How to Source Attica Hydraulics Michigan Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for attica hydraulics michigan

In today’s competitive landscape, effectively sourcing hydraulic components from Attica Hydraulics in Michigan can be a daunting challenge for international B2B buyers. With the increasing demand for reliable hydraulic systems across industries, understanding the nuances of hydraulic pumps, motors, valves, and cylinders is crucial for making informed purchasing decisions. This guide is designed to assist buyers from Africa, South America, the Middle East, and Europe, including regions like Vietnam and Saudi Arabia, in navigating the complexities of the global market.

Throughout this comprehensive resource, we will delve into various types of hydraulic products, their specific applications, and the critical factors to consider when vetting suppliers. Additionally, we will explore cost considerations and the importance of quality assurance in maintaining operational efficiency. By providing actionable insights and expert advice, this guide empowers buyers to confidently assess their options and make strategic decisions that align with their business needs.

As the hydraulic industry continues to evolve, staying informed about the latest trends and technologies is essential for maintaining a competitive edge. Whether you are looking to source new components or seeking reliable repair services, this guide serves as your roadmap to successfully navigating the global market for Attica Hydraulics in Michigan. Embrace the opportunity to enhance your operations and drive growth through informed procurement practices.

Understanding attica hydraulics michigan Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

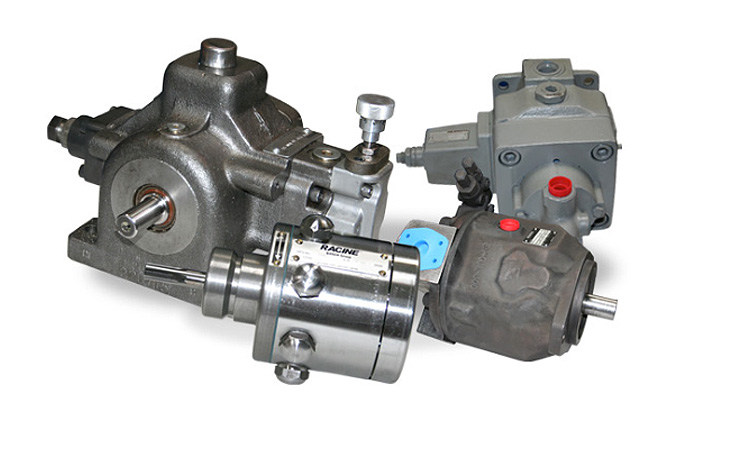

| Hydraulic Pumps | Mechanisms that move hydraulic fluid; available in various types (gear, vane, piston) | Industrial machinery, construction, agriculture | Pros: Versatile, wide applications. Cons: Requires regular maintenance. |

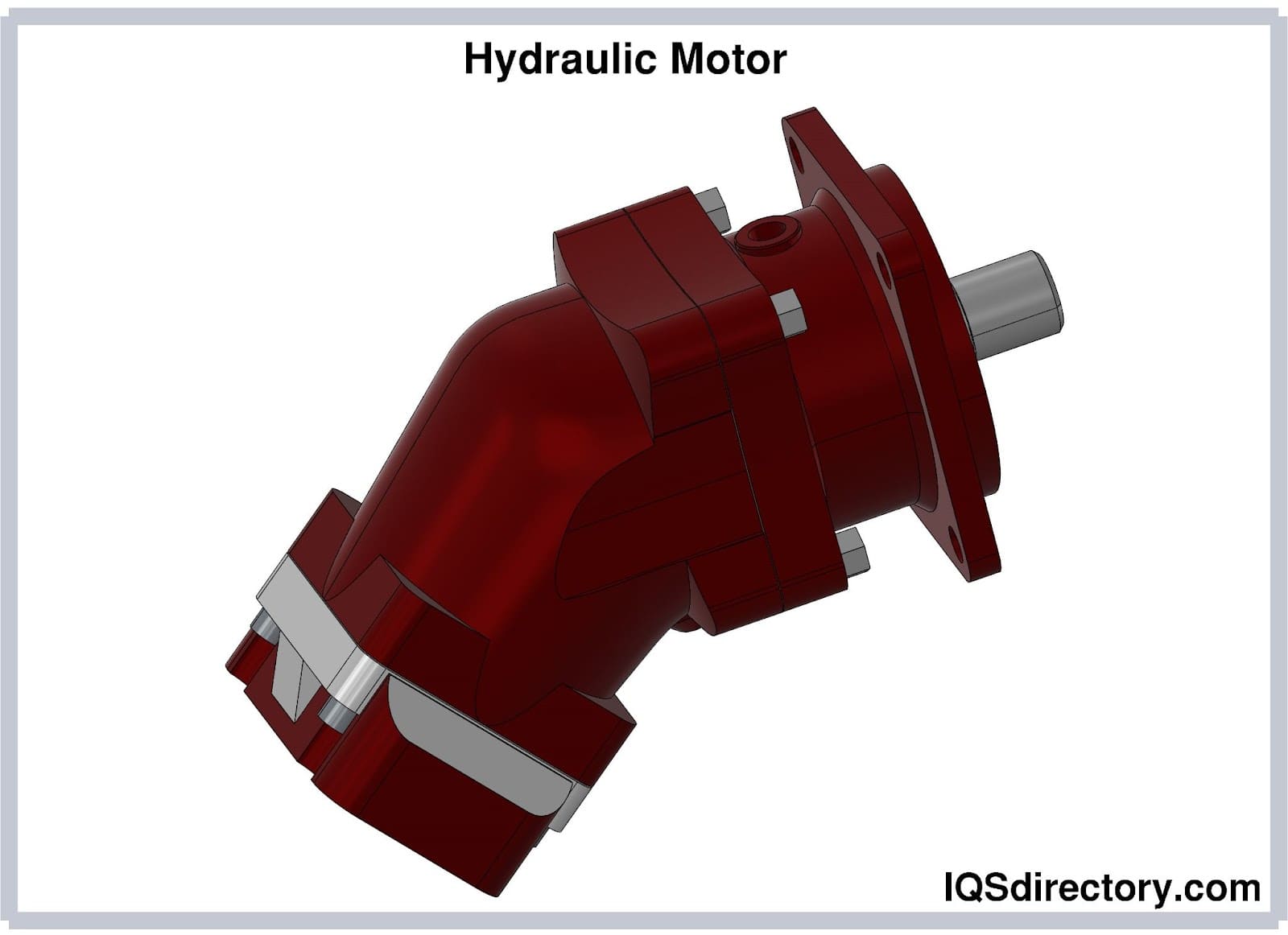

| Hydraulic Motors | Converts hydraulic energy into mechanical power; includes gear, vane, and piston types | Manufacturing, automotive, marine | Pros: Efficient power conversion. Cons: Higher initial investment. |

| Hydraulic Valves | Regulates fluid flow and pressure; essential for system control | Fluid power systems across industries | Pros: Improves system efficiency. Cons: Can be complex to install. |

