How to Source Ceiling Retracting Steps Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for ceiling retracting steps

In an increasingly competitive global market, sourcing reliable ceiling retracting steps can pose a significant challenge for international B2B buyers. These innovative access solutions are essential for maximizing space in various environments, from residential lofts to commercial warehouses. However, navigating the diverse offerings—ranging from manual and electric options to custom designs—can be overwhelming. This guide aims to demystify the complexities of selecting the right ceiling retracting steps by exploring various types, applications, and essential considerations for procurement.

Throughout this comprehensive resource, buyers will find crucial insights into supplier vetting processes, cost factors, and installation requirements. Each section is tailored to address the unique needs and preferences of B2B buyers from regions such as Africa, South America, the Middle East, and Europe, including specific markets like Nigeria and Germany. By providing actionable strategies and expert advice, this guide empowers businesses to make informed purchasing decisions that enhance operational efficiency and optimize space utilization.

As the demand for multifunctional and space-saving solutions continues to rise, understanding the nuances of ceiling retracting steps will position your organization for success. Equip yourself with the knowledge to navigate this market effectively, ensuring you select products that meet both your operational needs and budgetary constraints.

Understanding ceiling retracting steps Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Manual Attic Ladders | Operated by hand, typically lightweight and cost-effective. | Residential lofts, small warehouses | Pros: Affordable, easy to install. Cons: Requires manual operation, not suited for frequent use. |

| Electric Attic Ladders | Motorized operation for ease of use, often with remote control. | Commercial buildings, large warehouses | Pros: Convenient, reduces physical strain. Cons: Higher initial cost, requires power source. |

| Wall-Mounted Folding Ladders | Space-saving design that folds against the wall when not in use. | Retail spaces, workshops | Pros: Maximizes floor space, versatile. Cons: Installation may be complex, limited weight capacity. |

| Telescoping Ladders | Adjustable height, compact storage, often made of lightweight materials. | Construction sites, maintenance access points | Pros: Flexible height, portable. Cons: May lack stability for heavy-duty tasks. |

| Insulated Ceiling Ladders | Designed with thermal insulation for energy efficiency. | Energy-efficient buildings, attics | Pros: Reduces energy loss, adds comfort. Cons: Heavier and potentially more expensive. |

What are the Characteristics of Manual Attic Ladders?

Manual attic ladders are a straightforward solution for accessing loft spaces. They are typically lightweight, making them easy to operate by hand. These ladders are best suited for residential applications or smaller commercial spaces where cost-efficiency is paramount. When purchasing, buyers should consider the ladder’s weight capacity and installation requirements, as they may need to be mounted securely for safety.

How Do Electric Attic Ladders Enhance Accessibility?

Electric attic ladders offer a convenient motorized option for accessing higher spaces. With remote control operation, these ladders minimize physical effort, making them ideal for commercial settings where frequent access is needed. B2B buyers should evaluate the power requirements and installation complexity, as these ladders often come at a higher price point due to their advanced features.

Why Choose Wall-Mounted Folding Ladders?

Wall-mounted folding ladders are designed to fold flat against the wall, maximizing floor space in areas where every square meter counts. They are suitable for retail environments and workshops where space is limited. When considering these ladders, businesses should assess installation difficulty and the ladder’s weight capacity to ensure it meets their operational needs.

What Advantages Do Telescoping Ladders Offer?

Telescoping ladders are versatile and can be adjusted to various heights, making them ideal for construction sites or maintenance tasks. Their compact design allows for easy transport and storage, which is particularly beneficial for businesses that require mobility. However, buyers must consider the balance between portability and stability, especially for heavy-duty applications.

How Do Insulated Ceiling Ladders Contribute to Energy Efficiency?

Insulated ceiling ladders are specifically designed to minimize energy loss in buildings, making them an excellent choice for energy-efficient projects. These ladders often feature thermal insulation that helps maintain comfortable temperatures in attics. B2B buyers should weigh the benefits of energy savings against the initial investment and potential increase in weight, which may affect installation and usage.

Key Industrial Applications of ceiling retracting steps

| Industry/Sector | Specific Application of ceiling retracting steps | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Renovation | Accessing loft spaces for storage or utilities | Maximizes space efficiency in residential projects | Load capacity, ease of installation, and compliance with local building codes |

| Warehousing & Logistics | Facilitating access to overhead storage areas | Enhances operational efficiency and safety | Durability, material quality, and safety certifications |

| Retail & Commercial | Creating access to storage areas above retail spaces | Improves inventory management and access control | Customization options for size and design, weight limits |

| Industrial Manufacturing | Enabling maintenance access to machinery and equipment | Reduces downtime and enhances safety protocols | Stability under load, ease of use, and maintenance requirements |

| Hospitality & Tourism | Providing access to rooftop facilities or storage areas | Increases guest experience and operational capacity | Aesthetic design, safety features, and compliance with hospitality standards |

How Are Ceiling Retracting Steps Used in Construction and Renovation Projects?

In the construction and renovation sectors, ceiling retracting steps serve as a practical solution for accessing loft spaces, attics, or other elevated areas. These steps enable contractors and homeowners to utilize vertical space effectively, transforming underused areas into functional storage or utility zones. Buyers from regions like Africa and Europe should consider factors such as load capacity and compliance with local building regulations to ensure safety and durability in their projects.

What Role Do Ceiling Retracting Steps Play in Warehousing and Logistics?

In warehousing and logistics, ceiling retracting steps provide essential access to overhead storage areas, streamlining operations and enhancing safety. By allowing workers to reach stored items quickly, these steps contribute to improved inventory management and reduce the risk of accidents. Businesses in South America and the Middle East should prioritize sourcing options that emphasize stability, material quality, and safety certifications to meet their operational needs effectively.

How Can Retail and Commercial Spaces Benefit from Ceiling Retracting Steps?

