How to Source Aluminum Channel Extrusions Effectively: A 2025 Checklist

Introduction: Navigating the Global Market for aluminum channel extrusions

In the dynamic landscape of global manufacturing, sourcing aluminum channel extrusions presents unique challenges and opportunities for B2B buyers. These versatile profiles, often utilized in door framing, shelving, and wire management, demand careful consideration to meet both structural and aesthetic needs. With a plethora of suppliers and variations available, navigating this market can be daunting, especially for businesses in regions such as Africa, South America, the Middle East, and Europe, including key markets like Saudi Arabia and Brazil.

This comprehensive guide serves as your essential resource for understanding aluminum channel extrusions. It covers critical aspects such as types and applications, effective supplier vetting strategies, and cost considerations. Whether you are looking to implement lightweight and corrosion-resistant materials in construction projects or seeking custom solutions for intricate designs, this guide empowers you to make informed purchasing decisions.

By providing actionable insights and practical advice, we aim to streamline your sourcing process, ensuring that you can confidently select high-quality aluminum channel extrusions tailored to your specific project requirements. Equip your business with the knowledge needed to thrive in a competitive marketplace and leverage the advantages of aluminum’s unique properties, enhancing both functionality and design in your applications.

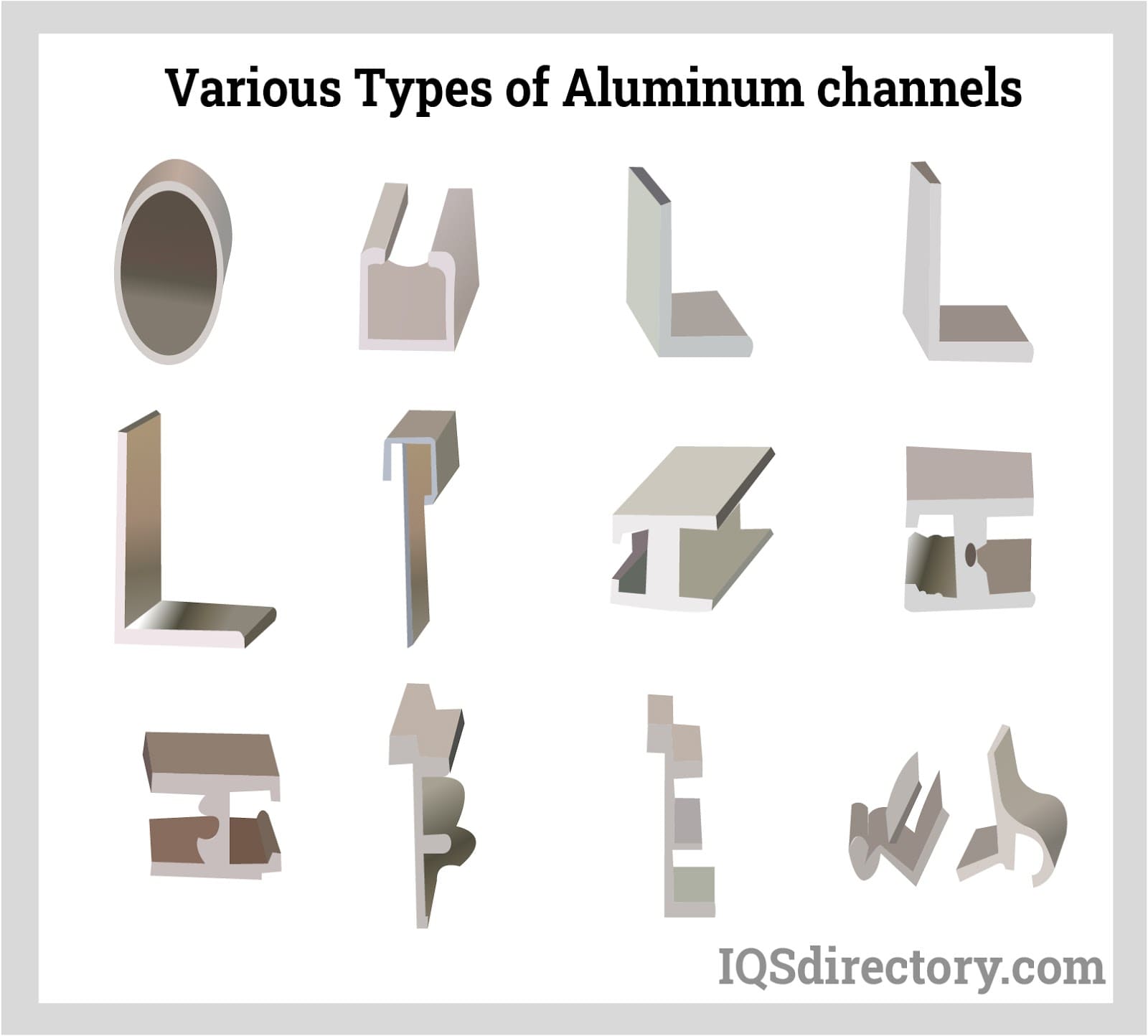

Understanding aluminum channel extrusions Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Aluminum U Channel | U-shaped profile with two parallel legs | Door framing, edge protection, cable management | Pros: Lightweight, easy to cut; Cons: Limited load capacity compared to other types. |

| Aluminum C Channel | C-shaped profile with one leg longer than the other | Framing, decorative trim, custom shelving | Pros: Aesthetic appeal, versatile; Cons: Less structural strength than U channels. |

| Aluminum Z Channel | Z-shaped profile with flanges extending in opposite directions | Roofing, metal framing, and construction | Pros: Strong and stable; Cons: More complex installation. |

| Hat Channel | Two horizontal flanges with vertical dimensions | Leveling walls, supporting drywall | Pros: Excellent for structural integrity; Cons: Limited aesthetic options. |

| J Channel | J-shaped profile with one angled leg | Framing mirrors, store fixtures | Pros: Attractive design, easy to mount; Cons: Not ideal for heavy loads. |