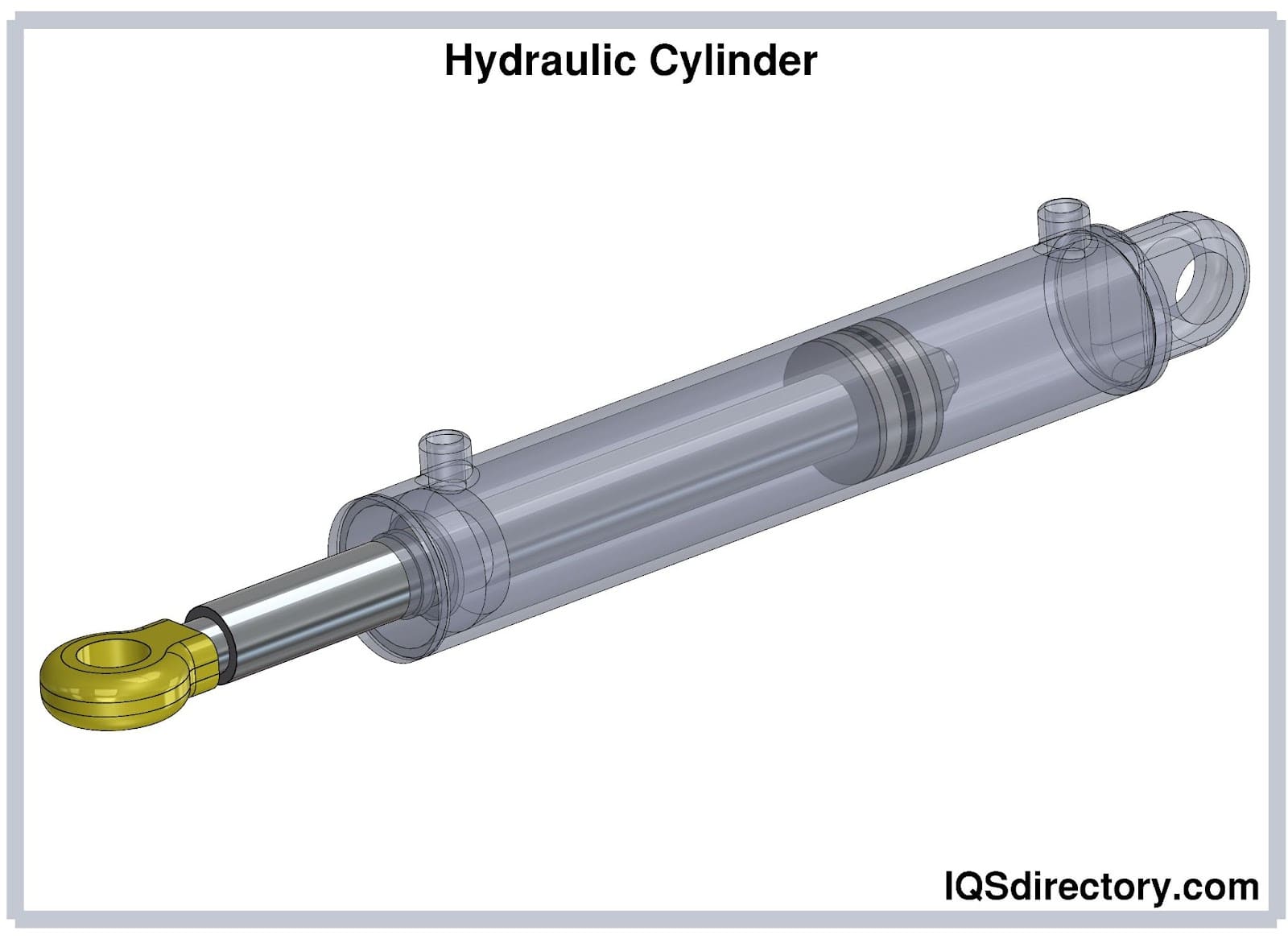

| Hydraulic Cylinders | Provides linear motion; various sizes and pressure ratings available | Construction, manufacturing, automotive | Pros: Reliable performance in heavy-duty applications. Cons: Space constraints may limit options. |

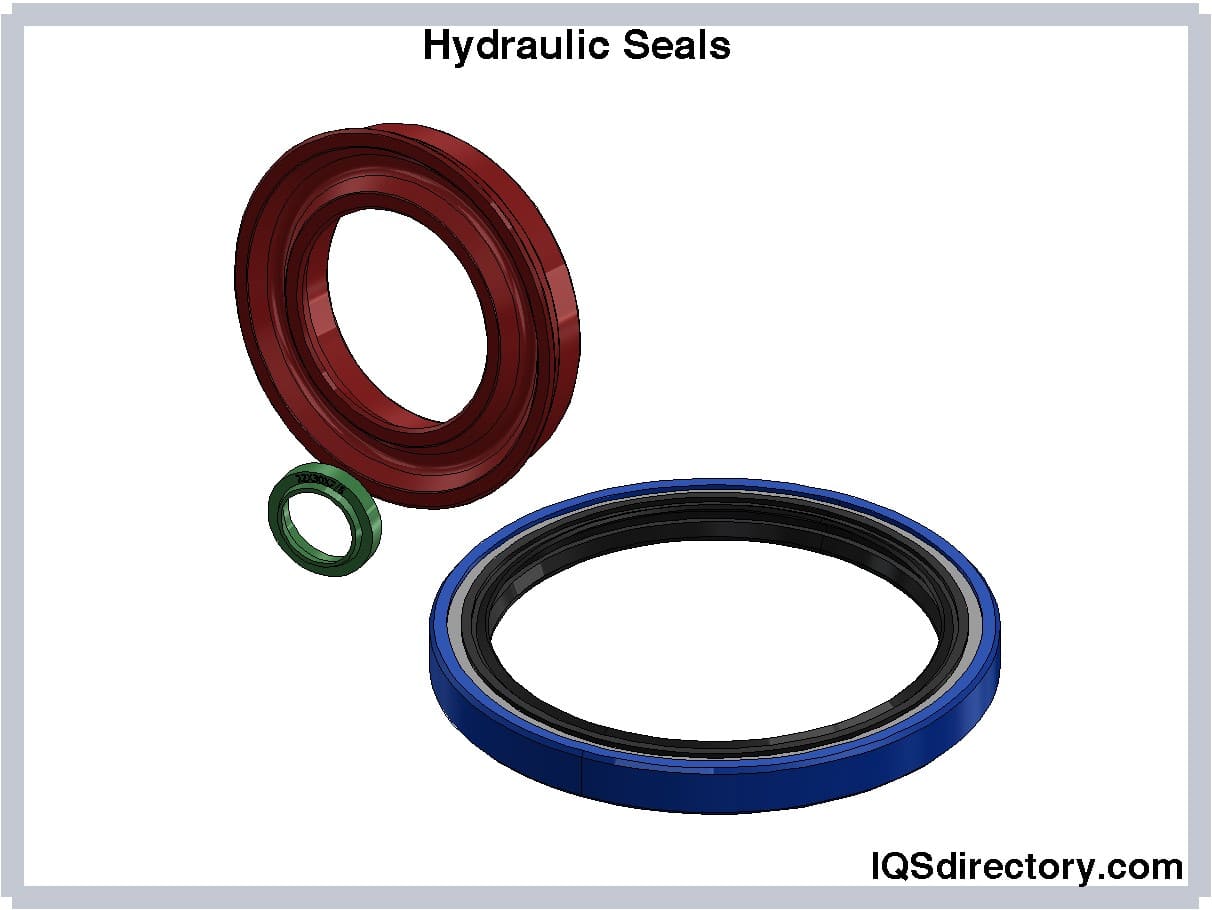

| Hydraulic Seals | Gasket-like components that prevent fluid leakage; various designs available | Used in cylinders, pumps, and motors | Pros: Essential for system integrity. Cons: Vulnerable to wear and tear. |

