How to Source Cam Latch Mechanism Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for cam latch mechanism

In today’s competitive landscape, sourcing the right cam latch mechanism can present a significant challenge for B2B buyers, particularly those operating across diverse regions such as Africa, South America, the Middle East, and Europe. As businesses strive for enhanced security and functionality in their products—from toolboxes to access panels—understanding the intricacies of cam latches becomes crucial. This guide delves into the multifaceted world of cam latch mechanisms, covering various types, applications, and materials.

Buyers will find comprehensive insights into the operational mechanics of cam latches, including the differences between keyed and non-keyed options, as well as considerations for installation and durability. Additionally, we will explore supplier vetting processes, helping you identify reliable partners that can meet your specific needs. Cost analysis will also be a focal point, equipping you with the knowledge to make informed purchasing decisions that align with your budget constraints.

By navigating through this guide, international B2B buyers will be empowered to select the most suitable cam latch solutions for their applications, ensuring they enhance both security and efficiency in their operations. Whether you are in Brazil, Vietnam, or elsewhere, understanding these mechanisms will enable you to optimize your product offerings and meet the demands of your markets effectively.

Understanding cam latch mechanism Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Keyed Cam Latch | Requires a key for operation; enhanced security. | Lockers, cabinets, and secure enclosures. | Pros: High security; Cons: Requires key management. |

| Non-Keyed Cam Latch | Simple operation without a key; cost-effective. | Toolboxes, drawers, and access panels. | Pros: Easy to use; Cons: Lower security level. |

| Quarter-Turn Cam Latch | Rotates 90 degrees for locking; compact design. | Industrial equipment, electrical cabinets. | Pros: Space-saving; Cons: Limited to specific applications. |

| Compression Latch | Applies pressure to create a tight seal; durable. | Automotive, transportation, and machinery. | Pros: Excellent sealing; Cons: Installation complexity. |

| Heavy-Duty Cam Latch | Built for high-stress environments; robust materials. | Industrial storage and heavy machinery. | Pros: Extremely durable; Cons: Higher cost. |

What Are the Characteristics of Keyed Cam Latches?

Keyed cam latches are designed for applications where security is paramount. These latches require a key to operate, making them ideal for environments like lockers and secure storage cabinets. Buyers should consider the key management process, as losing keys can lead to accessibility issues. Additionally, the material quality and corrosion resistance are crucial, especially in outdoor or industrial settings.

How Do Non-Keyed Cam Latches Work and Where Are They Used?

Non-keyed cam latches offer a straightforward, keyless operation, making them suitable for applications such as toolboxes and office drawers. Their simplicity translates to lower costs and easier installation. However, businesses must weigh the trade-off in security, as these latches do not provide the same level of protection as their keyed counterparts. Buyers should assess the environmental conditions where the latch will be used to ensure durability.

Why Choose Quarter-Turn Cam Latches for Industrial Applications?

Quarter-turn cam latches are characterized by their compact design and 90-degree rotation mechanism, which allows for quick access. These latches are commonly used in industrial settings, particularly for electrical cabinets and machinery access. When purchasing, businesses should consider the latch’s mounting style and compatibility with existing equipment. The space-saving design is a key advantage, but users must ensure that the latch meets their security needs.

What Are Compression Latches and Their Advantages?

Compression latches are designed to apply pressure, creating a secure seal that is particularly beneficial in automotive and transportation applications. They are known for their durability and ability to withstand harsh conditions. However, the installation process can be more complex than other latch types. Buyers should evaluate the specific sealing requirements and ensure that the latch can withstand the operational environment.

What Makes Heavy-Duty Cam Latches Ideal for Tough Environments?

Heavy-duty cam latches are built to endure high-stress environments, making them suitable for industrial storage and heavy machinery applications. These latches are typically made from robust materials designed to resist wear and tear. While they offer exceptional durability, the upfront cost may be higher compared to standard latches. Businesses should consider the long-term investment in reliability versus initial expenditure when selecting heavy-duty options.

Key Industrial Applications of cam latch mechanism

| Industry/Sector | Specific Application of cam latch mechanism | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Manufacturing | Toolboxes and Equipment Lockers | Enhances security for valuable tools and equipment, reducing theft risks. | Material durability, corrosion resistance, and installation ease. |

| Automotive | Access Panels in Vehicles | Provides secure access while maintaining aesthetic integrity of vehicles. | Compatibility with vehicle design, resistance to elements, and ease of operation. |

| Telecommunications | Control Panels and Cabinets | Protects sensitive equipment and ensures reliability in operation. | Size, locking mechanism type, and environmental resistance. |

| Furniture & Fixtures | Office Cabinets and Desks | Secures personal belongings and confidential documents, improving user trust. | Design compatibility, ease of installation, and finish options. |

| Logistics & Shipping | Shipping Containers and Enclosures | Secures cargo during transit, minimizing damage and loss. | Strength, weather resistance, and ease of use in high-volume operations. |

How are Cam Latch Mechanisms Used in Manufacturing Toolboxes and Equipment Lockers?

In the manufacturing sector, cam latch mechanisms are commonly employed in toolboxes and equipment lockers to secure valuable tools and machinery. These latches prevent unauthorized access and theft, which is crucial for businesses that rely on expensive equipment. For international buyers, sourcing cam latches that are durable and resistant to corrosion is essential, particularly in regions with high humidity or industrial exposure. Additionally, ease of installation can significantly reduce downtime during setup.

What Role Do Cam Latch Mechanisms Play in Automotive Access Panels?

