How to Source Best Chicken Cages Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for best chicken cages

Navigating the global market for the best chicken cages presents a unique challenge for international B2B buyers, particularly those in regions like Africa, South America, the Middle East, and Europe. Sourcing reliable, durable, and efficient chicken cages is crucial for ensuring the welfare of poultry while optimizing productivity and profitability. With a myriad of options available, from traditional coops to modern, high-tech enclosures, making the right choice can be daunting.

This comprehensive guide will delve into various types of chicken cages, their applications, and the critical factors to consider when selecting a supplier. We will explore essential aspects such as design features, space requirements, cost considerations, and the importance of ease of maintenance. Additionally, the guide will provide actionable insights on vetting suppliers to ensure quality and reliability, thereby facilitating informed purchasing decisions.

By equipping B2B buyers with the necessary knowledge and tools, this guide aims to simplify the decision-making process and enhance operational efficiency. Whether you are a poultry farmer looking to expand your business or a supplier seeking to meet the growing demand for poultry products, understanding the nuances of the chicken cage market is imperative. Together, we will navigate the complexities of sourcing the best chicken cages to support your poultry operations effectively.

Understanding best chicken cages Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Backyard Chicken Coop | Compact, often with integrated runs; designed for small flocks | Urban farming, small-scale egg production | Pros: Space-efficient, easy to maintain. Cons: Limited space for larger flocks. |

| Commercial Poultry House | Large-scale structures, often modular; designed for high-density housing | Large-scale egg production, meat production | Pros: Maximizes space, optimized for efficiency. Cons: Higher initial investment, requires more management. |

| Free-Range Chicken Run | Open area with shelter options; promotes natural behaviors | Organic farming, specialty egg production | Pros: Healthier chickens, better egg quality. Cons: Vulnerable to predators, requires larger land area. |

| Mobile Chicken Tractor | Movable enclosures that allow for rotational grazing | Small farms, sustainable practices | Pros: Promotes soil health, easy to relocate. Cons: Limited space for large flocks. |

| Specialty Breeder Cages | Designed for specific breeds or purposes; can include climate control | Breeding programs, exotic birds | Pros: Tailored environments for specific needs. Cons: More expensive, less versatility. |

What Are the Characteristics of Backyard Chicken Coops?

Backyard chicken coops are designed for urban and suburban settings, accommodating small flocks of chickens. Typically compact, these structures often come with integrated runs and are built for easy access and maintenance. When considering a purchase, B2B buyers should evaluate the coop’s construction quality, ventilation, and ease of cleaning. They are ideal for small-scale egg production and are particularly popular among urban farmers looking to supplement their food sources.

How Do Commercial Poultry Houses Maximize Production?

Commercial poultry houses are expansive, modular structures designed to house a high density of birds for egg or meat production. Their robust design often incorporates automated systems for feeding, watering, and waste management, optimizing efficiency and reducing labor costs. B2B buyers should consider factors like scalability, biosecurity features, and compliance with local regulations. These houses are suited for large-scale operations needing to meet significant market demand.

Why Choose Free-Range Chicken Runs for Poultry Farming?

Free-range chicken runs provide chickens with access to outdoor spaces while ensuring shelter from the elements. This type of setup promotes natural behaviors, leading to healthier birds and better-quality eggs. B2B buyers must assess the land requirements and predator protection measures when considering this option. While free-range systems can be more labor-intensive and require a larger area, they appeal to consumers seeking organic and ethically sourced products.

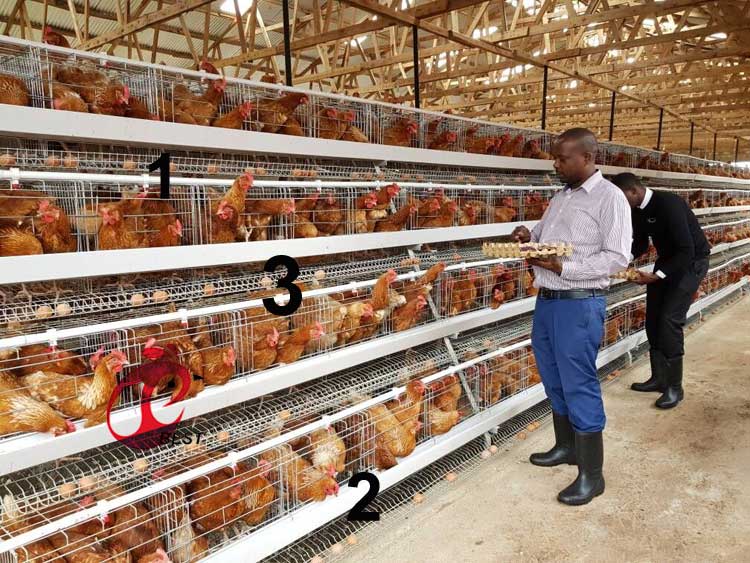

Illustrative image related to best chicken cages

What Are the Benefits of Mobile Chicken Tractors?

Mobile chicken tractors are portable enclosures that allow for rotational grazing, benefiting both the chickens and the land. This design encourages natural foraging behaviors and soil rejuvenation, making it an excellent choice for sustainable farming practices. Buyers should consider the size of the tractor and the number of birds it can accommodate. While these tractors are ideal for small farms, they may not be suitable for larger operations due to space constraints.

How Do Specialty Breeder Cages Cater to Specific Needs?

Specialty breeder cages are tailored for specific poultry breeds or purposes, often including climate control features to ensure optimal conditions. These cages are essential for breeding programs and for those raising exotic birds. B2B buyers should focus on the specific needs of the breeds they intend to house, including space, temperature control, and socialization requirements. While they offer specialized benefits, these cages can be more costly and less versatile than standard options.

