How to Source Aluminum Extruded Profiles Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for aluminum extruded profiles

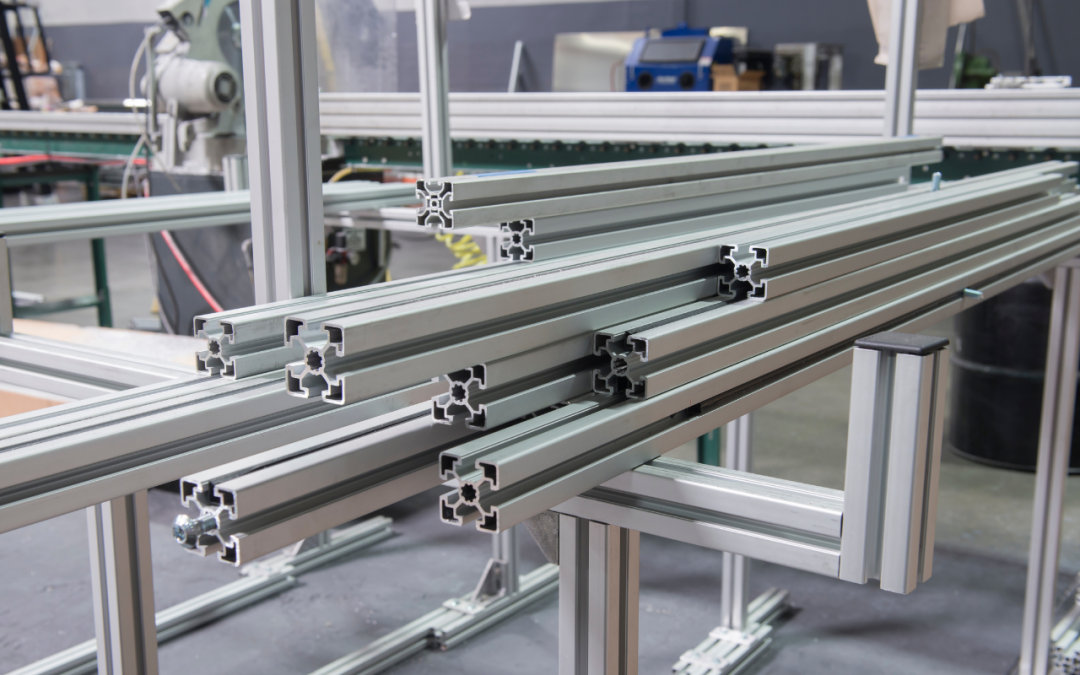

In the rapidly evolving global market, sourcing aluminum extruded profiles poses a significant challenge for international B2B buyers, particularly those operating in diverse regions such as Africa, South America, the Middle East, and Europe. With a myriad of options available, from T-slotted profiles to specialized shapes, understanding the nuances of these products is essential for making informed purchasing decisions. This guide aims to equip buyers with the knowledge needed to navigate this complex landscape, addressing key factors such as types, applications, supplier vetting, and cost implications.

Aluminum extruded profiles are not only vital for construction and manufacturing but also serve a wide range of applications, including automotive, aerospace, and consumer goods. By delving into the specifics of profile types and their respective uses, this guide empowers buyers to identify the most suitable solutions for their unique needs. Furthermore, it emphasizes the importance of thorough supplier vetting, ensuring that businesses engage with reputable manufacturers who can deliver quality products on time.

In an era where efficiency and reliability are paramount, this comprehensive resource serves as a roadmap for B2B buyers, enabling them to make strategic decisions that enhance their operations. Whether you are in Saudi Arabia looking for durable framing solutions or in Nigeria sourcing lightweight aluminum components, this guide will provide you with actionable insights to streamline your procurement process and drive your business forward.