In the automotive industry, cam latch mechanisms are vital for access panels, providing secure yet convenient access to various vehicle components. These latches are designed to maintain the aesthetic integrity of vehicles while ensuring that critical parts are protected. International buyers must consider compatibility with specific vehicle designs, resistance to environmental factors, and the ease of operation, especially in regions with diverse climatic conditions.

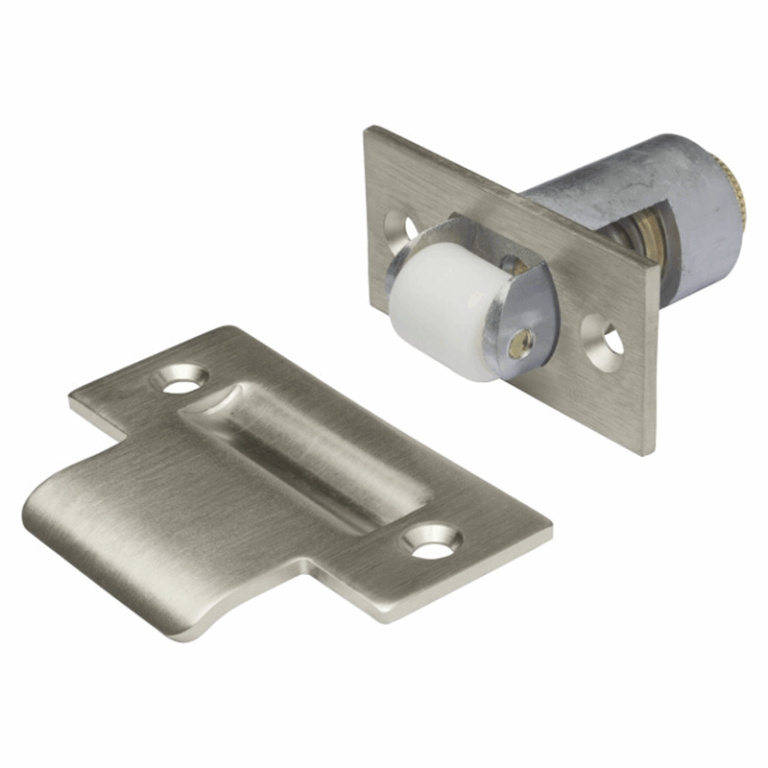

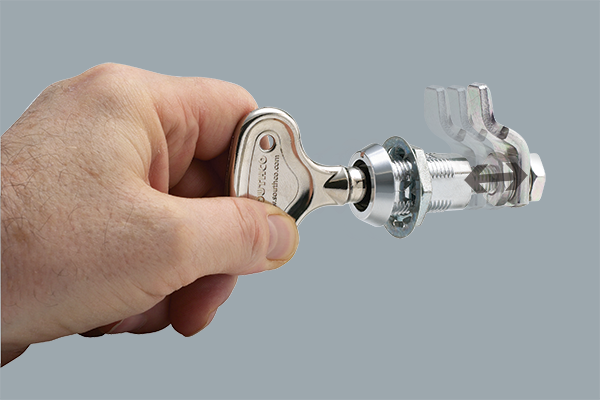

Illustrative image related to cam latch mechanism

How Do Cam Latch Mechanisms Benefit Telecommunications Control Panels?

Telecommunications companies utilize cam latch mechanisms in control panels and cabinets to safeguard sensitive equipment from unauthorized access. These latches ensure that the equipment remains operational while providing a layer of security that is essential for maintaining service reliability. Buyers in this sector should prioritize size compatibility, the type of locking mechanism, and the environmental resistance of the latches to ensure optimal performance in various settings.

Why are Cam Latch Mechanisms Important for Office Furniture?

In the realm of office furniture, cam latch mechanisms are frequently used in cabinets and desks to secure personal belongings and confidential documents. This added security fosters user trust and enhances workplace organization. For B2B buyers, it is important to consider design compatibility with existing furniture, ease of installation, and the availability of various finish options to match the office decor.

How Do Cam Latch Mechanisms Secure Logistics and Shipping Containers?

In logistics and shipping, cam latch mechanisms are critical for securing containers and enclosures during transit. These latches help minimize cargo damage and loss, which is vital for maintaining supply chain efficiency. Buyers must focus on sourcing cam latches that offer strength and weather resistance, as well as ease of use in high-volume operations, especially in international markets where shipping conditions can vary greatly.

3 Common User Pain Points for ‘cam latch mechanism’ & Their Solutions

Scenario 1: Difficulty in Securing Access Panels in Harsh Environments

The Problem: For many B2B buyers, especially in sectors like construction, manufacturing, and logistics, ensuring the security of access panels or cabinets in harsh environments can be a significant challenge. Dust, moisture, and extreme temperatures can compromise traditional locking mechanisms, leading to potential security breaches or operational disruptions. Buyers often find that standard cam latches do not withstand these conditions, causing frequent replacements or repairs that impact their bottom line and project timelines.

The Solution: To address these challenges, it is essential to source cam latches that are specifically designed for rugged environments. Buyers should look for cam latches made from corrosion-resistant materials such as stainless steel or zinc-plated steel, which offer enhanced durability and resistance to environmental factors. Additionally, selecting models with seals or gaskets can help prevent dust and moisture from entering enclosures. When specifying these latches, consider the operational environment and the level of security required. Engaging with suppliers who understand these nuances can lead to customized solutions tailored to specific needs, ensuring longevity and reliability.

Scenario 2: Complexity in Installation and Compatibility Issues

The Problem: Many businesses face issues with the installation of cam latches, particularly when retrofitting them into existing equipment or cabinetry. Compatibility with different materials and sizes can lead to frustration, wasted time, and increased labor costs. Buyers often discover that not all cam latches are designed for universal application, leading to mismatches that can halt progress on projects.

