How to Source Blade Bracket Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for blade bracket

In today’s competitive landscape, sourcing high-quality blade brackets can be a significant challenge for international B2B buyers, especially those operating across diverse regions such as Africa, South America, the Middle East, and Europe. With the need for durable, aesthetically pleasing, and versatile solutions that cater to various applications—from retail signage to ceiling fan components—understanding the nuances of the global market for blade brackets is crucial. This guide provides a comprehensive overview of blade bracket types, their applications, and the critical factors to consider when evaluating suppliers.

As you navigate this complex market, you will find detailed insights on how to vet potential suppliers, ensuring you partner with reliable manufacturers who meet your specific needs. Additionally, we delve into cost considerations, helping you make informed decisions that align with your budget and quality requirements. Whether you are seeking standard brackets or custom solutions tailored to unique projects, this guide empowers you with the knowledge to enhance your purchasing strategy effectively.

By equipping yourself with the right information, you can streamline your sourcing process, mitigate risks, and ultimately enhance your operational efficiency. Join us as we explore the world of blade brackets, ensuring you make informed choices that drive your business forward in a globalized economy.

Understanding blade bracket Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Blade Bracket | Typically made of stainless steel, features a 2-hole design for easy installation. | Ideal for ceiling fans and lightweight signs. | Pros: Affordable, easy to install. Cons: Limited to lighter applications. |

| Decorative Blade Bracket | Crafted with ornate designs, often made from powder-coated steel for durability. | Retail storefronts, cafés, and boutiques. | Pros: Enhances aesthetic appeal. Cons: Higher cost, may not suit all branding. |

| Heavy-Duty Blade Bracket | Designed for larger and heavier signs, typically features reinforced support. | Commercial signage in high-traffic areas. | Pros: Excellent stability and durability. Cons: Bulkier, may require professional installation. |

| Adjustable Blade Bracket | Features a flexible design allowing for angle adjustments. | Wayfinding signage and dynamic displays. | Pros: Versatile for various signage angles. Cons: More complex installation. |

| Custom Blade Bracket | Tailored to specific needs, available in various sizes and finishes. | Unique signage projects requiring specific designs. | Pros: Perfect fit for branding needs. Cons: Longer lead times and potentially higher costs. |

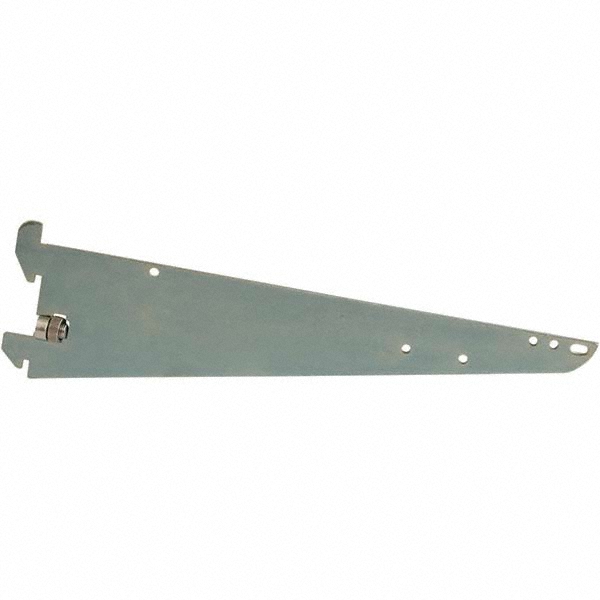

What are the Characteristics of Standard Blade Brackets?

Standard blade brackets are characterized by their straightforward, functional design, typically made from durable stainless steel. They often feature a 2-hole configuration, which simplifies installation, making them a popular choice for both ceiling fans and lightweight signage. B2B buyers looking for cost-effective solutions for less demanding applications will find these brackets appealing due to their affordability and ease of use.

Illustrative image related to blade bracket

How Do Decorative Blade Brackets Enhance Aesthetics?

Decorative blade brackets stand out for their ornate designs and finishes, often made from powder-coated steel to ensure longevity and resistance to weather elements. These brackets are particularly suitable for retail environments, cafés, and boutiques where visual appeal is paramount. While they enhance the aesthetic value of a storefront, buyers should consider the higher costs associated with these stylish options compared to standard designs.

Why Choose Heavy-Duty Blade Brackets for Commercial Use?

Heavy-duty blade brackets are engineered to support larger and heavier signs, making them ideal for commercial applications in high-traffic areas. Their reinforced construction provides exceptional stability, which is crucial for ensuring signage remains secure in various conditions. While they are more robust and reliable, B2B buyers should be aware of their bulkier design and potential need for professional installation.

What Benefits Do Adjustable Blade Brackets Offer for Dynamic Signage?

Adjustable blade brackets feature a design that allows for angle adjustments, making them versatile for applications like wayfinding signage and dynamic displays. This adaptability can enhance visibility and engagement, particularly in environments where signage needs to be repositioned frequently. However, the more complex installation process may deter some buyers who prefer simpler solutions.

Illustrative image related to blade bracket

When Should B2B Buyers Consider Custom Blade Brackets?

