How to Source Application Brushes Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for application brushes

In the ever-evolving landscape of global commerce, sourcing high-quality application brushes can present significant challenges for B2B buyers. With diverse needs ranging from industrial applications to cosmetic uses, understanding the nuances of different brush types is crucial for making informed purchasing decisions. This guide offers a comprehensive exploration of application brushes, addressing key factors such as types, applications across various industries, supplier vetting processes, and cost considerations.

International buyers from regions such as Africa, South America, the Middle East, and Europe (including countries like Vietnam and Brazil) will find valuable insights tailored to their unique market dynamics. By delving into the specifics of brush materials, handling requirements, and industry-specific applications, this guide equips buyers with the knowledge necessary to identify the right products that meet both quality and budgetary constraints.

Furthermore, the guide emphasizes the importance of supplier reliability and compliance with international standards, ensuring that buyers can confidently establish partnerships that enhance their operational efficiency. With a focus on empowering businesses to navigate the complexities of sourcing application brushes, this resource stands as an essential tool for those looking to thrive in a competitive global market.

Understanding application brushes Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Chemical Resistant Brushes | Made from materials that withstand harsh chemicals; durable. | Aerospace, electronics, janitorial, and maintenance sectors. | Pros: Long-lasting, safe for sensitive applications. Cons: Typically higher cost. |

| Precision Applicator Brushes | Fine bristles for detailed work; adjustable handle length. | Dental, cosmetic applications, and intricate arts. | Pros: High accuracy, versatile. Cons: May not be suitable for large applications. |

| Disposable Applicator Brushes | Single-use design; often made from synthetic materials. | Medical, beauty, and food service industries. | Pros: Hygienic, convenient. Cons: Not eco-friendly; ongoing costs. |

| Multi-Purpose Brushes | Versatile design; can be used for various applications. | Manufacturing, construction, and DIY projects. | Pros: Cost-effective, adaptable. Cons: May lack specialization for specific tasks. |

| Artist Brushes | High-quality natural or synthetic fibers; crafted for art. | Fine arts, craft industries, and education. | Pros: Excellent control, premium quality. Cons: Higher price point for top brands. |

What Are the Key Characteristics of Chemical Resistant Brushes?

Chemical resistant brushes are specifically engineered to endure exposure to harsh solvents and chemicals without deteriorating. This makes them essential in industries like aerospace and electronics, where contamination can lead to significant issues. When purchasing, buyers should consider the brush’s material compatibility with the chemicals they will encounter, as well as its durability and ease of use. While these brushes offer longevity and reliability, they typically come at a higher price point, which can be a consideration for budget-conscious businesses.

How Do Precision Applicator Brushes Enhance B2B Operations?

Precision applicator brushes feature fine bristles that allow for meticulous application in various fields, such as dental work and cosmetics. Their adjustable handle length adds to their versatility, making them suitable for intricate tasks. B2B buyers should evaluate the specific needs of their applications, including the required level of detail and the types of materials they will be working with. While these brushes provide exceptional accuracy, they may not be ideal for larger tasks, limiting their utility in some industrial applications.

Why Choose Disposable Applicator Brushes for Your Business?

Disposable applicator brushes are designed for single-use, making them a hygienic option for industries like healthcare and food service. They are often made from synthetic materials that can be discarded after use, reducing the risk of cross-contamination. For B2B buyers, the primary consideration should be the cost-effectiveness of ongoing purchases versus the benefits of maintaining hygiene standards. While convenient, these brushes may contribute to environmental waste, which is an important factor for companies committed to sustainability.

What Advantages Do Multi-Purpose Brushes Offer in Various Industries?

Multi-purpose brushes are designed to be versatile, allowing them to be used across different applications, from manufacturing to construction. Their adaptability makes them a cost-effective solution for businesses looking to streamline their tool inventory. Buyers should consider the specific tasks they need the brushes for, as a lack of specialization may lead to less effective results in certain applications. Despite this, their affordability and functional flexibility make them a popular choice in many industries.

How Do Artist Brushes Stand Out in the B2B Market?

Artist brushes are crafted from high-quality natural or synthetic fibers, designed for precision and control in fine arts and craft applications. They are essential for artists and educators who require reliable tools for their work. When purchasing, B2B buyers should focus on the quality of the bristles and the type of brush that best suits their artistic needs. While artist brushes can be more expensive, their superior craftsmanship often justifies the investment for businesses in the creative sector.

Key Industrial Applications of application brushes

| Industry/Sector | Specific Application of application brushes | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Application of adhesives and coatings in aircraft assembly | Ensures precision and reduces waste in high-stakes environments | Compliance with aerospace standards; chemical resistance |

| Automotive | Painting and detailing of vehicle interiors and exteriors | Enhances product finish and customer satisfaction | Availability of various bristle types for different surfaces |

| Electronics | Cleaning and applying coatings on circuit boards | Prevents damage and enhances the longevity of electronic components | ESD-safe materials and precision bristle sizes |

| Medical | Application of disinfectants and coatings in healthcare | Ensures sterile environments and compliance with health regulations | FDA compliance; easy-to-clean and chemical-resistant options |

| Food Service | Application of glazes, oils, and sauces in food preparation | Improves food presentation and flavor while ensuring hygiene | Food-grade materials; easy to sterilize |

How Are Application Brushes Used in Aerospace and What Challenges Do They Address?

In the aerospace industry, application brushes are vital for the precise application of adhesives and coatings during aircraft assembly. These brushes help ensure that materials are applied evenly, reducing waste and enhancing the structural integrity of aircraft components. Buyers in this sector must consider brushes that comply with stringent aerospace standards, including chemical resistance to withstand various solvents and adhesives used in the industry.

