How to Source Calibrated Leak Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for calibrated leak

In today’s competitive landscape, sourcing calibrated leaks poses a significant challenge for international B2B buyers. These precision instruments are critical for ensuring the integrity and performance of various systems across industries, from automotive to aerospace. However, the complexities involved in selecting the right type, understanding their applications, and navigating supplier reliability can be daunting. This comprehensive guide aims to simplify the process, covering essential aspects such as the different types of calibrated leaks, their applications, effective supplier vetting strategies, and cost considerations.

By providing in-depth insights into the calibrated leak market, this guide empowers buyers from Africa, South America, the Middle East, and Europe—including key markets like Vietnam and Nigeria—to make informed purchasing decisions. We delve into the specifications and features that define high-quality calibrated leaks, ensuring that you can identify products that meet your operational requirements. Additionally, the guide offers practical tips for assessing suppliers, emphasizing the importance of certifications and customer support in maintaining optimal equipment performance.

Whether you are a seasoned professional or new to the realm of leak detection technology, this guide is designed to equip you with the knowledge needed to navigate the global market confidently. By leveraging the insights provided, you can enhance your procurement strategy, ultimately driving efficiency and reliability in your operations.

Understanding calibrated leak Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Calibrated Helium Leaks | High sensitivity, suitable for small leak detection | Aerospace, automotive, vacuum systems | Pros: High accuracy, versatile. Cons: Costly, requires specialized handling. |

| Capillary Leaks | Stable leak rates, low temperature coefficient | Electronics, medical device testing | Pros: Durable, easy integration. Cons: Limited to specific applications. |

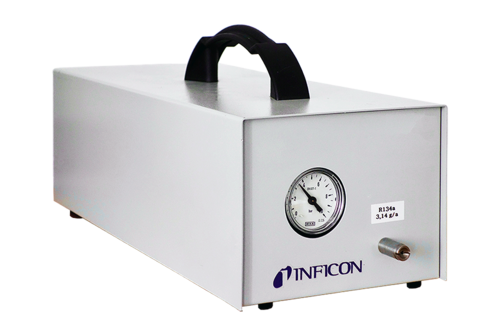

| Permeation Leaks | Eliminates clogging, suitable for various gases | Food packaging, pharmaceuticals | Pros: Long-lasting, minimal maintenance. Cons: May require specific gas types. |

| Fixed Sniffer Leaks | Consistent flow rates, easy probe positioning | Leak detection in industrial settings | Pros: Reliable results, adaptable. Cons: May need calibration for accuracy. |

| General Purpose Calibrated Leaks | Versatile leak rates, suitable for multiple applications | Research and development, manufacturing | Pros: Flexible, wide range of uses. Cons: May lack precision in niche applications. |

What Are Calibrated Helium Leaks and Their Applications?

Calibrated helium leaks are renowned for their high sensitivity, making them ideal for detecting minute leaks in critical applications such as aerospace and automotive industries. Their ability to function effectively in vacuum systems also positions them as a preferred choice for manufacturers needing precise leak detection. However, the cost associated with these leaks can be a barrier for some businesses, necessitating careful consideration of their specific testing needs.

How Do Capillary Leaks Function in Various Industries?

Capillary leaks are characterized by their stable leak rates and low temperature coefficients, making them suitable for testing in electronics and medical devices. Their robust stainless-steel construction ensures durability and reliability in harsh environments. While they can be easily integrated into production processes, buyers should note that their application may be limited to specific industry requirements, which could affect their versatility.

What Makes Permeation Leaks Unique for B2B Buyers?

Permeation leaks are designed to prevent clogging, thus ensuring consistent performance over time. They are particularly valuable in industries like food packaging and pharmaceuticals, where maintaining purity and quality is essential. The long-lasting nature of these leaks means less frequent replacements, although buyers must ensure compatibility with the gases they intend to use, which can limit options in certain scenarios.

Why Choose Fixed Sniffer Leaks for Industrial Applications?

Fixed sniffer leaks provide consistent flow rates and straightforward probe positioning, making them an excellent option for industrial leak detection. Their reliability in producing repeatable results is crucial in maintaining quality control in manufacturing environments. However, while they are adaptable, buyers should be aware that regular calibration may be necessary to maintain accuracy, which can introduce additional operational considerations.

How Do General Purpose Calibrated Leaks Benefit Diverse Industries?

General purpose calibrated leaks offer flexibility with a wide range of leak rates, making them suitable for various applications, from research and development to manufacturing. Their versatility allows businesses to use them across different testing scenarios, enhancing operational efficiency. However, buyers should consider that while they are adaptable, they may not provide the precision required for specialized applications, which could be a drawback in highly regulated environments.

Key Industrial Applications of calibrated leak

| Industry/Sector | Specific Application of calibrated leak | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Testing fuel systems for leaks | Ensures safety and compliance with strict regulatory standards | Require calibrated leaks that can simulate specific leak rates and gases. |

| Pharmaceuticals | Calibration of leak detection systems in sterile environments | Protects product integrity and compliance with health regulations | Look for certified calibrated leaks that meet ISO standards for accuracy. |

| Automotive | Leak testing in fuel and air conditioning systems | Enhances efficiency and reduces warranty claims | Seek suppliers with a range of leak rates suitable for various automotive applications. |

| Oil & Gas | Monitoring pipelines for gas leaks | Prevents environmental hazards and financial losses | Focus on durability and resistance to corrosion in calibrated leaks. |

| Electronics Manufacturing | Testing for leaks in vacuum-sealed packaging | Ensures product reliability and longevity | Choose calibrated leaks that can handle a variety of gases and pressures. |

How Are Calibrated Leaks Used in the Aerospace Industry?

In the aerospace sector, calibrated leaks are crucial for testing fuel systems to ensure they are leak-free. This is vital for safety and compliance with stringent regulations governing aviation. By utilizing calibrated leaks, manufacturers can accurately simulate leak rates, allowing them to validate the integrity of their systems. International buyers should ensure that the calibrated leaks they source can replicate the specific conditions their systems will encounter, including the required gas types and pressures.

