How to Source Block Creel Construction Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for block creel construction

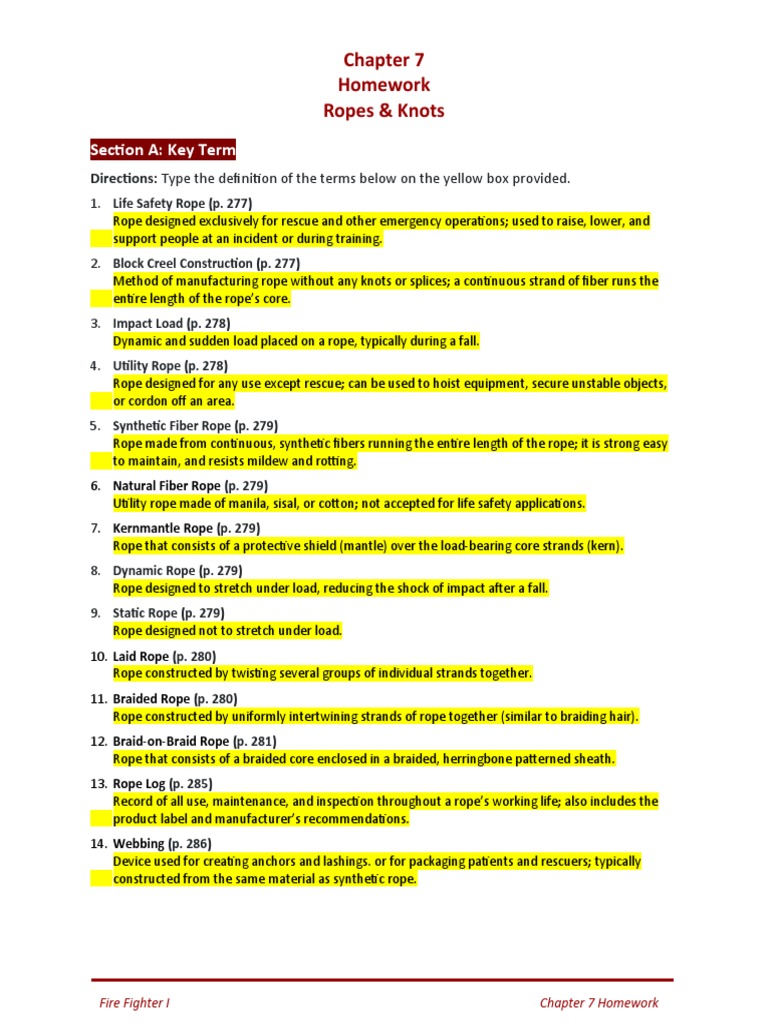

In the ever-evolving landscape of industrial materials, the demand for high-quality ropes manufactured through block creel construction is on the rise. However, international B2B buyers often face challenges in sourcing reliable suppliers who can deliver ropes that meet stringent performance standards without compromising on quality or cost. This guide aims to equip you with the knowledge necessary to navigate the complexities of block creel construction, offering insights into various types of ropes, their applications across different industries, and the critical factors to consider when vetting suppliers.

From understanding the intricacies of manufacturing processes to evaluating performance characteristics such as abrasion resistance and tensile strength, this comprehensive resource serves as a roadmap for making informed purchasing decisions. It delves into the nuances of cost structures and provides actionable strategies for negotiating terms that align with your business objectives.

Designed specifically for international buyers from regions such as Africa, South America, the Middle East, and Europe—including key markets like Brazil and Vietnam—this guide empowers you to identify and engage with the right suppliers. By leveraging expert insights and practical tips, you can streamline your sourcing process, reduce risks, and enhance the reliability of your supply chain in the competitive global market for block creel construction.

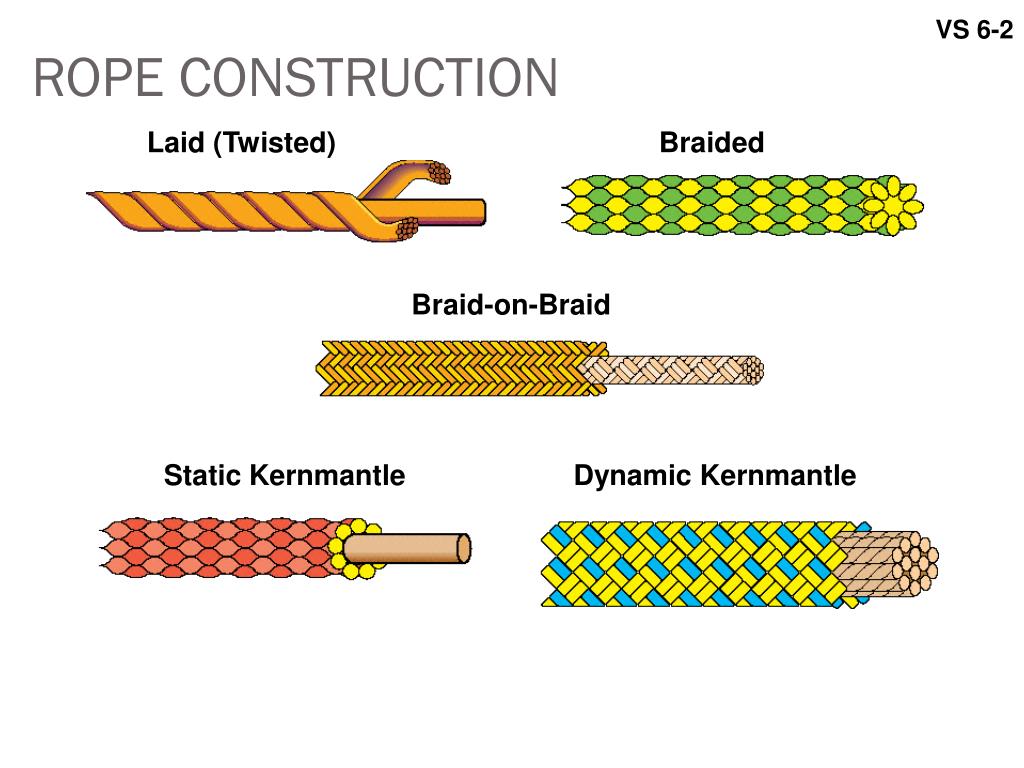

Understanding block creel construction Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Block Creel | Continuous strand without knots or splices; uniform diameter. | General rope manufacturing, shipping. | Pros: High strength, consistent quality. Cons: Limited flexibility in customization. |

| Braid-on-Braid Block | Inner braided core with an outer braided sheath; enhanced durability. | Marine applications, climbing gear. | Pros: Superior abrasion resistance. Cons: More complex manufacturing process. |

| Kernmantle Block Creel | Protective outer layer (mantle) over a strong inner core (kern). | Safety and rescue operations. | Pros: Excellent shock absorption. Cons: Higher cost due to specialized design. |

| Laid Block Creel | Twisted strands forming a traditional rope structure. | Agriculture, towing, and utility uses. | Pros: Cost-effective and easy to manufacture. Cons: Lower strength compared to braided options. |

| Specialty Block Creel | Customized configurations for specific applications. | Industrial lifting, specialized fishing. | Pros: Tailored to specific needs. Cons: Longer lead times and potential higher costs. |

What are the Key Characteristics of Standard Block Creel Construction?