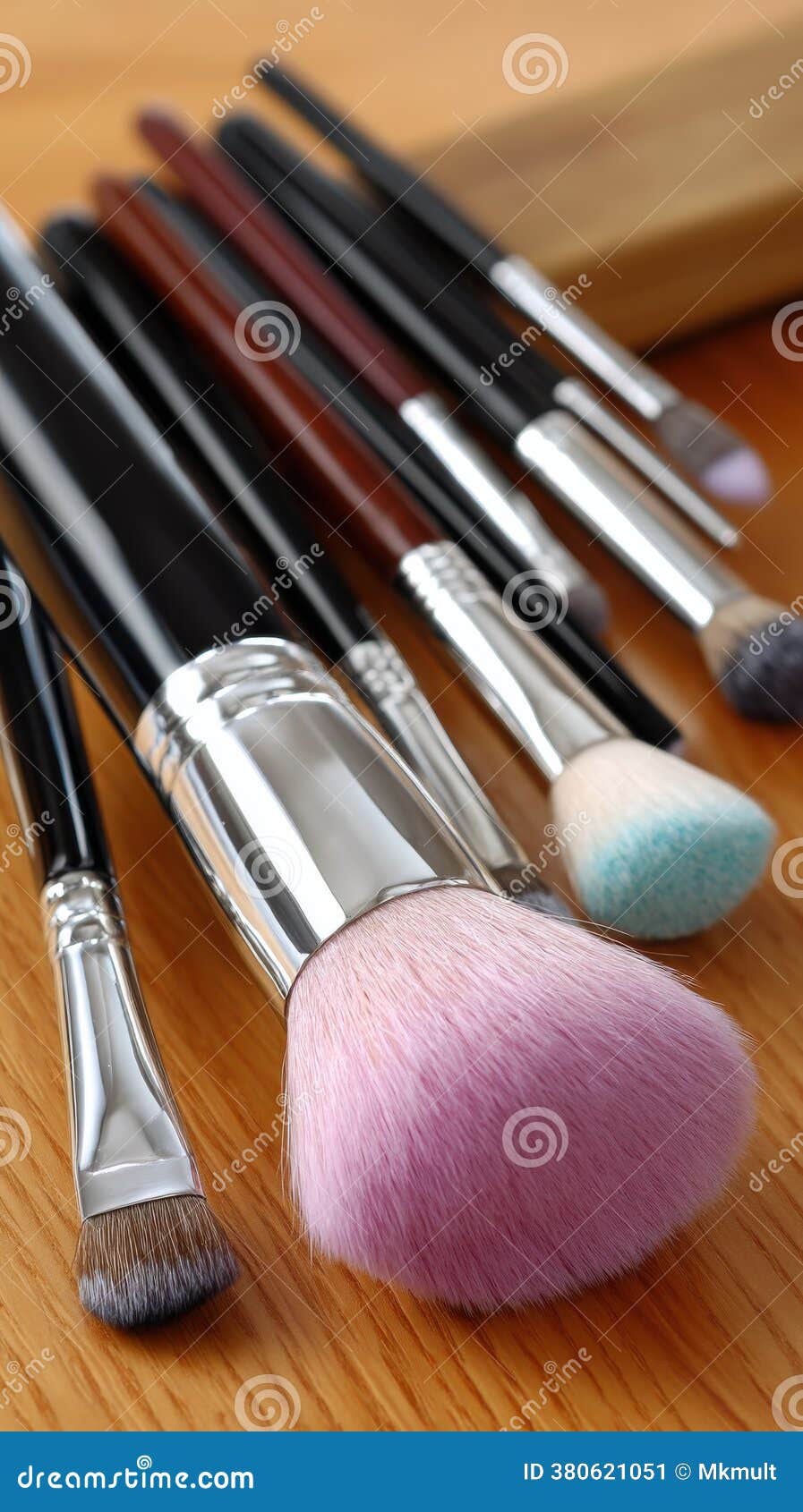

Illustrative image related to application brushes

What Role Do Application Brushes Play in the Automotive Sector?

Application brushes in the automotive sector are crucial for painting and detailing vehicle surfaces, both interiors and exteriors. They allow for a smooth and streak-free finish, significantly improving the overall aesthetic appeal of vehicles, which is essential for customer satisfaction. International buyers should focus on sourcing brushes that offer a variety of bristle types suitable for different surfaces, ensuring compatibility with various paint types and finishes.

Why Are Application Brushes Essential in Electronics Manufacturing?

In electronics manufacturing, application brushes are used to clean and apply coatings on sensitive circuit boards. They help prevent damage to delicate components and ensure that coatings are applied uniformly, enhancing the longevity and reliability of electronic devices. Buyers should prioritize sourcing brushes made from ESD-safe materials to mitigate static electricity risks, as well as those with precision bristle sizes to cater to the intricate designs of modern electronics.

How Do Application Brushes Contribute to Medical Environments?

In the medical field, application brushes are utilized for the application of disinfectants and coatings to maintain sterile environments. This is critical for compliance with health regulations and ensuring patient safety. Buyers in this sector must look for brushes that are FDA compliant and made from easy-to-clean, chemical-resistant materials to ensure effective sterilization and longevity.

What Benefits Do Application Brushes Offer in Food Service Applications?

In the food service industry, application brushes are employed for the application of glazes, oils, and sauces, enhancing the presentation and flavor of dishes. These brushes are essential for maintaining hygiene standards while ensuring that food is prepared attractively. Buyers should consider sourcing food-grade materials that are easy to sterilize, ensuring both safety and compliance with health regulations.

