How to Source Barber Spring Company Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for barber spring company

In the dynamic landscape of global manufacturing, sourcing high-quality springs can pose significant challenges for B2B buyers, particularly when navigating the complexities of international markets. For those looking to procure from a reputable barber spring company, understanding the variety of spring types and their specific applications is crucial. This guide serves as an essential resource for international buyers from regions such as Africa, South America, the Middle East, and Europe—including major markets like Brazil and Saudi Arabia—who seek to make informed purchasing decisions.

Throughout this comprehensive guide, we delve into the diverse types of springs, including coil, compression, extension, and torsion springs, along with their respective applications across various industries. We provide insights into the supplier vetting process, helping buyers identify reliable manufacturers that can meet their unique specifications. Additionally, we explore cost considerations, delivery timelines, and customization options that can enhance product performance and align with specific project requirements.

By equipping buyers with the knowledge and tools necessary to navigate the global market, this guide empowers them to establish strong partnerships with barber spring manufacturers. With a focus on innovation, quality, and customer service, buyers can confidently source the right products that not only fulfill their operational needs but also drive their business success.

Understanding barber spring company Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

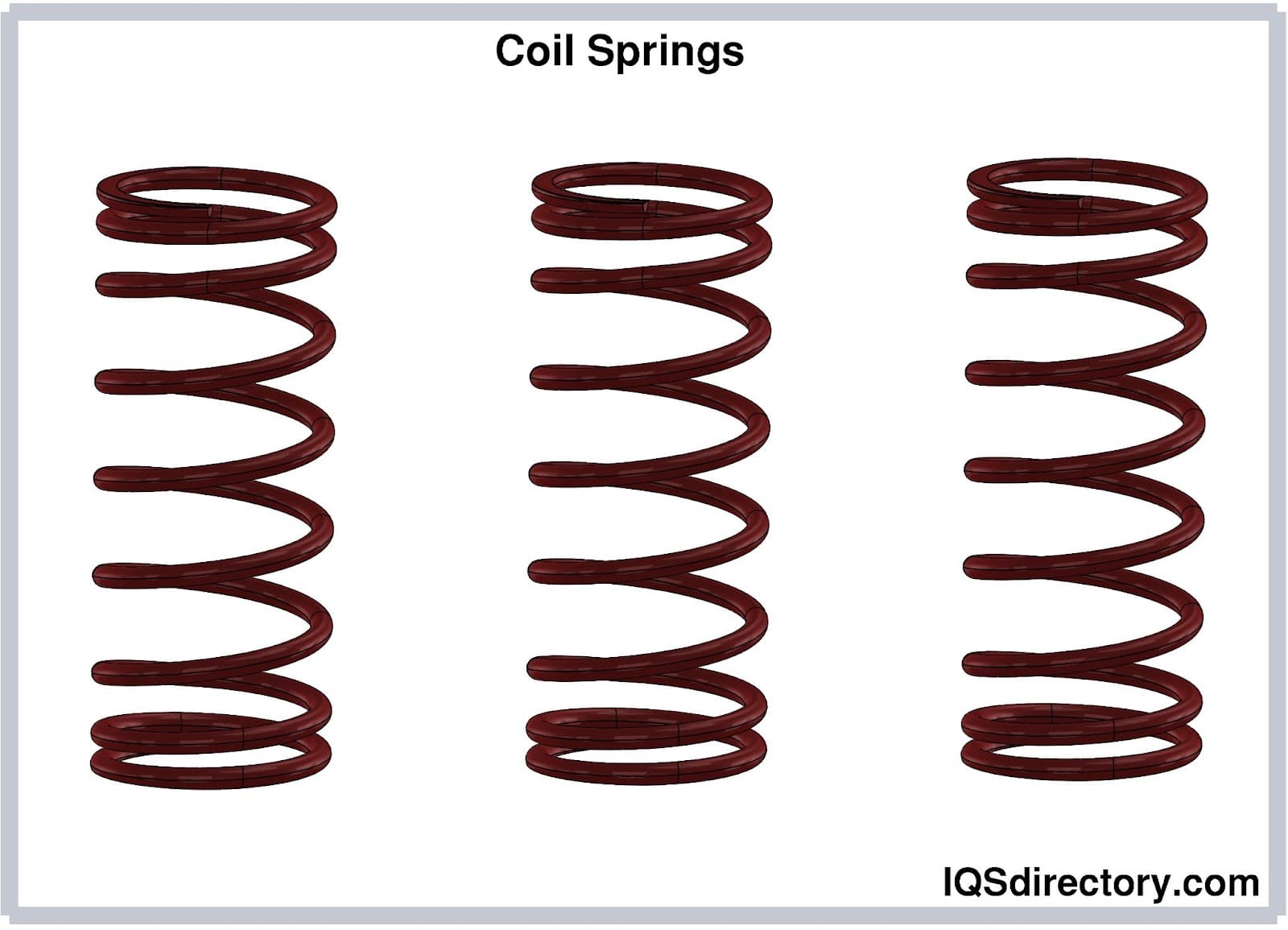

| Coil Springs | Made from round wire, available in various diameters, designed for compression and extension. | Automotive, aerospace, machinery | Pros: Versatile, customizable; Cons: Limited load capacity compared to other types. |

