How to Source Baggies Plastic Bags Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for baggies plastic bags

In today’s fast-paced global market, sourcing high-quality baggies plastic bags can be a daunting challenge for international B2B buyers, especially those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With varying regulations, material standards, and environmental considerations, it’s essential to navigate this landscape with a clear strategy. This comprehensive guide is designed to empower businesses by detailing the types of plastic baggies available, their numerous applications across industries, and the critical steps for vetting suppliers effectively.

From food service to medical applications, plastic baggies serve as versatile solutions for packaging and storage needs. Buyers will find insights into selecting the right materials, understanding cost implications, and ensuring compliance with regional regulations, including safety standards and environmental impact. Furthermore, we will address the growing concern over the use of harmful chemicals in plastics, providing actionable strategies for sourcing safer alternatives.

By leveraging the information provided in this guide, B2B buyers can make informed purchasing decisions that align with their operational goals and ethical standards. Whether you are seeking suppliers in Saudi Arabia or Brazil, this resource is your go-to tool for navigating the complexities of the baggies plastic bags market, ensuring you secure the best products for your business needs.

Understanding baggies plastic bags Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Resealable Plastic Baggies | Lightweight, easy to seal, moisture-resistant | Food service, retail, medical | Pros: Convenient, reusable; Cons: Potential chemical concerns (PFAS). |

| Heavy-Duty Plastic Baggies | Thicker material, extra durability | Industrial storage, shipping | Pros: Stronger protection; Cons: Higher cost than standard options. |

| Anti-Static Plastic Baggies | Designed to prevent static electricity | Electronics packaging, semiconductor industry | Pros: Protects sensitive components; Cons: Limited general use. |

| Food-Grade Plastic Baggies | Compliant with food safety standards | Food packaging, meal prep services | Pros: Safe for food contact; Cons: May require special sourcing. |

| Custom-Printed Plastic Baggies | Personalized branding options | Retail, promotional items | Pros: Enhances brand visibility; Cons: Longer lead times for production. |

What Are the Characteristics of Resealable Plastic Baggies?

Resealable plastic baggies are versatile packaging solutions, typically made from polyethylene. They feature a zip-seal closure that allows for easy access and reusability, making them ideal for food service and retail applications. B2B buyers should consider the material thickness and quality, as these factors affect durability and moisture resistance. While they are convenient for everyday use, concerns about chemicals like PFAS may influence purchasing decisions.

How Do Heavy-Duty Plastic Baggies Differ from Standard Options?

Heavy-duty plastic baggies are crafted from thicker materials, providing enhanced durability for industrial applications. They are suitable for shipping and storage of heavier items, ensuring that contents remain secure during transit. Buyers should evaluate the strength and tear resistance when selecting heavy-duty options, as these attributes are critical for protecting valuable products. However, the cost may be higher compared to standard baggies, which could impact budget considerations.

Why Are Anti-Static Plastic Baggies Important in Electronics?

Anti-static plastic baggies are specifically designed to protect sensitive electronic components from static electricity, which can cause damage during storage and transportation. These bags are crucial in industries such as electronics and semiconductors, where precision and safety are paramount. When purchasing, B2B buyers should ensure compliance with industry standards for static protection. The limited application scope means they may not be suitable for general use, which could limit their utility for some businesses.

What Makes Food-Grade Plastic Baggies Essential for Food Packaging?

Food-grade plastic baggies are manufactured to meet stringent safety standards for food contact, making them essential for any business involved in food storage or packaging. They are commonly used in restaurants and meal prep services to ensure food safety and freshness. Buyers should prioritize sourcing from reputable manufacturers to guarantee compliance with health regulations. However, availability may vary, and special sourcing could be necessary, impacting procurement timelines.

How Can Custom-Printed Plastic Baggies Enhance Brand Visibility?

Custom-printed plastic baggies offer businesses an opportunity to enhance brand visibility through personalized branding options. These baggies can be tailored with logos and designs, making them ideal for retail and promotional items. B2B buyers should consider the lead times for production, as custom orders may take longer to fulfill. While they can significantly boost marketing efforts, the cost may be higher than standard options, requiring careful budgeting.

Key Industrial Applications of baggies plastic bags

| Industry/Sector | Specific Application of baggies plastic bags | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food Service | Food storage and portion control | Maintains freshness and prevents contamination | Ensure compliance with food safety regulations and certifications. |

| Retail | Product packaging and display | Enhances product visibility and customer appeal | Look for customizable options that align with branding. |

| Pharmaceuticals | Secure storage of medications and samples | Protects sensitive products from moisture and tampering | Source FDA-approved materials for compliance and safety. |

| Electronics | Packaging for components and devices | Prevents static damage and provides organization | Choose anti-static options for sensitive electronic parts. |

| Craft and Hobby | Organizing supplies and materials | Increases efficiency in inventory management | Consider various sizes and thicknesses to meet specific needs. |

How Are Baggies Plastic Bags Used in Food Service?

In the food service industry, baggies plastic bags are essential for food storage and portion control. They help maintain freshness, prevent contamination, and extend shelf life, which is crucial for both safety and cost-effectiveness. Businesses sourcing these bags must ensure they comply with local food safety regulations, particularly in regions like Africa and the Middle East, where standards may vary. Buyers should also consider materials that are BPA-free and suitable for various temperature ranges to accommodate different food types.

What Role Do Baggies Plastic Bags Play in Retail Packaging?

Retailers utilize baggies plastic bags for product packaging and display, enhancing product visibility and customer appeal. These bags can be customized with branding elements, which can significantly influence purchasing decisions. When sourcing, international buyers, particularly from South America and Europe, should prioritize suppliers that offer eco-friendly options, as consumer demand for sustainable packaging is on the rise. Custom sizing and thickness options are also vital to accommodate diverse product shapes and weights.

How Are Baggies Plastic Bags Essential in the Pharmaceutical Sector?

