How to Source Aquastrong Booost Mode Vs Standard Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for aquastrong booost mode vs standard

In the competitive landscape of international B2B procurement, selecting the right water boosting pump can be a daunting task, especially when evaluating the differences between the Aquastrong Boost Mode and Standard models. Buyers from regions like Africa, South America, the Middle East, and Europe (including countries like Saudi Arabia and Vietnam) face unique challenges such as varying water demands, energy efficiency requirements, and regulatory compliance. This guide is designed to demystify the selection process by providing a comprehensive analysis of these two Aquastrong variants, focusing on their specifications, operational applications, and cost implications.

Throughout this guide, B2B buyers will gain insights into the specific features of both models, enabling them to identify the best fit for their operational needs. We will explore the technological advancements that set the Boost Mode apart from the Standard model, including energy consumption, automation features, and maintenance considerations. Additionally, we will cover supplier vetting strategies to ensure quality and reliability, as well as cost assessments to help buyers make financially sound decisions.

By empowering international buyers with actionable insights and expert evaluations, this guide aims to facilitate informed purchasing decisions that align with their business objectives and regional requirements. Whether you are looking to enhance water supply efficiency or meet stringent environmental standards, understanding the nuances between Aquastrong’s Boost Mode and Standard pumps will be critical to your success in the global market.

Understanding aquastrong booost mode vs standard Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aquastrong Boost Mode | Inverter-controlled variable speed, automatic pressure adjustment | Residential buildings, offices, agriculture | Pros: Energy-efficient, consistent pressure; Cons: Higher initial cost. |

| Aquastrong Standard | Fixed speed operation, manual pressure settings | Small commercial settings, irrigation | Pros: Lower upfront cost; Cons: Less energy-efficient, inconsistent pressure. |

| Aquastrong Smart 45 | Advanced monitoring, LED control panel, automatic fault detection | High-demand residential, industrial sectors | Pros: User-friendly, minimal maintenance; Cons: Complexity may require training. |

| Aquastrong Smart Eco | Eco-friendly design, optimized for low-water applications | Eco-conscious projects, sustainable farming | Pros: Reduced environmental impact; Cons: Limited to specific applications. |

| Aquastrong Compact | Space-saving design, suitable for tight installations | Urban apartments, small offices | Pros: Ideal for limited space; Cons: Lower capacity compared to larger models. |

What are the Key Characteristics of Aquastrong Boost Mode?

The Aquastrong Boost Mode features inverter-controlled variable speed technology, allowing the pump to adjust its operation based on water demand. This ensures a consistent water supply while minimizing energy consumption. Ideal for residential buildings and agricultural applications, this mode offers a significant advantage in energy efficiency. However, its higher initial cost may be a consideration for budget-conscious buyers.

How Does Aquastrong Standard Differ from Boost Mode?

The Aquastrong Standard operates at a fixed speed, which means it does not automatically adjust to varying water demands. This makes it suitable for smaller commercial settings or irrigation systems where consistent pressure is less critical. The lower upfront cost can be attractive; however, the lack of energy efficiency and potential for pressure fluctuations could lead to higher operational costs over time.

What Makes Aquastrong Smart 45 a Preferred Choice?

The Aquastrong Smart 45 model stands out with its advanced monitoring capabilities and user-friendly LED control panel. It is designed for high-demand applications in residential and industrial sectors, providing automatic fault detection to minimize downtime. While it requires minimal maintenance, the complexity of its features may necessitate training for optimal use, making it essential for buyers to consider their team’s technical expertise.

Why Choose Aquastrong Smart Eco for Sustainable Projects?

The Aquastrong Smart Eco is optimized for low-water applications, making it an excellent choice for eco-conscious projects and sustainable farming practices. This model significantly reduces environmental impact while maintaining efficiency. However, its specific design may limit its application range, requiring buyers to assess whether it aligns with their operational needs.

How Does Aquastrong Compact Address Space Constraints?

The Aquastrong Compact is designed for installations in tight spaces, making it perfect for urban apartments and small offices. Its space-saving design does not compromise on performance, but it does come with a lower capacity than larger models. Buyers should weigh the benefits of space efficiency against the potential need for more robust solutions in higher-demand scenarios.

Key Industrial Applications of aquastrong booost mode vs standard

| Industry/Sector | Specific Application of aquastrong booost mode vs standard | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Residential & Commercial | Automatic water supply for multi-story buildings | Ensures consistent water pressure, enhancing user satisfaction and operational efficiency | Energy efficiency, ease of installation, and maintenance requirements |

| Agriculture | Irrigation systems in remote areas | Reliable water supply for crops, increasing yield and productivity | Adaptability to varying water sources and energy costs |

| Hospitality | Water supply in hotels and resorts | Improved guest experience through reliable water availability and pressure | Durability, noise levels, and compliance with local regulations |

| Industrial Manufacturing | Water cooling systems for machinery | Optimal machine performance and longevity through consistent cooling | Compatibility with existing systems and energy consumption levels |

| Healthcare Facilities | Water supply for sanitation and medical applications | Ensures hygiene and safety standards are met, crucial for patient care | Reliability and responsiveness to fluctuating demand |

How is ‘aquastrong booost mode vs standard’ Used in Residential & Commercial Applications?

In residential and commercial settings, the aquastrong booost mode provides automatic water supply management for multi-story buildings. By maintaining consistent water pressure across various floors, it addresses common issues like low water pressure during peak usage times. This technology is particularly beneficial for international buyers in regions with fluctuating water availability, ensuring a steady supply that enhances tenant satisfaction and operational efficiency. Buyers should consider energy efficiency and ease of installation to optimize their investment.