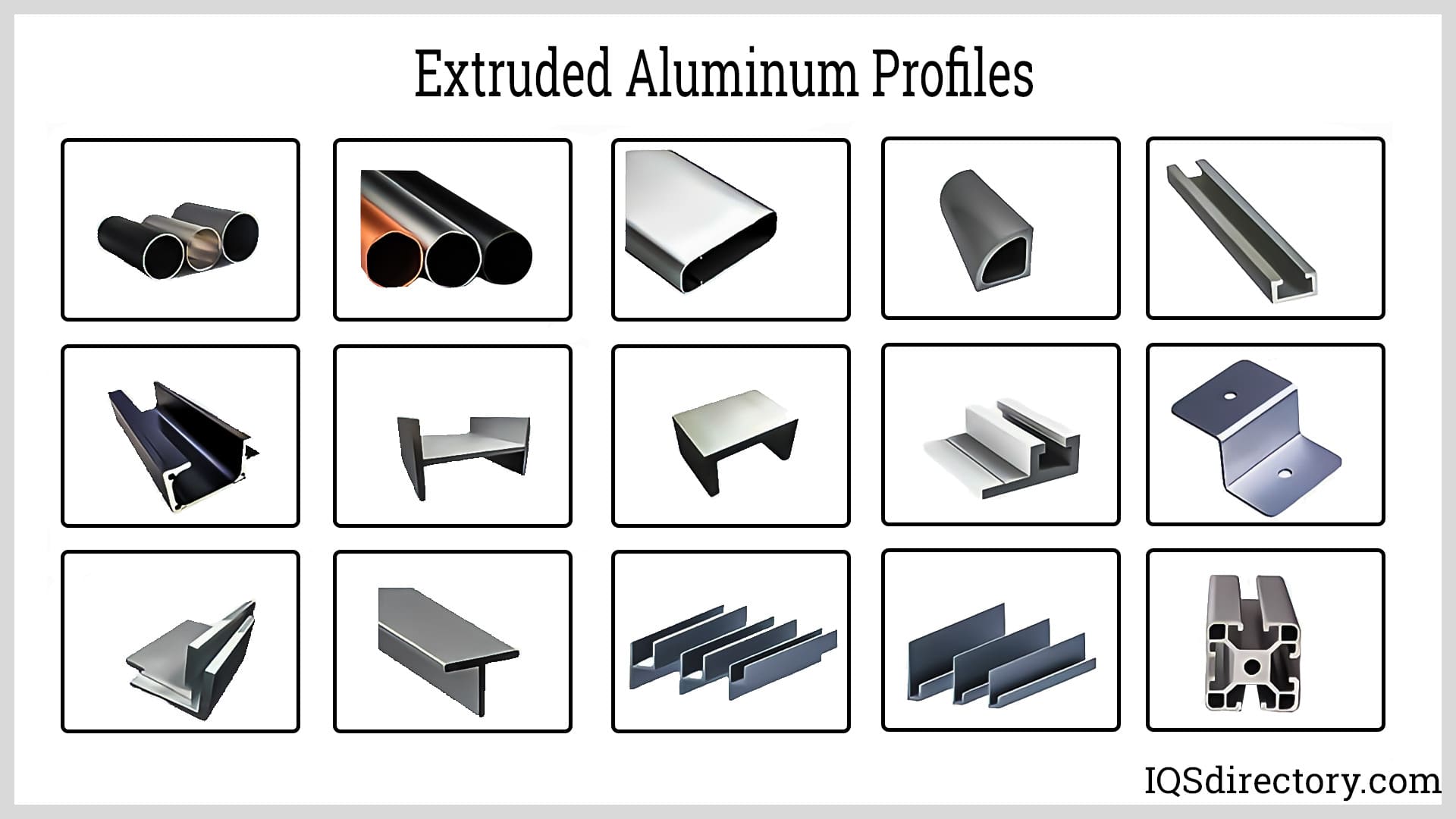

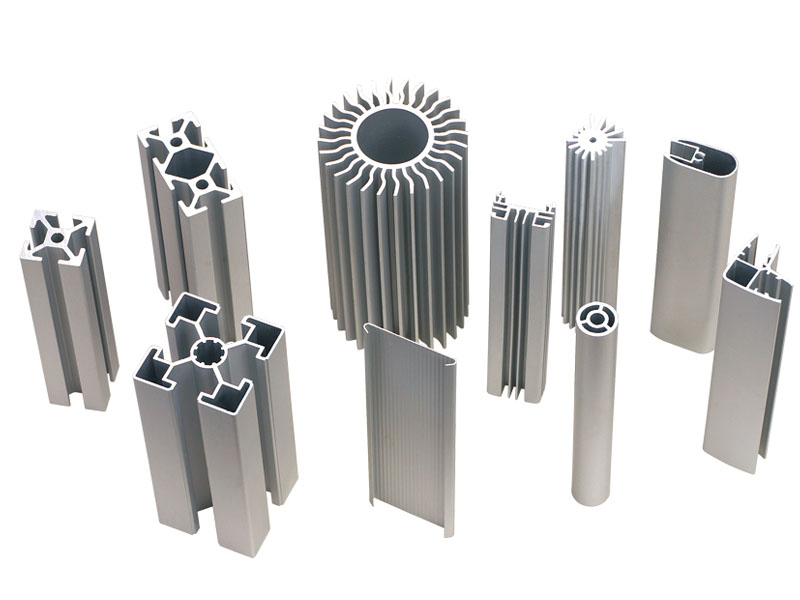

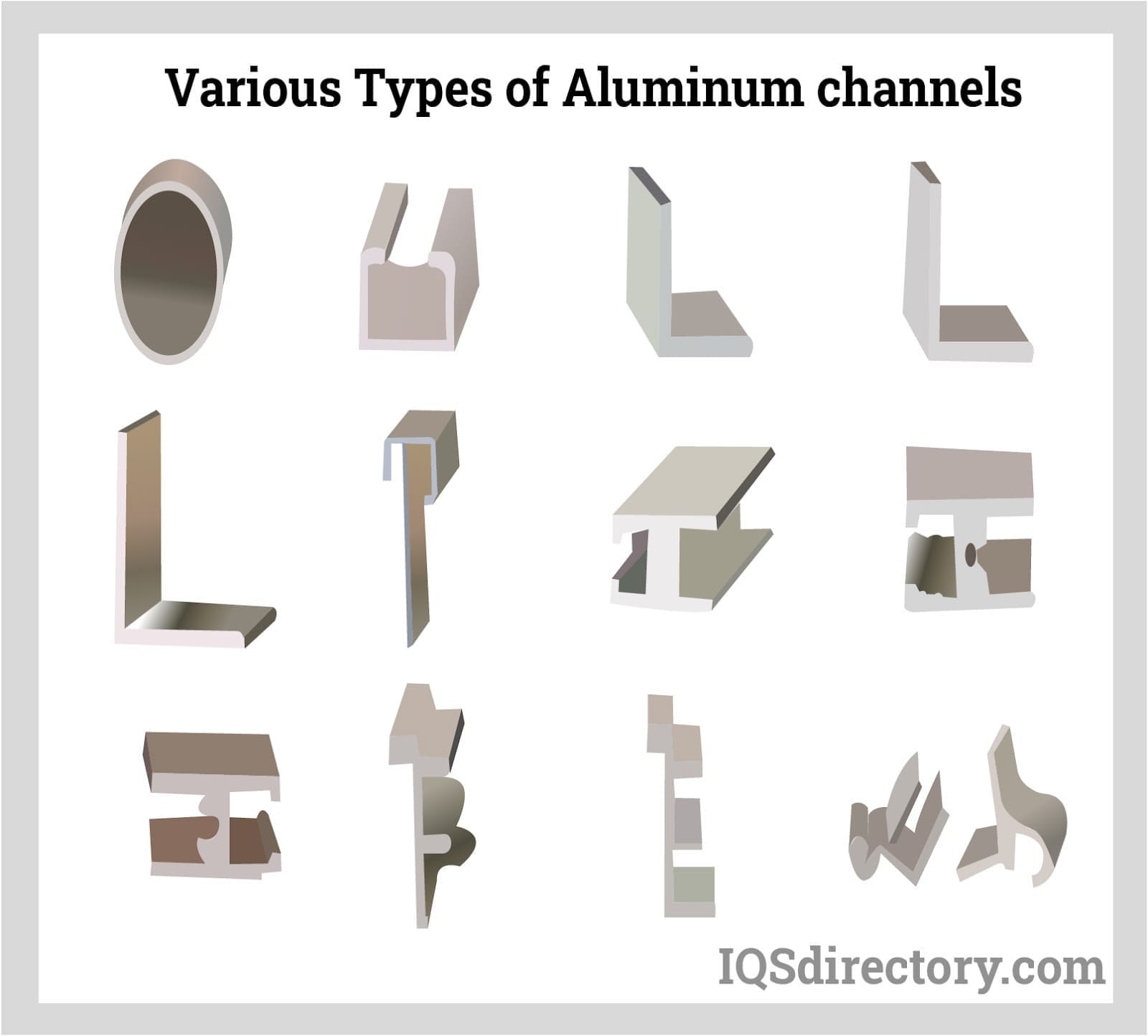

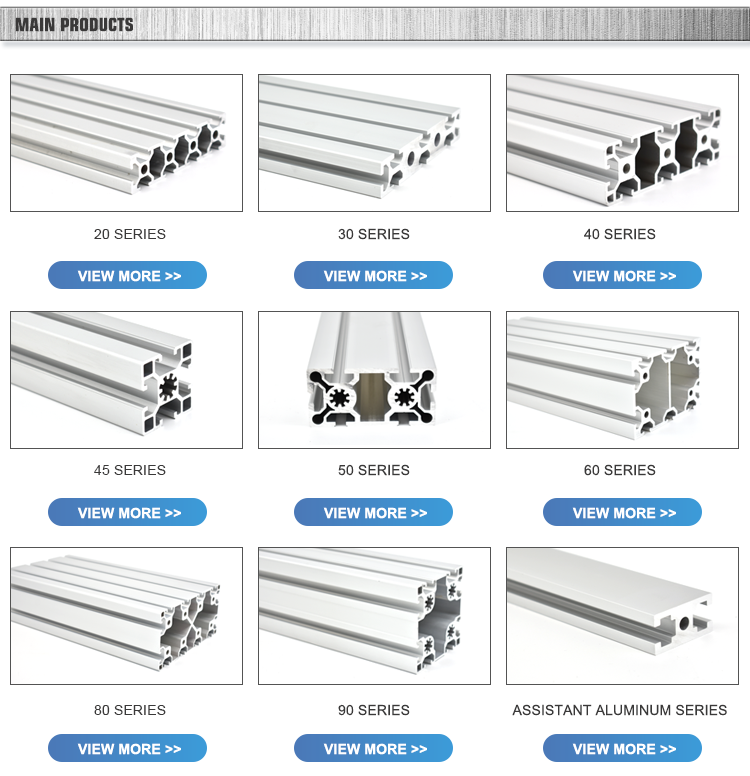

Understanding aluminum extruded profiles Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| T-Slot Profiles | Features multiple slots for easy assembly and versatility | Machinery frames, workstations, automation systems | Pros: Flexible designs, easy to modify. Cons: May require additional components for stability. |

| Structural Aluminum Profiles | High strength-to-weight ratio, often used in construction | Building frameworks, bridges, and supports | Pros: Durable and lightweight. Cons: Higher initial costs compared to other materials. |

| Round Aluminum Extrusions | Circular cross-section, ideal for aesthetic applications | Handrails, furniture, and decorative items | Pros: Visually appealing and strong. Cons: Limited load-bearing capacity compared to square profiles. |

| Channel Profiles | U-shaped design, provides excellent load distribution | Framing, shelving, and rail systems | Pros: Good structural integrity. Cons: Less versatile than T-slot profiles. |

| Heat Sink Profiles | Designed for thermal management, maximizing surface area | Electronics cooling solutions | Pros: Efficient heat dissipation. Cons: Requires precise engineering for optimal performance. |

