How to Source Chemical Milling Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for chemical milling

Navigating the complex landscape of chemical milling can be a daunting challenge for international B2B buyers, especially when sourcing reliable suppliers and ensuring quality. The intricacies involved in selecting the right chemical milling processes—whether it’s acid etching, photochemical machining, or water jet cutting—demand a thorough understanding of the various types and their specific applications. This guide aims to equip buyers from diverse regions, including Africa, South America, the Middle East, and Europe (notably Brazil and Germany), with the knowledge necessary to make informed purchasing decisions.

In this comprehensive resource, we will delve into the various types of chemical milling processes, their applications across industries, and the critical factors to consider when vetting suppliers. Additionally, we will address cost considerations and emerging trends in the chemical milling market that could impact procurement strategies. By providing actionable insights and expert guidance, this guide empowers B2B buyers to navigate the global market confidently, ensuring that they can secure high-quality services that meet their operational needs while optimizing costs. Whether you are looking to enhance production efficiency or innovate your product offerings, understanding the nuances of chemical milling will be essential for your business success.

Understanding chemical milling Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Acid Etching | Utilizes strong acids to etch designs on metal surfaces. | Aerospace components, medical devices | Pros: High precision, excellent surface finish. Cons: Hazardous materials, requires careful handling. |

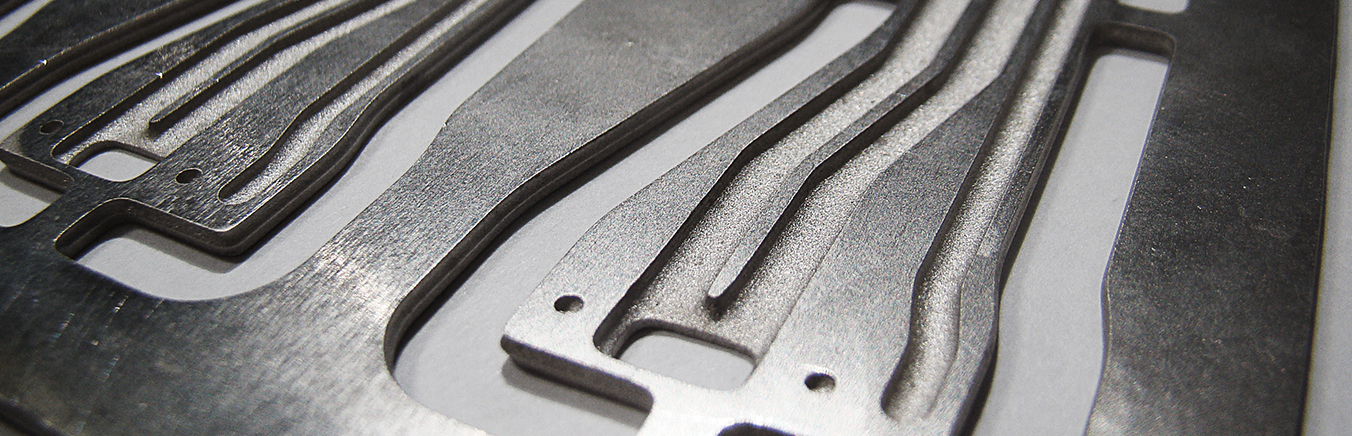

| Photochemical Etching | Combines photographic techniques with chemical etching. | Electronics, microfabrication | Pros: High accuracy for intricate designs. Cons: Higher initial setup costs, requires specialized equipment. |

| Water Jet Cutting | Employs high-pressure water jets for material cutting. | Aerospace, automotive, and construction | Pros: Versatile, no heat-affected zones. Cons: Slower cutting speed for thick materials. |

| Laser Cutting | Uses focused laser beams for precise cutting and etching. | Signage, automotive parts, and tooling | Pros: Fast processing, minimal waste. Cons: Limited material thickness capability. |

| EMI/RF Shielding | Creates barriers to protect sensitive electronics from interference. | Telecommunications, aerospace, and defense | Pros: Essential for device functionality. Cons: Can be costly, requires precise engineering. |

What Are the Characteristics of Acid Etching in Chemical Milling?

Acid etching is a widely used method that employs strong acids to dissolve material selectively from the surface of metals. This technique is particularly suitable for creating intricate designs on aerospace components and medical devices, where precision is paramount. Buyers should consider the safety implications of handling hazardous materials and ensure that suppliers adhere to strict safety regulations. The process provides excellent surface finishes but requires meticulous handling to avoid accidents.

How Does Photochemical Etching Differ from Other Chemical Milling Techniques?

Photochemical etching integrates photographic methods with chemical processes, enabling the production of highly detailed and complex designs. This technique is ideal for applications in electronics and microfabrication, where precision is critical. While photochemical etching offers high accuracy, it demands specialized equipment and can incur higher initial setup costs. Buyers should evaluate the supplier’s capabilities in terms of technology and experience in photochemical processes to ensure quality outcomes.

Why Choose Water Jet Cutting for Chemical Milling Applications?

Water jet cutting is a unique chemical milling method that utilizes high-pressure jets of water to cut through various materials, including metals. Its versatility makes it suitable for industries such as aerospace, automotive, and construction. A significant advantage of water jet cutting is that it does not produce heat-affected zones, preserving the integrity of the material. However, buyers should be aware that the cutting speed may be slower for thicker materials, which could impact production timelines.

What Advantages Does Laser Cutting Offer in Chemical Milling?

Laser cutting is a non-traditional machining method known for its speed and precision. By focusing laser beams on the material, this technique can efficiently cut and etch various components, including signage and automotive parts. Buyers benefit from reduced material waste and quick processing times, making it an attractive option for high-volume production. However, potential limitations include the thickness of materials that can be processed, which should be considered based on specific project requirements.

How Is EMI/RF Shielding Relevant to Chemical Milling?

EMI and RF shielding are essential applications of chemical milling, particularly in protecting sensitive electronic devices from electromagnetic interference. This process creates barriers that ensure the functionality of telecommunications and aerospace equipment. While the shielding is crucial for device performance, buyers must consider the associated costs and the necessity for precise engineering in the design phase. Partnering with experienced suppliers in this niche can help mitigate risks and enhance product reliability.

Key Industrial Applications of chemical milling

| Industry/Sector | Specific Application of Chemical Milling | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Lightweight component manufacturing | Reduces weight without compromising strength, enhancing fuel efficiency | Supplier certifications, material traceability, and precision capabilities |

| Electronics | EMI/RF shielding components | Protects sensitive electronics from interference, improving reliability | Quality assurance processes, compliance with international standards |

| Medical Devices | Fabrication of intricate parts | Enables the production of complex geometries for precision instruments | Regulatory compliance, materials biocompatibility, and production scalability |

| Automotive | Custom tooling and die manufacturing | Enhances design flexibility while reducing lead times | Supplier experience, technology capabilities, and material availability |

| Defense | Production of armor plating and weaponry parts | Provides durability and resistance to wear, enhancing operational effectiveness | Adherence to defense industry regulations and material specifications |

