How to Source Baggies Bags Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for baggies bags

In the dynamic landscape of global commerce, sourcing high-quality baggies bags presents unique challenges for international B2B buyers. Whether you are in Nigeria seeking reliable storage solutions or in Brazil looking for versatile packaging options, navigating the myriad of suppliers and product types can be daunting. This guide aims to simplify your journey by providing a comprehensive overview of the baggies bags market, covering various types such as sandwich, storage, and specialty bags, as well as their diverse applications across industries.

We delve into critical aspects of the procurement process, including supplier vetting, cost considerations, and sustainability practices. By arming you with actionable insights and best practices, this guide empowers you to make informed purchasing decisions that align with your business needs. With a focus on the specific requirements and preferences of buyers from Africa, South America, the Middle East, and Europe, we ensure that you have the tools necessary to navigate the complexities of the baggies bags market effectively.

As you explore the sections ahead, you will gain a deeper understanding of how to select the right products, negotiate favorable terms, and leverage global supply chains to your advantage. The insights provided here will not only enhance your purchasing strategy but also contribute to the overall efficiency and profitability of your operations.

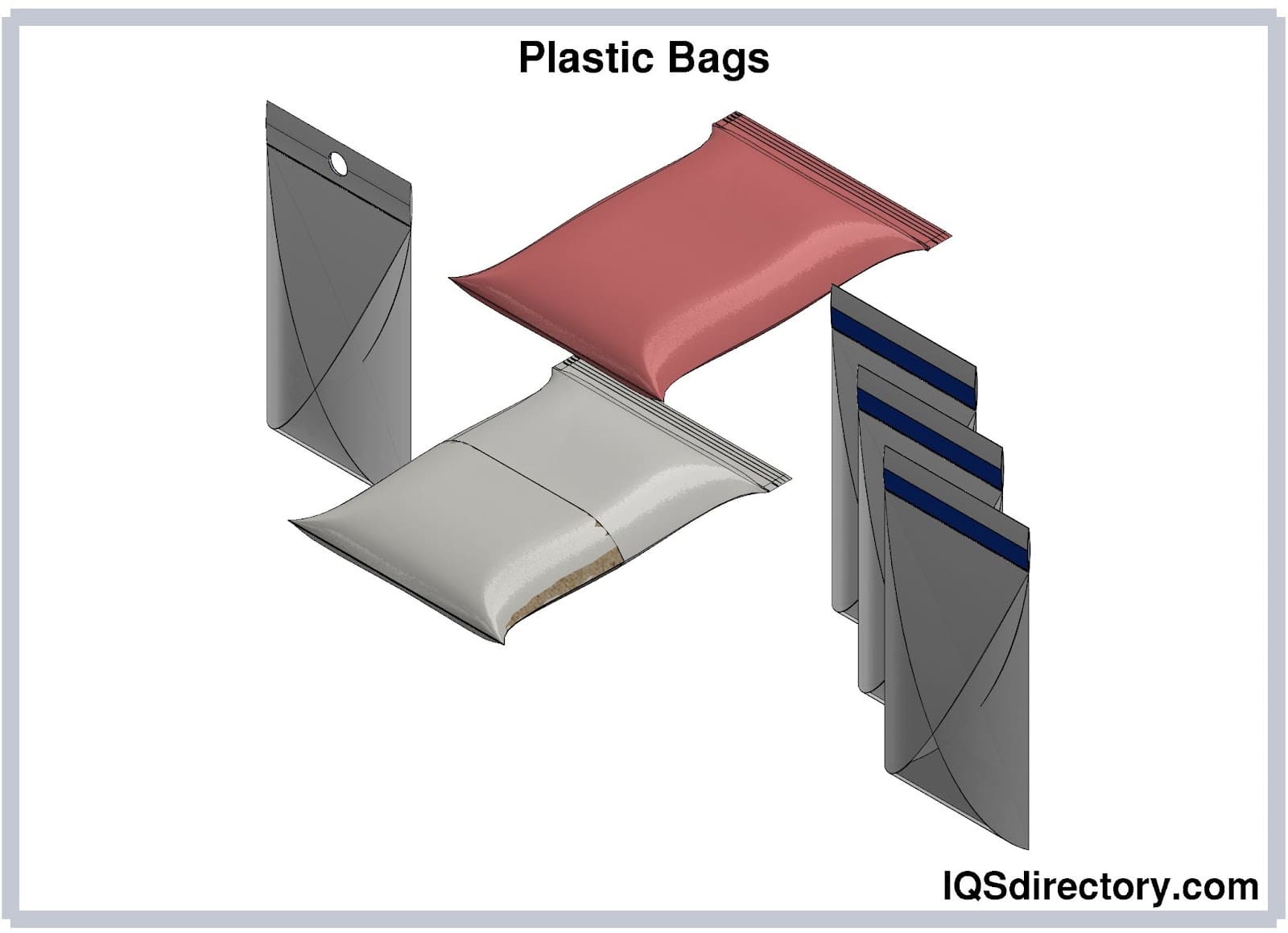

Understanding baggies bags Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Standard Storage Baggies | Clear plastic, resealable, various sizes | Food service, retail packaging | Pros: Cost-effective, versatile. Cons: Less durable for heavy items. |

| Smell-Proof Baggies | Odor-blocking technology, often made from thicker materials | Cannabis packaging, specialty products | Pros: Discreet, high-quality seal. Cons: Higher cost than standard bags. |

| Slider Seal Baggies | Easy-to-use slider closure, expandable bottom | Food storage, catering | Pros: Secure seal, user-friendly. Cons: Slightly bulkier than traditional bags. |

| Freezer Baggies | Designed for low temperatures, thicker material | Food storage, meal prep | Pros: Prevents freezer burn, durable. Cons: Limited to cold storage applications. |

| Specialty Baggies (e.g., Apple Bags) | Custom designs, various sizes, often for specific products | Retail, promotional items | Pros: Customizable, attractive for branding. Cons: May require higher minimum orders. |

What are the Characteristics and Suitability of Standard Storage Baggies?