Key Industrial Applications of best chicken cages

| Industry/Sector | Specific Application of best chicken cages | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Poultry Farming | Commercial egg production using large-scale chicken cages | Maximizes egg yield and operational efficiency | Durability, ease of cleaning, and predator-proof features |

| Organic Farming | Free-range chicken systems integrated with mobile cages | Enhances organic certification and sustainability practices | Compliance with organic standards and mobility features |

| Urban Agriculture | Chicken coops for urban farms and community gardens | Promotes local food production and community engagement | Space efficiency, design aesthetics, and ease of access |

| Veterinary Services | Temporary housing for sick or recovering chickens | Facilitates better animal care and recovery environments | Hygiene, ventilation, and ease of monitoring |

| Educational Institutions | Chicken coops for agricultural education programs | Provides hands-on learning experiences for students | Safety, accessibility, and educational value |

How Are Best Chicken Cages Utilized in Poultry Farming?

In the poultry farming industry, best chicken cages are predominantly used for commercial egg production. These cages are designed to maximize space and ensure optimal living conditions for chickens, which leads to increased egg yield. For international B2B buyers, particularly in regions like Africa and South America, sourcing durable cages that are easy to clean and maintain is critical. These features not only enhance operational efficiency but also reduce labor costs associated with maintenance and hygiene.

Illustrative image related to best chicken cages

What Role Do Best Chicken Cages Play in Organic Farming?

In organic farming, mobile chicken cages are essential for integrating free-range systems. These cages allow farmers to rotate their chickens across different areas, enhancing soil health and promoting sustainable practices. For buyers in the Middle East and Europe, compliance with organic certification standards is paramount. Thus, sourcing cages that are both functional and capable of meeting these regulations ensures that businesses can successfully market their products as organic.

How Are Best Chicken Cages Beneficial for Urban Agriculture?

Urban agriculture has seen a rise in the use of chicken coops, particularly in community gardens. Best chicken cages designed for urban settings help maximize space while promoting local food production. For B2B buyers in densely populated areas, such as cities in Germany or Vietnam, the design must focus on aesthetics and functionality. These cages should be easy to access and maintain, facilitating community engagement and educational opportunities.

How Do Best Chicken Cages Support Veterinary Services?

Veterinary services utilize best chicken cages for the temporary housing of sick or recovering chickens. These cages are designed to provide a safe and comfortable environment, which is crucial for the recovery of the birds. Buyers in this sector must prioritize hygiene and ventilation to prevent the spread of diseases. Sourcing cages with these features is essential for ensuring the health and safety of the chickens under care.

Illustrative image related to best chicken cages

What Educational Benefits Do Best Chicken Cages Provide?

Educational institutions leverage best chicken cages in agricultural programs to provide hands-on learning experiences for students. These cages allow students to engage in practical poultry management, enhancing their understanding of animal husbandry. For international buyers, safety and accessibility are key considerations. Cages should be designed to facilitate easy access for students while ensuring the welfare of the animals, thus creating a valuable educational resource.

3 Common User Pain Points for ‘best chicken cages’ & Their Solutions

Scenario 1: Inadequate Space and Comfort for Chickens

The Problem: A common issue faced by B2B buyers, particularly those operating in regions with diverse climates like Africa or South America, is selecting chicken cages that do not provide sufficient space for the flock. Many suppliers may offer standard models without considering the specific needs of larger breeds or varying chicken sizes. This can lead to overcrowding, causing stress among the birds, increased competition for resources, and lower egg production. Buyers may feel overwhelmed by the variety of options and uncertain about how to assess the right fit for their specific needs.

The Solution: To address this problem, buyers should prioritize chicken cages that comply with space guidelines—aiming for at least 2-3 square feet of floor space per chicken within the coop and a minimum of 10 square feet in the run. When sourcing these cages, conduct a thorough evaluation of the specifications provided by manufacturers. Look for modular designs that can be easily expanded as the flock grows. Additionally, consider cages with adjustable features such as removable dividers or customizable run extensions to accommodate fluctuating flock sizes. Engaging directly with suppliers to discuss your specific requirements can also lead to tailored solutions that ensure optimal comfort and productivity for your chickens.

Scenario 2: Vulnerability to Predators

The Problem: In many regions, especially those with diverse wildlife like the Middle East or parts of Europe, predator attacks on chicken coops can be devastating. B2B buyers often find themselves purchasing cages that appear secure but are inadequately designed to fend off common threats such as raccoons, foxes, or birds of prey. This vulnerability can lead to substantial financial losses, not only from the loss of livestock but also from the resulting need to replace compromised cages.

Illustrative image related to best chicken cages

The Solution: To mitigate predator risks, buyers should invest in chicken cages specifically designed with reinforced security features. Look for products that incorporate heavy-duty materials such as galvanized steel mesh, sturdy locking mechanisms, and burrowing prevention measures like underground wire extensions. It’s also advisable to conduct regular assessments of the coop’s integrity and to implement additional security measures such as motion-activated lights or surveillance cameras. Collaborating with suppliers who offer predator-proof kits or designs can further enhance safety, allowing for peace of mind and a more sustainable poultry operation.

Scenario 3: Difficulty in Maintenance and Cleaning

The Problem: B2B buyers often encounter chicken cages that are challenging to clean and maintain, leading to increased labor costs and potential health issues for the flock. This is particularly pressing for operations in humid climates, where inadequate ventilation can exacerbate the accumulation of waste and moisture, creating an environment conducive to disease. Buyers may struggle to find solutions that offer both functionality and ease of upkeep, leading to frustration and inefficiencies in their operations.