What Role Do Calibrated Leaks Play in Pharmaceuticals?

In pharmaceuticals, calibrated leaks are employed to calibrate leak detection systems used in sterile environments. This is essential for maintaining product integrity and compliance with health regulations. Calibrated leaks help to verify that packaging is airtight, preventing contamination and ensuring that products remain safe for consumption. Buyers in this industry should prioritize suppliers who provide ISO-certified calibrated leaks, ensuring that they meet the necessary accuracy and reliability standards.

Illustrative image related to calibrated leak

How Are Calibrated Leaks Applied in the Automotive Sector?

The automotive industry utilizes calibrated leaks for testing fuel and air conditioning systems. This application is critical for enhancing vehicle efficiency and minimizing warranty claims due to leaks. By simulating specific leak rates, manufacturers can assess the performance of their components under various conditions. Buyers should look for suppliers who offer a diverse range of calibrated leaks, capable of addressing different automotive applications and leak rate specifications.

Why Are Calibrated Leaks Important in Oil & Gas?

In the oil and gas sector, calibrated leaks are essential for monitoring pipelines for potential gas leaks. This application is critical in preventing environmental hazards and financial losses associated with leaks. Calibrated leaks allow companies to conduct regular maintenance checks and ensure the integrity of their infrastructure. International buyers must consider the durability and corrosion resistance of calibrated leaks, especially when sourcing for harsh environments.

How Do Calibrated Leaks Benefit Electronics Manufacturing?

In electronics manufacturing, calibrated leaks are used for testing leaks in vacuum-sealed packaging, which is crucial for ensuring product reliability and longevity. This application helps manufacturers confirm that their products are protected from moisture and contaminants that could compromise functionality. Buyers should select calibrated leaks that can accommodate a variety of gases and pressure requirements, ensuring they meet the unique challenges posed by electronics packaging.

3 Common User Pain Points for ‘calibrated leak’ & Their Solutions

Scenario 1: Difficulty in Achieving Accurate Calibration for Leak Testing

The Problem:

B2B buyers often face challenges in ensuring the accuracy of their leak detection systems, particularly when the calibration of these systems is not consistent or reliable. This can lead to false positives or negatives during testing, resulting in costly downtime or production delays. For instance, a manufacturing facility in Nigeria might find that their helium leak detectors are not calibrated correctly, which could compromise the integrity of their products and lead to significant financial losses.

The Solution:

To overcome this issue, it’s crucial to invest in high-quality calibrated leaks that are specifically designed for the gas and pressure requirements of your leak detection system. When sourcing calibrated leaks, ensure they are traceable and come with a certification of calibration, ideally in accordance with ISO 9001 standards. Regularly scheduled recalibration of your leaks is essential; consider establishing a service contract with your supplier for ongoing support. Additionally, ensure that your team receives proper training on how to use and maintain these calibrated leaks effectively. This proactive approach will not only enhance the accuracy of your leak detection but will also extend the lifespan of your equipment.

Scenario 2: Uncertainty Over Customization Needs for Specific Applications

The Problem:

Another common pain point for B2B buyers is the lack of clarity regarding the customization needs of calibrated leaks for specific applications. Different industries, from aerospace to pharmaceuticals, have unique requirements concerning leak rates, gases, and environmental conditions. For instance, a company in South America may struggle to find a calibrated leak that meets the stringent standards required for testing medical devices, leading to regulatory compliance issues.

The Solution:

To address this challenge, engage directly with manufacturers that offer customizable calibrated leaks tailored to your specific needs. Provide detailed specifications regarding the required leak rate, gas type, and operational conditions when placing your order. Collaborating closely with your supplier can help ensure that you receive a product that meets your exact requirements. Additionally, leverage the expertise of application engineers who can assist in designing a testing system that incorporates these customized leaks effectively. This collaboration not only ensures compliance but also enhances the overall reliability of your testing processes.

Illustrative image related to calibrated leak

Scenario 3: High Costs Associated with Maintenance and Downtime

The Problem:

B2B buyers often experience high costs related to the maintenance and potential downtime of their leak detection systems. This is particularly true for organizations in the Middle East where maintenance resources may be limited or delayed. The need for frequent repairs or the inability to quickly identify leaks can lead to increased operational costs and loss of productivity.

The Solution:

To mitigate these costs, consider implementing a comprehensive maintenance strategy that includes regular preventative care and the use of high-quality calibrated leaks. Establish a service contract with your supplier, which can provide you with peace of mind through scheduled maintenance and immediate support when issues arise. Additionally, invest in training your staff on proper handling and maintenance of calibrated leaks to reduce the risk of damage. By prioritizing quality and maintenance, you can significantly reduce unexpected downtimes and associated costs, ensuring smoother operations and a healthier bottom line.

Strategic Material Selection Guide for calibrated leak

What Are the Key Materials Used in Calibrated Leaks?

When selecting materials for calibrated leaks, several factors come into play, including performance, durability, and cost. Here, we analyze four common materials used in the production of calibrated leaks: stainless steel, brass, Teflon, and glass. Each material has unique properties that make it suitable for specific applications in leak detection systems.

How Does Stainless Steel Perform in Calibrated Leak Applications?

Stainless steel is a popular choice for calibrated leaks due to its excellent corrosion resistance and durability. It can withstand high temperatures and pressures, making it suitable for a wide range of applications. Stainless steel leaks are often used in environments where exposure to harsh chemicals or extreme conditions is expected.

Pros: The primary advantages of stainless steel include its long lifespan and resistance to corrosion, which ensures consistent performance over time. It also meets various international standards, making it a reliable option for global buyers.

Cons: However, stainless steel can be more expensive than other materials, and its manufacturing process can be complex, potentially leading to higher costs for buyers.