Retail and commercial spaces utilize ceiling retracting steps to create efficient access to storage areas located above sales floors. This solution not only optimizes space but also facilitates better inventory management and accessibility for staff. For international buyers, particularly in Europe, sourcing options should include customization possibilities to fit specific store designs and weight limits to ensure that the steps can accommodate various storage needs.

Why Are Ceiling Retracting Steps Important in Industrial Manufacturing?

In industrial manufacturing, ceiling retracting steps are vital for enabling maintenance access to machinery and equipment located at height. This access reduces downtime associated with repairs and enhances overall workplace safety. Buyers in the Middle East and Africa must consider the stability of the steps under load, ease of operation, and ongoing maintenance requirements to ensure a reliable solution for their facilities.

How Do Ceiling Retracting Steps Enhance Hospitality and Tourism Experiences?

In the hospitality and tourism sector, ceiling retracting steps can provide essential access to rooftop facilities or storage areas, thus improving guest experiences and operational capacity. These steps allow for easy access to amenities that may otherwise be difficult to reach. Buyers in this sector should focus on sourcing aesthetically pleasing designs that incorporate safety features to align with hospitality standards, ensuring both functionality and appeal.

3 Common User Pain Points for ‘ceiling retracting steps’ & Their Solutions

Scenario 1: Difficulty in Space Optimization for Commercial Spaces

The Problem: In urban areas, especially in regions like Europe and South America, commercial buildings often face constraints due to limited floor space. B2B buyers, such as facility managers or architects, struggle to provide effective access to lofts or storage areas without compromising valuable real estate. This issue becomes even more pressing when trying to meet regulatory standards for safety and accessibility while ensuring ease of use for employees.

Illustrative image related to ceiling retracting steps

The Solution: To address this challenge, buyers should consider investing in high-quality ceiling retracting steps designed specifically for commercial environments. When sourcing these products, prioritize models that maximize space efficiency and ease of installation. For example, look for retractable ladders with compact designs that fold neatly into the ceiling, thus maintaining a clear floor space when not in use. Moreover, ensure that the chosen ladder has a robust weight capacity and complies with local safety regulations. Collaborating with reputable suppliers who offer customization options can also help meet specific architectural requirements while enhancing the overall utility of the space.

Scenario 2: Safety Concerns with Frequent Use

The Problem: Safety is a paramount concern for B2B buyers overseeing workplaces, particularly when employees frequently access elevated areas using retractable steps. For instance, in warehouses or manufacturing plants, the risk of falls increases if the equipment is not user-friendly or lacks safety features. This can lead to workplace injuries, increased insurance costs, and decreased employee morale.

The Solution: To mitigate safety risks, it is crucial to select retracting steps that come equipped with essential safety features. Look for models that include non-slip treads, handrails, and stability mechanisms to prevent wobbling during use. Additionally, implementing training sessions for employees on the proper usage of these steps can significantly reduce accidents. Regular maintenance checks should also be scheduled to ensure the integrity and functionality of the equipment over time. Engaging with manufacturers who provide comprehensive warranties and support can further enhance safety and reliability.

Scenario 3: Incompatibility with Building Structures

The Problem: A common issue faced by B2B buyers is the incompatibility of standard retractable steps with existing building structures. For instance, in regions like Nigeria and the Middle East, older buildings may have unique ceiling heights or opening sizes that do not match the specifications of readily available retractable steps. This can lead to costly modifications or even the inability to install the desired access solutions.

The Solution: To overcome this challenge, it is advisable to work closely with manufacturers who offer customizable retractable steps. Provide them with precise measurements of the intended installation site, including ceiling height and opening dimensions. Many suppliers can create bespoke solutions that cater to non-standard requirements, ensuring a perfect fit. Additionally, consider modular designs that can be adjusted post-installation to accommodate future changes in building layout or usage. By engaging in early discussions with suppliers about potential customization options, B2B buyers can save time and costs associated with retrofitting or re-engineering existing structures.