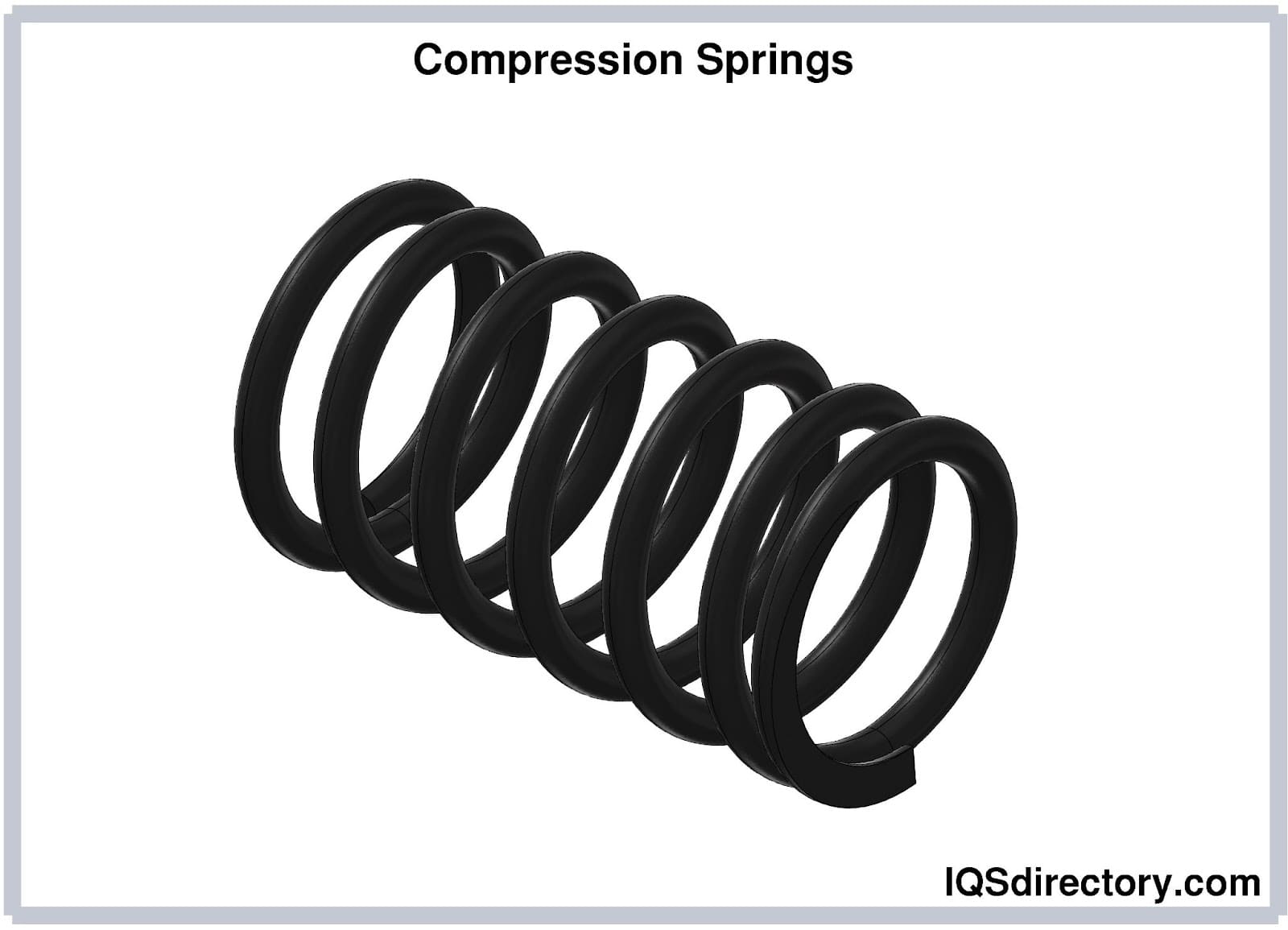

| Compression Springs | Open-coiled design that provides resistance when compressed, storing mechanical energy. | Industrial machinery, automotive parts | Pros: Excellent energy storage; Cons: Performance can degrade under excessive load. |

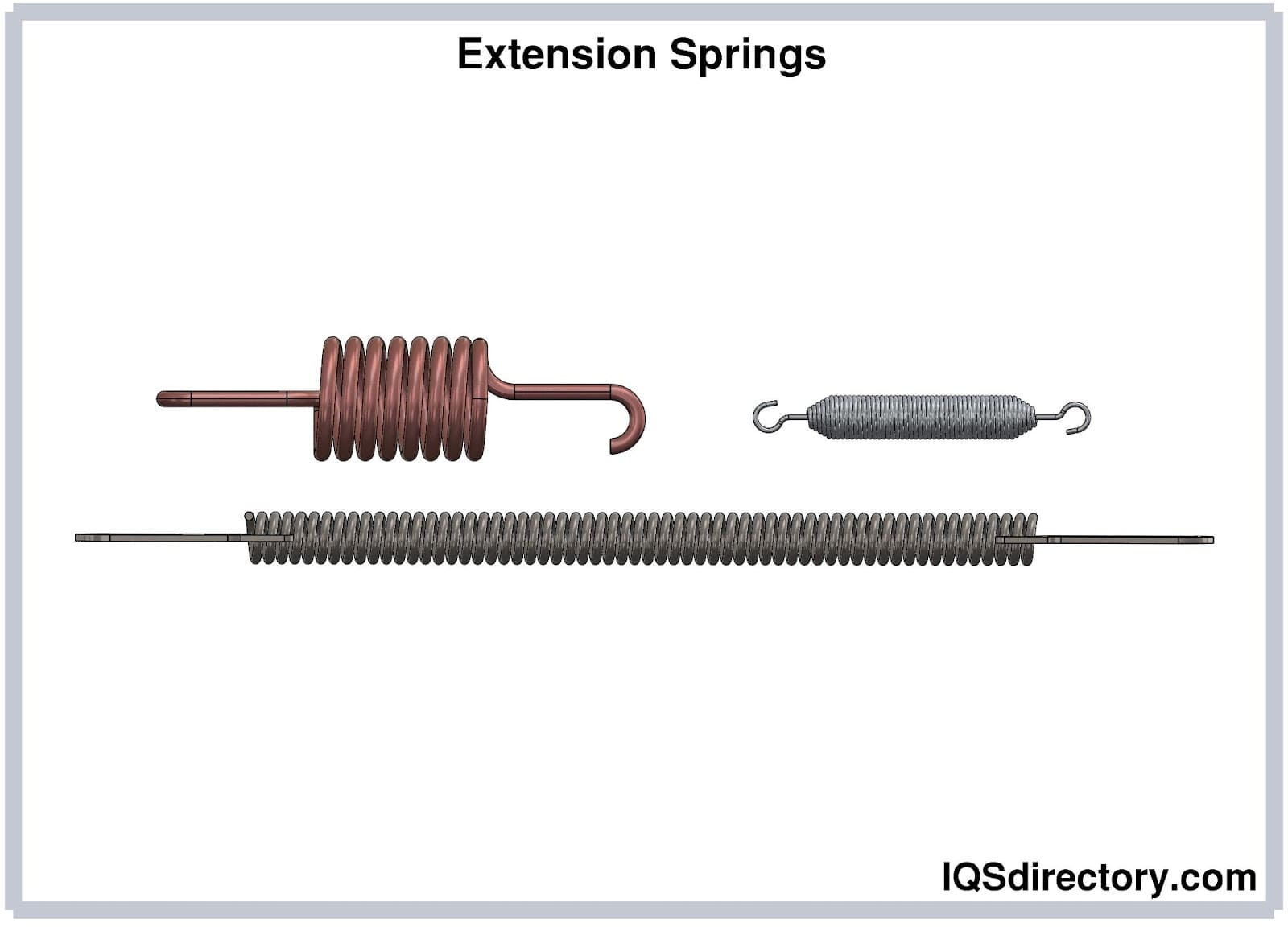

| Extension Springs | Closely coiled to create initial tension, ideal for applications requiring stretching. | Fitness equipment, automotive, hardware | Pros: High tensile strength; Cons: Limited to applications with extension forces. |

| Torsion Springs | Designed to store and release rotational energy, with ends connected to mechanical components. | Door hinges, automotive systems | Pros: Efficient in rotational applications; Cons: Requires precise installation for optimal performance. |

| Wire Forms | Custom shapes created through bending and forming wire, adaptable for various uses. | Retail displays, automotive, aerospace | Pros: Highly customizable; Cons: May require longer lead times for complex designs. |

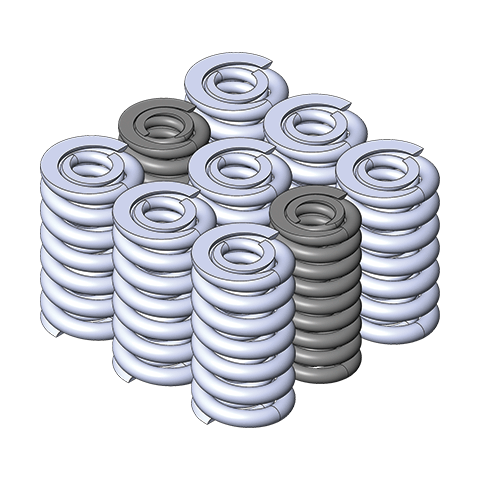

What Are the Key Characteristics of Coil Springs in B2B Applications?