The Solution: To streamline the installation process, buyers should conduct thorough compatibility assessments before purchasing cam latches. This involves measuring existing latch sizes and understanding the material of the cabinets or enclosures where the latches will be installed. Collaborating with manufacturers or suppliers who offer installation guides or technical support can significantly reduce installation challenges. Additionally, opting for cam latches that come with adjustable mounting options can provide more flexibility, allowing for a smoother integration into various applications.

Scenario 3: Security Concerns with Non-Keyed Cam Latches

The Problem: In settings where sensitive information or valuable assets are stored, security is paramount. Many B2B buyers express concern about using non-keyed cam latches, as these can be easily manipulated or accessed by unauthorized individuals. This is particularly true in environments such as schools, offices, or shared facilities where multiple users may have access to the same equipment.

The Solution: To enhance security, buyers should consider upgrading to keyed cam latches or electronic locking mechanisms. Keyed latches provide a physical barrier that requires a key for operation, significantly reducing the risk of unauthorized access. For added convenience, electronic cam locks can be integrated, allowing for controlled access through keypads or card readers. When selecting these locking mechanisms, ensure that they meet security standards relevant to your industry. Partnering with a reputable supplier who offers a range of security options can also facilitate the selection of the best fit for your specific operational needs, ultimately enhancing the overall security of your assets.

Strategic Material Selection Guide for cam latch mechanism

What Are the Key Properties of Common Materials Used in Cam Latch Mechanisms?

When selecting materials for cam latch mechanisms, it is crucial to consider their properties, performance characteristics, and suitability for specific applications. Here, we analyze four common materials: stainless steel, carbon steel, aluminum, and zinc alloy.

What Are the Key Properties of Stainless Steel for Cam Latch Mechanisms?

Stainless steel is renowned for its excellent corrosion resistance, high strength, and durability. It typically performs well in a range of temperatures and can withstand moderate pressure, making it suitable for various environments. The most common grades used in cam latches include 304 and 316, with 316 offering superior resistance to chlorides and marine environments.

Pros: Stainless steel cam latches are highly durable, resistant to rust, and require minimal maintenance. Their aesthetic appeal is also a plus for applications where appearance matters, such as in high-end furniture.

Cons: The primary drawback is the cost, as stainless steel is generally more expensive than other materials. Additionally, manufacturing processes can be more complex due to the material’s hardness.

Impact on Application: Stainless steel is ideal for applications exposed to moisture, chemicals, or marine conditions, ensuring a long lifespan and reliable operation.

Considerations for International Buyers: Buyers from regions like Europe and the Middle East should ensure compliance with relevant standards such as ASTM A240 for corrosion resistance. In Africa and South America, local sourcing of stainless steel can mitigate costs.

How Does Carbon Steel Compare for Cam Latch Mechanisms?

Carbon steel is another common choice for cam latch mechanisms, offering high strength and versatility. It is generally less expensive than stainless steel but lacks the same level of corrosion resistance unless treated.

Pros: Carbon steel cam latches are durable and can be manufactured at a lower cost, making them suitable for budget-sensitive projects. They can also be heat-treated to enhance strength.

Cons: The major limitation is their susceptibility to rust and corrosion, particularly in humid or wet environments. Protective coatings may be necessary, which can add to manufacturing complexity.

Impact on Application: Carbon steel is best suited for indoor applications or environments where exposure to moisture is limited.

Considerations for International Buyers: Buyers should consider local regulations regarding carbon steel coatings and treatments to ensure durability. Standards like ASTM A36 are relevant for structural applications.

What Advantages Does Aluminum Offer for Cam Latch Mechanisms?

Aluminum is a lightweight, corrosion-resistant material that is often used in cam latches for applications requiring low weight and high strength-to-weight ratios. It performs well under varying temperatures and is easy to machine.

Pros: The primary advantage of aluminum is its lightweight nature, which is beneficial for portable applications. It also resists corrosion naturally, reducing the need for additional coatings.

Cons: However, aluminum may not be as strong as stainless or carbon steel, making it less suitable for heavy-duty applications. Additionally, it can be more expensive than carbon steel.

Impact on Application: Aluminum cam latches are ideal for applications in the automotive and aerospace industries, where weight reduction is critical.

Considerations for International Buyers: Buyers in regions like South America and Africa should check local availability and pricing of aluminum, as it may vary significantly. Compliance with standards such as ASTM B221 for aluminum alloys is also essential.

What Role Does Zinc Alloy Play in Cam Latch Mechanisms?

Zinc alloy is often used for its excellent castability and corrosion resistance, making it a popular choice for decorative cam latches. It can be easily molded into complex shapes, providing design flexibility.

Pros: Zinc alloy cam latches are cost-effective and offer good corrosion resistance, especially when plated. They are also aesthetically pleasing, making them suitable for consumer-facing applications.

Cons: The main disadvantage is that zinc alloys can be less durable than steel options, particularly under high-stress conditions.

Impact on Application: Zinc alloy is ideal for light-duty applications, such as in furniture or cabinets, where aesthetic appeal is important.

Considerations for International Buyers: Buyers should ensure compliance with local standards for zinc alloy products, such as JIS H 8601 in Japan or EN 12844 in Europe.