Standard block creel construction involves the manufacturing of rope using a continuous strand without any knots or splices, ensuring uniformity in diameter. This method is widely used in general rope manufacturing and shipping applications due to its high strength and consistent quality. Buyers should consider the limitations in customization, as standard designs may not meet specific operational needs.

How Does Braid-on-Braid Block Construction Enhance Durability?

Braid-on-braid block construction features an inner braided core encased in a braided sheath, providing enhanced durability and flexibility. This type is particularly suitable for marine applications and climbing gear, where abrasion resistance is crucial. While the manufacturing process is more complex, the resulting product offers superior performance, making it a valuable investment for businesses prioritizing safety and reliability.

Why Choose Kernmantle Block Creel for Safety Applications?

Kernmantle block creel construction is characterized by its protective outer layer (mantle) over a strong inner core (kern), making it ideal for safety and rescue operations. This design offers excellent shock absorption, which is vital during high-stress situations. However, the specialized design comes at a higher cost, so buyers should weigh the benefits against their budgetary constraints.

What are the Advantages and Disadvantages of Laid Block Creel Construction?

Laid block creel construction utilizes twisted strands to create a traditional rope structure, making it a cost-effective option for agricultural, towing, and utility applications. While it is easy to manufacture, buyers should note that this type generally has lower strength compared to braided options. This trade-off may be acceptable for less demanding applications, but for critical uses, stronger alternatives should be considered.

How Can Specialty Block Creel Construction Meet Specific Needs?

Specialty block creel construction allows for customized configurations tailored to specific industrial applications, such as lifting or specialized fishing. While this type offers the advantage of meeting precise operational requirements, buyers should be aware of potential longer lead times and higher costs associated with custom manufacturing. Companies should assess whether the benefits of tailored solutions justify the investment.

Key Industrial Applications of block creel construction

| Industry/Sector | Specific Application of block creel construction | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Maritime & Shipping | Manufacturing of mooring lines and anchor ropes | Enhanced durability and strength for critical applications | Sourcing high-tensile strength fibers; compliance with maritime safety standards |

| Construction | Production of heavy-duty lifting slings | Improved safety and reliability in lifting operations | Specifications for load capacity; resistance to abrasion and environmental factors |

| Agriculture | Creation of baling twine for hay and forage | Increased efficiency and reduced downtime during harvesting | Availability of biodegradable options; compatibility with various balers |

| Mining | Development of haulage ropes for underground transport | Reliability under extreme conditions, minimizing downtime | Compliance with industry safety regulations; tensile strength and fatigue resistance |

| Telecommunications | Fiber optic cable sheathing | Protection against environmental factors, ensuring signal integrity | Resistance to moisture and UV; compatibility with existing infrastructure |

How is Block Creel Construction Used in Maritime & Shipping?

In the maritime and shipping industry, block creel construction is utilized to manufacture robust mooring lines and anchor ropes. These ropes are crucial for securing vessels and ensuring safety during docking and anchoring. The continuous strand design eliminates weak points, providing enhanced durability and strength necessary to withstand harsh marine environments. Buyers in this sector must consider sourcing high-tensile strength fibers that meet international maritime safety standards to ensure reliability.

What Role Does Block Creel Construction Play in Construction?

In construction, block creel construction is employed to produce heavy-duty lifting slings used in various lifting operations. These slings must be able to handle significant loads while ensuring safety for personnel and equipment. The continuous fiber structure provides superior strength and minimizes the risk of failure. Buyers should focus on specifications related to load capacity, as well as the material’s resistance to abrasion and environmental factors, to ensure long-lasting performance on job sites.

How is Block Creel Construction Beneficial in Agriculture?

The agricultural sector leverages block creel construction for the production of baling twine used in hay and forage harvesting. This twine must be strong yet flexible, allowing it to secure bales efficiently. The continuous construction method improves the twine’s reliability, reducing downtime during the harvesting process. Buyers should seek suppliers who can provide biodegradable options that are compatible with various balers, aligning with sustainable agricultural practices.

What Advantages Does Block Creel Construction Offer in Mining?

In mining, block creel construction is critical for developing haulage ropes used in underground transport systems. These ropes must be incredibly reliable to handle extreme conditions, ensuring minimal downtime and maximizing productivity. The construction method’s emphasis on continuous strands enhances the ropes’ tensile strength and fatigue resistance. Buyers should ensure that their sourcing aligns with industry safety regulations to maintain operational integrity.

How is Block Creel Construction Applied in Telecommunications?

In the telecommunications sector, block creel construction is used for the sheathing of fiber optic cables. This application is essential for protecting cables from environmental factors, ensuring signal integrity and longevity. The continuous strand design provides superior resistance to moisture and UV exposure. Buyers should prioritize sourcing materials that meet compatibility requirements with existing infrastructure to ensure seamless integration and functionality.

3 Common User Pain Points for ‘block creel construction’ & Their Solutions

Scenario 1: Quality Control Challenges in Block Creel Production

The Problem: B2B buyers often encounter significant challenges in ensuring the quality of ropes produced using block creel construction. Variations in raw material quality, inconsistencies in production processes, or inadequate maintenance of machinery can lead to defective products. These issues can result in higher return rates, increased costs due to re-manufacturing, and potential reputational damage if low-quality ropes are supplied to end-users. International buyers, particularly in regions like Africa and South America, may struggle to find reliable suppliers who consistently meet stringent quality standards.