3 Common User Pain Points for ‘application brushes’ & Their Solutions

Scenario 1: Ensuring Chemical Resistance for Specialized Applications

The Problem: B2B buyers in industries such as aerospace, automotive, or pharmaceuticals often face the challenge of selecting application brushes that can withstand harsh chemicals. Using the wrong brush can lead to bristle degradation, contamination of materials, and costly production downtimes. This issue is particularly pressing for companies that require precision and compliance with strict safety standards, as the wrong choice can not only impair product quality but also result in safety hazards.

The Solution: To mitigate this risk, it is crucial to source application brushes specifically designed for chemical resistance. Buyers should prioritize suppliers that offer a variety of brushes made from materials such as nylon or polyester, which have proven durability against solvents and corrosive substances. Additionally, confirming that the brushes meet industry standards, such as ISO 9001:2015 certification, ensures quality assurance. It is advisable to request samples for testing in real-world conditions before making bulk purchases. Collaborating with manufacturers that can provide custom solutions tailored to specific applications can also enhance operational efficiency and product integrity.

Illustrative image related to application brushes

Scenario 2: Achieving Consistent Application Quality Across Diverse Products

The Problem: In sectors like cosmetics or food service, ensuring a consistent application quality is essential. B2B buyers often struggle with variations in brush performance due to differences in bristle density, material, or handle design. This inconsistency can lead to uneven product application, affecting customer satisfaction and brand reputation.

The Solution: To address this pain point, buyers should invest in application brushes that are meticulously designed for their specific use case. For instance, selecting brushes with uniform bristle lengths and densities will help ensure a smooth and consistent application. Engaging with suppliers that offer comprehensive product specifications and user guides can facilitate informed decision-making. Moreover, establishing a regular review and testing process of the application brushes in operational environments will help identify any performance issues early on, allowing for timely adjustments in sourcing or application techniques.

Scenario 3: Overcoming Supply Chain Disruptions and Availability Issues

The Problem: International B2B buyers, especially those operating in regions like Africa or South America, frequently encounter supply chain disruptions that can lead to delays in obtaining application brushes. This can severely impact production schedules and lead to financial losses. Factors such as political instability, transportation challenges, and import regulations can exacerbate these issues, making it difficult for businesses to maintain a steady supply of essential tools.

The Solution: To combat these supply chain challenges, buyers should adopt a proactive sourcing strategy. This includes establishing relationships with multiple suppliers across different regions to create a diversified supply chain. Buyers should also consider sourcing brushes that are locally manufactured or have shorter lead times. Implementing inventory management systems that allow for better forecasting and ordering based on usage patterns can help ensure that businesses maintain adequate stock levels. Additionally, discussing potential supply agreements with manufacturers for bulk orders can lock in pricing and availability, providing a safety net against future disruptions.

Strategic Material Selection Guide for application brushes

What Are the Key Properties of Common Materials Used in Application Brushes?

When selecting application brushes for various industries, the choice of material is critical. Different materials offer unique properties that can significantly affect performance, durability, and compatibility with specific applications. Below, we analyze four common materials used in application brushes: natural bristles, synthetic fibers, metal, and plastic.

How Do Natural Bristles Perform in Application Brushes?

Natural bristles, often made from animal hair such as hog, horse, or goat, are known for their softness and ability to hold and distribute liquids effectively. They typically have a temperature rating suitable for moderate heat applications but can degrade when exposed to harsh chemicals.

Pros: Natural bristles provide a smooth application and are excellent for media that require gentle handling, such as paints and cosmetics. They are often preferred in high-end applications due to their ability to create a flawless finish.

Illustrative image related to application brushes

Cons: However, natural bristles can be more expensive and less durable than synthetic options. They may also present challenges in terms of ethical sourcing and compliance with cruelty-free standards, which are increasingly important to buyers in regions like Europe.

What Advantages Do Synthetic Fibers Offer in Application Brushes?

Synthetic fibers, such as nylon or polyester, are engineered to withstand a range of conditions, including high temperatures and exposure to chemicals. These materials are often resistant to moisture and can maintain their shape and performance over time.

Pros: Synthetic brushes are typically more durable and cost-effective, making them suitable for high-volume applications in industries like automotive and manufacturing. They are also easier to clean, which is crucial for maintaining hygiene in sectors such as food service and medical.

Cons: One downside is that synthetic fibers may not provide the same level of finesse in application as natural bristles, which can be a consideration for high-precision tasks.

Why Choose Metal for Application Brushes?

Metal brushes, often constructed with stainless steel or brass, are primarily used for abrasive applications, such as cleaning or surface preparation. They can withstand high temperatures and are resistant to corrosion, making them ideal for industrial settings.

Pros: The durability of metal brushes allows for repeated use without significant wear, and they can effectively handle tough materials. They are often used in aerospace and automotive industries where precision and durability are paramount.

Cons: However, metal brushes may not be suitable for delicate surfaces or applications where scratching could be an issue. They can also be more expensive due to manufacturing complexity.

How Does Plastic Material Affect Application Brushes?

Plastic brushes, made from materials like polypropylene or polyethylene, are lightweight and resistant to moisture and chemicals. They are commonly used in disposable applications, such as medical or cosmetic sectors.

Illustrative image related to application brushes

Pros: The cost-effectiveness and versatility of plastic brushes make them a popular choice for disposable applications. They are also easy to manufacture and can be produced in various shapes and sizes.

Cons: On the downside, plastic brushes may not offer the same level of performance as natural or synthetic options in terms of liquid retention and application finesse. Additionally, they may not be as environmentally friendly, which is a growing concern for international buyers.

What Should International Buyers Consider When Selecting Brush Materials?

