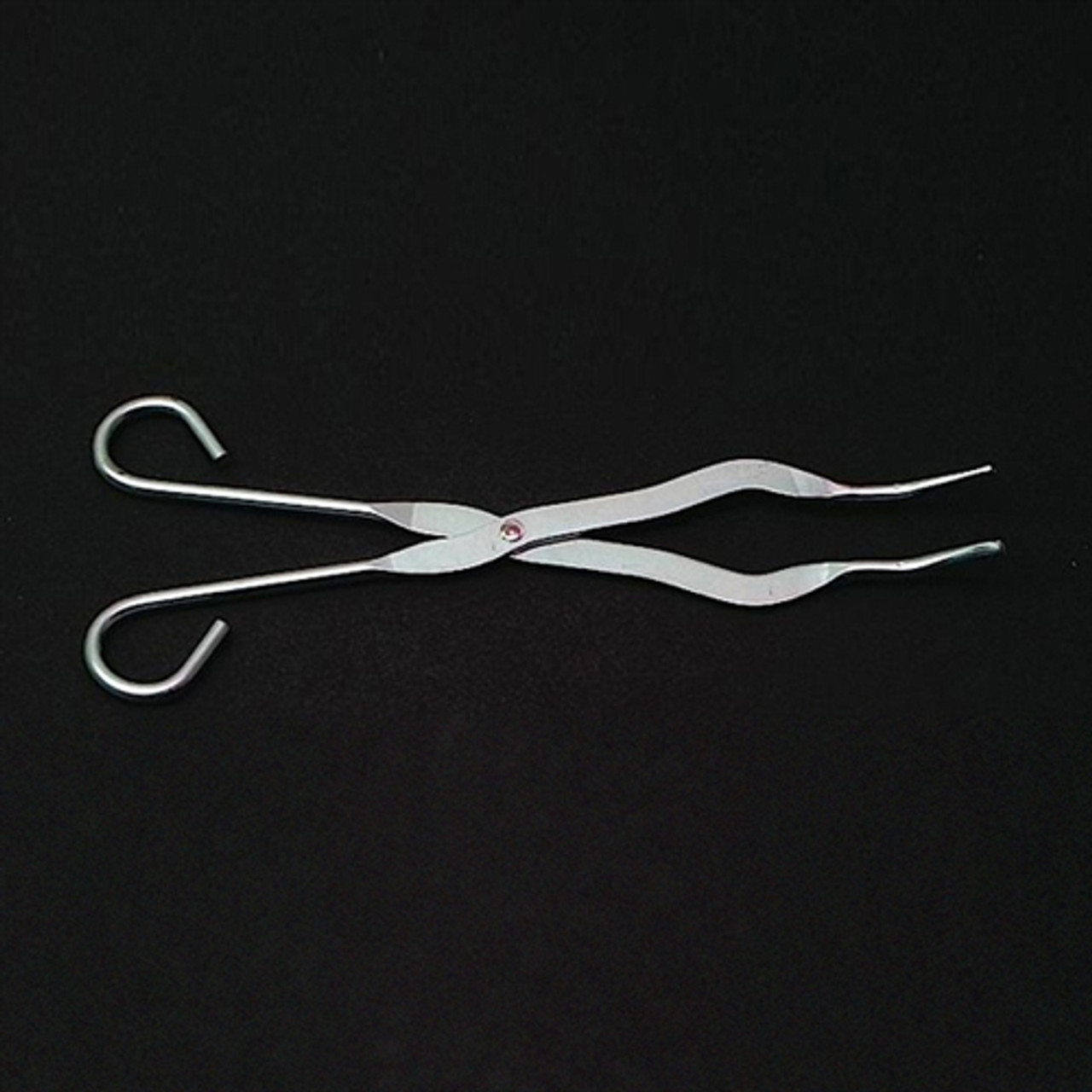

Illustrative image related to crucible and tongs

How Are Crucibles and Tongs Assembled and Finished?

After forming, the next step is assembly. This stage may involve welding, fastening, or riveting components together. For tongs, careful attention is given to the joints and grips to ensure they can withstand the stresses of lifting and pouring molten materials.