What Are the Characteristics of Aluminum U Channels?

Aluminum U channels feature a distinctive U-shaped profile, making them ideal for applications requiring structural support. Commonly used in door framing, edge protection, and cable management, these channels are lightweight and corrosion-resistant, offering a clean finish. When purchasing, consider the channel’s thickness and length to ensure it meets specific load requirements. U channels are particularly suitable for projects where both functionality and aesthetics are paramount.

How Do Aluminum C Channels Stand Out?

The C channel is characterized by its flat profile, with one leg longer than the other, making it a popular choice for framing and decorative applications. This type is especially useful in creating custom shelving and display units, thanks to its versatility. When sourcing C channels, buyers should evaluate the alloy grade, as this affects strength and corrosion resistance. The aesthetic appeal of C channels makes them a preferred choice in both commercial and residential projects.

What Makes Aluminum Z Channels a Reliable Choice?

Aluminum Z channels are designed with flanges that extend in opposite directions, providing enhanced structural stability. They are often employed in roofing and metal framing applications due to their strength. Buyers should consider the installation complexity and whether additional support is needed, as Z channels can be more challenging to install than simpler profiles. Their durability and load-bearing capacity make them an excellent investment for robust construction projects.

Why Choose Hat Channels for Structural Support?

Hat channels, with their unique shape featuring two horizontal flanges, are primarily used for leveling uneven walls and ceilings. They maintain structural integrity while providing support for drywall and other materials. For B2B buyers, the key considerations include the channel’s dimensions and load-bearing capacity. While hat channels excel in structural applications, they may lack the aesthetic versatility of other profiles, limiting their use in decorative projects.

What Are the Advantages of J Channels?

J channels are known for their attractive design and ease of mounting, making them ideal for framing mirrors and creating store fixtures. The J-shaped profile allows for a snug fit, enhancing visual appeal. When purchasing J channels, buyers should assess their load capacity, as they are not typically suited for heavy-duty applications. Their combination of aesthetics and practicality makes them a valuable addition to various commercial settings.