Coil springs are a fundamental type of spring made from round wire, available in various diameters and tailored for both compression and extension applications. They are commonly used in automotive, aerospace, and machinery sectors due to their ability to absorb shock and maintain structural integrity under load. B2B buyers should consider the specific requirements for diameter, load capacity, and environmental factors when selecting coil springs, as these parameters significantly influence performance and longevity.

How Do Compression Springs Function and Where Are They Used?

Compression springs are characterized by their open-coiled structure, which allows them to store mechanical energy when compressed. This type of spring is widely utilized in industrial machinery and automotive parts, where reliable energy storage and release are critical. Buyers should assess the spring’s load capacity and material composition to ensure compatibility with their application, as excessive compression can lead to failure.

What Makes Extension Springs Ideal for Specific Applications?

Extension springs are designed with closely coiled wire that creates initial tension, making them suitable for applications that require stretching. Commonly found in fitness equipment, automotive components, and hardware, these springs offer high tensile strength. When purchasing extension springs, B2B buyers should evaluate the initial tension and load specifications to ensure the spring meets operational demands without compromising safety.

Illustrative image related to barber spring company

What Are the Advantages of Using Torsion Springs in Mechanical Systems?

Torsion springs are unique in their ability to store and release rotational energy, with each end connected to a mechanical component. This design is often employed in door hinges and automotive systems, where controlled movement is essential. Buyers must consider the torque requirements and installation precision, as improper setup can lead to inefficiencies or failure in the system’s functionality.

Why Are Wire Forms a Flexible Solution for Various Industries?

Wire forms are versatile products created by bending and shaping wire into custom configurations, making them suitable for diverse applications, including retail displays and automotive components. Their adaptability allows for creative solutions tailored to specific needs. When sourcing wire forms, B2B buyers should factor in design complexity and lead times, as intricate forms may require more extensive manufacturing processes.

Key Industrial Applications of barber spring company

| Industry/Sector | Specific Application of barber spring company | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Suspension Systems | Enhanced vehicle stability and comfort | Specifications for load capacity, durability, and environmental factors must be clearly defined. |

| Aerospace | Landing Gear Mechanisms | Improved safety and reliability | Compliance with stringent industry regulations and certifications is crucial. |

| Industrial Machinery | Custom Machinery Components | Increased efficiency and reduced downtime | Customization capabilities and lead times should align with production schedules. |

| Mass Transit | Rail Suspension Systems | Greater durability and performance in transit | Need for rapid prototyping and testing to meet specific transit standards. |

| Furniture Manufacturing | Bedding and Seating Springs | Enhanced comfort and product longevity | Material specifications and ergonomic design considerations are essential. |

How Does Barber Spring Company Serve the Automotive Industry?

In the automotive sector, Barber Spring specializes in manufacturing high-performance suspension systems that enhance vehicle stability and comfort. These springs are crucial for absorbing shocks and supporting vehicle weight, thus improving ride quality. B2B buyers in Africa, South America, and the Middle East must ensure that the springs meet specific load capacities and environmental durability standards, particularly in regions with extreme weather conditions.

What Role Does Barber Spring Play in Aerospace Applications?

Barber Spring’s expertise extends into aerospace, where it provides springs for landing gear mechanisms. These components are vital for ensuring safe takeoffs and landings. International buyers, especially from Europe, must consider compliance with stringent aviation regulations, ensuring that all products are certified and tested for reliability. The focus on safety and performance makes Barber Spring a key partner in the aerospace industry.

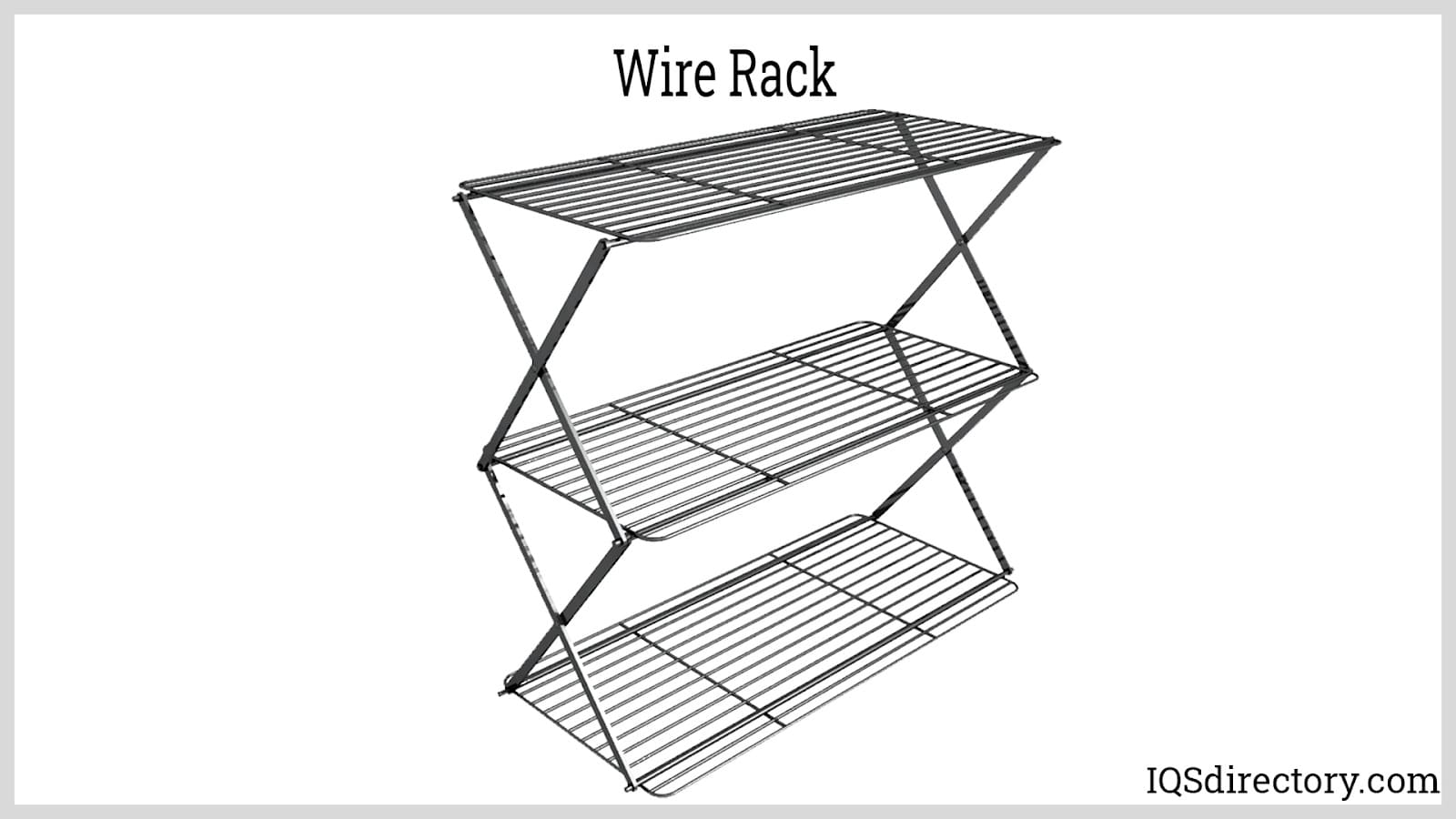

Illustrative image related to barber spring company

How Can Barber Spring Enhance Industrial Machinery Efficiency?