Impact on Application: Stainless steel’s compatibility with various gases, including helium and air, makes it versatile for different leak detection systems.

Considerations for International Buyers: Buyers from regions like Africa and South America should ensure compliance with ISO standards, as many suppliers offer certification that guarantees quality.

What Benefits Does Brass Offer for Calibrated Leaks?

Brass is another material commonly used for calibrated leaks, particularly in applications that do not involve extreme temperatures or corrosive environments. Its good machinability allows for precise manufacturing, making it suitable for creating specific leak rates.

Illustrative image related to calibrated leak

Pros: Brass is generally less expensive than stainless steel, making it a cost-effective option for many businesses. Its ease of manufacture allows for quick production times.

Cons: The primary drawback of brass is its susceptibility to corrosion, especially in moist environments. This can lead to reliability issues over time.

Impact on Application: Brass is often used in lower-pressure applications and can be effective for gases like air and nitrogen.

Considerations for International Buyers: Buyers should be aware of local regulations regarding the use of brass in specific applications, as some regions may have restrictions due to environmental concerns.

Why Choose Teflon for Calibrated Leaks?

Teflon, known for its chemical resistance and low friction properties, is an excellent choice for calibrated leaks that require compatibility with aggressive chemicals. Its non-stick surface prevents clogging, making it suitable for applications where cleanliness is crucial.

Pros: Teflon’s chemical resistance and low maintenance requirements are significant advantages. It is also lightweight, making it easier to handle and install.

Cons: However, Teflon may not withstand high temperatures as effectively as metals, which limits its use in high-temperature applications.

Impact on Application: Teflon is particularly useful in applications involving corrosive gases, ensuring that the integrity of the calibrated leak is maintained.

Considerations for International Buyers: Buyers should verify that Teflon products meet relevant international standards, such as ASTM, to ensure safety and performance.

How Does Glass Compare as a Material for Calibrated Leaks?

Glass is less commonly used for calibrated leaks but can be effective in specific applications where visibility of the leak is essential. Its inert nature makes it suitable for use with various gases without risk of contamination.

Pros: Glass offers excellent chemical resistance and stability, making it ideal for laboratory settings where precision is critical.

Cons: The fragility of glass can be a significant drawback, as it is prone to breakage during handling and installation.

Impact on Application: Glass is typically used in low-pressure applications where visibility of the leak is necessary, such as in research and development environments.

Considerations for International Buyers: Buyers should ensure that glass products are packaged securely to prevent damage during transit, especially in regions with less stable infrastructure.

Illustrative image related to calibrated leak

Summary Table of Material Selection for Calibrated Leaks

| Material | Typical Use Case for calibrated leak | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | High-pressure, corrosive environments | Excellent durability and corrosion resistance | Higher manufacturing complexity and cost | High |

| Brass | Lower-pressure applications | Cost-effective and easy to machine | Susceptible to corrosion | Medium |

| Teflon | Chemical applications | Chemical resistance and low maintenance | Limited high-temperature use | Medium |

| Glass | Laboratory settings | Excellent chemical stability | Fragile and prone to breakage | Medium |

This strategic material selection guide provides B2B buyers with essential insights to make informed decisions when sourcing calibrated leaks. Understanding the properties and implications of each material will facilitate better alignment with specific application requirements and regional compliance standards.

In-depth Look: Manufacturing Processes and Quality Assurance for calibrated leak

What Are the Main Stages of the Manufacturing Process for Calibrated Leaks?

The manufacturing process for calibrated leaks involves several critical stages that ensure precision and reliability. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with the selection of high-quality materials, primarily stainless steel, known for its durability and resistance to corrosion. Suppliers must ensure that the raw materials meet specific chemical and physical property standards. Rigorous inspections and certifications of these materials are conducted to confirm their compliance with industry standards.

-

Forming: After materials are prepared, they undergo forming techniques, which may include machining, welding, or sintering. For instance, capillary leaks might require precise machining to create the desired leak rate. Advanced techniques such as laser welding may also be employed to ensure that joints are robust and leak-proof, which is vital for maintaining the integrity of the leak during operation.

-

Assembly: The assembly stage involves integrating various components, including fittings, seals, and calibration elements. Each component must be installed with precision to ensure that the calibrated leak functions as intended. Assembly often requires specialized tools and equipment to maintain the required tolerances and avoid contamination.

-

Finishing: The final stage of manufacturing includes surface treatments and additional quality checks. Finishing processes may involve polishing, coating, or passivation to enhance the corrosion resistance of the product. This stage is critical as it not only improves the aesthetics of the calibrated leak but also its performance and longevity.

What Quality Assurance Measures Are Commonly Implemented?

Quality assurance is paramount in the production of calibrated leaks to ensure that they meet rigorous international standards.

Illustrative image related to calibrated leak

-

Adherence to International Standards: Many manufacturers adhere to ISO 9001:2015 standards, which provide a framework for consistent quality management systems. Compliance with these standards ensures that processes are documented, monitored, and continually improved. Additionally, industry-specific certifications such as CE and API may be required, depending on the application and regional regulations.

-

Quality Control Checkpoints: Quality control (QC) checkpoints are integrated throughout the manufacturing process. These typically include:

– Incoming Quality Control (IQC): Raw materials are inspected upon receipt to verify compliance with specifications.

– In-Process Quality Control (IPQC): Continuous monitoring during the manufacturing stages ensures that processes remain within defined parameters.

– Final Quality Control (FQC): The finished product undergoes rigorous testing to confirm that it meets the specified leak rate and performance criteria. -

Common Testing Methods: Various testing methods are employed to validate the performance of calibrated leaks. These may include:

– Helium Leak Testing: A standard method for measuring leak rates, where helium is used due to its small atomic size.

– Pressure Decay Testing: This method checks for leaks by monitoring pressure changes over time in a sealed system.

– Mass Spectrometry: This advanced technique can detect minute leaks by analyzing the mass-to-charge ratio of ions.