Standard storage baggies are typically made from clear plastic and come in a variety of sizes, making them versatile for many applications. They are resealable, which aids in keeping contents fresh. These bags are widely used in food service and retail packaging, making them essential for businesses in these sectors. When purchasing, consider factors like thickness and size to ensure they meet your specific storage needs.

How Do Smell-Proof Baggies Stand Out in the Market?

Smell-proof baggies are characterized by their unique odor-blocking technology, often made from thicker materials to enhance durability. These bags are particularly suited for packaging cannabis products and other specialty items where discretion is key. B2B buyers should evaluate the quality of the seal and material, as these factors directly impact the effectiveness of odor containment and product integrity.

What Advantages Do Slider Seal Baggies Offer for Food Storage?

Slider seal baggies feature an easy-to-use closure mechanism that ensures a secure seal, making them ideal for food storage and catering applications. The expandable bottom allows for easy filling, which is beneficial for businesses dealing with bulk items. When considering these bags, assess the slider mechanism’s reliability and the bag’s overall sturdiness, especially for heavier items.

What Makes Freezer Baggies Essential for Food Storage?

Freezer baggies are specifically designed to withstand low temperatures, featuring thicker materials that prevent freezer burn. These bags are crucial for businesses involved in food storage and meal prep, as they ensure the longevity and quality of frozen goods. Buyers should focus on the bag’s capacity to seal properly and its resistance to punctures or tears during freezing.

Why Consider Specialty Baggies like Apple Bags for Branding?

Specialty baggies, such as apple bags, come in various sizes and can feature custom designs, making them ideal for retail and promotional purposes. These bags not only serve a functional purpose but also enhance brand visibility. When purchasing, consider the customization options and minimum order quantities, as these factors can affect overall marketing strategies and costs.

Key Industrial Applications of baggies bags

| Industry/Sector | Specific Application of baggies bags | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Food and Beverage | Packaging for food items and ingredients | Enhances food safety and extends shelf life | Compliance with food safety standards, material quality |

| Agriculture | Seed and soil sample storage | Protects samples from contamination | Durability, size variety, and UV resistance |

| Pharmaceuticals | Secure storage for medical supplies | Ensures product integrity and safety | Regulatory compliance, tamper-evidence features |

| Retail | Product display and packaging | Improves customer appeal and convenience | Customization options, branding capabilities |

| Electronics | Component protection during shipping | Reduces damage risk and enhances logistics | Anti-static properties, size specifications |

How Are Baggies Bags Used in the Food and Beverage Industry?

In the food and beverage sector, baggies bags are crucial for packaging various food items, from raw ingredients to prepared meals. They help ensure food safety by providing an airtight seal that extends shelf life and prevents contamination. International buyers must consider compliance with local food safety regulations, ensuring that materials used are food-grade and free from harmful chemicals. Additionally, the ability to customize sizes and designs can enhance brand visibility and appeal to consumers.

What Role Do Baggies Bags Play in Agriculture?

In agriculture, baggies bags are commonly used for storing seeds and soil samples. Their protective qualities help prevent contamination from pests and environmental factors, ensuring that samples remain viable for testing and planting. For buyers in regions with diverse climates, sourcing bags that offer UV resistance and durability is essential. This guarantees that the bags can withstand varying environmental conditions, particularly in tropical or arid regions.

How Are Baggies Bags Essential for the Pharmaceutical Sector?

Pharmaceutical companies utilize baggies bags for secure storage of medical supplies and samples. These bags protect products from external factors, ensuring integrity and safety during transportation and storage. Buyers in this industry must prioritize sourcing bags that meet stringent regulatory requirements, including tamper-evident features and compliance with health standards. Quality assurance is vital, as any compromise can lead to significant health risks and liability issues.

In What Ways Do Retailers Benefit from Baggies Bags?

Retailers leverage baggies bags for product display and packaging, enhancing customer experience through convenience and accessibility. These bags can be customized with branding elements, making them an effective marketing tool. For B2B buyers, key considerations include the availability of various sizes and styles that fit different product types, as well as the potential for eco-friendly materials to appeal to environmentally conscious consumers.

Why Are Baggies Bags Important in the Electronics Industry?

In the electronics sector, baggies bags are essential for protecting components during shipping and storage. Their anti-static properties safeguard sensitive electronic parts from damage caused by static electricity. Buyers should focus on sourcing bags that meet specific size requirements and provide adequate protection during transit. Additionally, understanding the logistics of shipping components internationally can help in selecting appropriate packaging solutions that minimize risk and ensure product integrity.

3 Common User Pain Points for ‘baggies bags’ & Their Solutions

Scenario 1: Navigating Quality Consistency in Bulk Purchases

The Problem: B2B buyers often face the challenge of inconsistent quality when sourcing baggies bags in bulk. This inconsistency can stem from different manufacturing processes, variations in materials, or changes in suppliers. For businesses that rely on these bags for packaging, storage, or distribution, receiving subpar products can lead to operational disruptions, financial losses, and damage to brand reputation.