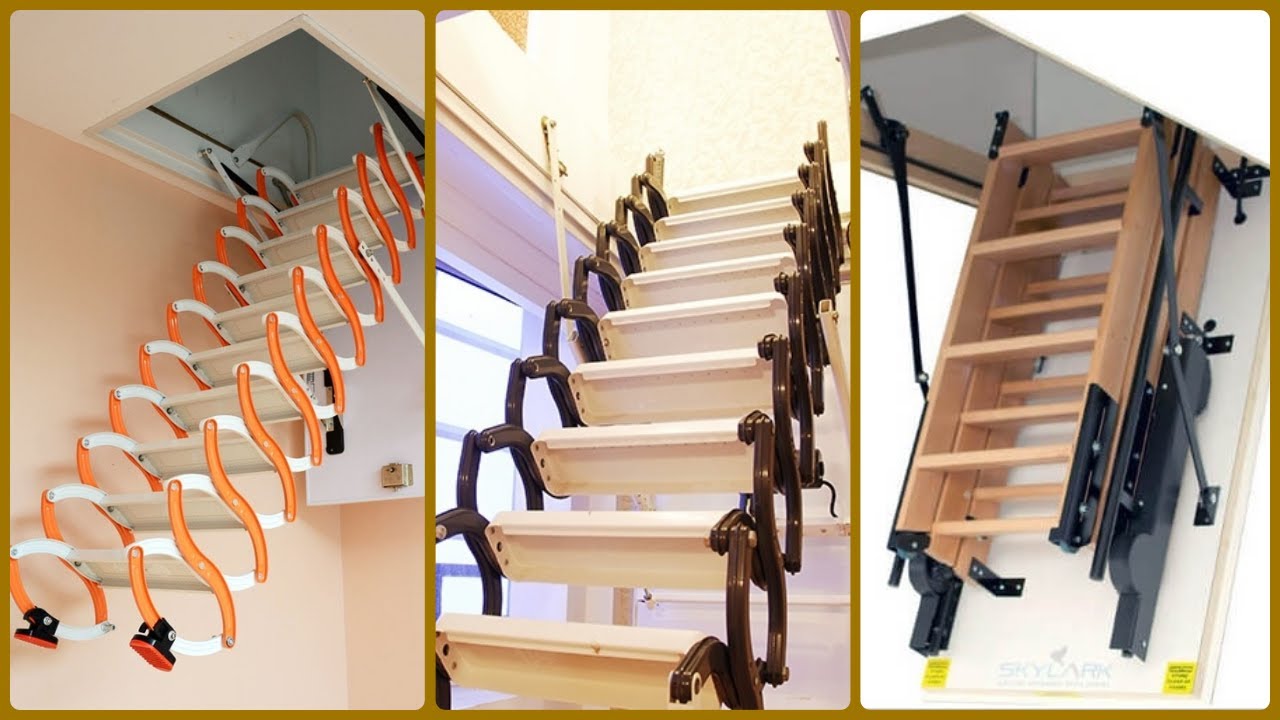

Illustrative image related to ceiling retracting steps

Strategic Material Selection Guide for ceiling retracting steps

What Are the Key Properties of Common Materials Used in Ceiling Retracting Steps?

When selecting materials for ceiling retracting steps, it is crucial to consider properties such as strength, weight, corrosion resistance, and thermal performance. The most commonly used materials include aluminum, steel, fiberglass, and wood. Each material has unique characteristics that can significantly impact performance, durability, and cost.

How Does Aluminum Perform as a Material for Ceiling Retracting Steps?

Aluminum is a lightweight yet strong material, making it an ideal choice for retractable steps. It has excellent corrosion resistance, which is particularly beneficial in humid or coastal environments. Aluminum can withstand a temperature range of -40°C to 80°C, ensuring reliable performance in various climates.

Pros: Aluminum’s lightweight nature facilitates easier installation and operation. Its resistance to rust and corrosion enhances longevity, making it suitable for both indoor and outdoor applications.

Cons: While aluminum is durable, it can be more expensive than other materials like wood. Additionally, it may not support as much weight as heavier materials, which could limit its use in certain applications.

What Are the Advantages of Using Steel for Ceiling Retracting Steps?

Steel, particularly galvanized or stainless steel, is known for its exceptional strength and durability. It can handle high loads and is resistant to deformation under pressure. Steel typically has a temperature rating of -20°C to 150°C, making it versatile for various environments.

Pros: Steel’s high strength-to-weight ratio allows for robust designs that can support significant weight. It is also relatively cost-effective compared to aluminum, making it a popular choice for industrial applications.

Cons: Steel is prone to rust and corrosion if not properly treated, which can lead to maintenance issues over time. Its heavier weight can complicate installation and operation compared to aluminum.

How Does Fiberglass Compare as a Material for Ceiling Retracting Steps?

Fiberglass is a composite material that combines glass fibers with resin, resulting in a lightweight and strong product. It is highly resistant to corrosion and can withstand temperatures from -40°C to 80°C, making it suitable for various environments.

Illustrative image related to ceiling retracting steps

Pros: Fiberglass is non-conductive, making it a safe choice for electrical environments. Its resistance to moisture and chemicals also enhances its durability in various applications.

Cons: The manufacturing process of fiberglass can be complex and costly. Additionally, while it is strong, it may not support as much weight as steel, which could limit its application in heavy-duty scenarios.

Why Is Wood Still a Viable Option for Ceiling Retracting Steps?

Wood, particularly hardwoods like oak or maple, offers a traditional aesthetic and good strength. It is typically rated for temperatures from -30°C to 60°C, making it suitable for indoor applications.

Pros: Wood is often more affordable than metal options, and its natural appearance can be appealing in residential settings. It can also be easily customized and modified.

Illustrative image related to ceiling retracting steps

Cons: Wood is susceptible to rot, insects, and warping, especially in humid environments. Its weight can also make installation more challenging compared to lighter materials like aluminum or fiberglass.

What Should International B2B Buyers Consider When Selecting Materials?

When selecting materials for ceiling retracting steps, international buyers must consider compliance with local standards such as ASTM (American Society for Testing and Materials), DIN (Deutsches Institut für Normung), and JIS (Japanese Industrial Standards). Buyers from regions like Africa, South America, the Middle East, and Europe should also evaluate the material’s performance in local climates, availability, and potential import tariffs.

Summary Table of Material Selection for Ceiling Retracting Steps

| Material | Typical Use Case for ceiling retracting steps | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum | Residential and commercial retractable steps | Lightweight and corrosion-resistant | Higher cost than wood | Medium |

| Steel | Industrial applications requiring high strength | Exceptional load-bearing capacity | Prone to rust without treatment | Medium |

| Fiberglass | Environments requiring chemical resistance | Non-conductive and moisture-resistant | Complex manufacturing process | High |

| Wood | Residential settings with aesthetic appeal | Cost-effective and customizable | Susceptible to rot and warping | Low |

This guide provides a comprehensive overview of material options for ceiling retracting steps, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for ceiling retracting steps

The manufacturing of ceiling retracting steps involves a series of well-defined processes, ensuring that the final product meets rigorous quality standards. This section delves into the various stages of production, key techniques employed, and the quality assurance measures that B2B buyers should consider when sourcing these products.

Illustrative image related to ceiling retracting steps

What Are the Main Stages of Manufacturing Ceiling Retracting Steps?

The manufacturing process for ceiling retracting steps typically includes the following stages:

1. Material Preparation

The first step in the manufacturing process is the selection and preparation of materials. Common materials used for retracting steps include high-strength aluminum, carbon steel, and various alloys. These materials are chosen for their durability, weight capacity, and resistance to corrosion.

-

Material Sourcing: Manufacturers often establish partnerships with reputable suppliers to ensure that the raw materials meet international standards. This is particularly important for B2B buyers who may be importing products into regions with specific regulatory requirements.

-

Material Testing: Prior to processing, incoming materials undergo rigorous testing for tensile strength, weight capacity, and corrosion resistance. This initial quality check, known as Incoming Quality Control (IQC), helps to identify any substandard materials before they enter the production line.