Finishing processes, such as surface treatment and coating, are crucial for enhancing durability and resistance to corrosion. Crucibles might be coated with protective layers, while tongs are often nickel-plated to improve their resistance to heat and oxidation. Quality finishing not only extends the lifespan of the products but also enhances their aesthetic appeal.

What Quality Assurance Standards Are Relevant to Crucibles and Tongs?

Quality assurance is paramount in the manufacturing of crucibles and tongs, especially given the safety implications of their use in high-temperature applications. Various international and industry-specific standards guide these processes.

Which International Standards Should B2B Buyers Look For?

ISO 9001 is a widely recognized quality management standard that indicates a company’s commitment to quality in its processes. Compliance with ISO 9001 ensures that manufacturers have established effective quality management systems, which are essential for consistent product quality.

Illustrative image related to crucible and tongs

Additionally, certifications such as CE (Conformité Européenne) are crucial for products sold within Europe, as they demonstrate compliance with health, safety, and environmental protection standards. API (American Petroleum Institute) certifications may also be relevant for tongs used in the oil and gas industries.

How Are Quality Control Checkpoints Implemented During Manufacturing?

Quality control (QC) checkpoints are integrated into various stages of the manufacturing process to ensure that products meet the required standards.

What Are the Key QC Checkpoints for Crucibles and Tongs?

-

Incoming Quality Control (IQC): At this initial stage, raw materials are inspected for quality and compliance with specifications. Any materials that do not meet the required standards are rejected.

-

In-Process Quality Control (IPQC): During the manufacturing process, regular inspections are conducted to monitor critical parameters, such as dimensions and material properties. This helps identify issues early, minimizing waste and ensuring consistent quality.

-

Final Quality Control (FQC): Once products are completed, a final inspection is carried out. This may include dimensional checks, visual inspections for defects, and functional testing to ensure the products perform as intended.

What Common Testing Methods Are Used to Validate Quality?

To verify the quality of crucibles and tongs, several testing methods are employed:

- Mechanical Testing: This includes tensile tests, impact tests, and hardness tests to evaluate the strength and durability of materials.

- Thermal Testing: Crucibles are subjected to thermal cycling tests to assess their resistance to thermal shock and high temperatures.

- Visual Inspections: A thorough visual examination checks for surface defects, misalignments, or any signs of damage that could affect performance.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying supplier quality control processes is essential for ensuring product reliability.

What Steps Should Buyers Take to Ensure Supplier Compliance?

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control systems. Buyers should request access to audit reports and certifications.

-

Request Documentation: Suppliers should provide documentation regarding their quality management systems, including ISO certifications, quality manuals, and inspection records.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of the supplier’s operations and product quality. This is particularly important when dealing with new suppliers or entering new markets.

What Are the Quality Control Nuances for International B2B Buyers?

B2B buyers from different regions may face unique challenges when it comes to quality control and assurance. For instance, varying regulations and standards across countries can complicate compliance.

How Do Regional Standards Impact Quality Assurance?

In Europe, CE marking is mandatory, while in the Middle East, buyers may need to consider local compliance certifications. Buyers should stay informed about specific regional regulations that may affect their purchasing decisions.

Illustrative image related to crucible and tongs

Additionally, cultural differences in business practices can impact communication and transparency regarding quality assurance processes. Establishing clear lines of communication and setting expectations upfront can help mitigate these challenges.

Conclusion

Understanding the manufacturing processes and quality assurance standards for crucibles and tongs is critical for B2B buyers looking to source reliable products. By familiarizing themselves with the stages of manufacturing, relevant quality standards, and effective verification methods, buyers can make informed decisions that enhance their operational efficiency and safety in high-temperature applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘crucible and tongs’

When sourcing crucibles and tongs for industrial applications, a structured approach can streamline the procurement process, ensuring that you select the best products for your needs. This guide provides a comprehensive checklist for B2B buyers, helping you navigate the essential steps in sourcing these critical tools.

Step 1: Define Your Technical Specifications

Understanding your specific requirements is the first step in sourcing crucibles and tongs. Consider factors such as the type of materials you will be melting, the volume of production, and the temperature ranges involved. This will help you identify the right materials (e.g., clay graphite, ceramic) and sizes (e.g., 1 kg to 10 kg) needed for your operations.