Summary Table of Material Selection for Cam Latch Mechanisms

| Material | Typical Use Case for cam latch mechanism | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-end furniture, marine applications | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Carbon Steel | Indoor cabinets, toolboxes | Durable and cost-effective | Susceptible to rust without treatment | Medium |

| Aluminum | Automotive, aerospace applications | Lightweight and corrosion-resistant | Less strong than steel options | Medium |

| Zinc Alloy | Decorative furniture, light-duty cabinets | Cost-effective and aesthetically pleasing | Less durable under high stress | Low |

This strategic material selection guide provides a comprehensive overview of the materials used in cam latch mechanisms, helping international B2B buyers make informed decisions tailored to their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for cam latch mechanism

What Are the Main Stages of Manufacturing Cam Latch Mechanisms?

The manufacturing of cam latch mechanisms is a multi-stage process that combines precision engineering with quality assurance. Understanding these stages is crucial for B2B buyers looking to source reliable locking solutions.

How Is Material Prepared for Cam Latch Manufacturing?

The first step in the manufacturing process is material preparation, which involves selecting high-quality raw materials. Common materials for cam latches include stainless steel, zinc-plated steel, and aluminum, chosen for their durability and resistance to corrosion.

Once the materials are selected, they undergo cutting and shaping into specific dimensions required for the cam and body components. This may involve processes such as laser cutting or CNC machining to achieve the necessary tolerances. Quality checks at this stage often include verifying material specifications and dimensions before moving on to the forming process.

What Techniques Are Used in Forming Cam Latch Components?

Forming is the next critical stage in the manufacturing process. Techniques such as stamping, forging, or casting are employed to shape the components of the cam latch. Stamping is frequently used for producing high volumes of parts with consistent precision, while forging enhances the strength of metal components through deformation under high pressure.

During this stage, manufacturers must ensure that the formed parts meet exact specifications. This is often achieved through in-process inspections, where operators verify dimensions and structural integrity. Non-destructive testing methods, such as ultrasonic testing or dye penetrant inspection, may also be utilized to identify any internal defects in the material.

How Are Cam Latch Components Assembled?

After forming, the next phase is assembly. This involves the precise fitting of the cam and body, along with any additional components such as locks or handles. Automated assembly lines may be employed to improve efficiency and reduce human error.

At this stage, quality control is critical. Manufacturers typically implement in-process quality checks to ensure that all components fit together correctly and function as intended. This may include functional testing to verify that the latch operates smoothly and securely.

What Finishing Processes Are Applied to Cam Latch Mechanisms?

The finishing stage is where the cam latch components receive treatments to enhance their aesthetic and functional properties. Common finishing processes include powder coating, anodizing, and plating. These treatments not only improve the appearance of the latches but also provide additional protection against environmental factors such as moisture and dust.

Quality assurance during this stage often involves visual inspections and adhesion tests to ensure that the finish is uniform and durable. Ensuring that the surface finish meets customer specifications is crucial, particularly for products intended for high-visibility applications.

What Quality Assurance Practices Are Relevant for Cam Latch Manufacturing?

Quality assurance (QA) is integral to the manufacturing of cam latch mechanisms. B2B buyers should be aware of the various international standards and industry-specific certifications that can indicate the reliability of a supplier.

Which International Standards Should B2B Buyers Consider?

ISO 9001 is one of the most recognized quality management standards worldwide. Compliance with ISO 9001 indicates that a manufacturer has established a robust quality management system, ensuring consistent product quality and customer satisfaction.

In addition to ISO standards, certain industries may have specific certifications such as CE marking for products sold in Europe or API standards for components used in the oil and gas sector. These certifications ensure that the products meet regulatory requirements and industry-specific safety standards.

What Are the Key Quality Control Checkpoints in Manufacturing?

Quality control (QC) checkpoints are critical throughout the manufacturing process to ensure that each component meets the required specifications. Common QC checkpoints include:

- Incoming Quality Control (IQC): Verification of raw materials against specifications before they are used in production.

- In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing process to identify and rectify defects.

- Final Quality Control (FQC): Comprehensive testing of the finished product to ensure it meets all design and performance standards.

These checkpoints are vital in maintaining the integrity of the manufacturing process and ensuring that only high-quality cam latches reach the market.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential. Buyers should consider the following methods:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes and quality control measures in place.

- Quality Reports: Requesting detailed quality reports from suppliers can provide insights into their QC practices, including defect rates and corrective actions taken.

- Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s manufacturing and quality processes.

What Nuances Should International B2B Buyers Be Aware Of?

When sourcing cam latch mechanisms from manufacturers in different regions, B2B buyers should be aware of various nuances. For instance, different countries may have varying regulations regarding product safety and environmental impact. Buyers should ensure that their suppliers comply with local laws and international standards.

Additionally, language barriers and cultural differences may impact communication regarding quality expectations. Establishing clear channels of communication and setting precise specifications can help mitigate these challenges.

Conclusion

In summary, the manufacturing processes and quality assurance practices for cam latch mechanisms are vital for ensuring the reliability and durability of these products. By understanding the main stages of manufacturing, relevant international standards, and effective verification methods, B2B buyers can make informed decisions when sourcing cam latches. This knowledge is particularly crucial for buyers operating in diverse markets such as Africa, South America, the Middle East, and Europe, where quality expectations and regulatory requirements can vary significantly.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘cam latch mechanism’

When sourcing cam latch mechanisms, it is essential to follow a structured approach to ensure that you find the right products for your specific needs. This checklist provides a step-by-step guide for B2B buyers, particularly those operating in diverse markets such as Africa, South America, the Middle East, and Europe.