The Solution: To mitigate quality control issues, buyers should conduct thorough due diligence when selecting suppliers. This includes requesting certifications that demonstrate compliance with international quality standards, such as ISO 9001. Additionally, buyers should establish a robust quality assurance protocol, including regular audits of the supplier’s production facilities. Implementing a comprehensive inspection regime upon receipt of goods can also help identify defects early. Furthermore, developing a long-term partnership with a supplier who is willing to collaborate on quality improvements and share best practices can significantly enhance product consistency.

Scenario 2: Limited Customization Options for Specific Applications

The Problem: In many industrial applications, the need for customized rope solutions is paramount. However, B2B buyers often find that suppliers utilizing block creel construction offer limited options for customization, such as specific lengths, diameters, or specialized fiber compositions. This lack of flexibility can hinder operations, particularly in sectors like marine, construction, and rescue services, where unique requirements are common. Buyers may face delays or increased costs when attempting to source custom products from multiple suppliers.

The Solution: To address customization challenges, buyers should clearly communicate their specific requirements to potential suppliers during the initial discussions. This includes providing detailed specifications regarding the intended use, environmental conditions, and any necessary performance criteria. Engaging with suppliers who have a reputation for flexibility in their manufacturing processes can also be beneficial. Buyers should inquire about the supplier’s ability to produce small batch runs or variations in existing products. Collaborating on product development from the outset can lead to tailored solutions that meet unique operational needs without significant delays.

Scenario 3: Navigating Supply Chain Disruptions

The Problem: Global supply chain disruptions can pose a serious threat to B2B buyers relying on block creel construction for their rope needs. Factors such as political instability, natural disasters, and fluctuating transportation costs can lead to delays in delivery, increased lead times, and unpredictable pricing. This uncertainty can severely impact production schedules and project timelines, especially for companies in fast-paced industries requiring just-in-time inventory.

The Solution: To combat supply chain vulnerabilities, buyers should diversify their supplier base to include multiple manufacturers across different geographical regions. This approach mitigates risks associated with relying on a single source. Additionally, establishing a clear communication channel with suppliers can provide insight into potential disruptions, allowing buyers to make proactive adjustments to their orders. Implementing a buffer stock strategy can also help maintain operational continuity during unexpected supply chain delays. Buyers should regularly review and analyze market trends to anticipate changes in availability and pricing, enabling them to adapt their procurement strategies accordingly.

Strategic Material Selection Guide for block creel construction

What are the Key Properties of Common Materials Used in Block Creel Construction?

Block creel construction primarily involves the use of synthetic fibers and natural materials, each with distinct properties that influence their performance and suitability for various applications. Here, we analyze four common materials: nylon, polyester, polypropylene, and natural fibers.

Nylon: What Advantages Does This Material Offer?

Nylon is renowned for its high tensile strength and elasticity, making it a popular choice for block creel construction. It exhibits excellent abrasion resistance and can withstand high temperatures up to 120°C (248°F). However, nylon is susceptible to UV degradation and can absorb moisture, which may compromise its integrity over time.

Pros: Nylon’s durability and flexibility make it ideal for applications requiring high strength and resistance to wear. It is also relatively easy to manufacture and can be produced in various forms.

Cons: The cost of nylon is generally higher than that of other synthetic fibers, and its susceptibility to UV damage necessitates protective measures for outdoor applications.

Impact on Application: Nylon is suitable for applications involving dynamic loads, such as climbing or rescue operations, where elasticity is crucial.

Considerations for International Buyers: Compliance with international standards like ASTM and ISO is essential, especially in regions like Europe and the Middle East, where regulations are stringent. Buyers should also consider the availability of UV-resistant treatments.

Polyester: How Does It Compare to Other Synthetic Options?

Polyester is another widely used material in block creel construction, valued for its excellent resistance to UV light and moisture. It maintains its strength and shape even under varying temperatures, with a maximum operational temperature of around 150°C (302°F).

Illustrative image related to block creel construction

Pros: Polyester offers superior dimensional stability and resistance to environmental factors, making it suitable for long-term outdoor use. It is also more cost-effective compared to nylon.

Cons: While polyester has good abrasion resistance, it is not as elastic as nylon, which may limit its use in applications requiring significant stretch.

Impact on Application: Polyester is ideal for applications in marine environments or where exposure to sunlight is a concern, such as in fishing nets or outdoor rigging.

Considerations for International Buyers: Buyers should ensure that polyester products meet local standards and certifications, particularly in Europe, where compliance with EN standards is often required.

Illustrative image related to block creel construction

Polypropylene: What Makes This Material a Budget-Friendly Choice?

Polypropylene is a lightweight, cost-effective option for block creel construction, offering good resistance to chemicals and moisture. Its operational temperature range is lower than that of nylon and polyester, typically around 80°C (176°F).

Pros: The primary advantage of polypropylene is its affordability and resistance to water, making it suitable for applications in wet environments.

Cons: However, polypropylene’s lower tensile strength and UV resistance compared to nylon and polyester limit its use in high-stress applications. It can also become brittle over time when exposed to UV light.

Impact on Application: Polypropylene is commonly used in agricultural applications, such as baling twine, where cost and moisture resistance are critical.

Considerations for International Buyers: Buyers should be aware of the varying quality standards for polypropylene in different regions. Compliance with local regulations regarding material safety and performance is essential, especially in markets like South America and Africa.

Natural Fibers: Are They Still Relevant in Block Creel Construction?

Natural fibers, such as sisal and jute, are traditional materials used in block creel construction. They offer good tensile strength and are biodegradable, making them environmentally friendly.

Pros: Natural fibers are cost-effective and provide a good grip, making them suitable for applications where handling is frequent.

Cons: However, they are less durable than synthetic options and can degrade when exposed to moisture and UV light. Their performance can also be inconsistent due to variability in fiber quality.

Impact on Application: Natural fibers are suitable for low-stress applications, such as decorative ropes or temporary uses.

Considerations for International Buyers: Buyers should consider the sourcing and sustainability of natural fibers, as well as compliance with international environmental standards, particularly in Europe where eco-friendly materials are increasingly preferred.

Illustrative image related to block creel construction

Summary Table of Material Selection for Block Creel Construction

| Material | Typical Use Case for block creel construction | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Nylon | Climbing ropes, rescue applications | High tensile strength and elasticity | UV degradation and moisture absorption | High |

| Polyester | Marine applications, outdoor rigging | UV and moisture resistance | Less elastic than nylon | Medium |

| Polypropylene | Agricultural twine, low-stress applications | Cost-effective and lightweight | Lower tensile strength, UV sensitivity | Low |

| Natural Fibers | Decorative ropes, temporary applications | Biodegradable and cost-effective | Less durable, moisture degradation | Low |

This strategic material selection guide serves as a valuable resource for international B2B buyers, helping them make informed decisions based on performance characteristics, application suitability, and compliance considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for block creel construction

What Are the Key Stages in the Block Creel Construction Manufacturing Process?