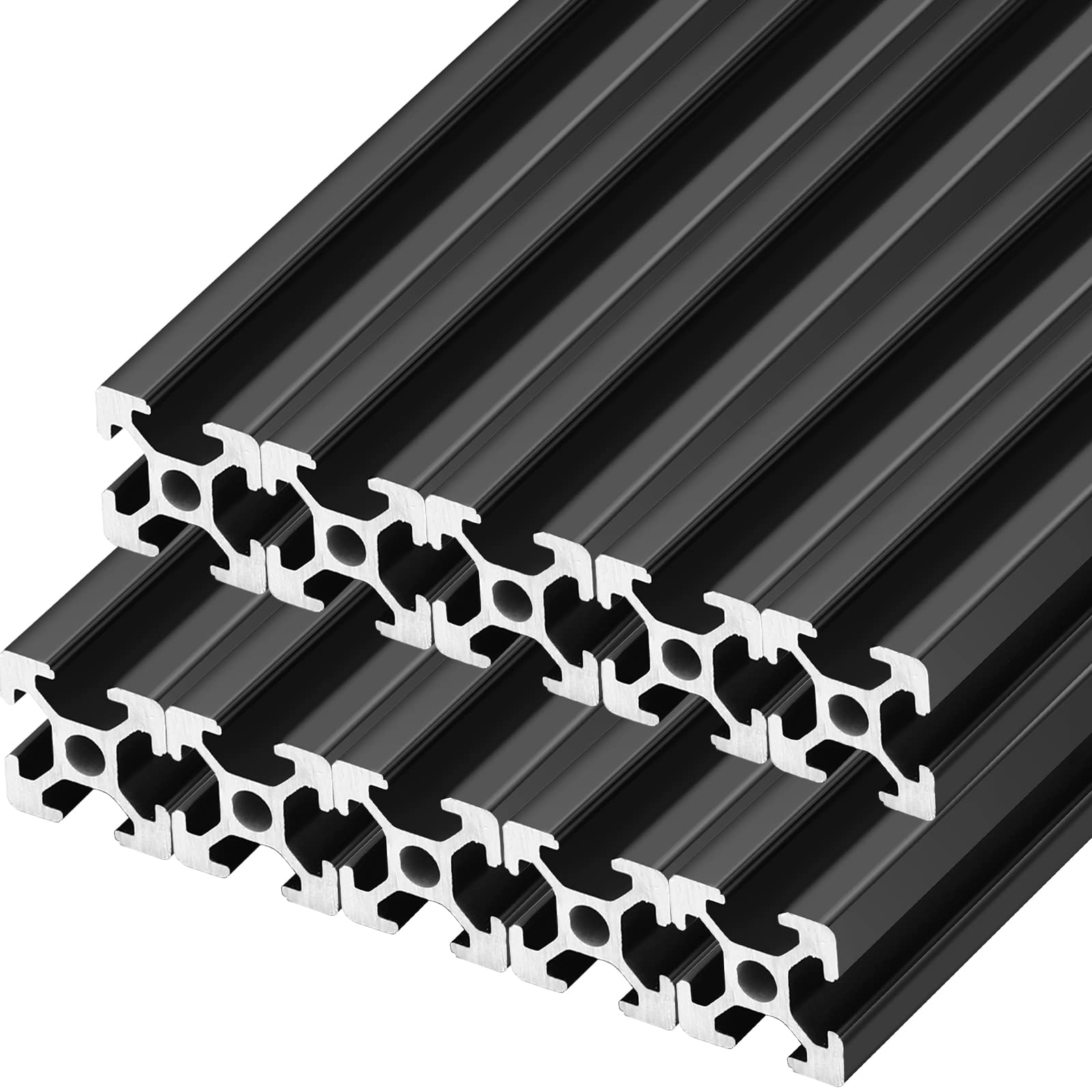

What Are T-Slot Profiles and Their B2B Relevance?

T-Slot profiles are characterized by their unique slot design, allowing for easy assembly and reconfiguration. This versatility makes them ideal for various applications, such as machinery frames, workstations, and automation systems. B2B buyers should consider the ease of customization and the availability of compatible accessories, which can enhance the adaptability of their designs. However, they may need to invest in additional components to ensure structural stability.

How Do Structural Aluminum Profiles Benefit Construction Projects?

Structural aluminum profiles are known for their high strength-to-weight ratio, making them suitable for demanding applications in construction. These profiles are often utilized in building frameworks, bridges, and support structures. Buyers should weigh the durability and lightweight nature of these profiles against their higher initial costs, as the long-term savings on maintenance and structural integrity can justify the investment.

In What Scenarios Are Round Aluminum Extrusions Preferred?

Round aluminum extrusions feature a circular cross-section, making them popular for aesthetic applications such as handrails and furniture. They provide a visually appealing finish while maintaining strength. B2B buyers should consider the load-bearing capacities and design flexibility of these profiles, as they may not support as much weight as square profiles. However, their aesthetic value often compensates for this limitation.

What Advantages Do Channel Profiles Offer for Various Applications?

Channel profiles, with their U-shaped design, excel in providing excellent load distribution, making them ideal for framing, shelving, and rail systems. Their structural integrity is a significant advantage for buyers looking for reliable solutions. However, while they offer good strength, they are generally less versatile than T-slot profiles, which may limit their application in dynamic environments requiring frequent modifications.

Why Are Heat Sink Profiles Essential for Electronics?

Heat sink profiles are specifically designed to manage thermal challenges in electronic applications. Their increased surface area allows for efficient heat dissipation, which is critical for maintaining optimal performance in electronics. Buyers should consider the engineering precision needed to ensure these profiles function effectively. While they are an essential investment for thermal management, they may require careful design considerations to achieve maximum efficiency.

Key Industrial Applications of aluminum extruded profiles

| Industry/Sector | Specific Application of aluminum extruded profiles | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive | Structural components in vehicle frames | Lightweight yet strong, improving fuel efficiency | Compliance with safety standards and weight specifications |

| Construction | Window frames and curtain wall systems | Enhanced durability and aesthetics | Customization options for size and finish |

| Aerospace | Aircraft fuselage and wing structures | High strength-to-weight ratio, essential for performance | Certification for aerospace-grade materials |

| Renewable Energy | Solar panel mounting systems | Corrosion resistance and lightweight properties | Sustainability certifications and material sourcing |

| Industrial Automation | Frameworks for conveyor systems and robotics | Flexibility in design and ease of assembly | Availability of a range of profiles and accessories |

How Are Aluminum Extruded Profiles Used in the Automotive Sector?

In the automotive industry, aluminum extruded profiles are utilized to create structural components such as vehicle frames and supports. Their lightweight nature contributes to improved fuel efficiency, a critical factor in modern vehicle design. Buyers in this sector must ensure that the profiles meet stringent safety and weight specifications, often requiring certifications that verify compliance with industry standards. Additionally, the ability to customize dimensions and finishes allows manufacturers to align with branding and functional needs.

What Role Do Aluminum Profiles Play in Construction?

Aluminum extruded profiles find extensive applications in the construction sector, particularly in window frames and curtain wall systems. Their durability and aesthetic appeal make them a preferred choice for modern architectural designs. For international buyers, sourcing aluminum profiles requires attention to customization options, as different regions may have unique architectural styles and climate considerations. Additionally, understanding local building codes and regulations is essential to ensure compliance and optimal performance.

Why Are Aluminum Extruded Profiles Important in Aerospace?

In aerospace applications, aluminum extruded profiles are critical for constructing aircraft fuselages and wing structures. Their high strength-to-weight ratio is vital for enhancing aircraft performance and fuel efficiency. Buyers in this sector must prioritize sourcing materials that come with aerospace certifications, ensuring they meet rigorous safety and performance standards. Additionally, understanding the specific alloy compositions required for different parts is crucial for maintaining structural integrity during flight.

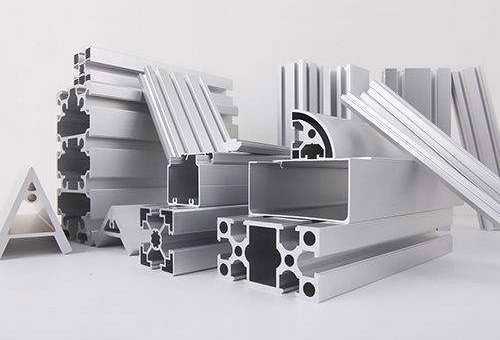

Illustrative image related to aluminum extruded profiles

How Do Aluminum Profiles Benefit Renewable Energy Applications?

Aluminum extruded profiles are increasingly used in renewable energy sectors, especially in solar panel mounting systems. Their corrosion resistance and lightweight properties make them ideal for outdoor applications, ensuring longevity and stability in various weather conditions. For businesses sourcing these profiles, it’s important to consider sustainability certifications, as many buyers are now focused on environmentally friendly materials. Furthermore, ensuring compatibility with existing solar technologies can enhance system efficiency.

In What Ways Are Aluminum Profiles Utilized in Industrial Automation?

In industrial automation, aluminum extruded profiles serve as frameworks for conveyor systems and robotic structures. Their versatility allows for easy assembly and customization, facilitating the creation of efficient manufacturing processes. Businesses looking to source these profiles should focus on the availability of a wide range of sizes and accessories, ensuring they can meet specific operational requirements. Additionally, understanding the compatibility of these profiles with existing systems is essential for seamless integration.