Illustrative image related to crucible and tongs

Step 2: Assess Quality Standards

Quality is paramount when selecting crucibles and tongs to ensure safety and efficiency. Look for products that comply with international quality standards, such as ISO certifications. Verify that the materials used are durable and capable of withstanding high temperatures without degrading, as this directly impacts the longevity of your equipment.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet potential suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. This not only confirms their credibility but also provides insights into their reliability and customer service. Additionally, consider their capacity to handle your order volumes and delivery timelines.

Step 4: Request Samples for Testing

Once you have shortlisted suppliers, ask for samples of the crucibles and tongs. Testing samples allows you to assess the quality, durability, and compatibility with your melting processes. Evaluate their performance under actual working conditions to ensure they meet your operational requirements before making a bulk purchase.

Step 5: Review Pricing and Payment Terms

Pricing can vary significantly among suppliers. Compare quotes while considering the quality of the products offered. Additionally, review the payment terms, including any bulk discounts, payment plans, or financing options. Understanding the total cost of ownership, including shipping and potential customs fees, is crucial for budgeting.

Step 6: Check for After-Sales Support

After-sales support can greatly impact your operational efficiency. Ensure that your chosen supplier offers comprehensive support, including warranty information, return policies, and maintenance services. A reliable support system will help address any issues promptly, minimizing downtime in your production processes.

Step 7: Finalize Contracts and Agreements

Once you have selected a supplier, ensure that all terms are documented in a formal contract. This should include specifications, pricing, delivery schedules, and after-sales support commitments. Clear agreements protect both parties and set expectations, which is essential for a successful long-term partnership.

By following this checklist, B2B buyers can confidently navigate the sourcing process for crucibles and tongs, ensuring they make informed decisions that enhance their operational efficiency and safety.

Comprehensive Cost and Pricing Analysis for crucible and tongs Sourcing

When sourcing crucibles and tongs, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers, especially those from regions such as Africa, South America, the Middle East, and Europe. This section explores the various cost components, price influencers, and practical buyer tips to facilitate informed purchasing decisions.

Illustrative image related to crucible and tongs

What Are the Key Cost Components for Crucibles and Tongs?

The cost structure for crucibles and tongs typically encompasses several key components:

-

Materials: The choice of materials significantly affects cost. Common materials include clay graphite, stainless steel, and nickel-plated steel. Higher-quality materials, such as those that can withstand extreme temperatures, often lead to increased costs but can enhance durability and performance.

-

Labor: Labor costs vary based on the manufacturing location. For instance, countries with higher labor costs may result in pricier products. Additionally, skilled labor is essential for producing high-quality tongs and crucibles, which can further elevate expenses.

-

Manufacturing Overhead: This includes all indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient production processes can help minimize these costs.

-

Tooling: The initial investment in tooling can be significant, especially for custom designs or specific sizes. This one-time cost is often distributed across the production run, influencing the per-unit price.

-

Quality Control (QC): Rigorous QC processes ensure product reliability, which is crucial in high-stakes industries like metallurgy. This can add to the overall cost but is essential for maintaining standards.

-

Logistics: Transportation costs vary based on the distance from the manufacturer to the buyer, shipping method, and any tariffs or import duties that may apply. Efficient logistics management can help mitigate these costs.

-

Margin: Suppliers typically add a margin to their costs to ensure profitability. This margin can vary widely depending on market dynamics and competitive factors.

How Do Price Influencers Affect Sourcing Decisions?

Several factors influence pricing in the crucible and tongs market:

-

Volume/MOQ (Minimum Order Quantity): Larger orders often lead to better pricing due to economies of scale. Buyers should negotiate for lower per-unit costs when purchasing in bulk.

-

Specifications and Customization: Customized products generally incur higher costs due to the additional design and production work involved. Buyers should clearly communicate their needs to avoid unexpected expenses.

-

Materials and Quality Certifications: Higher-quality materials and certifications (like ISO standards) can increase costs but are often necessary for specific applications. Buyers should weigh the benefits of these certifications against their budget.

-

Supplier Factors: The reputation and reliability of the supplier can influence prices. Established suppliers with a track record of quality may charge more but can also reduce risks associated with product failures.