How Can B2B Buyers Verify Supplier Quality Control Processes?

For international B2B buyers, especially from regions such as Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential for ensuring product reliability.

-

Supplier Audits: Conducting on-site audits allows buyers to evaluate the manufacturing processes, quality management systems, and compliance with international standards. This firsthand assessment helps buyers gauge a supplier’s commitment to quality.

-

Review of Quality Reports: Requesting detailed quality reports can provide insights into the supplier’s QC processes. These reports should include information on testing results, calibration certificates, and compliance with relevant industry standards.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased assessment of a supplier’s manufacturing and QC practices. These inspections can verify compliance with specifications and standards, ensuring that the calibrated leaks meet the required performance criteria.

What Nuances Should International B2B Buyers Consider Regarding Quality Control?

When dealing with international suppliers, B2B buyers must consider several nuances in quality control:

-

Cultural and Regulatory Differences: Different regions may have varying standards and regulations affecting manufacturing practices. Buyers should familiarize themselves with local industry standards and ensure that suppliers meet or exceed these requirements.

-

Documentation and Certification: Buyers should insist on comprehensive documentation, including calibration certificates and compliance statements. This documentation serves as proof of quality and can be essential for regulatory compliance in different markets.

-

Communication and Support: Establishing clear communication channels with suppliers is crucial. Buyers should ensure that they have access to ongoing technical support and that suppliers can provide timely responses to quality-related inquiries.

-

Logistics and Supply Chain Considerations: Quality control extends beyond manufacturing. Buyers should evaluate the entire supply chain, including transportation and storage conditions, which can impact the integrity of calibrated leaks. Ensuring that suppliers adhere to best practices in logistics will safeguard product quality throughout the delivery process.

In summary, understanding the manufacturing processes and quality assurance measures for calibrated leaks is vital for B2B buyers. By focusing on these aspects, buyers can make informed decisions, ensuring they procure reliable products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘calibrated leak’

Introduction

This sourcing guide is designed to assist B2B buyers in procuring calibrated leaks, essential components for various industrial applications. Whether you’re in the manufacturing, aerospace, or medical sectors, understanding the nuances of calibrated leaks and the sourcing process can lead to more informed purchasing decisions and better operational efficiency.

Step 1: Define Your Technical Specifications

Before you begin sourcing calibrated leaks, it’s crucial to establish your technical requirements. This includes specifying the desired leak rate, gas type, and operating pressure. Accurate specifications will help you communicate effectively with suppliers and ensure that the calibrated leak meets your testing needs.

- Leak Rate: Consider the range of leak rates you require, such as from 1 x 10⁻⁴ ml/s to 10 l/min.

- Gas Type: Identify which gases the calibrated leak will be used with, like helium or air.

Step 2: Research Potential Suppliers

Identifying reputable suppliers is key to ensuring quality and reliability. Look for manufacturers with a proven track record in producing calibrated leaks that meet industry standards.

- Certifications: Verify that suppliers are ISO certified and provide NIST-traceable calibration certificates.

- Industry Experience: Focus on suppliers with experience in your specific industry, as they will better understand your unique needs.

Step 3: Evaluate Supplier Capabilities

Once you have a shortlist of suppliers, assess their technical capabilities. This includes their ability to customize products according to your specifications and their after-sales support.

- Customization Options: Ensure the supplier can create calibrated leaks tailored to your specific requirements.

- Support Services: Consider whether they offer training, maintenance, and calibration services to support your purchase.

Step 4: Request and Review Samples

Before making a bulk purchase, request samples of the calibrated leaks. Testing samples allows you to assess quality and performance firsthand.

- Performance Testing: Evaluate how well the sample meets your leak detection thresholds.

- Documentation: Ensure that the sample comes with a certificate of calibration and other necessary documentation.

Step 5: Check for Compliance and Quality Standards

Confirm that the calibrated leaks comply with relevant industry standards and regulations. Compliance ensures that the products are safe and effective for their intended use.

- Regulatory Compliance: Verify adherence to local and international regulations pertinent to your industry.

- Quality Assurance: Look for suppliers who implement rigorous quality control processes in their production.

Step 6: Negotiate Terms and Conditions

Once you have selected a supplier, negotiate terms of purchase, including price, delivery schedules, and warranty conditions. Clear agreements can prevent misunderstandings and ensure a smooth transaction.

- Payment Terms: Discuss payment methods and timelines to align with your financial processes.

- Warranty and Returns: Understand the warranty coverage and the process for returns or exchanges.

Step 7: Establish a Long-Term Relationship

Building a strong relationship with your supplier can lead to better pricing, priority service, and access to new products. Consider establishing a service contract for ongoing support.

- Communication Channels: Maintain open lines of communication for future needs and inquiries.

- Feedback Loop: Provide feedback on product performance to help your supplier improve their offerings.

By following these steps, B2B buyers can ensure a well-informed and strategic approach to sourcing calibrated leaks, optimizing their purchasing process for better outcomes.

Illustrative image related to calibrated leak

Comprehensive Cost and Pricing Analysis for calibrated leak Sourcing

What Are the Key Cost Components for Sourcing Calibrated Leaks?

When sourcing calibrated leaks, several cost components contribute to the overall pricing structure. The primary components include:

-

Materials: The choice of materials significantly affects cost. Most calibrated leaks are constructed from stainless steel for durability and corrosion resistance, which is more expensive than other materials. Additionally, the type of gas used for calibration can also impact costs.

-

Labor: Skilled labor is essential in the production of calibrated leaks, particularly for custom orders. The labor costs vary based on the complexity of the leak specifications and the level of expertise required.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, rent, and administrative expenses associated with the production facility. Efficient manufacturing processes can help reduce overhead costs.

-

Tooling: Custom tooling may be required for specific leak rates or designs. This initial investment can increase upfront costs but may lead to long-term savings through improved efficiency and reduced waste.