The manufacturing process for block creel construction involves several critical stages that ensure the production of high-quality rope without knots or splices. These stages include material preparation, forming, assembly, and finishing.

-

Material Preparation: The first step in block creel construction is sourcing and preparing raw materials, typically synthetic fibers like polypropylene or polyester. These materials are selected for their strength, durability, and resistance to abrasion. The fibers are then treated to enhance their mechanical properties, ensuring they can withstand rigorous applications. This preparation may include processes such as drying, cutting, and combining different fiber types to achieve desired characteristics.

-

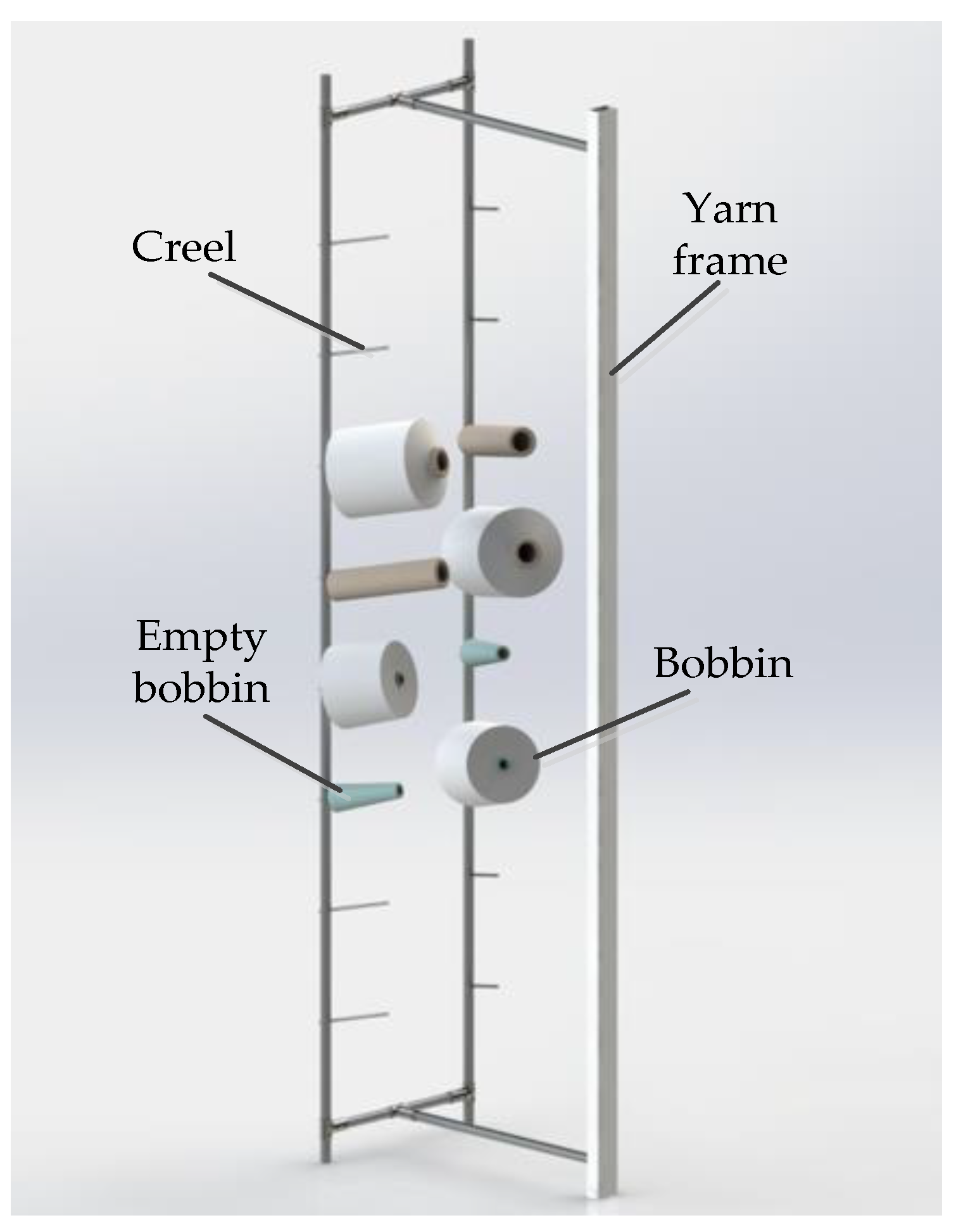

Forming: In this stage, the prepared fibers are fed into the block creel, which is a specialized machine designed to produce continuous strands of rope. The fibers are twisted and braided together to form a solid core without any interruptions. This continuous strand structure is fundamental to the block creel method, as it eliminates weak points typically found in spliced or knotted ropes. Advanced forming techniques, such as using multiple bobbins to maximize fiber utilization, are employed to ensure consistency and quality.

-

Assembly: Once the fibers are formed into a continuous strand, they are assembled into the final rope structure. This step may involve additional braiding or twisting to create the desired rope diameter and strength. The assembly process is carefully monitored to ensure that the rope maintains uniformity throughout its length. Quality control measures, such as tension testing during assembly, are critical to ensuring that the finished product meets specifications.

-

Finishing: The final stage involves treating the rope to improve its performance characteristics. This can include applying coatings for increased abrasion resistance or water repellency. The rope is then cut to length, and any necessary finishing touches, such as splicing or adding end fittings, are completed. Finishing processes often incorporate quality checks to ensure that the rope meets industry standards and customer specifications.

How Is Quality Assurance Implemented in Block Creel Construction?

Quality assurance (QA) is integral to the manufacturing process of block creel construction, ensuring that products meet both international and industry-specific standards. Key components of QA include adherence to relevant standards, establishment of quality checkpoints, and implementation of rigorous testing methods.

-

Adherence to International Standards: Many manufacturers in the block creel construction industry comply with international quality standards, such as ISO 9001. This standard outlines a framework for quality management systems (QMS), emphasizing customer satisfaction and continuous improvement. Additionally, manufacturers may adhere to industry-specific certifications like CE (Conformité Européenne) for European markets or API (American Petroleum Institute) standards for oil and gas applications. Compliance with these standards is crucial for B2B buyers, as it assures them of the product’s reliability and safety.