-

Incoterms: Understanding Incoterms is essential for determining who bears the costs and risks during shipping. Terms such as FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can significantly impact the total landed cost.

What Are the Best Negotiation Tips for Buyers?

-

Conduct Market Research: Understanding market prices and trends can give buyers leverage in negotiations. Use this information to set realistic budget expectations.

-

Assess Total Cost of Ownership (TCO): Beyond the purchase price, consider maintenance, potential downtime, and replacement costs. Investing in higher-quality products may lead to lower TCO over time.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better terms and pricing. Trust can facilitate negotiations and encourage suppliers to offer discounts or favorable terms.

-

Be Prepared to Walk Away: If the terms do not meet your budget or quality requirements, be willing to explore other suppliers. This can often prompt sellers to reconsider their offers.

Disclaimer on Pricing

The prices referenced in this analysis are indicative and may vary based on market conditions, supplier negotiations, and specific buyer requirements. Always obtain quotes from multiple suppliers to ensure competitive pricing.

Alternatives Analysis: Comparing crucible and tongs With Other Solutions

Understanding Alternatives to Crucible and Tongs

In the realm of metalworking and foundry applications, crucibles and tongs are staple tools for melting and handling molten materials. However, as industries evolve, various alternative solutions have emerged, each with distinct advantages and drawbacks. This section will explore these alternatives, assisting B2B buyers in making informed decisions tailored to their operational needs.

Comparison Table

| Comparison Aspect | Crucible and Tongs | Induction Melting Furnaces | Electric Arc Furnaces |

|---|---|---|---|

| Performance | Reliable for high-temperature melting; good for small batches | Efficient melting with minimal oxidation; ideal for larger volumes | High melting rates; excellent for scrap metal recycling |

| Cost | Generally low-cost initial investment; additional costs for tongs and safety gear | Higher initial capital investment; lower operational costs over time | Significant investment in equipment; high operational costs |

| Ease of Implementation | Simple setup; requires basic training | Requires skilled operators; installation can be complex | Requires specialized knowledge; setup can be lengthy |

| Maintenance | Low maintenance; occasional replacement of tongs | Moderate maintenance; regular checks needed | High maintenance; complex systems require expert care |

| Best Use Case | Small-scale foundries, jewelry making, hobbyist applications | Industrial applications needing efficient melting; large batch production | Heavy industrial operations focused on recycling and high-volume production |

What Are the Advantages and Disadvantages of Induction Melting Furnaces?

Induction melting furnaces utilize electromagnetic induction to heat materials, offering a cleaner and more efficient melting process compared to traditional crucibles. One of the primary advantages is their capability to melt larger quantities of metal quickly, which is ideal for industrial applications. However, the initial investment is significantly higher, and skilled operators are needed to manage the equipment effectively. While maintenance is moderate, it is essential to keep the system in optimal condition to avoid costly downtime.

How Do Electric Arc Furnaces Compare to Crucibles and Tongs?

Electric arc furnaces (EAFs) are designed for high-capacity operations, particularly in recycling scrap metal. Their performance is superior in terms of melting speed and energy efficiency, which makes them suitable for large-scale production. However, the costs associated with EAFs are substantial, both in terms of initial setup and ongoing operational expenses. Maintenance can be demanding due to the complexity of the technology, requiring specialized knowledge and skills. As a result, EAFs are best suited for industries with high throughput requirements.

Conclusion: How to Choose the Right Solution for Your Needs?

When selecting between crucibles and tongs versus alternative technologies, B2B buyers should consider various factors, including production scale, operational costs, and the specific needs of their applications. For small-scale operations or specific tasks like jewelry making, crucibles and tongs may be the most practical and cost-effective choice. In contrast, larger industrial operations that prioritize efficiency and high production rates may find induction melting or electric arc furnaces more suitable despite their higher costs. Ultimately, the decision should align with the operational goals and financial capabilities of the business, ensuring optimal performance and return on investment.

Essential Technical Properties and Trade Terminology for crucible and tongs

Understanding the essential technical properties and industry terminology related to crucibles and tongs is crucial for B2B buyers in sectors like metallurgy, foundry operations, and metalworking. This knowledge aids in making informed purchasing decisions and ensures the selection of equipment that meets specific operational needs.