In the realm of industrial machinery, Barber Spring manufactures custom components tailored to specific machinery requirements. These springs are designed to increase operational efficiency and minimize downtime, which is critical for manufacturers. Buyers should prioritize customization capabilities and lead times to ensure that their production schedules are not disrupted, especially in fast-paced markets in South America and Africa.

What Solutions Does Barber Spring Offer for Mass Transit Systems?

Barber Spring provides specialized rail suspension systems that contribute to the durability and performance of mass transit vehicles. These springs help in reducing vibrations and maintaining stability during transit, which is essential for passenger comfort and safety. B2B buyers in the Middle East and Europe should focus on rapid prototyping and testing capabilities to meet local transit standards and ensure timely project completion.

How Does Barber Spring Support the Furniture Manufacturing Sector?

In the furniture manufacturing industry, Barber Spring produces high-quality bedding and seating springs that enhance comfort and extend product longevity. These springs are designed to provide optimal support and durability, making them a preferred choice for manufacturers. Buyers in Europe and South America should pay close attention to material specifications and ergonomic designs to meet consumer expectations for comfort and quality.

3 Common User Pain Points for ‘barber spring company’ & Their Solutions

Scenario 1: Inconsistent Quality Across Different Orders

The Problem: A B2B buyer in the automotive sector often struggles with inconsistent quality in the spring components supplied by various manufacturers, including Barber Spring. The buyer may experience variations in strength, size, and finish that can lead to product failures, increased production costs, and potential delays in bringing their products to market. These inconsistencies can undermine trust and complicate inventory management, as the buyer must frequently check and possibly reject incoming shipments.

Illustrative image related to barber spring company

The Solution: To mitigate quality inconsistencies, B2B buyers should prioritize establishing clear specifications and quality standards before placing orders with Barber Spring. Engaging in detailed discussions about the required tolerances, material specifications, and testing protocols can significantly enhance the quality assurance process. Additionally, implementing a robust quality control system that includes regular audits of the manufacturing process at Barber Spring can help ensure adherence to agreed-upon standards. Buyers should also consider leveraging Barber Spring’s expertise in custom solutions, as their team can provide insights and recommendations tailored to specific applications, thus enhancing reliability and performance.

Scenario 2: Long Lead Times Affecting Production Schedules

The Problem: Many B2B buyers face challenges with long lead times when sourcing springs from manufacturers, which can disrupt their production schedules. For example, a buyer in the aerospace industry might find that delays in receiving essential spring components can halt assembly lines, leading to significant financial losses and missed delivery deadlines. This situation is exacerbated when buyers need to adjust their orders frequently due to design changes or increased demand.

The Solution: To address lead time issues, B2B buyers should take advantage of Barber Spring’s commitment to fast turnaround times. It is crucial to communicate anticipated production schedules and any potential changes in order volume early in the purchasing process. Buyers can also explore Barber Spring’s contract manufacturing options, which may provide more predictable lead times and streamlined production for ongoing projects. Establishing a collaborative relationship with Barber Spring, where buyers can provide feedback and share future forecasts, can also help optimize inventory levels and ensure that critical components are readily available when needed.

Scenario 3: Difficulty in Customization for Specific Applications

The Problem: B2B buyers often encounter challenges when seeking custom spring solutions tailored to unique applications. For instance, a buyer in the medical device industry may require springs with specific characteristics such as biocompatibility, unique dimensions, or specialized coatings. The complexity of these requirements can make it difficult to find a suitable manufacturer that can deliver the desired performance without compromising on quality or reliability.

Illustrative image related to barber spring company

The Solution: To successfully navigate the customization process, buyers should engage Barber Spring’s engineering team early in the design phase. Providing detailed specifications and outlining the intended application will allow Barber Spring’s experts to offer tailored advice and innovative solutions that meet the buyer’s specific needs. Furthermore, leveraging Barber Spring’s advanced technology and manufacturing capabilities can lead to the development of prototypes, enabling buyers to test and validate designs before full-scale production. Establishing a clear line of communication and setting up regular check-ins during the development process can ensure that the final product meets expectations and regulatory requirements, ultimately facilitating a smoother integration into the buyer’s overall product lineup.

Strategic Material Selection Guide for barber spring company

What are the Common Materials Used in Spring Manufacturing for Barber Spring Company?

Barber Spring Company utilizes a variety of materials to manufacture springs that meet the diverse needs of its international clientele. Understanding the properties, advantages, and limitations of these materials is crucial for B2B buyers, especially those from regions like Africa, South America, the Middle East, and Europe. Below are analyses of four common materials used in spring manufacturing.

How Does Steel Perform as a Spring Material?

Steel, particularly high-carbon steel, is one of the most widely used materials for spring manufacturing. It offers excellent tensile strength and elasticity, making it ideal for applications requiring high load-bearing capacity. High-carbon steel springs can withstand temperatures up to 300°C and exhibit good corrosion resistance when treated.

Pros and Cons: The primary advantage of steel springs is their durability and performance under stress. However, they can be prone to rust if not properly coated or treated, which may limit their use in corrosive environments. Manufacturing complexity is moderate, as steel requires precise heat treatment to achieve optimal performance.

Illustrative image related to barber spring company

Impact on Application: Steel springs are suitable for a wide range of applications, including automotive and industrial machinery. Buyers should be aware of the need for protective coatings in humid or saline environments, particularly in regions like Brazil or coastal areas in the Middle East.

What Role Does Stainless Steel Play in Spring Manufacturing?

Stainless steel is another popular choice for spring manufacturing, particularly in applications where corrosion resistance is critical. This material can withstand harsh environments, making it suitable for industries like food processing and pharmaceuticals. Stainless steel springs typically have a temperature rating of up to 400°C.

Pros and Cons: The key advantage of stainless steel is its inherent corrosion resistance, which extends the lifespan of the springs. However, it is generally more expensive than carbon steel, which may affect cost-sensitive projects. The manufacturing process can also be more complex due to the need for specialized equipment.

Impact on Application: Stainless steel springs are ideal for applications exposed to moisture or chemicals. International buyers should ensure compliance with standards such as ASTM A313 or DIN 17223 to guarantee product quality and performance.

How Do Copper Alloys Compare in Spring Applications?

Copper alloys, such as beryllium copper, are often used for springs that require excellent conductivity and fatigue resistance. These materials can operate effectively in temperatures up to 200°C and offer good corrosion resistance.

Illustrative image related to barber spring company

Pros and Cons: The primary advantage of copper alloys is their superior electrical conductivity, making them suitable for electronic applications. However, they are generally less durable than steel options and can be more expensive. Manufacturing complexity is high due to the need for precise alloying and heat treatment.