Key Industrial Applications of aluminum channel extrusions

| Industry/Sector | Specific Application of aluminum channel extrusions | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction | Structural framing for buildings and facades | Lightweight yet strong, enhancing structural integrity | Ensure compliance with local building codes and standards |

| Automotive | Support structures for vehicle components | Reduces overall vehicle weight, improving fuel efficiency | Look for corrosion resistance and high strength-to-weight ratio |

| Retail Fixtures | Custom display units and shelving systems | Enhances aesthetic appeal while providing durability | Consider customization options to fit specific design needs |

| Electrical & Lighting | Cable management and LED strip lighting installations | Improves organization and aesthetics in installations | Verify compatibility with electrical components and ease of installation |

| Aerospace | Framework for aircraft interiors and components | Meets stringent weight and performance standards | Ensure material meets industry-specific certifications and regulations |

How are Aluminum Channel Extrusions Used in Construction?

In the construction industry, aluminum channel extrusions serve as essential components for structural framing in buildings and facades. Their lightweight nature reduces the overall weight of structures, while their strength ensures stability and durability. For international B2B buyers, especially those in regions like Africa and the Middle East, sourcing aluminum channels that comply with local building codes is crucial. Buyers must also consider the specific grades of aluminum, such as 6061 or 6063, which offer varying levels of corrosion resistance and strength, depending on the application.

What Role Do Aluminum Channel Extrusions Play in the Automotive Sector?

In the automotive industry, aluminum channel extrusions are utilized for support structures in vehicle components, such as frames and body panels. The use of aluminum significantly reduces the weight of vehicles, contributing to improved fuel efficiency and performance. For buyers in South America and Europe, it is essential to source materials that not only meet rigorous safety standards but also offer high corrosion resistance. Understanding the specific requirements for strength and durability in automotive applications can help businesses optimize their supply chains and enhance product performance.

How are Retail Fixtures Enhanced with Aluminum Channel Extrusions?

Retail environments benefit from aluminum channel extrusions in the creation of custom display units and shelving systems. These extrusions provide a modern, sleek aesthetic while ensuring durability and ease of maintenance. For B2B buyers in sectors like retail, sourcing customizable aluminum channels can enhance the visual appeal of products displayed. It’s important to consider the finish and color options available, as these can significantly impact the overall customer experience and brand perception.