The Solution: Buyers should prioritize chicken cages that feature easy-clean designs, such as removable trays for droppings and surfaces that allow for quick sanitization. Look for coops with elevated floors and sloped roofs to facilitate drainage and prevent water accumulation. Additionally, consider sourcing cages with built-in ventilation systems to enhance air circulation and reduce humidity. Engaging with suppliers who offer modular designs can also enable more straightforward maintenance by allowing sections of the coop to be cleaned or replaced without disrupting the entire structure. Implementing a regular maintenance schedule with dedicated cleaning tools will ensure that the coop remains sanitary, thus promoting the health and productivity of the chickens.

Illustrative image related to best chicken cages

Strategic Material Selection Guide for best chicken cages

When selecting materials for chicken cages, it is essential to consider their properties, advantages, and disadvantages. This analysis will focus on four common materials used in the construction of chicken cages: wood, galvanized steel, plastic, and aluminum. Each material has unique characteristics that can significantly influence performance, durability, and suitability for various environments.

What Are the Key Properties of Wood in Chicken Cages?

Wood is a traditional choice for chicken coops, valued for its natural insulation properties and aesthetic appeal. Key properties include good thermal insulation, which helps maintain a stable internal temperature, and ease of customization. However, wood is susceptible to moisture, pests, and rot, requiring regular maintenance and treatment with preservatives.

Pros & Cons: The primary advantage of wood is its natural insulation and ease of construction. It is relatively low-cost and readily available in many regions. However, the disadvantages include its susceptibility to decay and the need for regular maintenance, which can increase long-term costs.

Illustrative image related to best chicken cages

Impact on Application: Wood is compatible with various bedding materials and provides a comfortable environment for chickens. However, its durability can be compromised in humid or wet climates, making it less suitable for regions with high rainfall.

Considerations for International Buyers: Buyers should ensure that the wood used complies with local regulations regarding chemical treatments. For instance, in Europe, adherence to the EU Timber Regulation is crucial.

How Does Galvanized Steel Perform in Chicken Cages?

Galvanized steel is a popular choice due to its strength and corrosion resistance. This material can withstand harsh environmental conditions and is less prone to damage from pests. Its key properties include high tensile strength and a protective zinc coating that prevents rust.

Pros & Cons: The main advantage of galvanized steel is its durability and low maintenance needs. It is suitable for various climates and provides excellent security against predators. However, it can be more expensive than wood, and the manufacturing process is more complex, which may lead to higher initial costs.

Impact on Application: Galvanized steel is ideal for outdoor chicken runs and cages, as it can endure exposure to moisture and temperature fluctuations. Its robustness ensures a long lifespan, making it a cost-effective option in the long run.

Illustrative image related to best chicken cages

Considerations for International Buyers: Compliance with standards such as ASTM A123 for hot-dip galvanized coatings is essential. Buyers should also consider the availability of galvanized steel in their region, as supply chains may vary.

What Are the Advantages of Using Plastic in Chicken Cages?

Plastic, particularly high-density polyethylene (HDPE), is becoming increasingly popular for chicken cages due to its lightweight and waterproof properties. Key properties include excellent resistance to corrosion and UV radiation, making it suitable for outdoor use.

Pros & Cons: The advantages of plastic include its lightweight nature, ease of cleaning, and resistance to rot and pests. However, it may not provide the same level of insulation as wood and can be less durable in extreme conditions.

Illustrative image related to best chicken cages

Impact on Application: Plastic is compatible with various cleaning agents and can be easily sanitized, which is crucial for maintaining hygiene in chicken farming. Its water-resistant properties make it suitable for humid environments.

Considerations for International Buyers: Buyers should look for plastics that meet food safety standards, such as FDA compliance in the U.S. or equivalent standards in Europe. Additionally, understanding local recycling regulations for plastic materials is important.

Why Choose Aluminum for Chicken Cages?

Aluminum is another viable material for chicken cages, known for its lightweight and corrosion-resistant properties. Key properties include a high strength-to-weight ratio and excellent resistance to the elements.

Pros & Cons: The primary advantage of aluminum is its durability and low maintenance requirements. It is resistant to rust and can withstand various environmental conditions. However, aluminum can be more expensive than other materials, and its thermal conductivity may require additional insulation in colder climates.

Illustrative image related to best chicken cages

Impact on Application: Aluminum is suitable for both indoor and outdoor applications, providing a safe and secure environment for chickens. Its lightweight nature allows for easy relocation of cages if necessary.

Considerations for International Buyers: Buyers should ensure that aluminum products comply with relevant standards, such as DIN EN 573 for aluminum alloys in Europe. Understanding the local market for aluminum products is also essential for cost management.

Summary Table

| Material | Typical Use Case for best chicken cages | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Wood | Traditional coops and nesting boxes | Natural insulation and aesthetics | Susceptible to rot and pests | Low |

| Galvanized Steel | Outdoor runs and predator-proof cages | High durability and low maintenance | Higher initial cost | Med |

| Plastic | Lightweight portable coops | Easy to clean and waterproof | Less insulation and durability | Med |

| Aluminum | Both indoor and outdoor cages | Lightweight and corrosion-resistant | Higher cost and thermal conductivity | High |

This strategic material selection guide provides B2B buyers with insights into the properties, advantages, and limitations of various materials used in chicken cage construction. Understanding these factors will enable informed purchasing decisions that align with specific operational needs and regional conditions.

In-depth Look: Manufacturing Processes and Quality Assurance for best chicken cages

What Are the Key Stages in the Manufacturing Process of Quality Chicken Cages?