2. Forming

Once materials are prepared, they move to the forming stage, where they are shaped into the required components of the retracting steps.

-

Techniques Used: Common forming techniques include stamping, bending, and welding. For instance, aluminum components might be extruded to create lightweight but strong profiles, while steel components may be welded to form a robust framework.

-

Precision Engineering: Advanced machinery and CNC (Computer Numerical Control) technology are often utilized to ensure precise dimensions and a high-quality finish. This precision is critical for ensuring the components fit together seamlessly during assembly.

3. Assembly

Following the forming stage, the various components are assembled into the final product.

-

Assembly Line Techniques: This stage typically involves both manual labor and automated processes. Workers might assemble the ladders using mechanical fasteners, while automated systems can be employed for tasks like applying adhesive or performing final checks.

-

Quality Control Integration: During assembly, manufacturers conduct in-process quality checks (IPQC) to ensure that each component meets design specifications. This includes verifying the correct alignment of parts and ensuring all safety features are operational.

4. Finishing

The final stage of manufacturing involves applying finishes that enhance the product’s durability and aesthetics.

-

Coating and Painting: Surface treatments such as powder coating or anodizing are applied to prevent corrosion and improve the visual appeal of the steps. These finishes are especially important for products intended for outdoor use.

-

Final Inspection: Before packaging, a final quality check (FQC) is performed. This inspection assesses the overall functionality, appearance, and safety of the product, ensuring that it meets both the manufacturer’s and international standards.

How Is Quality Assurance Ensured in Manufacturing Ceiling Retracting Steps?

Quality assurance is a critical aspect of the manufacturing process, particularly for products that must adhere to safety standards and regulations.

What International Standards Should B2B Buyers Be Aware Of?

For ceiling retracting steps, several international standards may apply:

-

ISO 9001: This standard outlines a framework for quality management systems, ensuring that manufacturers consistently provide products that meet customer and regulatory requirements.

-

CE Marking: In Europe, products must often bear the CE mark, indicating compliance with health, safety, and environmental protection standards.

-

API Standards: For manufacturers producing heavy-duty retracting steps, compliance with American Petroleum Institute (API) standards may be necessary, particularly for industrial applications.

What Are the Key Quality Control Checkpoints?

B2B buyers should be familiar with the various quality control checkpoints throughout the manufacturing process:

-

Incoming Quality Control (IQC): This initial inspection checks raw materials for defects before they enter production.

-

In-Process Quality Control (IPQC): Conducted during assembly, this ensures that each stage of production adheres to established quality standards.

-

Final Quality Control (FQC): A comprehensive inspection performed before the product is packaged and shipped, assessing overall quality and performance.

What Common Testing Methods Are Used?

Manufacturers employ a variety of testing methods to validate the quality and safety of ceiling retracting steps:

-

Load Testing: To ensure the steps can safely support the specified weight, manufacturers conduct load tests that simulate real-world usage.

-

Durability Testing: This may involve subjecting the product to environmental conditions (e.g., humidity, temperature changes) to assess its resistance to wear and tear.

-

Safety Testing: Features such as slip resistance and stability are evaluated to ensure that the product meets safety standards.

How Can B2B Buyers Verify Supplier Quality Control?

For international buyers, verifying the quality control processes of suppliers is essential to ensure product reliability.

What Steps Can Buyers Take to Verify Quality?

-

Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturer’s quality control processes firsthand. This can include reviewing documentation, inspecting production facilities, and observing manufacturing practices.

-

Requesting Quality Reports: Buyers should request detailed quality assurance reports that outline testing results, compliance with standards, and any corrective actions taken for past issues.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the manufacturer’s quality control practices and product quality before shipment.

What Are the Nuances of QC and Certification for International Buyers?

B2B buyers from regions such as Africa, South America, the Middle East, and Europe should be aware of specific nuances:

-

Regulatory Compliance: Different regions may have varying regulatory requirements. Buyers should ensure that their suppliers are familiar with and compliant with local laws regarding safety and quality.

-

Documentation and Certification: Ensuring that suppliers provide all necessary certifications (e.g., ISO, CE) is crucial for smooth customs clearance and market acceptance.

-

Cultural Considerations: Understanding cultural differences in business practices and quality expectations can aid in building successful partnerships with suppliers in different regions.

By understanding the manufacturing processes and quality assurance measures associated with ceiling retracting steps, B2B buyers can make informed decisions, ensuring they source reliable, high-quality products that meet their specific needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘ceiling retracting steps’

To assist international B2B buyers in sourcing ceiling retracting steps effectively, this guide provides a structured checklist that outlines essential actions to take before making a procurement decision. Following these steps will ensure that you select the right product and supplier for your needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful procurement process. Consider factors such as the maximum height the ladder needs to reach, the weight capacity, and the materials used. Be specific about dimensions and any unique requirements, such as insulation properties or compliance with local building codes.