In the pharmaceutical industry, baggies plastic bags are used for the secure storage of medications and samples. Their moisture-resistant properties protect sensitive products from environmental factors, ensuring efficacy and safety. Buyers in this sector need to source bags that are FDA-approved and compliant with international regulations, especially when exporting products. Transparency in sourcing materials is crucial to guarantee that all packaging meets stringent health and safety standards.

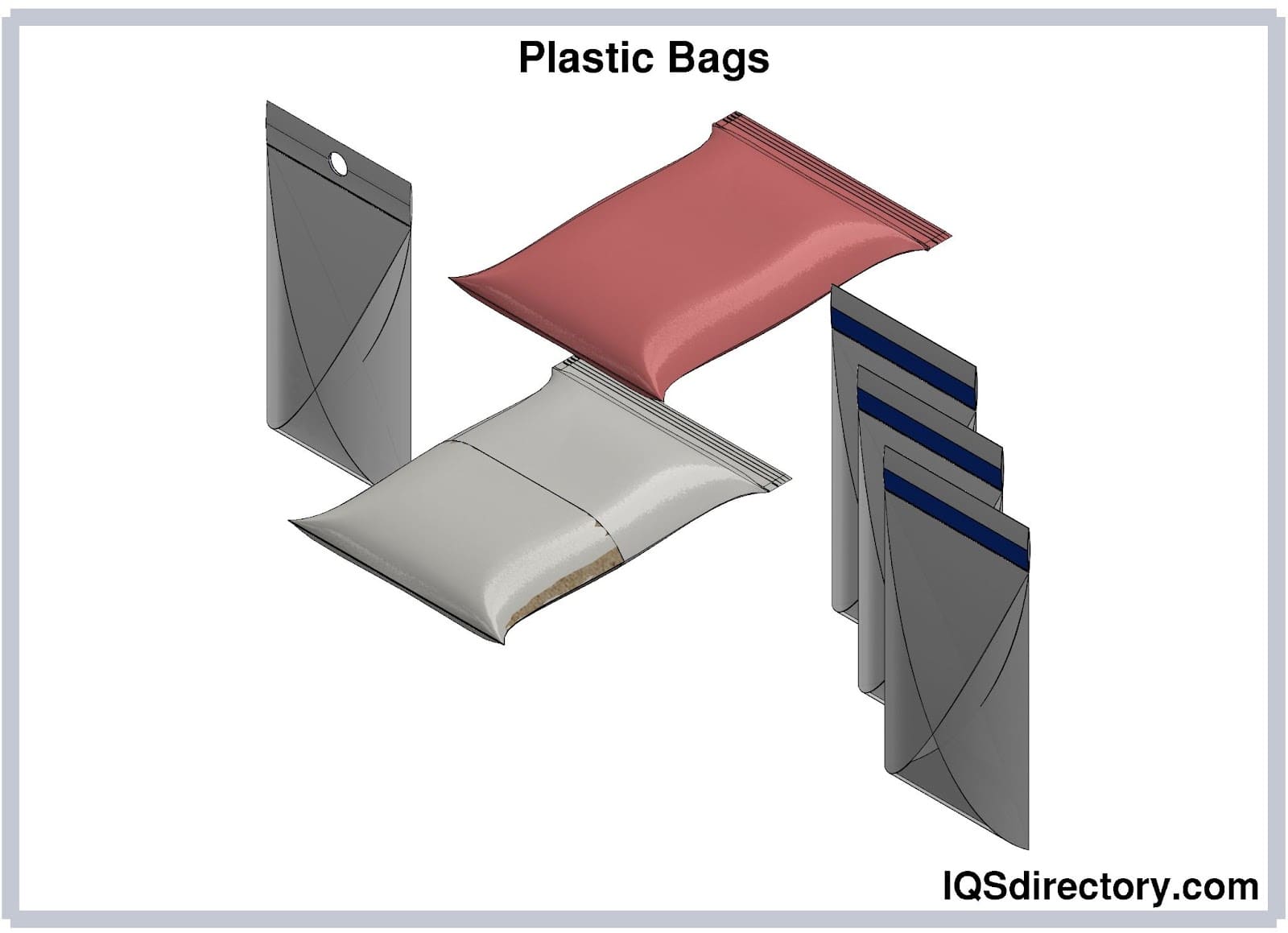

Illustrative image related to baggies plastic bags

Why Are Baggies Plastic Bags Important for Electronics?

Electronics manufacturers rely on baggies plastic bags to package components and devices, preventing static damage and providing organization during shipping and storage. These bags are often available in anti-static varieties, which are essential for safeguarding sensitive electronic parts. When sourcing, businesses should focus on suppliers who can provide bags with specific anti-static properties and offer bulk purchasing options to optimize costs, especially in markets like Saudi Arabia and Brazil where electronics manufacturing is growing.

How Do Baggies Plastic Bags Benefit Craft and Hobby Industries?

In the craft and hobby sectors, baggies plastic bags serve as an effective solution for organizing supplies and materials. They help increase efficiency in inventory management by allowing users to categorize and store various items conveniently. Buyers in this industry should consider the range of sizes and thicknesses available to meet specific needs, ensuring that the bags can accommodate everything from small beads to larger crafting tools. Sourcing from manufacturers that offer customization can further enhance usability for crafters and hobbyists alike.

3 Common User Pain Points for ‘baggies plastic bags’ & Their Solutions

Scenario 1: Concerns Over Chemical Safety in Plastic Baggies

The Problem: A growing number of businesses are becoming increasingly aware of the potential health risks associated with plastic products, particularly those containing PFAS (per- and polyfluoroalkyl substances). B2B buyers in industries such as food service or healthcare may face significant challenges when it comes to sourcing baggies that are free from harmful chemicals. This concern not only affects product safety but can also lead to regulatory compliance issues, damaging a company’s reputation and potentially resulting in financial penalties.

