How to Source Cleanroom Consumables Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for cleanroom consumables

In today’s global marketplace, sourcing cleanroom consumables presents a significant challenge for B2B buyers, especially in critical sectors such as pharmaceuticals, electronics, and aerospace. The need for high-quality, compliant products that ensure contamination control and operational efficiency cannot be overstated. This guide serves as a comprehensive resource, covering a wide range of cleanroom consumables, from gloves and wipes to matting and packaging solutions. We delve into various applications, helping you understand the specific requirements for different environments, such as ISO classifications and industry standards.

Additionally, we address essential aspects of supplier vetting, pricing strategies, and logistics tailored to international markets, particularly for buyers in Africa, South America, the Middle East, and Europe, including countries like Saudi Arabia and Germany. By empowering decision-makers with actionable insights, this guide ensures that you can navigate the complexities of purchasing cleanroom consumables with confidence and precision. Whether you are initiating a new project or optimizing existing operations, informed purchasing decisions will significantly enhance your cleanroom’s performance and compliance, ultimately driving your business success in a competitive landscape.

Understanding cleanroom consumables Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Cleanroom Gloves | High dexterity, low-lint materials, various sizes/types | Electronics, pharmaceuticals, healthcare | Pros: Protects against contamination; enhances grip. Cons: May require frequent replacement due to wear. |

| Cleanroom Wipes | Lint-free, presaturated options, various materials | Semiconductor manufacturing, labs | Pros: Effective contamination control; available in sterile and non-sterile variants. Cons: Cost can add up with frequent use. |

| Cleanroom Apparel | ESD-safe, breathable, compliant with ISO standards | Aerospace, automotive, medical facilities | Pros: Ensures worker safety and compliance; enhances comfort during long wear. Cons: Higher initial investment than regular clothing. |

| Cleanroom Packaging | Moisture barrier, ESD protection, customizable sizes | Electronics, medical device shipping | Pros: Protects sensitive components; customizable for specific needs. Cons: Requires careful handling to maintain integrity. |

| Adhesive Mats | Multi-layered, easy to install, various sizes and colors | Entryways of cleanrooms, laboratories | Pros: Reduces footborne contamination; easy to replace. Cons: Can be expensive over time due to replacement needs. |

What are the Characteristics and Suitability of Cleanroom Gloves?

Cleanroom gloves are specifically designed to minimize contamination risk in controlled environments. They are made from materials such as nitrile, latex, or vinyl, and are available in various sizes and styles to meet specific operational needs. These gloves provide high dexterity and comfort, making them suitable for tasks requiring fine motor skills. When purchasing, consider the glove’s material for potential allergies, the level of protection needed, and compliance with industry standards such as ISO. Regular replacement is essential to maintain effectiveness and ensure safety.

How do Cleanroom Wipes Contribute to Contamination Control?

Cleanroom wipes are essential for maintaining cleanliness in controlled environments. They are made from lint-free materials and can be presaturated with solvents for enhanced cleaning effectiveness. These wipes are utilized in various applications, including semiconductor manufacturing and laboratory work, where even minimal contamination can lead to significant issues. Buyers should assess the wipe’s material and saturation level based on their specific cleaning requirements. While they are effective, frequent use can lead to increased costs, making bulk purchasing a strategic consideration.

Why is Cleanroom Apparel Important for Worker Safety?

Cleanroom apparel, including gowns, gloves, and shoe covers, plays a critical role in maintaining the integrity of controlled environments. These garments are designed to be breathable, ESD-safe, and compliant with stringent industry standards. They protect both the product and the personnel from contamination. When selecting cleanroom apparel, businesses should consider comfort, fit, and compliance with applicable regulations. While the initial investment may be higher than regular clothing, the long-term benefits in safety and compliance are invaluable.

What Advantages Does Cleanroom Packaging Offer?

Cleanroom packaging is designed to protect sensitive components during storage and transit. This type of packaging often features moisture barriers and ESD protection, making it ideal for industries such as electronics and medical devices. When choosing cleanroom packaging, buyers should look for customizable options that meet specific product requirements. Although the upfront cost may be higher, the protection offered can prevent costly damages and product failures, justifying the investment.

How Do Adhesive Mats Help in Cleanroom Environments?

Adhesive mats are used at entry points to cleanrooms to trap dirt and debris from footwear, significantly reducing footborne contamination. They come in various sizes and colors and are designed for easy installation and replacement. When selecting adhesive mats, consider the foot traffic in the area and the specific cleanroom standards that need to be met. While they are effective, the ongoing need for replacement can lead to increased operational costs, making it essential to factor this into the overall cleanroom maintenance budget.

Key Industrial Applications of cleanroom consumables

| Industry/Sector | Specific Application of cleanroom consumables | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Pharmaceuticals | Sterile packaging and cleanroom wipes for drug manufacturing | Ensures product integrity and compliance with regulations | Need for ISO-certified products; reliable suppliers with global reach |

| Electronics | ESD-safe gloves and packaging for semiconductor production | Protects sensitive components from electrostatic discharge | Must meet specific ESD standards; availability of various sizes and types |

| Aerospace | Cleanroom apparel and cleaning materials for assembly lines | Maintains a contamination-free environment for critical parts | Compliance with aerospace industry standards; durability and comfort of apparel |

| Biotechnology | Cleanroom swabs and wipes for research labs | Facilitates contamination control in sensitive experiments | Availability of specialized products; bulk purchasing options for labs |

| Food & Beverage | Cleanroom cleaning supplies for production facilities | Ensures hygiene and safety in food processing environments | Products must be compliant with food safety regulations; sourcing from certified manufacturers |

How Are Cleanroom Consumables Used in Pharmaceuticals?

In the pharmaceutical industry, cleanroom consumables like sterile packaging and high-quality cleanroom wipes are vital for drug manufacturing. These products help maintain a sterile environment, which is crucial for preventing contamination that could compromise product safety and efficacy. Buyers in this sector must ensure that their suppliers provide ISO-certified products that meet strict regulatory standards, particularly for international operations across regions like Africa and Europe, where compliance can vary significantly.

Illustrative image related to cleanroom consumables

What is the Role of Cleanroom Consumables in Electronics Manufacturing?