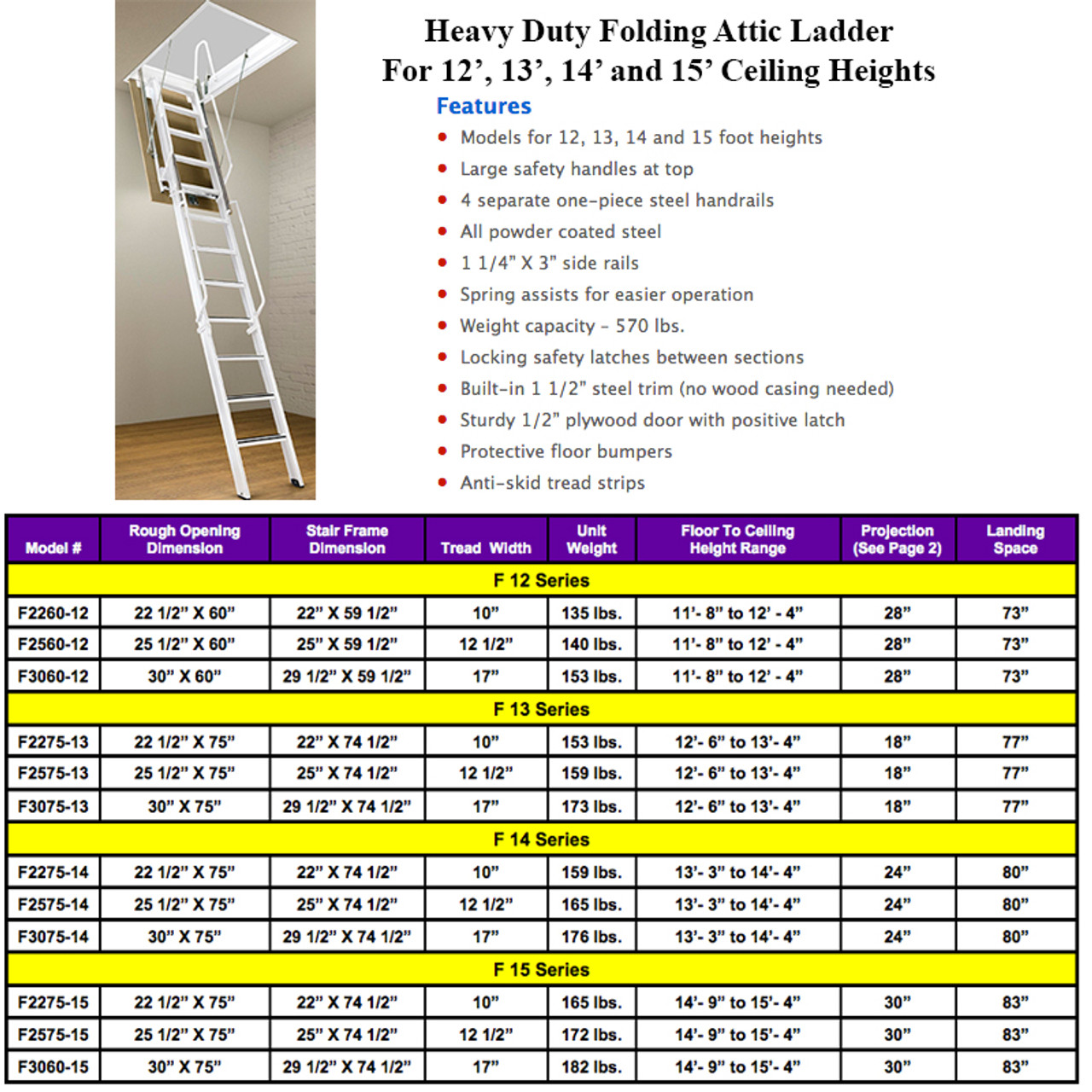

Illustrative image related to ceiling retracting steps

- Key Considerations:

- Maximum height (e.g., 2 to 3.5 meters).

- Load capacity (ensure it meets your operational needs).

- Materials (e.g., carbon steel for durability).

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in ceiling retracting steps. Look for companies with a solid reputation and experience in your target market regions, such as Africa, South America, and Europe.

- How to Evaluate:

- Review online presence, including customer testimonials and case studies.

- Check for industry certifications that verify quality standards.

Step 3: Verify Supplier Certifications

Ensuring that suppliers have the necessary certifications is crucial for compliance and safety. Certifications may vary by region but often include ISO standards or specific local building compliance certifications.

- Why This Matters:

- Certifications can indicate the quality and reliability of the products.

- They help mitigate risks associated with safety and regulatory compliance.

Step 4: Request Product Samples

Before placing a large order, request samples of the ceiling retracting steps. This allows you to assess the product’s quality, functionality, and ease of use firsthand.

Illustrative image related to ceiling retracting steps

- Sample Evaluation:

- Test the ladder for stability and ease of operation.

- Check for installation requirements and any included components.

Step 5: Analyze Pricing and Terms

Gather detailed pricing information from multiple suppliers and compare it against your budget. Be sure to consider total costs, including shipping, installation, and any potential customizations.

- Considerations:

- Ensure clarity on payment terms and any hidden fees.

- Look for bulk purchase discounts if applicable.

Step 6: Negotiate Contracts

Once you’ve selected a supplier, initiate contract negotiations. This step is critical for establishing terms that protect your interests, including warranty details, return policies, and service agreements.

- What to Include:

- Clearly defined delivery timelines.

- Warranty duration and conditions for claims.

Step 7: Plan for Installation and Maintenance

Finally, consider the logistics of installation and ongoing maintenance. Determine if the supplier provides installation services or if you need to arrange for a third-party contractor.

- Installation Tips:

- Ask for detailed installation instructions or videos.

- Ensure you understand the maintenance requirements to prolong the product’s lifespan.

Following this checklist will guide you through the procurement process for ceiling retracting steps, helping you make informed decisions that align with your operational needs and standards.

Illustrative image related to ceiling retracting steps

Comprehensive Cost and Pricing Analysis for ceiling retracting steps Sourcing

What are the Key Cost Components for Sourcing Ceiling Retracting Steps?

When sourcing ceiling retracting steps, understanding the cost structure is vital for making informed purchasing decisions. The primary cost components include:

-

Materials: The choice of materials significantly impacts the price. Common materials for retracting steps include aluminum, carbon steel, and engineered wood. Each material offers different strength, weight, and insulation properties, which in turn affects durability and cost.

-

Labor: Labor costs can vary widely based on geographic location and local wage standards. In countries like Germany, labor may be more expensive compared to regions in Africa or South America. This cost is associated with both manufacturing and assembly processes.

-

Manufacturing Overhead: This encompasses all costs not directly tied to production, such as utilities, rent, and administrative expenses. Efficient manufacturing processes can help minimize these overhead costs.

-

Tooling: The initial investment in tools and machinery necessary for production is another significant factor. Custom designs may require specialized tools, which can increase the upfront costs.