The Solution: To mitigate these risks, B2B buyers should prioritize sourcing baggies from manufacturers that offer transparency regarding their materials. It is essential to request certifications proving that their products are PFAS-free and comply with relevant regulations, such as the FDA for food-safe products. Engaging with suppliers who adhere to stringent material compliance protocols can provide peace of mind. Additionally, consider investing in alternative packaging solutions, such as biodegradable or compostable baggies, which not only address safety concerns but also enhance a brand’s commitment to sustainability. Conducting thorough supplier audits can also ensure that the manufacturing processes align with safety standards, thereby safeguarding both consumers and businesses.

Scenario 2: The Challenge of Sizing and Compatibility

The Problem: Many B2B buyers struggle with finding the right size and type of plastic baggies that meet their specific packaging needs. For instance, a company in the food industry may require various sizes for different products, such as sandwiches, fruits, or bulk items. Incompatibility between the bag size and the product can lead to inefficient storage, increased waste, and ultimately higher operational costs.

The Solution: To address this issue, businesses should conduct a thorough analysis of their packaging requirements before sourcing baggies. Create a detailed inventory of items that require packaging, including their dimensions and volume, to determine the necessary bag sizes. Once this assessment is complete, work with suppliers who offer customization options, allowing for tailored sizes that fit specific products perfectly. Additionally, consider investing in multi-pack options that include various sizes, ensuring that you have the flexibility to package different items without overspending. Engaging in discussions with manufacturers about your unique needs can also lead to the development of bespoke solutions that streamline your operations.

Scenario 3: Environmental Impact and Sustainability Concerns

The Problem: As global awareness of environmental issues rises, B2B buyers are increasingly pressured to consider the ecological impact of their packaging choices. Many companies are striving to enhance their sustainability practices, yet traditional plastic baggies often contribute to waste and pollution. This dilemma can make it difficult for businesses to balance cost-efficiency with environmental responsibility, particularly in regions where eco-consciousness is gaining traction, such as Europe and South America.

The Solution: To overcome these challenges, B2B buyers should explore sustainable alternatives to conventional plastic baggies. Research manufacturers that provide eco-friendly options, such as bags made from recycled materials or biodegradable plastics. Additionally, consider implementing a waste-reduction strategy by transitioning to reusable baggies for specific applications. Collaborate with suppliers who can provide insights into the lifecycle impact of their products, helping to ensure that your choices align with your corporate sustainability goals. By actively promoting eco-friendly packaging, companies can not only improve their environmental footprint but also enhance their brand image, appealing to a growing market of environmentally conscious consumers.

Strategic Material Selection Guide for baggies plastic bags

When selecting materials for baggies plastic bags, it is crucial for B2B buyers to consider the properties, advantages, disadvantages, and compliance standards associated with each material. This analysis focuses on four common materials: Low-Density Polyethylene (LDPE), High-Density Polyethylene (HDPE), Polypropylene (PP), and Polyvinyl Chloride (PVC). Each material offers unique characteristics that can influence product performance and suitability across various applications.

What are the Key Properties of Low-Density Polyethylene (LDPE) for Baggies Plastic Bags?

Low-Density Polyethylene (LDPE) is widely used in the production of plastic baggies due to its flexibility and low-density structure. LDPE has a temperature rating of approximately -50°C to 80°C, making it suitable for a variety of storage conditions. Its resistance to moisture and chemicals enhances its performance in food storage and other applications.

Pros and Cons: LDPE is lightweight and cost-effective, which makes it a popular choice for manufacturers. However, it has lower tensile strength compared to other materials, which may limit its use for heavier items. Additionally, while LDPE is recyclable, it is not biodegradable, raising environmental concerns.

Impact on Application: LDPE baggies are ideal for food packaging, medical supplies, and general storage. They provide excellent clarity, allowing for easy visibility of contents, which is essential in retail settings.

Considerations for International Buyers: Compliance with FDA regulations is essential for food-related applications. Buyers in regions like Europe and the Middle East should also consider adherence to local environmental regulations regarding plastic use and recycling.

How Does High-Density Polyethylene (HDPE) Perform in Baggies Plastic Bags?

High-Density Polyethylene (HDPE) is known for its strength and durability. With a temperature range of -40°C to 60°C, HDPE is suitable for a range of applications, including those requiring higher strength and resistance to impact.

Pros and Cons: HDPE offers superior tensile strength and is less permeable to moisture compared to LDPE. However, it is generally stiffer, which may limit its flexibility for certain applications. HDPE is also recyclable, making it a more environmentally friendly option compared to some alternatives.

Impact on Application: HDPE baggies are often used in industrial and commercial applications where sturdiness is required. They are also compatible with a variety of chemicals, making them suitable for packaging non-food items.

Considerations for International Buyers: Buyers should ensure that HDPE products meet relevant ASTM or DIN standards for strength and safety, particularly in regions with stringent regulations.

What are the Advantages of Using Polypropylene (PP) for Baggies Plastic Bags?

Polypropylene (PP) is recognized for its clarity and high resistance to heat, making it an excellent choice for applications requiring sterilization. It can withstand temperatures up to 100°C, which is beneficial for food storage that may require reheating.

Pros and Cons: PP is lightweight and offers good chemical resistance, making it suitable for a wide range of applications. However, it is generally more expensive than LDPE and HDPE, which may affect cost-sensitive projects.

Impact on Application: PP baggies are often used in medical and pharmaceutical applications due to their ability to maintain sterility. They are also popular in the food industry for packaging ready-to-eat meals.

Considerations for International Buyers: Compliance with health and safety standards is critical, especially in the medical field. Buyers should verify that suppliers provide certifications demonstrating compliance with relevant regulations.

What Role Does Polyvinyl Chloride (PVC) Play in Baggies Plastic Bags?

Polyvinyl Chloride (PVC) is less commonly used for baggies but offers unique properties such as high resistance to chemicals and moisture. PVC can operate within a temperature range of -10°C to 60°C.