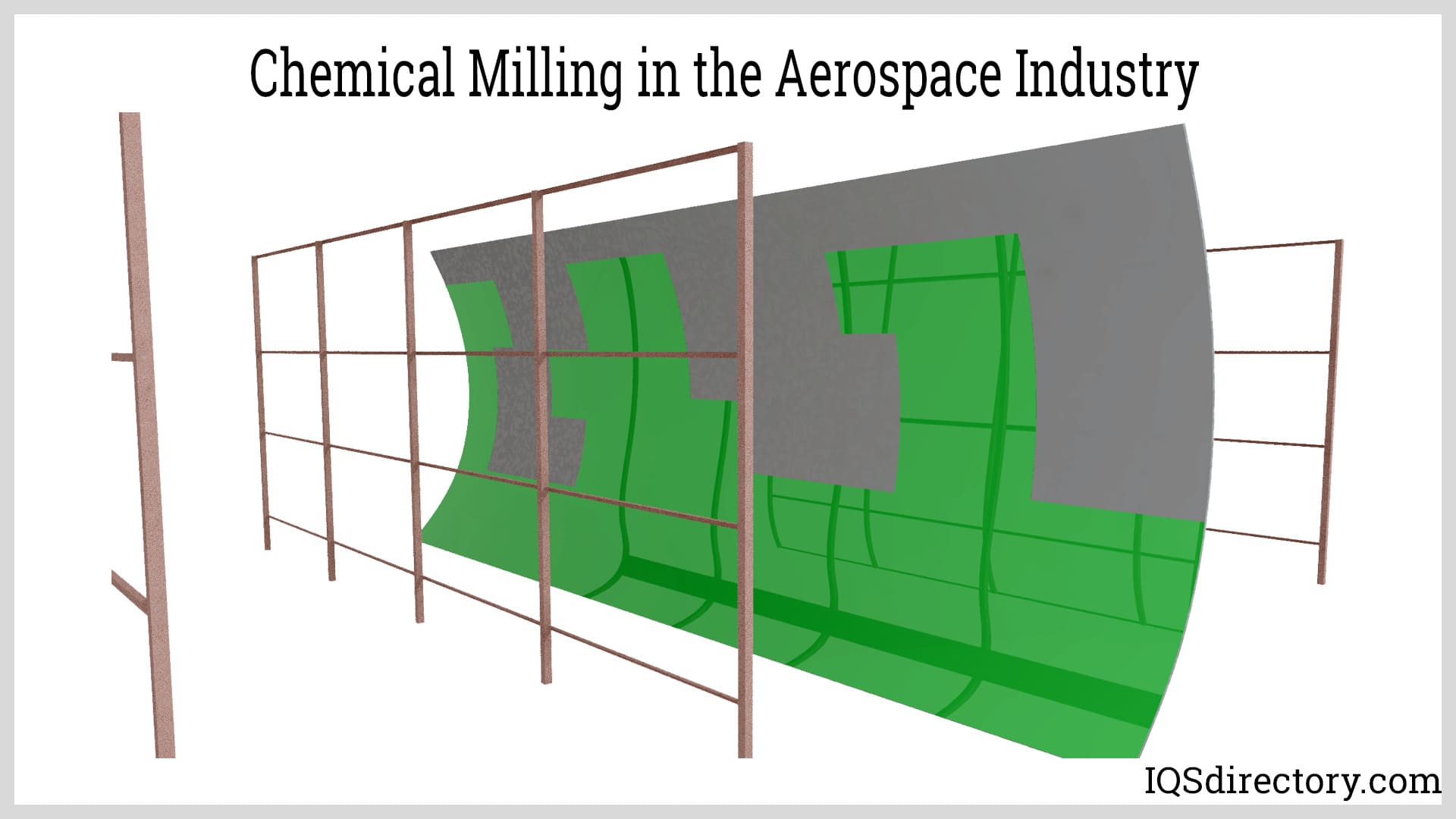

How is Chemical Milling Used in Aerospace Component Manufacturing?

In the aerospace industry, chemical milling is utilized to create lightweight components that are essential for improving fuel efficiency and performance. By removing material without compromising structural integrity, businesses can achieve optimal designs that meet stringent weight requirements. International buyers must prioritize suppliers with certifications, material traceability, and proven precision capabilities to ensure compliance with aerospace standards.

What Role Does Chemical Milling Play in Electronics for EMI/RF Shielding?

Chemical milling is instrumental in the production of EMI and RF shielding components, which are critical for protecting sensitive electronic devices from electromagnetic interference. This process allows for the creation of intricate designs that effectively block interference, thereby enhancing the reliability of electronic systems. Buyers, particularly in regions like Europe and South America, should focus on suppliers with robust quality assurance processes and compliance with international standards to ensure product effectiveness.

Illustrative image related to chemical milling

Why is Chemical Milling Important for Medical Device Fabrication?

In the medical device sector, chemical milling enables the fabrication of intricate parts that require high precision, such as surgical instruments and implantable devices. This method allows manufacturers to produce complex geometries that meet the stringent requirements of medical applications. Buyers must ensure that their suppliers comply with regulatory standards and prioritize materials that are biocompatible and suitable for medical use.

How Does Chemical Milling Benefit Automotive Tooling and Die Manufacturing?

Chemical milling is used in the automotive sector for custom tooling and die manufacturing, allowing for greater design flexibility and reduced lead times. This process can produce precise and lightweight tools that enhance production efficiency. B2B buyers should evaluate suppliers based on their experience, technological capabilities, and availability of materials to ensure that they meet specific automotive industry demands.

In What Ways Does Chemical Milling Contribute to Defense Manufacturing?

In defense applications, chemical milling is vital for producing durable armor plating and weaponry parts that can withstand extreme conditions. This process enhances the wear resistance and longevity of critical components, which is essential for operational effectiveness. Buyers in the defense sector must ensure that their suppliers adhere to industry regulations and meet specific material specifications to guarantee product reliability and performance.

Illustrative image related to chemical milling

3 Common User Pain Points for ‘chemical milling’ & Their Solutions

Scenario 1: Inconsistent Quality of Etched Components

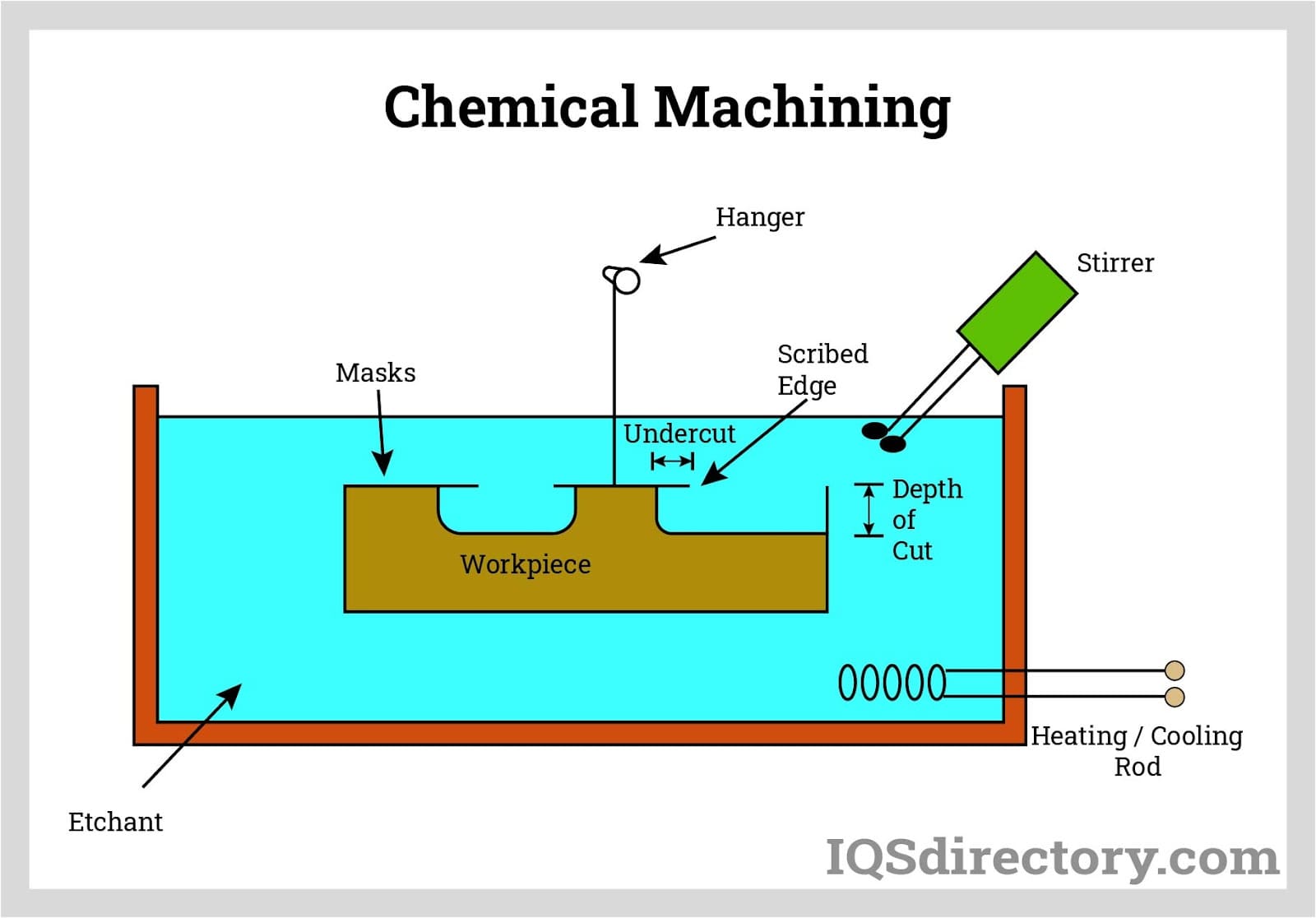

The Problem: B2B buyers often face challenges with the quality of components produced through chemical milling. Inconsistent etching depth, uneven surfaces, and defects such as undercuts can lead to parts that do not meet specifications. This not only affects the final product but can also result in costly rework, delays in production schedules, and damaged client relationships. For international buyers, variations in the quality of raw materials and differences in local manufacturing practices can exacerbate these issues, complicating the sourcing and production process.