For international B2B buyers, particularly in regions like Africa, South America, the Middle East, and Europe, compliance with local regulations and standards is crucial. Buyers should be aware of common standards such as ASTM, DIN, and JIS, which can impact material selection. Additionally, preferences for cruelty-free and environmentally sustainable products are increasingly influencing purchasing decisions.

Summary Table of Material Selection for Application Brushes

| Material | Typical Use Case for application brushes | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Natural Bristles | High-end cosmetic and paint applications | Smooth application and finish | Less durable, ethical concerns | High |

| Synthetic Fibers | Automotive and manufacturing applications | Durable and cost-effective | May lack finesse in application | Medium |

| Metal | Industrial cleaning and surface prep | Extremely durable and heat resistant | Can scratch delicate surfaces | High |

| Plastic | Disposable medical and cosmetic brushes | Lightweight and moisture-resistant | Less performance in liquid retention | Low |

By understanding the properties, advantages, and limitations of these materials, B2B buyers can make informed decisions that align with their specific application needs and compliance requirements.

Illustrative image related to application brushes

In-depth Look: Manufacturing Processes and Quality Assurance for application brushes

In the competitive landscape of application brushes, understanding the manufacturing processes and quality assurance protocols is crucial for B2B buyers, especially those looking to source these products from international suppliers. This section delves into the key stages of manufacturing and the quality control measures that ensure the reliability and performance of application brushes.

What are the Key Stages in the Manufacturing Process of Application Brushes?

The manufacturing process of application brushes involves several critical stages: material preparation, forming, assembly, and finishing. Each stage requires precision and adherence to industry standards to deliver high-quality products.

How is Material Prepared for Application Brushes?

The first step in manufacturing application brushes is material preparation. This involves selecting the appropriate fill materials—such as natural fibers (e.g., horsehair or hog bristle), synthetic fibers (e.g., nylon or polyester), or a combination of both—depending on the intended use of the brush. Additionally, the handle materials are chosen, which can range from wood to plastic or metal.

Once selected, these materials undergo cleaning and treatment processes to remove impurities that could affect performance. For instance, natural fibers may require sterilization to eliminate contaminants. This preparation ensures that the materials meet the required specifications for durability and performance.

Illustrative image related to application brushes

What Techniques are Used in Forming Application Brushes?

The forming stage is where the prepared materials are shaped into brush components. This involves cutting the fill material to the desired length and bundling it to form the bristle head. Advanced techniques such as tufting and knotting are employed to secure the bristles in place, ensuring they maintain their shape during use.

For handles, molding techniques are often used for plastic and metal, while wooden handles may be carved or shaped using CNC machines for precision. The forming stage is crucial as it directly influences the brush’s effectiveness and user experience.

How are Application Brushes Assembled?

After forming, the assembly stage brings together the bristle heads and handles. This process may involve gluing, screwing, or crimping, depending on the design of the brush. For high-quality application brushes, manufacturers often utilize ergonomic designs that enhance usability, which is particularly important for professionals who require precision and comfort.

The assembly process must be meticulously monitored to ensure that each brush is assembled correctly, as any misalignment can lead to poor performance or premature wear.

What Finishing Processes are Applied to Application Brushes?

Finishing processes enhance the aesthetic appeal and functionality of application brushes. This may include sanding, painting, or applying protective coatings to the handles. Additionally, quality checks are integrated into this stage to ensure that brushes meet design specifications and performance standards.

Finishing touches not only improve the brush’s appearance but also its durability, especially when exposed to various chemicals or environmental conditions. For instance, brushes intended for industrial use may receive chemical-resistant coatings.

What International Quality Assurance Standards Apply to Application Brushes?

Quality assurance is paramount in the manufacturing of application brushes, particularly for B2B buyers who need to ensure their suppliers adhere to international standards. Notable standards include ISO 9001, which sets criteria for quality management systems, and CE marking for products sold within the European Economic Area, ensuring compliance with safety and environmental requirements.

How are Quality Control Checkpoints Established in Manufacturing?

Quality control (QC) is integrated throughout the manufacturing process, with several checkpoints established to maintain high standards. These checkpoints typically include:

-

Incoming Quality Control (IQC): This stage verifies the quality of raw materials before they enter production. Suppliers must provide certificates of compliance to ensure that materials meet specified standards.

-

In-Process Quality Control (IPQC): During manufacturing, ongoing inspections are conducted to monitor the production process. This helps identify and rectify issues early, minimizing defects.

-

Final Quality Control (FQC): After assembly, finished products undergo rigorous testing to ensure they meet design specifications and performance standards. This may include functional testing, visual inspections, and packaging checks.

What Testing Methods are Commonly Used for Application Brushes?

B2B buyers should be aware of common testing methods utilized to evaluate the performance and durability of application brushes. These methods can include:

-

Durability Testing: Assessing how well brushes withstand repeated use and exposure to various substances.

-

Chemical Resistance Testing: Ensuring that the materials used do not degrade when exposed to specific chemicals, especially for industrial applications.

-

Performance Testing: Evaluating the brush’s ability to apply products evenly and effectively, which is critical for professional applications.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For international buyers, verifying a supplier’s quality control practices is essential to ensure they meet required standards. Here are several ways to do this:

-

Conduct Audits: Regular audits of suppliers can provide insights into their manufacturing processes and quality control measures. Buyers can assess compliance with international standards and identify areas for improvement.

-

Request Quality Assurance Reports: Suppliers should provide documentation detailing their quality assurance processes, including results from testing and inspections. This transparency helps buyers evaluate the reliability of the supplier.

-

Third-Party Inspections: Engaging third-party inspection services can provide an unbiased assessment of the supplier’s quality control practices. These inspections can be particularly beneficial for buyers unfamiliar with local manufacturing standards.