3 Common User Pain Points for ‘aluminum extruded profiles’ & Their Solutions

Scenario 1: Sourcing Quality Aluminum Extrusions for Diverse Applications

The Problem: B2B buyers often struggle to find suppliers that offer high-quality aluminum extruded profiles tailored to their specific applications. This challenge is compounded by a lack of standardized specifications across manufacturers, which can lead to confusion regarding material quality, dimensions, and finishes. Additionally, variations in local regulations and standards can create further obstacles, particularly for international buyers who may not be familiar with the compliance requirements in their regions. This situation can result in costly delays, rework, and even project failures.

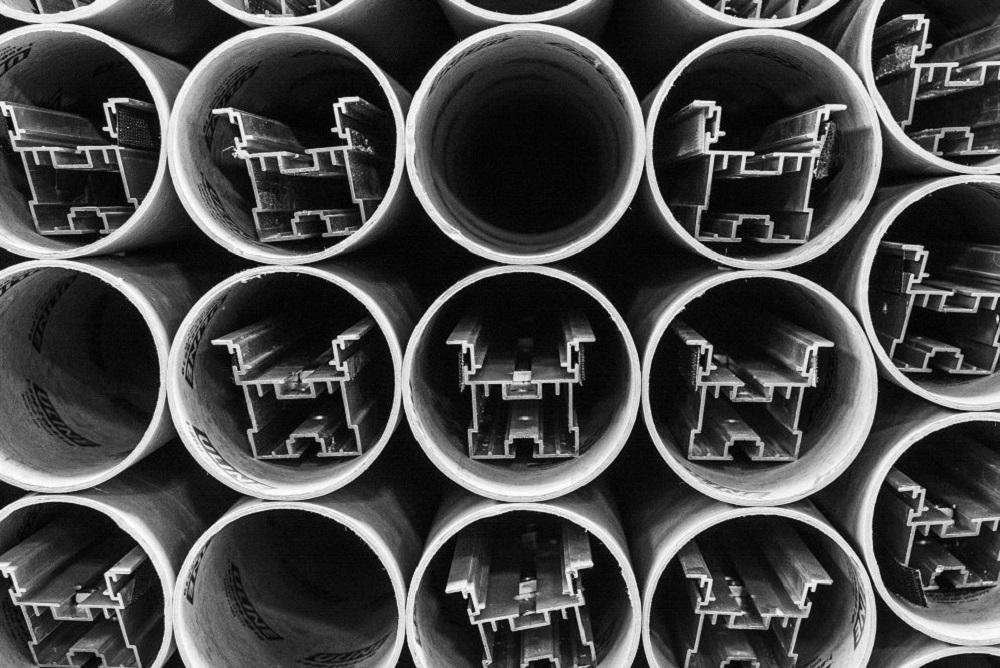

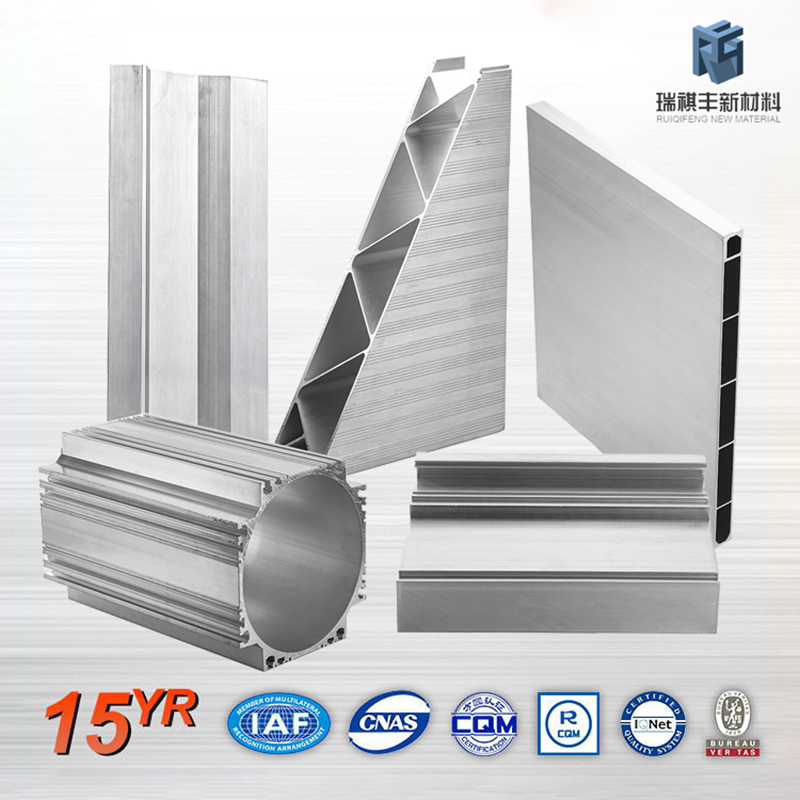

Illustrative image related to aluminum extruded profiles

The Solution: To effectively source aluminum extruded profiles, buyers should begin by conducting thorough research to identify reputable suppliers that specialize in their required profiles. It’s beneficial to request samples and detailed specifications for each product to ensure they meet the intended application. Building relationships with suppliers who understand local regulations and can provide certifications of compliance is crucial. Moreover, engaging in virtual or in-person consultations can help clarify specific needs and ensure that the selected profiles adhere to quality standards. Utilizing platforms that allow for comparison of multiple suppliers can also streamline the selection process, ensuring that buyers choose the best fit for their requirements.

Scenario 2: Customization Challenges in Aluminum Profiles

The Problem: Many businesses require custom aluminum extruded profiles to meet unique design specifications, but they often face challenges in communicating their needs effectively to manufacturers. Misunderstandings regarding design intent, dimensions, and tolerances can lead to prototypes that do not meet expectations, resulting in wasted resources and time. Additionally, the lack of advanced customization options can be a significant pain point, particularly for companies looking to innovate or create specialized products.

The Solution: To overcome customization challenges, B2B buyers should invest time in creating detailed design briefs that include drawings, specifications, and examples of similar products. Collaborating closely with manufacturers during the design phase is essential; this may involve using CAD software to share accurate models and facilitate better communication. Engaging manufacturers who offer design assistance or prototyping services can provide valuable insights and reduce the risk of errors. Furthermore, establishing a clear timeline for revisions and approvals can help keep the project on track and ensure that the final product aligns with expectations.

Scenario 3: Managing Inventory and Supply Chain for Aluminum Profiles

The Problem: Buyers often encounter difficulties managing inventory levels of aluminum extruded profiles, especially in industries with fluctuating demand. Excess inventory can tie up capital, while insufficient stock can lead to production delays. Additionally, navigating supply chain disruptions—such as those caused by international shipping challenges or raw material shortages—can significantly impact project timelines and costs.

The Solution: Implementing an effective inventory management system is vital for mitigating these issues. Buyers should consider adopting just-in-time (JIT) inventory practices that align stock levels with production schedules, reducing excess inventory while ensuring availability. Establishing strong relationships with multiple suppliers can provide a buffer against supply chain disruptions, allowing for quicker adjustments in sourcing when needed. Utilizing technology solutions like inventory tracking software can also enhance visibility into stock levels and automate reordering processes. Regularly reviewing demand forecasts and adjusting orders accordingly can further optimize inventory management, ensuring that businesses remain agile in response to market changes.

Illustrative image related to aluminum extruded profiles

Strategic Material Selection Guide for aluminum extruded profiles

What Are the Key Properties of Common Materials for Aluminum Extruded Profiles?

When selecting materials for aluminum extruded profiles, it is essential to consider properties such as weight, strength, corrosion resistance, and thermal conductivity. Here, we analyze four common materials used in the manufacturing of aluminum extruded profiles: 6061 aluminum alloy, 6063 aluminum alloy, anodized aluminum, and powder-coated aluminum. Each material has distinct characteristics that can influence performance, cost, and suitability for specific applications.

How Does 6061 Aluminum Alloy Perform in Aluminum Extruded Profiles?

6061 aluminum alloy is known for its excellent mechanical properties and versatility. It has a good strength-to-weight ratio, making it suitable for structural applications. This alloy exhibits good corrosion resistance and can withstand moderate to high temperatures.

Pros: The durability of 6061 allows it to perform well in demanding environments, making it ideal for applications in construction and transportation. Its relatively low cost compared to other alloys adds to its appeal.