What Role Does ‘aquastrong booost mode vs standard’ Play in Agricultural Applications?

In agriculture, the aquastrong booost mode is essential for irrigation systems, particularly in remote areas where water supply can be inconsistent. By ensuring a reliable and pressurized water source, it significantly boosts crop yield and productivity. Buyers from regions with variable climates should focus on the system’s adaptability to different water sources and the potential energy costs associated with operation. This ensures they can maintain efficient irrigation practices year-round.

Illustrative image related to aquastrong booost mode vs standard

How is ‘aquastrong booost mode vs standard’ Beneficial for the Hospitality Industry?

In the hospitality sector, water supply reliability is crucial for enhancing guest experience in hotels and resorts. The aquastrong booost mode enables a steady water supply, ensuring that guests have access to water at all times, which is vital for showers, pools, and dining services. International buyers should prioritize systems that offer durability and low noise levels to maintain a pleasant environment. Compliance with local regulations also plays a critical role in sourcing decisions.

How Does ‘aquastrong booost mode vs standard’ Improve Industrial Manufacturing Processes?

For industrial manufacturing, particularly in processes requiring cooling systems, the aquastrong booost mode ensures optimal performance of machinery by providing a consistent water supply for cooling. This helps in extending the lifespan of equipment and maintaining production efficiency. Buyers should assess compatibility with existing systems and evaluate energy consumption levels to ensure a cost-effective solution.

Why is ‘aquastrong booost mode vs standard’ Critical in Healthcare Facilities?

In healthcare settings, the aquastrong booost mode is vital for ensuring that water supply meets hygiene and sanitation standards. Reliable water availability is crucial for both patient care and operational functions, such as sterilization processes. Buyers in the healthcare sector must prioritize reliability and responsiveness to fluctuating demand to maintain safety and care standards, particularly in areas with inconsistent water supply.

3 Common User Pain Points for ‘aquastrong booost mode vs standard’ & Their Solutions

Scenario 1: Inconsistent Water Pressure Across Multiple Locations

The Problem: Many businesses face the challenge of inconsistent water pressure, especially when supplying multiple outlets across larger facilities. This can lead to operational inefficiencies, such as insufficient water supply for critical processes, affecting productivity and customer satisfaction. For example, a hotel might experience weak water flow in certain rooms, leading to complaints from guests and impacting the establishment’s reputation.

The Solution: Implementing the Aquastrong Boost Mode can address this issue effectively. This mode utilizes variable speed technology to adjust the pump’s output based on real-time water demand, ensuring consistent pressure across all outlets. To maximize efficiency, buyers should assess their facility’s water needs and set the pump’s pressure settings accordingly. For instance, if the facility requires a steady output of 4.0 bar for optimal performance, configuring the Aquastrong to maintain this pressure will help prevent fluctuations. Additionally, regular monitoring and maintenance of the pump’s settings can further ensure that water pressure remains stable, enhancing overall operational efficiency.

Scenario 2: High Energy Costs Due to Inefficient Pump Operation

The Problem: Businesses often struggle with rising energy costs attributed to outdated pump systems that operate continuously at a fixed speed, regardless of water demand. This inefficiency not only increases operational expenses but can also lead to unnecessary wear and tear on the equipment, resulting in higher maintenance costs and reduced lifespan of the pump.

The Solution: Transitioning to the Aquastrong Boost Mode offers a practical solution to energy inefficiency. The inverter-controlled technology allows the pump to operate at variable speeds, optimizing energy consumption by adjusting to real-time water needs. B2B buyers should conduct an energy audit to understand their current consumption patterns and project potential savings. By integrating the Aquastrong system and configuring it for automatic operation, businesses can expect significant reductions in energy use. Furthermore, promoting awareness among staff regarding the importance of maintaining optimal settings will help sustain energy savings over time.

Scenario 3: Complex Installation and Maintenance Challenges

The Problem: Many companies encounter difficulties during the installation and maintenance of water boosting systems, particularly with complex configurations and a lack of clear guidance. Inadequate installation can lead to operational failures, increased downtime, and costly repairs. For example, a manufacturing facility may find itself unable to maintain consistent water supply due to improper pump setup, leading to disruptions in production.

The Solution: To overcome these challenges, it’s essential to prioritize proper installation and maintenance practices for the Aquastrong system. Buyers should work with certified installers familiar with the specific requirements of the Aquastrong Boost Mode, ensuring that all components, such as the pressure and flow sensors, are correctly integrated. Additionally, providing training for staff on routine maintenance practices will enhance the longevity and performance of the system. Utilizing the pump’s LED control panel effectively can also simplify troubleshooting processes, allowing quick identification of any operational issues. Establishing a maintenance schedule and adhering to the manufacturer’s guidelines will further mitigate the risks associated with installation challenges, ensuring reliable water supply for business operations.

Strategic Material Selection Guide for aquastrong booost mode vs standard

What Are the Key Materials for Aquastrong Boost Mode vs Standard Pumps?