The Solution: To ensure consistent quality in chemical milling, it’s crucial to establish stringent quality control measures throughout the process. Start by working closely with suppliers to select high-quality raw materials that meet your specifications. Implement a robust cleaning protocol to prepare the workpiece surface, as contaminants can lead to inconsistent etching results. Regularly calibrate and monitor the etching baths to maintain the correct chemical concentrations and temperatures, as these factors significantly influence the etching rate and quality. Additionally, consider investing in automated systems for scribing and demasking to enhance precision and reduce human error. Continuous training for operators on best practices in chemical milling will also help maintain high standards and improve overall outcomes.

Scenario 2: Environmental Compliance and Safety Concerns

The Problem: Companies involved in chemical milling often encounter stringent environmental regulations and safety standards that can be difficult to navigate. The use of hazardous chemicals poses risks not only to worker safety but also to compliance with local and international environmental laws. Failure to adhere to these regulations can lead to severe penalties, legal issues, and damage to a company’s reputation. This is particularly pressing for businesses operating in regions like Africa and South America, where regulatory landscapes can vary significantly and change frequently.

The Solution: To address these challenges, B2B buyers should prioritize sourcing eco-friendly etching solutions and implement a comprehensive environmental management system. Begin by conducting a thorough assessment of the chemicals currently in use, replacing hazardous substances with less toxic alternatives wherever possible. Engage with suppliers who have a proven track record in sustainable practices and can provide environmentally friendly chemical milling options. Additionally, invest in proper safety equipment and training for employees to mitigate health risks. Regularly audit your processes to ensure compliance with local regulations and stay informed about any changes in environmental laws. This proactive approach will not only enhance safety but also position your company as a responsible player in the industry, appealing to environmentally conscious clients.

Scenario 3: High Costs Associated with Chemical Milling Processes

The Problem: The costs associated with chemical milling can be a significant concern for B2B buyers, especially when it comes to maintaining competitiveness in pricing. Factors such as expensive raw materials, waste disposal fees, and the maintenance of specialized equipment can inflate operational costs. For businesses operating in regions with fluctuating currency values, such as South America and parts of Africa, these costs can be unpredictable, impacting budgeting and profitability.

The Solution: To manage and reduce costs effectively, B2B buyers should explore options for process optimization and waste reduction. Start by analyzing the entire chemical milling workflow to identify inefficiencies or bottlenecks that can be streamlined. Consider implementing closed-loop systems that recycle chemicals, which can significantly reduce waste disposal costs and the need for new materials. Collaborate with suppliers to negotiate better pricing on bulk purchases or explore alternative suppliers who can offer competitive rates without compromising quality. Additionally, investing in training for your workforce can lead to more efficient use of resources, reducing material waste and enhancing overall productivity. By adopting a strategic approach to cost management, companies can maintain high-quality standards while improving their bottom line.

Strategic Material Selection Guide for chemical milling

What are the Key Properties of Aluminum in Chemical Milling?

Aluminum is one of the most commonly used materials in chemical milling due to its favorable properties. It has a low density, excellent corrosion resistance, and good thermal conductivity, making it suitable for various applications, including aerospace and automotive components. Aluminum typically withstands temperatures up to 200°C and pressures of around 5,000 psi, depending on the specific alloy. Its ability to be etched at a rate of approximately 0.178 cm/h allows for precise and intricate designs.

Pros & Cons: The advantages of using aluminum include its lightweight nature, which is crucial for applications requiring reduced weight without sacrificing strength. However, its cost can be moderate to high depending on the alloy, and its manufacturing complexity may increase with the need for specialized etchants. Additionally, while aluminum is versatile, it may not be suitable for high-stress applications compared to stronger metals.

How Does Stainless Steel Perform in Chemical Milling Applications?

Stainless steel is another popular choice for chemical milling, valued for its exceptional strength and corrosion resistance. It can withstand higher temperatures (up to 800°C) and pressures, making it ideal for demanding environments. The etching rate for stainless steel varies but is generally lower than that of aluminum, requiring more time in the chemical bath.

Pros & Cons: The primary advantage of stainless steel is its durability and ability to maintain structural integrity under extreme conditions. However, it is typically more expensive than aluminum and may require more complex processing techniques due to its hardness. This can lead to longer lead times and increased manufacturing costs.

What are the Benefits of Copper in Chemical Milling Processes?

Copper is often used in chemical milling, particularly for applications requiring excellent electrical conductivity, such as in electronic components. Copper’s etching rate is relatively high, around 0.5 cm/h, which allows for quick processing. It is also highly malleable, making it easy to form intricate designs.

Illustrative image related to chemical milling

Pros & Cons: The key advantage of copper is its superior conductivity, making it essential in electrical applications. However, it is more susceptible to corrosion compared to aluminum and stainless steel, which can limit its use in harsh environments. Additionally, copper can be relatively expensive, impacting overall project costs.

What Role Does Magnesium Play in Chemical Milling?

Magnesium is a lightweight metal with excellent machinability and corrosion resistance. It is particularly useful in applications requiring weight reduction, such as aerospace components. Magnesium can withstand moderate temperatures (up to 150°C) and has a relatively high etching rate of about 0.46 cm/h.

Pros & Cons: The main advantage of magnesium is its low density, which significantly contributes to weight savings. However, its lower strength compared to aluminum and stainless steel can be a limitation in high-stress applications. Furthermore, magnesium’s susceptibility to corrosion can pose challenges in certain environments, necessitating protective coatings.

Summary Table of Material Selection for Chemical Milling

| Material | Typical Use Case for chemical milling | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Aerospace components | Lightweight and corrosion-resistant | Moderate to high cost | Medium |

| Stainless Steel | High-stress industrial applications | Exceptional strength | Higher cost and manufacturing complexity | High |

| Copper | Electrical components | Superior electrical conductivity | Susceptible to corrosion | High |

| Magnesium | Aerospace and automotive parts | Significant weight reduction | Lower strength and corrosion issues | Medium |

This strategic material selection guide provides B2B buyers with essential insights into the properties, advantages, and limitations of common materials used in chemical milling. Understanding these factors will aid in making informed decisions that align with specific application requirements and regional standards.

In-depth Look: Manufacturing Processes and Quality Assurance for chemical milling

What Are the Main Stages of the Chemical Milling Manufacturing Process?