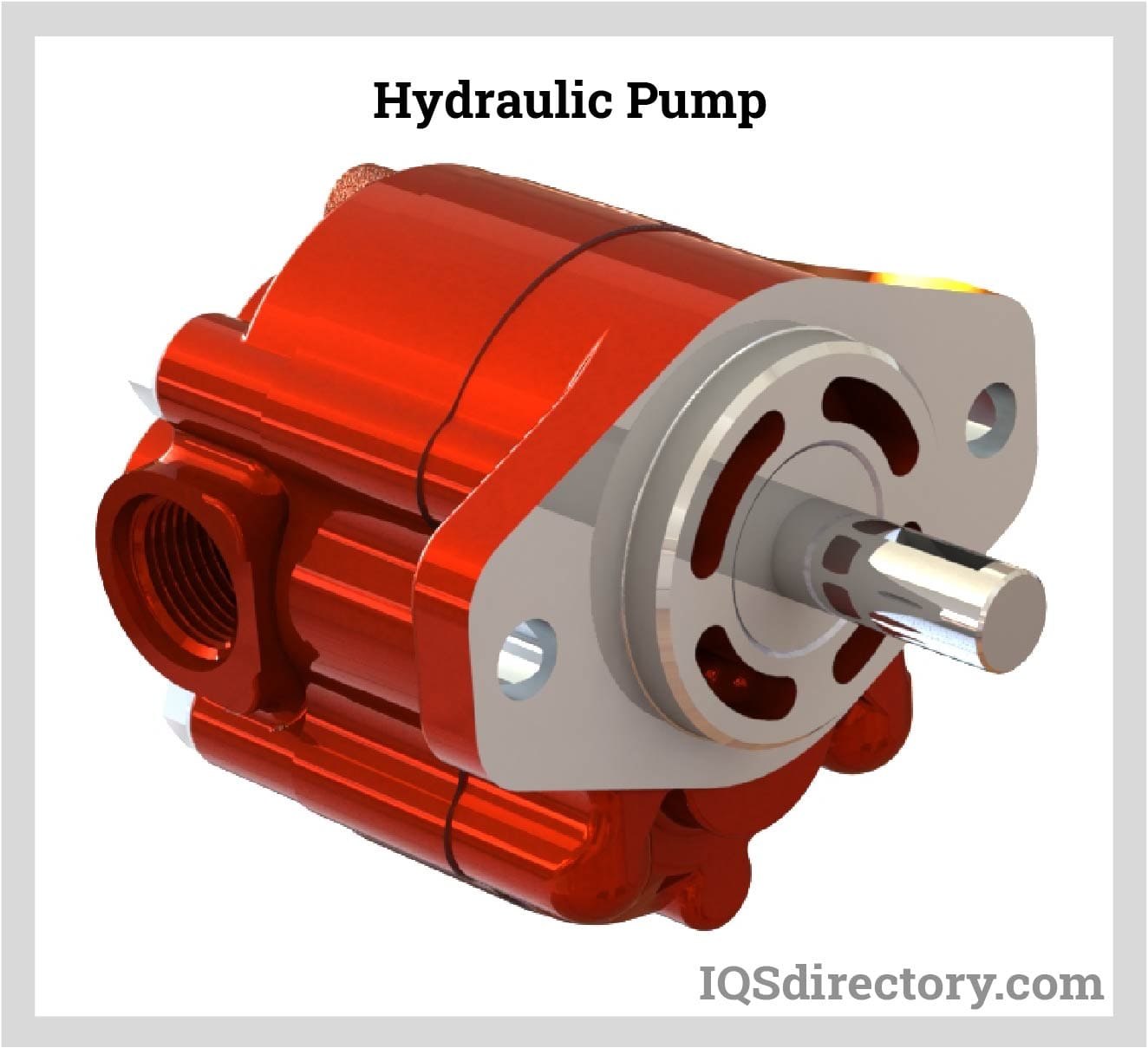

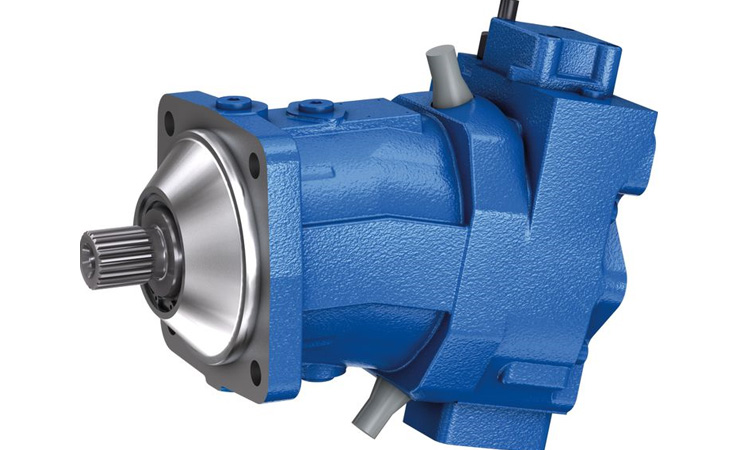

What Are the Key Characteristics of Hydraulic Pumps in Attica Hydraulics, Michigan?

Hydraulic pumps are vital components in hydraulic systems, designed to transfer hydraulic fluid and generate hydraulic power. They come in several types, including gear, vane, and piston pumps, each suited for specific applications. B2B buyers in industries such as construction and agriculture benefit from their versatility and ability to handle various fluid types. When purchasing, consider factors such as flow rate, pressure requirements, and compatibility with existing systems to ensure optimal performance.