Cons: While it is strong, 6061 may not be as aesthetically pleasing as other options, and its machining can be more complex, potentially increasing manufacturing costs.

Illustrative image related to aluminum extruded profiles

Impact on Application: 6061 is compatible with various media, including water and certain chemicals, making it suitable for structural components in industrial settings.

What Advantages Does 6063 Aluminum Alloy Offer for Extruded Profiles?

6063 aluminum alloy is often preferred for architectural applications due to its excellent finish and aesthetic appeal. It has good extrudability and is known for its superior corrosion resistance.

Pros: The smooth surface finish of 6063 allows for easy anodizing and painting, making it ideal for decorative applications. Its strength is adequate for many structural applications while remaining lightweight.

Cons: It is generally less strong than 6061, which may limit its use in high-stress applications. Additionally, 6063 can be more expensive due to its finishing processes.

Impact on Application: This alloy is often used in window frames, door frames, and other architectural elements where appearance is critical.

How Does Anodized Aluminum Enhance the Performance of Extruded Profiles?

Anodized aluminum undergoes an electrochemical process that enhances its corrosion resistance and surface hardness. This treatment creates a protective layer that can be dyed in various colors.

Pros: Anodized surfaces are highly resistant to corrosion and wear, making them suitable for outdoor applications. The aesthetic versatility allows for customization in design.

Cons: The anodizing process can add to manufacturing costs and may limit the alloy’s structural integrity if not done correctly.

Illustrative image related to aluminum extruded profiles

Impact on Application: Anodized aluminum is ideal for applications exposed to harsh environments, such as marine or coastal settings, where corrosion resistance is paramount.

What Role Does Powder-Coated Aluminum Play in Extruded Profiles?

Powder-coated aluminum is coated with a dry powder that is cured under heat to create a durable finish. This method provides a wide range of color options and textures.

Pros: The powder coating offers excellent UV resistance and can withstand various environmental conditions, making it suitable for outdoor use. It is also more environmentally friendly than traditional paint.

Cons: While durable, powder coating can chip or scratch, potentially exposing the underlying aluminum to corrosion. The initial cost of powder coating can also be higher than other finishing methods.

Impact on Application: Powder-coated aluminum is commonly used in furniture, signage, and architectural applications where aesthetics and durability are essential.

Summary Table of Material Properties for Aluminum Extruded Profiles

| Material | Typical Use Case for Aluminum Extruded Profiles | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 6061 Aluminum Alloy | Structural components in construction and transportation | Good strength-to-weight ratio | Less aesthetically pleasing, complex machining | Medium |

| 6063 Aluminum Alloy | Architectural elements like window and door frames | Excellent finish and corrosion resistance | Weaker than 6061, higher finishing costs | Medium |

| Anodized Aluminum | Outdoor applications, marine environments | Superior corrosion resistance and aesthetics | Higher manufacturing costs, potential structural integrity issues | High |

| Powder-Coated Aluminum | Furniture, signage, and outdoor structures | UV resistance and environmental friendliness | Can chip or scratch, higher initial costs | Medium |

This guide provides a comprehensive overview of the materials commonly used in aluminum extruded profiles, helping international B2B buyers make informed decisions based on their specific application needs and regional considerations.

In-depth Look: Manufacturing Processes and Quality Assurance for aluminum extruded profiles

What Are the Main Stages in the Manufacturing Process of Aluminum Extruded Profiles?

The manufacturing process for aluminum extruded profiles consists of several key stages: material preparation, forming, assembly, and finishing. Understanding these stages is crucial for B2B buyers looking to source high-quality aluminum products.

Material Preparation

The process begins with the selection of high-grade aluminum alloys, which are chosen based on the desired mechanical properties and applications. The aluminum is typically delivered in billet form, which is then heated to around 400-500°C, making it malleable for the extrusion process. This heating phase is critical, as it affects the flow characteristics of the aluminum during forming.

How Is Aluminum Formed into Profiles?

Once the aluminum is prepared, it undergoes the extrusion process. This involves forcing the heated aluminum billet through a die, which gives the profile its specific shape. The extrusion can be done using two primary techniques: direct and indirect extrusion. In direct extrusion, the billet is pushed through the die, while in indirect extrusion, the die is moved towards the billet. Each method has its advantages; direct extrusion is typically more efficient, while indirect extrusion can yield better surface finishes.

After extrusion, the profiles may undergo a cooling process, often involving air or water quenching to enhance mechanical properties. This step can also affect the dimensional accuracy of the extruded profiles.

What Are the Key Techniques Used in Assembly and Finishing?

Following forming, the profiles may need to be cut to length, drilled, or otherwise machined for specific applications. This assembly stage often includes the addition of features such as slots or holes, which enhance the functionality of the profiles in their intended use.

Finishing processes, such as anodizing, powder coating, or painting, are employed to improve corrosion resistance and aesthetic appeal. Anodizing, for instance, involves an electrochemical process that thickens the natural oxide layer on the aluminum, thereby enhancing its durability.

How Is Quality Assurance Implemented in Aluminum Extrusion?

Quality assurance is an essential component of the manufacturing process for aluminum extruded profiles. It ensures that the products meet international standards and customer specifications, which is particularly important for B2B buyers.

What Are the Relevant International Standards for Aluminum Profiles?

International standards such as ISO 9001 are pivotal for maintaining quality management systems. These standards outline the requirements for a quality management system, ensuring consistent quality in the manufacturing process. Additionally, industry-specific certifications like CE marking for European markets or API standards for the oil and gas sector may apply, depending on the end-use of the profiles.

What Are the Key Quality Control Checkpoints in the Manufacturing Process?

Quality control (QC) checkpoints are established at various stages of the manufacturing process. These include:

-

Incoming Quality Control (IQC): This involves inspecting the raw materials upon arrival to ensure they meet the specified standards.

-

In-Process Quality Control (IPQC): During the manufacturing stages, regular inspections are conducted to monitor the process and identify any deviations from quality standards.

-

Final Quality Control (FQC): Once the profiles are completed, they undergo a final inspection, which includes dimensional checks, visual inspections, and testing for mechanical properties.

What Testing Methods Are Commonly Used for Aluminum Extruded Profiles?

Several testing methods are employed to ensure that aluminum extruded profiles meet quality and performance standards:

-

Mechanical Testing: This includes tensile strength tests, hardness tests, and impact tests to assess the material properties of the extrusions.

-

Dimensional Inspection: Utilizing calipers, gauges, and coordinate measuring machines (CMM) to verify that the profiles meet specified dimensions and tolerances.

-

Surface Finish Testing: Techniques such as gloss measurement and roughness testing assess the quality of surface finishes applied to the profiles.

How Can B2B Buyers Verify Supplier Quality Control?

For international B2B buyers, particularly those in regions such as Africa, South America, the Middle East, and Europe, verifying supplier quality control is paramount. Here are key strategies to ensure supplier reliability:

-

Audits and Inspections: Conducting regular audits of suppliers can provide insights into their quality management practices. Buyers should request access to their quality management certifications and audit reports.

-

Third-Party Inspections: Engaging third-party inspection services can add an extra layer of assurance. These independent agencies can evaluate the manufacturing processes and quality controls in place.

-

Documentation and Reporting: Request comprehensive documentation from suppliers that detail their quality control processes, including inspection reports, material certifications, and compliance with international standards.

What Are the Quality Control Nuances for International B2B Buyers?

International buyers must navigate various quality control nuances when sourcing aluminum extruded profiles. Understanding local regulations, certifications, and industry standards is critical. For instance, different regions may have specific material compliance requirements, such as RoHS or REACH in Europe, which restrict the use of certain hazardous substances.

Additionally, cultural differences may influence communication and expectations regarding quality. Establishing clear quality agreements and maintaining open lines of communication with suppliers can help mitigate misunderstandings and ensure that quality standards are consistently met.

Conclusion

The manufacturing processes and quality assurance measures for aluminum extruded profiles are intricate and vital for ensuring product reliability. By understanding these processes and implementing effective verification strategies, B2B buyers can source high-quality aluminum products that meet their specific needs and comply with international standards. Investing time in supplier evaluation and quality control will ultimately lead to more successful business relationships and higher satisfaction with the products received.