-

Quality Control (QC): Implementing robust QC measures ensures that the final product meets safety and performance standards. While this can add to production costs, it is crucial for maintaining product integrity and reducing returns.

-

Logistics: Shipping and handling costs vary based on the distance, weight, and dimensions of the product. Additionally, factors like import duties and taxes can considerably influence the overall logistics expenses.

-

Margin: Suppliers typically add a profit margin to cover their costs and risks, which can vary widely between manufacturers. Understanding the standard margins in the industry can help buyers negotiate better prices.

How Do Price Influencers Affect the Cost of Ceiling Retracting Steps?

Several factors can influence the pricing of ceiling retracting steps:

-

Volume and Minimum Order Quantity (MOQ): Bulk purchases often lead to lower per-unit costs. Manufacturers may offer significant discounts for larger orders, making it essential to consider long-term needs.

-

Specifications and Customization: Custom designs or specifications can lead to increased costs due to the need for specialized materials or manufacturing processes. Buyers should weigh the benefits of customization against the potential for higher expenses.

-

Material Quality and Certifications: Higher quality materials and certifications (e.g., ISO, CE) can increase costs but often lead to better performance and safety. Buyers should evaluate whether the additional investment aligns with their specific needs.

-

Supplier Factors: The reputation and reliability of suppliers can impact pricing. Established suppliers may charge a premium for their proven quality and service, while less-known suppliers may offer lower prices with higher risks.

-

Incoterms: The chosen Incoterms (International Commercial Terms) dictate the responsibilities of buyers and sellers in shipping and handling costs. For instance, “CIF” (Cost, Insurance, and Freight) includes shipping costs, while “FOB” (Free on Board) places shipping responsibilities on the buyer.

What Buyer Tips Can Enhance Cost-Efficiency When Sourcing Ceiling Retracting Steps?

For international B2B buyers, particularly from Africa, South America, the Middle East, and Europe, optimizing costs requires strategic approaches:

-

Negotiation: Always negotiate prices and terms. Suppliers may have room to adjust their margins, especially for larger orders or long-term partnerships.

-

Total Cost of Ownership (TCO): Consider not just the initial purchase price but also maintenance, durability, and potential replacement costs over time. Investing in higher-quality products may yield lower overall costs.

-

Pricing Nuances for International Purchases: Be aware of currency fluctuations and their impact on pricing. Additionally, factor in potential delays and costs associated with customs clearance, which can affect the total cost.

-

Research and Due Diligence: Thoroughly vet suppliers and compare multiple quotes to ensure you are getting the best value. Look for reviews or case studies that demonstrate a supplier’s reliability and product quality.

Disclaimer on Indicative Prices

Prices for ceiling retracting steps can vary widely based on the aforementioned factors. The figures provided in reference materials are indicative and subject to change based on market conditions, supplier pricing strategies, and changes in production costs. Always request current pricing directly from suppliers to ensure accurate budgeting.

Alternatives Analysis: Comparing ceiling retracting steps With Other Solutions

Exploring Alternatives to Ceiling Retracting Steps

When considering access solutions for lofts, attics, or high storage areas, ceiling retracting steps stand out for their convenience and space-saving design. However, it is crucial for B2B buyers to evaluate alternative solutions that may offer comparable benefits or fit specific operational needs. This analysis compares ceiling retracting steps with two viable alternatives: traditional fixed ladders and electric attic ladders.

Illustrative image related to ceiling retracting steps

| Comparison Aspect | Ceiling Retracting Steps | Traditional Fixed Ladders | Electric Attic Ladders |

|---|---|---|---|

| Performance | High; easy to operate | Moderate; requires manual effort | Very high; automated operation |

| Cost | Moderate ($250 – $2,000) | Low ($100 – $500) | High ($1,000 – $3,000) |

| Ease of Implementation | Simple installation | Moderate; requires more planning | Complex; needs professional installation |

| Maintenance | Low; minimal upkeep | Low; occasional checks | Moderate; electrical components require maintenance |

| Best Use Case | Limited space, frequent use | Occasional access needs | High-frequency access, convenience-focused environments |

What Are the Advantages and Disadvantages of Traditional Fixed Ladders?

Traditional fixed ladders are a common alternative that offers a straightforward solution for accessing elevated areas. They are typically less expensive, making them an attractive option for budget-conscious buyers. However, they require more space and can be cumbersome to use regularly. Fixed ladders also lack the safety features found in retractable steps, potentially increasing the risk of accidents. While they serve well in settings where access is infrequent, they are less suited for environments requiring regular use.

How Do Electric Attic Ladders Compare in Functionality and Cost?

Electric attic ladders represent a high-tech alternative that provides automated access to loft spaces. These ladders are particularly advantageous for environments where safety and convenience are paramount, as they often come equipped with remote controls and safety features such as anti-slip treads and automatic locking mechanisms. However, the initial investment is significantly higher than both ceiling retracting steps and traditional ladders, making them less feasible for smaller budgets. Furthermore, installation can be complex and typically requires professional assistance, which adds to the overall cost.

What Should B2B Buyers Consider When Choosing Between These Options?

When selecting the right access solution, B2B buyers should assess their specific needs, including frequency of use, available space, and budget constraints. Ceiling retracting steps are ideal for businesses with limited room and a need for frequent access. In contrast, traditional fixed ladders may suffice for occasional usage in less demanding environments. For companies prioritizing ease of use and safety, electric attic ladders offer a modern solution but come at a higher cost and complexity.

In conclusion, understanding the unique advantages and limitations of each option will empower buyers to make informed decisions tailored to their operational requirements. By evaluating factors such as performance, cost, and ease of installation, businesses can choose an access solution that aligns best with their goals and workspace dynamics.

Essential Technical Properties and Trade Terminology for ceiling retracting steps

What are the Essential Technical Properties of Ceiling Retracting Steps?