Impact on Application: Copper alloy springs are commonly used in electrical and electronic applications. Buyers should consider the specific conductivity requirements and ensure that the material meets local standards, especially in regions with strict electrical safety regulations.

What Advantages Do Plastic Springs Offer in Specific Applications?

Plastic springs, made from materials like nylon or polypropylene, are increasingly used in applications where weight reduction and corrosion resistance are paramount. These springs can perform well in temperatures ranging from -40°C to 80°C.

Pros and Cons: The main advantage of plastic springs is their lightweight nature and resistance to corrosion, making them suitable for various consumer products. However, they may not be suitable for high-load applications and can have a shorter lifespan compared to metal springs. Manufacturing complexity is low, as plastic can be easily molded.

Impact on Application: Plastic springs are ideal for lightweight applications, such as in consumer electronics or automotive interiors. International buyers should ensure that the selected plastic complies with relevant standards, such as ISO 9001, to ensure quality.

Summary Table of Material Selection for Barber Spring Company

| Material | Typical Use Case for barber spring company | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Automotive and industrial machinery | High tensile strength and durability | Prone to corrosion without treatment | Medium |

| Stainless Steel | Food processing and pharmaceuticals | Excellent corrosion resistance | Higher cost and complex manufacturing | High |

| Copper Alloys | Electrical and electronic applications | Superior electrical conductivity | Less durable and more expensive | High |

| Plastic | Consumer electronics and automotive interiors | Lightweight and corrosion-resistant | Limited load capacity and shorter lifespan | Low |

This guide provides B2B buyers with valuable insights into material selection for springs, enabling informed decisions that align with their operational needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for barber spring company

What Are the Key Stages in the Manufacturing Process of Barber Spring Company?

Barber Spring Company employs a meticulous manufacturing process designed to ensure the highest quality springs for various applications. The main stages of their manufacturing process include material preparation, forming, assembly, and finishing. Each stage is critical to delivering a product that meets the rigorous demands of various industries.

How Does Material Preparation Work?

The manufacturing journey begins with the careful selection of raw materials. Barber Spring typically utilizes high-grade steel and other alloys, chosen for their mechanical properties and durability. Advanced techniques such as heat treatment may be employed to enhance material characteristics. The company ensures that the materials are free from defects through rigorous inspections before they enter the production line.

Illustrative image related to barber spring company

What Techniques Are Used in the Forming Stage?

In the forming stage, Barber Spring employs several advanced techniques, including hot and cold coiling, which allow for the creation of different types of springs such as compression, extension, and torsion springs. The use of computer numerical control (CNC) machinery ensures precise dimensions and consistent quality. Additionally, Barber Spring incorporates advanced wire forming techniques to produce custom shapes and configurations, tailored to specific client needs.

How Does the Assembly Process Ensure Quality?

Once formed, the springs undergo an assembly process where components are integrated if necessary. This stage may involve welding, soldering, or other joining techniques, depending on the complexity of the spring system. The assembly is closely monitored to ensure that all components fit together seamlessly, maintaining the integrity and functionality of the final product.

What Finishing Techniques Are Applied?

The finishing stage is essential for enhancing the springs’ performance and longevity. Barber Spring employs various finishing techniques, including surface treatments, coating, and plating. These processes not only improve corrosion resistance but also enhance the aesthetic appeal of the springs. The company’s commitment to using environmentally friendly finishing options aligns with global sustainability trends, making their products suitable for international markets.

What Quality Assurance Measures Are Implemented at Barber Spring Company?

Quality assurance is a cornerstone of Barber Spring’s manufacturing philosophy. The company adheres to international standards such as ISO 9001, ensuring a consistent quality management system. This commitment to quality is crucial for B2B buyers who require reliable products for their operations.

How Does Barber Spring Ensure Compliance with International Standards?

Barber Spring’s adherence to ISO 9001 involves regular audits and continuous monitoring of processes. This certification is not just a badge; it signifies that the company has implemented a robust quality management system that consistently meets customer and regulatory requirements. B2B buyers can trust that the springs they receive have been manufactured under stringent quality controls.

What Are the Key QC Checkpoints in the Production Process?

Quality control (QC) at Barber Spring includes several key checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

- IQC: This initial stage involves inspecting raw materials upon arrival to verify that they meet specified standards.

- IPQC: Throughout the manufacturing process, random samples are tested to ensure that production remains within tolerances. Any deviations are addressed immediately.

- FQC: Before shipment, every product batch undergoes a final inspection, ensuring that all specifications have been met.

These checkpoints are critical for maintaining the integrity of the springs and ensuring that they perform reliably in their applications.

Illustrative image related to barber spring company

What Common Testing Methods Are Utilized?

Barber Spring employs various testing methods to ensure the springs meet performance standards. Common tests include tensile strength testing, fatigue testing, and dimensional inspections. These tests help assess the springs’ ability to withstand operational stresses and confirm their compliance with customer specifications.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying the quality control practices of suppliers like Barber Spring is essential. Here are actionable steps:

-

Conduct Audits: Buyers should consider conducting on-site audits to evaluate the manufacturing processes and quality assurance measures firsthand. This provides insights into the supplier’s operational integrity.

-

Request Quality Reports: Buyers can request detailed quality assurance reports that outline the results of various tests and inspections conducted throughout the manufacturing process.

-

Engage Third-Party Inspectors: Utilizing third-party inspection services can provide an unbiased evaluation of the supplier’s quality control practices. This is particularly useful for buyers in regions like Africa and South America, where local standards may differ.

-

Understand Certification Nuances: Buyers should familiarize themselves with the specific certifications relevant to their industry. For instance, certifications like API (American Petroleum Institute) may be crucial for oil and gas applications, while CE marking may be essential for products entering the European market.

What Are the International QC/CERT Nuances for B2B Buyers?

For buyers from regions such as the Middle East and Europe, understanding the nuances of quality certification is crucial. Different markets may have unique regulatory requirements, impacting how products are certified and what standards must be met. For example, the CE marking signifies compliance with European safety standards, while ISO certifications are recognized globally.

Moreover, buyers should be aware of potential trade regulations and import/export requirements that could affect the procurement process. By aligning with suppliers like Barber Spring, who have established quality assurance practices and certifications, B2B buyers can mitigate risks and ensure a seamless supply chain.

Conclusion

Barber Spring Company’s rigorous manufacturing processes and quality assurance practices position it as a trusted partner for international B2B buyers. By understanding the key stages of manufacturing and the comprehensive quality control measures in place, buyers can make informed decisions and ensure that they are sourcing high-quality spring solutions tailored to their needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘barber spring company’

Introduction

This practical sourcing guide is designed to assist B2B buyers in navigating the procurement process for high-quality springs from Barber Spring Company. With its extensive experience and reputation for precision manufacturing, Barber Spring can be a valuable partner for various industries. This checklist will help you ensure that your sourcing decisions are informed, efficient, and aligned with your specific needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the cornerstone of successful sourcing. This involves detailing the type of springs required—be it coil, compression, extension, or torsion—along with dimensions, materials, and load requirements. Precise specifications will streamline communication with potential suppliers and ensure that the products meet your application needs.

- Key Considerations:

- Identify the spring type based on application.

- Specify material requirements (e.g., stainless steel, carbon steel).

- Define performance criteria such as load capacity and lifespan.