Illustrative image related to aluminum extruded profiles

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminum extruded profiles’

In the competitive landscape of B2B procurement, sourcing aluminum extruded profiles effectively is crucial for ensuring quality, cost-effectiveness, and timely delivery. This guide provides a practical checklist to help you navigate the sourcing process, whether you are a buyer in Africa, South America, the Middle East, or Europe.

Step 1: Define Your Technical Specifications

Establishing clear technical specifications is the foundation of a successful sourcing strategy. Detail the dimensions, weight, surface finish, and alloy requirements necessary for your application. This clarity will help you communicate effectively with potential suppliers and ensure that the products meet your operational needs.

- Consider application-specific requirements: Different industries may have unique standards (e.g., aerospace, automotive) that must be adhered to.

- Include tolerances and performance standards: Specify any necessary tolerances to avoid costly errors later in the manufacturing process.

Step 2: Research and Shortlist Suppliers

Conduct thorough research to identify potential suppliers of aluminum extruded profiles. Create a shortlist based on criteria such as industry reputation, product range, and previous client feedback.

- Utilize online resources: Leverage platforms like industry directories, trade shows, and professional networks to gather supplier options.

- Evaluate geographical advantages: Consider suppliers that are strategically located to minimize shipping costs and lead times.

Step 3: Evaluate Potential Suppliers

Before committing, it’s crucial to vet suppliers thoroughly. Request company profiles, case studies, and references from buyers in a similar industry or region. Don’t just rely on their website.

- Check for certifications: Ensure suppliers have the necessary industry certifications (e.g., ISO, ASTM) that guarantee quality and compliance.

- Review financial stability: A financially sound supplier is less likely to experience disruptions that could affect your supply chain.

Step 4: Request Samples and Prototypes

After narrowing down your options, request samples or prototypes of the aluminum extruded profiles. This step allows you to assess the quality and suitability of the products before placing a larger order.

- Conduct quality tests: Evaluate the samples against your specifications to ensure they meet your requirements.

- Assess lead times for future orders: Understanding the time it takes to produce and deliver samples will help you plan your procurement strategy better.

Step 5: Negotiate Pricing and Terms

Once you’ve selected a supplier based on quality and reliability, enter into negotiations regarding pricing, payment terms, and delivery schedules. Effective negotiation can yield better pricing and more favorable terms.

- Discuss bulk order discounts: If you plan to order in large quantities, inquire about discounts that can reduce your overall costs.

- Clarify payment terms: Ensure that payment methods and timelines are clearly defined to avoid misunderstandings.

Step 6: Finalize Contracts and Agreements

After negotiations, finalize the contract with your chosen supplier. Ensure that all terms discussed are documented clearly to protect both parties.

- Include quality assurance clauses: Specify quality control measures and acceptable tolerance levels in the contract to safeguard against defects.

- Outline delivery expectations: Clearly define delivery schedules and penalties for delays to ensure accountability.

Step 7: Establish a Communication Plan

Effective communication is key to maintaining a strong supplier relationship. Establish a plan for regular updates and feedback to address any issues that may arise during the sourcing process.

- Schedule regular check-ins: Frequent communication can help anticipate potential issues before they escalate.

- Use collaborative tools: Implement project management or communication tools to streamline interactions and document decisions.

Following this checklist will help you navigate the complexities of sourcing aluminum extruded profiles, ensuring that you find reliable suppliers who meet your specific needs.

Comprehensive Cost and Pricing Analysis for aluminum extruded profiles Sourcing

What Are the Key Cost Components in Sourcing Aluminum Extruded Profiles?

When sourcing aluminum extruded profiles, understanding the cost structure is crucial for B2B buyers. The primary cost components include:

-

Materials: The cost of aluminum itself is influenced by global market prices, which can fluctuate due to demand, supply chain constraints, and geopolitical factors. Buyers should stay informed about market trends to anticipate cost changes.

-

Labor: Labor costs vary by region and can significantly impact pricing. Countries with higher labor costs may lead to increased overall prices for extrusions.

-

Manufacturing Overhead: This includes expenses related to factory operations such as utilities, maintenance, and equipment depreciation. Efficient manufacturing processes can help reduce these costs.

-

Tooling: Custom tooling for specific profiles can be a significant upfront cost. However, this is often amortized over larger production runs, making it essential to consider long-term needs when evaluating tooling expenses.

-

Quality Control (QC): Ensuring that extrusions meet specified standards adds costs. Implementing robust QC processes can prevent costly defects but may require investment in testing equipment or personnel.

-

Logistics: Transportation costs can vary widely based on distance, mode of transport, and logistics provider. International shipping may involve additional fees related to customs clearance and duties.

-

Margin: Suppliers will add a profit margin to cover their costs and risks. Understanding a supplier’s margin can provide insight into the pricing strategy and help in negotiations.

How Do Price Influencers Affect the Cost of Aluminum Extrusions?

Several factors can influence the pricing of aluminum extruded profiles:

-

Volume/MOQ: Suppliers often offer better pricing for larger orders due to economies of scale. Establishing a Minimum Order Quantity (MOQ) can affect unit costs significantly.

-

Specifications and Customization: Custom profiles and specific tolerances can increase costs. Buyers should clearly define specifications to avoid unexpected charges.

-

Materials and Quality Certifications: The type of aluminum alloy and its certifications (e.g., aerospace-grade or marine-grade) can impact pricing. Higher-quality materials typically command higher prices.

-

Supplier Factors: The reputation and reliability of the supplier can influence pricing. Established suppliers may charge more due to perceived reliability and quality assurance.

-

Incoterms: Understanding Incoterms is essential for cost calculations. Terms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) can affect the total landed cost of products.

What Are Effective Buyer Tips for Cost-Efficiency in Sourcing Aluminum Profiles?

For international buyers, particularly in regions like Africa, South America, the Middle East, and Europe, several strategies can enhance cost-efficiency:

Illustrative image related to aluminum extruded profiles

-

Negotiation: Engage in open discussions with suppliers about pricing, especially for larger orders. Building a relationship can lead to better terms and pricing.

-

Total Cost of Ownership (TCO): Evaluate not just the purchase price, but also the long-term costs associated with the product, including maintenance, durability, and potential waste.

-

Pricing Nuances for International Transactions: Be aware of currency fluctuations and their impact on pricing. Consider locking in prices or using currency hedging strategies to mitigate risks.

-

Supplier Diversification: Relying on multiple suppliers can enhance bargaining power and reduce risks associated with supply chain disruptions.

-

Stay Informed: Keep abreast of industry trends, material costs, and regional market dynamics to make informed purchasing decisions.

Disclaimer on Indicative Prices

It is important to note that prices for aluminum extruded profiles can vary widely based on the factors discussed above. The information provided is for indicative purposes only and should be verified through direct supplier engagement to ensure accuracy.

Alternatives Analysis: Comparing aluminum extruded profiles With Other Solutions

Aluminum extruded profiles are widely recognized for their versatility and strength in various industrial applications. However, buyers often face a myriad of options when it comes to selecting the most suitable solution for their specific needs. This analysis compares aluminum extruded profiles against two viable alternatives: steel fabrication and plastic injection molding, highlighting their respective strengths and weaknesses.

| Comparison Aspect | Aluminum Extruded Profiles | Steel Fabrication | Plastic Injection Molding |

|---|---|---|---|

| Performance | High strength-to-weight ratio; excellent structural integrity | Very strong; ideal for heavy-duty applications | Good for complex shapes but less durable than metals |

| Cost | Moderate initial cost; lower long-term maintenance costs | Higher upfront costs; long-term durability may offset costs | Lower initial cost; high tooling costs can be a barrier |

| Ease of Implementation | Quick assembly with minimal tooling; customizable | Requires skilled labor and longer lead times | Complex setup; needs specialized equipment |

| Maintenance | Low maintenance; corrosion-resistant finishes available | May require regular maintenance; prone to rust without treatment | Low maintenance; however, repairs can be complicated |

| Best Use Case | Lightweight frames, machine guards, and architectural features | Heavy-duty construction, automotive, and industrial applications | Consumer products, toys, and components with intricate designs |

What Are the Advantages and Disadvantages of Steel Fabrication Compared to Aluminum Extruded Profiles?

Steel fabrication offers unparalleled strength and durability, making it ideal for heavy-duty applications such as construction and machinery. Its high tensile strength is beneficial when extreme loads are a concern. However, steel typically incurs higher initial costs due to raw material prices and fabrication complexity. Additionally, it is prone to rust and corrosion unless treated, which can lead to increased maintenance costs over time. While steel can be a great choice for strength, it may not always be the best option for lightweight applications.