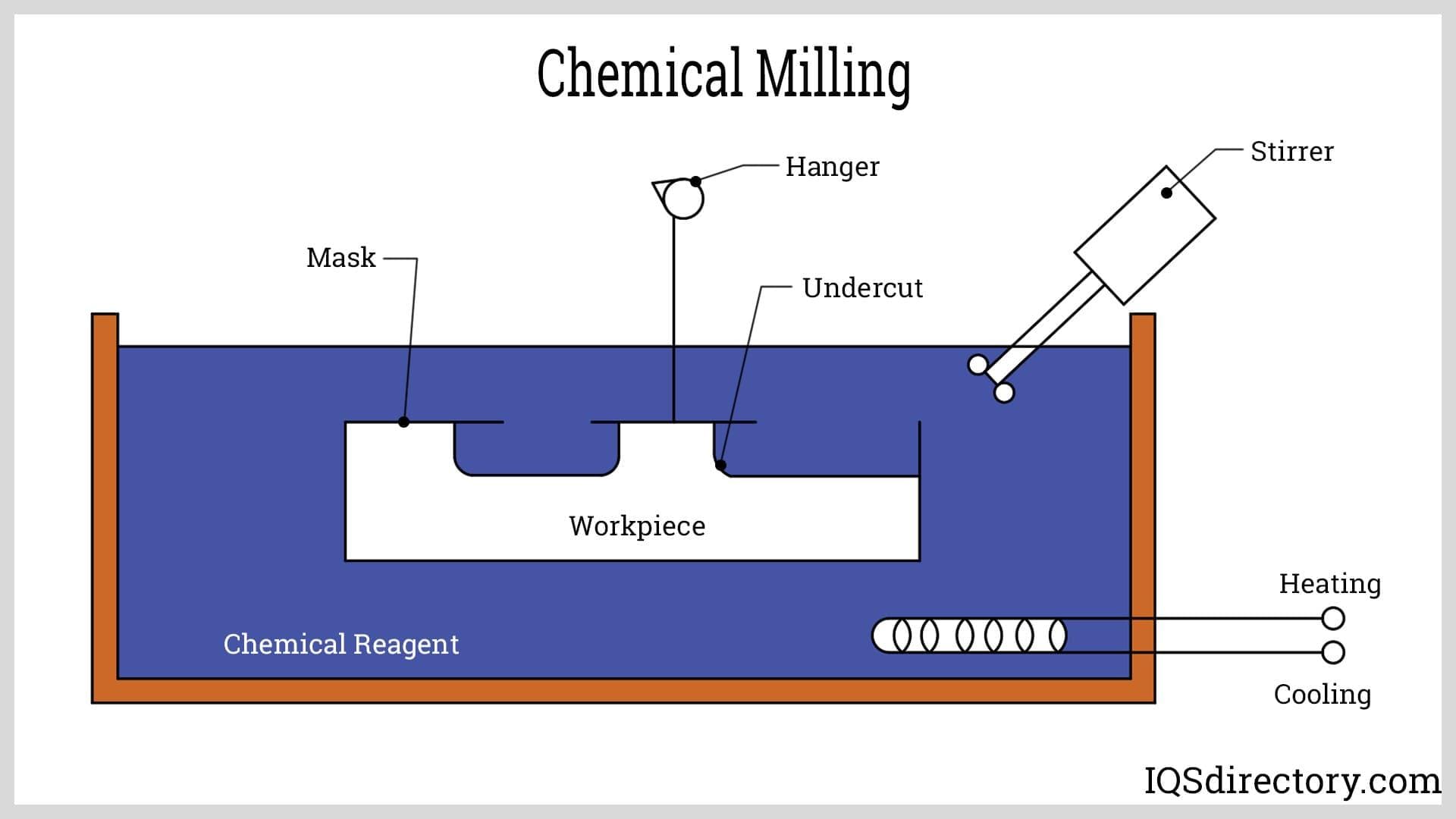

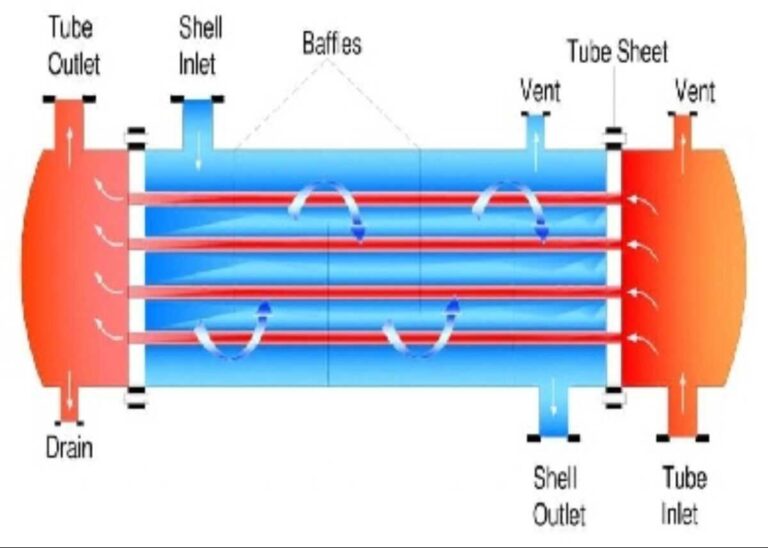

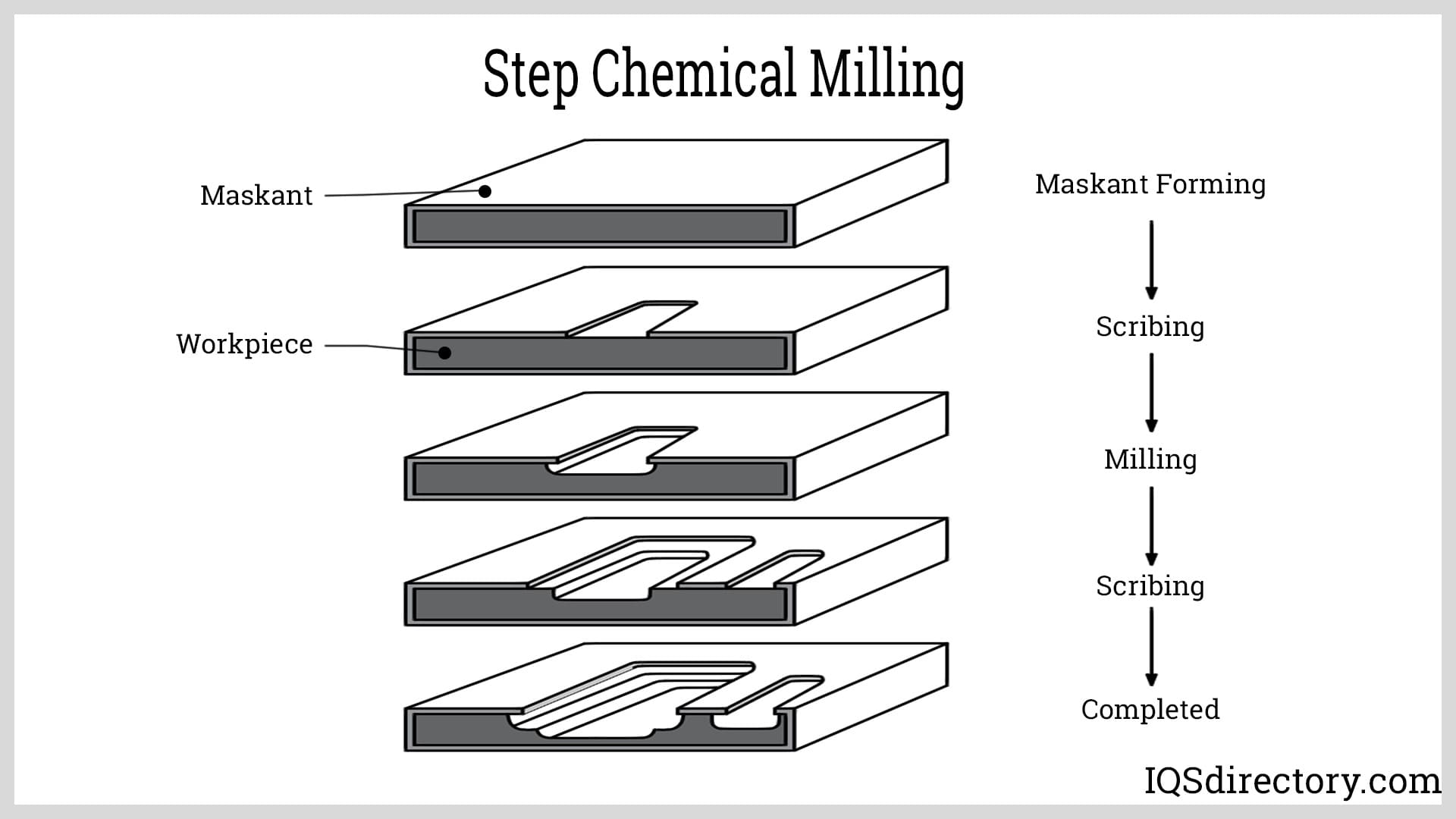

Chemical milling is a highly specialized subtractive manufacturing process that relies on controlled chemical reactions to etch away material from a workpiece. The process typically involves several key stages, each crucial for ensuring the precision and quality of the final product.