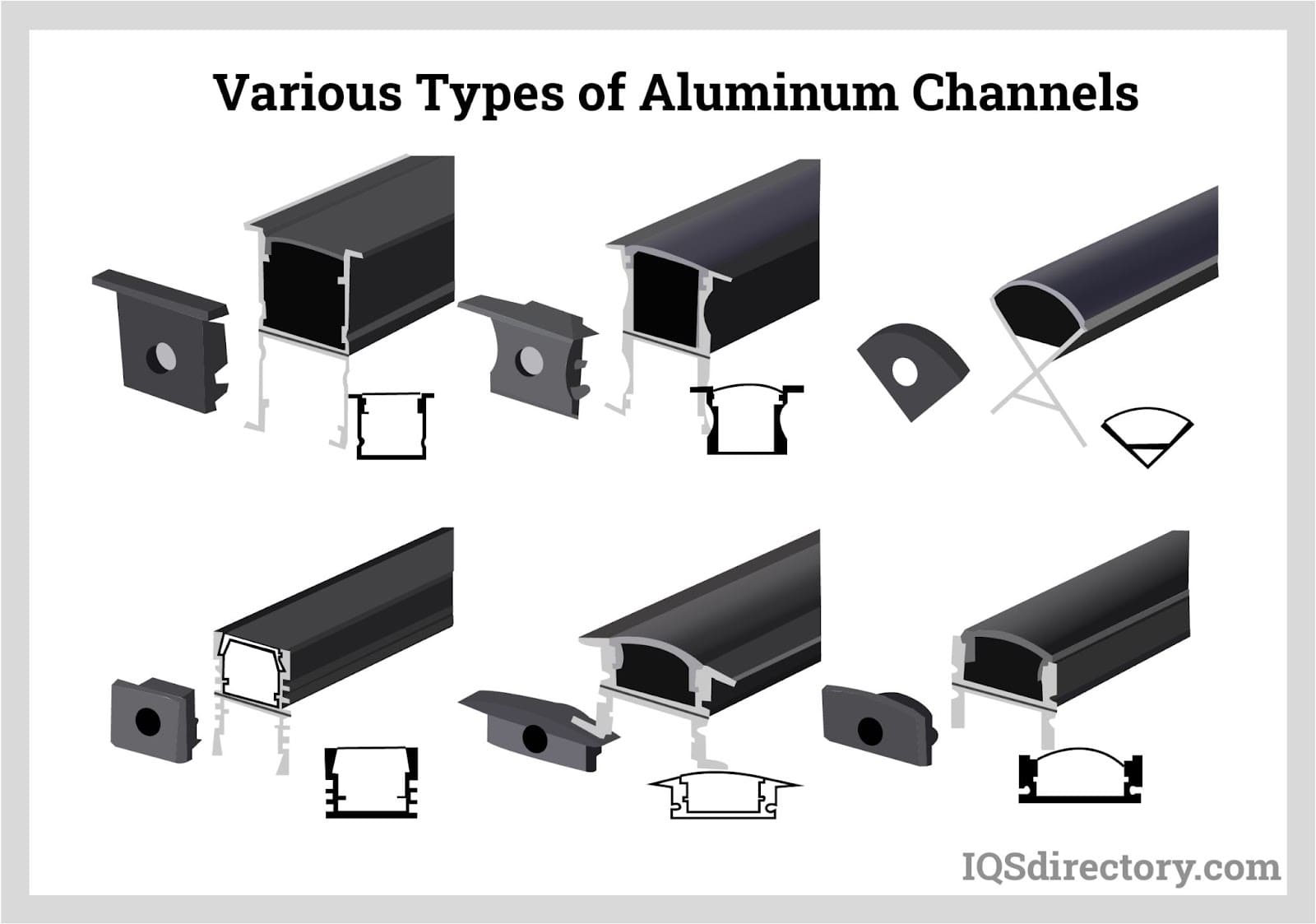

In What Ways are Aluminum Channel Extrusions Used for Electrical and Lighting Solutions?

Aluminum channel extrusions are pivotal in the electrical and lighting sectors, particularly for cable management and LED strip lighting installations. They provide a clean and organized way to manage cables while enhancing the visual appeal of lighting systems. Buyers from regions like Saudi Arabia and Brazil should prioritize sourcing aluminum channels that are compatible with various electrical components and ensure ease of installation. Additionally, verifying the thermal management capabilities of the extrusions can lead to improved performance in lighting applications.

How Do Aerospace Applications Utilize Aluminum Channel Extrusions?

In the aerospace industry, aluminum channel extrusions are critical for creating frameworks within aircraft interiors and components. The lightweight nature of aluminum is paramount in this sector, as it helps to meet strict performance standards while ensuring safety and efficiency. International buyers must ensure that the materials sourced comply with specific aerospace regulations and certifications. Understanding the distinct performance requirements for aerospace applications can facilitate better sourcing decisions and enhance product reliability.

3 Common User Pain Points for ‘aluminum channel extrusions’ & Their Solutions

Scenario 1: Difficulty in Customization for Specific Applications

The Problem: B2B buyers often encounter challenges when sourcing aluminum channel extrusions tailored for unique applications. For instance, a construction firm in Saudi Arabia may require specific dimensions and finishes for aluminum channels used in architectural projects. If the extrusions are not available in the desired sizes or configurations, it can lead to delays in project timelines, increased costs, and the need for additional machining, which complicates the procurement process.

The Solution: To overcome this issue, buyers should prioritize suppliers that offer custom fabrication services, allowing for precise specifications that meet project needs. When engaging with suppliers, it’s essential to provide detailed drawings and application requirements, including dimensions, alloy types (like 6061 or 6063), and surface finishes. Additionally, using a supplier with a robust inventory management system can help ensure that the necessary materials are readily available, minimizing lead times and disruptions. Regular communication with the supplier during the design phase can also aid in identifying potential challenges and addressing them proactively.

Scenario 2: Inconsistent Quality and Specifications

The Problem: Inconsistent quality of aluminum channel extrusions can be a significant pain point for B2B buyers, especially when sourcing from different regions. A buyer in Brazil may find that the extrusions received do not conform to the expected tolerances or mechanical properties, leading to structural failures in applications like shelving supports or framing systems. Such discrepancies not only affect project integrity but can also lead to financial losses due to rework or replacements.