Pros and Cons: PVC is durable and provides excellent barrier properties. However, it can be less flexible than other materials and may contain harmful additives that raise health concerns. Additionally, PVC is not widely recyclable, which can pose environmental challenges.

Impact on Application: PVC baggies are suitable for industrial applications where chemical resistance is paramount. However, they are less favored for food storage due to potential health risks.

Considerations for International Buyers: Buyers must be aware of the regulatory landscape regarding PVC usage, particularly in Europe where restrictions on certain additives may apply.

Summary Table of Material Selection for Baggies Plastic Bags

| Material | Typical Use Case for baggies plastic bags | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Low-Density Polyethylene (LDPE) | Food storage, general storage | Flexible and cost-effective | Lower tensile strength | Low |

| High-Density Polyethylene (HDPE) | Industrial applications, chemical packaging | Superior strength and durability | Less flexible | Medium |

| Polypropylene (PP) | Medical applications, food packaging | High heat resistance and clarity | Higher cost | High |

| Polyvinyl Chloride (PVC) | Industrial applications | Excellent chemical resistance | Less flexible and health concerns | Medium |

This guide provides a comprehensive overview of the materials used in baggies plastic bags, enabling international B2B buyers to make informed decisions based on their specific needs and compliance requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for baggies plastic bags

What Are the Main Stages in the Manufacturing Process of Baggies Plastic Bags?

The manufacturing of baggies plastic bags involves several key stages that ensure the final product meets quality and performance standards. These stages typically include material preparation, forming, assembly, and finishing.

Illustrative image related to baggies plastic bags

-

Material Preparation: The process begins with the selection and preparation of raw materials, usually polyethylene (PE) or polypropylene (PP). These materials are chosen for their durability, flexibility, and moisture resistance. The granules of plastic are fed into an extruder, where they are melted and formed into a continuous sheet or film. This is a critical stage where the quality of the raw materials directly influences the final product’s strength and clarity.

-

Forming: After the film is produced, it undergoes a process called bag formation. This can be achieved through various methods, including blow molding or extrusion. The chosen method will depend on the desired thickness and properties of the bag. For instance, the blown film extrusion method is widely used, where the molten plastic is inflated into a bubble, cooled, and flattened into sheets suitable for cutting and sealing.

-

Assembly: In this stage, the bags are cut to the specified dimensions and sealed at the edges. Different closure types, such as zip seals or heat seals, are applied depending on the intended use of the bags. Quality control checks are often integrated into this process to ensure that seals are properly aligned and secure.

-

Finishing: The final stage involves adding any necessary features such as printing or labeling, which can include brand logos or usage instructions. This is also when the bags are packaged for distribution. Quality assurance protocols are crucial here to ensure that all specifications are met before the bags leave the factory.

How Is Quality Assurance Ensured in the Production of Baggies Plastic Bags?

Quality assurance (QA) in the manufacturing of baggies plastic bags is vital for ensuring compliance with international standards and customer expectations. Several industry-specific and international standards guide this process, including ISO 9001, which outlines quality management systems, and other certifications such as CE and API.

-

International Standards Compliance: B2B buyers should look for suppliers that adhere to ISO 9001 standards, which indicate a commitment to quality management and continuous improvement. Additionally, compliance with CE marking demonstrates that the products meet European health, safety, and environmental requirements.

-

Quality Control Checkpoints:

– Incoming Quality Control (IQC): Raw materials are assessed for quality upon arrival at the manufacturing facility. This includes testing for material specifications and compliance with relevant safety standards.

– In-Process Quality Control (IPQC): During production, continuous monitoring is performed to identify any deviations from the set specifications. This can involve checking the thickness of the film, the strength of seals, and other critical parameters.

– Final Quality Control (FQC): Once production is completed, final inspections are conducted to ensure that each batch meets quality standards. Common tests include stress tests, seal integrity tests, and dimensional checks. -

Common Testing Methods: Various testing methods are employed to verify the quality of baggies plastic bags. These include:

– Tensile Strength Testing: Measures the force required to break the plastic, ensuring it can withstand typical usage conditions.

– Moisture Resistance Testing: Assesses the bag’s ability to protect contents from moisture, which is particularly important for food storage applications.

– Chemical Resistance Testing: Ensures that the bags can withstand exposure to different substances without degrading.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers, especially those from diverse regions such as Africa, South America, the Middle East, and Europe, should employ several strategies to verify the quality control processes of their suppliers.

-

Supplier Audits: Conducting on-site audits can provide insights into the manufacturing processes and quality control measures in place. This allows buyers to assess compliance with international standards and the overall operational efficiency of the supplier.

-

Quality Control Reports: Requesting detailed QC reports from suppliers can help buyers understand the testing methods and results associated with their products. These reports should include documentation of IQC, IPQC, and FQC processes.

-

Third-Party Inspections: Engaging third-party inspection services can offer an unbiased evaluation of the supplier’s quality control measures. This is particularly beneficial for international transactions where buyers cannot easily perform on-site inspections.

What Are the QC and Certification Nuances for International Buyers?

International buyers should be aware of specific nuances related to quality control and certification when sourcing baggies plastic bags.

-

Regional Regulations: Different regions have varying regulations regarding plastic products. For instance, the European Union has stringent guidelines regarding food safety and environmental impact that may not be present in other regions. Buyers should ensure that their suppliers are compliant with local regulations pertinent to their target markets.

-

Environmental Considerations: With increasing awareness of environmental sustainability, buyers should inquire about the materials used in production. Certifications such as those from the Forest Stewardship Council (FSC) or the Recycling symbol can indicate eco-friendly practices.

-

Cultural Sensitivities: Understanding cultural attitudes towards plastic use can influence purchasing decisions. For example, regions with strong environmental movements may prefer suppliers that provide biodegradable or recyclable options.