-

Quality Checkpoints: Throughout the manufacturing process, various quality checkpoints are established to monitor and verify product quality. These checkpoints typically include:

– Incoming Quality Control (IQC): This involves inspecting raw materials upon receipt to ensure they meet specified standards before production begins.

– In-Process Quality Control (IPQC): During the manufacturing process, operators conduct regular checks to ensure that the production parameters are within acceptable limits.

– Final Quality Control (FQC): After production, the finished product undergoes comprehensive testing and inspection to verify its quality and compliance with specifications. -

Common Testing Methods: Several testing methods are employed to assess the performance of block creel ropes. These methods may include tensile strength tests, elongation tests, and abrasion resistance tests. Testing ensures that the ropes can withstand the intended loads and environmental conditions. Moreover, regular audits and inspections help identify potential issues early in the production process, mitigating risks before they impact the final product.

How Can B2B Buyers Verify Supplier Quality Control?

For B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for ensuring product reliability and performance. Here are some strategies that buyers can employ:

-

Supplier Audits: Conducting on-site audits of potential suppliers is one of the most effective ways to assess their quality control processes. During an audit, buyers can evaluate the manufacturing facilities, review quality management systems, and observe production practices firsthand. This direct engagement provides insights into the supplier’s commitment to quality and adherence to industry standards.

-

Quality Reports: Requesting quality reports from suppliers can provide additional assurance of their quality practices. These reports should detail the results of various tests and inspections conducted during the manufacturing process. Regular reporting on quality metrics, such as defect rates and compliance with standards, can help buyers make informed decisions.

-

Third-Party Inspections: Engaging third-party inspection services can further validate a supplier’s quality control measures. Independent inspectors can conduct assessments and testing to verify that the products meet specified standards and performance criteria. This additional layer of scrutiny is particularly valuable for buyers concerned about compliance and product integrity.

What Are the Quality Control Nuances for International B2B Buyers?

International B2B buyers must navigate various quality control nuances when sourcing block creel products. Understanding these nuances can enhance the procurement process and ensure the selection of reliable suppliers.

Illustrative image related to block creel construction

-

Regional Standards and Certifications: Different regions may have unique quality standards and certifications that manufacturers must comply with. For instance, European buyers may prioritize CE marking, while Middle Eastern buyers might focus on local certifications. Buyers should familiarize themselves with these requirements to ensure that suppliers can meet them.

-

Cultural Differences in Quality Expectations: Quality perceptions can vary significantly across cultures. For example, buyers from Europe may have more stringent quality expectations compared to those in other regions. Understanding these cultural differences can help buyers communicate their quality requirements more effectively.

-

Supply Chain Transparency: In international trade, transparency in the supply chain is crucial. Buyers should seek suppliers who provide clear documentation regarding sourcing, manufacturing processes, and quality control practices. This transparency builds trust and confidence in the supplier’s ability to deliver high-quality products consistently.

By considering these aspects of manufacturing processes and quality assurance, B2B buyers can make informed decisions when sourcing block creel products, ensuring they partner with suppliers who prioritize quality and reliability.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘block creel construction’

Introduction

This guide provides a practical checklist for B2B buyers interested in procuring block creel construction services or materials. By following these steps, you will ensure that you select a reliable supplier who meets your technical requirements and adheres to industry standards, ultimately enhancing your project outcomes.

Step 1: Define Your Technical Specifications

Before engaging with suppliers, it’s essential to outline your specific needs regarding block creel construction. This includes determining the type of materials, dimensions, and performance characteristics required for your application.

– Material Types: Specify whether you need synthetic or natural fibers based on your durability and flexibility requirements.

– Performance Standards: Consider factors such as breaking strength, abrasion resistance, and environmental conditions the product will face.

Step 2: Conduct Market Research

Understanding the market landscape is vital for making informed purchasing decisions. Research potential suppliers, their product offerings, and customer reviews to gauge their reputation.

– Supplier Background: Look for established companies with a proven track record in block creel construction.

– Customer Feedback: Analyze reviews and case studies to understand the experiences of other businesses similar to yours.

Illustrative image related to block creel construction

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Certifications and Compliance: Ensure that the supplier adheres to relevant quality and safety standards.

– Production Capabilities: Assess their ability to meet your order volume and timelines.

Step 4: Request Samples

Obtaining product samples allows you to evaluate the quality of the materials firsthand. This step is crucial in confirming that the supplier can deliver products that meet your specifications.

– Testing for Standards: Perform necessary tests on the samples to ensure they meet your defined technical specifications.

– Quality Assurance: Look for consistency in the samples to ensure they reflect the supplier’s production standards.

Step 5: Verify Supplier Certifications

Confirm that your chosen supplier possesses the necessary certifications and licenses to operate in their respective markets. This verification is essential for ensuring compliance with international standards.

– Quality Management Systems: Look for ISO certifications that indicate adherence to quality control processes.

– Environmental Compliance: Ensure they follow regulations related to environmental impact, particularly if your operations are in regions with strict guidelines.

Step 6: Negotiate Terms and Conditions

Once you have shortlisted potential suppliers, negotiate the terms of your purchase agreement. This includes pricing, delivery schedules, and payment terms.

– Transparent Pricing: Ensure that all costs are clearly outlined to avoid hidden fees.

– Delivery Commitments: Agree on realistic timelines that align with your project schedule.

Illustrative image related to block creel construction

Step 7: Establish a Communication Plan

Effective communication is key to a successful supplier relationship. Establish a clear plan for ongoing communication to address any issues that may arise during the procurement process.

– Regular Updates: Schedule periodic check-ins to monitor progress and resolve any concerns promptly.

– Feedback Mechanism: Create a channel for providing feedback on product performance and supplier service.

By following this checklist, B2B buyers can ensure a strategic approach to sourcing block creel construction, ultimately leading to successful project execution and long-term supplier relationships.

Comprehensive Cost and Pricing Analysis for block creel construction Sourcing

What Are the Key Cost Components in Block Creel Construction Sourcing?

When sourcing block creel construction, understanding the cost structure is essential for B2B buyers. The primary cost components include:

-

Materials: The choice of fibers—such as nylon, polyester, or natural fibers—significantly impacts the overall cost. Higher-quality materials typically result in stronger and more durable products but come at a premium price.

-

Labor: Labor costs vary by region and can be influenced by local wage standards and the skill level required for production. Automated manufacturing processes can reduce labor costs but may require higher initial investments.