1. Material Preparation

The first stage involves thorough cleaning of the workpiece to eliminate contaminants such as oils, dust, and oxidation. This is critical because any foreign material can lead to uneven etching and affect the final dimensions. Common cleaning agents include solvents or alkaline solutions, which are applied to ensure a clean surface. Once cleaned, the workpiece is dried and prepared for the next phase.

2. Masking

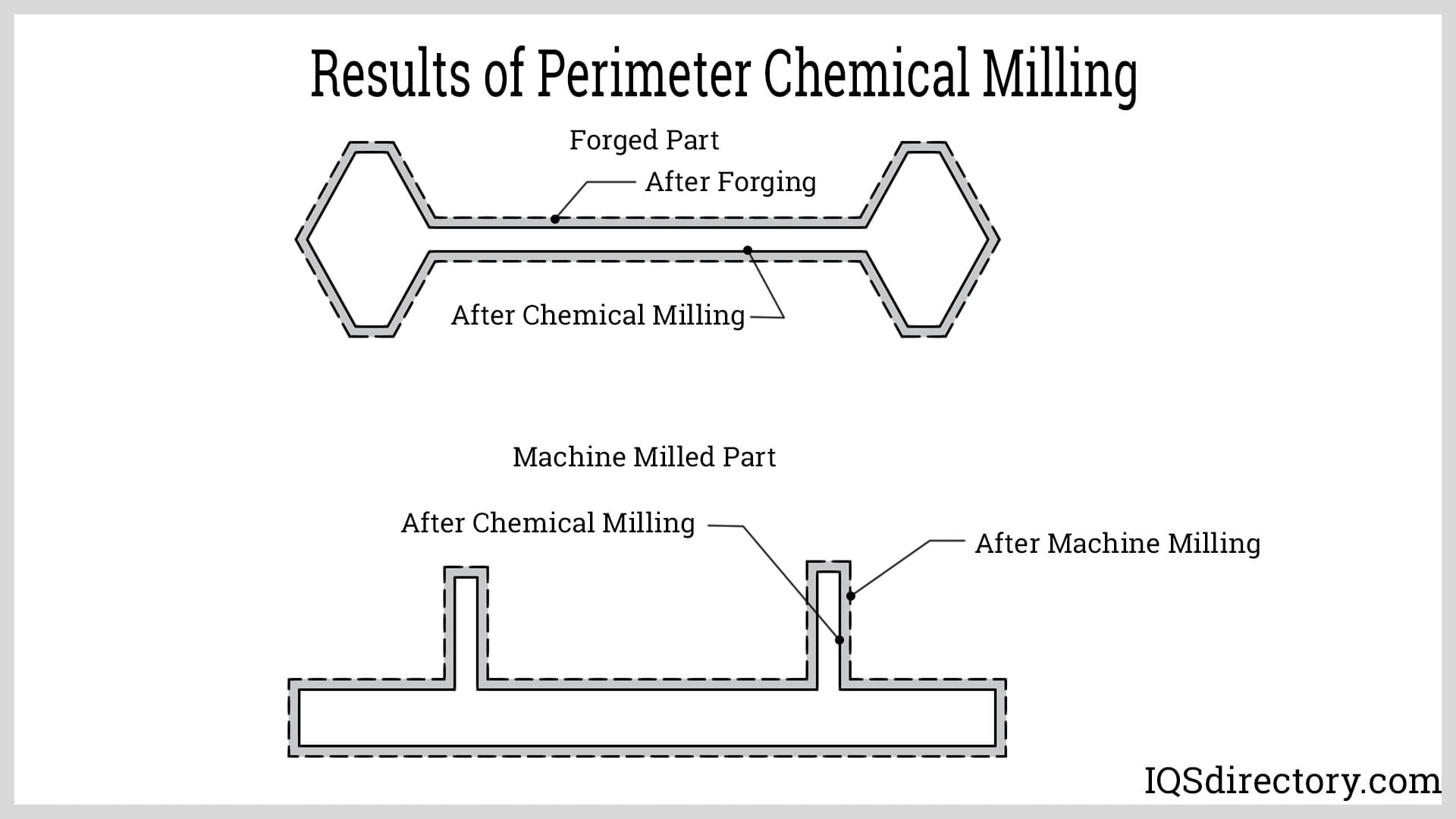

Masking is the application of a protective layer to areas of the workpiece that should not be etched. This can be done using various techniques, such as dip-masking, where the workpiece is submerged in a liquid maskant, or electrostatic deposition, where charged maskant particles adhere to the surface. The choice of maskant is crucial; it must be chemically inert to the etchant while providing adequate adhesion to withstand the etching process.

3. Scribing

After masking, the next step is scribing, where the maskant is precisely removed from the areas intended for etching. This can be done manually with tools or using computer numerical control (CNC) systems for intricate designs. The accuracy of this step directly influences the quality of the etched features, making it essential for achieving the desired specifications.

4. Etching

The core of the chemical milling process is etching, where the workpiece is immersed in a chemical bath. The etchant—typically a strong acid or base—reacts with the exposed material, dissolving it to create the desired shape. The immersion time and agitation levels of the etchant are critical parameters that affect the etching rate and depth. For example, aluminum may etch at a rate of approximately 0.178 cm/h, while magnesium can etch at a rate of 0.46 cm/h.

5. Demasking

Once etching is complete, the final step is demasking, where the protective layer is removed to reveal the finished product. This stage must be handled delicately to avoid damaging the newly formed features. The workpiece is then inspected to ensure that it meets the specified tolerances and quality standards.

How Does Quality Assurance Ensure High Standards in Chemical Milling?

Quality assurance (QA) is an integral part of the chemical milling process, ensuring that the final products meet both industry standards and customer expectations. Several international and industry-specific standards guide the QA practices in this sector.

Illustrative image related to chemical milling

What International Standards Apply to Chemical Milling?

ISO 9001 is one of the most recognized quality management standards globally. It provides a framework for organizations to ensure consistent quality in their products and services. Compliance with ISO 9001 indicates that a supplier has established effective quality management systems that can enhance operational efficiency and customer satisfaction.

In addition to ISO standards, industry-specific certifications such as CE marking (for products sold within the European Economic Area) and API specifications (for oil and gas applications) are crucial. These certifications ensure that the products meet stringent safety, health, and environmental protection requirements.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) in chemical milling typically involves several checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial checkpoint verifies the quality of raw materials before they enter production. Suppliers must provide material certifications that detail the chemical composition and properties, ensuring they meet the required specifications.

-

In-Process Quality Control (IPQC): Throughout the manufacturing stages, regular inspections are conducted to monitor process parameters, such as etching rates and adhesion of maskants. This helps identify and rectify issues early in the production cycle.

-

Final Quality Control (FQC): After demasking, the finished products undergo a thorough inspection. This may include dimensional checks using coordinate measuring machines (CMMs), surface finish evaluations, and visual inspections to identify any defects.

What Testing Methods Are Commonly Used in Quality Assurance?

Several testing methods are employed in the QC phase to ensure that the chemical milling process meets quality standards:

-

Dimensional Inspection: This involves measuring the finished part against its specifications using precision measuring tools or machines to ensure it meets the required tolerances.

-

Surface Finish Evaluation: Techniques such as surface roughness testing may be employed to assess the quality of the etched surface. This is crucial for applications where surface finish impacts functionality.

-

Material Testing: Chemical analysis may be conducted to confirm that the material composition aligns with specifications. This can include techniques like X-ray fluorescence (XRF) or spectroscopy.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers must take proactive steps to verify that their suppliers adhere to stringent quality control practices. Here are actionable strategies:

-

Conduct Audits: Regular audits of suppliers can help buyers assess the effectiveness of their quality management systems. This includes reviewing their documentation, processes, and compliance with international standards.