In summary, a thorough understanding of the manufacturing processes and quality assurance practices surrounding baggies plastic bags is essential for B2B buyers. By focusing on supplier compliance with international standards, implementing rigorous verification methods, and considering regional nuances, buyers can ensure that they source high-quality, reliable products that meet their business needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘baggies plastic bags’

Introduction

This guide aims to provide international B2B buyers with a practical checklist for sourcing baggies plastic bags. As these versatile packaging solutions are crucial across various industries—such as food service, retail, and pharmaceuticals—understanding the procurement process can lead to better decisions and optimized supply chains. Use this checklist to navigate the complexities of sourcing while ensuring compliance, quality, and sustainability.

Step 1: Define Your Technical Specifications

Clearly outline the specifications for the baggies you need. Consider factors such as size, thickness, material type (e.g., food-grade, anti-static), and closure style (zip-seal, heat-sealed). These specifications will guide your selection process and help you communicate effectively with suppliers.

- Common Sizes: Gallon, quart, sandwich, and custom sizes.

- Material Requirements: Ensure compliance with industry standards, especially for food and medical applications.

Step 2: Identify Your Target Suppliers

Compile a list of potential suppliers who specialize in plastic baggies. Research manufacturers known for quality and reliability, especially those with a strong reputation in your target regions like Africa, South America, the Middle East, and Europe.

- Directories to Consider: Utilize platforms like IQS Directory and industry-specific trade shows to find reputable suppliers.

- Local vs. International Suppliers: Assess the benefits of local sourcing for reduced shipping costs versus international suppliers who might offer better pricing or specific product varieties.

Step 3: Evaluate Potential Suppliers

Before committing, thoroughly vet your shortlisted suppliers. Request company profiles, case studies, and references from buyers in similar industries or regions. This step helps ensure that the supplier can meet your expectations and requirements.

- Check Reviews and Ratings: Look for feedback from other businesses regarding product quality and service.

- Request Samples: Always ask for product samples to evaluate quality before placing a larger order.

Step 4: Verify Supplier Certifications

Ensure that your suppliers have the necessary certifications and compliance with local and international regulations. Certifications such as ISO, FDA approval for food-grade materials, and environmental compliance are crucial for ensuring product safety and sustainability.

- Documentation to Request: Ask for copies of certifications and compliance documents to verify authenticity.

- Environmental Considerations: Inquire about sustainable practices and whether the bags are recyclable or made from recycled materials.

Step 5: Discuss Pricing and Payment Terms

Engage in discussions about pricing, payment terms, and any potential bulk order discounts. It’s essential to have clarity on all costs involved, including shipping and handling, to avoid unexpected expenses.

- Negotiate: Don’t hesitate to negotiate terms that suit your budget while ensuring product quality is not compromised.

- Payment Methods: Ensure that the payment methods are secure and offer protection for both parties.

Step 6: Assess Logistics and Delivery Options

Consider the logistics of order fulfillment, including shipping timelines and delivery methods. Understand the lead times associated with your orders to ensure that your supply chain remains efficient.

- Shipping Costs: Factor in shipping costs when comparing suppliers, as these can significantly impact your total expenditure.

- Delivery Reliability: Evaluate the supplier’s track record for on-time delivery and their ability to meet your deadlines.

Step 7: Establish a Trial Order

Before placing a large order, consider initiating a trial order to assess the supplier’s reliability, product quality, and service. This step allows you to evaluate the supplier’s capabilities in real-world conditions without a significant financial commitment.

Illustrative image related to baggies plastic bags

- Feedback Loop: Use this opportunity to provide feedback to the supplier, which can help refine future orders.

- Quality Control Checks: Implement quality control measures to inspect the trial order upon receipt to ensure it meets your specifications.

Comprehensive Cost and Pricing Analysis for baggies plastic bags Sourcing

What Are the Key Cost Components in Baggies Plastic Bags Sourcing?

When considering the sourcing of baggies plastic bags, understanding the cost structure is essential for effective budgeting and price negotiation. The primary cost components include:

-

Materials: The type of plastic resin used significantly impacts cost. Common materials include polyethylene and polypropylene, with prices fluctuating based on market demand and availability. High-quality, FDA-compliant materials often command higher prices but provide better durability and safety for food-related applications.

-

Labor: Labor costs vary by region and production scale. Countries with lower labor costs may offer competitive pricing, but international buyers should factor in potential language barriers and cultural differences that could affect communication and project timelines.

-

Manufacturing Overhead: This includes costs related to utilities, equipment maintenance, and facility management. Efficient factories may have lower overhead, translating into competitive pricing for buyers.

-

Tooling: Custom tooling for specific bag sizes or features (like zip-seals) can require significant upfront investment. Buyers should weigh the necessity of customization against potential long-term savings from bulk production.

-

Quality Control (QC): Ensuring product quality is crucial, especially in regulated industries. The costs associated with QC processes can vary, impacting overall pricing. Suppliers with stringent QC measures may charge a premium but can reduce the risk of defects and returns.

-

Logistics: Transportation costs can vary significantly based on shipping methods, distances, and the chosen Incoterms. Buyers should anticipate additional costs for customs duties and tariffs, particularly when sourcing internationally.

-

Margin: Suppliers will typically add a margin to cover their operational costs and profit. Understanding the supplier’s cost structure can aid in negotiations, especially when considering volume discounts.

How Do Price Influencers Affect Baggies Plastic Bags Sourcing?

Several factors can influence the pricing of baggies plastic bags, which international buyers should consider:

-

Volume and Minimum Order Quantities (MOQ): Higher order volumes often lead to lower per-unit costs. Establishing a long-term partnership with a supplier can lead to favorable pricing agreements, especially for businesses with consistent demand.

-

Specifications and Customization: Custom sizes, colors, or features (like anti-static properties) can increase costs. Buyers should evaluate whether customization is necessary or if standard options suffice.

-

Quality and Certifications: Products meeting specific certifications (like FDA compliance for food safety) may have higher prices. Buyers in regulated industries must prioritize quality, even if it means higher upfront costs.

-

Supplier Factors: Supplier reputation, reliability, and location can all influence pricing. Established suppliers with a track record of quality may charge more but can offer peace of mind.