-

Manufacturing Overhead: This includes costs associated with utilities, rent, and equipment maintenance. Overhead can be substantial in regions with higher operational costs, such as Europe or North America.

-

Tooling: Initial tooling costs for specialized machinery can be significant, particularly for custom orders. This is an upfront investment that may be amortized over large production runs.

-

Quality Control (QC): Implementing rigorous QC procedures ensures product reliability but adds to the overall cost. Certifications for safety and quality (such as ISO standards) can also influence pricing.

-

Logistics: Shipping costs can fluctuate based on distance, weight, and mode of transport. Incoterms will define the responsibilities of buyers and sellers, impacting total logistics costs.

-

Margin: Supplier margins can vary widely based on market conditions, competition, and the perceived value of the product. Understanding the typical margins in your target market can aid in negotiating fair pricing.

How Do Price Influencers Affect Sourcing Decisions for Block Creel Construction?

Several factors can influence pricing in block creel construction, including:

-

Volume/MOQ: Minimum order quantities (MOQs) can significantly affect pricing. Larger orders often lead to lower per-unit costs, making it essential for buyers to forecast needs accurately.

-

Specifications and Customization: Custom designs or specific performance specifications can increase costs due to the need for specialized materials or manufacturing processes. Buyers should weigh the benefits of customization against the increased costs.

-

Material Quality and Certifications: Higher-quality materials and certifications enhance product value but also raise costs. Buyers should assess their quality requirements against budget constraints.

-

Supplier Factors: The reputation, reliability, and location of suppliers can impact pricing. Established suppliers with a strong track record may charge more, but they often provide better quality assurance and service.

-

Incoterms: Understanding the implications of various Incoterms is crucial for buyers. Terms like CIF (Cost, Insurance, and Freight) or FOB (Free on Board) can affect the total landed cost of the product.

What Tips Can Help Buyers Optimize Cost-Efficiency in Block Creel Construction?

To achieve cost-efficiency when sourcing block creel construction, consider the following strategies:

-

Negotiation: Effective negotiation skills can significantly reduce costs. Building relationships with suppliers and discussing long-term commitments can lead to better pricing and terms.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the initial purchase price. Consider maintenance, longevity, and potential savings from using higher-quality products.

-

Pricing Nuances for International Buyers: When sourcing from different regions, be mindful of currency fluctuations, tariffs, and trade regulations that can affect pricing. Familiarize yourself with local market conditions to better understand pricing structures.

-

Research and Compare: Conduct thorough market research to compare prices from various suppliers. This will provide insight into standard pricing and help identify the best value options.

-

Leverage Technology: Utilize supply chain management software to analyze costs and streamline procurement processes, enhancing overall efficiency.

Disclaimer for Indicative Prices

It is important to note that prices for block creel construction can vary widely based on the factors outlined above. Buyers should engage with multiple suppliers to obtain accurate quotes and ensure that they are making informed purchasing decisions.

Alternatives Analysis: Comparing block creel construction With Other Solutions

Understanding the Need for Alternatives in Rope Manufacturing

In the dynamic landscape of rope manufacturing, businesses often seek various construction methods to optimize performance, cost, and usability. Block creel construction is a popular choice due to its unique design that eliminates knots and splices, creating a continuous strand of fiber. However, understanding alternative methods can help B2B buyers make informed decisions based on their specific operational requirements.

Illustrative image related to block creel construction

Comparison of Block Creel Construction and Alternative Solutions

| Comparison Aspect | Block Creel Construction | Braided Rope | Kernmantle Rope |

|---|---|---|---|

| Performance | High tensile strength and low elongation; ideal for heavy-duty applications | Good flexibility; suitable for various applications | Excellent abrasion resistance and shock absorption; suitable for climbing and rescue |

| Cost | Moderate initial investment; lower long-term maintenance costs | Generally lower cost due to simpler manufacturing | Higher initial cost due to complex design and materials |

| Ease of Implementation | Requires specialized machinery; longer setup time | Easier to produce; widely available | Requires specific training for safe use and handling |

| Maintenance | Low; less wear due to absence of knots | Moderate; knots may require regular inspection | High; requires frequent inspections and careful handling |

| Best Use Case | Heavy industrial applications, marine use | General utility, outdoor activities | Climbing, rescue operations, and safety applications |

In-Depth Analysis of Alternatives

Braided Rope: What Are Its Benefits and Drawbacks?

Braided rope consists of multiple strands intertwined together, resulting in a flexible and versatile product. Its manufacturing process is generally simpler and less expensive than block creel construction, making it an attractive option for budget-conscious buyers. However, the presence of knots can lead to potential weaknesses in the rope’s structure, requiring regular inspections to ensure safety. Braided rope is best suited for general utility tasks and outdoor activities where high flexibility is needed.

Kernmantle Rope: How Does It Compare in Performance?

Kernmantle rope is characterized by its dual-layer structure, comprising a strong inner core (kern) and a protective outer sheath (mantle). This design provides exceptional abrasion resistance and shock absorption, making it ideal for applications in climbing and rescue operations. While kernmantle ropes offer superior safety features, they come at a higher price point and require specialized knowledge for effective use and maintenance. This rope is best used in high-stakes environments where safety is paramount.

Making the Right Choice: How Can B2B Buyers Decide?

When considering which rope construction method to invest in, B2B buyers should assess their specific needs, including the intended application, budget constraints, and operational environment. Block creel construction is ideal for heavy-duty applications that demand durability and low maintenance, while braided ropes serve well in general utility roles. Kernmantle ropes are best for safety-critical applications, despite their higher costs and maintenance requirements. Ultimately, the right choice will depend on aligning the product features with business objectives and operational demands.

Essential Technical Properties and Trade Terminology for block creel construction

What Are the Key Technical Properties of Block Creel Construction?