Custom blade brackets are tailored to meet specific project requirements, available in various sizes and finishes to align with unique branding needs. These brackets are ideal for businesses with distinctive signage projects that require a perfect fit. While they provide a solution that meets precise specifications, buyers should consider the longer lead times and potentially higher costs associated with custom orders.

Key Industrial Applications of blade bracket

| Industry/Sector | Specific Application of blade bracket | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail | Mounting signage for storefronts | Increases visibility and foot traffic | Durability, weather resistance, and customization options |

| Hospitality | Displaying promotional signs for restaurants | Attracts customers and enhances brand image | Aesthetic design, material quality, and ease of installation |

| Transportation | Supporting signage on vehicles or trailers | Improves navigation and information dissemination | Compatibility with vehicle models and weather resistance |

| Construction & Architecture | Securing signage in commercial buildings | Aids in wayfinding and enhances user experience | Load capacity, material strength, and installation method |

| Home Improvement | Supporting ceiling fan blades | Ensures functionality and safety of ceiling fans | Compatibility with fan models and material durability |

How Are Blade Brackets Used in Retail Signage?

In the retail sector, blade brackets are essential for mounting signage that extends from storefronts, enhancing visibility to passersby. These brackets help attract foot traffic, crucial for businesses in competitive environments. Retailers must consider the durability and weather resistance of materials, particularly in regions with harsh climates. Customization options can also be a deciding factor, allowing businesses to align their signage with branding strategies while ensuring that the brackets can accommodate various sign sizes.

What Role Do Blade Brackets Play in the Hospitality Industry?

Within the hospitality industry, blade brackets are utilized to display promotional signage for restaurants, cafés, and hotels. These brackets not only serve a functional purpose but also contribute to the aesthetic appeal of the establishment, drawing in customers. For international buyers, especially in regions like Africa and South America, it’s important to source brackets that combine style with durability, as these signs are often exposed to outdoor elements. Additionally, ease of installation can be a critical factor for businesses looking to set up quickly and efficiently.

How Are Blade Brackets Essential for Transportation Signage?

In the transportation sector, blade brackets are vital for mounting signage on vehicles and trailers. They improve navigation and provide essential information to drivers and pedestrians alike. Buyers in this sector need to ensure that the brackets are compatible with specific vehicle models and can withstand varying weather conditions. The strength of the material is also crucial, as transportation signage must endure vibrations and impacts during transit without compromising visibility.

Why Are Blade Brackets Important in Construction and Architecture?

Blade brackets play a significant role in construction and architecture by securing signage in commercial buildings. They assist in wayfinding, guiding visitors through complex environments like malls or office buildings. For B2B buyers in this industry, key considerations include load capacity and material strength, as the brackets must support heavy signs without risk of failure. Understanding the installation methods is also essential to ensure compliance with local building codes and standards.

Illustrative image related to blade bracket

How Do Blade Brackets Contribute to Home Improvement Projects?

In home improvement applications, blade brackets are primarily used to support ceiling fan blades, ensuring that they operate safely and effectively. Buyers looking for these brackets should prioritize compatibility with various fan models and the durability of materials to withstand wear and tear. Additionally, buyers may seek aesthetically pleasing designs that match the decor of the home, making the sourcing of these components an important consideration for enhancing both functionality and style.

3 Common User Pain Points for ‘blade bracket’ & Their Solutions

Scenario 1: Difficulty in Sourcing Durable Blade Brackets for Outdoor Use

The Problem:

B2B buyers, particularly those in regions with harsh weather conditions such as parts of Africa and South America, often struggle to find blade brackets that can withstand extreme temperatures, moisture, and other environmental factors. These conditions can lead to rapid deterioration of inferior materials, resulting in costly replacements and operational downtime. Buyers may face the added challenge of identifying suppliers who understand these regional needs and can deliver quality products that stand the test of time.

The Solution:

To address this issue, buyers should prioritize sourcing blade brackets made from high-quality, weather-resistant materials such as powder-coated steel or stainless steel. When selecting a supplier, ensure they provide clear specifications regarding the material properties and weather resistance ratings of their products. Additionally, look for manufacturers that offer a warranty or guarantee on their products, which can serve as an assurance of durability. Engaging with suppliers that have a strong reputation and positive reviews from other businesses in similar climates can also enhance confidence in the quality of the blade brackets. Furthermore, consider custom options that can be tailored to specific environmental conditions to ensure maximum longevity.

Scenario 2: Challenges with Installation and Compatibility of Blade Brackets

The Problem:

Many B2B buyers experience difficulties during the installation of blade brackets, particularly when compatibility with existing signage or fixtures is a concern. This can be particularly true for businesses upgrading their signage systems or retrofitting new brackets into older buildings. The potential for mismatched sizes or designs can lead to delays, increased labor costs, and frustration among staff, ultimately affecting the business’s ability to present its brand effectively.

The Solution:

To mitigate installation challenges, it is crucial for buyers to conduct a thorough assessment of their existing signage and mounting requirements before purchasing blade brackets. Specifying the correct dimensions, weight capacity, and style that aligns with current signage can prevent compatibility issues. Collaborating with a supplier that offers a wide range of customizable options can also help ensure a perfect fit. Additionally, consider suppliers who provide comprehensive installation guides or services, as well as customer support to assist with any installation queries. This proactive approach can streamline the process and ensure that the installation is completed efficiently, minimizing disruption to business operations.