-

Incoterms: Understanding the chosen Incoterms (e.g., FOB, CIF) is crucial, as they dictate who bears costs and risks at various points in the shipping process. This knowledge can help buyers avoid unexpected expenses.

What Are Essential Tips for International B2B Buyers of Baggies Plastic Bags?

Navigating the complexities of international sourcing requires strategic thinking. Here are practical tips for buyers:

-

Negotiate Wisely: Leverage your understanding of the cost components and price influencers during negotiations. Discuss potential discounts for bulk orders and explore flexible payment terms.

-

Focus on Cost-Efficiency: Analyze the Total Cost of Ownership (TCO), which includes not only purchase price but also logistics, quality control, and potential waste. Sometimes, a higher upfront cost can lead to lower overall expenses due to better quality.

-

Understand Pricing Nuances: Currency fluctuations can impact pricing for international buyers. Be aware of exchange rates and consider hedging strategies if purchasing in a foreign currency.

-

Build Relationships: Establishing strong relationships with suppliers can lead to better pricing, priority production, and more favorable terms in the long run. Regular communication and feedback are key.

-

Stay Informed on Regulations: Be aware of import regulations and potential changes in tariffs or trade agreements that could affect pricing. This is especially pertinent for buyers in regions like Africa, South America, the Middle East, and Europe.

In summary, a thorough understanding of the cost components, price influencers, and negotiation strategies will empower international B2B buyers to make informed decisions when sourcing baggies plastic bags. These insights can lead to more effective sourcing strategies that align with business goals and budget constraints.

Alternatives Analysis: Comparing baggies plastic bags With Other Solutions

Exploring Alternatives to Baggies Plastic Bags in Packaging Solutions

In the evolving landscape of packaging solutions, businesses are continuously seeking alternatives to traditional baggies plastic bags. This is driven by a combination of environmental concerns, cost-effectiveness, and functionality. Below, we compare baggies plastic bags against two notable alternatives: reusable silicone bags and biodegradable bags. Each option presents unique advantages and drawbacks, making it essential for B2B buyers to evaluate their specific needs.

| Comparison Aspect | Baggies Plastic Bags | Reusable Silicone Bags | Biodegradable Bags |

|---|---|---|---|

| Performance | Lightweight, moisture-resistant, available in various sizes | Durable, airtight seal, reusable multiple times | Compostable, limited lifespan compared to plastic |

| Cost | Generally low-cost, bulk purchasing options available | Higher initial investment, but cost-effective over time | Moderate cost, often more expensive than plastic |

| Ease of Implementation | Widely available, easy to use | Requires cleaning and storage, may need initial training for staff | Easy to implement, but may require education on disposal |

| Maintenance | Single-use, disposal required | Requires regular cleaning, can be dishwasher safe | Minimal maintenance, but must be disposed of properly |

| Best Use Case | Food storage, small item organization | Long-term food storage, snacks, travel | Environmentally conscious packaging for food or products |

What Are the Advantages and Disadvantages of Reusable Silicone Bags?

Reusable silicone bags offer a sustainable alternative to traditional plastic baggies. They are made from food-grade silicone, making them durable and capable of withstanding extreme temperatures, which is ideal for food storage. The airtight seal ensures freshness, while their reusability reduces waste over time. However, the initial cost is higher compared to disposable plastic bags, and they require regular cleaning, which might not be feasible for every business. Additionally, proper storage is necessary to avoid damage.

How Do Biodegradable Bags Compare to Baggies Plastic Bags?

Biodegradable bags are designed to break down in composting conditions, making them an environmentally friendly choice. They are suitable for businesses focused on sustainability and can be used for food items, retail packaging, or waste disposal. While they are often more expensive than conventional plastic bags, they provide a clear advantage in reducing plastic waste. However, their lifespan is shorter, and they may not perform as well in moisture-rich environments. Businesses must also educate their customers on proper disposal methods to ensure the bags decompose as intended.

How Can B2B Buyers Choose the Right Packaging Solution for Their Needs?

When selecting the appropriate packaging solution, B2B buyers should assess their specific operational requirements, budget constraints, and environmental goals. For companies prioritizing sustainability, reusable silicone or biodegradable bags may align better with their values, despite potentially higher costs. Conversely, if immediate cost and convenience are critical, baggies plastic bags might still be the best option. Ultimately, the choice should reflect a balance between performance, cost-effectiveness, and the long-term environmental impact of the packaging solution. By considering these factors, businesses can make informed decisions that meet both their operational needs and corporate responsibility objectives.

Essential Technical Properties and Trade Terminology for baggies plastic bags

What Are the Key Technical Properties of Baggies Plastic Bags?

Understanding the critical specifications of baggies plastic bags is essential for B2B buyers, especially in diverse markets across Africa, South America, the Middle East, and Europe. Here are some vital technical properties that influence purchasing decisions:

Illustrative image related to baggies plastic bags

Material Grade: Why Does It Matter?

Baggies plastic bags are typically made from materials such as low-density polyethylene (LDPE) or high-density polyethylene (HDPE). The material grade affects the bag’s flexibility, durability, and resistance to punctures. For instance, LDPE is often chosen for its softness and flexibility, making it ideal for food storage, while HDPE is more rigid and is preferred for industrial applications. Buyers must assess the appropriate material grade based on the intended use to ensure product integrity and compliance with safety standards.

Thickness (Gauge): How Does It Impact Performance?

Thickness, measured in mils or microns, is a critical specification that determines the strength and durability of the bag. Thicker bags provide enhanced protection against tearing and punctures, which is particularly important for packaging heavy or sharp items. For example, a bag with a thickness of 3 mils is suitable for everyday household use, while a 6 mil bag is ideal for industrial applications. Selecting the right thickness can reduce costs associated with product loss or damage.

Closure Type: What Are Your Options?