In electronics manufacturing, particularly in semiconductor production, ESD-safe gloves and specialized packaging play a critical role in protecting sensitive components from electrostatic discharge. This can prevent costly damage and ensure product reliability. Buyers should seek suppliers who offer a wide range of ESD-safe products that adhere to specific industry standards, as well as those who can accommodate bulk orders to meet production demands in regions like South America and the Middle East.

How Do Cleanroom Consumables Support Aerospace Applications?

The aerospace sector requires stringent cleanliness standards to ensure the integrity of critical components during assembly. Cleanroom apparel, such as lab coats and gloves, along with specialized cleaning materials, are essential for preventing contamination. Businesses must source products that comply with aerospace industry standards and ensure durability and comfort for the workforce, particularly when dealing with suppliers in Europe, where regulations can be particularly rigorous.

Why Are Cleanroom Consumables Essential for Biotechnology?

In biotechnology research labs, cleanroom swabs and wipes are crucial for maintaining a contamination-free environment during experiments. These consumables help in the meticulous cleaning of surfaces and equipment, ensuring accurate and reliable results. Buyers should look for suppliers who offer specialized products that can cater to specific research needs, as well as bulk purchasing options to support ongoing research projects, especially in regions like Africa where laboratory resources may be limited.

How Do Cleanroom Consumables Ensure Safety in Food & Beverage Production?

In the food and beverage industry, cleanroom cleaning supplies are essential for maintaining hygiene and safety in production facilities. These consumables help prevent contamination that could lead to foodborne illnesses. Buyers should prioritize sourcing products that comply with food safety regulations and are manufactured by certified suppliers, ensuring that they meet the high standards required in this industry, particularly in regions like the Middle East where food safety is paramount.

3 Common User Pain Points for ‘cleanroom consumables’ & Their Solutions

Scenario 1: Navigating Compliance and Regulatory Standards

The Problem: B2B buyers in industries such as pharmaceuticals, electronics, and aerospace often grapple with the complexities of compliance with strict regulatory standards. These regulations dictate the types of cleanroom consumables that can be used, their specifications, and how they must be documented. Failure to comply can lead to costly penalties, product recalls, and damage to reputation. The challenge is compounded for buyers operating across multiple countries, each with its own set of regulations and certifications.

Illustrative image related to cleanroom consumables

The Solution: To navigate these regulatory waters, it is crucial for buyers to invest time in understanding the specific compliance requirements relevant to their industry and geographic location. Start by conducting a thorough audit of your cleanroom processes and consumables. Collaborate with your suppliers to obtain documentation that confirms their products meet required standards, such as ISO classifications or industry-specific certifications. Establish a centralized compliance management system to track and manage documentation and certifications for all consumables. Regular training sessions for staff on compliance protocols can also help mitigate risks associated with non-compliance. By being proactive and well-informed, businesses can ensure they remain compliant and avoid potential pitfalls.

Scenario 2: Managing Supply Chain Disruptions

The Problem: Global supply chain disruptions can severely impact the availability of cleanroom consumables, leading to delays in production and increased operational costs. Buyers may face shortages of critical items like cleanroom gloves or wipes, which can halt processes and compromise cleanliness standards. This situation creates stress for procurement teams, who must scramble to find alternative sources without sacrificing quality.

The Solution: To combat supply chain vulnerabilities, B2B buyers should adopt a multi-sourcing strategy. Identify multiple suppliers for essential consumables to ensure redundancy; this can be particularly effective in regions prone to disruption. Establish long-term relationships with these suppliers to create a reliable network that can respond swiftly to changes in demand. Additionally, consider investing in local suppliers or those within the same region to reduce lead times and shipping costs. Implementing a just-in-time inventory system can help manage stock levels efficiently, minimizing excess while ensuring availability. By diversifying your supply base and optimizing inventory management, businesses can better navigate disruptions and maintain operational continuity.

Scenario 3: Ensuring Quality and Performance Consistency

The Problem: Inconsistent quality of cleanroom consumables can lead to contamination issues, affecting product integrity and operational efficiency. B2B buyers may struggle with variations in performance, such as differences in lint-free capabilities of wipes or the effectiveness of gloves in preventing contamination. This inconsistency can result in costly reworks, increased waste, and damage to brand reputation.

The Solution: To ensure quality and performance consistency, buyers should implement a robust vendor qualification process. This includes rigorous testing of consumables before bulk purchasing, establishing clear quality criteria that products must meet. Regular audits and evaluations of suppliers can help maintain quality standards over time. Additionally, consider utilizing third-party testing services to verify the performance of cleanroom consumables against industry benchmarks. Encourage feedback from end-users in cleanroom environments to identify any issues early. By prioritizing supplier quality and involving end-users in the evaluation process, businesses can secure high-quality consumables that meet their stringent operational needs, ultimately reducing risk and enhancing overall performance.

Strategic Material Selection Guide for cleanroom consumables

What Are the Key Materials Used in Cleanroom Consumables?

When selecting cleanroom consumables, the choice of materials is crucial for ensuring compliance with stringent industry standards and operational efficiency. Below are analyses of four common materials used in cleanroom consumables, focusing on their properties, advantages, disadvantages, and relevant considerations for international B2B buyers.

1. Polyester

Key Properties:

Polyester is known for its excellent chemical resistance, low moisture absorption, and durability. It can withstand a range of temperatures, typically from -40°C to 150°C, making it suitable for various cleanroom applications.

Pros & Cons:

The durability of polyester makes it ideal for long-term use in cleanrooms. However, it can be more expensive than alternatives like cotton. Manufacturing polyester products can also be complex, requiring specialized techniques to ensure they meet cleanroom standards.

Illustrative image related to cleanroom consumables

Impact on Application:

Polyester is compatible with a wide range of cleaning agents and is often used in wipes and garments. It is particularly effective in environments that require stringent contamination control, such as pharmaceuticals and electronics.

Considerations for International Buyers:

Buyers from regions like Europe and the Middle East should ensure that polyester products comply with local regulations such as REACH (Registration, Evaluation, Authorisation and Restriction of Chemicals) in Europe, which governs the use of chemical substances.