What Nuances Should International Buyers Consider in Quality Control?

International buyers, particularly from regions like Africa, South America, the Middle East, and Europe, must consider specific nuances when it comes to quality control:

-

Regulatory Compliance: Understanding local regulations and compliance requirements is critical, as these can vary significantly by region. Buyers should ensure that suppliers are compliant with both local and international standards.

-

Cultural Differences: Different regions may have varying approaches to quality assurance and manufacturing practices. Establishing clear communication and expectations can help bridge these gaps.

-

Logistics and Supply Chain Management: Quality control does not end at the factory. Buyers should consider the entire supply chain, including transportation and storage conditions, which can impact product quality.

By understanding the manufacturing processes and quality assurance measures associated with application brushes, B2B buyers can make informed sourcing decisions that ensure product reliability and performance across diverse applications.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘application brushes’

To effectively procure application brushes for your business, it is essential to follow a systematic approach that ensures you meet your operational needs while maintaining quality and compliance. This checklist serves as a comprehensive guide to help B2B buyers navigate the complexities of sourcing application brushes.

Illustrative image related to application brushes

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of your sourcing process. Consider the materials, sizes, and types of bristles that will best suit your intended application, whether it’s for industrial, cosmetic, or medical use. Additionally, define any specific requirements regarding chemical resistance, ESD safety, or vegan materials, as these factors can greatly influence performance and compatibility.

Step 2: Research Potential Suppliers

Conduct thorough research to identify potential suppliers that align with your specifications. Utilize online directories, trade shows, and industry associations to compile a list of manufacturers and distributors. Focus on suppliers with a proven track record in your specific industry, as they are more likely to understand your unique needs and challenges.

Step 3: Evaluate Supplier Certifications

Before entering negotiations, verify the certifications and compliance of potential suppliers. Look for ISO 9001 or other relevant industry certifications that demonstrate a commitment to quality and safety standards. These certifications are particularly important in industries like aerospace, medical, and food services, where compliance is non-negotiable.

Step 4: Request Samples for Testing

Once you have shortlisted potential suppliers, request samples of the application brushes you are considering. Testing these samples in real-world conditions will allow you to evaluate their performance, durability, and user-friendliness. Pay attention to factors such as bristle retention, ease of cleaning, and overall finish quality, as these will affect your operational efficiency.

Illustrative image related to application brushes

Step 5: Compare Pricing and Payment Terms

Engage with suppliers to obtain detailed quotes and compare pricing structures. Ensure that you understand the payment terms, including any bulk order discounts or shipping fees. It is essential to balance cost-effectiveness with quality; the cheapest option may not always provide the best long-term value.

Step 6: Assess Supplier Support and Communication

Effective communication is critical in maintaining a successful supplier relationship. Evaluate how responsive and supportive potential suppliers are during your inquiry process. Look for partners who offer robust customer service, including technical support, timely updates on orders, and clear channels for addressing concerns.

Step 7: Finalize Contracts and Place Orders

After selecting a supplier, carefully review and finalize all contractual agreements. Ensure that all specifications, pricing, delivery schedules, and warranty terms are clearly outlined in the contract. Once everything is confirmed, place your order and establish a plan for ongoing communication to manage future needs and potential adjustments.

By adhering to this checklist, B2B buyers can streamline their sourcing process for application brushes, ensuring they make informed decisions that align with their business objectives.

Comprehensive Cost and Pricing Analysis for application brushes Sourcing

What Are the Key Cost Components in Application Brush Sourcing?

When sourcing application brushes, understanding the cost structure is crucial for effective budgeting and pricing strategies. The cost components generally include:

Illustrative image related to application brushes

-

Materials: The choice of materials significantly impacts the overall cost. Synthetic bristles may be cheaper than natural options, while specialty materials like chemical-resistant filaments can drive costs up.

-

Labor: Labor costs encompass not just the wages of workers involved in manufacturing but also the training and expertise required for skilled labor, especially for high-quality or specialized brushes.

-

Manufacturing Overhead: This includes the indirect costs associated with production, such as utilities, rent, and equipment maintenance. Efficient factories tend to have lower overhead, which can translate to better pricing for buyers.

-

Tooling: The cost of molds and tools used in the manufacturing process can be substantial, especially for custom designs. These costs are often amortized over large production runs.

-

Quality Control (QC): Ensuring that products meet specified standards can add to the costs. Rigorous QC processes are essential, particularly for industries like aerospace or pharmaceuticals, where compliance is critical.

-

Logistics: Shipping and handling costs can vary widely based on the geographic location of the supplier and buyer, as well as the chosen Incoterms. These costs should be factored into the total price.

-

Margin: Suppliers typically add a profit margin on top of their costs. The margin can vary based on competition, market demand, and the supplier’s positioning.

How Do Price Influencers Affect Application Brush Sourcing?

Several factors can influence the pricing of application brushes, impacting the total cost for buyers:

-

Volume and Minimum Order Quantity (MOQ): Higher order volumes often lead to lower per-unit costs. Suppliers may offer discounts for bulk purchases, making it advantageous for buyers to consolidate orders.

-

Specifications and Customization: Customized brushes can incur additional costs due to tooling and design requirements. Buyers should clearly communicate their needs to avoid unexpected expenses.

-

Materials and Quality Certifications: Brushes made from premium materials or those with specific certifications (e.g., FDA compliance) may come at a higher price. Buyers should weigh the benefits of quality against budget constraints.

-

Supplier Factors: The supplier’s reputation, location, and production capabilities can significantly affect pricing. Established suppliers may command higher prices due to reliability and quality assurance.