Scenario 3: Customization Limitations for Unique Branding Needs

The Problem:

In competitive markets, businesses often seek unique and eye-catching branding elements to attract customers. However, many standard blade brackets available in the market may not offer the necessary customization options to meet specific branding requirements. This limitation can hinder a company’s ability to stand out in crowded spaces, particularly in retail and hospitality sectors, where visual appeal is crucial for drawing foot traffic.

Illustrative image related to blade bracket

The Solution:

To overcome customization limitations, B2B buyers should seek suppliers who specialize in bespoke solutions for blade brackets. When discussing your project with potential vendors, clearly outline your branding vision, including dimensions, materials, colors, and any specific design elements you wish to incorporate. Suppliers who are willing to collaborate on custom designs can create tailored solutions that enhance your brand identity. It’s also beneficial to review previous custom projects completed by the supplier to gauge their capability and creativity. Investing in custom brackets can elevate your brand’s visibility and create a lasting impression on customers, ultimately driving sales and enhancing brand loyalty.

Strategic Material Selection Guide for blade bracket

What Are the Key Materials for Blade Brackets and Their Properties?

When selecting materials for blade brackets, it is essential to consider their properties, pros and cons, and how they align with specific applications. Here, we analyze four common materials: stainless steel, aluminum, powder-coated steel, and plastic composites.

Stainless Steel: The Durable Choice for Heavy-Duty Applications

Stainless steel is widely recognized for its exceptional strength and corrosion resistance. It can withstand high temperatures and pressures, making it suitable for various demanding environments. The key advantage of stainless steel is its durability, which translates to a longer lifespan for blade brackets, especially in outdoor settings where exposure to moisture and harsh weather is common.

However, stainless steel can be more expensive than other materials, which may deter cost-sensitive buyers. The manufacturing complexity is also higher, requiring specialized tools and processes. For international buyers, particularly in regions like Europe, compliance with standards such as ASTM and DIN is crucial, as these materials often meet stringent quality regulations.

Aluminum: Lightweight and Versatile

Aluminum is a lightweight alternative that offers good corrosion resistance and is easier to work with than stainless steel. Its lower weight makes it ideal for applications where reducing overall mass is a priority, such as in portable signage or temporary installations. Additionally, aluminum can be anodized or painted, providing aesthetic versatility.

On the downside, aluminum is not as strong as stainless steel, which may limit its use in heavy-duty applications. It is also more susceptible to deformation under high stress. For buyers in Africa and South America, the cost-effectiveness of aluminum can be appealing, but they should ensure that the material meets local standards for durability.

Powder-Coated Steel: A Balance of Strength and Aesthetics

Powder-coated steel combines the strength of steel with a protective coating that enhances its resistance to rust and corrosion. This makes it an excellent choice for outdoor applications where aesthetics and durability are both critical. The powder coating can be customized in various colors, allowing businesses to align their signage with branding.

The primary disadvantage of powder-coated steel is that the coating can chip or scratch, exposing the underlying steel to corrosion over time. Additionally, the manufacturing process can be more complex, affecting lead times. International buyers should consider the environmental regulations regarding coatings in their regions, as compliance with local standards is vital.

Plastic Composites: Cost-Effective and Lightweight

Plastic composites are increasingly being used in blade brackets due to their lightweight nature and resistance to corrosion. They are particularly suitable for low-stress applications and environments where moisture is a concern. The ease of manufacturing and lower costs make plastic composites an attractive option for budget-conscious buyers.

However, the primary limitation is their strength compared to metal options. In high-stress applications, plastic composites may not provide the necessary support. Buyers from the Middle East and Africa should assess the suitability of plastic composites against local climate conditions, ensuring they can withstand temperature fluctuations and UV exposure.

Illustrative image related to blade bracket

Summary Table of Material Selection for Blade Brackets

| Material | Typical Use Case for blade bracket | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Heavy-duty outdoor signage | Exceptional strength and corrosion resistance | Higher cost and manufacturing complexity | High |

| Aluminum | Portable signage and temporary displays | Lightweight and versatile | Lower strength and deformation risk | Medium |

| Powder-Coated Steel | Aesthetic outdoor signage | Strong and customizable with protective coating | Coating can chip, exposing steel to corrosion | Medium |

| Plastic Composites | Low-stress applications | Cost-effective and lightweight | Limited strength for high-stress applications | Low |

This guide provides a comprehensive overview of material options for blade brackets, helping international B2B buyers make informed decisions based on their specific needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for blade bracket

What Are the Key Stages in the Manufacturing Process of Blade Brackets?

The manufacturing of blade brackets involves several critical stages that ensure the final product meets the necessary specifications and quality standards. These stages typically include material preparation, forming, assembly, and finishing.

-

Material Preparation: The process begins with selecting the right materials, often high-grade stainless steel or powder-coated steel, known for their durability and resistance to environmental factors. Sheets or rods of these materials are cut to size using laser cutting or CNC machining, ensuring precision in dimensions.

-

Forming: In this stage, the cut materials are shaped into the desired bracket form. Techniques such as bending, stamping, or forging are employed, depending on the complexity of the design. Advanced machinery ensures that the forming process is efficient and consistent, minimizing waste and maximizing output.