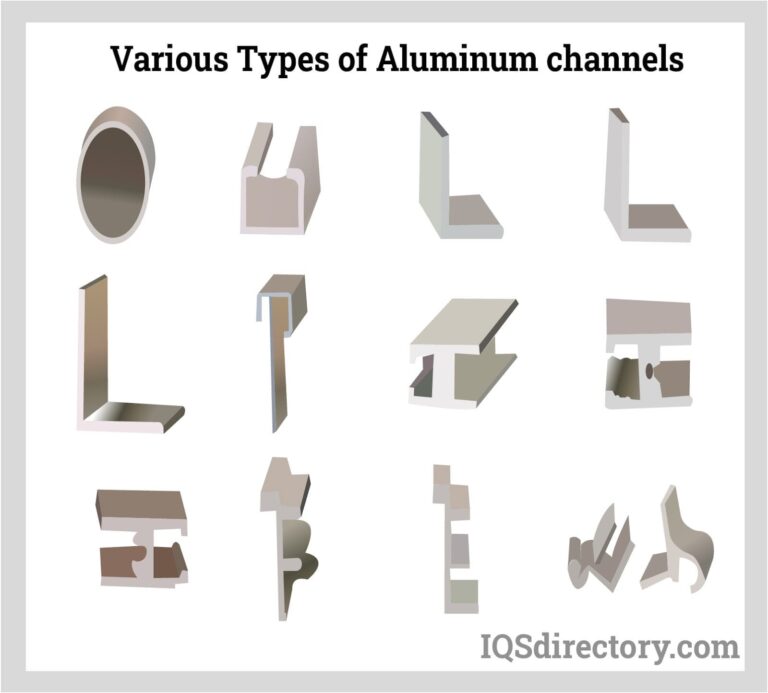

When selecting materials for the Aquastrong Boost Mode and Standard models, several factors come into play, including performance, cost, and international compliance. Below, we analyze four common materials used in these pumps: stainless steel, thermoplastics, cast iron, and brass.

How Does Stainless Steel Perform in Aquastrong Pumps?

Key Properties: Stainless steel, particularly AISI 304, is renowned for its excellent corrosion resistance and high tensile strength. It can withstand temperatures up to 80°C and pressures exceeding typical operational limits, making it ideal for water applications.

Pros & Cons: The durability of stainless steel is a significant advantage, as it resists rust and chemical degradation. However, it is more expensive than other materials, which can impact the overall cost of the pump. Manufacturing complexity is moderate, requiring specialized machining but is manageable for experienced manufacturers.

Impact on Application: Stainless steel’s compatibility with clean, non-aggressive liquids makes it suitable for various water boosting applications. Its robustness ensures long-term performance, even in challenging environments.

Considerations for International Buyers: Buyers in regions like Africa and the Middle East should ensure compliance with local standards, such as ASTM or DIN, especially when dealing with water quality regulations. The higher initial investment may be offset by lower maintenance costs over time.

What Role Do Thermoplastics Play in Aquastrong Pumps?

Key Properties: Thermoplastics, such as polypropylene and PVC, are lightweight and resistant to many chemicals, making them suitable for specific applications. They can handle moderate temperatures and pressures, typically up to 60°C.

Pros & Cons: The primary advantage of thermoplastics is their cost-effectiveness and ease of manufacturing, allowing for rapid production. However, they may not be as durable as metals, leading to a shorter lifespan in high-stress applications.

Impact on Application: These materials are ideal for applications where chemical resistance is critical, such as in agricultural or industrial settings. However, they may not perform well in high-pressure situations, limiting their use in certain boosting scenarios.

Considerations for International Buyers: Buyers should verify that the selected thermoplastic complies with local regulations. In markets like South America, where chemical exposure is common, choosing the right type of thermoplastic can significantly affect performance.

How Does Cast Iron Compare for Aquastrong Pumps?

Key Properties: Cast iron is known for its high durability and ability to withstand high pressures and temperatures. It is often used in pump housings and components that require structural integrity.

Pros & Cons: The primary advantage of cast iron is its strength and ability to absorb vibrations, which can lead to quieter operation. However, it is susceptible to corrosion if not properly coated, and its weight can complicate installation.

Impact on Application: Cast iron is suitable for heavy-duty applications, especially in industrial settings where high pressure is common. Its robustness makes it ideal for long-term installations but requires careful maintenance to prevent rust.

Considerations for International Buyers: In regions like Europe, compliance with environmental and safety standards is crucial. Buyers should ensure that the cast iron components are treated to resist corrosion, particularly in humid climates.

Why Is Brass Used in Aquastrong Pumps?

Key Properties: Brass is a copper-zinc alloy known for its excellent machinability and corrosion resistance. It can handle moderate pressures and temperatures, making it suitable for fittings and connectors.

Pros & Cons: Brass components are durable and provide good sealing properties, making them ideal for threaded connections. However, the cost of brass can be higher than that of other metals, and it may not be suitable for all water types due to potential leaching.

Illustrative image related to aquastrong booost mode vs standard

Impact on Application: Brass is commonly used in fittings and valves where a reliable seal is essential. Its resistance to corrosion in freshwater applications makes it a popular choice, although care must be taken in saltwater environments.

Considerations for International Buyers: Buyers should be aware of local regulations regarding the use of brass in potable water systems. In regions like the Middle East, where water quality is a concern, ensuring compliance with health standards is essential.

Summary Table of Material Selection for Aquastrong Pumps

| Material | Typical Use Case for aquastrong booost mode vs standard | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Pump housing and impellers | Excellent corrosion resistance | Higher initial cost | High |

| Thermoplastics | Chemical handling applications | Cost-effective and lightweight | Limited durability | Low |

| Cast Iron | Heavy-duty industrial applications | High strength and vibration absorption | Susceptible to corrosion | Medium |

| Brass | Fittings and connectors | Good sealing properties | Potential leaching in water | Medium |

This strategic material selection guide provides valuable insights for B2B buyers considering the Aquastrong Boost Mode and Standard pumps. By understanding the properties, advantages, and limitations of each material, buyers can make informed decisions that align with their operational needs and regulatory requirements.