-

Request Quality Reports: Suppliers should provide detailed quality reports that outline their QC processes, results of inspections, and any corrective actions taken. This transparency fosters trust and reliability.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can cover everything from material quality to process adherence.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

For international B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, several nuances should be considered:

-

Regulatory Compliance: Different regions have varying regulations and standards, which can affect product acceptance. Buyers must ensure that their suppliers comply with both local and international standards relevant to their market.

-

Cultural Differences: Understanding the cultural context of suppliers can impact communication and expectations. This is vital for establishing successful partnerships.

-

Supply Chain Logistics: Quality control does not end at manufacturing. Buyers must consider logistics and transportation conditions that could affect product quality during shipment. Ensuring that suppliers have quality controls in place for packaging and transportation is essential.

In conclusion, understanding the chemical milling manufacturing process and the associated quality assurance measures is crucial for B2B buyers aiming to source high-quality products. By focusing on these elements, buyers can make informed decisions that align with their operational needs and market standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘chemical milling’

Introduction

This practical sourcing guide is designed to assist B2B buyers in the procurement of chemical milling services and materials. By following this step-by-step checklist, you can ensure that you select a reliable supplier who meets your specific requirements, ultimately leading to successful project outcomes.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is critical for successful chemical milling. This includes defining the materials to be used, the dimensions of the components, and any specific design requirements. A well-defined specification helps suppliers understand your needs and reduces the likelihood of errors during production.

- Material Types: Identify whether you need milling for aluminum, copper, or other metals.

- Design Complexity: Consider the intricacy of the designs to ensure they can be achieved with chemical milling.

Step 2: Research and Shortlist Potential Suppliers

Conduct thorough research to identify potential suppliers who specialize in chemical milling. Utilize industry directories, online reviews, and trade shows to gather information on various companies. This step is crucial to creating a shortlist of suppliers who have the necessary capabilities and experience.

- Industry Experience: Look for suppliers with a proven track record in chemical milling.

- Regional Considerations: Consider suppliers who are familiar with local regulations and standards in your region.

Step 3: Evaluate Supplier Certifications and Compliance

Before finalizing a supplier, verify their certifications and compliance with industry standards. This is essential to ensure that they adhere to quality control measures and safety regulations, which can significantly impact your project’s success.

Illustrative image related to chemical milling

- ISO Certifications: Check for ISO 9001 or other relevant certifications that indicate quality management systems.

- Environmental Compliance: Ensure that the supplier meets environmental regulations, especially if your project involves hazardous materials.

Step 4: Request Detailed Quotes

Once you have shortlisted potential suppliers, request detailed quotes that outline pricing, lead times, and terms of service. This step is important to ensure transparency and enables you to compare offers effectively.

- Breakdown of Costs: Request a breakdown of material, labor, and additional service costs.

- Lead Time Estimates: Understand the expected timelines for production to align with your project schedule.

Step 5: Ask for References and Case Studies

Request references and case studies from your shortlisted suppliers. This will provide insight into their capabilities and reliability based on past performance. Engaging with previous clients can help you gauge their satisfaction level and the quality of the final products.

- Client Feedback: Inquire about their experience, particularly in projects similar to yours.

- Quality of Work: Look for evidence of high-quality outcomes in case studies shared by the supplier.

Step 6: Conduct a Site Visit or Virtual Tour

If feasible, arrange for a site visit or a virtual tour of the supplier’s facility. This step allows you to assess their equipment, processes, and overall operational standards firsthand. Observing their environment can provide reassurance about their capabilities.

- Equipment Assessment: Check if the supplier uses modern and well-maintained equipment for chemical milling.

- Safety Protocols: Observe their safety measures to ensure compliance with industry standards.

Step 7: Negotiate Terms and Finalize the Agreement

Once you have selected a supplier, negotiate terms of service, including pricing, payment schedules, and delivery conditions. A well-negotiated contract protects both parties and sets clear expectations for the project.

- Payment Terms: Agree on payment milestones that align with project phases.

- Quality Assurance Clauses: Include clauses that outline quality expectations and remedies for potential issues.

By following this checklist, you can streamline the sourcing process for chemical milling and make informed decisions that align with your business objectives.

Comprehensive Cost and Pricing Analysis for chemical milling Sourcing

What Are the Key Cost Components in Chemical Milling?

Understanding the cost structure of chemical milling is essential for international B2B buyers. The primary cost components include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and supplier margin.

-

Materials: Chemical milling relies heavily on specialized etchants and maskants. The cost of these materials can vary significantly based on the chemical composition and source. For instance, common etchants like hydrochloric acid and ferric chloride may have different price points depending on local market conditions.

-

Labor: Skilled labor is required for the preparation, execution, and quality assurance of the chemical milling process. Labor costs can fluctuate based on geographical location and the complexity of the work being performed.

-

Manufacturing Overhead: This includes costs associated with facility maintenance, utilities, and equipment depreciation. Efficient overhead management can lead to lower overall pricing for buyers.

-

Tooling: The initial investment in tooling can be substantial, especially for customized projects. Tooling costs are amortized over the volume of production, making it crucial for buyers to consider their order quantities.

-

Quality Control: Ensuring that finished products meet specified standards incurs additional costs. These may include inspections, testing, and certifications, which are particularly important for industries with stringent regulatory requirements.

-

Logistics: Transportation costs can vary widely, especially for international shipments. Factors such as distance, shipping method, and packaging requirements all contribute to the logistics budget.

-

Margin: Suppliers typically include a profit margin in their pricing, which can vary based on market demand and competition.

What Influences Pricing in Chemical Milling?

Several factors can influence the pricing of chemical milling services, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders usually lead to lower per-unit costs due to economies of scale. Buyers should negotiate favorable terms based on their projected volumes.

-

Specifications and Customization: Custom projects often incur higher costs due to the need for specialized materials or processes. Clear communication about specifications can help in obtaining accurate quotes.

-

Material Quality and Certifications: Higher-quality materials and certifications (e.g., ISO standards) can increase costs but are essential for ensuring product reliability and compliance in regulated industries.

-

Supplier Factors: The reputation, location, and reliability of the supplier can impact pricing. Established suppliers may charge a premium for their experience and quality assurance processes.

-

Incoterms: Understanding the terms of delivery and responsibilities for costs (such as shipping and insurance) can affect the total cost. Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) delineate who bears which costs and risks.

How Can Buyers Negotiate for Better Pricing?

Effective negotiation is key for buyers looking to optimize costs in chemical milling. Here are some strategies:

-

Leverage Total Cost of Ownership (TCO): Instead of focusing solely on the upfront price, consider the total cost over the lifecycle of the product, including maintenance and operational costs. This approach may justify a higher initial investment for better quality.

-

Understand Pricing Nuances: Familiarize yourself with the regional market dynamics in Africa, South America, the Middle East, and Europe. Prices may vary based on local demand, currency fluctuations, and supply chain constraints.

-

Build Relationships: Establishing long-term relationships with suppliers can lead to better pricing and service. Trust can encourage suppliers to offer discounts or better terms.

-

Be Prepared to Walk Away: Having alternative suppliers can give buyers leverage in negotiations. If a supplier knows you have other options, they may be more willing to adjust their pricing.

Conclusion

Navigating the cost and pricing landscape of chemical milling requires a comprehensive understanding of various components and influencing factors. By strategically managing these elements, international B2B buyers can secure favorable terms that enhance their competitiveness in the marketplace. Remember that prices can fluctuate based on numerous variables, so always seek indicative quotes tailored to your specific needs.