-

Assembly: Once formed, the components are assembled. This may involve welding or riveting, depending on the bracket’s design. Each assembly is performed under strict guidelines to ensure structural integrity and reliability. Automated assembly lines are often used to enhance efficiency, particularly for bulk orders.

-

Finishing: The final stage involves surface treatment and finishing processes, such as powder coating or galvanization. This not only enhances the aesthetic appeal but also provides additional protection against corrosion and wear. Quality checks during this stage ensure that the finishing meets the specified standards.

How Is Quality Assurance Implemented in Blade Bracket Manufacturing?

Quality assurance (QA) is a fundamental aspect of the manufacturing process, particularly for B2B buyers who require reliable and durable products. Various international standards and industry-specific guidelines govern QA practices.

-

International Standards: Compliance with ISO 9001 is crucial, as it outlines the requirements for a quality management system. This certification ensures that manufacturers consistently produce products that meet customer and regulatory requirements. Other relevant standards may include CE marking for European markets and API standards for specific applications.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): This initial checkpoint involves inspecting raw materials before they enter the production process. Suppliers must provide material certifications to verify quality.

– In-Process Quality Control (IPQC): During manufacturing, regular inspections are conducted to ensure that each stage adheres to the established quality standards. This may include dimensional checks and visual inspections.

– Final Quality Control (FQC): Before shipping, the finished products undergo rigorous testing to confirm their compliance with specifications. This may include load testing, durability assessments, and surface inspections. -

Common Testing Methods: Various testing methods are employed to ensure product integrity. These may include tensile strength tests, corrosion resistance tests, and fatigue tests. Non-destructive testing (NDT) techniques such as ultrasonic testing may also be used to identify internal flaws without damaging the product.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control processes is essential to ensure product reliability.

-

Supplier Audits: Conducting on-site audits is one of the most effective ways to evaluate a supplier’s manufacturing processes and quality control measures. During these audits, buyers can assess compliance with international standards and the effectiveness of the supplier’s quality management system.

-

Quality Control Reports: Requesting detailed quality control reports can provide insights into a supplier’s QA processes. These reports should include results from IQC, IPQC, and FQC stages, highlighting any non-conformance issues and corrective actions taken.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the manufacturing processes and the quality of the finished products. These inspections can validate compliance with specified standards and provide additional assurance to buyers.

What Are the Quality Control and Certification Nuances for International Buyers?

Understanding the nuances of quality control and certification can be critical for B2B buyers, particularly in a global context. Different regions may have varying expectations regarding quality and certification.

-

Regional Standards: Buyers must be aware of the specific standards applicable in their regions. For instance, CE marking is essential for products sold within the European Union, while other regions may have local certifications. Understanding these requirements can prevent regulatory issues and ensure market access.

-

Cultural Considerations: Quality expectations may vary across cultures. For example, buyers in Germany may prioritize precision and durability, while those in Africa may focus more on cost-effectiveness and availability. Suppliers should be aware of these differences and tailor their quality assurance practices accordingly.

-

Documentation and Transparency: Clear documentation of the quality control processes and certifications is vital for building trust with international buyers. Suppliers should provide all necessary documentation, including material certifications, test reports, and compliance certificates, to facilitate smooth transactions.

In summary, a thorough understanding of the manufacturing processes and quality assurance practices is essential for B2B buyers seeking reliable blade brackets. By emphasizing quality control and compliance with international standards, manufacturers can better meet the needs of their diverse customer base.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘blade bracket’

When sourcing blade brackets for your business, a structured approach can significantly improve your procurement process. This guide outlines essential steps to help you make informed decisions, ensuring you find the right products that meet your operational needs.

1. Define Your Technical Specifications

Start by clearly outlining the technical specifications of the blade brackets you require. This includes dimensions, material preferences, load-bearing capacity, and intended application. By defining these parameters upfront, you can streamline your search and ensure compatibility with existing equipment or signage.

2. Research Potential Suppliers

Conduct thorough research to identify reputable suppliers. Look for companies that specialize in blade brackets and have a proven track record in your target markets, such as Africa, South America, the Middle East, and Europe. Pay attention to their product range, customer reviews, and industry reputation.

3. Evaluate Supplier Certifications

Before finalizing your supplier, verify their certifications and compliance with international quality standards. This step is critical, especially when sourcing from different regions, as it ensures that the products meet safety and quality benchmarks. Look for ISO certifications or industry-specific compliance documents.

4. Request Samples for Testing

Always request samples before placing bulk orders. Testing samples allows you to evaluate the quality and durability of the blade brackets firsthand. Consider factors such as ease of installation, finish quality, and overall sturdiness. This proactive measure can prevent costly mistakes down the line.

5. Understand Pricing and Payment Terms

Engage with suppliers to gain a clear understanding of their pricing structures and payment terms. Compare quotes from different suppliers to ensure you are getting competitive pricing. Additionally, clarify any shipping costs, potential discounts for bulk orders, and payment options, as these can significantly affect your total expenditure.

Illustrative image related to blade bracket

6. Assess Customization Options

If your project requires specific designs or sizes, inquire about customization options. Many suppliers offer tailored solutions to meet unique business needs, which can enhance your branding or functionality. Ensure that you understand the lead times and costs associated with custom orders.