The manufacturing of high-quality chicken cages involves several distinct stages, each critical to ensuring durability, functionality, and safety for poultry. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

1. Material Preparation: What Materials Are Used and Why?

The first step in the manufacturing process is material preparation. High-quality chicken cages are typically made from galvanized steel, stainless steel, or durable plastic. Galvanized steel is favored for its corrosion resistance, while stainless steel offers enhanced durability and hygiene, crucial for livestock environments.

During this phase, raw materials undergo inspection to ensure they meet specified criteria, such as tensile strength and resistance to rust. Suppliers often source materials that comply with international standards, providing an added layer of quality assurance.

2. Forming: How Are Chicken Cages Shaped?

The forming stage involves shaping the materials into the required components of the chicken cage. This is usually achieved through techniques such as welding, bending, and cutting. Advanced technologies like laser cutting and CNC (Computer Numerical Control) machining are often employed to achieve precise dimensions and improve efficiency.

Illustrative image related to best chicken cages

Utilizing automated machinery minimizes human error and enhances consistency across production batches. This is particularly important for B2B buyers who require uniformity in large orders.

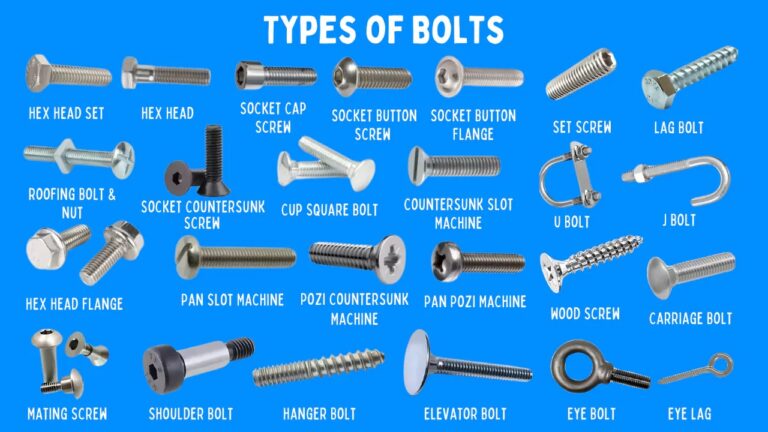

3. Assembly: What Are the Assembly Techniques?

Once the individual components are formed, they are assembled into the final product. Assembly can be manual or automated, depending on the scale of production. Key techniques include:

- Welding: Used for joining metal parts, ensuring structural integrity and durability.

- Fastening: Utilizes bolts and screws for easy assembly and disassembly, which is beneficial for maintenance.

- Modular Design: Many modern chicken cages are designed to be modular, allowing for easy expansion or reconfiguration based on the buyer’s needs.

During this stage, manufacturers often implement jigs and fixtures to maintain alignment and quality throughout the assembly process.

Illustrative image related to best chicken cages

4. Finishing: How Is the Final Product Treated?

The finishing stage is crucial for enhancing the longevity and aesthetic appeal of chicken cages. Common finishing techniques include:

- Powder Coating: Provides a protective layer against rust and scratches while allowing for color customization.

- Galvanization: A process that coats steel with zinc to prevent corrosion, making it suitable for outdoor use.

- Quality Checks: Before the product leaves the factory, it undergoes visual inspections and testing to ensure it meets the required specifications.

What Quality Control Measures Are Essential for Chicken Cage Manufacturing?

Quality control (QC) is an integral part of the manufacturing process, ensuring that the final product meets both safety and performance standards. International and industry-specific standards are essential for B2B buyers to consider.

Understanding International Standards: How Do They Apply?

For chicken cage manufacturers, compliance with international standards such as ISO 9001 is critical. This standard focuses on quality management systems and helps ensure that products consistently meet customer and regulatory requirements. Additionally, certifications like CE mark (Conformité Européenne) indicate compliance with European health, safety, and environmental protection standards.

What Are the Key QC Checkpoints?

Quality control is often divided into several checkpoints throughout the manufacturing process:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet specified quality criteria.

- In-Process Quality Control (IPQC): Ongoing inspections during manufacturing help identify defects early, reducing waste and rework.

- Final Quality Control (FQC): The finished product undergoes rigorous testing and inspection before shipment. This includes dimensional checks, load testing, and surface quality assessments.

What Testing Methods Are Commonly Used in Chicken Cage Production?

Testing methods vary depending on the materials used and the intended application of the chicken cages. Common testing methods include:

- Tensile Strength Testing: Assesses the strength of materials to ensure they can withstand the weight and stress from chickens and environmental factors.

- Corrosion Resistance Testing: Simulates environmental conditions to evaluate how materials hold up against rust and decay.

- Safety Testing: Ensures that all edges are smooth and that there are no sharp points that could harm the animals or handlers.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, particularly those from Africa, South America, the Middle East, and Europe, verifying the quality control measures of suppliers is essential. Here are some strategies:

- Supplier Audits: Conduct regular audits to assess compliance with quality standards and manufacturing processes. This can be done by the buyer’s quality assurance team or through third-party services.

- Requesting Quality Reports: Suppliers should provide documentation that outlines their quality control processes, including any certifications they hold.

- Third-Party Inspections: Engaging third-party inspection agencies can provide an unbiased assessment of the supplier’s quality assurance measures.

What Are the Unique QC Considerations for International B2B Buyers?

International B2B buyers should be aware of specific nuances in quality control that may vary by region. For example:

Illustrative image related to best chicken cages

- Regulatory Compliance: Different countries have varying regulations regarding animal housing standards. Ensuring that suppliers comply with local regulations is crucial for buyers.

- Cultural Considerations: Understanding local manufacturing practices and quality expectations can help buyers effectively communicate their needs and expectations.

- Logistics and Supply Chain Management: Ensure that the QC processes are robust enough to handle the complexities of international shipping, including customs checks and potential delays.