-

Incoterms: Understanding the chosen Incoterms is vital, as they determine who bears the shipping costs and risks. Incoterms like CIF (Cost, Insurance, and Freight) may increase upfront costs but reduce risk for buyers.

What Are the Best Buyer Tips for Cost-Efficiency in Application Brush Procurement?

To optimize costs and ensure value in sourcing application brushes, consider the following strategies:

-

Negotiate with Suppliers: Establish open communication with suppliers and negotiate pricing based on volume, long-term relationships, or bundling with other products.

-

Consider Total Cost of Ownership (TCO): Evaluate not only the purchase price but also the long-term costs associated with maintenance, durability, and performance. A cheaper brush may lead to higher costs in replacements or inefficiencies.

-

Understand Pricing Nuances for International Transactions: International buyers should be aware of currency fluctuations, tariffs, and import duties that can affect pricing. Building relationships with local agents can aid in navigating these complexities.

-

Conduct Market Research: Regularly benchmark prices against competitors to ensure you are receiving competitive rates. This can also help identify emerging suppliers offering innovative solutions at lower costs.

-

Leverage Local Suppliers: For buyers in regions like Africa and South America, sourcing from local manufacturers can reduce shipping costs and lead times, providing a competitive edge.

Disclaimer

Prices mentioned in various sources are indicative and may fluctuate based on market conditions, availability, and specific buyer-supplier agreements. Always request formal quotes to ensure accurate budgeting.

Illustrative image related to application brushes

Alternatives Analysis: Comparing application brushes With Other Solutions

Introduction to Alternatives in Application Solutions

In the realm of industrial and commercial applications, the effectiveness of a tool can significantly impact operational efficiency. While application brushes are widely utilized for their precision and versatility, it’s essential for B2B buyers to consider alternative solutions that might offer enhanced performance or cost-effectiveness. This analysis explores how application brushes compare with other viable methods—specifically, spray applicators and rollers—to help buyers make informed decisions tailored to their unique operational needs.

Comparison of Application Brushes with Alternative Solutions

| Comparison Aspect | Application Brushes | Spray Applicators | Rollers |

|---|---|---|---|

| Performance | High precision for detail work | Quick coverage, less precision | Moderate precision, good for large areas |

| Cost | Generally low cost (e.g., $4.30 for a duo set) | Moderate cost (varies widely) | Low to moderate cost, depending on type |

| Ease of Implementation | Simple to use; minimal training required | Requires some skill for even application | Easy to use; suitable for most users |

| Maintenance | Low; occasional cleaning needed | Moderate; needs regular cleaning and upkeep | Low; easy to clean, but may require replacement |

| Best Use Case | Ideal for detailed work and small applications | Best for large areas needing quick application | Suitable for medium to large surfaces where speed is essential |

Detailed Breakdown of Alternatives

Spray Applicators

Spray applicators offer a fast and efficient method for applying coatings, paints, or adhesives over large surfaces. Their primary advantage lies in their ability to cover vast areas quickly, making them ideal for projects where time is of the essence. However, they may lack the precision required for intricate detailing, and users often need to develop skills to achieve an even application. Additionally, spray applicators can generate overspray, leading to potential waste and the need for masking off areas.

Rollers

Rollers are a traditional solution for applying paint and coatings, known for their speed and efficiency on larger surfaces. They are relatively easy to use and maintain, often requiring just a quick rinse after use. While rollers can cover large areas effectively, they may not provide the fine detail that application brushes can. This makes them less suitable for detailed work but ideal for general applications where uniformity is more critical than precision.

Conclusion: Choosing the Right Application Method for Your Needs

Selecting the right application method depends on various factors, including the nature of the project, the required precision, and budget constraints. Application brushes excel in detail-oriented tasks, making them a preferred choice for intricate applications in industries such as cosmetics or small-scale manufacturing. In contrast, spray applicators and rollers shine in scenarios demanding speed and efficiency over precision. B2B buyers should assess their specific requirements, considering factors such as the scale of the project, desired finish quality, and overall cost-effectiveness to determine the optimal solution for their operations.

Essential Technical Properties and Trade Terminology for application brushes

What Are the Key Technical Properties of Application Brushes?

Understanding the technical properties of application brushes is crucial for B2B buyers, especially when making decisions that impact efficiency and quality in production processes. Here are several essential specifications to consider:

Illustrative image related to application brushes

1. Fill Material

The fill material of an application brush can significantly affect its performance. Common materials include natural fibers (like hog bristle or horsehair), synthetic fibers (such as nylon or polyester), and specialty materials (like ESD-safe fibers). Each material has unique characteristics; for example, natural fibers provide excellent paint application, while synthetic options offer durability and resistance to chemicals. Choosing the right fill material ensures optimal performance for specific applications, such as aerospace or medical uses.

2. Handle Material

The handle material plays a pivotal role in the brush’s usability and durability. Handles can be made from plastic, metal, or wood. Plastic handles are lightweight and resistant to moisture, making them suitable for environments where hygiene is critical, such as food service. Metal handles provide strength and stability for heavy-duty applications, while wooden handles offer a traditional feel and comfort. Selecting the appropriate handle material impacts user experience and the brush’s longevity.

3. Bristle Diameter

Bristle diameter determines the brush’s coverage and application precision. A smaller diameter allows for intricate work, while a larger diameter covers more surface area quickly. This specification is particularly important in industries like automotive and electronics, where precision is crucial for quality assurance. Buyers should assess the application requirements to choose the correct bristle diameter for their needs.