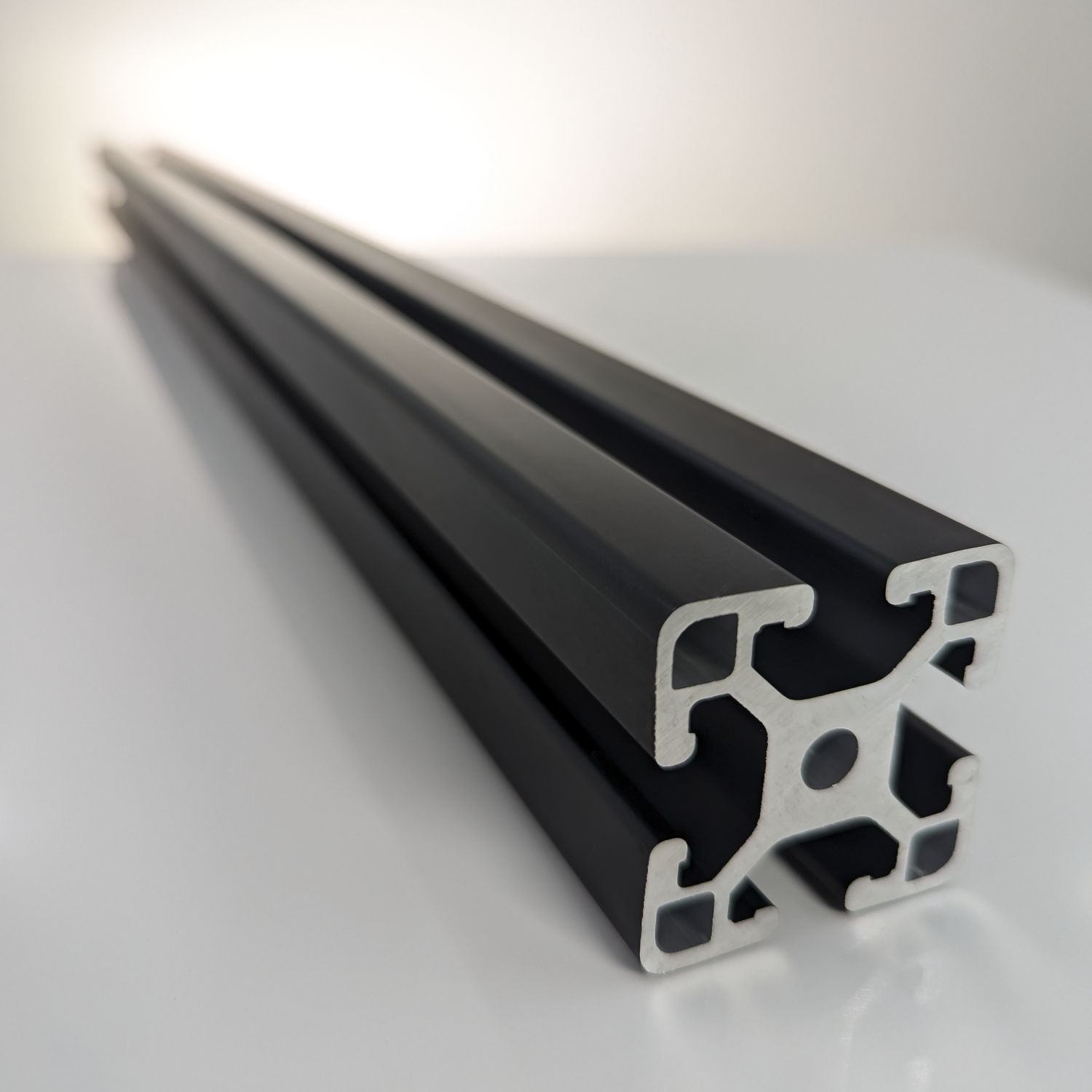

Illustrative image related to aluminum channel extrusions

The Solution: To mitigate quality concerns, buyers should establish relationships with reputable manufacturers known for their quality assurance processes. Before placing bulk orders, it is advisable to request samples for testing, ensuring that the products meet the specified standards. Additionally, buyers should inquire about the supplier’s certifications (such as ISO 9001) and production practices to confirm adherence to industry standards. Implementing a quality control check during the receiving process, including dimensional and visual inspections, can further ensure that the products align with project requirements.