Step 1: Define Your Technical Specifications

Before initiating your procurement process, clearly outline the technical requirements for the cam latches you need. Consider factors such as size, material (e.g., stainless steel, zinc-plated), locking mechanism (keyed vs. non-keyed), and environmental conditions (resistance to dust and water). A precise specification will help you communicate your needs effectively to suppliers and ensure compatibility with your intended applications.

Step 2: Research Market Trends and Applications

Understanding current market trends and common applications for cam latches is vital. Investigate how similar businesses in your industry utilize these mechanisms, which can guide your choices and help you identify innovative solutions. Additionally, being aware of industry standards and regulations can prevent compliance issues down the line.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Look for suppliers with a solid reputation for quality and reliability, as well as those who offer customization options to meet your specific needs.

Illustrative image related to cam latch mechanism

- Key Considerations:

- Verify their production capabilities and quality control processes.

- Assess their customer service and support options.

Step 4: Request Samples for Testing

Obtaining samples of the cam latches you are considering is an essential step in the sourcing process. Testing samples allows you to evaluate their functionality, durability, and ease of installation. This hands-on experience can help you determine whether the latch meets your expectations and specifications.

Step 5: Verify Certifications and Compliance

Ensure that potential suppliers hold relevant certifications and comply with industry standards. This includes quality management systems like ISO 9001, as well as any specific certifications required in your region or industry. Compliance not only enhances product quality but also mitigates legal and operational risks.

Step 6: Compare Pricing and Terms

Once you have shortlisted suppliers, compare their pricing structures and payment terms. Be cautious of prices that seem too low, as they may indicate inferior quality. Look for suppliers who offer transparent pricing, bulk discounts, and favorable payment options that align with your budget and financial strategy.

Step 7: Establish a Long-term Relationship

Finally, consider the potential for a long-term partnership with your chosen supplier. A reliable supplier can provide ongoing support, timely deliveries, and access to new products as your needs evolve. Building a strong relationship can also lead to better pricing and priority service in the future.

By following this checklist, B2B buyers can make informed decisions when sourcing cam latch mechanisms, ensuring that they select the most suitable products for their operations.

Comprehensive Cost and Pricing Analysis for cam latch mechanism Sourcing

Analyzing the cost structure and pricing dynamics for cam latch mechanisms is essential for international B2B buyers seeking to optimize their sourcing strategies. Understanding the components that contribute to the overall cost and the factors influencing pricing can lead to better decision-making and improved procurement efficiency.

What Are the Key Cost Components in Cam Latch Manufacturing?

The cost of cam latch mechanisms can be broken down into several key components:

-

Materials: The choice of materials significantly influences the price of cam latches. Common materials include stainless steel, carbon steel, aluminum, and zinc-plated finishes. Higher-grade materials, which offer better corrosion resistance and durability, typically incur higher costs.

-

Labor: Labor costs vary based on the manufacturing location. Countries with lower labor costs may offer more competitive pricing, but this can be offset by quality considerations. Skilled labor is essential for producing high-quality cam latches, particularly those with intricate designs or custom features.

-

Manufacturing Overhead: This includes costs associated with utilities, equipment maintenance, and factory space. Efficient manufacturing processes can help reduce overhead, which in turn can lower the overall cost of the cam latches.

-

Tooling: Initial tooling costs can be significant, especially for custom designs. These costs are amortized over the production volume; thus, larger orders can reduce the per-unit tooling cost.

-

Quality Control (QC): Implementing stringent QC measures is crucial for ensuring product reliability and performance. While this adds to the cost, it can prevent costly returns and enhance customer satisfaction.

-

Logistics: Shipping costs, including freight, customs duties, and insurance, can vary widely based on the origin and destination. Incoterms (International Commercial Terms) play a critical role in defining responsibilities and costs associated with logistics.

-

Margin: Suppliers will typically include a profit margin in their pricing. Understanding the market landscape and competitive pricing can aid buyers in negotiating better margins.

What Influences Pricing for Cam Latch Mechanisms?

Several factors can influence the pricing of cam latches:

-

Volume/MOQ (Minimum Order Quantity): Bulk purchases often lead to lower per-unit costs. Suppliers may offer discounts for larger orders, making it advantageous for businesses to consolidate their purchasing.

-

Specifications and Customization: Custom designs or specific requirements can significantly increase costs. Buyers should clearly define their needs to avoid unexpected expenses.

-

Quality and Certifications: Products that meet industry standards or have certifications (e.g., ISO, CE) generally command higher prices due to the assurance of quality and compliance.

-

Supplier Factors: The reputation and reliability of the supplier can affect pricing. Established suppliers with a track record of quality may charge more but offer greater reliability.

-

Incoterms: The chosen Incoterm can affect the overall cost by defining who is responsible for shipping, insurance, and duties. Buyers should be aware of these implications when negotiating contracts.

How Can Buyers Effectively Negotiate and Manage Costs?

To enhance cost-efficiency in sourcing cam latches, consider the following tips:

-

Negotiate with Multiple Suppliers: Engage with several suppliers to compare prices and terms. This competitive approach can yield better deals and terms.

-

Evaluate Total Cost of Ownership (TCO): Look beyond the initial purchase price. Consider the long-term costs associated with maintenance, durability, and replacement to make informed purchasing decisions.

-

Understand Pricing Nuances in International Markets: Different regions may have distinct pricing structures due to labor costs, tariffs, and market demand. For example, sourcing from countries with lower production costs may be appealing, but factor in logistics and potential quality issues.

-

Leverage Relationships: Building strong relationships with suppliers can lead to better pricing, priority service, and flexibility in negotiations.