7. Confirm After-Sales Support and Warranty

Before completing your order, confirm the after-sales support and warranty policies offered by the supplier. Reliable support can be invaluable in case of installation issues or product defects. A robust warranty can also provide peace of mind, protecting your investment in case of unforeseen problems.

By following these steps, you can effectively navigate the sourcing process for blade brackets, ensuring you select high-quality products that align with your business requirements.

Comprehensive Cost and Pricing Analysis for blade bracket Sourcing

Understanding the cost structure and pricing dynamics for blade bracket sourcing is essential for B2B buyers, especially in diverse international markets. This analysis breaks down the key cost components and influencers that can affect your purchasing decisions, along with actionable tips for maximizing value.

What Are the Key Cost Components in Blade Bracket Manufacturing?

-

Materials: The primary materials used in blade brackets include steel, aluminum, and various coatings (e.g., powder coating for weather resistance). The choice of material significantly influences the overall cost, with stainless steel typically commanding a higher price due to its durability and corrosion resistance.

-

Labor: Labor costs can vary widely based on the region and the complexity of the manufacturing process. In countries with lower labor costs, such as those in Southeast Asia, you may find more competitive pricing. However, consider the trade-off with quality assurance and production standards.

-

Manufacturing Overhead: This encompasses indirect costs such as utilities, rent, and equipment maintenance. Efficient manufacturing processes can help reduce overhead, impacting the final price of blade brackets.

-

Tooling: Initial tooling costs can be substantial, especially for custom or high-precision brackets. If your project requires unique designs or specifications, factor in these costs as they can significantly increase the price per unit.

-

Quality Control (QC): Implementing rigorous QC measures is essential to ensure product reliability. This process can add to the overall cost but is crucial for maintaining quality standards, particularly for international buyers who may require certifications.

-

Logistics: Shipping costs depend on the distance, mode of transport, and Incoterms used. Buyers should consider both freight and customs duties when calculating the total landed cost of products.

-

Margin: Suppliers typically add a margin to cover their risks and profit. Understanding the competitive landscape can help buyers gauge whether the margins are fair or negotiable.

How Do Price Influencers Affect Blade Bracket Costs?

-

Volume and Minimum Order Quantity (MOQ): Pricing is often tiered based on order size. Larger orders can benefit from economies of scale, reducing the cost per unit. Be sure to negotiate MOQs that align with your needs.

-

Specifications and Customization: Custom designs or specific dimensions can lead to increased costs. Ensure that your specifications are clear and explore whether standard options can meet your requirements.

-

Material Quality and Certifications: Higher-quality materials or certifications (e.g., ISO, CE) may elevate prices but can lead to long-term savings through durability and reduced failure rates.

-

Supplier Factors: Supplier reliability, reputation, and location can affect pricing. Building a strong relationship with suppliers can lead to better pricing and terms.

-

Incoterms: Understanding shipping terms is crucial. Ex-Works (EXW) pricing might look lower but can lead to higher costs for logistics and customs. Choose terms that offer clarity on responsibilities and costs.

What Negotiation Strategies Can Buyers Employ?

-

Total Cost of Ownership (TCO): Focus on the TCO rather than just the purchase price. Consider aspects like durability, maintenance, and replacement costs to make informed decisions.

-

Leverage Long-Term Relationships: Establishing a long-term partnership with suppliers can lead to better pricing and terms. Regular communication and feedback can enhance trust and collaboration.

-

Requesting Quotes: Solicit multiple quotes from suppliers to compare pricing structures and terms. This can provide leverage in negotiations and help identify the best value.

-

Be Informed About Pricing Nuances: Understand that international markets may have varying pricing norms. Familiarize yourself with local market conditions in regions like Africa, South America, the Middle East, and Europe, as these can influence negotiation strategies.

Conclusion

While indicative prices can serve as a reference point, actual costs will vary based on the specific circumstances of your purchase. By understanding the intricate cost structure and leveraging effective negotiation strategies, B2B buyers can make informed decisions that enhance their sourcing efficiency and overall value.

Alternatives Analysis: Comparing blade bracket With Other Solutions

Introduction to Alternative Solutions for Blade Brackets

In the realm of signage and structural support, blade brackets are a popular choice for their durability and aesthetic appeal. However, there are alternative solutions that may better suit specific business needs depending on various factors such as performance, cost, and ease of implementation. This analysis will compare blade brackets against two viable alternatives: traditional wall-mounted brackets and hanging sign systems. By examining these options, B2B buyers can make informed decisions tailored to their unique requirements.

Comparison Table

| Comparison Aspect | Blade Bracket | Traditional Wall-Mounted Bracket | Hanging Sign System |

|---|---|---|---|

| Performance | High visibility, sturdy support | Moderate visibility, stable | Excellent visibility, flexible |

| Cost | Moderate ($10 – $150) | Low ($5 – $50) | High ($100 – $300) |

| Ease of Implementation | Moderate (requires installation) | Easy (simple mounting) | Moderate (requires setup) |

| Maintenance | Low (durable materials) | Low (generally maintenance-free) | Moderate (occasional adjustments) |

| Best Use Case | Retail storefronts, cafes | Indoor signage, basic displays | Malls, exhibitions, events |

Detailed Breakdown of Alternatives

Traditional Wall-Mounted Brackets

Traditional wall-mounted brackets offer a straightforward approach to displaying signage. They are typically less expensive and easier to install than blade brackets. These brackets are ideal for indoor settings where visibility is not a primary concern. However, they may not provide the same level of aesthetic appeal or visibility as blade brackets, particularly in high-traffic areas. Their simplicity can be a drawback if a business aims to make a strong visual impact.