When considering ceiling retracting steps for business applications, understanding the technical properties is crucial for ensuring safety, efficiency, and suitability for specific environments. Here are several key specifications to keep in mind:

1. Material Grade

The material used in ceiling retracting steps, typically carbon steel, aluminum, or fiberglass, directly affects durability and weight capacity. Carbon steel is known for its strength and longevity, while aluminum offers a lightweight alternative that resists rust. For B2B buyers, selecting the appropriate material is vital to match the ladder’s intended use, whether for residential lofts or commercial warehouses.

2. Load Capacity

Load capacity refers to the maximum weight the ladder can support, usually expressed in pounds or kilograms. This specification is critical for businesses that require heavy equipment access or multiple users at once. A standard load capacity for robust retracting steps may range from 300 kg to 700 kg. Ensuring that the chosen model meets or exceeds the expected load is essential for safety and compliance.

Illustrative image related to ceiling retracting steps

3. Height Range

The height range indicates the maximum vertical distance the ladder can accommodate, typically measured from the floor to the ceiling opening. Most retracting steps are designed for heights between 2 to 3.5 meters. For B2B operations, knowing the height range helps ensure that the product fits the specific architectural constraints of a facility, facilitating effective access without compromising safety.

4. Opening Size Compatibility

This specification refers to the standard dimensions of the ceiling opening where the retracting steps will be installed, commonly expressed in millimeters. Common sizes might include 700x900mm or 800x1200mm. Understanding opening size compatibility is essential for seamless installation and operation, reducing the need for costly modifications post-purchase.

5. Insulation Properties

Insulation properties are critical for retracting steps that lead to attics or lofts. A well-insulated ladder can prevent heat loss and maintain energy efficiency in buildings. B2B buyers should look for ladders that feature insulated hatch doors, which can significantly reduce heating and cooling costs in commercial spaces.

What are Common Trade Terms Associated with Ceiling Retracting Steps?

In the B2B market for ceiling retracting steps, familiarity with trade terminology can streamline negotiations and procurement processes. Here are some common terms:

Illustrative image related to ceiling retracting steps

1. OEM (Original Equipment Manufacturer)

OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. For B2B buyers, working with an OEM can ensure that products meet specific standards and specifications, which is critical for maintaining quality in large-scale applications.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest number of units a supplier is willing to sell. Understanding MOQ is vital for businesses looking to balance inventory needs with cost efficiency. Lower MOQs can be beneficial for smaller companies or those testing a new product line.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products. For B2B transactions, issuing an RFQ can help buyers compare offerings from multiple suppliers, ensuring they receive the best value and service.

4. Incoterms (International Commercial Terms)

Incoterms define the responsibilities of buyers and sellers for the delivery of goods. Familiarity with these terms is crucial for international transactions, as they clarify who bears the costs and risks at various points in the shipping process.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times helps businesses plan their inventory and project timelines effectively, which is essential for operations that depend on timely access to equipment.

By grasping both the technical properties and the associated trade terminology, B2B buyers can make informed decisions that optimize their procurement processes and enhance operational efficiency.

Navigating Market Dynamics and Sourcing Trends in the ceiling retracting steps Sector

What Are the Current Market Dynamics Influencing the Ceiling Retracting Steps Sector?

The ceiling retracting steps sector is experiencing a notable transformation, driven by a convergence of technological advancements and evolving market demands. Global drivers such as urbanization, space optimization, and the rising trend of multifunctional living spaces are reshaping the way ceiling retracting steps are perceived and utilized. As urban centers expand, especially in regions like Africa and South America, the need for efficient space management becomes paramount. This is leading to increased demand for compact, retractable solutions that can maximize functionality without compromising aesthetics.

Emerging trends in B2B technology are also influencing sourcing strategies. Buyers are increasingly leveraging digital platforms for procurement, allowing for easier access to a global marketplace of suppliers. Innovations such as smart home integration and enhanced safety features are becoming essential selling points. Companies are now offering customizable solutions that cater to specific requirements, such as varying ceiling heights and load capacities, which is particularly appealing to international buyers in diverse markets, including Germany and Nigeria.

Furthermore, sustainability is becoming a critical consideration in procurement decisions. Buyers are seeking products that not only meet functional needs but also align with their corporate social responsibility goals. As a result, manufacturers who can demonstrate compliance with environmental standards and offer eco-friendly materials are gaining a competitive edge.

Illustrative image related to ceiling retracting steps

How Is Sustainability Shaping the Sourcing of Ceiling Retracting Steps?

Sustainability and ethical sourcing are pivotal in the ceiling retracting steps sector. The environmental impact of manufacturing processes is under scrutiny, prompting buyers to prioritize suppliers that adhere to sustainable practices. This includes the use of recyclable materials, reduced energy consumption during production, and responsible waste management.

Incorporating ‘green’ certifications into product offerings is becoming a necessity for manufacturers aiming to attract environmentally conscious buyers. Certifications such as ISO 14001 (Environmental Management) and FSC (Forest Stewardship Council) for wood products are increasingly influencing purchasing decisions. Buyers are not only looking for products that are functional but also those that contribute positively to the environment.

Additionally, ethical supply chains are gaining importance. B2B buyers are keen on understanding the sourcing practices of their suppliers, ensuring that labor conditions are fair and materials are sourced responsibly. Companies that can provide transparency in their supply chain are likely to build stronger relationships with international buyers, fostering trust and loyalty.

What Is the Evolution of Ceiling Retracting Steps in the B2B Market?

The evolution of ceiling retracting steps can be traced back to traditional fixed staircases, which were often bulky and space-consuming. Over time, the need for more adaptable and efficient solutions led to the development of retractable designs. Early models were primarily functional, but advancements in materials and engineering have allowed for more aesthetically pleasing and versatile options.

In recent years, innovations such as lightweight materials and automated mechanisms have revolutionized the market. Modern retractable steps are not only more user-friendly but also offer enhanced safety features, catering to a broader audience. As the market continues to evolve, the integration of smart technology is likely to further transform how these products are used in both residential and commercial settings, making them an essential component of modern architecture and design.