2. Nitrile

Key Properties:

Nitrile is a synthetic rubber known for its resistance to oils, chemicals, and punctures. It typically performs well in temperatures ranging from -20°C to 100°C, making it suitable for various cleanroom tasks.

Pros & Cons:

Nitrile gloves provide excellent barrier protection, making them ideal for handling sensitive materials. However, they can be less breathable than latex, which may affect comfort during prolonged use. The cost of nitrile gloves is generally moderate.

Illustrative image related to cleanroom consumables

Impact on Application:

Nitrile is often used in environments where chemical exposure is a concern, such as laboratories and manufacturing facilities. Its compatibility with a wide range of chemicals makes it a versatile choice.

Considerations for International Buyers:

In regions like Africa and South America, buyers should verify that nitrile products meet local health and safety regulations. Certifications such as ASTM D6319 for medical gloves may be required.

3. Polypropylene

Key Properties:

Polypropylene is lightweight, resistant to moisture, and has a melting point of around 160°C. It is often used in disposable cleanroom garments and packaging.

Illustrative image related to cleanroom consumables

Pros & Cons:

The affordability and disposability of polypropylene make it a popular choice for cleanroom applications. However, it lacks the durability of materials like polyester and may not be suitable for high-stress environments.

Impact on Application:

Polypropylene is ideal for single-use applications, such as coveralls and shoe covers, where contamination risk is high. It is effective in maintaining cleanliness but may not withstand repeated use.

Considerations for International Buyers:

Buyers in Europe should ensure that polypropylene products comply with EN 13795 standards for surgical drapes and gowns, which may be applicable in healthcare settings.

4. Vinyl

Key Properties:

Vinyl is a synthetic plastic polymer that is flexible and resistant to moisture. It is commonly used in gloves and protective wear.

Illustrative image related to cleanroom consumables

Pros & Cons:

Vinyl gloves are cost-effective and suitable for low-risk applications. However, they offer less protection against chemicals and are less durable than nitrile or latex options.

Impact on Application:

Vinyl is typically used in food handling and light-duty applications where chemical exposure is minimal. Its lower barrier protection limits its use in more sensitive cleanroom environments.

Considerations for International Buyers:

In markets like Saudi Arabia, compliance with local health regulations is essential, especially in food and pharmaceutical sectors where vinyl gloves may be used.

Illustrative image related to cleanroom consumables

Summary Table of Material Selection for Cleanroom Consumables

| Material | Typical Use Case for cleanroom consumables | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyester | Wipes, garments | Excellent durability and chemical resistance | Higher cost and complex manufacturing | High |

| Nitrile | Gloves | Strong barrier protection | Less breathable than latex | Medium |

| Polypropylene | Disposable garments | Cost-effective and disposable | Less durable for repeated use | Low |

| Vinyl | Gloves | Economical for low-risk tasks | Limited chemical protection | Low |

This guide provides a comprehensive overview of material selection for cleanroom consumables, assisting B2B buyers in making informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for cleanroom consumables

What Are the Main Stages in the Manufacturing Process of Cleanroom Consumables?

The manufacturing of cleanroom consumables involves a series of meticulously controlled stages to ensure that products meet the stringent requirements for contamination control across critical sectors.

Material Preparation

The first step in the manufacturing process is material preparation. This involves sourcing high-quality raw materials that comply with industry standards. For cleanroom consumables, materials such as non-woven fabrics, plastics, and specialized coatings are often used. Suppliers typically conduct thorough evaluations of material specifications, ensuring they are free from contaminants and suitable for cleanroom applications.

Forming Techniques

Once the materials are prepared, they undergo various forming techniques to create the desired product shapes. Common methods include die-cutting for wipes, injection molding for packaging, and weaving for textiles used in apparel. Advanced techniques such as ultrasonic welding may also be employed for seam sealing, particularly in gloves and clothing, to prevent particle generation.

Assembly Processes

After forming, components are assembled. This stage may involve manual or automated processes depending on the complexity of the product. For instance, cleanroom wipes may be packaged in a controlled environment to maintain sterility, while gloves are often assembled with attention to reducing lint and ensuring a secure fit.

Finishing and Packaging

The finishing stage includes any additional treatments or coatings that enhance the product’s performance, such as anti-static finishes or moisture barriers. Finally, products are packaged in materials designed to protect them from contamination during transport and storage. Packaging often adheres to specific guidelines to maintain product integrity until they reach the end user.

How Is Quality Assurance Implemented in Cleanroom Consumables Manufacturing?

Quality assurance (QA) is critical in the manufacturing of cleanroom consumables to ensure compliance with international and industry-specific standards.

What International Standards Are Relevant for Cleanroom Consumables?

Manufacturers typically adhere to internationally recognized standards such as ISO 9001, which focuses on quality management systems. Additionally, specific industry standards like CE marking for medical devices and API guidelines for pharmaceutical products may apply. These standards help ensure that products meet safety and efficacy requirements.

Illustrative image related to cleanroom consumables

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

To maintain quality throughout the manufacturing process, several quality control (QC) checkpoints are implemented:

-

Incoming Quality Control (IQC): This step involves inspecting raw materials upon arrival to ensure they meet specifications.

-

In-Process Quality Control (IPQC): During manufacturing, random sampling is conducted to monitor processes and detect any deviations from quality standards. This includes checks for dimensional accuracy, contamination levels, and overall product integrity.

-

Final Quality Control (FQC): After assembly and finishing, a thorough inspection is performed on the final products. This may include testing for sterility, particle counts, and functionality.

What Testing Methods Are Commonly Used to Ensure Quality?

Testing methods for cleanroom consumables can vary based on the product but often include:

-

Microbial Testing: Ensures that products such as wipes and apparel are free from microbial contamination.

-

Particulate Testing: Measures the number and size of particles released from products during use.

-

Chemical Testing: Assesses the presence of harmful substances or residues in materials.

-

Mechanical Testing: Evaluates the durability and performance of products, such as tensile strength for gloves.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control is essential to ensure product reliability.

What Are the Best Practices for Supplier Audits?