Step 2: Research Barber Spring’s Capabilities

Understanding Barber Spring’s manufacturing capabilities is essential for ensuring they can meet your needs. Review their product offerings, production techniques, and industry experience. Their advanced machinery and skilled workforce are critical factors that contribute to the quality and reliability of their springs.

- What to Look For:

- Customization options for unique applications.

- Lead times and production capacity.

- Certifications and industry standards compliance.

Step 3: Evaluate Supplier Certifications

Before proceeding, verify that Barber Spring holds the necessary certifications relevant to your industry. Certifications such as ISO 9001 indicate a commitment to quality management systems, while industry-specific certifications may reflect compliance with safety and performance standards.

- Why This Matters:

- Certifications can mitigate risks associated with product quality.

- They demonstrate the supplier’s commitment to continuous improvement.

Step 4: Request Samples for Testing

Requesting product samples allows you to evaluate the quality and performance of the springs firsthand. Testing samples in your application can provide valuable insights into their suitability and durability, helping to prevent costly mistakes later in the procurement process.

Illustrative image related to barber spring company

- Considerations for Testing:

- Assess the springs’ performance under load conditions.

- Evaluate the fit and compatibility with existing systems.

Step 5: Discuss Pricing and Terms

Engaging in discussions about pricing and payment terms is crucial for establishing a mutually beneficial relationship. Understand the pricing structure, including any discounts for bulk orders or long-term contracts, and clarify payment terms to avoid potential misunderstandings.

- Important Aspects:

- Inquire about lead times and shipping costs.

- Confirm warranty and return policies.

Step 6: Check References and Reviews

Before finalizing your order, check references and seek feedback from other businesses that have worked with Barber Spring. This will provide insights into their reliability, customer service, and overall satisfaction.

- How to Proceed:

- Ask for case studies or testimonials.

- Research online reviews and ratings.

Step 7: Establish Clear Communication Channels

Effective communication is vital for a successful partnership. Establish clear channels for ongoing communication regarding order status, potential issues, and future needs. A responsive supplier can significantly enhance your sourcing experience.

- Key Points:

- Determine preferred communication methods (email, phone, etc.).

- Set up regular check-ins to discuss any concerns or updates.

By following these steps, you can ensure a streamlined and effective sourcing process with Barber Spring, leading to successful procurement of high-quality springs tailored to your business needs.

Comprehensive Cost and Pricing Analysis for barber spring company Sourcing

What Are the Key Cost Components in Sourcing from Barber Spring Company?

When sourcing springs from Barber Spring Company, understanding the cost structure is essential for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials directly impacts cost. Barber Spring utilizes high-quality metals and alloys, which can vary in price based on market demand and availability. For international buyers, fluctuations in currency exchange rates can also affect material costs.

-

Labor: Skilled labor is crucial in manufacturing precision springs. Barber Spring employs a team of experienced technicians and engineers, which contributes to higher labor costs. However, this investment in talent ensures superior product quality and reliable delivery.

-

Manufacturing Overhead: This includes costs associated with maintaining the facility, equipment depreciation, utilities, and administrative expenses. Barber Spring’s advanced manufacturing facility is equipped with cutting-edge technology, which, while increasing overhead, enhances efficiency and output quality.

-

Tooling: Custom tooling can represent a significant upfront investment, especially for tailored spring designs. Buyers should inquire about tooling costs for specific projects, as these can be amortized over larger production runs.

-

Quality Control (QC): Rigorous QC processes ensure that each spring meets stringent industry standards. This commitment to quality may involve additional costs but is critical for long-term reliability and performance.

-

Logistics: Transportation and handling fees can vary based on shipping methods and distances. For international buyers, understanding Incoterms is vital, as they dictate responsibilities for shipping costs, risk, and insurance during transit.

-

Margin: Barber Spring’s pricing also incorporates a profit margin, which reflects the company’s reputation, expertise, and the value of the tailored solutions they provide.

How Do Price Influencers Affect Sourcing Decisions?

Several factors influence the pricing of springs from Barber Spring, including:

-

Volume and Minimum Order Quantity (MOQ): Larger orders typically result in lower per-unit costs due to economies of scale. Buyers should assess their needs carefully to maximize cost efficiency.

-

Specifications and Customization: Custom designs will incur additional costs. Buyers are encouraged to clearly define their specifications to avoid unexpected charges during production.

-

Material Quality and Certifications: Higher quality materials and specific certifications (e.g., ISO, AAR standards) can drive up costs. However, investing in certified products may reduce long-term maintenance and replacement costs.

-

Supplier Factors: Barber Spring’s established reputation and expertise justify a premium price. However, this also translates to reliability and superior product performance, which can reduce the total cost of ownership.

-

Incoterms: Understanding shipping terms can significantly influence overall costs. Buyers should negotiate Incoterms that align with their logistics capabilities to avoid hidden charges.

What Negotiation Tips Can Enhance Cost-Efficiency for International Buyers?

International buyers can leverage several strategies to optimize costs when sourcing from Barber Spring:

-

Negotiate Bulk Discounts: Engage in discussions about pricing tiers based on order volume. Securing a favorable price for larger orders can lead to substantial savings.

-

Consider Total Cost of Ownership: Evaluate not just the purchase price but also the long-term costs associated with maintenance, performance, and potential downtime. Quality springs can lead to lower total costs over their lifespan.

-

Clarify Specifications Early: Providing detailed specifications upfront minimizes the risk of costly changes later in the production process. It also helps in accurately estimating costs.

-

Research and Build Relationships: Establishing a strong relationship with Barber Spring can lead to better pricing and service. Regular communication can help in understanding their pricing structure and any potential for flexibility.

-

Be Aware of Pricing Nuances: For buyers from Africa, South America, the Middle East, and Europe, understanding regional market conditions can aid in negotiations. Local economic factors may influence pricing, allowing savvy buyers to identify optimal purchasing windows.

Conclusion

While the costs associated with sourcing from Barber Spring Company can vary based on several factors, understanding the intricate cost structure and price influencers is essential for international B2B buyers. By applying strategic negotiation tactics and focusing on total cost of ownership, businesses can secure high-quality spring solutions that enhance their operational efficiency and profitability.

Illustrative image related to barber spring company

Alternatives Analysis: Comparing barber spring company With Other Solutions

When evaluating spring manufacturing solutions, businesses often seek alternatives that can meet their specific needs for quality, performance, and cost-effectiveness. Barber Spring Company, with its decades of expertise, provides a robust offering in the spring manufacturing landscape. However, B2B buyers may also want to consider other viable options to ensure they make informed decisions. Below is a comparison of Barber Spring Company against two prominent alternatives in the industry.

| Comparison Aspect | Barber Spring Company | Coiling Technologies, Inc. | Anderson Quality Spring Manufacturing, Inc. |

|---|---|---|---|

| Performance | High precision, custom solutions | Specialized in high-volume production | Strong focus on quality control |

| Cost | Competitive pricing for custom work | Generally lower for standard products | Higher due to premium quality |

| Ease of Implementation | Tailored solutions may require time | Quick turnaround for standard orders | Requires detailed specifications |

| Maintenance | Low maintenance with durable products | Varies by product type | Regular checks recommended |

| Best Use Case | Custom applications across industries | Mass production of standard springs | High-quality applications needing durability |

What Are the Pros and Cons of Coiling Technologies, Inc.?