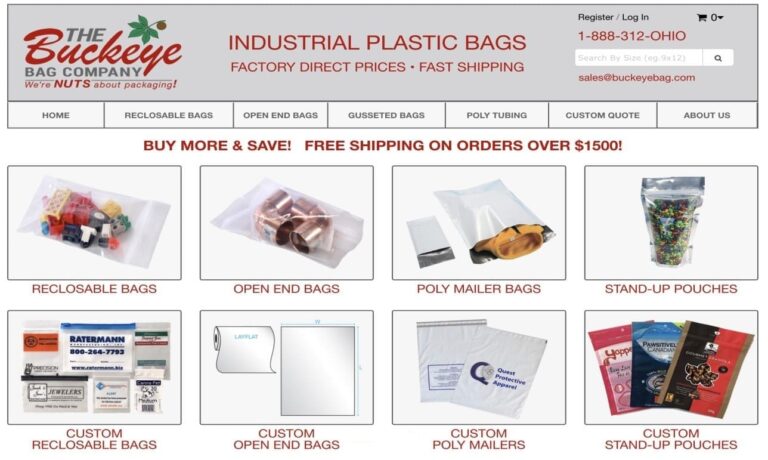

Illustrative image related to baggies bags

The Solution: To mitigate quality issues, it’s essential to establish a robust supplier evaluation process. Start by creating a set of quality criteria that includes material specifications, thickness, durability, and seal integrity. Request samples from potential suppliers and conduct thorough testing to assess performance. Additionally, consider suppliers who offer certifications for their products, such as ISO or ASTM standards, which can serve as indicators of quality. Regular audits of supplier facilities can also ensure that quality remains consistent over time. By prioritizing quality in the sourcing process, businesses can enhance their operational efficiency and customer satisfaction.

Scenario 2: Addressing Environmental Concerns with Baggies Bags

The Problem: As sustainability becomes a focal point for many businesses, B2B buyers often grapple with the dilemma of sourcing environmentally friendly baggies bags. Traditional plastic bags contribute to pollution and landfill waste, which can harm a company’s public image and violate increasingly stringent regulations in various regions.

The Solution: To address environmental concerns, buyers should seek out suppliers that provide eco-friendly options, such as biodegradable or recyclable baggies bags. Look for materials that meet international environmental standards, and verify the supplier’s claims with third-party certifications. Engaging with suppliers who prioritize sustainability in their manufacturing processes can also be beneficial. Consider implementing a take-back program where used bags can be returned for recycling. This not only reduces waste but also positions your company as a leader in sustainability, appealing to environmentally conscious consumers and partners.

Illustrative image related to baggies bags

Scenario 3: Managing Inventory and Supply Chain Challenges

The Problem: Fluctuations in demand can create significant inventory management challenges for businesses that use baggies bags. Over-ordering can tie up capital and storage space, while under-ordering can lead to stockouts, disrupting operations and causing delays in service delivery.

The Solution: Implementing a just-in-time (JIT) inventory system can help manage these challenges effectively. Start by analyzing sales data to identify patterns in demand, and collaborate closely with suppliers to establish reliable lead times. Utilize inventory management software that provides real-time visibility into stock levels and automates reorder alerts based on preset thresholds. Additionally, maintaining a good relationship with suppliers can facilitate faster turnaround times for urgent orders. By optimizing inventory levels, businesses can reduce costs while ensuring they have the necessary supplies to meet customer demand promptly.

Strategic Material Selection Guide for baggies bags

What Are the Common Materials Used in Baggies Bags?

When selecting materials for baggies bags, B2B buyers must consider several factors, including performance characteristics, cost, and compliance with international standards. Below are analyses of four common materials used in the production of baggies bags: polyethylene (PE), polypropylene (PP), nylon, and biodegradable plastics.

How Does Polyethylene (PE) Perform in Baggies Bags?

Polyethylene is one of the most widely used materials for baggies bags due to its excellent flexibility and moisture barrier properties. It can withstand temperatures ranging from -40°C to 60°C, making it suitable for various storage needs. However, while PE is resistant to many chemicals, it can be susceptible to UV degradation over time.

Pros include its low cost and ease of manufacturing, which makes it a popular choice for bulk production. Cons involve its limited durability against punctures and tears, which may affect its suitability for heavy-duty applications. For buyers in regions like Africa and South America, where UV exposure can be significant, considering UV-stabilized variants may be beneficial.

What Are the Benefits of Polypropylene (PP) for Baggies Bags?

Polypropylene offers superior clarity and stiffness compared to polyethylene, making it an excellent choice for applications requiring visibility and rigidity. It has a temperature tolerance of up to 120°C, which allows for hot-fill applications. However, it is less flexible than PE, which can limit its use in certain contexts.

The key advantages of PP include its higher chemical resistance and better barrier properties against moisture and oxygen. On the downside, PP can be more expensive than PE, and its manufacturing process is slightly more complex. For international buyers, especially in Europe, compliance with food safety standards (e.g., EU regulations) is crucial when sourcing PP baggies.

How Does Nylon Compare for Baggies Bags?

Nylon is known for its exceptional strength and durability, making it suitable for heavy-duty applications where puncture resistance is essential. It can withstand temperatures up to 180°C, which is advantageous for applications requiring heat resistance. However, nylon is more permeable to gases than PE and PP, which could affect its performance in certain storage scenarios.

The advantages of nylon include its high tensile strength and resistance to wear, while the disadvantages encompass its higher cost and more complex manufacturing process. Buyers from the Middle East, where high temperatures are prevalent, may find nylon particularly useful for applications requiring robust performance under heat.