In-depth Look: Manufacturing Processes and Quality Assurance for aquastrong booost mode vs standard

What Are the Main Stages of Manufacturing for Aquastrong Boost Mode vs Standard Pumps?

The manufacturing of Aquastrong Boost Mode and Standard pumps involves several crucial stages, each designed to ensure high-quality output and reliability. The primary stages include material preparation, forming, assembly, and finishing.

Material Preparation

This initial stage involves sourcing high-grade materials, such as AISI304 stainless steel for impellers and robust polymers for housing. Suppliers are typically vetted to ensure compliance with international standards, ensuring that only materials that meet durability and performance criteria are used. Rigorous inspections are performed on incoming materials to verify their quality.

Forming

During the forming stage, materials are shaped into components using techniques such as casting, machining, and injection molding. For instance, the pump casing and impellers are often produced via precision casting to achieve the desired specifications. Advanced CNC (Computer Numerical Control) machines may be utilized for machining parts to ensure high precision, which is critical for the efficient operation of the pumps.

Illustrative image related to aquastrong booost mode vs standard

Assembly

The assembly stage is where the individual components are brought together. This process is often automated to enhance efficiency and reduce human error. Skilled technicians perform critical tasks such as installing mechanical seals and pressure sensors, ensuring that each assembly meets predefined standards. The integration of advanced technologies, such as inverter controls for the variable speed feature, is carefully managed to guarantee functionality.

Finishing

Finishing processes include surface treatments, painting, and quality checks. Surface treatments are essential for enhancing corrosion resistance, especially for components exposed to water. Final inspections are conducted to confirm that each pump meets aesthetic and functional specifications before packaging.

How Is Quality Assurance Implemented During the Manufacturing Process?

Quality assurance (QA) is integral to the manufacturing process of Aquastrong pumps, ensuring that every product is reliable and meets international standards.

Illustrative image related to aquastrong booost mode vs standard

What International Standards Guide Quality Assurance for Aquastrong Pumps?

The manufacturing process adheres to several international standards, such as ISO 9001 for quality management systems. Compliance with CE marking requirements indicates that products meet EU safety, health, and environmental protection standards, which is particularly important for international buyers in regions like Europe and the Middle East. Additionally, adherence to industry-specific standards, such as API (American Petroleum Institute) for pumps used in oil and gas applications, enhances credibility.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) is typically structured around three main checkpoints: Incoming Quality Control (IQC), In-Process Quality Control (IPQC), and Final Quality Control (FQC).

-

IQC: At this stage, all incoming materials undergo rigorous testing to ensure they meet specified standards. This may involve chemical composition analysis and mechanical testing.

-

IPQC: Throughout the manufacturing process, continuous monitoring is conducted. This includes checking dimensions, assembly accuracy, and the performance of critical components, such as the inverter control system. Statistical Process Control (SPC) methods may be employed to analyze data and identify trends, allowing for real-time adjustments.

-

FQC: Finally, the pumps undergo comprehensive testing before packaging. This includes performance tests for pressure and flow rates, as well as noise level assessments to ensure compliance with operational specifications.

What Common Testing Methods Are Used for Quality Assurance?

Testing methods are vital for validating the quality and performance of Aquastrong pumps. Common testing techniques include:

-

Hydraulic Testing: This test measures the pump’s performance under various flow and pressure conditions, ensuring it meets operational specifications.

-

Noise and Vibration Testing: This assessment ensures that the pumps operate within acceptable noise levels and identifies any potential issues related to vibration that could affect longevity.

-

Electrical Testing: For models with electronic components, electrical testing verifies that motors operate within specified voltage and current ranges without overheating or malfunctioning.

How Can B2B Buyers Verify Supplier Quality Control Practices?

International B2B buyers, particularly those from Africa, South America, the Middle East, and Europe, must ensure that their suppliers adhere to stringent quality control practices. Here are actionable strategies:

Conduct Supplier Audits

Regular audits can provide insights into a supplier’s manufacturing processes and quality control measures. This includes reviewing documentation related to quality management systems, inspection reports, and compliance certifications.

Illustrative image related to aquastrong booost mode vs standard

Request Quality Control Reports

Buyers should request detailed QC reports that outline testing procedures and results. This transparency allows buyers to assess the reliability of the products before making purchasing decisions.

Engage Third-Party Inspectors

Utilizing third-party inspection services can add an extra layer of assurance. Independent inspectors can evaluate the manufacturing process and product quality, providing unbiased reports to buyers.

What Are the Quality Control and Certification Nuances for International Buyers?

Navigating the complexities of quality control and certification can be challenging for international buyers. Understanding regional regulations and certification requirements is crucial. For instance, while CE certification is essential for the European market, other regions may have different standards that must be met.

Additionally, buyers should be aware of the potential for variations in quality standards across different manufacturing facilities. Therefore, verifying that the supplier maintains consistent quality across all production sites is vital.

Illustrative image related to aquastrong booost mode vs standard

Final Thoughts

The manufacturing processes and quality assurance measures for Aquastrong Boost Mode and Standard pumps are designed to meet high standards of reliability and efficiency. By understanding these processes and implementing robust verification strategies, international B2B buyers can ensure that they source quality products that meet their operational needs.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aquastrong booost mode vs standard’

In the competitive landscape of water supply solutions, choosing between the Aquastrong Boost Mode and Standard modes is crucial for optimizing efficiency and cost-effectiveness. This guide serves as a practical checklist to assist B2B buyers in making informed procurement decisions tailored to their specific needs.