Illustrative image related to blade bracket

Hanging Sign Systems

Hanging sign systems are another alternative that excels in visibility, often used in settings like shopping malls and exhibitions. These systems allow for flexible positioning and can be designed to accommodate various sign sizes and styles. While they generally provide excellent visibility and can be quite striking, they come with a higher cost and may require more complex installation. Additionally, maintenance can be an issue, as hanging signs may need periodic adjustments or repairs due to environmental factors.

Conclusion: Choosing the Right Solution for Your Needs

When selecting between blade brackets and alternative solutions, B2B buyers should assess their specific needs, including budget, desired visibility, and installation capabilities. Blade brackets offer a balance of aesthetic appeal and durability, making them suitable for businesses focused on attracting foot traffic. In contrast, traditional wall-mounted brackets are best for budget-conscious projects with less emphasis on visibility, while hanging sign systems are ideal for high-impact environments despite their higher costs. By carefully evaluating these factors, buyers can choose the solution that aligns best with their operational goals and branding strategies.

Essential Technical Properties and Trade Terminology for blade bracket

What Are the Essential Technical Properties of Blade Brackets?

When evaluating blade brackets for commercial applications, understanding their technical specifications is crucial. Here are some key properties to consider:

-

Material Composition

Blade brackets are typically made from materials like stainless steel, aluminum, or powder-coated steel. Stainless steel offers corrosion resistance, making it suitable for outdoor use, while aluminum is lightweight and cost-effective. The choice of material impacts durability, weight capacity, and resistance to environmental factors. For B2B buyers, selecting the right material ensures longevity and reduces replacement costs. -

Load Capacity

This specification indicates the maximum weight a blade bracket can support. Load capacity varies based on design and material; for instance, heavy-duty brackets may support signs weighing over 100 pounds, while standard models might only support lighter signage. Understanding load capacity is essential for ensuring safety and compliance with local regulations, particularly in high-traffic areas. -

Mounting Style

Blade brackets can feature different mounting styles, such as fixed, swinging, or adjustable. Fixed brackets provide a secure hold for static signs, while swinging brackets allow for flexibility in positioning. Adjustable styles offer versatility for businesses that may change signage frequently. Choosing the appropriate mounting style can enhance visibility and adaptability for various marketing needs. -

Finish and Coating

The finish of a blade bracket, often powder-coated or galvanized, plays a significant role in its weather resistance and aesthetic appeal. A powder-coated finish not only protects against rust and corrosion but also allows for customization in color, which can align with a brand’s identity. For international buyers, selecting the right finish can help maintain the bracket’s appearance over time and in diverse climates. -

Dimensions and Tolerances

Blade brackets come in various sizes, accommodating sign blanks typically ranging from 24 inches to 48 inches. Tolerances indicate the acceptable variation in dimensions, ensuring a proper fit during installation. Accurate dimensions are vital for achieving the desired visual impact and ensuring compatibility with existing signage.

Which Trade Terminology Is Important for Blade Bracket Procurement?

Understanding industry jargon is equally important for making informed purchasing decisions. Here are some common terms:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce components that are later used in another company’s product. In the context of blade brackets, an OEM may manufacture brackets that are then sold under a different brand. For buyers, sourcing from an OEM can ensure product quality and compatibility with specific applications. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest number of units a supplier is willing to sell in a single order. This term is critical for B2B buyers, as it affects inventory levels and cash flow. Understanding MOQ helps businesses plan their purchases according to budget and demand. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specified products or services. For buyers, issuing an RFQ can lead to better pricing and terms, allowing for competitive sourcing of blade brackets. -

Incoterms (International Commercial Terms)

These are globally recognized terms that define the responsibilities of buyers and sellers in international trade. Understanding Incoterms helps clarify shipping arrangements, risk management, and cost responsibilities, which are crucial when importing blade brackets from different regions. -

Lead Time

This term refers to the time taken from placing an order to delivery. Lead time is essential for project planning, especially for businesses needing to coordinate signage installation with marketing campaigns or events. Knowing the lead time can help buyers manage expectations and schedules effectively.

By familiarizing themselves with these essential properties and trade terms, B2B buyers can make more informed decisions when sourcing blade brackets, ultimately enhancing their marketing and operational strategies.

Navigating Market Dynamics and Sourcing Trends in the blade bracket Sector

What Are the Key Market Dynamics and Sourcing Trends in the Blade Bracket Sector?

The blade bracket sector is witnessing transformative changes driven by globalization, technological advancements, and evolving consumer preferences. International B2B buyers, particularly from Africa, South America, the Middle East, and Europe, are increasingly influenced by a need for versatile and durable products. The demand for blade brackets that cater to both aesthetic and functional requirements is surging, with businesses seeking customizable solutions that enhance brand visibility.