When considering block creel construction for rope manufacturing, certain technical properties are essential for ensuring product quality and performance. Here are some critical specifications to consider:

Illustrative image related to block creel construction

-

Material Grade

The choice of materials, such as synthetic fibers (e.g., nylon, polyester) or natural fibers (e.g., manila, sisal), significantly impacts the rope’s strength, durability, and application. Higher-grade materials typically offer superior abrasion resistance and tensile strength, making them suitable for demanding environments, such as construction or marine applications. -

Tensile Strength

This refers to the maximum load that a rope can withstand while being pulled before breaking. In B2B contexts, understanding tensile strength is crucial for ensuring that the rope can handle the intended loads without risk of failure, which can lead to operational delays and safety hazards. -

Elongation Percentage

Elongation measures how much a rope stretches under load. A rope with low elongation is critical in applications where minimal stretch is necessary, such as lifting heavy loads. Conversely, some applications may benefit from ropes that stretch to absorb shock, reducing the risk of sudden breaks. -

Abrasion Resistance

This property indicates the rope’s ability to resist wear from friction against surfaces. Ropes with high abrasion resistance are essential for applications where they may rub against rough surfaces, such as winches or pulleys. Selecting a rope with adequate abrasion resistance minimizes maintenance costs and extends product lifespan. -

Moisture Resistance

For ropes used in wet or humid environments, moisture resistance is vital. Ropes that absorb water can become heavier and weaker, leading to performance issues. Understanding the moisture absorption properties of different fibers helps in selecting the right rope for specific environmental conditions. -

UV Resistance

Ultraviolet (UV) exposure can degrade materials over time, particularly synthetic fibers. Selecting ropes with UV-resistant properties is essential for outdoor applications to ensure longevity and performance, reducing the frequency of replacements.

What Are Common Trade Terms Used in Block Creel Construction?

Understanding industry jargon is crucial for effective communication and decision-making in the B2B marketplace. Here are several common terms associated with block creel construction:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of block creel construction, an OEM might provide specialized machinery or components for rope production. -

MOQ (Minimum Order Quantity)

MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding the MOQ is crucial for businesses to manage inventory and cash flow effectively, particularly when entering new markets. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and other details for specific products or services. This is a vital step in the procurement process, enabling buyers to compare offers and negotiate better terms. -

Incoterms (International Commercial Terms)

These are internationally recognized terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with Incoterms helps businesses understand shipping responsibilities, insurance, and risk management, crucial for international trade. -

Lead Time

This term refers to the time taken from placing an order to delivery. In the context of block creel construction, understanding lead times is essential for planning production schedules and meeting project deadlines. -

Certification Standards

These are industry-specific quality standards that products must meet to ensure safety and reliability. Knowing the relevant certification standards for block creel construction helps buyers ensure that the ropes they procure meet the necessary safety and performance criteria.

By grasping these technical properties and trade terminologies, international B2B buyers can make informed decisions regarding block creel construction, ensuring they select the right products for their specific needs and applications.

Navigating Market Dynamics and Sourcing Trends in the block creel construction Sector

What Are the Key Market Dynamics and Trends in Block Creel Construction?

The block creel construction sector is experiencing significant growth driven by several global factors. The increasing demand for high-quality, durable ropes in industries such as marine, construction, and rescue operations is a primary driver. Additionally, technological advancements in manufacturing processes are enabling more efficient production, which is appealing to international B2B buyers. Emerging markets in Africa, South America, the Middle East, and Europe are particularly significant, as local industries seek to enhance safety and operational efficiency.

One notable trend is the integration of digital technologies in sourcing and supply chain management. Companies are increasingly adopting e-procurement platforms that facilitate direct sourcing from manufacturers, reducing costs and improving transparency. This trend is particularly relevant for buyers in regions like Brazil and Vietnam, where direct access to suppliers can lead to better pricing and quality assurance. Furthermore, the rise of automation in manufacturing processes, including advanced robotics and AI, is expected to enhance production capabilities while maintaining high standards of quality.

How Is Sustainability and Ethical Sourcing Impacting the Block Creel Construction Sector?

Sustainability is becoming a central focus for the block creel construction sector, with environmental impact and ethical sourcing taking precedence among B2B buyers. The production of ropes often involves synthetic materials, which raise concerns about plastic pollution and resource depletion. As a result, buyers are increasingly prioritizing suppliers that adopt sustainable practices, such as using recycled materials or innovative bio-based alternatives.

Ethical supply chains are crucial for maintaining brand integrity and consumer trust. International buyers are now looking for suppliers with certifications that attest to their commitment to sustainable practices. Green certifications, such as ISO 14001 for environmental management systems, are increasingly sought after. Moreover, the use of eco-friendly materials in block creel construction, such as organic cotton or biodegradable fibers, is gaining traction. This shift not only meets regulatory requirements but also aligns with the growing consumer preference for environmentally responsible products.

What Is the Evolution of Block Creel Construction and Its Relevance Today?

Block creel construction has evolved significantly since its inception, primarily driven by technological advancements and changing market demands. Initially developed as a method to produce strong, continuous strands of rope without knots or splices, this technique has seen improvements in efficiency and quality over the years. Early applications were mostly limited to the marine and agricultural sectors, where durability was paramount.

Today, the relevance of block creel construction spans multiple industries, including construction, safety, and rescue operations. The emphasis on safety standards has propelled the demand for high-strength ropes that can withstand extreme conditions. Additionally, as industries continue to modernize, block creel construction remains a preferred method due to its ability to produce reliable and consistent rope products, reinforcing its importance in the global marketplace. This historical context is vital for B2B buyers seeking to understand the strengths and applications of block creel construction in today’s dynamic market.

Frequently Asked Questions (FAQs) for B2B Buyers of block creel construction

-

How do I ensure the quality of block creel construction ropes?

To guarantee the quality of block creel construction ropes, it’s essential to conduct thorough supplier vetting. Look for manufacturers with certifications such as ISO 9001, which demonstrates a commitment to quality management systems. Request samples for testing, and consider third-party quality assurance inspections. Establishing a clear quality assurance process, including regular audits and compliance checks, will help maintain standards throughout the production and delivery phases. -

What are the advantages of block creel construction over traditional rope manufacturing methods?

Block creel construction offers significant advantages, including the elimination of knots and splices, which can weaken the rope. This method produces a continuous strand, enhancing strength and durability. Additionally, the manufacturing process allows for greater consistency in diameter and performance characteristics, making block creel ropes ideal for demanding applications in various industries, such as marine, construction, and rescue operations. -

What is the minimum order quantity (MOQ) for block creel construction ropes?

Minimum order quantities (MOQs) for block creel construction ropes can vary significantly by supplier and the specific materials used. Typically, MOQs range from 100 to 1,000 meters, depending on the manufacturer’s capabilities and production efficiencies. When negotiating with suppliers, clarify the MOQ upfront and explore options for smaller initial orders, especially if you are testing the market or seeking customized products. -

What customization options are available for block creel construction ropes?