Baggies plastic bags come with various closure types, including zip-seal, heat seal, and tie closures. Zip-seal bags are popular for their ease of use and resealability, making them ideal for food storage and small item organization. In contrast, heat-sealed bags offer a tamper-proof option for pharmaceuticals and sensitive items. Understanding the benefits of each closure type helps buyers choose the best solution for their specific application.

Compliance Standards: Why Are They Important?

In many regions, especially in Europe and North America, plastic bags must meet specific regulatory standards, such as FDA compliance for food-grade materials. Compliance ensures that the bags are safe for their intended use and do not leach harmful substances. Buyers should verify that their suppliers adhere to these regulations to mitigate legal risks and enhance product credibility.

What Common Trade Terms Should B2B Buyers Know?

Navigating the purchasing process for baggies plastic bags involves understanding specific trade terminology. Here are some common terms that can facilitate smoother transactions:

What is OEM (Original Equipment Manufacturer)?

OEM refers to companies that produce products that are marketed by another company under its brand name. For buyers, sourcing from OEMs can provide cost-effective solutions while ensuring quality and brand reliability. Understanding OEM relationships can help in negotiating better prices and terms.

How to Determine MOQ (Minimum Order Quantity)?

MOQ is the smallest quantity of a product that a supplier is willing to sell. Knowing the MOQ is crucial for buyers to manage inventory costs effectively. Suppliers may set MOQs based on production costs, so buyers should evaluate their needs and negotiate MOQs to align with their purchasing strategy.

What Does RFQ (Request for Quotation) Entail?

An RFQ is a formal document sent to suppliers requesting pricing and terms for specific products. It is a critical step in the procurement process, allowing buyers to compare offers and select the best supplier based on cost, quality, and delivery terms. Crafting a detailed RFQ can lead to better pricing and terms.

Illustrative image related to baggies plastic bags

How Do Incoterms Affect Shipping?

Incoterms are internationally recognized rules that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Understanding these terms is vital for B2B buyers, as they dictate who bears the costs and risks at different stages of the shipping process. Familiarity with Incoterms can help prevent misunderstandings and ensure smooth logistics.

By grasping these essential properties and trade terms, B2B buyers can make informed decisions when sourcing baggies plastic bags, ensuring they meet their specific operational needs while optimizing costs and compliance.

Navigating Market Dynamics and Sourcing Trends in the baggies plastic bags Sector

What Are the Key Trends Shaping the Global Baggies Plastic Bags Market?

The global market for baggies plastic bags is experiencing a dynamic shift influenced by several key drivers. Firstly, the increasing demand for convenience in packaging across various sectors, including food service, retail, and healthcare, is propelling the growth of this market. In emerging economies in Africa and South America, the expansion of the retail and e-commerce sectors is creating new opportunities for suppliers of plastic baggies.

Illustrative image related to baggies plastic bags

Technological advancements are also revolutionizing sourcing processes. Automation in manufacturing and the implementation of advanced materials technology are improving production efficiency and product quality. For instance, suppliers are increasingly adopting custom sizing and varied closure options to meet specific customer needs. Moreover, the rise of digital platforms is facilitating easier sourcing and procurement processes, allowing B2B buyers to compare prices and quality from multiple suppliers quickly.

Another notable trend is the shift towards transparency and traceability in supply chains. International buyers are becoming more discerning, seeking suppliers who can provide detailed information about product origins and manufacturing practices. This trend is particularly pronounced in regions like Europe and the Middle East, where regulatory frameworks are increasingly stringent.

How Is Sustainability Influencing the Sourcing of Baggies Plastic Bags?

The environmental impact of plastic baggies is becoming a pivotal concern for B2B buyers. The growing awareness of issues like plastic pollution and the presence of harmful chemicals such as PFAS (per- and polyfluoroalkyl substances) in some plastic products is prompting businesses to reconsider their sourcing strategies.

Ethical sourcing is now a priority, with companies actively seeking suppliers who adhere to sustainable practices. This includes the use of recycled materials, biodegradable options, and adherence to environmental regulations. Certifications such as the Forest Stewardship Council (FSC) and ISO 14001 are becoming essential for suppliers looking to establish credibility in the market.

Furthermore, businesses are increasingly recognizing the importance of implementing ‘green’ supply chains. This involves not only sourcing environmentally friendly materials but also optimizing logistics to reduce carbon footprints. For international buyers, particularly in regions like Saudi Arabia and Brazil, aligning with sustainable suppliers can enhance brand reputation and meet the expectations of eco-conscious consumers.

How Have Baggies Plastic Bags Evolved Over Time?

The evolution of baggies plastic bags can be traced back to the mid-20th century when advancements in polymer technology made the production of lightweight, durable plastic feasible. Initially, these bags were primarily used for food storage and packaging, but their versatility soon found applications across various sectors, including healthcare and retail.

Over the years, the demand for resealable and moisture-resistant options has increased, leading to innovations in closure mechanisms like zip-seal and heat-sealed designs. As consumer preferences shifted towards convenience and hygiene, manufacturers responded by developing specialized baggies for specific applications, such as anti-static bags for electronics or food-grade options for culinary use.

Today, the focus is not just on functionality but also on sustainability, with manufacturers working towards minimizing environmental impacts through innovative materials and responsible sourcing practices. This evolution reflects a broader trend in the market where consumer awareness and regulatory pressures are driving a significant transformation in product offerings and sourcing strategies.

Frequently Asked Questions (FAQs) for B2B Buyers of baggies plastic bags

-

How do I choose the right plastic baggies for my business needs?

Choosing the right plastic baggies involves assessing your specific requirements, such as size, thickness, and intended use. Consider whether you need food-safe, anti-static, or moisture-resistant options based on your industry—food service, medical, or retail, for example. It’s also crucial to evaluate the baggie’s closure style, such as zip-seal or heat-sealed, which can affect usability and product protection. Collaborating with a reputable manufacturer can help ensure that the bags meet regulatory compliance and quality standards. -

What types of plastic baggies are available for commercial use?