Frequently Asked Questions (FAQs) for B2B Buyers of ceiling retracting steps

-

How do I choose the right ceiling retracting steps for my project?

When selecting ceiling retracting steps, consider the specific height requirements and weight capacity needed for your application. Evaluate the material—aluminum, steel, or fiberglass—based on durability and environmental conditions. Also, assess the design features such as insulation properties, ease of operation, and safety measures like handrails. It’s advisable to consult with manufacturers about customization options to ensure the product meets your precise specifications. -

What are the key features to look for in ceiling retracting steps?

Key features include load capacity, material quality, insulation effectiveness, and ease of installation. Look for retracting steps with robust safety features such as anti-slip treads and handrails. Consider models that offer space-saving designs, especially if space is limited. Additionally, check for warranties and customer support services, as these can be crucial for long-term reliability and maintenance. -

What is the typical lead time for ordering ceiling retracting steps internationally?

Lead times can vary based on the supplier and the complexity of your order. Generally, expect a lead time of 3-4 weeks for standard products, while custom orders may take longer, potentially 6-8 weeks or more. Factors such as shipping methods, customs clearance, and order size can also impact delivery times. Always confirm lead times with your supplier before placing an order to manage expectations. -

How do I vet suppliers for ceiling retracting steps?

To vet suppliers, start by researching their reputation through reviews and testimonials from other B2B buyers. Check their certifications and compliance with international quality standards. Request references and inquire about their manufacturing processes, quality assurance practices, and after-sales support. Visiting their facilities or attending trade shows can also provide insights into their operational capabilities and reliability. -

What are the minimum order quantities (MOQ) for ceiling retracting steps?

MOQs can vary significantly between suppliers and depend on the product type and customization options. Typically, for standard ceiling retracting steps, MOQs might range from 10 to 50 units. Custom orders often have higher MOQs due to the specific manufacturing requirements. Always discuss your needs with the supplier to negotiate favorable terms that align with your project scale. -

What payment terms should I expect when sourcing ceiling retracting steps?

Payment terms can vary by supplier but often include options such as full payment upfront, a deposit with the balance due upon delivery, or net 30/60 terms. It’s essential to clarify these terms before finalizing your order. Some suppliers may also offer discounts for early payment or bulk purchases. Always ensure that payment methods are secure and that you receive an invoice for your records. -

How can I ensure quality assurance for my ceiling retracting steps?

To ensure quality, request certifications and compliance documents from your supplier that demonstrate adherence to international standards. Consider conducting factory audits or inspections before shipment. Establish a clear quality control process, including specifications for materials, dimensions, and load capacities. Additionally, inquire about the warranty and return policy, as these can provide further assurance of product quality. -

What logistics considerations should I be aware of when importing ceiling retracting steps?

Logistics considerations include understanding shipping methods (air vs. sea), customs regulations, and potential tariffs or import duties specific to your country. Coordinate with your supplier to determine the best shipping options that balance cost and delivery time. It’s also advisable to work with a reputable freight forwarder who can assist with documentation and customs clearance to facilitate a smooth import process.

Top 3 Ceiling Retracting Steps Manufacturers & Suppliers List

1. Blakley Equipment – TECHTONGDA Attic Ceiling Ladder

Domain: blakleyequipment.com

Registered: 2010 (15 years)

Introduction: {“product_name”:”TECHTONGDA Attic Ceiling Ladder Pull Down Attic Stairs 9.8ft”,”type”:”Attic Ladder”,”height”:”9.8 feet”,”features”:[“Pull down mechanism”,”Space-saving design”,”Durable construction”,”Easy installation”],”material”:”Wood”,”weight_capacity”:”300 lbs”,”dimensions”:{“ladder_length”:”9.8 ft”,”ladder_width”:”N/A”,”ladder_height”:”N/A”},”color”:”Natural wood finish”,”brand”:”TECHTONGDA”…

2. Henan Youpin – Ceiling Mounted Roof Access Retractable Folding Zip Step Attic Ladders

Domain: adaladder.com

Registered: 2022 (3 years)

Introduction: Product Name: Ceiling Mounted Roof Access Retractable Folding Zip Step Attic Ladders

Manufacturer: Henan Youpin Home Ladder Co., Ltd.

Price: $277

Inventory: 20 remaining

Key Features:

– Enhanced Stability: S-bent skeleton design, stainless steel rivets, max loading capacity of 700 lbs.

– Space-saving Design: Retractable with two galvanized Mn-steel springs, reaches up to 11.2 ft/3.4 m.

– Considera…

3. Img Dosificacion – Retractable Loft Stairs

Domain: imgdosificacion.com

Registered: 2016 (9 years)

Introduction: Ladder Retractable Loft Stairs, Capacity: 660 lbs, Maximum Height: 9.8 ft

Strategic Sourcing Conclusion and Outlook for ceiling retracting steps

In conclusion, the strategic sourcing of ceiling retracting steps presents a unique opportunity for businesses to enhance their operational efficiency while maximizing space utilization. The diverse range of products available—from manual to electric retractable ladders—ensures that international buyers can select solutions tailored to their specific needs, whether in residential, commercial, or industrial settings. Key factors such as stability, ease of installation, and thermal insulation should guide purchasing decisions, ensuring that investments yield long-term benefits.

As the global market continues to evolve, particularly in regions like Africa, South America, the Middle East, and Europe, it is crucial for businesses to stay ahead of trends in innovative access solutions. By prioritizing strategic sourcing, companies can not only reduce operational costs but also improve safety and accessibility within their facilities.

We encourage international buyers to explore partnerships with reliable suppliers and manufacturers who can provide high-quality products that meet their unique requirements. Embrace the future of efficient space management with ceiling retracting steps, and position your business for success in an increasingly competitive landscape.

Illustrative image related to ceiling retracting steps

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.