-

Quality Control (QC): Given the critical nature of calibrated leaks in applications such as testing and calibration, robust QC processes are necessary. This includes testing for accuracy and stability, which adds to the overall cost.

-

Logistics: Shipping and handling costs can vary greatly depending on the location of the buyer and the supplier. International shipping may include tariffs and customs duties that can further affect pricing.

-

Margin: Suppliers will typically add a margin to cover their costs and profit. This margin can vary based on the supplier’s pricing strategy and market conditions.

How Do Price Influencers Impact the Cost of Calibrated Leaks?

Several factors influence the pricing of calibrated leaks, making it essential for buyers to understand these nuances:

-

Volume/MOQ (Minimum Order Quantity): Suppliers often provide discounts for bulk orders, making it economically advantageous for buyers to purchase larger quantities when feasible.

-

Specifications and Customization: Custom calibrated leaks tailored to specific requirements (e.g., leak rate, gas type) can lead to higher prices. Standard products typically have lower costs due to streamlined production processes.

-

Material Quality and Certifications: The presence of certifications (such as ISO or NIST traceability) can increase costs but also ensures reliability and compliance with industry standards, which is critical in regulated environments.

-

Supplier Factors: The supplier’s location, reputation, and experience can affect pricing. Established suppliers may charge more due to their proven track record, while newer suppliers might offer lower prices to gain market share.

-

Incoterms: The terms of shipping can significantly affect the total cost. Buyers should be aware of who is responsible for shipping costs, insurance, and duties, as these can vary widely depending on the chosen Incoterm.

What Buyer Tips Can Help Optimize Costs When Sourcing Calibrated Leaks?

International B2B buyers should consider the following strategies to optimize costs when sourcing calibrated leaks:

-

Negotiate Effectively: Engaging suppliers in negotiations can lead to better pricing, especially for larger orders or long-term contracts. Building a relationship with suppliers may also yield additional benefits.

-

Assess Total Cost of Ownership (TCO): Beyond the purchase price, consider maintenance, calibration, and potential downtime costs. Investing in higher-quality calibrated leaks may save money in the long run due to reduced failure rates and maintenance needs.

-

Understand Pricing Nuances for International Markets: Buyers from regions like Africa, South America, the Middle East, and Europe may encounter varying pricing due to local market conditions, logistics costs, and currency fluctuations. Staying informed about these factors can aid in making more strategic purchasing decisions.

-

Consider Local Suppliers: Whenever possible, sourcing from local suppliers can reduce logistics costs and lead times. Additionally, local suppliers may have a better understanding of regional regulations and requirements.

-

Stay Updated on Industry Trends: Keeping abreast of market trends and technological advancements in leak detection can help buyers make informed decisions and potentially identify cost-saving innovations.

Disclaimer

Prices for calibrated leaks can fluctuate based on market conditions, supplier agreements, and specific customer requirements. Therefore, it is advisable for buyers to request detailed quotes and confirm pricing before finalizing any purchase.

Alternatives Analysis: Comparing calibrated leak With Other Solutions

Exploring Alternatives to Calibrated Leaks for Leak Detection

In the realm of leak detection, calibrated leaks are a well-established solution, particularly valued for their precision and reliability. However, businesses often seek alternatives that may better align with specific operational needs or budget constraints. This section will compare calibrated leaks with other viable leak detection methods, highlighting their respective strengths and weaknesses to assist B2B buyers in making informed decisions.

| Comparison Aspect | Calibrated Leak | Sniffer Leak Detection | Mass Spectrometry Leak Detection |

|---|---|---|---|

| Performance | High precision, stable leak rates | Good for locating leaks in large areas | Extremely sensitive, can detect trace gases |

| Cost | Moderate to high, depending on specifications | Generally lower initial cost | Higher upfront costs for equipment |

| Ease of Implementation | Requires specific setup and calibration | Simple setup, portable equipment | Complex setup, requires technical expertise |

| Maintenance | Needs regular calibration and care | Minimal maintenance, easy to use | Requires regular calibration and upkeep |

| Best Use Case | Laboratory settings and production testing | Field applications for quick checks | High-precision applications in research labs |

What Are the Advantages and Disadvantages of Sniffer Leak Detection?

Sniffer leak detection systems utilize portable devices equipped with sensors to detect gases escaping from systems. The primary advantage of sniffer technology is its simplicity and cost-effectiveness, making it an attractive option for companies looking for quick assessments. These systems are particularly effective in large areas where pinpointing leaks can be challenging. However, they may not provide the same level of precision as calibrated leaks and can be influenced by environmental factors, potentially leading to false readings.

How Does Mass Spectrometry Compare to Calibrated Leaks?

Mass spectrometry offers an advanced method of leak detection, known for its sensitivity in identifying trace amounts of gases. This technology is ideal for applications requiring high precision, such as in the semiconductor or pharmaceutical industries. While mass spectrometry is highly effective, it comes with a higher cost and complexity, necessitating trained personnel for operation and maintenance. Additionally, the setup can be cumbersome, making it less practical for routine leak checks compared to more straightforward solutions like calibrated leaks or sniffer detectors.

Conclusion: How Can B2B Buyers Choose the Right Leak Detection Solution?

When selecting a leak detection solution, B2B buyers should consider several factors, including the specific application, budget, and the required precision level. Calibrated leaks provide high accuracy and are suitable for controlled environments, while sniffer leak detection offers a cost-effective and straightforward alternative for field applications. Mass spectrometry stands out for high-precision needs but comes at a greater expense and complexity. Ultimately, understanding the operational context and intended use will guide buyers in choosing the most suitable leak detection technology for their business.

Essential Technical Properties and Trade Terminology for calibrated leak

What Are the Key Technical Properties of Calibrated Leaks?

Calibrated leaks are essential components in various industries, particularly in vacuum technology and gas detection. Understanding their technical properties can significantly impact purchasing decisions and operational efficiency.