Conducting supplier audits is a proactive approach to verify compliance with quality standards. Buyers should request access to the supplier’s QA documentation, including:

-

Certificates of Compliance: Documents proving adherence to relevant standards.

-

Test Reports: Detailed results from QC testing that demonstrate product reliability.

-

Quality Management System Documentation: Insights into the processes and protocols the supplier follows.

What Are the Quality Control and Certification Nuances for International Buyers?

B2B buyers must navigate various certification requirements based on their region and industry. For example, products sold in the European Union may require CE marking, while those in the pharmaceutical sector must comply with FDA regulations in the U.S. Understanding these nuances is crucial for ensuring that products are market-ready and compliant with local regulations.

Illustrative image related to cleanroom consumables

How Can Buyers Ensure Continued Quality After Purchase?

Buyers should establish long-term relationships with suppliers that include regular communication regarding quality updates and any changes in manufacturing processes. Additionally, engaging third-party inspection services can provide an independent assessment of product quality and compliance.

Conclusion: The Importance of Quality in Cleanroom Consumables

The manufacturing processes and quality assurance measures for cleanroom consumables are designed to ensure that products meet the highest standards of cleanliness and functionality. For B2B buyers, understanding these processes and implementing best practices for supplier verification can significantly enhance the reliability of their cleanroom operations. By investing time in supplier audits and familiarizing themselves with international standards, buyers can secure high-quality consumables that support their critical environments.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cleanroom consumables’

Introduction

This practical sourcing guide provides a step-by-step checklist for B2B buyers looking to procure cleanroom consumables. Understanding the unique requirements of cleanroom environments is critical for ensuring compliance with industry standards and maintaining product integrity. This checklist will help streamline your sourcing process, ensuring you make informed decisions when selecting suppliers and products.

Illustrative image related to cleanroom consumables

Step 1: Define Your Technical Specifications

Before initiating your sourcing process, it is essential to clearly define your technical specifications for cleanroom consumables. This includes understanding the cleanliness levels required (ISO class), the types of materials that are compatible with your cleanroom environment, and any specific certifications needed for compliance.

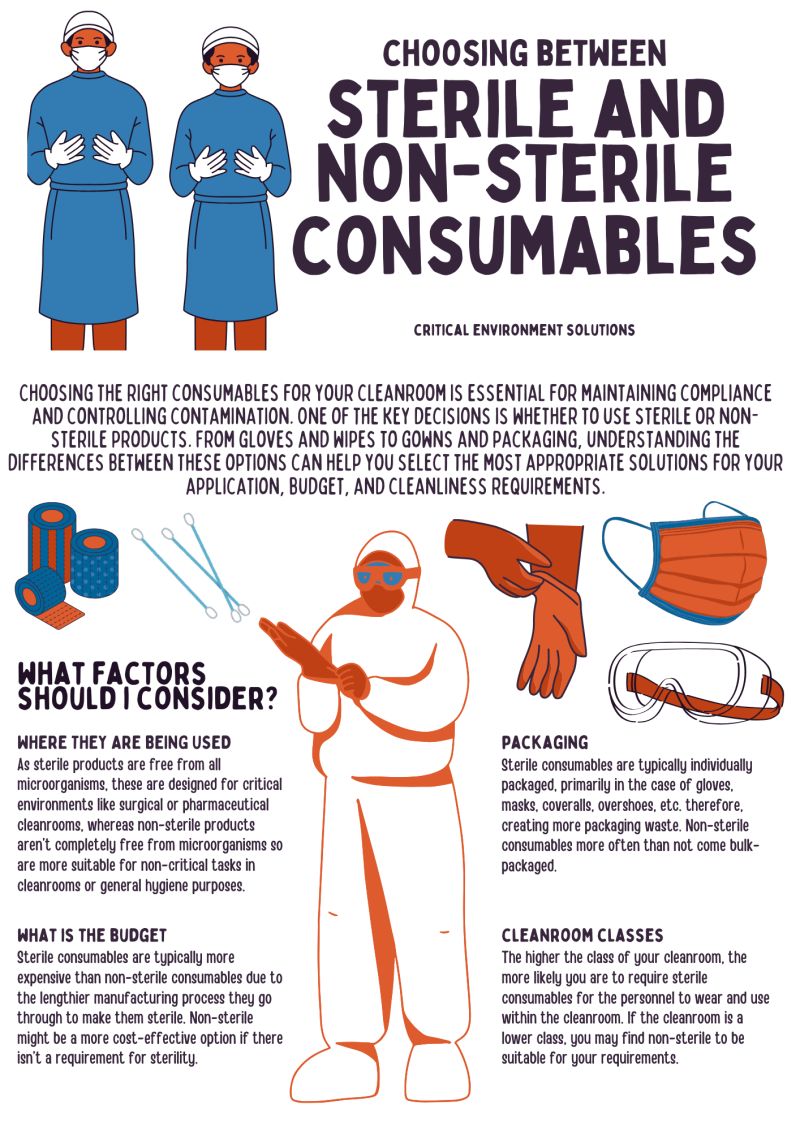

– Considerations: Identify whether you need sterile or non-sterile products, ESD-safe materials, or specific lint-free characteristics.

– Documentation: Ensure that you have documentation detailing the specific standards your cleanroom must meet, as this will guide your procurement process.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in cleanroom consumables. Look for suppliers with a proven track record in your industry and who can demonstrate compliance with relevant standards.

– Supplier Reputation: Check online reviews, industry forums, and references from other businesses to gauge their reliability.

– Product Range: Ensure the supplier offers a comprehensive range of products that meet your specific needs, from gloves to wipes and packaging solutions.

Step 3: Evaluate Supplier Certifications

It is crucial to verify the certifications of your potential suppliers to ensure they meet industry standards. Look for certifications such as ISO 9001 for quality management systems and ISO 13485 for medical device manufacturing.

– Quality Assurance: Certifications indicate that the supplier adheres to rigorous quality control processes.

– Regulatory Compliance: Ensure that the products comply with local and international regulations relevant to your industry, such as FDA or EU standards.

Step 4: Request Samples for Testing

Before making a bulk purchase, request samples of the cleanroom consumables you are considering. This allows you to assess the quality and performance of the products in your specific environment.