By understanding the manufacturing processes and quality assurance measures in the production of chicken cages, B2B buyers can make informed decisions that align with their operational needs and compliance requirements. Investing time in verifying supplier capabilities will ultimately lead to better outcomes in poultry management and production efficiency.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘best chicken cages’

Introduction

This practical sourcing guide serves as a comprehensive checklist for B2B buyers looking to procure the best chicken cages. Whether you are establishing a poultry farm or enhancing an existing operation, understanding the critical elements of cage selection will ensure you make informed decisions that align with your business needs and goals.

Step 1: Define Your Technical Specifications

Begin by outlining the specific requirements for your chicken cages. Consider the type of chickens you will be housing, the number of birds, and their growth stages.

– Space Requirements: Ensure you adhere to industry standards, allowing at least 2-3 square feet per chicken in the coop.

– Ventilation Needs: Identify the necessary airflow and lighting conditions to promote the health and productivity of your flock.

Step 2: Research and Compare Suppliers

Conduct thorough research to identify potential suppliers who specialize in chicken cages. Look for those with a proven track record in the poultry industry.

– Supplier Reputation: Read reviews and testimonials from other B2B buyers to gauge reliability and service quality.

– Product Variety: Ensure the supplier offers a range of cage designs to accommodate different needs, such as free-range or battery cages.

Illustrative image related to best chicken cages

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region.

– Certifications: Verify that suppliers hold relevant certifications that meet both local and international standards for animal welfare and safety.

– Production Capacity: Assess whether the supplier can meet your order quantity and delivery timelines.

Step 4: Assess Durability and Quality

Inspect the materials and construction quality of the chicken cages. A durable cage is essential for the long-term welfare of your birds and the protection of your investment.

– Material Standards: Look for cages made from rust-resistant materials, such as galvanized steel, which can withstand harsh environmental conditions.

– Design Features: Ensure that the cages have features like easy access for cleaning, proper nesting boxes, and secure locking mechanisms to prevent predator intrusion.

Step 5: Confirm Maintenance and Cleaning Ease

Evaluate how easy the cages are to clean and maintain, as this is critical for preventing disease and ensuring optimal hygiene.

– Cleaning Features: Cages with removable trays or easy-access panels can significantly reduce cleaning time and effort.

– Hygiene Protocols: Inquire about recommended cleaning protocols and products to maintain the cages effectively.

Step 6: Understand Warranty and Support Policies

Review the warranty and customer support options offered by the supplier. A solid warranty can protect your investment and provide peace of mind.

– Warranty Length: Look for warranties that cover defects in materials and workmanship for an extended period.

– Support Availability: Ensure that the supplier offers responsive customer service for troubleshooting and maintenance inquiries.

Step 7: Finalize Your Purchase Agreement

Once you have selected a supplier and confirmed all details, finalize your purchase agreement. This should include pricing, delivery schedules, and payment terms.

– Transparent Terms: Ensure all terms are clearly outlined to avoid any misunderstandings.

– Delivery Logistics: Discuss logistics to ensure timely delivery and setup of the cages on your premises.

By following this checklist, B2B buyers can confidently source the best chicken cages that meet their operational needs while ensuring the health and safety of their poultry.

Illustrative image related to best chicken cages

Comprehensive Cost and Pricing Analysis for best chicken cages Sourcing

What Are the Key Cost Components in Sourcing Chicken Cages?

When assessing the cost structure for sourcing chicken cages, several components come into play. The primary cost factors include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

-

Materials: The choice of materials significantly influences costs. Higher-quality, durable materials like galvanized steel or treated wood may have a higher initial cost but can lead to lower maintenance and replacement costs over time.

-

Labor: Labor costs can vary based on the region of production. Countries with lower labor costs may offer more competitive pricing, but this can sometimes come at the expense of quality.

-

Manufacturing Overhead: This includes costs associated with utilities, facility maintenance, and equipment. Efficient manufacturing processes can help lower these overhead costs.

-

Tooling: The cost of tools and machinery needed to produce the cages can be substantial, particularly for custom designs.

-

Quality Control (QC): Investing in rigorous QC processes ensures that the products meet industry standards, which can prevent costly returns and enhance customer satisfaction.

-

Logistics: Transportation and handling costs can vary widely depending on distance and shipping methods. International shipping may involve additional tariffs and duties.

-

Margin: Suppliers typically add a profit margin that reflects the risk and investment involved in producing and delivering the product.

How Do Price Influencers Affect the Cost of Chicken Cages?

Several factors can influence the pricing of chicken cages, particularly for B2B buyers operating on an international scale.

-

Volume/MOQ: Larger orders often lead to lower per-unit prices. Understanding a supplier’s minimum order quantity (MOQ) can help buyers negotiate better pricing.

-

Specifications and Customization: Customized cages tailored to specific needs can increase costs. Buyers should balance the need for customization with budget constraints.

-

Materials and Quality Certifications: Cages made from higher-quality materials or those that have received certifications (e.g., organic or humane treatment standards) generally command higher prices.

-

Supplier Factors: The reputation and reliability of a supplier can impact costs. Established suppliers may charge more but can also provide better quality assurance and service.

-

Incoterms: Understanding the terms of trade (e.g., FOB, CIF) is critical. These terms define who is responsible for shipping, insurance, and tariffs, affecting the total cost.

What Buyer Tips Can Help Optimize Cost-Efficiency When Sourcing Chicken Cages?

For B2B buyers, especially those in Africa, South America, the Middle East, and Europe, optimizing costs while sourcing chicken cages requires strategic approaches.

-

Negotiation Strategies: Engage in open discussions with suppliers about pricing and terms. Establishing a good relationship can lead to better deals and potential discounts.