1. Material Grade

Calibrated leaks are typically constructed from high-grade stainless steel, which offers exceptional durability and resistance to corrosion. This material choice is critical for maintaining integrity over time, especially in harsh environments. Buyers should prioritize calibrated leaks made from materials that conform to industry standards, as this can affect both performance and longevity.

Illustrative image related to calibrated leak

2. Leak Rate Specification

The leak rate is a fundamental specification that indicates how much gas can escape through the leak per unit of time. It is measured in units such as ml/s or atm-cc/sec. Understanding the required leak rate is vital for applications that involve precise calibration of leak detection systems. A mismatch can lead to inaccurate readings and compromised operational efficiency.

3. Temperature Coefficient

The temperature coefficient reflects how the leak rate changes with temperature variations. A low temperature coefficient (e.g., 0.2% per degree Celsius) indicates that the leak maintains its specified rate across temperature fluctuations. This stability is crucial for industries that operate under varying thermal conditions, ensuring consistent performance and reliable results.

4. Pressure Tolerance

Calibrated leaks must operate within specified pressure ranges, which can vary from low vacuum conditions to high pressure (e.g., 50 mbar to 5 Bar). Understanding these tolerances is essential for buyers to ensure compatibility with their existing systems, preventing potential operational failures or leaks that could lead to costly downtime.

5. Traceability and Calibration Certification

Traceability is a critical feature for calibrated leaks, often ensured through ISO or NIST certification. This guarantees that the leak has been accurately calibrated and can be traced back to national standards. For B2B buyers, this certification provides peace of mind and ensures compliance with regulatory requirements, particularly in sensitive applications like pharmaceuticals or aerospace.

6. Ease of Use and Maintenance

Features such as quick-fit connections and user-friendly designs facilitate easy installation and removal for maintenance or recalibration. This is particularly important for businesses looking to minimize downtime and streamline their operational processes. A well-designed calibrated leak can save time and reduce the complexity of maintenance tasks.

Illustrative image related to calibrated leak

What Are Common Trade Terms Related to Calibrated Leaks?

Familiarity with industry terminology is vital for effective communication and negotiation in the B2B marketplace.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce components that are used in another company’s end product. When purchasing calibrated leaks, understanding whether the supplier is an OEM can help buyers assess quality and compatibility with their systems.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. For B2B buyers, being aware of MOQ can influence purchasing decisions, especially for smaller companies that may not need large quantities of calibrated leaks.

3. RFQ (Request for Quotation)

An RFQ is a document that a buyer sends to suppliers requesting pricing and other relevant information about a product or service. Utilizing an RFQ can help buyers gather competitive quotes and make informed decisions based on cost and specifications.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions. Understanding these terms is crucial for B2B buyers to clarify who is responsible for shipping, insurance, and tariffs, ultimately affecting total costs.

5. Calibration Cycle

The calibration cycle refers to the interval at which a calibrated leak should be checked and recalibrated to maintain accuracy. Knowing the recommended calibration cycle helps businesses schedule maintenance effectively, ensuring operational reliability.

6. Service Contracts

A service contract provides assurance of ongoing support, including maintenance and repair services for calibrated leaks. For B2B buyers, investing in service contracts can enhance the longevity and performance of their equipment, making it a valuable consideration in procurement decisions.

By understanding these technical properties and trade terms, international B2B buyers can make more informed decisions regarding calibrated leaks, ensuring they select products that meet their specific operational needs.

Navigating Market Dynamics and Sourcing Trends in the calibrated leak Sector

What Are the Key Market Drivers and Trends in the Calibrated Leak Sector?

The global calibrated leak market is experiencing significant growth driven by advancements in leak detection technologies and increasing demand across various industries, including aerospace, automotive, and pharmaceuticals. As international B2B buyers from regions such as Africa, South America, the Middle East, and Europe seek to enhance quality control measures, the importance of precise leak detection cannot be overstated. Emerging technologies, such as digital leak detection systems and IoT-enabled devices, are revolutionizing the calibration process, allowing for real-time monitoring and enhanced accuracy.

Another notable trend is the customization of calibrated leaks to meet specific industry requirements. Manufacturers are increasingly offering tailored solutions, enabling buyers to specify leak rates, gases, and pressure levels, which enhances operational efficiency. Additionally, the rise of remote support and training services is facilitating better adoption of these technologies, especially in regions where technical expertise may be limited.

The market dynamics are also influenced by the increasing emphasis on regulatory compliance and quality assurance in various sectors. As industries strive to adhere to stringent standards, the demand for traceable and certified calibrated leaks is expected to rise, creating opportunities for suppliers to differentiate themselves through quality and reliability.

How Are Sustainability and Ethical Sourcing Influencing the Calibrated Leak Market?

In recent years, sustainability has become a critical consideration for B2B buyers, particularly in the calibrated leak sector. The environmental impact of manufacturing processes and product lifecycle is under scrutiny, driving companies to seek suppliers committed to sustainable practices. Buyers are increasingly prioritizing manufacturers that utilize eco-friendly materials, such as recyclable stainless steel, and follow ethical sourcing practices.

The importance of ethical supply chains cannot be overstated. By ensuring that suppliers adhere to fair labor practices and environmental regulations, buyers can mitigate risks associated with reputational damage and regulatory penalties. Furthermore, obtaining ‘green’ certifications can enhance a company’s marketability, appealing to environmentally conscious clients and stakeholders.

Manufacturers are responding to this demand by adopting sustainability-focused strategies, such as reducing waste, optimizing energy consumption, and implementing recycling programs. B2B buyers should consider these factors when evaluating potential suppliers, as partnerships with environmentally responsible manufacturers can lead to long-term benefits and alignment with corporate social responsibility goals.

What Is the Historical Context of Calibrated Leaks in the Industry?