Step 1: Define Your Technical Specifications

Establish clear technical requirements based on your operational needs. Consider factors such as pump capacity, flow rate, and pressure settings. Knowing your specifications helps in comparing models effectively and ensures you select a pump that meets your demands without overspending.

Step 2: Assess Energy Efficiency Requirements

Evaluate the energy efficiency of the Aquastrong Boost Mode compared to the Standard mode. The Boost Mode often employs variable speed technology, which can significantly reduce energy consumption. Look for details on the power ratings and expected energy savings to justify the upfront investment.

Step 3: Evaluate Supplier Certifications and Compliance

Ensure that potential suppliers hold the necessary certifications and comply with international standards. Look for ISO certifications and compliance with local regulations relevant to your region, such as those in Europe or the Middle East. This step is vital for guaranteeing product quality and reliability.

Illustrative image related to aquastrong booost mode vs standard

Step 4: Analyze Installation and Maintenance Needs

Examine the installation requirements for both modes. The Aquastrong Boost Mode may have specific installation guidelines, such as required space and piping configurations. Understanding these needs upfront can save you time and additional costs during the installation phase.

Step 5: Request Performance Data and Case Studies

Seek performance data and case studies from suppliers to understand how each mode performs in real-world applications. This information can help you gauge reliability and efficiency based on similar operational contexts. Case studies provide insights into how the pumps have been utilized effectively in various sectors.

Step 6: Compare Warranty and Support Options

Review the warranty terms and customer support offered by suppliers. A robust warranty can minimize your risk, while accessible customer support ensures that you have assistance when needed. Compare different suppliers to find one that offers comprehensive support and service agreements.

Illustrative image related to aquastrong booost mode vs standard

Step 7: Conduct a Cost-Benefit Analysis

Finally, perform a detailed cost-benefit analysis to weigh the initial investment against the long-term operational savings. Factor in energy costs, maintenance expenses, and potential downtime. This analysis will help justify your decision and ensure that you choose a model that delivers value over its lifespan.

By following this checklist, B2B buyers can navigate the complexities of selecting the right Aquastrong water boosting system, ensuring they make a decision that aligns with their operational needs and financial goals.

Comprehensive Cost and Pricing Analysis for aquastrong booost mode vs standard Sourcing

What Are the Key Cost Components for Aquastrong Boost Mode vs Standard Sourcing?

When considering the Aquastrong Boost Mode versus Standard sourcing options, it is essential to break down the cost structure into key components. These typically include materials, labor, manufacturing overhead, tooling, quality control (QC), logistics, and profit margin.

Illustrative image related to aquastrong booost mode vs standard

-

Materials: The Boost Mode often incorporates advanced inverter technology and high-efficiency components, which may elevate material costs compared to the Standard model. For instance, the use of AISI304 stainless steel impellers and premium mechanical seals in the Boost Mode contributes to its higher durability and efficiency, thus impacting the overall pricing.

-

Labor: Labor costs can vary based on the complexity of the assembly process. The more sophisticated Boost Mode may require specialized skills for installation and maintenance, translating into higher labor costs compared to the Standard model.

-

Manufacturing Overhead: Overhead costs will also differ, as the production of the Boost Mode involves additional processes for quality assurance and testing to ensure it meets the specified performance standards. This is particularly important for B2B buyers in regions where reliability is paramount.

-

Tooling: Investment in tooling for the Boost Mode may be greater due to the need for specialized manufacturing equipment to handle advanced components. This cost is often amortized over production volume, influencing the unit price.

-

Quality Control (QC): Enhanced QC measures for the Boost Mode, which includes rigorous testing for efficiency and performance, can lead to increased costs. This is a vital consideration for buyers who prioritize long-term reliability.

-

Logistics: Shipping costs can vary based on the weight and size of the units. The Boost Mode’s advanced features may make it slightly heavier or larger, impacting logistics costs. Additionally, international shipping considerations, such as customs duties and tariffs, should be factored into the total cost.

-

Margin: Suppliers often set higher margins on advanced products like the Boost Mode due to their enhanced capabilities and perceived value. Understanding this can aid buyers in negotiating better deals.

How Do Price Influencers Affect Aquastrong Boost Mode and Standard Pricing?

Several factors can influence the pricing of the Aquastrong Boost Mode compared to the Standard model:

-

Volume/MOQ: Bulk purchasing can significantly reduce the cost per unit. Buyers should consider negotiating minimum order quantities (MOQs) to leverage better pricing, especially in international markets.

-

Specifications and Customization: Custom specifications can increase costs. Buyers should weigh the benefits of customization against the potential for higher prices, particularly if standard models meet their needs.

-

Materials and Quality Certifications: The Boost Mode’s reliance on higher-quality materials and certifications (like GS certification) can lead to a premium price. Buyers in regions such as Europe and the Middle East may value these certifications more due to regulatory requirements.

-

Supplier Factors: Supplier reliability and reputation can impact pricing. Established suppliers may charge more due to brand value, while newer entrants may offer competitive pricing to build market presence.

-

Incoterms: Understanding Incoterms is critical for international buyers. The choice of Incoterms (e.g., FOB, CIF) will affect the total landed cost of the products, including shipping, insurance, and duties.