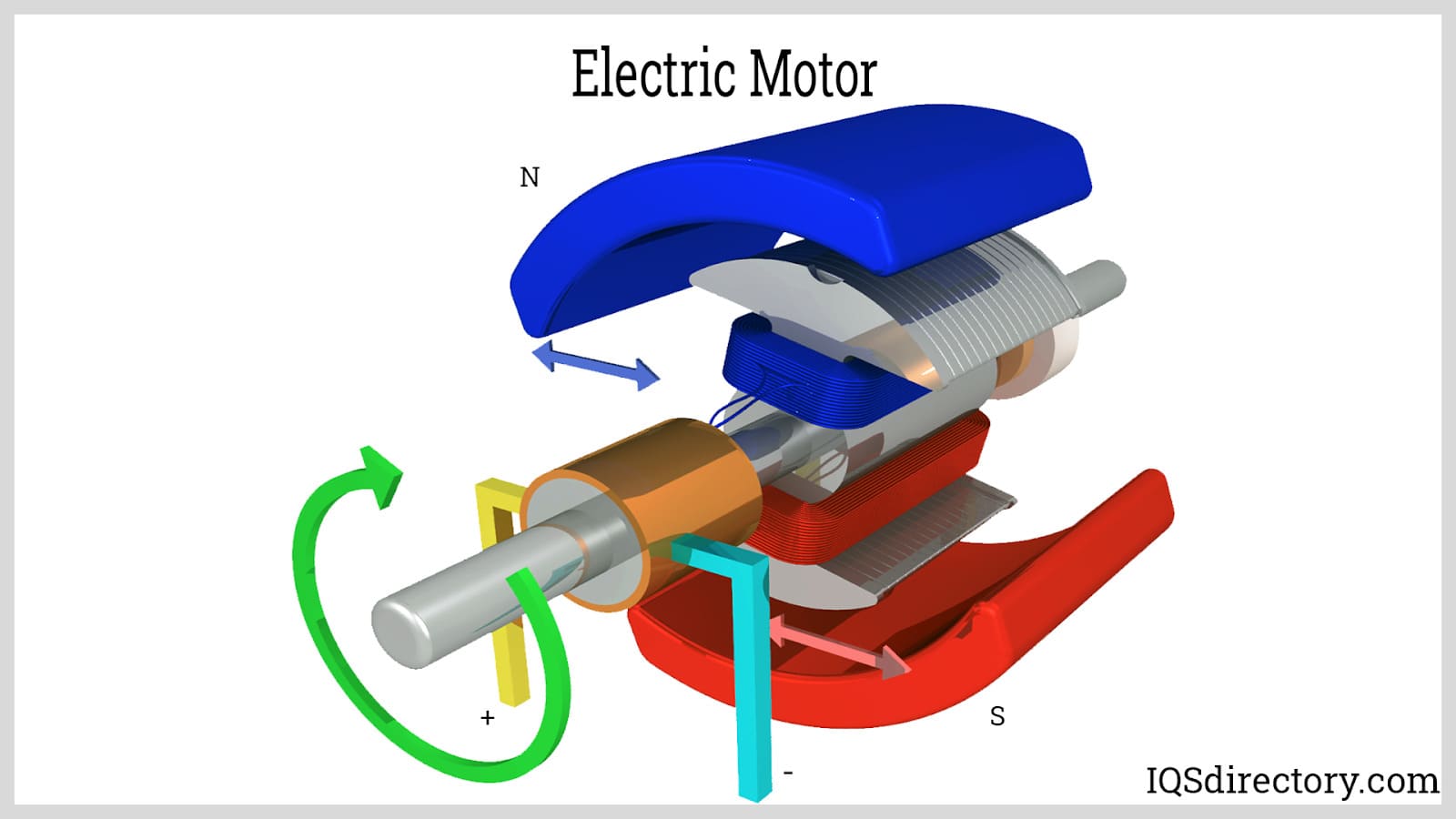

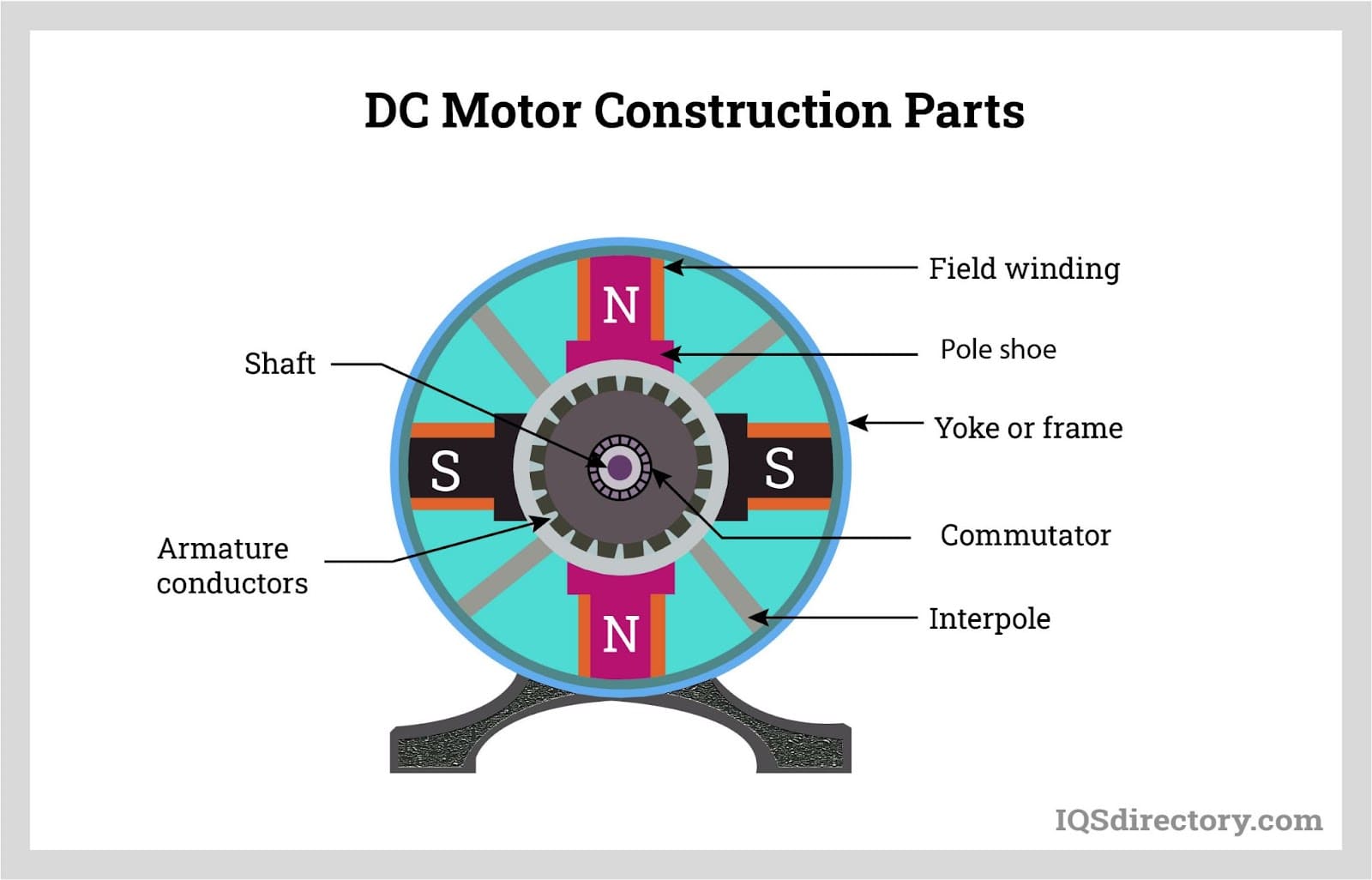

How Do Hydraulic Motors Differ and What Applications Benefit from Them?

Hydraulic motors are essential for converting hydraulic pressure into rotational motion, making them crucial in applications that require high torque and speed. Available in configurations like gear, vane, and piston motors, they are widely used in manufacturing and automotive sectors. Buyers should evaluate the motor’s efficiency, size, and torque capacity against their operational needs. While they deliver exceptional power, their initial cost may be a consideration for budget-conscious companies.

What Role Do Hydraulic Valves Play in System Efficiency?

Hydraulic valves are integral for controlling the flow and pressure of hydraulic fluid within a system, directly impacting overall efficiency and performance. They come in various forms, such as directional and pressure control valves, and are used across multiple industries, including fluid power systems. When selecting valves, B2B buyers should assess their operational specifications, installation complexity, and potential need for maintenance. While they enhance system functionality, the intricacy of installation may pose challenges.

Why Are Hydraulic Cylinders Important for Linear Motion?

Hydraulic cylinders are designed to produce linear motion through hydraulic pressure, making them indispensable in construction and manufacturing applications. They are available in different sizes and pressure ratings to accommodate various operational demands. B2B buyers should consider the required stroke length, bore size, and mounting configurations when purchasing. Although they are reliable for heavy-duty tasks, spatial limitations might restrict the types of cylinders that can be utilized effectively.

How Do Hydraulic Seals Contribute to System Integrity?

Hydraulic seals are critical for maintaining the integrity of hydraulic systems by preventing fluid leaks between components. They come in various designs suited for different applications, including pumps and cylinders. For B2B buyers, selecting the right seal involves evaluating the operating environment, fluid compatibility, and pressure ratings. While they are essential for system reliability, seals can experience wear over time, necessitating regular inspection and replacement to avoid costly downtimes.

Key Industrial Applications of attica hydraulics michigan

| Industry/Sector | Specific Application of Attica Hydraulics Michigan | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Agriculture | Hydraulic systems in tractors and harvesters | Enhanced efficiency in farming operations | Ensure compatibility with existing machinery and local regulations. |

| Construction | Hydraulic pumps in excavators and cranes | Increased lifting capacity and operational reliability | Assess durability under varying weather conditions and terrain. |

| Marine | Hydraulic motors in ship propulsion systems | Improved fuel efficiency and power output | Look for corrosion-resistant materials suitable for marine environments. |

| Oil & Gas | Hydraulic valves in drilling equipment | Precision control and safety in high-pressure systems | Verify certifications for high-pressure applications and compliance with safety standards. |

| Recycling | Hydraulic cylinders in material handling systems | Streamlined operations and reduced downtime | Focus on availability of spare parts for maintenance and repairs. |

How is Attica Hydraulics Michigan Used in Agriculture?

In the agriculture sector, Attica Hydraulics Michigan provides hydraulic systems crucial for tractors and harvesters. These systems facilitate the movement and operation of various attachments, enhancing overall farming efficiency. International buyers should consider compatibility with existing machinery and local agricultural regulations. Additionally, the ability to source replacement parts quickly can minimize downtime during critical planting and harvesting seasons.

What Role Does Attica Hydraulics Michigan Play in Construction?

Attica Hydraulics Michigan is instrumental in the construction industry, particularly through hydraulic pumps used in excavators and cranes. These pumps are essential for lifting heavy loads and performing complex maneuvers, thereby increasing operational reliability on construction sites. B2B buyers must assess the durability of these components, especially in regions with extreme weather conditions or rugged terrain, ensuring they meet local safety and performance standards.

Illustrative image related to attica hydraulics michigan

How is Attica Hydraulics Michigan Beneficial for Marine Applications?

In the marine industry, Attica Hydraulics Michigan supplies hydraulic motors for ship propulsion systems. These motors are designed to enhance fuel efficiency while delivering robust power output, which is vital for marine operations. Buyers in this sector should prioritize corrosion-resistant materials to withstand harsh marine environments, along with ensuring compliance with maritime safety regulations.

Why is Attica Hydraulics Michigan Important for Oil & Gas Operations?

Attica Hydraulics Michigan’s hydraulic valves are crucial in the oil and gas industry, especially in drilling equipment where precision control is paramount. These valves help manage the flow and pressure of fluids, enhancing safety and operational efficiency. Buyers should verify that the components meet the stringent safety and performance standards required for high-pressure applications, ensuring reliability in critical operations.

How Does Attica Hydraulics Michigan Support Recycling Efforts?

In recycling operations, hydraulic cylinders from Attica Hydraulics Michigan are used in material handling systems to facilitate the movement and processing of recyclable materials. These cylinders contribute to streamlined operations and reduced downtime, which is essential for maintaining profitability in recycling plants. B2B buyers should focus on the availability of spare parts for ongoing maintenance and the adaptability of the systems to various recycling processes.

3 Common User Pain Points for ‘attica hydraulics michigan’ & Their Solutions

Scenario 1: Challenges in Sourcing Quality Hydraulic Components

The Problem: B2B buyers often struggle with sourcing high-quality hydraulic components for their operations. In regions like Africa and South America, access to reliable suppliers can be limited, leading to frustration when trying to procure essential hydraulic pumps, motors, and valves. Many buyers face issues with counterfeit or substandard parts, which can compromise equipment performance and safety. The pressure to maintain operational efficiency exacerbates these concerns, as downtime due to equipment failure can result in significant financial losses.