One of the key trends is the integration of smart technology into sourcing processes. Digital platforms and marketplaces are streamlining procurement, allowing buyers to easily compare products, evaluate suppliers, and make informed purchasing decisions. Furthermore, the rise of e-commerce is reshaping how businesses approach inventory management and logistics, particularly in regions with developing infrastructure.

Illustrative image related to blade bracket

Sustainability is another critical driver in the blade bracket market. Buyers are not only focused on cost and quality but also on the environmental impact of their sourcing choices. This trend is particularly pronounced in Europe, where regulatory frameworks are pushing manufacturers towards greener practices. As a result, suppliers are increasingly highlighting their use of eco-friendly materials and processes, catering to a market that values ethical consumption.

How Can Businesses Ensure Sustainability and Ethical Sourcing in the Blade Bracket Sector?

The environmental impact of the blade bracket industry cannot be overlooked, especially as global awareness of sustainability rises. Manufacturers are now under pressure to adopt practices that minimize waste and reduce carbon footprints. Ethical sourcing has become a cornerstone of competitive advantage, with buyers looking for suppliers who demonstrate transparency in their supply chains.

Utilizing ‘green’ certifications such as ISO 14001 can significantly enhance a company’s credibility among B2B buyers. Materials such as recycled steel or sustainably sourced wood not only appeal to environmentally conscious consumers but also help businesses comply with regulatory standards. Moreover, investing in local suppliers can reduce transportation emissions, aligning with sustainability goals while also supporting regional economies.

In regions like Africa and South America, where resource management is crucial, ethical sourcing can also provide a pathway to sustainable development. By ensuring that sourcing practices are socially responsible, companies can build stronger relationships with local communities, enhancing their brand reputation and customer loyalty.

How Has the Blade Bracket Sector Evolved Over Time?

The evolution of the blade bracket sector reflects broader trends in manufacturing and consumer behavior. Initially designed purely for functionality, blade brackets have transformed into essential components of aesthetic branding, particularly in retail and hospitality sectors. As urban environments become more competitive, businesses recognize the importance of eye-catching signage, and thus, the demand for stylish blade brackets has surged.

Historically, blade brackets were crafted from basic materials with limited design options. However, advancements in manufacturing technologies have enabled the creation of diverse styles and materials, including powder-coated steel and aluminum, which offer enhanced durability and weather resistance. This evolution has not only expanded the market but has also encouraged innovation, leading to customized solutions that cater to specific business needs.

As we move forward, the blade bracket sector is poised for further growth, driven by technological advancements and a heightened focus on sustainability, making it a critical area for B2B buyers to consider.

Frequently Asked Questions (FAQs) for B2B Buyers of blade bracket

-

How do I choose the right blade bracket for my signage needs?

Choosing the right blade bracket involves considering the size, weight, and style of your signage. Look for brackets that can support the dimensions of your sign, typically ranging from 24” to 48”. Additionally, assess the bracket material; powder-coated steel offers durability and weather resistance, making it suitable for outdoor use. If you have specific design preferences, many suppliers offer customizable options that can match your brand aesthetics. Always consult with your supplier to ensure compatibility with your signage. -

What are the benefits of using powder-coated steel blade brackets?

Powder-coated steel blade brackets provide exceptional durability and resistance to rust and corrosion, making them ideal for outdoor applications in various climates. The coating enhances their aesthetic appeal and ensures long-lasting performance, reducing the need for frequent replacements. Additionally, these brackets can support a wide range of signage, from lightweight to heavy-duty, making them versatile for different business environments, such as retail stores, cafes, and office buildings. -

What customization options are available for blade brackets?

Many suppliers offer customization options for blade brackets, allowing you to tailor the size, finish, and design to fit your specific needs. Whether you require a unique shape to align with your brand’s visual identity or a specific color to match your storefront, inquire about custom capabilities with potential suppliers. Custom brackets can enhance the visual impact of your signage and ensure a perfect fit for your business. -

What is the minimum order quantity (MOQ) for blade brackets?

Minimum order quantities (MOQ) for blade brackets can vary significantly between suppliers. Some may have a low MOQ of just a few units, while others may require bulk orders of dozens or hundreds, particularly for custom designs. It’s essential to discuss MOQ with potential suppliers early in the sourcing process to align your purchasing needs with their capabilities, especially if you are entering new markets or launching a new product line. -

What payment terms should I expect when sourcing blade brackets internationally?

When sourcing blade brackets internationally, payment terms can vary based on the supplier and your business relationship. Common terms include payment in advance, partial payments upon order confirmation, or payment upon delivery. For larger orders, you may negotiate terms such as letters of credit or escrow services to protect both parties. Always clarify payment methods accepted (e.g., bank transfer, credit card) and ensure you understand any currency exchange implications. -

How can I ensure the quality of blade brackets from international suppliers?

To ensure quality, conduct thorough supplier vetting before placing an order. Request samples to assess the craftsmanship and materials used. Additionally, inquire about the supplier’s quality assurance processes and certifications. Establishing clear specifications and expectations in your purchase agreement can also help maintain quality standards. Consider third-party inspections or audits if you are sourcing from regions with varying manufacturing practices. -

What are the logistics considerations for importing blade brackets?