-

Total Cost of Ownership (TCO): Consider not just the upfront costs, but also the long-term costs associated with maintenance, durability, and energy efficiency. A slightly higher initial investment may pay off in lower operational costs.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and taxes that can affect the final price. It’s advisable to factor in these elements during the budgeting process.

-

Research and Compare Suppliers: Take the time to evaluate multiple suppliers. Request quotes and assess them not only on price but also on quality, delivery times, and after-sales support.

Conclusion: What Should Buyers Keep in Mind?

When sourcing chicken cages, understanding the intricate cost components and pricing influencers is essential for making informed purchasing decisions. By leveraging negotiation tactics, considering the total cost of ownership, and being cognizant of international pricing nuances, buyers can optimize their sourcing strategies effectively.

Illustrative image related to best chicken cages

Disclaimer: Prices for chicken cages can vary widely based on the factors discussed. The figures provided are indicative and should be verified with suppliers for accurate quotes.

Alternatives Analysis: Comparing best chicken cages With Other Solutions

Exploring Alternatives to Best Chicken Cages for Poultry Management

In the realm of poultry management, selecting the appropriate housing solution for chickens is critical. While ‘best chicken cages’ are a popular choice for their specific benefits, there are viable alternatives that can cater to different operational needs and preferences. This section compares traditional chicken cages with mobile chicken coops and free-range systems, highlighting their respective strengths and weaknesses.

| Comparison Aspect | Best Chicken Cages | Mobile Chicken Coops | Free-Range Systems |

|---|---|---|---|

| Performance | Excellent for space-saving; ideal for small flocks | Provides flexibility and access to fresh pasture | Promotes natural behaviors; high productivity |

| Cost | Moderate initial investment; durable | Higher upfront costs; requires maintenance | Variable cost; depends on land and infrastructure |

| Ease of Implementation | Easy to set up; minimal requirements | Requires planning for movement and setup | Needs more land and fencing; management intensive |

| Maintenance | Moderate; includes regular cleaning and inspections | Higher maintenance due to mobility; cleaning can be easier | High maintenance; requires monitoring and protection |

| Best Use Case | Ideal for urban environments and small farms | Suitable for pasture-based systems and small to medium flocks | Best for large-scale operations prioritizing animal welfare |

What Are the Advantages and Disadvantages of Mobile Chicken Coops?

Mobile chicken coops, often referred to as chicken tractors, provide a unique solution for poultry management. These coops are designed to be easily relocated, allowing chickens access to fresh grass and insects. The main advantages include the ability to provide natural foraging opportunities, which can enhance the health and egg production of the flock. However, they require a higher initial investment and ongoing maintenance to ensure the coops are moved regularly and kept clean. This approach is best suited for farms looking to integrate sustainable practices while maintaining a flexible housing option.

How Do Free-Range Systems Compare to Best Chicken Cages?

Free-range systems allow chickens to roam freely in a designated area, which can lead to improved animal welfare and productivity. These systems encourage natural behaviors, such as foraging and nesting, which can result in healthier birds and higher-quality eggs. However, the challenges include the need for larger plots of land, significant investment in fencing and security measures to protect against predators, and increased management requirements. This method is ideal for larger operations that prioritize animal welfare and have the resources to maintain such a system.

How Should B2B Buyers Choose the Right Poultry Housing Solution?

When selecting the right poultry housing solution, B2B buyers should consider their operational goals, budget, and available resources. Best chicken cages are suitable for urban or small-scale operations where space is limited. Mobile chicken coops offer flexibility and a balance between traditional and free-range systems, making them ideal for pasture-based farming. Conversely, free-range systems are best for larger farms focused on animal welfare and sustainability. Ultimately, the decision should align with the buyer’s specific needs, ensuring the chosen solution supports both the well-being of the chickens and the operational goals of the farm.

Essential Technical Properties and Trade Terminology for best chicken cages

What Are the Key Technical Properties to Consider for Chicken Cages?

When selecting chicken cages, understanding the technical specifications is essential for ensuring the longevity and effectiveness of the investment. Here are some critical properties to consider:

1. Material Grade

The material used in constructing chicken cages significantly impacts durability and safety. Common materials include galvanized steel, treated wood, and high-density polyethylene (HDPE). Galvanized steel is preferred for its rust resistance and strength, making it ideal for outdoor use. The choice of material affects not only the cage’s lifespan but also its ability to withstand harsh environmental conditions, which is crucial for buyers in regions with extreme weather.

2. Tolerance Levels

Tolerance refers to the allowable deviation from specified dimensions in the cage’s construction. Precise tolerances ensure that components fit together correctly, reducing the risk of structural failure and enhancing safety. For B2B buyers, understanding tolerance levels helps in assessing the quality of workmanship and the suitability of cages for specific needs, such as accommodating larger breeds of chickens.

Illustrative image related to best chicken cages

3. Ventilation Specifications

Adequate ventilation is vital for maintaining the health of the chickens. Cages should be designed with adjustable vents or mesh panels that allow for airflow while keeping predators out. B2B buyers should prioritize cages that offer customizable ventilation options to adapt to varying climates, ensuring the well-being of the livestock.

4. Cleaning Accessibility

Cages should be designed for easy cleaning and maintenance to prevent disease. Features like removable trays, hinged roofs, and smooth surfaces facilitate quick sanitation processes. For businesses, this translates to lower labor costs and improved hygiene standards, which are particularly important in commercial poultry operations.

5. Load-Bearing Capacity

The load-bearing capacity indicates the weight a cage can support without compromising its integrity. This is especially critical for larger breeds or when housing multiple chickens. Ensuring that the cages meet or exceed the necessary load-bearing specifications will prevent structural failures and enhance long-term usability.