What Are the Key Technical Properties of Crucibles and Tongs?

-

Material Grade: Crucibles are commonly made from materials such as clay graphite, ceramic, or metal alloys. Each material offers distinct thermal resistance and chemical stability. For instance, clay graphite crucibles are preferred for their high thermal conductivity and resistance to thermal shock, making them ideal for melting metals. Understanding material grades helps buyers choose the right crucible for their specific melting applications.

-

Temperature Rating: The temperature rating indicates the maximum temperature a crucible or tong can withstand without degrading. For example, some crucible tongs can handle temperatures up to 2912°F (1600°C). Knowing the temperature ratings ensures that the selected equipment can safely operate within the intended application, preventing accidents and material failure.

-

Weight Capacity: Crucibles and tongs are designed to handle specific weights. For example, a #10 bilge crucible might be paired with tongs rated for lifting that weight. Buyers need to consider the weight capacity to avoid equipment failure, which could lead to safety hazards or loss of molten material.

-

Dimensions and Tolerance: The dimensions of crucibles and tongs, including their length and grip size, are crucial for compatibility with furnaces and other equipment. Tolerance levels refer to the acceptable variations in these dimensions. Proper fit ensures efficiency in operations and minimizes the risk of spills or accidents during handling.

-

Grip Design: The design of the tongs’ grip is essential for safety and functionality. Tongs with a claw design can apply even pressure on the crucible, reducing the risk of slippage. Buyers should assess grip designs based on the type and size of crucibles they intend to use, ensuring secure handling during pouring or transferring.

-

Safety Features: Many tongs come equipped with locking mechanisms or safety latches to prevent accidental drops. Understanding these features is vital for ensuring workplace safety, especially when handling molten materials.

What Are Common Trade Terms Related to Crucibles and Tongs?

-

OEM (Original Equipment Manufacturer): This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of crucibles and tongs, OEMs often provide customized solutions that meet specific industry needs, which is crucial for buyers seeking tailored equipment.

-

MOQ (Minimum Order Quantity): MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is important for B2B buyers, as it impacts inventory management and budgeting, especially for smaller operations that may not require large quantities.

-

RFQ (Request for Quotation): An RFQ is a document sent to suppliers requesting pricing and terms for specific products. Buyers should utilize RFQs when seeking competitive pricing on crucibles and tongs, ensuring they receive detailed information to make informed purchasing decisions.

-

Incoterms (International Commercial Terms): These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms helps buyers navigate shipping costs, risks, and responsibilities, facilitating smoother cross-border transactions.

-

Foundry: A foundry is a facility where metal casting is performed. Familiarity with foundry operations helps buyers understand the context in which crucibles and tongs will be used, guiding them in selecting the appropriate equipment.

-

Bilge Crucible: This term refers to a type of crucible with a specific shape designed to hold molten metal safely. Recognizing the characteristics of bilge crucibles is essential for buyers when choosing compatible tongs and ensuring safe handling.

By familiarizing themselves with these technical properties and trade terms, B2B buyers can enhance their procurement strategies, ensuring they select the right crucibles and tongs for their operational needs.

Navigating Market Dynamics and Sourcing Trends in the crucible and tongs Sector

What Are the Key Market Dynamics and Trends in the Crucible and Tongs Sector?

The crucible and tongs market is witnessing significant evolution driven by various global factors. A growing demand for high-performance materials across industries, particularly in metal casting and jewelry making, is pushing manufacturers to innovate. The rise of automated manufacturing processes and smart technologies is also reshaping sourcing strategies, making it essential for international B2B buyers to stay informed about these advancements. Key trends include the increasing adoption of lightweight and heat-resistant materials, which enhance operational efficiency and safety. Buyers from Africa, South America, the Middle East, and Europe, particularly in countries like Saudi Arabia and Germany, are increasingly looking for suppliers who offer both quality and adaptability to changing market needs.