Illustrative image related to chemical milling

Alternatives Analysis: Comparing chemical milling With Other Solutions

Exploring Alternatives to Chemical Milling: A Comparative Analysis

In the realm of precision machining and metalworking, various methods exist to achieve similar results to chemical milling. Understanding the strengths and weaknesses of these alternatives is crucial for B2B buyers seeking the most effective solution for their specific applications. This analysis compares chemical milling with two viable alternatives: laser cutting and water jet cutting, providing insights into their performance, cost, ease of implementation, maintenance, and best use cases.

| Comparison Aspect | Chemical Milling | Laser Cutting | Water Jet Cutting |

|---|---|---|---|

| Performance | High precision; ideal for intricate designs; can create complex geometries | Excellent for thick materials; precise cuts; minimal thermal distortion | Versatile; cuts various materials; no heat-affected zone |

| Cost | Moderate; costs depend on chemical materials and equipment | Generally higher; costs associated with equipment and operation | Higher initial setup costs; cost-effective for thicker materials |

| Ease of Implementation | Requires specialized knowledge; multi-step process | Relatively easy; requires trained operators | Straightforward; less training required than laser cutting |

| Maintenance | Regular maintenance of chemical baths; chemical handling safety | Requires periodic maintenance of laser equipment | Low maintenance; regular inspections needed |

| Best Use Case | Aerospace, electronics, and medical industries for lightweight components | Automotive and metal fabrication for thicker materials | Construction and manufacturing for diverse material cutting |

Analyzing Laser Cutting: Advantages and Disadvantages

Laser cutting utilizes focused light to melt or vaporize material, achieving high precision and clean cuts. One of its primary advantages is its ability to handle thick materials and produce complex shapes with minimal thermal distortion, making it ideal for industries like automotive and metal fabrication. However, the initial investment in laser cutting equipment can be substantial, and operational costs may also be higher than those of chemical milling. Additionally, while the process is relatively straightforward, it still requires trained operators to maximize efficiency and output.

Evaluating Water Jet Cutting: Pros and Cons

Water jet cutting employs high-pressure water streams to cut through materials, making it a versatile choice for various applications. Its ability to cut through different materials without introducing heat makes it perfect for sensitive components. The maintenance requirements are lower compared to laser cutting, as there are fewer moving parts involved. However, the initial setup cost can be high, and while it is effective for thicker materials, the cutting speed may be slower than that of laser cutting, which could impact project timelines in high-volume settings.

Conclusion: How to Choose the Right Solution for Your Needs

When selecting the appropriate machining method, B2B buyers should consider specific project requirements, including material type, thickness, desired precision, and budget constraints. Chemical milling excels in applications requiring intricate designs and lightweight components, particularly in the aerospace and medical industries. Conversely, laser cutting is preferred for thicker materials and high-speed production, while water jet cutting offers versatility across various material types. By carefully evaluating these alternatives, businesses can make informed decisions that align with their operational goals and enhance their competitive edge.

Essential Technical Properties and Trade Terminology for chemical milling

What Are the Key Technical Properties of Chemical Milling?

When evaluating chemical milling processes, several critical specifications must be considered to ensure optimal results and alignment with business objectives. Here are the essential technical properties:

-

Material Grade

The material grade refers to the specific type of metal or substrate being processed, such as aluminum, copper, or stainless steel. Each material has distinct properties affecting the etching process, including its reactivity with various etchants. Understanding material grades helps manufacturers select the right chemical milling process to achieve the desired results while minimizing waste and maximizing efficiency. -

Tolerance

Tolerance indicates the permissible limits of variation in a physical dimension. In chemical milling, maintaining tight tolerances is crucial for ensuring the accuracy and functionality of components, especially in industries like aerospace and automotive where precision is paramount. Establishing clear tolerance requirements helps avoid costly reworks and ensures compatibility with other parts in assembly. -

Etch Depth

Etch depth refers to the thickness of material removed during the chemical milling process, which can be controlled by adjusting immersion time and etchant concentration. Different applications may require varying etch depths, and understanding these specifications allows businesses to optimize production processes for specific applications while ensuring compliance with engineering requirements. -

Maskant Adhesion Strength

The adhesion strength of the maskant is vital for effective chemical milling. A maskant with too strong adhesion may complicate the scribing process, while inadequate adhesion can lead to unintended etching. Businesses must specify the required maskant properties to ensure efficient operations and high-quality outcomes. -

Etching Rate

The etching rate is the speed at which material is removed from the workpiece during the chemical milling process. This rate is influenced by factors such as the type of etchant, temperature, and material composition. Knowing the etching rates for different materials helps businesses plan production timelines and resource allocation effectively. -

Chemical Composition of Etchants

The specific chemical composition of etchants plays a critical role in the efficacy of the chemical milling process. Different metals require tailored etchants to achieve the desired results. For example, aluminum may be etched using sodium hydroxide or Keller’s reagent, while copper may require ferric chloride. Understanding these compositions allows buyers to select the right chemicals for their applications.

What Are Common Terms in the Chemical Milling Industry?

Navigating the chemical milling industry requires familiarity with specific jargon and trade terminology. Here are some common terms that B2B buyers should know:

-

OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. Understanding OEM relationships is crucial for buyers looking to source components or materials that meet specific standards and certifications. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is significant for B2B buyers as it can impact inventory levels, cash flow, and overall purchasing strategy. Buyers should negotiate MOQs that align with their production needs without incurring excessive costs. -

RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. This term is essential for initiating procurement processes and ensuring competitive pricing and terms. -

Incoterms (International Commercial Terms)

Incoterms are a series of predefined commercial terms published by the International Chamber of Commerce (ICC) that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps B2B buyers understand shipping responsibilities, risk transfer, and costs associated with their purchases. -

Lead Time

Lead time refers to the amount of time between the initiation of an order and its delivery. Understanding lead times is crucial for supply chain management, allowing businesses to plan production schedules and inventory levels effectively. -

Surface Finish

Surface finish refers to the texture of a surface after processing, which can significantly impact the performance and aesthetics of a part. Buyers should specify surface finish requirements to ensure parts meet functional and visual standards.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions in the chemical milling landscape, ultimately leading to better procurement strategies and enhanced operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the chemical milling Sector

What are the Current Market Dynamics and Key Trends in the Chemical Milling Sector?

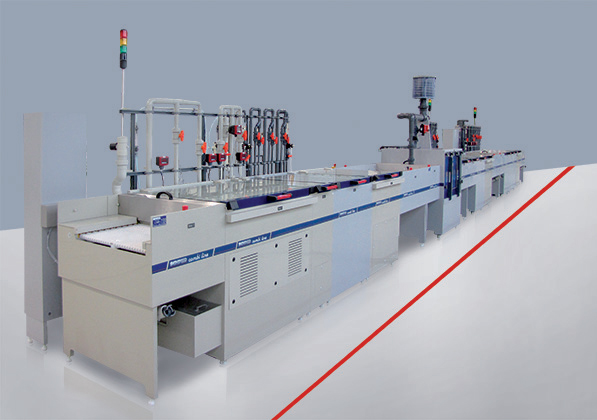

The chemical milling sector is witnessing a notable transformation driven by technological advancements, evolving customer demands, and environmental considerations. Key global drivers include the rising need for precision manufacturing and lightweight components in industries such as aerospace, automotive, and electronics. As these sectors increasingly prioritize intricate designs and complex geometries, chemical milling stands out due to its ability to produce highly accurate components with minimal material waste.

Emerging B2B technology trends are reshaping sourcing strategies in the chemical milling market. The integration of automation and digitalization, such as AI-driven process optimization and real-time monitoring systems, allows manufacturers to enhance efficiency and reduce lead times. Furthermore, the adoption of advanced materials, including high-performance alloys and composites, is expanding the scope of chemical milling applications. This trend is particularly significant for international buyers from regions like Africa and South America, where local industries are striving to improve competitiveness through modern manufacturing techniques.

Market dynamics are also influenced by regional considerations. For instance, European buyers are increasingly focused on compliance with stringent environmental regulations, prompting suppliers to adopt cleaner processes and materials. In contrast, buyers from the Middle East may prioritize cost-effectiveness and rapid delivery due to the region’s fast-paced industrial growth. Consequently, international B2B buyers must remain vigilant to these shifting dynamics to align their sourcing strategies effectively.

How is Sustainability and Ethical Sourcing Impacting the Chemical Milling Industry?

Sustainability is becoming a cornerstone of the chemical milling sector, as environmental impacts and ethical sourcing practices gain prominence among international buyers. The chemical milling process traditionally involves the use of strong acids and other hazardous materials, which can pose environmental risks if not managed properly. As a result, companies are increasingly investing in green technologies and alternatives that minimize harmful emissions and waste.