The evolution of calibrated leaks can be traced back to the early developments in vacuum technology and leak detection systems. Initially, calibrated leaks were rudimentary devices used primarily in laboratory settings for testing and calibration purposes. However, as industries expanded and technology advanced, the demand for precise and reliable leak detection grew, leading to innovations in design and materials.

Over the decades, calibrated leaks have evolved from simple mechanical devices to sophisticated, customizable solutions that meet stringent industry standards. This evolution has been driven by the increasing complexity of manufacturing processes and the necessity for high-quality assurance. Today, calibrated leaks are indispensable tools across various sectors, ensuring that products meet safety and quality standards, thereby reinforcing their critical role in modern industrial applications.

In summary, the calibrated leak sector is characterized by technological advancements, a growing emphasis on sustainability, and a rich history that underscores its importance in contemporary manufacturing and quality control processes. B2B buyers looking to navigate this market should remain informed about these trends and consider their implications for sourcing and supply chain strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of calibrated leak

-

How do I ensure the accuracy of calibrated leaks?

To guarantee the accuracy of calibrated leaks, it’s essential to source them from reputable manufacturers who provide a certificate of calibration in accordance with established quality standards, such as ISO 9001:2008. Regular calibration checks should be scheduled, ideally annually, to maintain their reliability. Additionally, understanding the specific requirements of your application—such as the type of gas, desired leak rate, and operating pressures—will help you select the most appropriate calibrated leak for your needs. -

What is the best calibrated leak for my application?

The ideal calibrated leak depends on your specific application requirements, including the type of gas you are testing and the desired leak rate. For instance, if you need a leak for helium testing, a helium capillary leak might be best. Additionally, consider factors like long-term stability, corrosion resistance, and whether the leak can be easily integrated into your testing system. Consulting with manufacturers about your application can help you identify the best solution tailored to your needs. -

What customization options are available for calibrated leaks?

Many manufacturers offer customization for calibrated leaks based on specific requirements, such as gas type, leak rate, and inlet pressure. When placing an order, ensure you provide detailed specifications to receive a product that meets your exact needs. Custom solutions can enhance the performance of your leak detection systems and improve overall testing accuracy. Always inquire about the manufacturer’s capabilities and previous projects to ensure they can meet your customization requests. -

What are the minimum order quantities (MOQs) for calibrated leaks?

Minimum order quantities can vary significantly among manufacturers. Some may offer single units, while others may require bulk orders to ensure cost-effectiveness. It’s advisable to discuss your purchasing needs with suppliers to find one that aligns with your volume requirements. If you’re a smaller business or a startup, some manufacturers may offer flexible options or sample orders to facilitate your initial purchase. -

What payment terms should I expect when purchasing calibrated leaks?

Payment terms can vary depending on the supplier and your location. Many manufacturers require a deposit upon order confirmation, with the balance due before shipping. Others may offer net payment terms, allowing you to pay within a specified period after receiving the product. It’s crucial to discuss payment options upfront to ensure they align with your financial processes and cash flow management. -

How do I vet suppliers for calibrated leaks?

When vetting suppliers, consider their industry reputation, certifications, and experience in producing calibrated leaks. Request references from previous clients, and check their compliance with international quality standards, such as ISO certifications. Additionally, inquire about their customer service capabilities, including support for installation and maintenance, as well as their responsiveness to inquiries. Conducting thorough research will help ensure you partner with a reliable supplier. -

What logistics considerations should I keep in mind when sourcing calibrated leaks internationally?

When sourcing calibrated leaks from international suppliers, consider shipping options, lead times, and customs regulations. Confirm that the supplier has experience with international shipping and can provide necessary documentation for customs clearance. Additionally, understand the associated costs, including shipping fees and potential tariffs, to avoid unexpected expenses. Effective communication with your supplier regarding logistics can help streamline the process and prevent delays. -

How can I ensure the quality assurance of calibrated leaks?

To ensure quality assurance, select suppliers who adhere to recognized quality management systems and provide documentation for their products, such as calibration certificates and test reports. Regular maintenance and re-calibration of the leaks are crucial for sustained accuracy. Additionally, consider suppliers that offer warranties or service agreements, which can provide peace of mind and support for any future issues you may encounter with the calibrated leaks.

Top 5 Calibrated Leak Manufacturers & Suppliers List

1. Agilent – Calibrated Helium Leaks

Domain: agilent.com

Registered: 1995 (30 years)

Introduction: Agilent offers a wide range of calibrated helium leaks available in several ranges from 10–6 to 10–10 atm cc/sec. The calibrated leaks are essential for ensuring the accuracy of helium mass spectrometers and are used to calibrate entire systems by mounting an external calibrated leak. The product features NW25 or 1 1/8′ inlet flange.

2. Pfeiffer Vacuum – Calibrated Leak Detection Devices

Domain: leak-detection.pfeiffer-vacuum.com

Registered: 1996 (29 years)

Introduction: Calibrated leak channels and orifices by Pfeiffer Vacuum include Equivalent Channel Standard (ECS) and Equivalent Channel Device (ECD). ECS devices have a length to diameter ratio >100 and come with a traceable gaging certificate for inlet diameter, outlet diameter, and length. ECD devices are certified for flow rate at pressure, with standard calibration points for air/nitrogen and barometric out…

3. Duniway – Helium Leak Standards

Domain: duniway.com

Registered: 1996 (29 years)

Introduction: [{‘part_number’: ‘LEAK-7-CERT’, ‘description’: ‘Helium Leak, 10 -7 std cc/sec, with NIST Certificate’, ‘price’: ‘$700.00’}, {‘part_number’: ‘LEAK-8-CERT’, ‘description’: ‘Helium Leak, 10 -8 std cc/sec, with NIST Certificate’, ‘price’: ‘$735.00’}, {‘part_number’: ‘LEAK-CERTIFY’, ‘description’: ‘NIST Certification Renewal, Helium Leak’, ‘price’: ‘$400.00’}, {‘part_number’: ‘LEAK-T-7-CERT’, ‘descript…