Coiling Technologies, Inc. focuses on high-volume production, making it an excellent choice for businesses that require large quantities of standard springs. The main advantage of this alternative is its ability to provide quick turnaround times, which can be crucial for companies with tight deadlines. However, their specialization in standard products may limit customization options, which could be a drawback for businesses needing unique spring designs tailored to specific applications.

How Does Anderson Quality Spring Manufacturing, Inc. Compare?

Anderson Quality Spring Manufacturing, Inc. prides itself on its rigorous quality control processes, ensuring that each product meets high standards. This makes it a suitable choice for industries where reliability and durability are paramount, such as aerospace or automotive sectors. The downside, however, is that their products tend to be more expensive due to the emphasis on quality, which may not be feasible for every budget. Additionally, the implementation process can be more complex, as customers must provide detailed specifications for their orders.

Conclusion: How Should B2B Buyers Choose the Right Spring Solution?

When selecting a spring manufacturing solution, B2B buyers should assess their specific needs, including performance requirements, budget constraints, and the level of customization necessary. Barber Spring Company excels in providing tailored solutions with a focus on precision and reliability, making it ideal for custom applications. In contrast, Coiling Technologies, Inc. offers efficiency in mass production, while Anderson Quality Spring Manufacturing, Inc. ensures high-quality standards. By evaluating these aspects, businesses can make informed decisions that align with their operational goals and enhance their product offerings.

Essential Technical Properties and Trade Terminology for barber spring company

What Are the Key Technical Properties of Barber Springs?

When selecting springs from Barber Spring, understanding the essential technical properties is crucial for ensuring optimal performance in your applications. Here are some critical specifications:

1. Material Grade

The material used in spring manufacturing significantly influences its strength, flexibility, and overall performance. Common materials include high-carbon steel, stainless steel, and alloy steels. High-carbon steel is often chosen for its excellent tensile strength, while stainless steel provides corrosion resistance. Choosing the right material grade is vital for applications in various environments, ensuring longevity and reliability.

2. Tolerance

Tolerance refers to the permissible limit of variation in a physical dimension. In spring manufacturing, maintaining tight tolerances ensures that the springs perform as expected under load. Tighter tolerances often translate to better fit and function in assemblies, reducing the risk of failure in critical applications. Understanding the required tolerances for your specific use case is essential for both performance and safety.

3. Load Capacity

Load capacity indicates the maximum load a spring can safely support while maintaining its structural integrity. This property is crucial for applications where springs are subjected to dynamic loads, such as in automotive or aerospace industries. Knowing the load capacity helps ensure that the selected spring will perform effectively without deformation or failure under operational conditions.

4. Spring Rate

The spring rate measures the stiffness of a spring, typically expressed in force per unit of deflection (e.g., pounds per inch). This property is critical for applications requiring precise control of movement, as it directly affects how much a spring compresses or extends under a given load. Understanding the spring rate allows engineers to design systems that respond predictably to applied forces.

5. End Type

The design of the spring’s ends can affect its performance and compatibility with other components. Common end types include open ends, closed ends, and ground ends. Each type serves different functional needs, and selecting the appropriate end type is crucial for ensuring proper installation and operation in specific applications.

What Are Common Trade Terms in the Spring Manufacturing Industry?

Familiarity with industry jargon can streamline communication and improve procurement processes. Here are some essential terms to know:

Illustrative image related to barber spring company

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that produce parts or components that are used in another company’s end product. In the context of Barber Spring, customers may need springs designed for specific OEM applications, ensuring compatibility and adherence to industry standards.

2. MOQ (Minimum Order Quantity)

MOQ is the minimum number of units a supplier is willing to produce or sell. Understanding the MOQ is essential for B2B buyers as it impacts inventory management and budgeting. Barber Spring may set MOQs based on manufacturing capabilities and material costs, influencing how businesses plan their purchases.

3. RFQ (Request for Quotation)

An RFQ is a document issued by a buyer to solicit price quotes from suppliers for specific products or services. When considering Barber Spring, submitting an RFQ allows buyers to receive detailed pricing and lead time information tailored to their needs, facilitating informed decision-making.

4. Incoterms

Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in international transactions. These terms clarify who is responsible for shipping, insurance, and tariffs, which can significantly affect total costs and logistics planning when sourcing from Barber Spring.

5. Custom Manufacturing

Custom manufacturing refers to the production of goods tailored to specific customer requirements. Barber Spring specializes in custom springs, allowing businesses to receive products designed to meet unique application specifications, enhancing performance and reliability.

Understanding these technical properties and industry terms is crucial for B2B buyers looking to procure high-quality springs from Barber Spring. By leveraging this knowledge, decision-makers can ensure they select the right products to meet their operational needs effectively.

Illustrative image related to barber spring company

Navigating Market Dynamics and Sourcing Trends in the barber spring company Sector

What are the Current Market Dynamics and Key Trends in the Barber Spring Company Sector?

The global market for spring manufacturing, particularly within the barber spring sector, is currently experiencing significant transformation driven by technological advancements and evolving customer needs. A key market driver is the increasing demand for customized and high-performance spring solutions across various industries, including automotive, aerospace, and industrial machinery. Buyers are increasingly seeking suppliers that can offer tailored products that meet specific operational requirements, thus enhancing functionality and performance.

Emerging technologies, such as Industry 4.0 innovations—including automation, IoT, and advanced manufacturing techniques—are reshaping sourcing strategies. These technologies enable manufacturers to streamline production processes, reduce lead times, and enhance product quality. International B2B buyers, particularly in Africa, South America, the Middle East, and Europe, are encouraged to leverage these advancements when sourcing springs. For instance, suppliers like Barber Spring utilize state-of-the-art machinery and skilled engineers to provide quick turnaround times and customized solutions, which can significantly benefit buyers looking for efficiency and reliability.

In addition to technological trends, the market is also influenced by shifting economic landscapes. For instance, the growing industrialization in developing regions such as Africa and South America is creating new opportunities for spring manufacturers to expand their reach. This trend is compounded by increased global trade, which allows buyers from different continents to access high-quality products from established manufacturers like Barber Spring.

Illustrative image related to barber spring company

How is Sustainability Influencing B2B Sourcing Decisions in the Barber Spring Sector?

Sustainability is becoming a cornerstone of modern B2B sourcing strategies, particularly in the spring manufacturing sector. The environmental impact of production processes is under scrutiny, prompting businesses to prioritize ethical sourcing and sustainable practices. For international buyers, especially from regions like Europe and the Middle East, the demand for suppliers that adhere to green manufacturing principles is growing.

Barber Spring, for instance, is committed to sustainable practices by utilizing eco-friendly materials and processes that minimize waste and energy consumption. This commitment not only aligns with global sustainability goals but also appeals to buyers who are increasingly concerned about the environmental footprint of their supply chains. Certifications such as ISO 14001 (Environmental Management) can serve as indicators for buyers looking to partner with manufacturers who prioritize sustainability.