What Are Common Trade Terms Used in the Chicken Cage Industry?

Familiarity with trade terminology is vital for effective communication and negotiation in the B2B market. Here are some key terms:

1. OEM (Original Equipment Manufacturer)

An OEM refers to a company that produces parts or equipment that may be marketed by another manufacturer. In the chicken cage industry, understanding OEM relationships can help buyers identify quality standards and brand reliability, ensuring they are purchasing from reputable sources.

Illustrative image related to best chicken cages

2. MOQ (Minimum Order Quantity)

MOQ denotes the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for B2B buyers as it affects inventory management and financial planning. It allows businesses to understand their purchasing power and negotiate better terms with suppliers.

3. RFQ (Request for Quotation)

An RFQ is a document sent by buyers to potential suppliers requesting pricing and terms for specific products. It is an essential step in the procurement process, enabling buyers to compare offers and make informed purchasing decisions based on cost, quality, and delivery timelines.

4. Incoterms (International Commercial Terms)

Incoterms are a set of international rules that define the responsibilities of buyers and sellers in the shipping process. Familiarity with Incoterms helps B2B buyers understand who is responsible for shipping costs, insurance, and risk during transportation, which is crucial for managing logistics and ensuring timely delivery.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. Understanding lead times is essential for effective planning in poultry operations, particularly when scaling production or responding to market demands.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when selecting chicken cages, ensuring that they meet their operational needs and maintain high standards of animal welfare.

Navigating Market Dynamics and Sourcing Trends in the best chicken cages Sector

What Are the Current Market Dynamics and Key Trends in the Best Chicken Cages Sector?

The global market for chicken cages is experiencing significant growth, driven by increasing poultry consumption, the rise of backyard farming, and a growing demand for sustainable agricultural practices. In regions like Africa and South America, the push for food security is prompting investments in poultry farming, leading to a surge in demand for quality chicken cages. In Europe and the Middle East, there is a noticeable trend towards higher welfare standards, influencing the design and functionality of chicken housing solutions.

Emerging technologies such as IoT-based monitoring systems are becoming more prevalent, allowing farmers to track environmental conditions and flock health in real-time. This technological integration not only optimizes production but also enhances biosecurity measures. Furthermore, the trend of modular and scalable cage designs is gaining traction, enabling farmers to expand operations with ease. International buyers are increasingly seeking suppliers that can provide innovative solutions that align with their specific needs, whether for small-scale operations or large commercial farms.

How Does Sustainability and Ethical Sourcing Impact the Best Chicken Cages Market?

Sustainability and ethical sourcing have become critical considerations for international B2B buyers in the chicken cages sector. The environmental impact of poultry farming practices is under scrutiny, and suppliers are being urged to adopt eco-friendly materials and processes. This includes the use of recycled materials for cage construction, non-toxic finishes, and energy-efficient designs that minimize resource consumption.

Moreover, ethical supply chains are essential for building trust with consumers who are increasingly aware of animal welfare issues. Certifications such as the Global Animal Partnership (GAP) and organic farming standards are gaining importance, as they demonstrate a commitment to humane treatment of livestock and environmentally responsible practices. By choosing suppliers who prioritize sustainability, international buyers can enhance their brand reputation and meet the growing consumer demand for ethically sourced products.

What Is the Brief Evolution and History of Chicken Cages Relevant to B2B Buyers?

The evolution of chicken cages has been shaped by changing agricultural practices and consumer demands over the decades. Historically, chickens were often kept in simple enclosures or free-range setups, which offered limited protection from predators and environmental factors. The mid-20th century saw the introduction of battery cages, which maximized space but raised serious ethical concerns regarding animal welfare.

In response to these issues, the late 20th and early 21st centuries marked a shift towards more humane housing solutions. Modern chicken cages now emphasize comfort, safety, and ease of maintenance, with designs that incorporate features such as proper ventilation, nesting areas, and predator-proofing. This evolution reflects a broader trend in agriculture towards sustainability and responsible farming, making it essential for B2B buyers to consider not only the functionality of the products but also their impact on animal welfare and the environment. As the market continues to evolve, staying informed about these changes will be crucial for buyers seeking to align with best practices in poultry farming.

Frequently Asked Questions (FAQs) for B2B Buyers of best chicken cages

-

How do I choose the best chicken cage for my needs?

When selecting a chicken cage, consider factors like size, material, ventilation, and predator protection. Assess your flock size to ensure adequate space—generally, 2-3 square feet per chicken inside the coop and at least 10 square feet in a run is recommended. Look for cages made from durable materials that can withstand local weather conditions. Additionally, ensure the design allows for easy cleaning and maintenance, which is crucial for the health of your flock. -

What is the best material for chicken cages?

The best materials for chicken cages include galvanized steel, treated wood, and high-quality plastic. Galvanized steel offers durability and resistance to rust, making it ideal for outdoor conditions. Treated wood provides a natural aesthetic but requires regular maintenance to prevent rot. High-quality plastic is lightweight and easy to clean, but it may not offer the same level of predator protection. Choose materials based on your specific environmental conditions and budget. -

How can I ensure my chicken cage is predator-proof?

To ensure your chicken cage is predator-proof, use heavy-duty materials and secure hardware. Reinforce weak points with additional fencing or wire mesh, particularly around the base to prevent digging. Consider adding motion-activated lights and alarms to deter predators. Regularly inspect the cage for any signs of wear or damage, and make necessary repairs promptly. Implementing these measures will enhance the safety of your flock. -

What are the typical payment terms for purchasing chicken cages internationally?