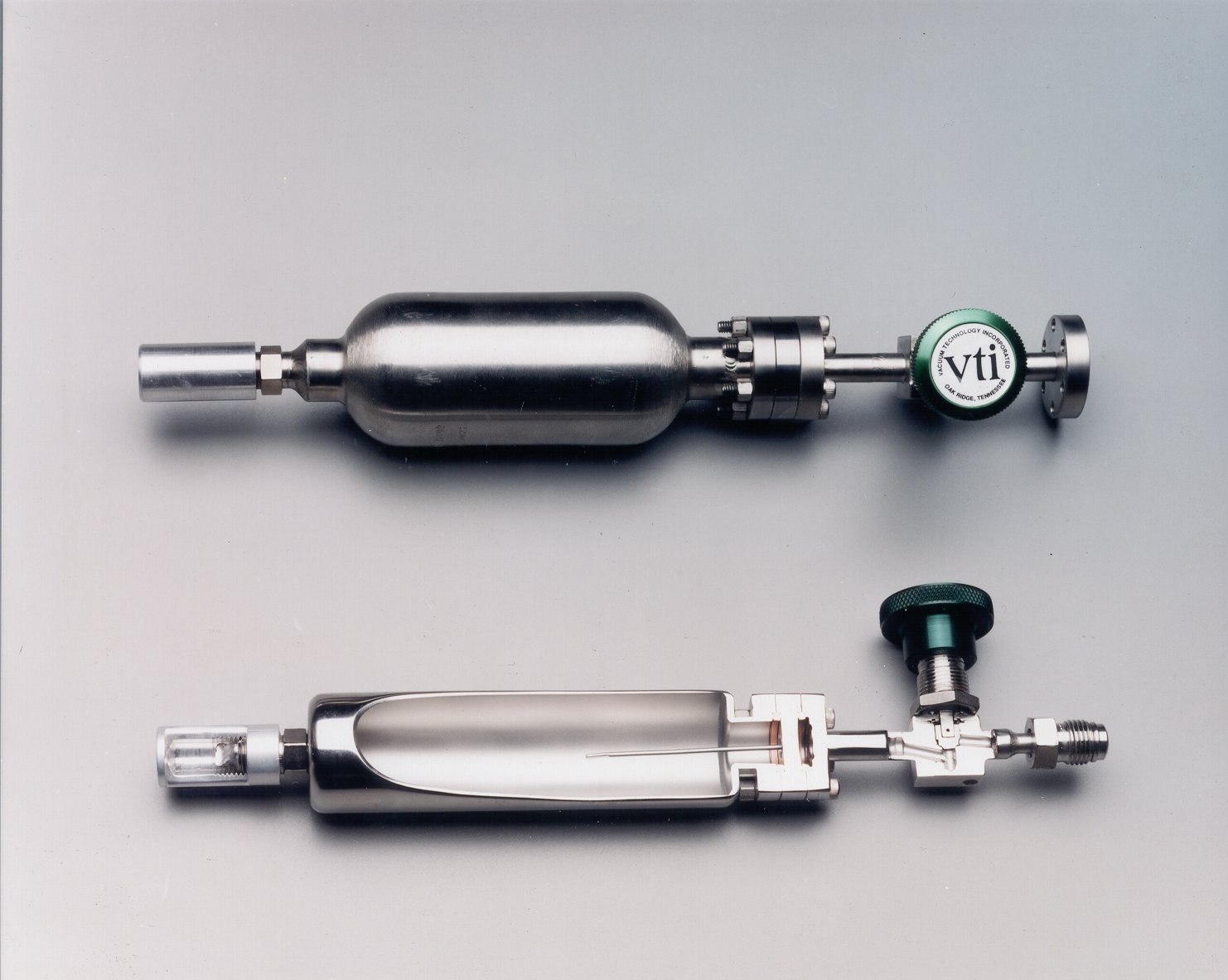

4. MTM Inc – Calibrated Helium Leaks

Domain: mtm-inc.com

Registered: 1997 (28 years)

Introduction: Calibrated leaks are used for calibrating helium leak detectors, typically of the reservoir type, operating in the 10-7 to 10-8 std-cc/sec helium range. They consist of a reservoir of helium gas contained within a metal cylinder (nickel-plated carbon steel or aluminum) with a hollow pyrex-glass tube and an isolation valve. Helium gas permeates through the pyrex-glass tube at atmospheric pressure, …

5. Spectro Physics – Calibrated Leak Standards

Domain: spectrophysics.com

Registered: 2011 (14 years)

Introduction: Calibrated Leak Standards from Spectro Physics are precision-calibrated devices designed for various industries and testing needs. They support calibration, verification, and performance assurance for leak detection systems. Key features include:

1. **Leak Detector Calibration**: Used for calibrating automated and manual leak detection systems.

2. **Establish Reject Limits**: Ensures consistent p…

Strategic Sourcing Conclusion and Outlook for calibrated leak

In the evolving landscape of leak detection technology, the strategic sourcing of calibrated leaks is vital for international businesses aiming to enhance their operational efficiency and compliance standards. Key takeaways highlight the importance of selecting calibrated leaks that meet specific requirements—such as gas type, pressure, and leak rate—ensuring accurate and reliable testing outcomes. By partnering with reputable manufacturers who offer comprehensive training and support services, companies can optimize their leak detection systems and maintain long-term stability in their operations.

Furthermore, the significance of ISO-certified products cannot be overstated; they ensure traceability and adherence to international quality standards, which is particularly crucial for industries across Africa, South America, the Middle East, and Europe. As the demand for precision in leak detection continues to rise, investing in high-quality calibrated leaks is not just a necessity but a strategic advantage.

Looking ahead, B2B buyers are encouraged to explore partnerships with trusted suppliers who offer tailored solutions and robust customer support. By doing so, businesses can not only meet their immediate leak detection needs but also position themselves for future success in a competitive global market.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.