The Solution: To effectively source quality hydraulic components from Attica Hydraulics in Michigan, buyers should first conduct thorough market research to understand the company’s offerings and reputation. Establish direct communication with Attica Hydraulics to discuss specific needs and to verify product authenticity. Buyers should request detailed specifications and certifications for components, ensuring they align with industry standards. Additionally, leveraging Attica’s extensive inventory, which includes both new and remanufactured parts, can provide cost-effective solutions without sacrificing quality. By fostering a transparent relationship with the supplier, buyers can ensure they receive reliable products that enhance their operational efficiency.

Illustrative image related to attica hydraulics michigan

Scenario 2: Technical Support and Expertise Gaps

The Problem: Many B2B buyers encounter challenges when dealing with complex hydraulic systems, particularly when integrating new components or troubleshooting existing equipment. Often, there is a lack of in-house expertise to effectively manage these systems, which can lead to prolonged downtime and increased maintenance costs. This is especially true for businesses operating in specialized industries like agriculture or construction, where the hydraulic systems are critical to daily operations.

The Solution: Attica Hydraulics offers comprehensive technical support and expertise that B2B buyers can leverage. It is crucial to engage with their experienced professionals early in the purchasing process. Buyers should not hesitate to ask for technical consultations or assistance in selecting the right hydraulic products for their specific applications. Utilizing resources like detailed product guides and technical documentation provided by Attica can also enhance understanding and facilitate better decision-making. Moreover, establishing a routine maintenance schedule with Attica’s services can help mitigate issues before they escalate, ensuring that hydraulic systems operate smoothly and efficiently.

Scenario 3: Managing Repair and Maintenance Needs Efficiently

The Problem: For many businesses, the cost and time involved in repairing or replacing hydraulic components can be daunting. B2B buyers may find themselves under pressure to minimize downtime while also managing tight budgets. The decision of whether to repair existing components or invest in new ones often creates a dilemma, particularly if the necessary expertise and resources are not readily available.

The Solution: Attica Hydraulics provides a robust repair service that can help buyers manage their maintenance needs efficiently. Businesses should conduct a cost-benefit analysis to determine when to repair versus replace hydraulic components, considering factors such as the age of the equipment, frequency of breakdowns, and overall operational impact. Engaging with Attica’s repair services allows buyers to benefit from their expertise in remanufactured parts, which can extend the life of existing equipment at a fraction of the cost of new components. Implementing a preventative maintenance program with Attica can further reduce the likelihood of unexpected failures, allowing for smoother operations and improved budget management. By actively participating in maintenance discussions and scheduling regular check-ups, buyers can ensure that their hydraulic systems remain in optimal condition, minimizing disruptions to their operations.

Strategic Material Selection Guide for attica hydraulics michigan

What Are the Key Materials Used in Hydraulic Systems for Attica Hydraulics Michigan?

When selecting materials for hydraulic systems, particularly for applications involving Attica Hydraulics Michigan, it is essential to consider properties such as temperature and pressure ratings, corrosion resistance, and compatibility with various hydraulic fluids. Below is an analysis of four common materials used in hydraulic components, focusing on their properties, advantages, disadvantages, and considerations for international buyers.

1. Steel

Key Properties:

Steel is known for its high tensile strength and ability to withstand high pressures, making it suitable for hydraulic cylinders and pumps. It typically has a temperature rating of up to 500°F (260°C) and can handle pressures exceeding 3000 psi, depending on the grade.

Pros & Cons:

Steel’s durability and strength make it ideal for heavy-duty applications, but it is susceptible to corrosion unless properly treated. While it is relatively affordable, the manufacturing complexity can increase due to machining and welding requirements.

Impact on Application:

Steel is compatible with a wide range of hydraulic fluids, including water-based and petroleum-based fluids. However, it may not be suitable for applications involving highly corrosive media without additional protective coatings.

International Considerations:

For buyers in regions like Africa and the Middle East, compliance with ASTM standards is crucial for ensuring quality and reliability. Additionally, understanding local corrosion conditions can influence the choice of steel grades.

2. Aluminum

Key Properties:

Aluminum is lightweight and offers good corrosion resistance, with a temperature rating typically up to 300°F (150°C). Its pressure rating is lower than steel but can still accommodate up to 2000 psi in specific applications.

Pros & Cons:

The primary advantage of aluminum is its weight, which can reduce the overall weight of hydraulic systems, enhancing mobility. However, it is less durable than steel and can be more expensive, particularly when considering the need for specialized machining.

Illustrative image related to attica hydraulics michigan

Impact on Application:

Aluminum is suitable for hydraulic systems where weight is a critical factor, such as in mobile equipment. Its compatibility with various fluids is generally good, but caution is advised with certain solvents that can degrade the material.

International Considerations:

European buyers often prefer aluminum for its lightweight properties, especially in automotive applications. Compliance with DIN standards is essential for ensuring product quality and performance.

3. Cast Iron

Key Properties:

Cast iron is known for its excellent wear resistance and ability to withstand high pressures, typically rated up to 2500 psi. It has a temperature tolerance similar to steel, making it suitable for demanding environments.

Illustrative image related to attica hydraulics michigan

Pros & Cons:

While cast iron is highly durable and offers good vibration dampening, it is also heavier and more brittle compared to steel, which can complicate transportation and installation. The cost is moderate, but the manufacturing process can be complex due to casting requirements.

Impact on Application:

Cast iron is often used in hydraulic pumps and valves where durability is paramount. It is compatible with most hydraulic fluids, but its brittleness can be a concern in applications involving high-impact forces.

International Considerations:

For buyers in South America and Europe, adherence to JIS standards is important for ensuring compatibility with local manufacturing practices. Additionally, understanding the local supply chain for cast iron components can enhance procurement efficiency.

4. Composite Materials

Key Properties:

Composite materials, such as reinforced plastics, offer unique properties like lightweight and corrosion resistance. They can typically handle temperatures up to 250°F (120°C) and pressures around 1500 psi, depending on the formulation.

Illustrative image related to attica hydraulics michigan

Pros & Cons:

The main advantage of composites is their resistance to corrosion and lightweight nature, making them suitable for specialized applications. However, they may not be as durable as metals and can be more expensive to produce, particularly for custom applications.

Impact on Application:

Composite materials are ideal for hydraulic systems in corrosive environments, such as those found in marine applications. However, compatibility with specific hydraulic fluids must be verified to avoid chemical degradation.

International Considerations:

In regions like the Middle East, where corrosion is a significant concern, composites can provide a viable alternative to metals. Buyers should ensure compliance with international standards to guarantee product performance.

Illustrative image related to attica hydraulics michigan

Summary Table

| Material | Typical Use Case for attica hydraulics michigan | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Steel | Hydraulic cylinders and pumps | High strength and durability | Susceptible to corrosion | Medium |

| Aluminum | Mobile hydraulic systems | Lightweight | Less durable than steel | High |

| Cast Iron | Hydraulic pumps and valves | Excellent wear resistance | Heavy and brittle | Medium |

| Composite Materials | Corrosive environment applications | Corrosion resistance | May lack durability | High |

This strategic material selection guide provides valuable insights for international B2B buyers, ensuring informed decisions when sourcing hydraulic components from Attica Hydraulics Michigan.

In-depth Look: Manufacturing Processes and Quality Assurance for attica hydraulics michigan

What Are the Main Stages of Manufacturing Processes at Attica Hydraulics Michigan?

Attica Hydraulics Michigan employs a systematic approach to manufacturing hydraulic components, ensuring high quality and reliability. The manufacturing process is divided into several key stages: material preparation, forming, assembly, and finishing.

Material Preparation

The first stage involves sourcing high-grade raw materials that meet stringent specifications for hydraulic applications. Materials like steel, aluminum, and composite materials are carefully selected for their durability and performance. Rigorous testing is conducted to ensure that these materials conform to industry standards. This stage may also include cutting and machining materials to the required dimensions before they move on to the forming process.

What Techniques Are Used in the Forming Process?

In the forming stage, various techniques are utilized to shape the materials into the desired forms. Common methods include machining, forging, and casting. Advanced CNC (Computer Numerical Control) machines are often used to achieve high precision in machining components such as hydraulic pumps and motors. Forging processes may involve heating materials to enhance their malleability, while casting allows for complex shapes that are difficult to achieve through machining alone.

How Is the Assembly Process Structured?

The assembly stage is critical as it brings together all the manufactured components into a complete hydraulic system. Skilled technicians carefully follow detailed assembly instructions, ensuring that each part fits correctly and operates efficiently. This stage also involves the installation of seals and other components that prevent leaks and ensure optimal performance. Automated assembly lines may be employed for high-volume production, enhancing efficiency while maintaining quality.