Plastic baggies come in a variety of types tailored for different applications. Clear, colored, food-grade, and anti-static options are among the most common. Businesses in food service often prefer food-grade baggies for safe storage, while electronics manufacturers may require anti-static varieties to protect sensitive components. Understanding your application will help you select the most suitable type for your business needs and compliance requirements. -

What are the minimum order quantities (MOQs) for bulk purchases of plastic baggies?

Minimum order quantities (MOQs) for plastic baggies can vary significantly depending on the manufacturer and specific product type. Typically, MOQs may range from a few thousand to tens of thousands of units. It’s advisable to discuss your needs with potential suppliers to negotiate terms that align with your inventory requirements. Some manufacturers may offer flexibility for first-time buyers or smaller businesses, making it easier to establish a partnership. -

What payment terms should I expect when ordering from international suppliers?

Payment terms can vary widely among international suppliers. Common options include upfront payments, partial payments, or net terms based on established credit lines. Many suppliers accept various payment methods, such as wire transfers, letters of credit, or PayPal. It’s essential to clarify payment terms before finalizing orders to avoid misunderstandings and ensure smooth transactions, particularly when dealing with cross-border logistics. -

How can I ensure the quality of plastic baggies before making a bulk purchase?

To ensure product quality, request samples from potential suppliers before committing to bulk orders. Assess the material, thickness, closure mechanisms, and overall durability of the baggies. Additionally, inquire about the manufacturer’s quality assurance processes, certifications (like FDA compliance for food-grade bags), and customer reviews. Establishing a clear communication channel for quality expectations can help mitigate issues down the line. -

What logistics considerations should I keep in mind for importing plastic baggies?

When importing plastic baggies, consider logistics factors such as shipping costs, transit times, and customs regulations. Research shipping methods, including sea or air freight, and choose based on your urgency and budget. Understand the import duties and compliance regulations in your country to avoid unexpected costs. Collaborating with a logistics provider experienced in international shipping can help navigate these complexities efficiently. -

Are there customization options available for plastic baggies?

Many manufacturers offer customization options for plastic baggies, including size, color, and printing. Custom branding can enhance product visibility and align with your marketing strategies. Discuss your specific requirements with potential suppliers to understand the available customization options, lead times, and any additional costs involved. Customization can be a valuable investment for businesses looking to differentiate their products in competitive markets. -

What are the environmental considerations regarding plastic baggies?

Environmental concerns are increasingly relevant in the plastic industry. Many manufacturers are now offering biodegradable or recyclable baggie options to meet sustainability goals. When sourcing, inquire about the materials used and the manufacturer’s commitment to eco-friendly practices. Understanding the lifecycle impact of the products you choose can help your business align with sustainability initiatives and respond to consumer demand for environmentally responsible packaging solutions.

Top 5 Baggies Plastic Bags Manufacturers & Suppliers List

1. Plastic Bags – Resealable Packaging Solutions

Domain: plastic-bags.net

Registered: 2002 (23 years)

Introduction: Plastic baggies are lightweight, resealable, and moisture-resistant packaging solutions used for organizing and protecting small items. They come in various sizes and thicknesses, with closure styles including zip-seal and heat-sealed options. Available types include clear, colored, anti-static, and food-grade varieties. Applications include packaging jewelry, food storage, pharmaceutical uses, an…

2. Target – Kitchen Storage Baggies

Domain: target.com

Registered: 1997 (28 years)

Introduction: This company, Target – Kitchen Storage Baggies, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

3. Reddit – Storage Solutions

Domain: reddit.com

Registered: 2005 (20 years)

Introduction: 1. Jewelers bags: Packs of 200 available at local hobby stores for approximately $3.

2. 4″x6″ zip bags: Available in the craft section of big box stores, suitable for various storage needs.

3. Plastic containers with lids: Available at Dollar Tree, 10 containers for $1.25.

4. Reusable baggies: Suggested to collect baggies from other products for economical storage.

4. Lunds & Byerlys – Hefty Baggies Gallon Storage Bags with Ties

Domain: lundsandbyerlys.com

Registered: 2006 (19 years)

Introduction: Hefty Baggies Gallon Storage Bags with Ties

5. Zip Top – Reusable Food Storage Bags

Domain: todaysparent.com

Registered: 1995 (30 years)

Introduction: 1. Zip Top Reusable Food Storage Bags: Available in 12 sizes and six colors, made from 100% platinum silicone, free from BPA, lead, PVC, latex, and phthalates. Dishwasher, freezer, and microwave-safe.

2. Stasher Reusable Silicone Storage Bags: Made from platinum-grade materials, available in three sizes and five colors. Durable, dishwasher-safe, microwave-friendly, and oven-ready up to 425°F.

…

Strategic Sourcing Conclusion and Outlook for baggies plastic bags

As the global demand for baggies plastic bags continues to rise across diverse sectors—ranging from food service to pharmaceuticals—strategic sourcing emerges as a vital process for international B2B buyers. By partnering with reliable manufacturers, businesses can ensure they are obtaining high-quality, compliant products that meet their specific needs. The versatility of plastic baggies, available in various sizes, materials, and closure types, allows companies to tailor their packaging solutions effectively while also promoting sustainability through options like recycled materials.

Additionally, being mindful of health concerns related to plastic baggies, such as the presence of PFAS, will be crucial for companies aiming to maintain a positive brand image and comply with evolving regulations. As environmental considerations gain importance, sourcing from suppliers who prioritize eco-friendly practices will not only enhance product appeal but also align with consumer expectations.

Looking ahead, international buyers from regions such as Africa, South America, the Middle East, and Europe should seize the opportunity to leverage strategic sourcing in their procurement strategies. Engaging with innovative suppliers can lead to improved operational efficiencies, cost savings, and a stronger market position. Now is the time to explore new partnerships and invest in sustainable packaging solutions that will drive business growth in the future.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to baggies plastic bags

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.