Conclusion

While the cost structure of cam latch mechanisms can be complex, understanding the components and pricing influencers is essential for making informed purchasing decisions. By strategically negotiating and evaluating total costs, international B2B buyers can optimize their sourcing processes and achieve significant savings. Always remember that prices can fluctuate based on market conditions, so staying informed is key.

Alternatives Analysis: Comparing cam latch mechanism With Other Solutions

Understanding Alternatives to Cam Latch Mechanisms

In the realm of securing cabinets, drawers, and various enclosures, cam latch mechanisms offer a reliable solution. However, B2B buyers often seek alternatives that may better suit their specific applications or budget constraints. This section evaluates cam latches against two alternative locking mechanisms: Compression Latches and Electronic Locks. By examining various aspects such as performance, cost, ease of implementation, maintenance, and best use cases, buyers can make informed decisions tailored to their operational needs.

| Comparison Aspect | Cam Latch Mechanism | Compression Latch | Electronic Lock |

|---|---|---|---|

| Performance | Reliable, quick access; operates with a simple turn | Provides a tight seal; ideal for high vibration environments | High security; can be integrated with access control systems |

| Cost | Generally low-cost | Moderate price range | Higher initial investment due to technology |

| Ease of Implementation | Simple installation; minimal tools required | Requires precise mounting; slightly more complex | Installation can be complex; may require professional setup |

| Maintenance | Low maintenance; durable materials | Low maintenance; however, may require adjustment over time | Moderate; battery changes and software updates needed |

| Best Use Case | Cabinets, lockers, toolboxes | Automotive, machinery access, outdoor cabinets | High-security areas, electronic access points |

What Are the Pros and Cons of Compression Latches?

Compression latches are designed to secure doors and panels by applying pressure, creating a tight seal. Their primary advantage is their ability to withstand vibration and shock, making them ideal for applications in automotive and machinery settings. However, they can be more complex to install than cam latches, requiring precise alignment during mounting. Compression latches also tend to be more expensive than traditional cam latches, making them a less attractive option for budget-conscious buyers.

What Are the Advantages and Disadvantages of Electronic Locks?

Electronic locks represent a significant leap in security technology, offering features like remote access and integration with security systems. Their main benefit is enhanced security, as they can utilize complex access codes and biometric authentication. However, the initial investment is higher, and installation may require specialized knowledge, which can add to the overall cost. Maintenance can also be a concern, as electronic locks may need battery replacements and software updates, which can be inconvenient for some businesses.

How Can B2B Buyers Choose the Right Solution?

When selecting the appropriate locking mechanism, B2B buyers should consider their specific operational needs, budget constraints, and security requirements. If ease of use and low cost are paramount, cam latch mechanisms may be the best choice. Conversely, for applications requiring a robust seal and vibration resistance, compression latches could be more suitable. For high-security environments where electronic access control is necessary, investing in electronic locks may provide the best long-term value. By evaluating these factors, businesses can select a solution that not only meets their immediate needs but also aligns with their strategic goals.

Essential Technical Properties and Trade Terminology for cam latch mechanism

What Are the Key Technical Properties of Cam Latch Mechanisms?

When selecting a cam latch mechanism for your business needs, understanding critical technical properties is essential. Here are some key specifications to consider:

Material Grade: Why Is It Important for Durability?

The material grade of a cam latch significantly influences its performance and lifespan. Common materials include stainless steel, carbon steel, and aluminum. Stainless steel is preferred for its corrosion resistance, making it ideal for outdoor or high-humidity environments. Carbon steel offers strength but may require additional coating for protection. Choosing the right material ensures that the latch can withstand the operational environment and maintains its integrity over time.

Tolerance: How Does It Affect Fit and Functionality?

Tolerance refers to the permissible limit of variation in a physical dimension. For cam latches, maintaining tight tolerances is crucial for ensuring a proper fit within enclosures. A latch that does not meet tolerance specifications may lead to misalignment, resulting in operational failure or security breaches. Precision in manufacturing is key to achieving consistent performance across various applications.

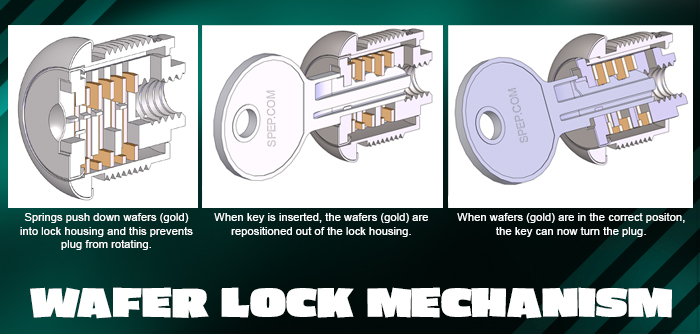

Locking Mechanism Type: What Are Your Security Needs?

Cam latches can feature different locking mechanisms, such as keyed, non-keyed, or electronic options. Keyed latches offer enhanced security for sensitive applications, while non-keyed versions are simpler and may suffice for less critical uses. Understanding the type of locking mechanism that best suits your needs is vital for ensuring the security and accessibility of your enclosures.

Actuation Angle: Why Does It Matter?

The actuation angle of a cam latch typically ranges from 90 to 180 degrees. This specification determines how far the latch must be turned to engage or disengage the locking mechanism. A greater actuation angle may provide a more secure closure, while a smaller angle can facilitate quicker access. Evaluating the actuation angle will help you choose a latch that meets both security and usability requirements.

Load Rating: How Much Force Can It Withstand?

Load rating specifies the amount of force that a cam latch can handle without failure. This is particularly important in heavy-duty applications, such as toolboxes or industrial enclosures. A latch with a higher load rating ensures that it can maintain security and functionality under stress, reducing the risk of malfunction.