Illustrative image related to attica hydraulics michigan

What Finishing Techniques Are Applied?

Finishing processes are essential for enhancing the aesthetic and functional qualities of the hydraulic components. Techniques such as surface treatment, painting, and coating are used to protect against corrosion and wear. Quality checks are integrated into this stage to ensure that the finishing meets both visual and performance standards. Additionally, the finishing process may include marking components with identification codes or certifications to facilitate tracking and quality assurance.

How Is Quality Assurance Implemented in Manufacturing?

Quality assurance at Attica Hydraulics Michigan is a multi-faceted approach that aligns with international standards, particularly ISO 9001:2015. This certification ensures that the company adheres to a quality management system that consistently meets customer expectations and regulatory requirements.

What Are the Key International Standards Relevant to Quality Assurance?

In addition to ISO 9001, Attica Hydraulics also complies with various industry-specific standards, such as CE marking for compliance with European health, safety, and environmental protection standards, and API standards for equipment used in the oil and gas industry. These certifications not only enhance the company’s credibility but also assure international B2B buyers of the quality and safety of their products.

What Are the QC Checkpoints in the Manufacturing Process?

Quality control checkpoints are integrated throughout the manufacturing process to ensure product integrity. The checkpoints typically include:

- Incoming Quality Control (IQC): This initial stage involves inspecting raw materials upon arrival to verify that they meet quality standards.

- In-Process Quality Control (IPQC): During manufacturing, continuous monitoring is conducted to ensure that processes remain within specified limits. This may involve measuring dimensions, checking tolerances, and assessing surface finishes.

- Final Quality Control (FQC): After assembly, a comprehensive inspection is performed. This includes functional testing of hydraulic pumps and motors under simulated operating conditions to ensure they perform as expected.

What Common Testing Methods Are Utilized?

Testing methods employed by Attica Hydraulics include:

- Hydraulic Testing: Components are subjected to high-pressure tests to verify their performance under operational conditions.

- Functional Testing: Hydraulic systems are tested for efficiency, ensuring they meet specifications for flow rates, pressure, and response times.

- Visual Inspections: A thorough examination for surface defects, such as scratches or corrosion, is conducted to ensure aesthetic quality.

How Can B2B Buyers Verify Supplier Quality Control?

B2B buyers looking to verify the quality control processes of Attica Hydraulics Michigan have several options:

- Supplier Audits: Conducting on-site audits allows buyers to assess the manufacturing processes, quality control systems, and adherence to international standards firsthand.

- Quality Reports: Requesting detailed quality assurance reports can provide insights into testing methods, failure rates, and compliance with standards.

- Third-Party Inspections: Engaging independent inspection agencies to evaluate the manufacturing and quality assurance processes can add an extra layer of confidence for international buyers.

What Are the QC and Certification Nuances for International Buyers?

For international B2B buyers, particularly from regions like Africa, South America, the Middle East, and Europe, understanding the nuances of quality control and certification is crucial. Different regions may have varying regulatory requirements, and certifications recognized in one market may not hold the same weight in another. Buyers should conduct thorough research to ensure that the products they procure meet their local regulatory standards.

Additionally, language barriers and cultural differences may impact communication regarding quality expectations. Establishing clear lines of communication and understanding local norms can facilitate smoother transactions and ensure that both parties are aligned on quality requirements.

Conclusion

Attica Hydraulics Michigan exemplifies a commitment to excellence through its structured manufacturing processes and stringent quality assurance measures. By understanding the intricacies of manufacturing and quality control, international B2B buyers can make informed decisions, ensuring they partner with a reliable supplier that meets their operational needs and quality standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘attica hydraulics michigan’

Introduction

This practical sourcing guide is designed to assist international B2B buyers in navigating the procurement process for hydraulic products from Attica Hydraulics in Michigan. Whether you are looking for hydraulic pumps, motors, or other components, this checklist will provide actionable steps to ensure a successful purchase, helping you to evaluate suppliers effectively, assess quality, and make informed decisions.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is vital for ensuring that you procure the right hydraulic components for your specific needs. This includes understanding the type of hydraulic pumps or motors required, their performance metrics, and compatibility with existing systems. Document any unique requirements, such as pressure ratings or dimensions, to streamline your discussions with suppliers.

Step 2: Research Potential Suppliers

Conduct thorough research to identify reputable suppliers of hydraulic products in Michigan. Focus on companies with a proven track record in the hydraulic industry, such as Attica Hydraulic Exchange. Utilize online resources, industry forums, and supplier directories to gather insights about their offerings, customer reviews, and market presence.

Illustrative image related to attica hydraulics michigan

Step 3: Evaluate Supplier Certifications and Quality Standards

Before proceeding with a supplier, verify their certifications and adherence to quality standards. Look for ISO certifications, as they indicate a commitment to quality management systems. Additionally, inquire about their manufacturing processes and quality control measures to ensure that the products meet international standards.

Step 4: Request Detailed Quotes

Once you have shortlisted potential suppliers, request detailed quotes that outline product specifications, pricing, lead times, and payment terms. This step is essential to compare offers effectively. Ensure that the quotes include information on warranty terms and after-sales support, as these factors can significantly impact your overall satisfaction.

Step 5: Assess Supplier Reliability and Support Services

Evaluate the reliability of the suppliers by checking their responsiveness and the quality of customer service. Reach out with questions regarding their products or services to gauge their level of support. Additionally, inquire about their logistics capabilities and delivery timelines, as timely delivery is critical for maintaining your operational efficiency.

Step 6: Examine Warranty and Return Policies

Understanding the warranty and return policies of your chosen supplier is crucial for mitigating risks. Review the terms to determine how long the warranty lasts and what it covers. A comprehensive warranty can provide peace of mind and protect your investment against manufacturing defects or performance issues.

Step 7: Establish Clear Communication Channels

Before finalizing your order, establish clear communication channels with your supplier. This includes agreeing on points of contact for order tracking, technical support, and issue resolution. Effective communication can help prevent misunderstandings and ensure a smoother procurement process, ultimately enhancing your relationship with the supplier.

By following these steps, you can effectively source hydraulic components from Attica Hydraulics in Michigan, ensuring that you make informed decisions that align with your operational needs.

Comprehensive Cost and Pricing Analysis for attica hydraulics michigan Sourcing

When considering sourcing hydraulic components from Attica Hydraulics in Michigan, understanding the comprehensive cost structure and pricing dynamics is crucial for international B2B buyers. This analysis outlines the key cost components, price influencers, and strategic tips for negotiating effectively, particularly for buyers from Africa, South America, the Middle East, and Europe.

What Are the Key Cost Components in Hydraulic Sourcing?

The cost structure for hydraulic products typically includes several key components:

-

Materials: The cost of raw materials—such as metals and polymers—can significantly affect pricing. Fluctuations in global commodity prices can lead to variability in final costs.

-

Labor: Labor costs encompass wages for skilled technicians involved in manufacturing and assembly. In the U.S., labor costs tend to be higher compared to many countries, which can influence overall pricing.

-

Manufacturing Overhead: This includes expenses related to facility maintenance, utilities, and administrative costs. Efficient manufacturing processes can help mitigate these costs.

-

Tooling: The design and development of specialized tooling for hydraulic systems can incur substantial upfront costs. These costs are often amortized over production runs, affecting unit pricing.

-

Quality Control (QC): Ensuring that hydraulic products meet industry standards requires investment in quality assurance processes, which can influence overall pricing.

-

Logistics: Shipping costs can vary widely based on distance, mode of transport, and customs duties. Buyers should consider these costs when evaluating total expenditure.

-

Margin: Supplier profit margins are also factored into the final price. These margins can fluctuate based on market competition and demand.

What Influences Pricing for Hydraulic Products?

Several factors can influence the pricing of hydraulic components:

-

Volume/MOQ: Bulk purchasing typically leads to lower per-unit costs. Understanding the minimum order quantities (MOQ) can help buyers plan their purchases effectively.

-

Specifications and Customization: Customized products often come with higher costs due to additional engineering and manufacturing processes. Buyers should weigh the necessity of custom solutions against standard offerings.

-

Materials and Quality Certifications: Higher-quality materials and certifications (e.g., ISO 9001) can increase costs but may offer better performance and reliability, translating to long-term savings.

-

Supplier Factors: Established suppliers with a strong reputation may command higher prices due to perceived value. It’s essential to assess the supplier’s reliability and service quality in relation to their pricing.