What Are the Considerations for Biodegradable Plastics in Baggies Bags?

Biodegradable plastics are gaining popularity due to increasing environmental concerns. These materials can decompose under specific conditions, making them an eco-friendly choice for consumers. However, their performance can vary significantly depending on the specific formulation and environmental conditions.

Advantages include reduced environmental impact and compliance with sustainability initiatives, which are increasingly important for businesses in Europe and North America. However, the limitations often involve higher costs and potential performance issues under extreme conditions. For B2B buyers, understanding the specific biodegradation conditions is essential to ensure the bags meet their operational needs.

Summary of Material Selection for Baggies Bags

| Material | Typical Use Case for baggies bags | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Polyethylene (PE) | General storage and food packaging | Low cost and moisture barrier | Susceptible to UV degradation | Low |

| Polypropylene (PP) | Food storage and visibility needs | Higher chemical resistance | More expensive and less flexible | Medium |

| Nylon | Heavy-duty applications | Exceptional strength and durability | Higher cost and complex manufacturing | High |

| Biodegradable Plastics | Eco-friendly packaging | Reduced environmental impact | Higher costs and variable performance | Medium to High |

This strategic material selection guide aims to assist international B2B buyers in making informed decisions regarding the most suitable materials for baggies bags, taking into account their specific applications and regional requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for baggies bags

What Are the Main Stages in the Manufacturing Process of Baggies Bags?

The manufacturing process of baggies bags involves several critical stages, each contributing to the final product’s quality and functionality. Understanding these stages can empower B2B buyers to make informed decisions when sourcing these products.

Material Preparation: How Is the Raw Material Selected?

The first stage in manufacturing baggies bags is the selection and preparation of raw materials, typically high-density polyethylene (HDPE) or low-density polyethylene (LDPE). These materials are chosen for their durability, flexibility, and resistance to moisture and chemicals. Manufacturers often source these materials from certified suppliers to ensure compliance with international standards.

Once sourced, the raw materials are subjected to quality checks to assess their physical and chemical properties. This step ensures that the materials meet the specifications required for producing bags that can withstand various conditions, from storage to transportation.

Illustrative image related to baggies bags

Forming: What Techniques Are Used to Create Baggies Bags?

The forming stage involves the transformation of raw materials into baggies bags through processes such as extrusion and blow molding. In the extrusion process, plastic pellets are heated and melted, then forced through a die to create a continuous sheet. This sheet is then cut into the desired dimensions for bag production.

Blow molding, on the other hand, creates hollow bags by inflating a molten tube of plastic within a mold. This method is particularly useful for producing thicker, more robust bags that require additional strength. The choice of technique often depends on the intended use of the baggies, with certain applications requiring specific properties like smell-proof features or added thickness.

Assembly: How Are the Bags Completed?

After forming, the bags undergo assembly, which may involve adding features such as zippers, seals, or twist ties. This step is crucial for enhancing the functionality and usability of the bags. For instance, slider closures or zip seals are often incorporated to provide airtight storage, while twist ties may be added for convenience in sealing.

Manufacturers also perform inline quality checks during this stage to ensure that all features are correctly installed and function as intended. This can prevent costly reworks or returns later in the supply chain.

Finishing: What Happens in the Final Touches of Production?

The finishing stage includes processes such as printing, labeling, and packaging. Custom branding, product information, and recycling instructions can be printed directly onto the bags, adding value for B2B buyers looking to enhance their brand visibility.

After printing, the bags are packaged according to customer specifications, often in bulk quantities for wholesale distribution. Quality checks are performed to ensure that the bags are free from defects, properly labeled, and ready for shipping.

What Quality Assurance Standards Are Relevant for Baggies Bags?

Quality assurance is a critical aspect of the manufacturing process, especially for B2B buyers who require reliable and consistent products. Adhering to international standards helps manufacturers ensure that their products meet specific quality criteria.

What International Standards Should Buyers Look For?

For baggies bags, ISO 9001 is a fundamental quality management standard that outlines requirements for a quality management system (QMS). Manufacturers certified to ISO 9001 demonstrate their commitment to quality and continuous improvement.

In addition to ISO standards, B2B buyers should also look for compliance with other industry-specific certifications, such as CE marking for products sold in Europe, which indicates conformity with health, safety, and environmental protection standards. Buyers in the Middle East may also seek products that comply with Gulf Standards Organization (GSO) regulations, ensuring that the bags meet local quality requirements.

How Are Quality Control Checkpoints Structured?

Quality control (QC) in baggies bag manufacturing typically involves several checkpoints:

- Incoming Quality Control (IQC): Raw materials are inspected upon arrival to ensure they meet the required specifications.

- In-Process Quality Control (IPQC): Continuous monitoring occurs during the manufacturing process, where operators check for defects and adherence to specifications.

- Final Quality Control (FQC): Once the bags are completed, a final inspection is conducted to verify that the bags are free from defects and meet all packaging and labeling requirements.

What Common Testing Methods Are Used in Quality Assurance?

To ensure that baggies bags meet quality standards, various testing methods are employed:

- Physical Testing: This includes tensile strength tests, puncture resistance tests, and seal strength tests to evaluate the durability of the bags.

- Chemical Testing: Assessments are conducted to determine the presence of harmful substances, ensuring compliance with safety regulations.

- Environmental Testing: Tests to evaluate the bags’ recyclability and biodegradability are increasingly important, especially for environmentally-conscious buyers.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, verifying a supplier’s quality control processes is essential to ensure product reliability. Here are some effective strategies:

Illustrative image related to baggies bags

What Should Buyers Look for in Supplier Audits?