Scenario 3: Challenges in Delivery and Logistics

The Problem: B2B buyers frequently face logistical challenges when sourcing aluminum channel extrusions, particularly when shipping internationally. For instance, a company in Europe may experience delays due to customs issues or inadequate shipping options, which can disrupt the supply chain and affect project timelines. These delays can result in increased costs and lost business opportunities, especially in competitive markets.

The Solution: To streamline logistics, buyers should collaborate with suppliers who have experience in international shipping and a strong understanding of customs regulations in their target markets. Choosing suppliers that offer consolidated shipping options can also reduce costs and improve delivery times. It is beneficial for buyers to establish clear timelines with suppliers and maintain open lines of communication throughout the shipping process. Additionally, utilizing logistics software or working with third-party logistics providers can help track shipments in real-time, allowing buyers to proactively address potential delays before they impact project schedules.

Illustrative image related to aluminum channel extrusions

Strategic Material Selection Guide for aluminum channel extrusions

What Are the Key Properties of Common Aluminum Alloys Used in Channel Extrusions?

Aluminum channel extrusions are primarily made from specific aluminum alloys, each with unique properties that affect their performance in various applications. The most common alloys include 6061, 6063, and 6082, each offering distinct advantages and limitations.

6061 Aluminum Alloy: Key Properties and Applications

6061 aluminum is known for its excellent mechanical properties and corrosion resistance. It has a high strength-to-weight ratio and performs well under high-stress conditions, making it suitable for structural applications. Its temperature rating is also favorable, allowing it to withstand moderate heat without deforming.

Pros and Cons:

The primary advantage of 6061 is its versatility; it can be easily welded and machined, which simplifies manufacturing processes. However, its higher cost compared to other alloys may deter some buyers, particularly in budget-sensitive markets.

Impact on Application:

6061 is commonly used in demanding environments, such as in the construction of truck bodies and frames, where durability is essential. Buyers in regions like Saudi Arabia and Brazil should ensure compliance with local industry standards, such as ASTM or DIN, when selecting this material.