Many manufacturers offer customization options for block creel construction ropes, including variations in diameter, color, and material composition. You can request specific tensile strength requirements or incorporate additional features such as UV resistance or enhanced abrasion resistance. Engaging with suppliers early in the design process will help ensure that your specific needs are met, resulting in a product that aligns with your operational requirements. -

What payment terms should I expect when sourcing block creel construction ropes internationally?

Payment terms for international orders of block creel construction ropes typically include options such as advance payment, letters of credit, or net 30 to 90 days after delivery. It’s crucial to establish clear terms upfront to avoid misunderstandings. Many suppliers may require a deposit prior to production, with the balance payable upon shipment. Be sure to discuss and negotiate terms that are mutually beneficial while also considering the risks associated with international trade. -

How can I efficiently manage logistics for importing block creel construction ropes?

Efficient logistics management is critical for importing block creel construction ropes. Engage with freight forwarders who specialize in your destination region, as they can provide insights on the best shipping routes and methods. Ensure that all customs documentation is prepared in advance to avoid delays. Additionally, consider using a reliable tracking system to monitor shipments and communicate proactively with suppliers about any potential issues during transit. -

What are the best practices for vetting suppliers of block creel construction ropes?

When vetting suppliers, prioritize those with a proven track record in the industry. Request references and case studies from previous clients to gauge reliability and quality. Evaluate their production capacity and technology used in block creel construction, and verify compliance with international standards. Additionally, visiting the manufacturing facility, if possible, can provide valuable insights into their operations and quality assurance processes. -

How do I handle disputes with suppliers of block creel construction ropes?

Handling disputes with suppliers requires a structured approach. Start by documenting all communications and agreements related to the order. If issues arise, communicate directly with the supplier to discuss the problem and seek a resolution amicably. If necessary, refer to any contracts or terms of service to understand your rights and obligations. For unresolved disputes, consider mediation or arbitration as a means of reaching a solution while minimizing costs and maintaining business relationships.

Top 6 Block Creel Construction Manufacturers & Suppliers List

1. Rope Inc – Premium Ropes & Accessories

Domain: ropeinc.com

Registered: 2001 (24 years)

Introduction: Ropes and Cordage: 3 Strand Nylon, Double Braid Nylon, 8-Strand Nylon, Mega Braid, 12 Strand Double Braid Polyester, High Performance Line, AmSteel® Blue, 12 Strand Purple Plasma Rope, Manila Rope. Accessories: Shackles, Tylaska Snap Shackles, Chafe Gear, Anchor Chain, Mighty Tow, Dyneema Soft Shackles. Applications & Industries: Mega Yachts, Pleasure Marine, Commercial Marine, Military & Governme…

2. Wound About – Rope Terminology and Fiber Types

Domain: woundabout.com

Registered: 2000 (25 years)

Introduction: Rope Terminology includes various types of braids such as Diamond Braid, Double Braid, Flat Braid/Tubular Braid, Hollow Braid, Smooth Braid, Solid Braid, and Twisted Fibers. It also covers different fiber types including Cotton, Mono-Filament Polyethylene, Mono-Filament Polypropylene, Multi-Filament Polypropylene, Nylon, Polyester, Specialty Fibers, and Spun Polyester (SPstr). The terminology sect…

3. Studocu – Block Creel Construction for Synthetic Fiber Ropes

Domain: studocu.com

Registered: 2013 (12 years)

Introduction: Block creel construction is specifically designed for synthetic fiber ropes, enhancing performance and durability. It allows for better load distribution and reduces damage risk, making it ideal for applications requiring strength and reliability. Key features include continuous fibers running the entire length of the rope, eliminating weak points like knots or splices. Synthetic fiber ropes offer…

4. Ravenox – Fiber Rope Terminology

Domain: ravenox.com

Registered: 2017 (8 years)

Introduction: Terminology for Fiber Rope includes definitions and explanations of various terms related to fiber ropes, such as ABACA FIBER, ABRASION RESISTANCE, ACCESSORY CORD, ARAMID FIBER, BRAID patterns (Diamond, Double, Hollow, Plain, Single, Solid, Twill), BREAKING FORCE, BREAKING STRENGTH, and more. These terms are essential for clear communication among industry members, engineers, and consumers. The do…

5. CMC – Lifeline Rope

Domain: cmcpro.com

Registered: 2012 (13 years)

Introduction: {“product_name”: “CMC Lifeline”, “material”: “100% nylon kernmantle”, “features”: [“optimum balance of strength, handling, and durability”, “minimum sheath slippage”, “excellent knotability”, “high level of control with descent control device”], “certification”: “UL Classified to NFPA 1983 Standard on Life Safety Rope and Equipment for Emergency Services, 2017 Edition”, “construction”: “Block cree…

6. Pelican – 1/2 Inch Kernmantle Braided Rope (100-ft)

Domain: gmesupply.com

Registered: 2004 (21 years)

Introduction: {“product_name”: “Pelican Rope Rope (1/2 Inch) Kernmantle Braided (100-ft)”, “model_number”: “PL-2WP-162-01”, “price”: “$160.99”, “length”: “100 feet”, “diameter”: “1/2 inch”, “construction”: “Static Kernmantle Braided”, “color”: “Red/White”, “approval”: “UL Approved to NFPA Specifications”, “features”: [“Polyester cover over a Nylon core”, “Resistance to most chemicals”, “Excellent retention in e…

Strategic Sourcing Conclusion and Outlook for block creel construction

As the global demand for high-quality rope products continues to rise, the strategic sourcing of block creel construction emerges as a pivotal factor for international B2B buyers. This innovative manufacturing method, which ensures a continuous strand of fiber without knots or splices, not only enhances the durability and performance of ropes but also reduces production inefficiencies. Buyers in regions such as Africa, South America, the Middle East, and Europe must prioritize partnerships with suppliers who can deliver these advanced materials, ensuring they meet the growing standards of safety and reliability.

By leveraging strategic sourcing, businesses can optimize their supply chains, reduce costs, and enhance product offerings. Additionally, understanding the nuances of block creel construction can provide a competitive edge in markets that increasingly value quality and innovation.

Looking ahead, the potential for expansion in emerging markets like Brazil and Vietnam presents significant opportunities for collaboration and growth. International buyers are encouraged to seek out suppliers who not only understand the technical aspects of block creel construction but are also committed to sustainable practices. Engaging with these suppliers will position your business favorably in a dynamic marketplace, ensuring you remain at the forefront of industry advancements.

Illustrative image related to block creel construction

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.