Requesting third-party audits or certifications can provide assurance of a supplier’s commitment to quality. Buyers should inquire about the frequency and scope of these audits, as well as whether the supplier has undergone recent inspections by recognized certification bodies.

How Can Reports and Documentation Support Quality Assurance?

Suppliers should be able to provide documentation that outlines their quality control processes, including test reports and compliance certificates. These documents can help buyers assess the supplier’s adherence to international standards and their ability to meet specific product requirements.

What Are the QC and Certification Nuances for International Buyers?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, should be aware of the regulatory and certification nuances that may affect their purchasing decisions.

Illustrative image related to baggies bags

How Do Regional Standards Impact Sourcing?

Different regions may have varying regulations regarding plastic products, including baggies bags. Buyers should familiarize themselves with local standards and requirements to ensure compliance and avoid potential issues with customs or market entry.

Why Is It Important to Build Strong Supplier Relationships?

Building strong relationships with suppliers can facilitate better communication regarding quality standards and expectations. Regular discussions about quality assurance processes can lead to improved product quality and a more reliable supply chain.

In summary, understanding the manufacturing processes and quality assurance standards for baggies bags is crucial for B2B buyers. By familiarizing themselves with these aspects, buyers can make informed decisions, ensuring they source products that meet their quality and compliance needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘baggies bags’

In the competitive landscape of B2B sourcing, procuring baggies bags requires a strategic approach to ensure quality, compliance, and cost-effectiveness. This practical sourcing guide outlines a step-by-step checklist tailored for international buyers, especially from Africa, South America, the Middle East, and Europe. Follow these steps to streamline your procurement process and secure the best products for your business needs.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is crucial for ensuring that the baggies bags meet your specific needs. Consider factors such as size, material (e.g., plastic thickness), and functionality (e.g., reusability, odor-proof capabilities). Document these requirements to facilitate accurate supplier comparisons.

Step 2: Research Market Trends and Pricing

Understanding current market trends helps you gauge fair pricing and product demand. Analyze competitors and industry reports to identify popular features and pricing benchmarks. This knowledge enables you to negotiate effectively and avoid overpaying.

Step 3: Identify Potential Suppliers

Compile a list of potential suppliers through industry directories, trade shows, and online platforms. Focus on companies with a solid reputation for quality and reliability. Consider both local and international suppliers to broaden your options and leverage competitive pricing.

Step 4: Verify Supplier Certifications

Before entering into negotiations, ensure that your potential suppliers possess the necessary certifications. Look for compliance with international standards such as ISO, as well as any region-specific regulations relevant to your market. Certifications can indicate product quality and adherence to safety practices.

Step 5: Request Samples for Evaluation

Always request samples of the baggies bags before finalizing any order. Testing samples allows you to assess quality, durability, and functionality firsthand. Pay attention to the packaging and labeling, as these can reflect the supplier’s attention to detail and commitment to quality.

Step 6: Negotiate Terms and Conditions

Once you’ve identified a suitable supplier, engage in negotiations to establish favorable terms. Discuss pricing, minimum order quantities, payment terms, and delivery schedules. Ensure that the agreement includes clear conditions for returns or exchanges in case the products do not meet your expectations.

Illustrative image related to baggies bags

Step 7: Establish a Quality Assurance Process

Implement a quality assurance process to maintain product standards post-purchase. Set up regular audits and inspections, especially for bulk orders. This step is vital to ensure that the baggies bags delivered consistently meet your specifications and performance expectations.

By following this checklist, B2B buyers can confidently navigate the sourcing process for baggies bags, ensuring they secure quality products that meet their business needs while optimizing costs.

Comprehensive Cost and Pricing Analysis for baggies bags Sourcing

What Are the Key Cost Components in Baggies Bags Manufacturing?

When sourcing baggies bags, understanding the cost structure is vital for effective budgeting and negotiation. The primary cost components include:

-

Materials: The choice of materials significantly affects pricing. Common materials for baggies bags include polyethylene and polypropylene, with varying thicknesses and properties impacting costs. Sustainable options may have a higher upfront cost but can appeal to environmentally conscious buyers.

-

Labor: Labor costs are influenced by the manufacturing location. Regions with lower labor costs, such as parts of Asia, may offer competitive pricing. However, consider the potential for increased shipping costs and lead times.

-

Manufacturing Overhead: This includes utilities, rent, and other operational expenses. Efficient manufacturing processes can help keep these costs down. Suppliers with advanced technology may pass on savings, providing better pricing flexibility.

-

Tooling: Custom molds for specialized bag sizes or designs can incur significant initial costs. However, these costs can be amortized over larger production runs, making them more feasible for high-volume orders.

-

Quality Control (QC): Ensuring the bags meet required specifications involves QC measures, which can add to costs. Certifications for food safety or environmental standards can also impact pricing but are crucial for compliance in many markets.

-

Logistics: Transportation and handling costs vary based on the supplier’s location and the destination market. International shipping, customs duties, and local distribution logistics should be factored into the total cost.

-

Margin: Suppliers will add a profit margin to cover their costs and risks. Understanding the typical margins in the industry can help buyers negotiate more effectively.

How Do Price Influencers Impact Baggies Bags Sourcing?

Several factors can influence the pricing of baggies bags:

-

Volume/MOQ: Minimum order quantities (MOQ) often dictate pricing. Larger orders typically result in lower per-unit costs, making it advantageous for buyers to consolidate purchases.