Moreover, ethical sourcing practices are gaining traction, with businesses aiming to ensure that their suppliers maintain fair labor practices and responsible sourcing of materials. By selecting suppliers that uphold these values, international buyers can enhance their brand reputation and customer loyalty, particularly among environmentally conscious consumers.

What is the Historical Context of the Barber Spring Company?

Barber Spring has a rich history that spans over five decades, rooted in a commitment to quality and customer satisfaction. Founded in Pittsburgh, PA, the company established itself as a leading manufacturer of springs, known for its precision engineering and high-quality products. This legacy of excellence continues to inform the company’s operations today.

Illustrative image related to barber spring company

The evolution of Barber Spring reflects broader trends in the manufacturing sector, where innovation and responsiveness to market needs have become essential. By continuously refining its product offerings and embracing new technologies, Barber Spring has positioned itself as a trusted partner for B2B buyers across various industries. This historical context highlights the company’s dedication to not only meeting but exceeding the expectations of its international clientele, making it an attractive choice for businesses seeking reliable spring solutions.

Frequently Asked Questions (FAQs) for B2B Buyers of barber spring company

-

How can I determine the right type of spring for my application?

Choosing the right type of spring depends on the specific application and its requirements. Barber Spring offers various types, including compression, extension, torsion, and coil springs. Consider factors such as load capacity, space constraints, and environmental conditions. Collaborating with Barber Spring’s design engineers can help you analyze your needs and select the optimal spring, ensuring enhanced functionality and durability for your application. -

What customization options are available for springs?

Barber Spring specializes in custom solutions tailored to meet unique specifications. Buyers can request modifications in dimensions, material types, and spring configurations. The company’s advanced engineering team collaborates with clients to design springs that perfectly align with their operational needs. Whether you require specific load characteristics or specialized wire forms, Barber Spring’s customization capabilities can help you achieve your desired performance metrics. -

What is the minimum order quantity (MOQ) for international buyers?

Barber Spring typically has flexible MOQ policies, which can vary based on the type of spring and customization level. For international buyers, discussing specific requirements with the sales team is essential to determine the MOQ that aligns with your project. This approach ensures that you can procure the necessary quantities while optimizing cost-effectiveness and supply chain efficiency. -

What are the payment terms for international orders?

Payment terms for international orders with Barber Spring can vary. Common options include wire transfers, letters of credit, and payment upon delivery, depending on the buyer’s location and order size. It’s advisable to communicate your preferred payment method during the negotiation phase to establish clear expectations and facilitate smooth transactions. -

How does Barber Spring ensure quality assurance for its products?

Quality assurance is paramount at Barber Spring. The company employs rigorous testing protocols throughout the manufacturing process, including material inspections and performance testing of finished products. Certifications and compliance with industry standards further enhance their quality assurance measures. Buyers can request specific QA documentation to ensure that the springs meet their operational standards. -

What logistics support does Barber Spring provide for international shipping?

Barber Spring has a robust logistics framework to support international shipping. They partner with reputable freight forwarders to ensure timely and safe delivery of products. Buyers can discuss shipping options, estimated delivery times, and customs documentation requirements with the sales team. This proactive approach helps mitigate potential delays and ensures compliance with international shipping regulations. -

How can I initiate a quote request for my specific spring needs?

To initiate a quote request, you can visit the Barber Spring website and fill out the request form, providing detailed specifications of your spring requirements. Alternatively, you can contact their sales team directly via phone or email. Providing comprehensive information about your application, desired quantities, and customization needs will facilitate a faster and more accurate quote. -

What industries does Barber Spring serve, and can they accommodate specific industry standards?

Barber Spring serves a wide range of industries, including automotive, aerospace, industrial machinery, and mass transit. They are adept at accommodating specific industry standards and regulations, ensuring that their products meet the rigorous demands of various applications. Discussing your industry requirements with Barber Spring’s team will help ensure compliance and optimal performance in your specific application.

Top 6 Barber Spring Company Manufacturers & Suppliers List

1. Barber Spring – Custom Springs & Wire Forms

Domain: springmanufacturer.com

Registered: 2003 (22 years)

Introduction: Barber Spring is a leading manufacturer and supplier of high-quality springs for various industries, with over five decades of experience. The company specializes in custom-made springs and wire forms, providing tailored solutions to meet unique customer needs. Barber Spring offers expert design assistance, working closely with clients to enhance spring functionality, durability, and efficiency. T…

2. Wabtec Corp – AAR Standard Load & Custom Hot-Wound Springs

Domain: wabteccorp.com

Registered: 2018 (7 years)

Introduction: AAR Standard Load and Side Springs for all types of truck suspension systems; Custom Hot-Wound Springs for Industrial Applications; Available in 1/2″ to 4″ diameter bar.

3. Wabtec Barber Spring – Large Helical Hot Wound Springs

Domain: masstransitmag.com

Registered: 1998 (27 years)

Introduction: Wabtec Barber Spring offers one of the fastest lead times in the Industrial Spring Manufacturing Industry. Barber Spring specializes in making large helical hot wound springs over 4” (101 mm) bar diameter.

4. Barber Spring – Custom Spring Coils

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Barber Spring specializes in manufacturing high-quality custom spring coils, including standard railroad and special industrial springs. They utilize modern equipment and have an extensive inventory of steel to meet specific customer specifications.

5. Barber Manufacturing – Innerspring & Upholstery Solutions

Domain: barbermfg.com

Registered: 2000 (25 years)

Introduction: Barber Manufacturing Company offers a range of products including Rigid Bar Drop-In Construction, Rigid Bar Seat Strip, The Marshall Unit, Upholstery Springs, Barber Loop, Barber Loop Special Designs, Bedding Springs, and Low Height Bonnell Innerspring. The company emphasizes quality and customer service, with a focus on refining and improving bedding and furniture springs and spring assemblies.

6. Barber Spring – Springs & Wire Forming

Domain: mfg.com

Registered: 1991 (34 years)

Introduction: Barber Spring specializes in manufacturing Springs & Wire Forming. Located at 1 McCandless Avenue, Pittsburgh, Pennsylvania, 15201, United States. Manufacturing capabilities include Springs & Wire Forming with equipment such as a Southbend 16 x 84 Lathe. The company has 10-20 employees and has been a member of MFG since 11/11/2013.

Strategic Sourcing Conclusion and Outlook for barber spring company

Why Is Strategic Sourcing Essential for Your Business with Barber Spring?

In conclusion, Barber Spring stands out as a premier partner for businesses seeking high-quality, precision-engineered spring solutions. Their extensive experience of over five decades, coupled with a commitment to customization and innovation, positions them as a reliable source for a variety of industries. For international B2B buyers from Africa, South America, the Middle East, and Europe, strategic sourcing from Barber Spring ensures access to superior products that meet specific application needs while benefiting from fast lead times and exceptional customer service.

Investing in a relationship with Barber Spring can lead to enhanced operational efficiency and product performance, directly impacting your bottom line. As you consider your sourcing options, recognize the value of aligning with a manufacturer that prioritizes quality and customer satisfaction.

Looking ahead, the potential for collaboration with Barber Spring offers promising opportunities for growth and innovation in your own product offerings. Reach out today to explore how Barber Spring can support your business goals and elevate your product’s performance in an increasingly competitive market. Your success is just a partnership away.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to barber spring company

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.