-

Incoterms: Understanding the implications of Incoterms (International Commercial Terms) is vital for international transactions. These terms determine who is responsible for costs and risks at various points in the shipping process.

What Are the Best Negotiation Tips for International Buyers?

To ensure cost-efficiency in sourcing hydraulic products, international buyers should consider the following strategies:

Illustrative image related to attica hydraulics michigan

-

Negotiate Volume Discounts: Engage suppliers early to negotiate pricing based on anticipated order volumes. Larger orders can significantly reduce costs.

-

Evaluate Total Cost of Ownership (TCO): Look beyond initial purchase prices. Consider maintenance, operational efficiency, and lifespan when assessing total costs. This perspective can justify a higher upfront investment for superior products.

-

Understand Pricing Nuances: Be aware that pricing can vary by region due to different economic conditions and market demand. Buyers from regions like Africa and South America may find that currency fluctuations impact costs significantly.

-

Leverage Local Knowledge: If possible, utilize local representatives or consultants who understand the market dynamics and can assist in negotiations to secure favorable terms.

Conclusion

Sourcing hydraulic components from Attica Hydraulics in Michigan involves navigating a complex landscape of costs and pricing factors. By understanding the key components of cost structure and leveraging strategic negotiation tactics, international buyers can optimize their procurement processes and achieve better value in their investments. Always remember that indicative prices can vary based on the above factors, and it is advisable to request quotes tailored to specific requirements.

Alternatives Analysis: Comparing attica hydraulics michigan With Other Solutions

Understanding Alternatives in Hydraulic Solutions

In the competitive landscape of hydraulic systems, businesses often seek alternatives to optimize performance, reduce costs, and enhance reliability. This analysis compares Attica Hydraulics Michigan with other viable solutions in the hydraulic sector. By understanding the strengths and weaknesses of each option, B2B buyers can make informed decisions tailored to their operational needs.

Comparison Table

| Comparison Aspect | Attica Hydraulics Michigan | Hydraulex | Yates Industries |

|---|---|---|---|

| Performance | High-quality hydraulic pumps and motors with ISO certification ensuring reliability | Specializes in remanufactured units, with a focus on performance in industrial applications | Offers a wide range of hydraulic cylinders and components, tailored for heavy-duty applications |

| Cost | Competitive pricing for both new and remanufactured parts | Cost-effective for remanufactured options, but may have higher initial costs for OEM | Generally higher costs due to specialized products and services |

| Ease of Implementation | User-friendly service with a focus on customer support for installation | Requires understanding of remanufactured parts; may need training for optimal use | Comprehensive service but may require more extensive integration and setup due to specialized equipment |

| Maintenance | Offers extensive repair services with a focus on long-term relationships | Maintenance services available, but dependent on specific remanufactured products | Regular maintenance required for optimal performance of heavy-duty cylinders |

| Best Use Case | Ideal for diverse industrial applications, including agriculture and construction | Best suited for companies needing cost-effective solutions for existing hydraulic systems | Perfect for industries requiring robust solutions, such as steel mills and manufacturing |

Detailed Breakdown of Alternatives

Hydraulex

Hydraulex specializes in remanufactured hydraulic systems, making it a strong competitor for businesses looking to save costs on high-quality hydraulic units. Their focus on industrial applications, combined with their status as an authorized Linde service center, ensures that clients receive reliable products. However, while remanufactured units can be economical, they may require a learning curve for proper implementation and maintenance.

Yates Industries

Yates Industries is renowned for its heavy-duty hydraulic products, particularly in sectors like steel manufacturing. Their offerings include a comprehensive range of hydraulic cylinders designed to withstand rigorous conditions. Although Yates Industries may have higher initial costs, their products are often seen as investments due to their durability and performance in demanding environments. However, they may not be as versatile as Attica’s offerings for varied industrial applications.

Conclusion: Choosing the Right Hydraulic Solution for Your Business

When selecting the right hydraulic solution, B2B buyers should consider factors such as performance requirements, cost-effectiveness, and the specific needs of their industry. Attica Hydraulics Michigan stands out for its versatility and customer-focused services, making it a suitable choice for a wide range of applications. In contrast, alternatives like Hydraulex and Yates Industries offer specialized solutions that may be more beneficial for specific operational needs. Ultimately, understanding the nuances of each option will empower businesses to make strategic decisions that align with their operational goals and budget constraints.

Essential Technical Properties and Trade Terminology for attica hydraulics michigan

What Are the Essential Technical Properties of Hydraulic Systems in Attica Hydraulics Michigan?

When engaging with hydraulic systems, understanding key technical properties is crucial for making informed B2B decisions. Here are several critical specifications to consider:

-

Material Grade

– The material grade of hydraulic components, such as pumps and cylinders, determines their strength and durability. Common materials include steel and aluminum alloys. High-grade materials enhance resistance to wear and corrosion, which is essential for extending the lifespan of hydraulic systems, particularly in demanding environments like construction and mining. -

Pressure Rating

– Hydraulic systems operate under varying pressure levels, typically measured in Bar or PSI (pounds per square inch). A system’s pressure rating indicates the maximum pressure it can safely handle. Understanding this specification is vital for ensuring compatibility with existing systems and preventing failures that could lead to costly downtime. -

Tolerance

– Tolerance refers to the allowable deviation from specified dimensions in hydraulic components. Precise tolerances are critical for ensuring proper fit and function, especially in high-pressure applications. B2B buyers should prioritize components with tight tolerances to ensure optimal performance and minimize leaks or malfunctions. -

Flow Rate

– Measured in liters per minute (L/min) or gallons per minute (GPM), the flow rate indicates the volume of hydraulic fluid that can pass through a system in a given timeframe. Selecting components with the appropriate flow rate is essential for achieving desired operational speeds and efficiency, particularly in industrial applications where precision is key. -

Seal Type

– Hydraulic seals prevent fluid leakage and contamination, playing a critical role in system integrity. Different types of seals, such as O-rings and lip seals, are suitable for varying pressure and temperature conditions. Understanding seal specifications helps ensure the longevity and reliability of hydraulic systems.

What Are Common Trade Terms Used in the Hydraulic Industry?

Familiarity with industry jargon can facilitate smoother communication and negotiations. Here are some common trade terms relevant to Attica Hydraulics Michigan:

Illustrative image related to attica hydraulics michigan

-

OEM (Original Equipment Manufacturer)

– OEM refers to companies that produce parts and equipment that may be sold under another brand name. In the hydraulic industry, OEM components are often preferred for their guaranteed compatibility and quality. B2B buyers should consider OEM products to ensure performance consistency. -

MOQ (Minimum Order Quantity)

– MOQ indicates the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is crucial for B2B buyers to manage inventory effectively and negotiate better pricing terms, especially when sourcing hydraulic components in bulk. -

RFQ (Request for Quotation)

– An RFQ is a formal process where buyers request pricing and terms from suppliers for specific products or services. Providing a detailed RFQ can help streamline the procurement process, enabling buyers to receive accurate quotes and make informed purchasing decisions. -

Incoterms

– Incoterms (International Commercial Terms) define the responsibilities of buyers and sellers in shipping goods. Familiarity with these terms can help B2B buyers understand their obligations regarding shipping costs, insurance, and delivery timelines, which is vital for international transactions. -

Hydraulic Fluid

– Hydraulic fluid is the medium through which power is transmitted in hydraulic systems. Understanding the types of hydraulic fluids, such as water-based or petroleum-based, is essential for ensuring compatibility and optimal system performance, as different fluids have varying properties and applications. -

Actuator

– An actuator in hydraulic systems converts hydraulic energy into mechanical motion. They are critical components used in various applications, from machinery to automation. Knowing the types of actuators, such as linear or rotary, helps buyers select the right components for their specific operational needs.

By understanding these technical properties and trade terms, international B2B buyers can make more informed decisions when sourcing hydraulic components from Attica Hydraulics Michigan, ensuring they meet their operational requirements while maximizing value.

Navigating Market Dynamics and Sourcing Trends in the attica hydraulics michigan Sector

What Are the Key Trends Shaping the Attica Hydraulics Michigan Market for International Buyers?

The Attica hydraulics sector in Michigan is experiencing transformative shifts driven by global industrial demands and technological advancements. One significant driver is the increased demand for hydraulic systems in diverse applications, from construction to agriculture. As industries seek to enhance efficiency and reduce downtime, the focus on reliable and high-performance hydraulic components has intensified. International B2B buyers from regions like Africa, South America, the Middle East, and Europe are increasingly looking for suppliers who can provide not only high-quality products but also comprehensive after-sales support and maintenance services.