– Testing Criteria: Evaluate the samples based on factors such as lint-free performance, sterility, and compatibility with your cleanroom protocols.

– Feedback Loop: Involve your cleanroom personnel in the evaluation process to get their insights and preferences.

Step 5: Compare Pricing and Terms

Once you have identified suitable suppliers and tested their products, compare pricing and terms. This includes not only the cost of the consumables but also shipping fees, lead times, and payment terms.

– Total Cost of Ownership: Consider the long-term costs associated with the products, such as replacement frequency and maintenance.

– Negotiation Opportunities: Don’t hesitate to negotiate terms, especially if you are placing a large order or establishing a long-term relationship.

Illustrative image related to cleanroom consumables

Step 6: Establish a Procurement Plan

Create a procurement plan that outlines your purchasing strategy, including timelines, budgets, and inventory management practices. This ensures that you maintain a consistent supply of cleanroom consumables without excess inventory.

– Inventory Management: Utilize inventory management software to track usage and reorder points effectively.

– Supplier Relationship Management: Maintain open communication with your suppliers for updates on new products and potential disruptions.

Step 7: Monitor Supplier Performance

After procurement, continue to monitor the performance of your suppliers and the quality of the consumables. Regular evaluations will help identify any issues early and ensure that your cleanroom standards are consistently met.

– Performance Metrics: Establish metrics for delivery times, product quality, and customer service.

– Feedback Mechanism: Implement a feedback system to address any concerns promptly and foster a collaborative relationship with your suppliers.

Comprehensive Cost and Pricing Analysis for cleanroom consumables Sourcing

Understanding the cost structure and pricing dynamics of cleanroom consumables is crucial for international B2B buyers, especially those operating in diverse markets such as Africa, South America, the Middle East, and Europe. This analysis will cover the cost components, price influencers, and practical tips for buyers to optimize their sourcing strategies.

What Are the Key Cost Components in Cleanroom Consumables?

-

Materials: The primary cost driver in cleanroom consumables is the quality of materials used. High-grade polymers, specialized fabrics, and chemicals for cleaning and sterilization significantly influence the overall pricing. Suppliers often source materials that meet stringent industry standards, impacting the final cost.

-

Labor: Labor costs encompass the wages of workers involved in manufacturing, assembly, and quality control processes. In regions with higher labor costs, such as Europe, buyers may find that the price of consumables is elevated due to these factors.

-

Manufacturing Overhead: This includes costs associated with facilities, utilities, and equipment maintenance. Suppliers with advanced manufacturing capabilities may charge a premium, reflecting their investment in technology and automation to ensure quality and efficiency.

-

Tooling: For customized products, tooling costs can be substantial. This includes the design and fabrication of molds or specialized equipment needed for production. Buyers should inquire about these costs, especially when considering bespoke solutions.

-

Quality Control (QC): Strict QC measures are essential in cleanroom environments. The costs associated with testing and compliance can add to the price of consumables, particularly for products that require certification (e.g., ISO standards).

-

Logistics: Shipping and handling costs vary widely depending on the origin of the products and destination. International shipments may incur additional fees such as customs duties, which can affect the total cost.

-

Margin: Suppliers typically include a profit margin in their pricing. Understanding the market competition can help buyers negotiate better terms and pricing.

What Factors Influence Pricing for Cleanroom Consumables?

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to reduced per-unit costs due to economies of scale. Buyers should consider their consumption rates and negotiate favorable terms based on anticipated volumes.

-

Specifications and Customization: Custom products tailored to specific applications can command higher prices. Buyers need to weigh the benefits of customization against potential cost increases.

-

Material Quality and Certifications: Higher-quality materials and certified products generally come at a premium. Buyers should assess their needs to determine the necessary quality levels and certifications required for compliance.

-

Supplier Factors: The reputation and reliability of suppliers can also influence pricing. Established suppliers may charge more due to their proven track record, while newer entrants might offer competitive rates to gain market share.

-

Incoterms: Understanding the shipping terms is crucial for international buyers. Different Incoterms dictate the responsibilities of buyers and sellers regarding shipping costs, insurance, and liability, which can impact overall pricing.

What Are the Best Practices for Buyers When Sourcing Cleanroom Consumables?

-

Negotiation: Engage suppliers in discussions about pricing, especially for bulk orders or long-term contracts. Leverage competitive quotes from multiple suppliers to enhance negotiation leverage.

-

Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes initial costs plus ongoing expenses such as maintenance, disposal, and compliance costs. This holistic view can help in selecting the most cost-effective options.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and international shipping costs. Establishing agreements in stable currencies can mitigate risks associated with exchange rate volatility.

-

Research and Compare Suppliers: Conduct thorough research on potential suppliers, focusing on their quality standards, customer service, and delivery times. This ensures that you select a partner who can meet your specific needs reliably.

Conclusion

Navigating the cost structure and pricing of cleanroom consumables requires an informed approach. By understanding the key components that influence costs and leveraging best practices in procurement, international B2B buyers can optimize their sourcing strategies to ensure compliance and efficiency in their cleanroom operations.

Illustrative image related to cleanroom consumables

Alternatives Analysis: Comparing cleanroom consumables With Other Solutions

Understanding Alternatives to Cleanroom Consumables: A Comparative Analysis

In the realm of contamination control, cleanroom consumables have long been the standard for maintaining sterile environments essential for industries like pharmaceuticals, electronics, and aerospace. However, as technology advances and operational needs evolve, businesses must consider viable alternatives that may offer comparable or superior performance. This section presents a detailed analysis of cleanroom consumables in comparison to two alternative solutions: modular cleanroom systems and UV sterilization technology.