4. Temperature Resistance

Temperature resistance indicates how well a brush can withstand high or low temperatures without degrading. This property is essential for industries that involve heat-sensitive applications, such as automotive painting or electronics assembly. Brushes with high-temperature resistance maintain their integrity and functionality in extreme conditions, ensuring consistent performance.

5. Brush Length and Trim

The length of the brush and the trim (the height of the bristles) affect application style and technique. Longer brushes can reach difficult areas, while shorter brushes provide more control for detailed work. Understanding the optimal length and trim for specific applications helps in achieving the desired outcome, whether it’s a smooth finish or precise detailing.

What Are Common Trade Terms in the Application Brush Industry?

Familiarity with industry jargon is vital for effective communication and negotiation in the B2B sector. Here are some key terms that buyers should know:

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products that may be marketed by another company. In the context of application brushes, understanding OEM partnerships can help buyers identify quality sources for custom or specialty brushes tailored to specific needs.

2. MOQ (Minimum Order Quantity)

MOQ is the smallest quantity of a product that a supplier is willing to sell. This term is critical for buyers to understand, as it affects inventory management and cost-effectiveness. Knowing the MOQ helps businesses plan their purchases and avoid excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers to request pricing information for specific products or services. Buyers should use RFQs to gather competitive pricing and assess supplier capabilities. Crafting an effective RFQ can lead to better negotiation outcomes and more favorable terms.

4. Incoterms (International Commercial Terms)

Incoterms are a set of predefined commercial terms used in international trade that clarify the responsibilities of buyers and sellers. Understanding these terms helps buyers navigate shipping logistics, costs, and risks associated with the transportation of application brushes across borders.

5. Customization

Customization in the application brush industry refers to the ability to tailor brushes according to specific requirements, such as size, material, or design. This term is essential for businesses looking for specialized solutions that meet unique operational needs.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions when sourcing application brushes, ensuring they choose the right products for their specific applications and industry requirements.

Navigating Market Dynamics and Sourcing Trends in the application brushes Sector

What Are the Current Market Trends Influencing the Application Brushes Sector?

The global market for application brushes is experiencing significant growth driven by several factors. The increasing demand for precision in various industries, including cosmetics, automotive, and healthcare, is a primary driver. B2B buyers are increasingly looking for specialized brushes that cater to specific applications, such as chemical resistance in industrial settings or fine precision in cosmetic applications. Emerging technologies, such as automation in manufacturing, are also reshaping sourcing dynamics. For instance, the rise of e-commerce platforms has made it easier for buyers from regions like Africa, South America, the Middle East, and Europe to access a diverse range of application brushes, enabling them to make informed purchasing decisions.

Moreover, sustainability is becoming a crucial factor in the sourcing process. Buyers are prioritizing suppliers that demonstrate environmentally responsible practices, such as using recyclable materials and reducing waste in production. Trends like custom manufacturing are gaining traction, allowing buyers to specify their needs in brush design, including handle materials and bristle types. As the market evolves, international buyers must stay attuned to these trends to ensure they source products that meet both their operational needs and their customers’ expectations.

How Is Sustainability and Ethical Sourcing Impacting the Application Brushes Market?

Sustainability is increasingly at the forefront of purchasing decisions in the application brushes sector. The environmental impact of manufacturing processes and materials is being scrutinized more than ever. B2B buyers are now looking for suppliers who can provide transparency in their sourcing practices and demonstrate a commitment to ethical supply chains. This includes ensuring that raw materials are sourced responsibly and that production processes minimize carbon footprints.

Certifications such as ISO 14001 (Environmental Management) and the use of biodegradable or recycled materials are becoming essential criteria for buyers. For example, brushes made with synthetic fibers derived from recycled plastics are gaining popularity as they offer durability while reducing environmental impact. Furthermore, buyers are seeking suppliers that can provide documentation on the sustainability of their products, including certifications that affirm the brushes are free from harmful chemicals, such as parabens or sulfates. This shift towards greener products not only aligns with global sustainability goals but also enhances brand reputation and customer loyalty in increasingly eco-conscious markets.

What Is the Historical Context of Application Brushes Relevant to B2B Buyers?

The evolution of application brushes can be traced back to their early use in various trades, including painting and craftsmanship. Initially made from natural materials like animal hair or plant fibers, these brushes were primarily utilized for manual applications. Over time, as industrial processes advanced, the demand for brushes that could withstand harsher chemicals and environments grew, leading to innovations in materials and design.

In recent decades, the rise of specialized sectors, such as the beauty and healthcare industries, has further diversified the application brush market. Brushes designed for specific applications, like makeup or medical procedures, have become increasingly sophisticated, incorporating ergonomic designs and specialized bristles for improved performance. This evolution has not only expanded the market but has also influenced the standards and expectations B2B buyers have when sourcing application brushes today. Buyers must now consider not only the functionality and cost of these brushes but also the sustainability and ethical implications of their sourcing decisions.

Frequently Asked Questions (FAQs) for B2B Buyers of application brushes

-

How do I choose the right applicator brush for my needs?

Choosing the right applicator brush depends on the specific application and industry requirements. Consider factors such as bristle material, handle type, and size. For example, synthetic bristles are ideal for chemical applications, while natural bristles work well for paint and coatings. Additionally, assess the brush’s compatibility with the substances you’ll be using, ensuring it can withstand any chemicals without degrading. Don’t hesitate to request samples from suppliers to evaluate performance before making a bulk purchase. -

What types of applicator brushes are available for different industries?

Applicator brushes come in a variety of types tailored for specific industries, including aerospace, automotive, and food service. Common options include chemical-resistant brushes for industrial applications and precision brushes for delicate tasks. For example, ESD-safe brushes are essential in electronics manufacturing, while sterilizable brushes are crucial in the medical field. Evaluate your industry standards and select brushes that comply with necessary regulations and certifications to ensure safety and effectiveness. -

What is the minimum order quantity (MOQ) for applicator brushes?