What Are Common Trade Terms Related to Cam Latch Mechanisms?

Familiarity with industry jargon is essential for effective communication and negotiation in B2B transactions involving cam latch mechanisms. Here are some common terms:

What Is OEM (Original Equipment Manufacturer)?

An OEM is a company that manufactures products or components that are sold under another company’s brand name. In the context of cam latches, an OEM may produce latches that meet specific design and quality standards for various applications. Understanding OEM relationships can be critical for sourcing high-quality products that align with your business needs.

Illustrative image related to cam latch mechanism

What Does MOQ (Minimum Order Quantity) Mean?

MOQ refers to the minimum number of units that a supplier is willing to sell in a single order. Knowing the MOQ is essential for budgeting and inventory management. It can also impact your supply chain decisions, especially if you are a smaller business or starting a new project.

What Is an RFQ (Request for Quotation)?

An RFQ is a document sent to suppliers to request pricing information on specific products or services. In the context of cam latches, submitting an RFQ allows you to compare options from various manufacturers, ensuring that you get the best deal for your specifications and requirements.

What Are Incoterms (International Commercial Terms)?

Incoterms are internationally recognized trade terms that define the responsibilities of buyers and sellers in international transactions. They clarify who is responsible for shipping, insurance, and tariffs, minimizing misunderstandings and disputes. Familiarity with Incoterms is crucial for businesses engaged in cross-border procurement of cam latch mechanisms.

What Does Lead Time Refer To?

Lead time is the duration between placing an order and receiving the products. This term is particularly important when sourcing cam latches, as longer lead times can affect project timelines. Understanding lead times helps businesses plan their inventory and production schedules effectively.

Illustrative image related to cam latch mechanism

By grasping these technical properties and industry terms, B2B buyers can make informed decisions that enhance their procurement processes and ensure the successful integration of cam latch mechanisms into their operations.

Navigating Market Dynamics and Sourcing Trends in the cam latch mechanism Sector

What Are the Key Drivers Influencing the Cam Latch Mechanism Market?

The cam latch mechanism sector is experiencing significant growth driven by various global factors. The increasing demand for security solutions across multiple industries, including furniture, automotive, and electronic enclosures, is a primary driver. As urbanization rises in regions like Africa and South America, there is a growing need for reliable locking systems in residential and commercial properties. Additionally, the trend toward modular construction and smart homes is pushing manufacturers to innovate and integrate advanced cam latch technologies.

Emerging technologies, such as IoT-enabled locking mechanisms, are reshaping the cam latch landscape, with buyers increasingly seeking products that offer enhanced security features and convenience. For international B2B buyers, particularly from regions like the Middle East and Europe, sourcing suppliers that can provide customized solutions that meet local regulations and standards is crucial. Buyers are also focusing on suppliers that can demonstrate flexibility in design and production, catering to diverse applications from industrial cabinets to personal lockers.

Moreover, the competitive landscape is marked by an increasing emphasis on value-added services, such as quick turnaround times and comprehensive customer support. Suppliers that leverage digital platforms for marketing and sales are gaining a competitive edge, allowing buyers to make informed decisions based on product specifications, user reviews, and comparative analyses.

How Important Is Sustainability and Ethical Sourcing in the Cam Latch Mechanism Sector?

In today’s market, sustainability and ethical sourcing are paramount considerations for B2B buyers. Environmental impact is a critical concern, and manufacturers are under pressure to reduce their carbon footprints. This has led to a shift towards using sustainable materials in the production of cam latches, such as recycled metals and eco-friendly coatings. Buyers are increasingly favoring suppliers who can provide transparency in their sourcing practices and demonstrate compliance with environmental regulations.

Ethical supply chains are becoming a non-negotiable aspect for many businesses, particularly those operating in regions with stringent labor laws and sustainability mandates. Certifications like ISO 14001 for environmental management and other ‘green’ certifications are increasingly sought after, as they assure buyers of a supplier’s commitment to sustainable practices. This trend not only enhances brand reputation but also meets the growing demand from consumers for responsible sourcing.

By prioritizing sustainability, B2B buyers can reduce risks associated with supply chain disruptions and enhance their market competitiveness. As a result, sourcing cam latch mechanisms from suppliers committed to ethical and sustainable practices is not just a trend but a strategic necessity for businesses looking to align with global sustainability goals.

Illustrative image related to cam latch mechanism

What Is the Historical Context of Cam Latch Mechanisms in B2B Applications?

The cam latch mechanism has a rich history that dates back to the late 19th century when it was initially developed for simple locking applications. Over the decades, advancements in materials and design have transformed cam latches into versatile components used across various industries. Early applications were primarily in furniture and storage solutions, but as technology progressed, cam latches found their way into more complex systems, including automotive and industrial machinery.

The evolution of cam latches has been closely linked to the broader trends in security and convenience. With the rise of electronic and smart technologies, modern cam latches are being designed to integrate seamlessly with digital access systems, catering to the evolving needs of consumers and businesses alike. This historical context emphasizes the adaptability of cam latch mechanisms, making them a staple in modern B2B applications.

In summary, understanding these market dynamics, sustainability considerations, and the historical evolution of cam latch mechanisms can empower international B2B buyers to make informed sourcing decisions that align with their operational needs and ethical standards.

Frequently Asked Questions (FAQs) for B2B Buyers of cam latch mechanism

-

How do I choose the right cam latch mechanism for my application?