Comparison Table

| Comparison Aspect | Cleanroom Consumables | Modular Cleanroom Systems | UV Sterilization Technology |

|---|---|---|---|

| Performance | High efficacy in contamination control; tailored for specific tasks | Effective for maintaining sterile environments; customizable layouts | Rapid disinfection; effective against a broad spectrum of pathogens |

| Cost | Moderate upfront costs with ongoing supply needs | Higher initial investment; lower ongoing costs | Lower initial costs; maintenance may vary |

| Ease of Implementation | Simple to integrate into existing operations | Requires planning and installation | Easy to implement but requires training for effective use |

| Maintenance | Regular supply replenishment and waste management | Minimal maintenance; depends on use frequency | Regular bulb replacement and cleaning of UV units |

| Best Use Case | Short-term projects or specific tasks needing high precision | Permanent installations for critical environments | Rapid disinfection in various settings, including cleanrooms |

Detailed Breakdown of Alternatives

1. Modular Cleanroom Systems

Modular cleanroom systems offer a flexible and scalable solution for organizations needing controlled environments. These systems can be constructed using prefabricated panels that allow for quick assembly and disassembly. The primary advantage is their customization; businesses can design a cleanroom that fits their specific operational needs without extensive renovations. However, the initial investment can be significant, which might deter smaller enterprises. Additionally, while these systems are low-maintenance, any modifications can incur additional costs.

2. UV Sterilization Technology

UV sterilization is gaining traction as a fast and effective method for disinfection in cleanroom settings. This technology uses UV light to eliminate bacteria and viruses, providing a chemical-free solution for contamination control. The ease of implementation makes it appealing, as it can be integrated into existing workflows with minimal disruption. However, effective use requires proper training to ensure safety and efficacy, and regular maintenance of UV units is necessary to maintain performance levels.

Conclusion: Choosing the Right Solution for Your Needs

Selecting the appropriate solution for contamination control is critical for B2B buyers. Cleanroom consumables are ideal for high-precision tasks and short-term projects but come with ongoing supply costs. Modular cleanroom systems provide a permanent, customizable solution but require a larger upfront investment. On the other hand, UV sterilization technology offers a rapid disinfection method that can be easily implemented but necessitates proper training and maintenance. Buyers should assess their specific operational requirements, budget constraints, and long-term goals to determine the most suitable option for their cleanroom environments.

Illustrative image related to cleanroom consumables

Essential Technical Properties and Trade Terminology for cleanroom consumables

What Are the Key Technical Properties of Cleanroom Consumables?

Cleanroom consumables are essential in maintaining a controlled environment across various industries such as pharmaceuticals, electronics, and aerospace. Understanding their technical properties can help B2B buyers make informed purchasing decisions.

1. Material Grade

Material grade refers to the quality and type of materials used in manufacturing cleanroom consumables. Common materials include polyester, nylon, and nitrile. High-grade materials are crucial for ensuring durability, low particle generation, and chemical resistance. For B2B buyers, selecting the appropriate material grade can directly impact operational efficiency and compliance with industry regulations.

2. Particle Count

Particle count is a measure of the number of particles present in a given volume of air or on a surface. Cleanroom consumables must adhere to strict particle count standards based on the cleanroom classification (e.g., ISO 5, ISO 6). This property is vital for industries like pharmaceuticals, where even minute contaminants can compromise product integrity. Buyers should verify that products meet the required particle count specifications for their specific cleanroom environment.

3. ESD Properties

Electrostatic Discharge (ESD) properties refer to a material’s ability to dissipate static electricity. This is critical in environments dealing with sensitive electronic components. Cleanroom consumables, such as gloves and mats, are often designed to be antistatic or conductive to prevent ESD-related damage. For B2B buyers, understanding ESD properties ensures the protection of valuable assets and compliance with safety standards.

4. Sterility

Sterility is a crucial specification for consumables used in medical and laboratory settings. Products can be either sterile or non-sterile, with sterile items undergoing specific processes to eliminate microorganisms. Buyers in the healthcare sector must prioritize sterile consumables to prevent contamination and ensure patient safety.

Illustrative image related to cleanroom consumables

5. Tolerance Levels

Tolerance levels indicate the permissible limits of variation in dimensions or performance characteristics. For example, cleanroom gloves should fit snugly without compromising dexterity. Tolerance is critical for ensuring that consumables perform as expected within the stringent requirements of controlled environments. Understanding tolerance levels helps buyers choose products that will meet their operational needs.

What Are Common Trade Terms Used in Cleanroom Consumables?

Familiarity with industry jargon can facilitate smoother transactions and negotiations in the cleanroom consumables market.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce products or components that are purchased by another company and sold under that company’s brand name. Understanding OEM relationships can help buyers identify reliable suppliers for custom or branded cleanroom products.

Illustrative image related to cleanroom consumables

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units that a supplier is willing to sell. This term is critical for B2B buyers to consider, as it affects inventory management and cost efficiency. Knowing the MOQ helps businesses plan their purchases strategically to avoid overstock or stockouts.

3. RFQ (Request for Quotation)

An RFQ is a document used by buyers to solicit price quotes from suppliers for specific products or services. Including detailed specifications in an RFQ can streamline the procurement process and ensure that the received quotes meet the required standards.

4. Incoterms

Incoterms (International Commercial Terms) are a set of predefined commercial terms that clarify the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is essential for B2B buyers to manage shipping costs, risks, and delivery timelines effectively.

Illustrative image related to cleanroom consumables

5. EPA (Environmental Protection Agency) Compliance

EPA compliance refers to adherence to regulations set by environmental agencies regarding the handling and disposal of materials. For cleanroom consumables, compliance ensures that products meet environmental standards, which can influence purchasing decisions for environmentally conscious companies.

By understanding these technical properties and trade terminology, B2B buyers can enhance their procurement strategies for cleanroom consumables, ensuring they meet industry standards and operational needs effectively.

Navigating Market Dynamics and Sourcing Trends in the cleanroom consumables Sector

What Are the Current Market Dynamics and Key Trends in Cleanroom Consumables?

The cleanroom consumables market is witnessing significant growth driven by the increasing need for contamination control in critical sectors such as pharmaceuticals, electronics, and aerospace. With a heightened focus on health and safety standards globally, especially post-pandemic, there is an emerging demand for high-quality cleanroom supplies. International B2B buyers from regions like Africa, South America, the Middle East, and Europe are particularly keen on sourcing products that comply with stringent regulations and ISO standards.