Minimum order quantities can vary significantly between suppliers and depend on the type of applicator brush. Generally, MOQs range from 50 to several hundred units, particularly for custom or specialized brushes. It’s advisable to discuss your needs with potential suppliers to negotiate terms that suit your purchasing strategy. Some suppliers may offer flexibility on MOQs for first-time orders or bulk purchases, so be sure to inquire about available options. -

How can I ensure quality assurance when sourcing applicator brushes?

To ensure quality assurance, choose suppliers who adhere to recognized industry standards, such as ISO certifications. Request detailed product specifications and samples to assess quality firsthand. Additionally, inquire about the supplier’s quality control processes, including testing methods and compliance with international safety standards. Establishing a strong relationship with your supplier and conducting regular audits can also help maintain quality over time. -

What payment terms should I expect when buying applicator brushes internationally?

Payment terms can vary widely among suppliers, but common practices include upfront payments, letters of credit, or payment upon delivery. For international transactions, it’s advisable to negotiate terms that protect both parties, such as partial payments upfront and the remainder upon successful delivery. Ensure that all payment terms are clearly documented in your contract to avoid misunderstandings. Familiarize yourself with any currency exchange implications as well. -

How can I vet suppliers for applicator brushes effectively?

Vetting suppliers involves several steps, including checking their business credentials, reviews, and industry reputation. Utilize platforms like Alibaba or ThomasNet to find verified suppliers and read customer testimonials. Request references and conduct background checks to understand their production capabilities and reliability. Additionally, consider visiting their facilities or requesting virtual tours to assess their operations firsthand and ensure they meet your quality standards. -

What are the shipping options for applicator brushes in international trade?

Shipping options for applicator brushes typically include air freight, sea freight, and express courier services. Air freight is faster but more expensive, making it suitable for urgent orders, while sea freight is cost-effective for bulk shipments but takes longer. Discuss with your supplier about the best shipping method based on your timeline and budget. Ensure that the supplier provides appropriate packaging to protect the brushes during transit, minimizing the risk of damage. -

Can I customize applicator brushes to meet specific requirements?

Yes, many suppliers offer customization options for applicator brushes, including modifications to size, bristle material, and handle design. Customization can enhance performance for particular applications, making it a valuable option for businesses with unique needs. Engage with suppliers early in the sourcing process to discuss your specifications and obtain quotes for custom orders. Be prepared to provide details about the intended use to ensure the final product aligns with your expectations.

Top 3 Application Brushes Manufacturers & Suppliers List

1. Gordon Brush – Applicator Brushes

Domain: gordonbrush.com

Registered: 1998 (27 years)

Introduction: Applicator Brushes are multi-purpose industrial tools ideal for applying glue, coatings, or solvents in various applications. They are essential in aerospace, janitorial, construction, electronics, and maintenance industries. Key specifications include: Fill Materials: Nylon, Nylon (Static Dissipative), Peek, Polypropylene, PTFE; Handle Materials: Aluminum, Brass, Plastic (Acetal), Stainless Steel…

2. Infection Control Products – Applicator Brushes

Domain: infectioncontrolproducts.com

Registered: 2004 (21 years)

Introduction: Applicator Brushes: Handles attached to brushes or sponges used to apply adhesives to the tooth or restoration surface. Available products include: 1. Microbrush Bendable Micro Applicator – Sale price: $14.75 2. Microbrush Plus Applicators – Sale price: $58.95 3. EcoBee BeeSure Micro Applicators – Sale price: $6.25 4. Plasdent Bendable Applicator Brush – Sale price: $16.50 5. Microbrush Ultrabrush…

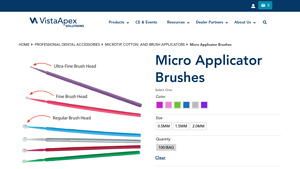

3. Vista Apex – Micro Applicator Brushes

Domain: vistaapex.com

Registered: 2020 (5 years)

Introduction: Micro Applicator Brushes – For etchants, sealants, bonding agents, and hemostatic agents. Features include: Lint-free brush tip, Non-absorbent, Bendable head. Available sizes and colors: Ultra-Fine (0.5mm) – Lavender, Fine (1.5mm) – Pink, Regular (2.0mm) – Blue, Regular (2.0mm) – Silver, Regular (2.0mm) – Purple, Regular (2.0mm) – Green. Price range: $12.41 – $16.34. Quantity: 100/bag.

Strategic Sourcing Conclusion and Outlook for application brushes

As the global demand for application brushes continues to rise, strategic sourcing has never been more vital for B2B buyers. By focusing on quality, compliance, and sustainability, businesses can ensure that they not only meet their operational needs but also align with consumer preferences increasingly leaning towards eco-friendly products. The diverse range of application brushes available—from chemical-resistant options to handcrafted artisan brushes—highlights the importance of selecting the right product for specific applications across industries such as beauty, medical, and manufacturing.

Investing in strategic partnerships with reputable suppliers can enhance supply chain resilience and foster innovation. Buyers should prioritize suppliers who demonstrate a commitment to quality standards, such as ISO certifications, and those who offer customization options to meet unique business requirements.

Looking ahead, international buyers from regions like Africa, South America, the Middle East, and Europe have a significant opportunity to leverage these insights. By making informed sourcing decisions today, businesses can position themselves for success in a competitive market. Engage with suppliers who share your values and vision for quality and sustainability—your choices today will shape the landscape of tomorrow’s industry.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Illustrative image related to application brushes