-

Specifications and Customization: Custom designs or specific dimensions can lead to higher costs. Buyers should assess whether the added cost aligns with their branding or functional needs.

-

Material Quality and Certifications: Higher quality materials or those with specific certifications (e.g., FDA-approved for food use) can increase costs. Buyers should weigh the benefits of these certifications against their budget.

-

Supplier Factors: The supplier’s reputation, reliability, and manufacturing capabilities can affect pricing. Established suppliers may charge a premium but offer better quality assurance and service.

-

Incoterms: The terms of shipping (e.g., FOB, CIF) will influence the total landed cost. Buyers should clarify these terms to avoid unexpected expenses.

What Are Effective Buyer Tips for Sourcing Baggies Bags?

Navigating the procurement process requires strategic approaches:

-

Negotiation: Engage suppliers in discussions about pricing, especially if you can commit to larger orders or long-term contracts. Demonstrating the potential for repeat business may incentivize suppliers to offer better rates.

-

Cost-Efficiency: Consider the Total Cost of Ownership (TCO), which includes not just the purchase price but also logistics, storage, and potential waste. A slightly higher upfront cost may yield savings in the long run through reduced waste and improved efficiency.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations and import tariffs that can affect pricing. Building relationships with local suppliers in your region can mitigate some of these costs and complexities.

-

Due Diligence: Research potential suppliers thoroughly. Request samples to assess quality and ensure they meet your specifications before placing a large order.

-

Stay Informed: Keep abreast of market trends and changes in material costs to anticipate price fluctuations. This knowledge can empower you during negotiations and sourcing decisions.

Disclaimer

The prices mentioned in this analysis are indicative and can vary based on market conditions, supplier negotiations, and specific buyer requirements. Always conduct thorough research and obtain multiple quotes before making purchasing decisions.

Alternatives Analysis: Comparing baggies bags With Other Solutions

Exploring Alternatives to Baggies Bags in B2B Applications

In the realm of packaging and storage solutions, baggies bags are a popular choice due to their versatility and convenience. However, various alternatives exist that can cater to specific business needs. This analysis will compare baggies bags with two viable alternatives: rigid containers and biodegradable bags, focusing on key aspects that influence purchasing decisions for B2B buyers.

Comparison Table

| Comparison Aspect | Baggies Bags | Rigid Containers | Biodegradable Bags |

|---|---|---|---|

| Performance | Good for lightweight items | Excellent for heavy or fragile items | Varies by material, generally good |

| Cost | Low cost per unit | Higher initial investment | Moderate cost, often premium |

| Ease of Implementation | Simple to use and store | Requires more space and setup | Easy to use, but sourcing can be complex |

| Maintenance | Minimal maintenance required | Requires cleaning and care | Limited durability, single-use |

| Best Use Case | Snacks, sandwiches, small items | Bulk storage, shipping, fragile items | Eco-conscious packaging for food or retail |

Detailed Breakdown of Alternatives

Rigid Containers

Rigid containers, such as plastic or glass jars, provide robust solutions for storing and transporting items. They excel in performance, particularly for heavy or delicate products, as they prevent damage during transit. While the initial cost is significantly higher compared to baggies bags, they offer long-term savings through reusability. However, rigid containers require more storage space and may necessitate cleaning and maintenance to ensure hygiene. Their best use case is in industries where product integrity is critical, such as food and pharmaceuticals.

Biodegradable Bags

Biodegradable bags represent a growing trend in sustainable packaging solutions. These bags are designed to decompose over time, making them an attractive option for environmentally conscious businesses. Their cost is generally moderate, falling between traditional plastic bags and premium packaging solutions. While they are easy to use and align with eco-friendly practices, they may not offer the same level of durability as baggies bags, especially for long-term storage. Best suited for food service or retail environments focused on sustainability, biodegradable bags can enhance a brand’s green image but may require careful sourcing to ensure quality.

Conclusion: How to Choose the Right Solution for Your Business Needs

When selecting between baggies bags and alternative solutions, B2B buyers should consider their specific requirements, including the type of products being stored, budget constraints, and sustainability goals. Baggies bags are ideal for lightweight, everyday items, while rigid containers offer superior protection for fragile goods. On the other hand, biodegradable bags appeal to companies prioritizing eco-friendliness, albeit with considerations around durability. A thorough assessment of these factors will enable businesses to make informed decisions that align with their operational needs and corporate values.

Essential Technical Properties and Trade Terminology for baggies bags

What Are the Key Technical Properties of Baggies Bags?

When sourcing baggies bags for various applications, several technical properties are essential for ensuring that the products meet business requirements and consumer expectations. Understanding these specifications can significantly influence purchasing decisions and supply chain efficiency.