Illustrative image related to crucible and tongs

Furthermore, the ongoing global shift towards digitalization is enabling more streamlined procurement processes. E-commerce platforms and digital marketplaces are becoming vital for sourcing crucibles and tongs, allowing buyers to compare products, prices, and suppliers more efficiently. This trend not only reduces lead times but also fosters competition among suppliers, ultimately benefiting buyers through better pricing and enhanced service. As demand continues to rise, especially in emerging markets, strategic partnerships and local sourcing will become crucial for mitigating risks related to supply chain disruptions.

How Are Sustainability and Ethical Sourcing Influencing the Crucible and Tongs Market?

Sustainability and ethical sourcing are increasingly paramount in the crucible and tongs sector, reflecting a broader trend towards environmental responsibility in manufacturing. The environmental impact of metal production is significant, with emissions and waste posing challenges to sustainability. As a result, many companies are adopting eco-friendly practices, such as using recycled materials in their crucibles and tongs, which not only reduces environmental footprints but also appeals to conscientious buyers.

International B2B buyers are urged to prioritize suppliers who demonstrate commitment to sustainability through certifications such as ISO 14001, which focuses on effective environmental management systems. Additionally, sourcing from manufacturers who utilize renewable energy in their production processes can further enhance sustainability efforts. Ethical supply chains are not merely a trend but a necessity, as buyers demand transparency regarding labor practices and material sourcing. This shift is particularly relevant in regions where ethical concerns may arise, ensuring that buyers can confidently engage with suppliers who align with their values.

How Has the Crucible and Tongs Sector Evolved Over Time?

The evolution of the crucible and tongs sector can be traced back to the early days of metallurgy, where basic tools were used for metal melting and casting. Initially crafted from rudimentary materials, advancements in metallurgy and engineering led to the development of specialized crucibles made from clay, graphite, and various alloys, enhancing durability and heat resistance. The introduction of tongs designed for specific crucible shapes and sizes further improved handling safety and efficiency.

Over the years, technological innovations have revolutionized the sector, introducing precision manufacturing techniques and materials that withstand extreme temperatures. This evolution not only increased the lifespan of crucibles and tongs but also optimized performance in foundries and metalworking industries. As the global market continues to expand, the focus has shifted towards customization and smart technologies, reflecting the changing needs of international B2B buyers. Today, the crucible and tongs market is characterized by a blend of tradition and modernity, where historical craftsmanship meets cutting-edge technology to meet diverse industrial demands.

Frequently Asked Questions (FAQs) for B2B Buyers of crucible and tongs

-

1. How do I choose the right crucible and tongs for my specific applications?

Selecting the appropriate crucible and tongs depends on several factors, including the type of metal you are melting, the volume of material, and the melting temperature. For high-temperature applications, look for tongs and crucibles made from materials that can withstand extreme heat, such as graphite or ceramic. Additionally, ensure the tongs are designed to securely grip the crucible type you are using, whether it’s a standard or bilge crucible. Consulting with suppliers about your specific requirements can also provide valuable insights. -

2. What is the best material for crucibles and tongs in foundry applications?

The best material largely depends on the metals being processed. For instance, clay-graphite crucibles are ideal for melting aluminum, while ceramic crucibles are suitable for high-temperature metals like gold and silver. Tongs made from nickel-plated steel or carbon steel offer durability and resistance to heat, making them suitable for a variety of applications. Always verify compatibility between the crucible material and the tongs to ensure safety and efficiency. -

3. What are the minimum order quantities (MOQs) for crucibles and tongs when sourcing from international suppliers?

Minimum order quantities can vary significantly among suppliers and regions. Typically, MOQs for crucibles and tongs can range from as low as 10 units to several hundred, depending on the product type and supplier policies. It’s advisable to negotiate MOQs with suppliers, especially if you’re looking to test a new product line. Some suppliers may offer flexible terms for first-time buyers or bulk orders, making it important to communicate your needs clearly. -

4. How can I vet suppliers when sourcing crucibles and tongs internationally?

To vet suppliers effectively, start by researching their reputation and customer reviews online. Look for certifications such as ISO to ensure quality standards. Request samples of the products to assess their quality firsthand. Additionally, consider asking for references from other international clients to gauge their experience. Utilizing platforms like Alibaba or TradeIndia can also provide insights into supplier credibility through buyer feedback and ratings. -