Payment terms for international purchases of chicken cages can vary by supplier but generally include options like advance payment, partial payment upon order confirmation, and the balance before shipment. It is common to use secure payment methods such as letters of credit or escrow services to protect both parties. Always clarify payment terms upfront and ensure they are documented in the purchase agreement to avoid any misunderstandings. -

What is the minimum order quantity (MOQ) for chicken cages?

The minimum order quantity (MOQ) for chicken cages typically depends on the supplier and the type of cages being ordered. Some suppliers may have a MOQ of 10-50 units, while others may allow smaller orders for custom designs. When sourcing from manufacturers, inquire about bulk discounts as larger orders often lead to better pricing. Understanding the MOQ will help you plan your procurement strategy effectively. -

How do I vet suppliers when sourcing chicken cages internationally?

To vet suppliers, start by checking their credentials, including business licenses and certifications related to quality standards. Request references from previous clients and assess their reputation in the industry through online reviews and ratings. Conduct video calls or visits to their facilities if possible, and ask about their production processes, lead times, and after-sales support. This due diligence will help ensure that you partner with a reliable and reputable supplier. -

What customization options should I consider for chicken cages?

Customization options for chicken cages can include size adjustments, additional features like nesting boxes, ventilation systems, and insulation for temperature control. Some manufacturers may offer branding options, allowing you to add your company logo. Discuss your specific needs with potential suppliers to understand what customization services they provide. Tailoring the cage to your requirements can enhance functionality and improve the welfare of your chickens. -

What logistics considerations should I be aware of when importing chicken cages?

When importing chicken cages, consider logistics aspects such as shipping methods, lead times, and customs regulations in your country. Choose a reliable freight forwarder experienced in handling agricultural equipment to navigate the complexities of international shipping. Be aware of import duties, taxes, and any necessary documentation required for customs clearance. Planning these logistics in advance will help ensure a smooth import process and timely delivery of your cages.

Top 6 Best Chicken Cages Manufacturers & Suppliers List

1. Chicken Coop Company – Key Products

Domain: chickencoopcompany.com

Registered: 2015 (10 years)

Introduction: Key Product Details:

1. **Leghorn Cottage Chicken Coop**

– Capacity: 4+ Chickens

– Price: $549.99 (Sale Price: $599.99)

– Status: In Stock

2. **Orpington Lodge Chicken Coop with Run**

– Capacity: 6+ Chickens

– Price: $999.99 (Sale Price: $1,099.00)

– Status: In Stock

3. **Rhode Island Homestead Coop with Run Extension**

– Capacity: 10+ Chickens

– Price: $1,599.00 (Sale P…

2. Omlet – Eglu Coop

Domain: thedomesticwildflower.com

Introduction: The Omlet Eglu Coop is easy to clean and move, elevated off the ground for chicken safety, features a removable tray for simple cleaning, and has heavy-duty non-porous plastic for easy maintenance. The coop includes a separate door for checking eggs, an automatic door option, and wheels for easy movement. The run is strong, assembled without power tools, and includes a wire skirt to prevent predat…

3. Reddit – Automated Chicken Coop System

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: Custom chicken coop based on “Carolina coop” style, 100% automated features including: Wifi enabled, app controlled, automatic coop door and run door, temperature sensing, automatic 55-gallon water heater for temperatures below 32F, automatic feed dispenser with daily portion control setting in app. Maintenance requires filling the feed hopper every 2 weeks and the water tank monthly.

4. Hatching Time – 15 Chicken Cages

Domain: hatchingtime.com

Registered: 2019 (6 years)

Introduction: 15″ Chicken Cages designed for compact and efficient poultry housing. Ideal for small flocks, backyard chickens, and breeding operations. Features include easy-to-clean trays, rust-resistant materials, and proper ventilation. Suitable for layers, broilers, and chicks. Available in multiple layers: 1 Layer ($249.99), 2 Layer ($399.99), 3 Layer ($524.99), 4 Layer ($629.99), and Layer Addition ($199….

5. Backyard Chickens – Affordable Coop Solutions

Domain: backyardchickens.com

Registered: 2000 (25 years)

Introduction: Coop for up to 4 full-sized hens, ideally with an attached run, budget under $500. Prefab coops are considered flimsy and susceptible to cold and predators. Alternatives suggested include modifying a storage shed or using a dog kennel as a run. Recommendations include looking for local carpenters to build a coop based on plans available online. A 5′ x 4′ steel shed is mentioned as an option for $1…

6. Nestera – Recycled Plastic Chicken Coops

Domain: bushcraftuk.com

Registered: 2003 (22 years)

Introduction: Nestera chicken coops, UK made from 100% recycled plastic, fully recyclable at end of life, robust construction, 25 year warranty, discount code available.

Strategic Sourcing Conclusion and Outlook for best chicken cages

In conclusion, the strategic sourcing of chicken cages is pivotal for enhancing poultry productivity and ensuring the welfare of your flock. Key considerations include durability, predator protection, ease of maintenance, and adequate ventilation—elements that are critical for fostering a healthy environment for chickens. As international B2B buyers, particularly from regions such as Africa, South America, the Middle East, and Europe, investing in high-quality chicken cages not only supports your operational efficiency but also contributes to the sustainable practices that are increasingly demanded in today’s market.

With the poultry industry continuing to evolve, now is the time to align your sourcing strategies with suppliers who prioritize quality and innovation. By doing so, you can ensure that your investment yields both immediate benefits and long-term returns.

As you look to the future, consider how your sourcing decisions today will shape your competitive advantage tomorrow. Engage with reputable suppliers, explore diverse options, and harness the benefits of strategic sourcing to elevate your poultry operations. Your commitment to quality and sustainability will resonate throughout your supply chain, paving the way for success in a dynamic marketplace.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.