What Buyer Tips Can Enhance Cost-Efficiency in Purchasing Aquastrong Products?

For B2B buyers, especially from Africa, South America, the Middle East, and Europe, strategic purchasing can lead to significant cost savings.

-

Negotiation: Leverage volume purchasing to negotiate better terms. Building a strong relationship with suppliers can also lead to improved pricing over time.

-

Total Cost of Ownership (TCO): Evaluate the TCO rather than just the upfront cost. The Boost Mode may have higher initial costs but lower energy consumption and maintenance costs, making it more cost-effective in the long run.

-

Pricing Nuances for International Buyers: Be aware of currency fluctuations, local market conditions, and economic factors that may influence prices. Understanding these nuances can help in making informed purchasing decisions.

-

Request for Proposals (RFPs): Utilize RFPs to solicit bids from multiple suppliers. This competitive approach can drive down costs and provide options that align with your budget and specifications.

-

Evaluate After-Sales Support: Consider the availability of after-sales support and warranty terms. A product with a robust warranty and support structure can save costs associated with repairs and replacements.

Disclaimer

The prices and cost structures provided are indicative and may vary based on market conditions, supplier negotiations, and specific project requirements. It is advisable for buyers to conduct thorough market research and engage with suppliers directly to obtain accurate pricing tailored to their needs.

Alternatives Analysis: Comparing aquastrong booost mode vs standard With Other Solutions

Introduction to Alternative Solutions for Water Boosting Systems

In the competitive landscape of water boosting systems, B2B buyers often face the challenge of selecting the most efficient solution for their specific needs. The Dayliff Aquastrong Booost Mode offers innovative features such as variable speed technology and automatic pressure adjustments, but it is essential to compare it against other viable alternatives to determine the best fit for various applications. This analysis will focus on comparing the Aquastrong Booost Mode with two alternative water boosting solutions: the conventional fixed-speed pump and a solar-powered water boosting system.

Comparison Table

| Comparison Aspect | Aquastrong Booost Mode | Conventional Fixed-Speed Pump | Solar-Powered Water Booster |

|---|---|---|---|

| Performance | Variable speed; maintains constant pressure at varying demands | Fixed speed; may cause pressure fluctuations | Efficient in sunny conditions; may struggle in low sunlight |

| Cost | Higher initial investment; energy savings over time | Lower upfront cost; higher operational costs | Moderate upfront cost; savings on energy bills |

| Ease of Implementation | Requires professional installation; clear guidelines provided | Easier to install; basic setup | Complex installation due to solar components |

| Maintenance | Low maintenance; built-in protections reduce risks | Regular maintenance required; potential wear and tear | Minimal maintenance; solar panels may need cleaning |

| Best Use Case | Residential and commercial applications requiring consistent pressure | Basic residential applications with stable water supply | Remote areas with high sunlight exposure needing sustainable solutions |

Detailed Breakdown of Alternatives

Conventional Fixed-Speed Pump

This traditional pumping solution is widely used due to its simplicity and lower initial cost. Fixed-speed pumps are straightforward to install and operate, making them suitable for basic applications where water demand is stable. However, they may lead to pressure fluctuations and increased energy consumption, particularly in scenarios where water demand varies significantly. For businesses prioritizing upfront cost over long-term efficiency, this option can be appealing.

Solar-Powered Water Booster

The solar-powered water booster represents a sustainable alternative, ideal for remote areas with ample sunlight. This system harnesses solar energy, significantly reducing operational costs and environmental impact. However, the initial setup can be complex due to the integration of solar panels and batteries. Additionally, performance may decline during cloudy days or in regions with inconsistent sunlight. This option is best suited for businesses focused on sustainability and operational cost reduction in areas with reliable solar resources.

Conclusion: Choosing the Right Water Boosting Solution

When selecting a water boosting solution, B2B buyers should evaluate their specific requirements against the performance, cost, and maintenance of each option. The Aquastrong Booost Mode is highly effective for applications needing consistent water pressure and efficiency, making it ideal for both residential and commercial settings. Conversely, buyers operating in areas with stable demand may find conventional fixed-speed pumps adequate. For those seeking sustainable solutions in remote locations, solar-powered systems present an eco-friendly option. Ultimately, understanding the unique needs of your business will guide you toward the most suitable water boosting solution.

Essential Technical Properties and Trade Terminology for aquastrong booost mode vs standard

What Are the Key Technical Properties of Aquastrong Boost Mode vs. Standard?

When evaluating the Aquastrong Boost Mode and Standard models, several technical properties stand out as critical for B2B buyers. Understanding these specifications can influence purchasing decisions and ensure that the selected pump meets operational needs effectively.