One key trend is the adoption of advanced technologies in cleanroom environments, such as automation and data analytics, which enhance operational efficiency. Moreover, the rise of e-commerce platforms has simplified the procurement process, allowing buyers to access a wider range of products and suppliers. Cleanroom consumables are also evolving, with innovations such as disposable cleanroom apparel and advanced cleaning solutions that offer improved performance while minimizing contamination risks.

Another notable market dynamic is the shift towards local sourcing. Buyers are increasingly prioritizing suppliers who can ensure shorter lead times and more responsive customer service, especially in regions that are developing their cleanroom infrastructures. This trend is particularly evident in emerging markets where the establishment of new cleanroom facilities is on the rise, driven by industrial growth and regulatory requirements.

How Is Sustainability and Ethical Sourcing Impacting Cleanroom Consumables?

Sustainability is becoming a core consideration for B2B buyers in the cleanroom consumables sector. The environmental impact of production processes and the lifecycle of cleanroom products are under scrutiny, prompting companies to seek out eco-friendly options. Ethical sourcing of materials, particularly those that are recyclable or biodegradable, is gaining traction as buyers look to align their procurement practices with corporate social responsibility (CSR) initiatives.

Certifications such as ISO 14001 for environmental management and the use of materials that carry green certifications are increasingly influencing purchasing decisions. Buyers are prioritizing suppliers who demonstrate a commitment to sustainable practices, such as reduced waste and energy-efficient manufacturing processes. Moreover, the demand for cleanroom consumables made from non-toxic materials is on the rise, as organizations strive to create safer environments for both workers and the products being manufactured.

As a result, suppliers that can provide transparency in their supply chains and demonstrate their sustainability credentials are likely to gain a competitive edge. This shift not only reflects a growing awareness of environmental issues but also resonates with end consumers who are becoming more conscious of the products they use and the companies they support.

Illustrative image related to cleanroom consumables

How Has the Cleanroom Consumables Market Evolved Over Time?

The evolution of the cleanroom consumables market can be traced back to the mid-20th century when the need for controlled environments became critical for industries such as pharmaceuticals and semiconductor manufacturing. Initially, cleanroom supplies were basic, focusing primarily on essential items like gloves and wipes. However, as technology advanced and industries grew more complex, the demand for specialized cleanroom consumables surged.

By the late 20th century, the introduction of rigorous international standards, such as ISO 14644, began to shape the landscape of cleanroom operations. This led to an expansion in the variety of consumables available, with innovations that catered to specific industry needs. The growth of the biotechnology and healthcare sectors further propelled this evolution, emphasizing the need for high-performance materials that could withstand stringent cleanliness requirements.

Today, the market is characterized by a diverse range of products, including advanced cleaning solutions, specialized apparel, and innovative packaging solutions designed to maintain the integrity of sensitive components. This ongoing evolution reflects not only technological advancements but also a deeper understanding of contamination control and its critical role in ensuring product quality across various industries.

Illustrative image related to cleanroom consumables

Frequently Asked Questions (FAQs) for B2B Buyers of cleanroom consumables

-

How do I ensure my cleanroom consumables meet industry standards?

To ensure compliance with industry standards, always source cleanroom consumables from reputable suppliers who provide certifications for their products. Look for items that adhere to ISO classifications relevant to your sector, such as ISO 14644 for cleanrooms. Request documentation that confirms the products have been tested and validated for their intended use, including particle counts, sterility, and material safety. Additionally, consider suppliers who have established quality management systems, as this indicates a commitment to maintaining high standards. -

What is the best type of cleanroom glove for electronics manufacturing?

For electronics manufacturing, nitrile gloves are often the best choice due to their excellent chemical resistance and low particulate shedding. Opt for gloves that are specifically designed for cleanroom environments and have ESD (Electrostatic Discharge) properties to protect sensitive electronic components. Ensure the gloves are free from contaminants and are compliant with industry regulations. Always check the glove’s ISO rating to confirm its suitability for your cleanroom classification. -

How can I vet suppliers of cleanroom consumables internationally?

Start by researching potential suppliers through industry directories, trade shows, and online platforms. Evaluate their reputation by checking customer reviews and testimonials. Request samples to assess product quality and verify certifications to ensure compliance with international standards. Engage in direct communication to gauge their responsiveness and willingness to address your specific needs. It can also be beneficial to ask for references from other international clients they serve. -

What are the typical minimum order quantities (MOQ) for cleanroom consumables?

Minimum order quantities can vary widely based on the type of consumable and the supplier. Generally, MOQs for cleanroom consumables range from a few hundred units to several thousand. Some suppliers may offer flexibility for custom orders or smaller projects, while others may have strict MOQs to justify production costs. It’s advisable to clarify MOQs upfront and discuss your specific needs to negotiate terms that work for both parties. -

What payment terms should I expect when ordering cleanroom consumables?

Payment terms can differ significantly among suppliers, but common practices include a 30% deposit upfront with the balance due upon shipment or net 30/60 days after delivery. International buyers may also encounter letters of credit or escrow services for larger orders to mitigate risks. Always negotiate payment terms before finalizing your order and ensure they align with your cash flow management strategies. -

How do I manage logistics and shipping for cleanroom consumables?

Managing logistics involves coordinating with your supplier to determine the best shipping method based on urgency and cost. Ensure that the supplier has experience with international shipping regulations, including customs clearance and compliance with import/export laws. Track shipments closely and communicate with logistics partners to avoid delays. It’s beneficial to discuss options for expedited shipping if time-sensitive materials are required. -

What quality assurance practices should I look for in cleanroom consumables?

Quality assurance practices should include regular product testing, adherence to ISO standards, and clear documentation of compliance. Suppliers should have established protocols for incoming inspection, in-process checks, and final product verification. Look for suppliers who offer a quality guarantee or warranty on their products. Additionally, consider those who are willing to provide third-party test results to validate their claims. -

Can I customize cleanroom consumables for specific applications?

Many suppliers offer customization options for cleanroom consumables to meet specific operational needs. This could include tailored sizes, materials, or branding on items like gloves, wipes, or apparel. Discuss your requirements with potential suppliers and inquire about their capabilities for customization, including lead times and cost implications. Custom solutions can enhance efficiency and ensure that the consumables align perfectly with your cleanroom protocols.