5. What are typical payment terms when importing crucibles and tongs from international suppliers?

Payment terms can vary but often include options such as full payment upfront, a 30% deposit with the balance upon shipment, or net 30 days after receipt of goods. Letters of credit are also common for larger transactions to ensure security for both parties. Always clarify payment methods accepted by the supplier and consider negotiating terms that align with your cash flow requirements. -

6. What quality assurance measures should I consider when purchasing crucibles and tongs?

Quality assurance is crucial to ensure the safety and longevity of crucibles and tongs. Inquire whether the supplier conducts regular quality checks and what standards they adhere to, such as ASTM or ISO certifications. Request documentation regarding material specifications and any testing results. Additionally, consider establishing a return policy or warranty terms to protect against defective products. -

7. What logistics considerations should I keep in mind when importing crucibles and tongs?

Logistics is a critical aspect of international sourcing. Ensure you understand the shipping options available, such as air freight for urgent orders or sea freight for cost-effective shipping. Be aware of customs duties, taxes, and any import regulations specific to your region. Collaborating with a logistics partner experienced in handling industrial goods can streamline the process, ensuring timely delivery and compliance with all regulations. -

8. How can I customize crucibles and tongs to meet my specific requirements?

Many suppliers offer customization options for crucibles and tongs, including size, material, and design alterations. When seeking customization, clearly communicate your specifications and intended applications to the supplier. Some manufacturers may require a minimum order for customized products. Engaging in a dialogue with the supplier can help you understand their capabilities and lead to tailored solutions that meet your operational needs effectively.

Top 3 Crucible And Tongs Manufacturers & Suppliers List

1. PMC Supplies – Adjustable Fly-Nut Tongs & Ceramic Crucible Set

Domain: pmcsupplies.com

Registered: 2013 (12 years)

Introduction: [{‘name’: ‘Adjustable Fly-Nut Tongs & Ceramic Crucible Set’, ‘price’: ‘$18.95’}, {‘name’: ‘No 3 – 4 Kg Clay Graphite Foundry Crucible Kit with 26″ Foundry Crucible Flask Tongs’, ‘price’: ‘$37.95’}, {‘name’: ‘100 Gram Ceramic Crucible and Whip Tongs Metal Melting Set’, ‘price’: ‘$18.95’}, {‘name’: ‘No 3 – 4 Kg Clay Graphite Foundry Crucible Kit with 26″ Foundry Crucible Flask Tongs and 13″ Cowhide …

2. Hach – Nickel-Plated Steel Wire

Domain: hach.com

Registered: 1995 (30 years)

Introduction: This company, Hach – Nickel-Plated Steel Wire, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Simond – 4 Kg Crucible Tongs Set

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Simond Store 4 Kg Crucible Tongs Set, Graphite Crucible Lifting and Metal Melting Pouring Tong, Metal Casting Tools for Jewelers Blacksmith Metalsmith Refiners Smelter – Set of 2 Tongs. Amazon Product Rating: 4.1. Fakespot Reviews Grade: B. Adjusted Fakespot Rating: 4.1.

Strategic Sourcing Conclusion and Outlook for crucible and tongs

In today’s global market, strategic sourcing of crucibles and tongs is essential for optimizing production efficiency and ensuring safety in metalworking processes. By leveraging diverse supplier networks across regions such as Africa, South America, the Middle East, and Europe, businesses can not only access high-quality products but also benefit from competitive pricing and innovative solutions. The variety of options—from adjustable tongs designed for different crucible sizes to specialized safety features—enables companies to tailor their purchases to meet specific operational needs.

As international B2B buyers, it is crucial to evaluate suppliers based on their ability to provide reliable, durable, and compliant products that adhere to industry standards. Establishing long-term relationships with trusted manufacturers can enhance supply chain resilience and foster collaboration on future innovations.

Looking ahead, the demand for advanced crucible and tongs solutions will likely grow as industries continue to prioritize efficiency and safety. Engage with suppliers who understand the unique challenges of your region and can offer tailored solutions that enhance your operational capabilities. The time to invest in strategic sourcing is now—empower your business with the right tools to excel in a competitive landscape.

Illustrative image related to crucible and tongs

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.