-

Variable Speed Technology

The Aquastrong Boost Mode features inverter-controlled variable speed technology, which allows the pump to adjust its speed based on water demand. This capability not only enhances energy efficiency but also ensures consistent water pressure, making it ideal for varying operational conditions. For B2B buyers, this means reduced energy costs and improved system reliability. -

Material Grade and Construction

The use of AISI304 stainless steel impellers is a notable feature of the Aquastrong Boost Mode. This high-grade material offers resistance to corrosion and wear, ensuring longevity and reliability in harsh environments. Buyers should prioritize pumps with durable materials to minimize maintenance costs and downtime. -

Maximum Operating Conditions

The Aquastrong Boost Mode is rated for a maximum liquid temperature of 80°C and a maximum ambient temperature of 55°C. Understanding these limits is crucial for B2B buyers to ensure the pump operates efficiently within the intended environment, preventing premature failure or performance issues. -

Pressure Settings

The adjustable pressure settings, ranging from 1.0 to 5.5 bar, allow for customization according to specific application needs. This flexibility is particularly important for buyers in diverse markets, where water supply conditions can vary significantly. Proper pressure settings can enhance system performance and prevent unnecessary wear on the pump components. -

Self-Priming Capability

The optimized self-priming design of the Aquastrong Boost Mode ensures that it can efficiently handle suction lifts up to 8 meters. This feature is vital for applications in regions with varying water source levels, making the pump versatile for different installations, such as wells and water tanks. -

Noise Level

Operating at a noise level of 60 dB, the Aquastrong Boost Mode is designed for quieter operation compared to many standard pumps. This aspect is particularly relevant for residential areas or environments where noise pollution is a concern, influencing buyer preferences in densely populated markets.

Which Trade Terms Should B2B Buyers Understand?

Navigating the procurement landscape for water pumps involves understanding specific trade terminology that can affect purchasing and operational decisions.

Illustrative image related to aquastrong booost mode vs standard

-

OEM (Original Equipment Manufacturer)

This term refers to a company that produces parts and equipment that may be marketed by another manufacturer. B2B buyers should consider OEM products for reliability and quality assurance, as they are typically produced to stringent standards. -

MOQ (Minimum Order Quantity)

MOQ represents the smallest quantity of a product that a supplier is willing to sell. Understanding MOQ is essential for buyers to manage inventory levels and avoid excess stock, which can tie up capital and impact cash flow. -

RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing and terms for specific products. For B2B buyers, issuing an RFQ can help gather competitive offers, allowing for better negotiation and informed purchasing decisions. -

Incoterms

These are international commercial terms that define the responsibilities of buyers and sellers regarding shipping, insurance, and tariffs. Familiarity with Incoterms is crucial for B2B transactions, as they help clarify costs and risks associated with international trade. -

Lead Time

Lead time refers to the time taken from placing an order to receiving the product. Understanding lead times is vital for planning and ensuring that water supply needs are met without delays, especially in projects with tight timelines. -

Warranty

A warranty is a guarantee provided by the manufacturer regarding the condition of the product. B2B buyers should carefully review warranty terms to understand coverage and limits, ensuring that they are protected against defects and operational failures.

By grasping these technical properties and trade terms, international B2B buyers can make informed decisions when investing in water boosting systems, ensuring they select products that align with their operational requirements and market conditions.

Navigating Market Dynamics and Sourcing Trends in the aquastrong booost mode vs standard Sector

What Are the Key Market Trends Influencing Aquastrong Boost Mode vs Standard Pumps?

The global market for water boosting solutions is witnessing significant growth, driven by urbanization, increasing water scarcity, and the demand for reliable water supply systems. In regions like Africa, South America, the Middle East, and Europe, where infrastructure varies widely, the need for efficient water management systems is more pronounced. Emerging technologies, particularly in variable speed pump systems such as the Aquastrong Boost Mode, are at the forefront of this transformation. These systems offer energy efficiency, reduced operational costs, and enhanced user control, aligning with modern B2B buyers’ preferences for smart solutions.

Moreover, the trend toward automation and IoT integration is reshaping sourcing strategies. Buyers are increasingly looking for pumps that not only meet basic operational requirements but also offer advanced features like real-time monitoring and data analytics. This shift is especially relevant for international buyers from regions like Saudi Arabia and Vietnam, where infrastructure investments are critical. As these markets evolve, suppliers that can demonstrate both technological innovation and a deep understanding of local challenges will hold a competitive edge.

How Is Sustainability Shaping the Sourcing of Aquastrong Boost Mode and Standard Pumps?

Sustainability is becoming a non-negotiable aspect of B2B purchasing decisions, particularly in sectors reliant on natural resources. For water boosting systems, this means considering the environmental impact of production, operation, and end-of-life processes. The Aquastrong Boost Mode, with its energy-efficient inverter technology, significantly reduces electricity consumption compared to standard pumps, aligning with global sustainability goals.

Ethical sourcing is also gaining traction, as businesses increasingly prioritize suppliers who adhere to sustainable practices. Certifications such as ISO 14001 (Environmental Management) and other green credentials are becoming essential for manufacturers looking to attract discerning buyers. Implementing transparent supply chains and using recyclable materials can enhance a company’s reputation and appeal, especially in regions where environmental regulations are tightening. For B2B buyers, investing in sustainable solutions not only fulfills regulatory requirements but also resonates with their corporate social responsibility objectives.

What Is the Evolution of Water Boosting Technology and Its Importance for B2B Buyers?

The evolution of water boosting technology can be traced back to the need for efficient water distribution in urbanized areas. Early systems relied heavily on fixed-speed pumps, which often resulted in energy wastage and inconsistent pressure levels. With advancements in inverter technology, systems like the Aquastrong Boost Mode have emerged, enabling variable speed control that optimizes performance based on real-time demand.

This evolution is particularly significant for B2B buyers who seek cost-effective solutions that adapt to fluctuating water needs without compromising performance. The shift from standard to advanced systems represents a broader trend towards smarter, more responsive infrastructure. As international markets continue to grow, understanding these technological advancements will be key for buyers looking to make informed purchasing decisions that enhance operational efficiency and sustainability.

Frequently Asked Questions (FAQs) for B2B Buyers of aquastrong booost mode vs standard

-

How do I choose between Aquastrong Boost Mode and Standard for my project?