How Does Plastic Injection Molding Compare to Aluminum Extruded Profiles?

Plastic injection molding is another alternative that allows for the creation of complex shapes at a lower initial cost compared to aluminum extrusion. This method is particularly effective for high-volume production runs, making it suitable for consumer products and components where design intricacy is crucial. However, the tooling costs associated with injection molding can be substantial, and the resultant products may lack the structural integrity and durability of aluminum profiles. Additionally, plastics can have limitations in high-temperature applications, which may restrict their usability in certain industries.

How Can B2B Buyers Choose the Right Solution for Their Needs?

Selecting the right solution ultimately depends on the specific requirements of the project. B2B buyers should assess factors such as the intended application, budget constraints, and desired product longevity. For lightweight structures requiring quick assembly, aluminum extruded profiles may be the best choice. Conversely, for projects demanding heavy-duty performance, steel fabrication may be warranted despite its higher cost. Meanwhile, for high-volume production of intricate designs, plastic injection molding could offer a cost-effective solution. Understanding these alternatives will empower buyers to make informed decisions that align with their operational needs and goals.

Illustrative image related to aluminum extruded profiles

Essential Technical Properties and Trade Terminology for aluminum extruded profiles

What Are the Key Technical Properties of Aluminum Extruded Profiles?

When evaluating aluminum extruded profiles for B2B applications, several technical properties are crucial for ensuring that the selected profiles meet specific performance and quality standards. Understanding these properties can help buyers make informed decisions, optimizing both cost and functionality.

1. Material Grade

Aluminum extrusions are categorized by material grades, such as 6061 and 6063. These grades signify the alloy composition, which affects strength, corrosion resistance, and workability. For instance, 6061 is often used for structural applications due to its high strength and weldability, while 6063 is preferred for architectural applications due to its excellent surface finish. Selecting the appropriate material grade is essential for meeting specific project requirements and ensuring longevity.

2. Tolerance

Tolerance refers to the permissible limits of variation in a physical dimension. In aluminum extrusions, tighter tolerances can significantly impact assembly and functionality, especially in precision applications. Standard tolerances may range from ±0.005 inches to ±0.020 inches, depending on the profile size and complexity. Understanding tolerance specifications helps buyers ensure compatibility with other components and avoid costly adjustments.

3. Surface Finish

The surface finish of aluminum extrusions can vary from smooth to anodized or powder-coated. Different finishes provide varying degrees of corrosion resistance, aesthetic appeal, and surface hardness. For example, anodized finishes enhance durability and resistance to environmental factors, making them suitable for outdoor applications. Buyers should consider the intended use of the profiles when selecting the surface finish to ensure optimal performance.

4. Weight

Weight specifications are vital for applications where load-bearing capacity is crucial. Aluminum is known for its lightweight properties, but different profiles can have varying weights based on dimensions and wall thickness. Understanding the weight of the extrusions helps in planning transportation and installation processes, making it easier to manage logistics and reduce costs.

5. Mechanical Properties

Key mechanical properties include tensile strength, yield strength, and elongation. These factors determine how well the material can withstand forces without deforming. For example, a tensile strength of 35,000 psi may be suitable for general applications, while higher strength profiles are necessary for more demanding environments. Evaluating these properties ensures that the selected profiles will perform as expected under load.

What Common Trade Terms Should B2B Buyers Know?

Navigating the B2B landscape of aluminum extruded profiles requires familiarity with industry jargon that can significantly affect procurement processes.

1. OEM (Original Equipment Manufacturer)

OEM refers to companies that manufacture products or components that are sold under another company’s brand. For buyers, understanding OEM relationships is essential when sourcing custom extruded profiles, as it can influence quality control and lead times.

Illustrative image related to aluminum extruded profiles

2. MOQ (Minimum Order Quantity)

MOQ is the minimum quantity that a supplier is willing to sell. This term is crucial for budget-conscious buyers, as larger orders often result in lower per-unit costs. Understanding MOQ can help buyers negotiate better terms and avoid excess inventory.

3. RFQ (Request for Quotation)

An RFQ is a formal document sent to suppliers to solicit price quotes for specific products. This process is vital for buyers looking to compare costs and terms from multiple suppliers, ensuring they receive the best value for their procurement needs.

4. Incoterms (International Commercial Terms)

Incoterms are standardized trade terms that define the responsibilities of buyers and sellers in international transactions. Familiarity with these terms helps buyers understand shipping costs, risk management, and delivery responsibilities, which can affect the total landed cost of the profiles.

5. Lead Time

Lead time refers to the time it takes from placing an order to receiving the product. This term is particularly important in B2B transactions, as longer lead times can disrupt project timelines. Understanding lead times allows buyers to plan effectively and mitigate risks associated with delays.

Illustrative image related to aluminum extruded profiles

By grasping these essential technical properties and trade terminology, B2B buyers can enhance their decision-making processes when procuring aluminum extruded profiles, ensuring that they meet their project requirements efficiently and effectively.

Navigating Market Dynamics and Sourcing Trends in the aluminum extruded profiles Sector

What Are the Current Market Dynamics and Key Trends in the Aluminum Extruded Profiles Sector?

The aluminum extruded profiles market is experiencing significant growth, driven by the increasing demand from various industries, including construction, automotive, and aerospace. The global push for lightweight materials that enhance fuel efficiency and reduce carbon footprints is propelling the use of aluminum. Emerging markets in Africa, South America, and the Middle East are witnessing heightened activity as infrastructure development accelerates, creating opportunities for international B2B buyers.

Technological advancements are reshaping sourcing practices in this sector. Automation and smart manufacturing processes are becoming integral, enhancing production efficiency and reducing lead times. The adoption of advanced software solutions for inventory and supply chain management allows for better tracking and forecasting, crucial for buyers in regions like Saudi Arabia and Nigeria, where supply chain disruptions can be significant. Additionally, the trend towards customization of aluminum profiles is on the rise, as clients seek tailored solutions that meet specific project requirements.

Furthermore, sustainability is becoming a pivotal factor influencing purchasing decisions. Buyers are increasingly prioritizing suppliers that demonstrate a commitment to sustainable practices, including responsible sourcing and recycling initiatives. As a result, suppliers offering a diverse range of eco-friendly aluminum products are likely to gain a competitive edge in the market.

How Is Sustainability Influencing Sourcing Decisions in the Aluminum Extruded Profiles Market?

Sustainability is at the forefront of global manufacturing practices, and the aluminum sector is no exception. The environmental impact of aluminum production, particularly regarding energy consumption and emissions, has led to a growing emphasis on ethical sourcing and sustainable practices. International B2B buyers are now more focused on partnering with suppliers who prioritize sustainability throughout their supply chains.

Certifications such as the Aluminum Stewardship Initiative (ASI) and ISO 14001 are increasingly important, signaling a commitment to environmental management and responsible sourcing. Buyers should seek suppliers who can provide transparency regarding their sourcing methods and the lifecycle impact of their products. This not only aligns with corporate social responsibility goals but also meets the growing consumer demand for greener products.

Additionally, the emphasis on recycling within the aluminum industry is noteworthy. Aluminum is highly recyclable, and initiatives promoting the use of recycled materials are gaining traction. Suppliers who can offer aluminum extruded profiles made from post-consumer recycled content are likely to appeal to environmentally conscious buyers, thereby enhancing their marketability.

What Has Been the Evolution of the Aluminum Extruded Profiles Industry?

The aluminum extruded profiles industry has evolved significantly over the past few decades, driven by technological advancements and changing market demands. Initially, aluminum was primarily used in traditional applications such as window frames and structural components. However, as industries began to recognize the material’s versatility, the applications expanded to include complex shapes and specialized designs.

The introduction of advanced extrusion techniques and alloys has enabled manufacturers to produce stronger, lighter, and more durable profiles tailored to specific industry needs. This evolution has coincided with the global trend towards lightweighting, particularly in the automotive and aerospace sectors, where fuel efficiency is paramount. As the industry continues to innovate, the focus on sustainability and ethical sourcing is set to define its future trajectory, influencing how B2B buyers approach their sourcing strategies in an increasingly competitive market.