-

Material Grade

Baggies bags are commonly made from polyethylene (PE) or polypropylene (PP). The material grade affects the bag’s durability, flexibility, and resistance to punctures and tears. For instance, high-density polyethylene (HDPE) offers greater strength and is ideal for heavy-duty applications, while low-density polyethylene (LDPE) is more flexible and is suitable for lightweight uses. Choosing the right material grade is crucial for ensuring that the bags can withstand the intended use, which can reduce returns and improve customer satisfaction. -

Thickness (Mil)

The thickness of baggies bags is often measured in mils (one mil equals one-thousandth of an inch). Thicker bags (e.g., 4 mils or more) provide better durability and protection, making them ideal for storing heavier items or products sensitive to environmental factors. In contrast, thinner bags (e.g., 1-2 mils) may be more cost-effective for lighter applications. B2B buyers must consider the thickness to align with their specific needs while managing costs effectively. -

Sealing Mechanism

Baggies bags come with various sealing mechanisms, such as zip locks, twist ties, or slider closures. The type of seal affects usability, security, and reusability. For instance, bags with slider closures provide an extra layer of security and are easier to open and close repeatedly. Understanding the sealing mechanism is vital for businesses that prioritize ease of use and product integrity. -

Size and Capacity

Baggies bags are available in a range of sizes, which can significantly impact their functionality. From small 1-inch bags for sample products to larger gallon-sized bags for bulk storage, the size must match the intended application. Additionally, understanding the capacity helps in inventory management and logistics, ensuring that products are delivered and stored efficiently. -

Transparency and Color Options

The clarity of baggies bags can vary, with options ranging from completely clear to colored or opaque. Transparent bags allow for easy visibility of contents, which is beneficial for retail settings, while colored bags can help in branding or product differentiation. The choice of transparency and color can influence customer appeal and brand perception. -

Recyclability

With increasing environmental concerns, the recyclability of baggies bags is becoming an essential consideration. Many manufacturers are now producing recyclable options, which can enhance a company’s sustainability profile. Understanding the recyclability of the bags can also align with corporate social responsibility goals and meet regulatory requirements in various markets.

Which Common Trade Terms Should B2B Buyers Know When Purchasing Baggies Bags?

Navigating the procurement of baggies bags involves understanding industry-specific terminology that can impact negotiations and purchasing decisions. Here are some essential terms that buyers should be familiar with:

-

OEM (Original Equipment Manufacturer)

This term refers to companies that produce parts or equipment that may be marketed by another manufacturer. In the context of baggies bags, an OEM might provide customized bags that meet specific client requirements. Understanding OEM relationships can lead to better product customization and pricing negotiations. -

MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is crucial for B2B buyers as it directly affects inventory management and cost-efficiency. Knowing the MOQ can help businesses plan their purchases and avoid excess inventory. -

RFQ (Request for Quotation)

An RFQ is a document that buyers send to suppliers to solicit price quotes for specific products. In the context of baggies bags, submitting an RFQ allows buyers to compare prices and terms from multiple suppliers, facilitating better decision-making. -

Incoterms (International Commercial Terms)

These are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Understanding Incoterms is vital for B2B transactions, as they clarify shipping costs, insurance, and risk management. This knowledge can help buyers avoid unexpected costs and logistical issues. -

Lead Time

Lead time refers to the amount of time it takes from placing an order to receiving the goods. For baggies bags, lead time can vary based on production schedules, shipping methods, and supplier locations. Awareness of lead times is essential for effective supply chain management and meeting customer demand. -

Customization

This term refers to the ability to tailor products to meet specific client needs. In the baggies bags market, customization can include size, color, material, and branding. Understanding customization options can help buyers create unique products that stand out in the market.

By grasping these technical properties and trade terms, B2B buyers can make informed decisions when sourcing baggies bags, ultimately leading to enhanced operational efficiency and customer satisfaction.

Navigating Market Dynamics and Sourcing Trends in the baggies bags Sector

What Are the Key Market Dynamics and Trends Influencing the Baggies Bags Sector?

The global market for baggies bags is witnessing significant transformation driven by several key factors. First, the increasing demand for versatile packaging solutions across various industries, including food service, retail, and pharmaceuticals, is propelling growth. B2B buyers from regions such as Africa, South America, the Middle East, and Europe are particularly focused on sourcing innovative packaging that enhances product shelf life and consumer convenience. The rise of e-commerce has also increased the need for secure and efficient packaging solutions, leading to a surge in demand for baggies that are not only functional but also visually appealing.

Emerging technologies are reshaping the sourcing landscape. Automation in manufacturing processes is allowing suppliers to offer customized baggies bags at competitive prices. Additionally, digital platforms are facilitating direct communication between manufacturers and international buyers, streamlining procurement processes. B2B buyers are increasingly leveraging data analytics to identify trends and optimize their supply chains, ensuring they stay ahead in a competitive marketplace.

How Are Sustainability and Ethical Sourcing Changing the Baggies Bags Market?

Sustainability has become a pivotal concern for businesses and consumers alike, driving the baggies bags sector towards greener practices. The environmental impact of plastic waste is prompting B2B buyers to seek suppliers who prioritize eco-friendly materials. Companies are increasingly adopting biodegradable and compostable materials, as well as recycled plastics, to meet the demands of environmentally conscious consumers.

Ethical sourcing is also gaining traction, with businesses evaluating their supply chains for transparency and social responsibility. Certifications such as FSC (Forest Stewardship Council) and ISO 14001 (Environmental Management Systems) are becoming crucial for suppliers looking to establish credibility in the market. Buyers are encouraged to partner with manufacturers who not only comply with environmental standards but also demonstrate a commitment to fair labor practices. This shift not only enhances brand reputation but also aligns with the values of consumers in regions like Europe, where sustainability is highly prioritized.

What Is the Historical Context of Baggies Bags in the B2B Sector?

The evolution of baggies bags can be traced back to the mid-20th century when the introduction of polyethylene revolutionized packaging. Initially designed for household use, baggies soon found their way into commercial applications due to their convenience and versatility. Over the years, advancements in materials and manufacturing techniques have led to the development of specialized baggies, such as smell-proof and freezer-safe variants.

As the global market continues to evolve, the focus on innovation and sustainability will shape the future of the baggies bags sector. B2B buyers must stay informed about these trends to ensure they are sourcing products that meet the needs of an increasingly discerning consumer base.