When selecting a cam latch mechanism, consider the specific requirements of your application, including security needs, material compatibility, and environmental conditions. For high-security applications, opt for keyed cam latches. If moisture or dust exposure is a concern, choose corrosion-resistant materials like stainless steel or zinc-plated options. Additionally, assess the size and design to ensure it fits seamlessly into your cabinets, lockers, or enclosures. Consult with manufacturers about customization options to meet any unique specifications you may have. -

What is the best material for cam latches in outdoor applications?

For outdoor applications, stainless steel is the best material for cam latches due to its resistance to rust and corrosion. This durability ensures the latch maintains its functionality and appearance over time, even in harsh weather conditions. Alternatively, zinc-plated options can offer a cost-effective solution, but they may require more frequent maintenance. Consider the environmental factors in your region, such as humidity and temperature fluctuations, when making your selection to ensure longevity and reliability. -

What are the common applications for cam latch mechanisms?

Cam latches are widely used in various applications, including cabinets, lockers, toolboxes, and access panels. They are particularly beneficial in environments requiring secure closure without compromising aesthetics, such as in furniture design and electronic enclosures. Additionally, they are found in industrial settings, securing machine access panels and equipment cabinets. Understanding the specific use case will help you choose the right type of cam latch for optimal performance and security. -

What customization options are available for cam latch mechanisms?

Many manufacturers offer customization options for cam latch mechanisms, including variations in size, material, finish, and locking mechanisms. You can request specific dimensions or materials to ensure compatibility with your design. Some suppliers also provide options for branding, allowing you to add your logo or specific color finishes to the latches. Engage directly with suppliers to discuss your unique requirements and explore their capabilities for tailored solutions. -

What are the minimum order quantities (MOQs) for cam latch mechanisms?

Minimum order quantities (MOQs) for cam latch mechanisms can vary significantly between suppliers and depend on factors such as the complexity of customization and the materials used. Typically, MOQs can range from as few as 100 units to several thousand. To get the best pricing and terms, it’s advisable to negotiate with suppliers and consider consolidating orders with other components if you require a lower quantity. Always clarify MOQs upfront to avoid any misunderstandings during the procurement process. -

What payment terms should I expect when sourcing cam latches internationally?

Payment terms can vary among suppliers, but common practices include net 30, net 60, or payment in advance for international orders. Some suppliers may require a deposit upfront, with the balance due upon shipment. It’s essential to discuss payment methods, such as wire transfers or letters of credit, to ensure secure transactions. Establishing clear payment terms in advance will help prevent delays and foster a smoother purchasing experience. -

How can I ensure quality assurance when sourcing cam latch mechanisms?

To ensure quality assurance, request certifications and compliance documentation from your suppliers, such as ISO certifications or material safety data sheets. Conduct factory audits or quality inspections before shipment to verify that the products meet your specifications. Additionally, consider ordering samples before placing a larger order to assess the fit and finish. Building a strong relationship with your supplier can also enhance communication about quality expectations and issues. -

What logistics considerations should I keep in mind when importing cam latch mechanisms?

When importing cam latch mechanisms, consider logistics factors such as shipping methods, lead times, and customs regulations. Choose reliable shipping options that balance cost and delivery speed. Ensure that all necessary documentation, including invoices and packing lists, is in order to facilitate smooth customs clearance. Additionally, stay informed about import duties and taxes specific to your region to avoid unexpected costs. Collaborating with a logistics partner can streamline the process and help navigate international shipping complexities.

Top 3 Cam Latch Mechanism Manufacturers & Suppliers List

1. McMaster – Cam Locks & Latches

Domain: mcmaster.com

Registered: 1994 (31 years)

Introduction: This company, McMaster – Cam Locks & Latches, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Reid Supply – Cam Latch Locks

Domain: reidsupply.com

Registered: 2004 (21 years)

Introduction: Cam latch locks are cylindrical locking mechanisms used to secure access points and panels in cabinets, lockers, desks, filing cabinets, and drawers. They consist of a latch and a body that rotates to release or secure. Key features include:

– Easy installation

– Resistance to dust and water

– Variety of styles and designs

– Operated by pin, key, or manual turn

– Available materials: zinc-pla…

3. JW Winco – Cam Latches GN 1150

Domain: jwwinco.com

Registered: 1997 (28 years)

Introduction: Cam Latches GN 1150 are designed for use in hygiene areas and meet strict hygiene requirements. They are made of stainless steel AISI 316L, with a latch arm made of stainless steel AISI 316. The latches feature a high surface quality (Ra < 0.8 µm) and dead-space-free mounting to prevent dirt accumulation and facilitate cleaning. The locking mechanism is protected by multiple seals, and the latches…

Strategic Sourcing Conclusion and Outlook for cam latch mechanism

In today’s competitive landscape, strategic sourcing of cam latch mechanisms presents a significant opportunity for international B2B buyers. By understanding the diverse applications and benefits of cam latches—ranging from security and ease of use to resistance against environmental elements—buyers can make informed decisions that enhance their product offerings. With options available in various materials and designs, sourcing the right cam latch can not only meet specific security needs but also ensure compatibility with existing systems.

Fostering relationships with reliable suppliers is crucial in securing high-quality products that align with your business goals. As markets in Africa, South America, the Middle East, and Europe continue to evolve, leveraging strategic sourcing will enable companies to stay ahead of industry trends and demand shifts.

As we look to the future, the demand for innovative and efficient locking solutions is set to rise. Now is the time for buyers to explore the potential of cam latch mechanisms to enhance product security and operational efficiency. Engage with trusted suppliers and consider the long-term benefits of integrating cam latches into your product lines to better serve your customers and expand your market reach.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.