Top 8 Cleanroom Consumables Manufacturers & Suppliers List

1. Antistat – Cleanroom Supplies

Domain: antistat.com

Registered: 2004 (21 years)

Introduction: Cleanroom Supplies for Controlled Environments, including bags (Black Conductive, Cleanroom, Moisture Barrier, Pink Antistatic, Static Shielding), cleaning products (ESD Brushes, Mopping Systems, Sticky Rollers, Swabs), gloves (Carbon, Copper, Cut Resistant, Latex, Nitrile, Vinyl), grounding equipment (ESD Testing Equipment, Foot Grounders, Wrist Straps), matting (Adhesive Floor Mats, Antistatic B…

2. Harmony Cleanroom Supplies – Key Products

Domain: harmonycr.com

Registered: 2005 (20 years)

Introduction: Cleanroom Supplies include a variety of products such as:

– Adhesive Mats & Rollers

– Cleanroom Apparel (Coveralls, Face Masks, Gloves, Lab Coats, Shoes, etc.)

– Cleanroom Documentation (Binders, Paper, Pens, Notebooks, Tape, Sticky Notes)

– Cleanroom Swabs (ESD, Polyester, etc.)

– Cleanroom Wipes (ESD, Microfiber, Pre-Saturated, Sterile, etc.)

– Disposable Apparel (Aprons, Boot Covers, Surgical M…

3. Cleanroom Connection – USP 797 & 800 Compliance Products

Domain: cleanroomsupplies.com

Registered: 2003 (22 years)

Introduction: Cleanroom Supplies & Products from Cleanroom Connection include: 1. USP 797 Compliance Products: Cleanroom apparel and cleaning supplies for sterile compounding pharmacies, hospitals, and medical facilities. 2. USP 800 Compliance Products: Personal protective equipment (PPE) and cleaning supplies for handling hazardous drugs in compounding pharmacies. 3. cGMP Compliant Products: Sterile cleanroom …

4. 4Bennett – Cleanroom Supplies

Domain: 4bennett.com

Registered: 2006 (19 years)

Introduction: Cleanroom Supplies include various categories such as Cleanroom Packaging, Clean Poly, Clean Anti-Static Poly, Clean Shielding, Clean Nylon ESD Packaging, Shielding, Moisture Barrier, Conductive Anti Static, Cleanroom Apparel (including Cleanroom Frocks, ESD Jackets, Shoe Covers), Cleanroom Equipment, and Static Control Solutions. Featured products include Paper, Sticky Mats, Sticky Mat Frame, Non…

5. Cleanroom World – Cleanroom Supplies

Domain: cleanroomworld.com

Registered: 2007 (18 years)

Introduction: Cleanroom Supplies, Equipment, Furniture, ISO 9001:2015 QMS Certified, Categories include: Cleanroom Construction Components, Low Cost Cleanroom Products, Cleanroom Apparel (including Autoclavable Shoes, Disposable Coveralls, and DuPont Tyvek Garments), Cleanroom Cleaning Supplies (including Brushes, Disinfectants, and Mops), Cleanroom Equipment (including Air Showers, Fume Hoods, and Particle Cou…

6. Uline – Cleanroom Supplies

Domain: uline.com

Registered: 1995 (30 years)

Introduction: Anti-Static Cleanroom Supplies, Clean Mats, Cleanroom Wipes, Cleanroom Gloves, Cleanroom Protective Clothing, Cleanroom Gowning Benches, Cleanroom Swabs, Cleanroom Labels, Cleanroom Poly Tubing, Cleanroom Poly Bags, Cleanroom Reclosable Poly Bags, Cleanroom Tape, Uline Cleanroom Mop, Cleanroom Sticky Roller, Work Stool, Clean Stride Mats.

7. ProLab Corp – Cleanroom Supplies

Domain: prolabcorp.com

Registered: 2019 (6 years)

Introduction: Cleanroom Supplies include a variety of products such as: Cabinets and Hoods (Class II A2, Class II B2, Horizontal Laminar Flow, Vertical Laminar Flow), Personal Protection Equipment (PPE) like Gloves, Masks, and Protective Coveralls, Filtration products (Bottle Top Filters, Disc Filters, Syringe Filters), and various laboratory consumables and accessories. The supplies cater to industries includi…

8. SOS Cleanroom – Clean Room Supplies

Domain: soscleanroom.com

Registered: 2006 (19 years)

Introduction: Clean Room Supplies, Texwipe, Clean Room Products, Ansell Apparel, Kimtech Apparel, Gloves, Chemo Prep / Spill Mats, Wipers by Material (Cellulose/Polyester, Cotton, Foam, Microdenier, Microfiber, Nylon, Polyester, Polypropylene), Sterile Wipers, Dry Wipers, Pre-Wetted Wipers, Industrial/Solvent Wipes, PPE (Face Masks, Gloves, Hand Sanitizers), Cleaning Validation Series, Disinfectants (NaDCC Chlo…

Strategic Sourcing Conclusion and Outlook for cleanroom consumables

As the cleanroom consumables market continues to evolve, strategic sourcing remains a critical component for businesses aiming to enhance operational efficiency and compliance. International buyers, particularly those from Africa, South America, the Middle East, and Europe, should prioritize partnerships with reputable suppliers who offer a diverse range of products tailored to specific industry standards. By focusing on quality and compliance, organizations can ensure their cleanroom environments remain effective in controlling contamination across sectors such as pharmaceuticals, electronics, and aerospace.

Investing in high-quality cleanroom consumables not only protects sensitive processes but also enhances overall productivity. With advancements in technology and manufacturing practices, buyers now have access to innovative solutions such as portable cleanroom setups and advanced cleaning materials that can streamline operations and reduce costs.

Looking forward, the demand for cleanroom consumables is expected to rise, driven by increasing regulatory scrutiny and the need for enhanced hygiene protocols. Businesses should act now to evaluate their sourcing strategies, align with trusted suppliers, and leverage the latest products in the market. This proactive approach will empower companies to stay ahead in a competitive landscape, ensuring they meet both current and future cleanroom requirements effectively.

Illustrative image related to cleanroom consumables

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.