Choosing between the Aquastrong Boost Mode and Standard depends on your specific water supply requirements. The Boost Mode is ideal for applications needing consistent pressure and variable flow, making it suitable for larger installations or those with fluctuating demand. In contrast, the Standard mode is better for smaller, more stable applications where pressure needs are less dynamic. Evaluate your project’s water demand patterns, installation space, and budget before making a decision. -

What are the key benefits of using Aquastrong Boost Mode over Standard?

Aquastrong Boost Mode offers several advantages, including energy efficiency due to its variable speed technology, which adjusts according to water demand, reducing operational costs. It also provides quieter operation and better pressure consistency, making it ideal for environments where noise reduction is crucial. Additionally, it includes advanced features like built-in sensors for dry run protection and thermal overload, enhancing reliability and safety. -

What are the minimum order quantities (MOQs) for Aquastrong pumps?

Minimum order quantities (MOQs) for Aquastrong pumps can vary based on the supplier and region. Typically, MOQs may range from a few units to a full shipping container, depending on the terms of your agreement and the supplier’s inventory. It is advisable to discuss your specific requirements directly with the supplier to negotiate MOQs that align with your business needs and to explore bulk purchasing discounts. -

What payment terms should I expect when sourcing Aquastrong pumps internationally?

Payment terms for international sourcing of Aquastrong pumps often vary based on the supplier’s policies and your negotiation. Common terms include upfront payment, letter of credit, or net 30/60 days after delivery. It’s essential to clarify these terms before finalizing your order to ensure that they align with your financial processes. Additionally, inquire about any potential fees related to currency exchange or international transactions. -

How can I vet suppliers for Aquastrong pumps in my region?

Vetting suppliers involves researching their reputation, certifications, and experience in the industry. Start by checking online reviews and testimonials from other B2B buyers. Request references and verify their compliance with international standards, such as ISO certifications. Additionally, consider visiting their facilities if possible or using third-party inspection services to assess their operational capabilities and product quality before committing to a purchase. -

Are customization options available for Aquastrong pumps?

Yes, many suppliers offer customization options for Aquastrong pumps to meet specific project requirements. Customizations may include adjustments to pressure settings, pump materials, or additional features tailored to unique applications. Discuss your needs with the supplier early in the procurement process to understand the feasibility, lead times, and any additional costs associated with customization. -

What quality assurance measures should I expect with Aquastrong products?

Quality assurance for Aquastrong products typically includes rigorous testing and compliance with international standards. Reputable suppliers will provide documentation of testing procedures, certifications, and warranty information. It’s crucial to inquire about the supplier’s quality control processes and whether they offer a warranty for their products, ensuring that you receive reliable and high-quality pumps for your applications. -

What logistics considerations should I keep in mind when importing Aquastrong pumps?

When importing Aquastrong pumps, consider shipping methods, delivery timelines, and customs regulations in your country. Determine whether you will use air freight for faster delivery or sea freight for cost-effectiveness. Additionally, ensure compliance with local import regulations, including tariffs and taxes. Working with a logistics partner experienced in international trade can help streamline the process and mitigate potential delays.

Top 2 Aquastrong Booost Mode Vs Standard Manufacturers & Suppliers List

1. DAYLIFF – AQUASTRONG SMART 45 Water Boosting Pump

Domain: manuals.plus

Introduction: DAYLIFF AQUASTRONG SMART 45 Water Boosting Pump

– Type: Variable speed water boosting pump

– Ideal for: Automatic pressurized water supply for houses, apartments, offices, and small-scale applications

– Key Features:

– Inverter controlled variable speed technology for energy efficiency

– Self-priming hydraulic design with four-stage AISI304 stainless steel impellers

– High-spec mechanical se…

2. AQUASTRONG – Smart 45 Automatic Water Pressure Booster Pump

Domain: ebay.com

Registered: 1995 (30 years)

Introduction: {“item_name”: “Aquastrong Smart 45 Automatic Water Pressure Booster Pump”, “brand”: “AQUASTRONG”, “condition”: “Used”, “price”: “$299.99”, “item_number”: “286788505608”, “category”: “Home & Garden > Home Improvement > Plumbing & Fixtures > Pumps & Water Filtration Systems > Pumps”, “shipping_estimate”: “Sat, Sep 20 – Wed, Sep 24”, “return_policy”: “Returns Accepted within 30 days, Seller pays retu…

Strategic Sourcing Conclusion and Outlook for aquastrong booost mode vs standard

In navigating the choice between the Aquastrong Boost Mode and Standard Pump, strategic sourcing emerges as a crucial element for international B2B buyers. The Boost Mode, with its advanced inverter technology, offers variable speed control that not only optimizes water pressure according to demand but also minimizes energy consumption—an essential factor for businesses focused on sustainability and operational efficiency. In contrast, the Standard Pump provides a reliable solution for consistent water supply at a fixed pressure, suitable for less variable environments.

For buyers in regions such as Africa, South America, the Middle East, and Europe, understanding the unique advantages of each model enables informed purchasing decisions that align with specific operational needs and budget constraints. As these markets continue to evolve, investing in innovative technologies like the Aquastrong Boost Mode can yield long-term cost savings and enhance service delivery.

We encourage all stakeholders to evaluate their water supply needs critically and consider the benefits of strategic sourcing in achieving optimal efficiency and performance. As the demand for advanced pumping solutions grows, embracing the latest technologies will position your business at the forefront of sustainable practices and operational excellence.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.