The importance of ethical supply chains cannot be overstated. B2B buyers are now more inclined to partner with suppliers who demonstrate a commitment to sustainability through certifications such as ISO 14001 (Environmental Management) and ISO 50001 (Energy Management). These certifications not only enhance a company’s reputation but also serve as a competitive differentiator in the global marketplace.

Furthermore, the trend toward using eco-friendly materials is gaining traction. For example, the development of biodegradable maskants and the use of less harmful etchants can significantly reduce the environmental footprint of chemical milling processes. B2B buyers should prioritize suppliers that are actively pursuing sustainable practices, as this not only aligns with corporate social responsibility goals but also meets the growing consumer demand for environmentally conscious products.

How Has the Chemical Milling Process Evolved Over Time?

The evolution of chemical milling dates back centuries, with its roots in traditional etching techniques. Originally used for decorative purposes, the process has transformed significantly, particularly since the mid-20th century. Early applications were limited to simple designs, but advancements in technology have allowed for the intricate designs and precise specifications demanded by modern industries.

The introduction of photochemical etching in the late 20th century marked a significant milestone, allowing for the production of highly detailed components with improved accuracy. This method has been widely adopted across various sectors, including electronics and medical devices, due to its ability to produce complex geometries without the need for extensive tooling.

Illustrative image related to chemical milling

Today, the chemical milling process is characterized by a high degree of automation and sophistication. Modern techniques incorporate digital controls and real-time monitoring, enabling manufacturers to achieve unprecedented levels of precision and efficiency. As the industry continues to evolve, ongoing innovations in materials and processes will further enhance the capabilities and applications of chemical milling, making it a vital component of advanced manufacturing strategies for B2B buyers worldwide.

Frequently Asked Questions (FAQs) for B2B Buyers of chemical milling

-

How do I choose the right chemical milling supplier for my business needs?

Choosing the right supplier involves assessing their experience, certifications, and technology capabilities. Look for suppliers with a proven track record in your specific industry and inquire about their quality assurance processes. It’s also essential to request samples of their previous work to evaluate their precision and quality. Additionally, consider their location, as this can affect shipping times and costs. Building a relationship with your supplier can lead to better pricing and support in the long run. -

What are the typical lead times for chemical milling projects?

Lead times can vary widely depending on the complexity of the project, the materials involved, and the supplier’s capacity. Generally, standard projects may take anywhere from a few days to several weeks. It’s advisable to communicate your timelines clearly with potential suppliers and ask for their typical turnaround times. For urgent projects, inquire about expedited services and any associated costs. -

What are the minimum order quantities (MOQ) for chemical milling services?

Minimum order quantities can differ significantly among suppliers. Some may have a MOQ of a few pieces, while others might require larger batches due to setup costs. When sourcing, discuss your specific needs with suppliers to find one that accommodates your volume requirements. Be sure to assess how MOQ impacts pricing, as larger orders often lead to lower per-unit costs. -

What quality assurance measures should I expect from a chemical milling supplier?

A reputable chemical milling supplier should implement rigorous quality control measures, including material inspections, process monitoring, and final product testing. Look for suppliers who hold industry certifications such as ISO 9001, which indicates a commitment to quality management. Additionally, ask about their inspection methods, such as dimensional checks and surface finish assessments, to ensure that the final products meet your specifications. -

How can I customize my chemical milling project to meet specific requirements?

Customization is often available in chemical milling processes. Discuss your specific design and material needs with potential suppliers, and inquire about their capabilities for custom tooling or unique etching patterns. Some suppliers may also offer flexibility in material selection and surface treatments. Providing detailed drawings and specifications will help suppliers understand your requirements and deliver tailored solutions. -

What payment terms are commonly offered by chemical milling suppliers?

Payment terms can vary widely based on the supplier’s policies and your business relationship. Common options include upfront payments, partial payments upon order confirmation, or net terms (e.g., net 30 or net 60 days). It’s essential to negotiate terms that align with your cash flow requirements. Additionally, consider discussing discounts for early payments or larger orders to optimize costs. -

What should I know about logistics and shipping when sourcing chemical milling services?

Logistics play a crucial role in the sourcing process, particularly when dealing with international suppliers. Understand the shipping options available, including air freight for speed or sea freight for cost efficiency. Be aware of customs regulations and duties in your country, which can impact delivery times and overall costs. Establish clear communication with your supplier regarding shipping timelines and tracking to avoid delays. -

What are the environmental considerations I should be aware of when sourcing chemical milling services?

When sourcing chemical milling, it’s important to consider the environmental impact of the processes involved. Inquire about the supplier’s waste management practices, use of eco-friendly chemicals, and compliance with environmental regulations. Suppliers that prioritize sustainability can enhance your brand’s reputation and ensure compliance with regulations in your market. Engaging with suppliers who have a commitment to reducing their environmental footprint is beneficial for both your business and the planet.

Top 5 Chemical Milling Manufacturers & Suppliers List

1. Ducommun – Chem Milling Solutions

Domain: ducommun.com

Registered: 1996 (29 years)

Introduction: Chem milling process selectively removes material while maintaining structural strength. Material weight reductions of 75% or more and thickness reductions down to .010″ or less. Capable of chemically milling a variety of materials including aluminums, titaniums, and steels. Suitable for rolled, cast, extruded, or formed materials. Provides close tolerance results that are difficult to achieve wit…

2. ScienceDirect – Chemical Milling

Domain: sciencedirect.com

Registered: 1997 (28 years)

Introduction: Chemical milling is a controlled dissolution process that removes material from a workpiece surface using strong inorganic acids or bases. It is a subtractive machining process that utilizes temperature-regulated etching chemicals to produce shapes, blind features like pockets and channels, and reduce weight. The process involves five steps: cleaning, masking, scribing, etching, and demasking. Key…

3. AAA Air Support – Chemical Milling Services

Domain: aaaairsupport.com

Registered: 2006 (19 years)

Introduction: Chemical milling, also known as industrial etching, is a manufacturing process that uses temperature-regulated etching chemicals to remove material and create desired shapes, primarily on metals like aluminum and steel. The process involves bathing the cutting areas of a metal part in a corrosive chemical, often an acid mixture, which dissolves the solid material. Maskants are used to protect area…

4. Nwetch – Key Product Details

Domain: nwetch.com

Registered: 1997 (28 years)

Introduction: Key Product Details: 1. Process: Photo Chemical Machining (PCM) 2. Metals Used: Stainless Steel, Spring Steel, Electrical Steel, Copper, Beryllium Copper, Brass, Aluminum, Bronze, Phosphor Bronze, Nickel 201, Nickel Alloys, Nickel Silver. 3. Design Guidelines: – Hole size must be at least 125% of metal thickness. – For metals up to .010″ thick, diameters of 110% of metal thickness can be achieved….

5. Master Etching – Chemical Etching Equipment

Domain: masteretching.com

Registered: 2012 (13 years)

Introduction: This company, Master Etching – Chemical Etching Equipment, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

Strategic Sourcing Conclusion and Outlook for chemical milling

What Are the Key Takeaways for B2B Buyers in Chemical Milling?

In summary, strategic sourcing in chemical milling offers significant advantages for B2B buyers, particularly in industries requiring precision and efficiency. Understanding the various etching techniques—such as acid etching and photochemical milling—allows companies to select the most suitable processes for their specific applications. The ability to adapt quickly to design changes and produce intricate components with high accuracy can greatly enhance product quality and reduce time-to-market.

Why Is Strategic Sourcing Crucial for International Buyers?

For international buyers, especially from regions like Africa, South America, the Middle East, and Europe, leveraging strategic sourcing can lead to cost savings and improved supply chain reliability. Engaging with reputable suppliers who understand local market dynamics and compliance requirements is essential for fostering successful partnerships.

What’s Next for Buyers in the Chemical Milling Sector?

Looking ahead, the demand for advanced chemical milling solutions is expected to grow as industries continue to embrace innovative manufacturing techniques. B2B buyers should actively seek partnerships with suppliers that prioritize sustainability and technological advancement. By doing so, they can ensure their operations remain competitive in a rapidly evolving market. Now is the time to explore these opportunities and make informed sourcing decisions that will drive future success.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to chemical milling

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.