Frequently Asked Questions (FAQs) for B2B Buyers of baggies bags

-

How do I choose the right type of baggies bags for my business needs?

Selecting the right baggies bags involves understanding the specific requirements of your business, such as the type of products you are storing or packaging. Consider factors like size, material, and functionality—whether you need resealable, smell-proof, or heavy-duty options. Additionally, assess the environmental impact of the materials. It’s advisable to request samples from suppliers to evaluate the quality and suitability before making a bulk purchase. -

What are the key factors to consider when sourcing baggies bags internationally?

When sourcing baggies bags internationally, consider the supplier’s reliability, product quality, and compliance with international regulations. Research the supplier’s manufacturing capabilities, certifications (such as ISO or FDA), and customer reviews. Additionally, evaluate shipping costs, delivery timelines, and customs regulations in your country. Establish clear communication regarding terms and conditions to ensure a smooth transaction. -

What minimum order quantities (MOQ) should I expect when purchasing baggies bags?

MOQs for baggies bags can vary significantly depending on the supplier and the type of bags you are ordering. Generally, MOQs can range from 500 to 10,000 bags. Some suppliers may offer lower MOQs for custom orders, while others might require higher quantities for standard products. It’s essential to discuss and negotiate MOQs with potential suppliers to align with your inventory needs and budget. -

How can I ensure the quality of baggies bags before making a large purchase?

To ensure the quality of baggies bags, request samples from suppliers before committing to a bulk order. Conduct thorough inspections of the samples for material durability, seal effectiveness, and overall construction. If possible, seek third-party testing or certifications that verify product quality. Additionally, consider establishing a quality assurance process that includes regular inspections of shipments upon arrival. -

What payment terms are commonly offered by suppliers of baggies bags?

Payment terms for baggies bags can vary widely, but common practices include payment in full upfront, a deposit followed by balance payment upon shipment, or net terms (e.g., net 30 or net 60 days). It’s crucial to clarify these terms before finalizing any agreements. Additionally, consider using secure payment methods, such as escrow services, to protect your transaction. -

What are the best practices for negotiating prices with baggies bags suppliers?

When negotiating prices with suppliers, start by researching the market rates for the types of baggies bags you need. Establish a clear understanding of your budget and desired quantity. Highlight your potential for long-term business and ask for discounts on bulk orders or loyalty programs. Don’t hesitate to compare quotes from multiple suppliers to leverage better pricing. -

How can I customize baggies bags to fit my branding needs?

Customization options for baggies bags often include printing your logo, selecting specific colors, or altering bag dimensions. Many suppliers offer various customization services, but minimum order quantities may apply. Before committing, request a mockup or sample of the customized product to ensure it meets your expectations. Clearly communicate your branding requirements and timeline to the supplier for a successful collaboration. -

What logistics considerations should I be aware of when importing baggies bags?

When importing baggies bags, consider logistics aspects such as shipping methods (air freight vs. sea freight), delivery timelines, and potential customs duties or tariffs. Work with a freight forwarder to navigate shipping regulations and documentation. Additionally, ensure your supplier is aware of the shipping arrangements and provides accurate labeling to avoid delays at customs. It’s also wise to factor in storage solutions upon arrival to manage your inventory effectively.

Top 3 Baggies Bags Manufacturers & Suppliers List

1. DIME BAGS® – Smell Proof Small Baggies

Domain: dimebags.com

Registered: 2002 (23 years)

Introduction: Product Name: Smell Proof Small Baggies

Brand: DIME BAGS®

Price: $2.99 USD

Available Sizes: 5 Inch, 7 Inch

Pack Sizes: Pack of 1, Pack of 6, Pack of 12, Pack of 24

Description: Smell proof small baggies for various uses.

2. Hefty – Storage Slider Bags

Domain: hefty.com

Registered: 1995 (30 years)

Introduction: Hefty Storage Slider Bags are designed for easy and reliable storage. Key features include an extra secure slider seal, a stand and fill expandable bottom, and a MaxLock track design with an extra strong seal. The bags provide a Clicks Closed sound to indicate they are securely closed. Available sizes are Quart (8″ x 2″ x 5 11/16″), Half Gallon (10 9/16″ x 3 1/2″ x 6 1/16″), and Gallon (10 9/16″ x…

3. Lunds & Byerly’s – Hefty Baggies Sandwich & Storage Bags

Domain: lundsandbyerlys.com

Registered: 2006 (19 years)

Introduction: Hefty Baggies Sandwich & Storage Bags with Ties

Strategic Sourcing Conclusion and Outlook for baggies bags

In conclusion, the strategic sourcing of baggies bags presents a significant opportunity for international B2B buyers, particularly in emerging markets across Africa, South America, the Middle East, and Europe. By leveraging a diverse supplier base and prioritizing quality, sustainability, and innovative designs, companies can enhance their product offerings while ensuring compliance with regional regulations.

Key takeaways include the importance of understanding local market demands, optimizing supply chain logistics, and fostering relationships with reliable manufacturers. As the demand for versatile storage solutions continues to grow, investing in high-quality baggies bags can result in increased customer satisfaction and loyalty.

Looking ahead, B2B buyers are encouraged to explore new partnerships and consider the integration of sustainable practices in their sourcing strategies. By doing so, they can not only meet consumer expectations but also contribute to a more environmentally responsible future. Engage with suppliers that align with your business values and stay ahead of market trends to maximize your competitive advantage.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

Illustrative image related to baggies bags

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.