Frequently Asked Questions (FAQs) for B2B Buyers of aluminum extruded profiles

1. How can I ensure the quality of aluminum extruded profiles when sourcing internationally?

To ensure quality, request detailed product specifications and certifications from suppliers. Conduct thorough research on potential manufacturers, looking for reviews or testimonials from previous customers. If possible, visit the factory or arrange for a third-party inspection service. Additionally, insist on quality assurance processes, such as ISO certifications, and request samples before placing large orders. Establish clear communication regarding your quality expectations to minimize risks.

2. What are the key considerations for selecting the right supplier of aluminum extruded profiles?

When selecting a supplier, evaluate their experience, production capacity, and quality control measures. Check for certifications such as ISO and industry-specific standards. Assess their ability to provide customization options and their compliance with international trade regulations. Furthermore, consider their logistics capabilities and customer service responsiveness. Engaging in initial discussions can help gauge their professionalism and willingness to meet your specific needs.

3. What minimum order quantities (MOQ) should I expect when sourcing aluminum extruded profiles?

MOQs vary widely based on the supplier and product type. Generally, larger manufacturers may have higher MOQs due to economies of scale, often ranging from 500 to 1,000 kg or more. Smaller suppliers might offer lower MOQs, but prices may be higher. It’s essential to communicate your requirements and negotiate terms that suit your project needs while considering the potential for future orders to justify larger quantities.

4. How can I customize aluminum extruded profiles to meet my specific project needs?

Customization options typically include dimensions, shapes, surface finishes, and alloy types. When discussing your project with suppliers, provide detailed drawings or specifications to convey your requirements. Many manufacturers have design teams that can assist with modifications. Be prepared to discuss lead times and any additional costs associated with customizations, as these can vary significantly depending on the complexity of your requests.

Illustrative image related to aluminum extruded profiles

5. What payment terms should I expect when sourcing aluminum extruded profiles internationally?

Payment terms can vary based on supplier policies and your negotiation. Common terms include upfront payments, letters of credit, or payment upon delivery. For first-time orders, suppliers may request a deposit (often 30% to 50% of the total order value). It’s crucial to clarify these terms in advance to avoid misunderstandings. Consider using secure payment methods to protect your investment, especially when dealing with international transactions.

6. What logistics considerations should I keep in mind when importing aluminum extruded profiles?

Logistics planning is critical for successful importation. Evaluate shipping options, including freight forwarders and shipping methods (air vs. sea), considering factors like cost, transit time, and reliability. Understand the customs clearance process in your country and ensure all documentation is in order to avoid delays. Additionally, factor in storage solutions upon arrival and the potential for tariffs or import duties that may apply.

7. How do I handle disputes or issues with my aluminum extruded profiles supplier?

To handle disputes effectively, maintain open and clear communication with your supplier. Document all correspondence and agreements to refer back to if issues arise. If a problem occurs, address it promptly by contacting the supplier to discuss potential resolutions. If necessary, involve a neutral third-party mediator or arbitration service. Establishing a dispute resolution process in your contract can also help mitigate future conflicts.

Illustrative image related to aluminum extruded profiles

8. What are the common surface finishes available for aluminum extruded profiles, and how do they impact performance?

Common surface finishes include anodizing, powder coating, and mill finish. Anodizing enhances corrosion resistance and surface hardness, making it ideal for outdoor applications. Powder coating offers aesthetic options and additional protection against wear and UV damage. Mill finish is the raw state of aluminum, providing a natural look but less protection. The choice of finish should align with your application requirements, considering environmental exposure and desired visual appeal.

Top 7 Aluminum Extruded Profiles Manufacturers & Suppliers List

1. EZTube – Aerospace 6063 Aluminum Extrusions

Domain: eztube.com

Registered: 1999 (26 years)

Introduction: Aerospace 6063 Aluminum Extrusions – EZTube offers a full line of ready-to-ship, USA-made 6063 T5 aerospace-grade aluminum extrusions and tubes. Dimensions: 1.00″ x 1.00″ x .050″ wall thickness. Compatible with EZTube connectors, hardware, and accessories for seamless integration and easy assembly. Price range for products varies from $4.95 to $42.00 depending on the specific extrusion. Available …

2. Alufab Inc – Metric Aluminum Extrusions

Domain: alufabinc.com

Registered: 2012 (13 years)

Introduction: Metric Aluminum Extrusion Profiles include a variety of T-Slot extrusions, fasteners, and brackets. Key product offerings include:

– 25mm Quarter Round T-Slotted Aluminum Framing Extrusion

– 25mm x 25mm T-Slotted Aluminum Framing Extrusion

– 25mm x 50mm T-Slotted Aluminum Framing Extrusion

– 25mm x 75mm T-Slotted Aluminum Framing Extrusion

– 40mm x 40mm Lite T-Slotted Aluminum Framing Extrusion

– …

3. Wellste – Standard Aluminum Extrusion Profiles

Domain: wellste.com

Registered: 2016 (9 years)

Introduction: Standard Aluminum Extrusion Profiles, Manufacturer: Wellste, Production Capability: 100,000 tons annually, Experience: 20+ years in aluminum extrusion, Tooling: 2000 types for standard profiles, Certifications: SGS & ISO audited, Quality Control: 100+ QC inspection team, 100% inspected before loading, Fast Delivery: 25 days, Alloys: 6063 (architectural), 6061 (structural), and various others (1000…

4. MISUMI – Aluminum Extrusions

Domain: us.misumi-ec.com

Registered: 2007 (18 years)

Introduction: Aluminum Extrusions, known as T-slot framing rails or profiles, offer a modular and flexible solution for various industrial applications. They feature slotted rails for easy assembly of carts, workstations, shelves, barriers, and more without welding. Designed for quick reconfiguration and expansion, they are ideal for adaptable manufacturing settings. Available in varied dimensions, shapes, and …

5. Extrude-A-Trim – Aluminum Extrusions Catalog

Domain: extrude-a-trim.com

Registered: 1998 (27 years)

Introduction: Aluminum Extrusions Catalog includes a variety of in-stock shapes such as:

– Angles (Equal Leg, Unequal Leg, Rounded Inside)

– Channels (Architectural, Structural, Rounded Inside/Outside)

– Mouldings (Corner, Divider, Drawer & Finger Pull, EX Sign Shapes)

– Tubes (Hollow, Rectangular, Round, Square, Structural Square, Telescopic)

– J-Channel, Mirror Trim, Awning Rail, Screen Door C Channel, S…

6. Tri-State Aluminum – Standard Extrusions & Profiles

Domain: tri-stateal.com

Registered: 2001 (24 years)

Introduction: Standard Aluminum Extrusions & Profiles, including Angles, Beams, Channels, Tees, Zees, Bar & Rod, Round Tube & Pipe, Square & Rectangular Tube. Made from 6000 series aluminum alloys such as 6005, 6061, 6063, 6105, and 6463. Over 40 years of experience, with 2000 standard extrusion dies available. Custom aluminum extrusions can be created to suit specific needs, resulting in lower production costs…

7. Orange Aluminum – Standard Profile Bar Stock

Domain: orangealuminum.com

Registered: 2006 (19 years)

Introduction: Standard Profile Bar Stock includes a variety of aluminum extrusion profiles such as Angles, Channels, Flat Bars, H Bars, Hex Bars, Hex Tubes, J-Channels, Round Bars, Round Tubes, Square Bars, Square Tubes, T Bars, and Z Bars. These profiles are American-made, offering superior strength and lightweight durability, compliant with RoHS. The product selection caters to diverse industrial applications…

Strategic Sourcing Conclusion and Outlook for aluminum extruded profiles

In conclusion, strategic sourcing of aluminum extruded profiles presents a significant opportunity for B2B buyers across Africa, South America, the Middle East, and Europe. By leveraging a diverse range of options—from fractional to metric profiles and various surface finishes—buyers can tailor their selections to meet specific project requirements. The ability to source high-quality, cost-effective materials will not only enhance operational efficiency but also foster innovation in design and application.

International buyers should prioritize establishing relationships with reliable suppliers who offer customization and flexibility, ensuring that they can adapt to changing market demands and technological advancements. As the global market for aluminum continues to evolve, staying informed about industry trends and emerging technologies will be crucial for maintaining a competitive edge.

Looking ahead, now is the time for businesses to explore partnerships and invest in sustainable sourcing practices. By doing so, companies can not only optimize their supply chains but also contribute to a more sustainable future. Engage with suppliers today to discover how aluminum extruded profiles can elevate your projects and drive your business forward.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

Illustrative image related to aluminum extruded profiles

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.