Logistics considerations include shipping methods, lead times, and customs regulations. Evaluate whether air or sea freight is more cost-effective based on your delivery timeline. Ensure your supplier provides necessary shipping documentation, including invoices and packing lists, to facilitate smooth customs clearance. It’s also advisable to work with a freight forwarder who can navigate international shipping complexities and ensure compliance with local regulations in your destination country. -

How do I handle potential delays or issues with my blade bracket order?

If you encounter delays or issues with your blade bracket order, promptly communicate with your supplier to identify the cause and explore solutions. Maintain a record of all correspondence and agreements to reference during discussions. Having a contingency plan, such as identifying alternate suppliers or adjusting delivery schedules, can help mitigate the impact of delays. Additionally, consider implementing a robust tracking system for your orders to stay informed throughout the shipping process.

Top 7 Blade Bracket Manufacturers & Suppliers List

1. StyleCraft – Standard 2-Hole Blade Bracket

Domain: stylecraftus.com

Registered: 2017 (8 years)

Introduction: {“name”:”Standard 2-Hole Blade Bracket”,”model”:”P-915″,”price”:”$10.95″,”sku”:”P-915″,”availability”:”In stock”,”features”:[“Fits StyleCraft and Gamma+ clipper models”,”Use with both click and floating levers”,”Quality and durable stainless-steel material”,”Easy to install 2-hole bracket, portable and functional”,”Clean with a damp cloth and wipe dry for the longest use”],”includes”:”1 standard 2…

2. Sign Bracket Store – Key Product

Domain: signbracketstore.com

Registered: 2008 (17 years)

Introduction: Key Product Details:

1. **Product Types:** Blade sign brackets designed for maximum visibility, extending perpendicularly from walls or posts.

2. **Material:** Crafted from powder-coated steel for durability and weather resistance.

3. **Size Accommodation:** Supports sign blanks ranging from 24″ to 48″.

4. **Styles Available:** Various styles including modern, traditional, and decorative designs.

…

3. Hunter – Blade Bracket Set-Fresh White

Domain: hunterfan.com

Registered: 1995 (30 years)

Introduction: {“product_name”: “Blade Bracket Set-Fresh White”, “product_code”: “K366803W42”, “price”: “30.00”, “currency”: “USD”, “availability”: “In Stock”, “shipping”: “Free shipping on orders over $199”, “description”: “This service part can be used on the following models: 59153, 59158”, “category”: “Service Parts”, “brand”: “Hunter Fan”, “image_url”: “https://www.hunterfan.com/cdn/shopifycloud/storefront/…

4. Slick Locks – PROMASTER Blade Bracket

Domain: slicklocks.com

Registered: 2009 (16 years)

Introduction: {“product_name”: “PROMASTER Blade Bracket – 2014-Present”, “sku”: “PM-FVK-SLIDE”, “original_price”: “$136.99”, “current_price”: “$136.99”, “included_items”: [“1 Back Door Left”, “1 Back Door Right”, “1 Slide Door”, “2 6 mm Allen Head Screws”], “description”: “Purchase Brackets only Kit! The kit includes side sliding and rear hinged door brackets.”}

5. Unbranded Ceiling Fan – Blade Bracket Replacement

Domain: diy.stackexchange.com

Registered: 2009 (16 years)

Introduction: The user has an unbranded ceiling fan with 4 blades. They broke a fan blade bracket and found that replacement brackets were listed by the dimensions between the mounting holes, but these dimensions were not standardized. The user experienced issues with the angle of attack of the fan blades after replacing the bracket, leading to wobbling at medium and high speeds. They replaced the broken bracke…

6. Reddit – Ceiling Fan Blade Bracket

7. MaxxAir – Blade Mounting Bracket for Ceiling Fans

Domain: mymaxxair.com

Registered: 2020 (5 years)

Introduction: {“product_name”:”Blade Mounting Bracket for 72 – 96 In. Ceiling Fans (ICF72/ICF88/ICF96)”,”sku”:”XXICFBLADEBRKT”,”price”:”$22.99″,”availability”:”Backordered”,”description”:”This bracket provides a secure placement for each blade to rest on and adds a more polished finish to your fan. Installed with the same 3 screws used by the blade and a standard Phillips screwdriver.”,”compatible_fan_models”:[…

Strategic Sourcing Conclusion and Outlook for blade bracket

In conclusion, the strategic sourcing of blade brackets is essential for businesses aiming to enhance their signage visibility and operational efficiency. Key takeaways from this guide highlight the importance of durability, customization, and the aesthetic appeal of blade brackets in attracting customer attention, particularly in retail and hospitality sectors. By investing in high-quality materials, such as powder-coated steel, companies can ensure longevity and performance, even in challenging weather conditions.

Furthermore, embracing custom solutions allows businesses to tailor their signage to specific branding needs, reinforcing their market presence. For international B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, this is an opportune moment to explore partnerships with reliable suppliers who offer innovative and sustainable solutions.

As the global marketplace continues to evolve, staying ahead of trends and investing in quality signage infrastructure will be crucial for competitive advantage. Engage with trusted manufacturers and distributors to secure the best options for your business needs, ensuring that your brand stands out in the increasingly crowded marketplace. Take the next step towards enhancing your visibility and operational success by exploring strategic sourcing opportunities today.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.