Emerging trends in B2B technology are reshaping sourcing strategies in this sector. Companies are leveraging digital platforms for streamlined procurement processes, enabling buyers to easily compare products, services, and suppliers. The rise of IoT (Internet of Things) in hydraulic systems is another trend, as it allows for real-time monitoring and predictive maintenance, which can significantly reduce operational costs. Additionally, the market is seeing a shift towards remanufactured and aftermarket hydraulic components, which not only offer cost savings but also contribute to sustainability efforts.

International buyers must also consider geopolitical factors and supply chain disruptions that can affect sourcing strategies. Establishing relationships with local suppliers like Attica Hydraulic Exchange Corporation can mitigate risks associated with international shipping and tariffs, ensuring a more reliable supply chain.

How Is Sustainability Influencing B2B Sourcing in the Attica Hydraulics Sector?

Sustainability is becoming an integral part of sourcing decisions in the hydraulic sector. Environmental impacts from manufacturing processes and the lifecycle of hydraulic products are under scrutiny, prompting companies to adopt more sustainable practices. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to environmental stewardship, which includes the use of ‘green’ materials and energy-efficient production processes.

Ethical sourcing is gaining traction as businesses recognize the importance of transparency in their supply chains. Suppliers that can provide certifications for environmentally friendly practices or materials—such as ISO 14001 for environmental management—are more appealing to conscientious buyers. The demand for remanufactured hydraulic components is also on the rise, as they not only reduce waste but also conserve resources, aligning with global sustainability goals.

In the context of Attica hydraulics, companies that embrace sustainability and ethical sourcing stand to gain a competitive edge. By investing in eco-friendly technologies and transparent supply chains, they can attract international buyers who are increasingly looking to align their procurement strategies with responsible practices.

Illustrative image related to attica hydraulics michigan

What Is the Historical Context of the Attica Hydraulics Sector?

The Attica hydraulics sector has its roots in the mid-20th century, evolving from basic hydraulic systems to sophisticated technologies that support a myriad of industrial applications. The establishment of firms like Attica Hydraulic Exchange Corporation in Chesterfield, Michigan, has played a pivotal role in shaping the landscape of hydraulic component supply and service. Over the decades, the industry has witnessed significant advancements in manufacturing techniques and product offerings, enabling more efficient and reliable hydraulic systems.

As global industries continue to expand, the Attica hydraulics sector has adapted to meet changing demands, focusing on innovation and quality. This evolution reflects the broader trends in industrial automation and the increasing reliance on hydraulic technologies across various sectors, solidifying Michigan’s position as a key player in the global hydraulic market.

Frequently Asked Questions (FAQs) for B2B Buyers of attica hydraulics michigan

-

How do I solve hydraulic system failures efficiently?

To address hydraulic system failures effectively, first identify the root cause of the issue, which may stem from worn-out components, fluid leaks, or incorrect fluid levels. Regular maintenance checks are essential to ensure that all parts, such as hydraulic pumps, motors, and valves, are functioning correctly. For urgent repairs, consider sourcing high-quality replacement parts from Attica Hydraulics Michigan, which specializes in remanufactured and new hydraulic components. Establishing a relationship with a reliable supplier can facilitate quicker turnaround times for parts and repairs, minimizing downtime in your operations. -

What is the best hydraulic pump for industrial applications?

The best hydraulic pump for industrial applications largely depends on the specific requirements of your system, including flow rate, pressure requirements, and the type of hydraulic fluid used. Attica Hydraulics Michigan offers a wide range of hydraulic pumps, including gear pumps, vane pumps, and piston pumps. Each type serves different applications; for instance, gear pumps are ideal for low viscosity fluids, while piston pumps excel in high-pressure situations. Assess your operational needs and consult with experts at Attica to select the most suitable pump for optimal performance. -

What are the typical lead times for hydraulic parts from Attica Hydraulics?

Lead times for hydraulic parts can vary based on availability and customization requirements. Generally, standard parts may ship within a few days, while custom orders or specialized components might take longer. It’s advisable to communicate your specific needs and timelines with Attica Hydraulics Michigan to obtain accurate delivery estimates. By planning ahead and placing orders in advance, you can mitigate potential delays and ensure that your operations remain uninterrupted. -

What customization options are available for hydraulic products?

Attica Hydraulics Michigan offers a variety of customization options for hydraulic products, including modifications to size, specifications, and performance characteristics. Custom solutions are particularly valuable for unique industrial applications where standard components may not suffice. Engage with their engineering team to discuss your requirements, and they will work collaboratively to develop tailored solutions that meet your operational needs while ensuring compliance with industry standards. -

What are the minimum order quantities (MOQs) for international buyers?

Minimum order quantities (MOQs) for international buyers can vary based on the type of product and the supplier’s policies. Attica Hydraulics Michigan typically sets MOQs that align with production capabilities and logistics considerations. It’s important to discuss your purchasing plans directly with their sales team to clarify any MOQ requirements and explore options for smaller orders if necessary. Building a strong relationship with the supplier can also lead to more flexible arrangements. -

What payment terms do Attica Hydraulics Michigan offer for international transactions?

Payment terms for international transactions with Attica Hydraulics Michigan may vary based on the buyer’s location and order size. Generally, options include advance payment, letter of credit, or net terms for established customers. It’s advisable to discuss payment options upfront during the negotiation phase to ensure that both parties are aligned. Clear communication regarding payment terms can help prevent misunderstandings and facilitate smoother transactions. -

How does Attica Hydraulics ensure quality assurance for their products?

Attica Hydraulics Michigan adheres to stringent quality assurance protocols, including ISO 9001:2015 certification, which outlines best practices for quality management systems. Each hydraulic component undergoes rigorous testing and inspection to meet industry standards before shipment. Buyers can request documentation to verify the quality of their products, ensuring that they receive reliable and durable components that meet their operational requirements. -

What logistics options are available for shipping hydraulic products internationally?

Attica Hydraulics Michigan provides various logistics options for international shipping, including air freight and sea freight, depending on the urgency and size of the order. Collaborating with reputable logistics partners allows for efficient handling and delivery of hydraulic products to your location. It is essential to discuss your preferred shipping methods and timelines with their team to ensure that your products arrive safely and on schedule, minimizing delays in your supply chain.

Top 2 Attica Hydraulics Michigan Manufacturers & Suppliers List

1. Power Motion Tech – Motion Control Solutions

Domain: powermotiontech.com

Registered: 2021 (4 years)

Introduction: This company, Power Motion Tech – Motion Control Solutions, is a notable entity in the market. For specific product details, it is recommended to visit their website directly.

2. Attica Hydraulic Exchange – Hydraulic Products

Domain: iqsdirectory.com

Registered: 2004 (21 years)

Introduction: Attica Hydraulic Exchange Corporation offers a wide range of hydraulic products including hydraulic pumps, motors, valves, cylinders, filters, hoses, and fittings. They also provide custom hydraulic systems tailored to specific customer requirements. Their products are suitable for applications in agriculture, construction, manufacturing, and transportation.

Strategic Sourcing Conclusion and Outlook for attica hydraulics michigan

As the hydraulic industry continues to evolve, strategic sourcing from Attica Hydraulics in Michigan emerges as a vital component for international B2B buyers. By leveraging their extensive catalog of hydraulic pumps, motors, and components, businesses can ensure the reliability and efficiency of their operations across diverse sectors, including agriculture, construction, and marine applications. The commitment to quality exemplified by Attica Hydraulics, highlighted by their ISO 9001:2015 certification, underscores the importance of sourcing from reputable suppliers to maintain operational excellence.

Moreover, the ability to access both new and remanufactured parts presents a cost-effective strategy for companies looking to optimize their hydraulic systems while managing budgets effectively. Attica’s focus on customer service and technical support further enhances its value proposition, ensuring buyers receive tailored solutions to meet their unique needs.

Illustrative image related to attica hydraulics michigan

Looking ahead, international buyers from Africa, South America, the Middle East, and Europe have a unique opportunity to forge partnerships with Attica Hydraulics. By prioritizing strategic sourcing, companies can not only enhance their operational capabilities but also position themselves for growth in an increasingly competitive marketplace. Now is the time to connect with Attica Hydraulics to explore how their offerings can elevate your business operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.