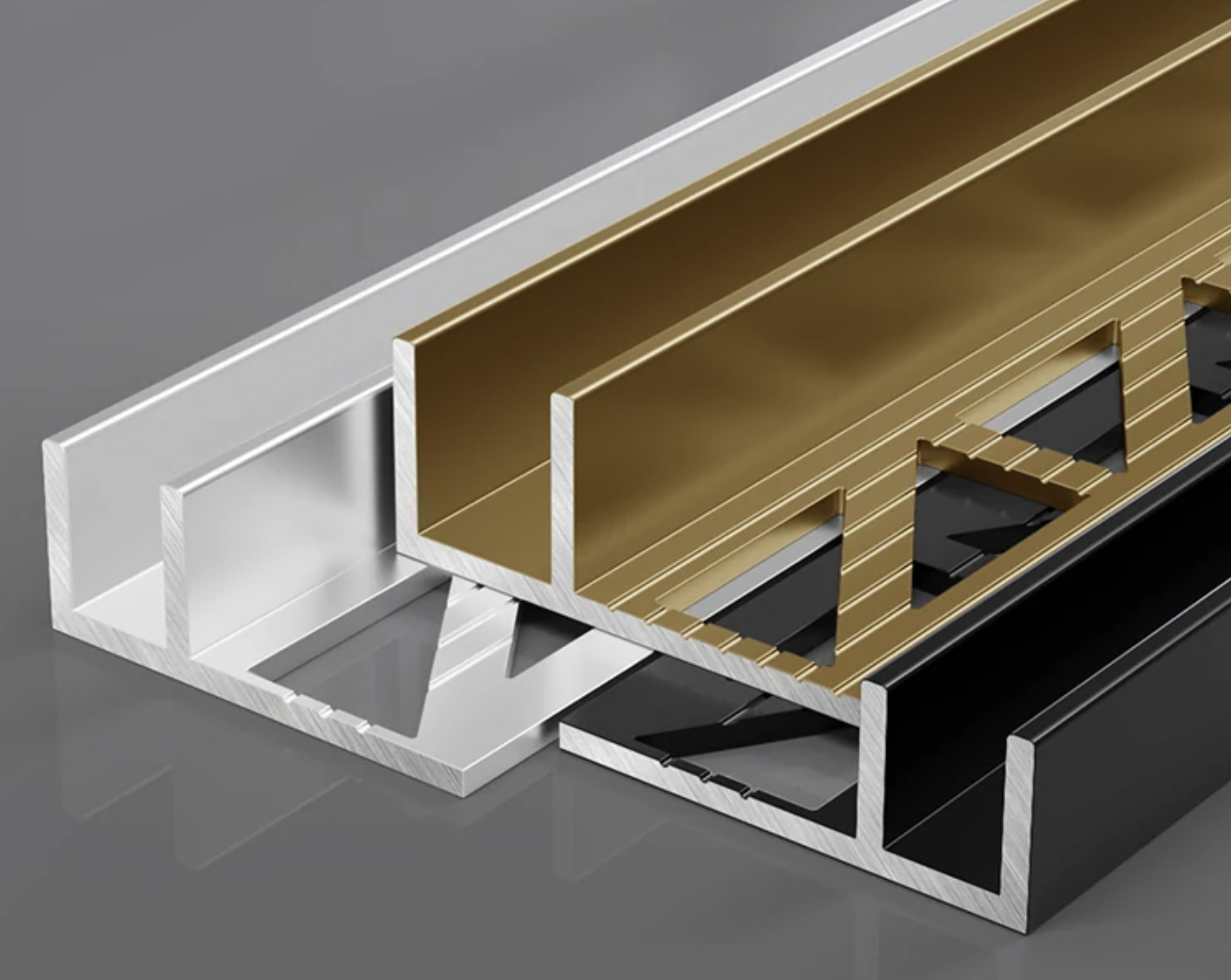

Illustrative image related to aluminum channel extrusions

6063 Aluminum Alloy: Key Properties and Applications

6063 aluminum is often referred to as architectural aluminum due to its aesthetic appeal and excellent formability. It offers good corrosion resistance and is typically used in applications requiring intricate shapes, such as window frames and decorative elements.

Pros and Cons:

The key advantage of 6063 is its ability to be extruded into complex designs, making it ideal for architectural applications. However, it has a lower strength compared to 6061, which may limit its use in structural applications.

Impact on Application:

For international buyers, especially in Europe, 6063 is often preferred for projects where visual appeal is crucial. Compliance with architectural standards is essential, and buyers should be aware of local regulations regarding building materials.

Illustrative image related to aluminum channel extrusions

6082 Aluminum Alloy: Key Properties and Applications

6082 aluminum is a medium-strength alloy that combines good corrosion resistance with excellent weldability. It is often used in heavy-duty applications, such as bridges and cranes, due to its superior strength.

Pros and Cons:

The main advantage of 6082 is its high strength, making it suitable for load-bearing applications. However, it can be more challenging to extrude than other alloys, potentially increasing manufacturing complexity and costs.

Impact on Application:

For buyers in regions like South America, where infrastructure development is critical, 6082 can be an excellent choice for projects requiring robust materials. Ensuring compliance with local construction standards is vital for successful implementation.

Summary Table of Material Selection for Aluminum Channel Extrusions

| Material | Typical Use Case for aluminum channel extrusions | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| 6061 | Structural applications (e.g., truck bodies) | High strength-to-weight ratio | Higher cost than other alloys | High |

| 6063 | Architectural elements (e.g., window frames) | Excellent formability and aesthetic appeal | Lower strength than 6061 | Medium |

| 6082 | Heavy-duty applications (e.g., bridges) | Superior strength for load-bearing applications | More challenging to extrude | Medium |

This strategic material selection guide aims to empower international B2B buyers by providing actionable insights into the properties, advantages, and limitations of common aluminum alloys used in channel extrusions. Understanding these factors will help in making informed decisions that align with specific project requirements and compliance standards across different regions.

In-depth Look: Manufacturing Processes and Quality Assurance for aluminum channel extrusions

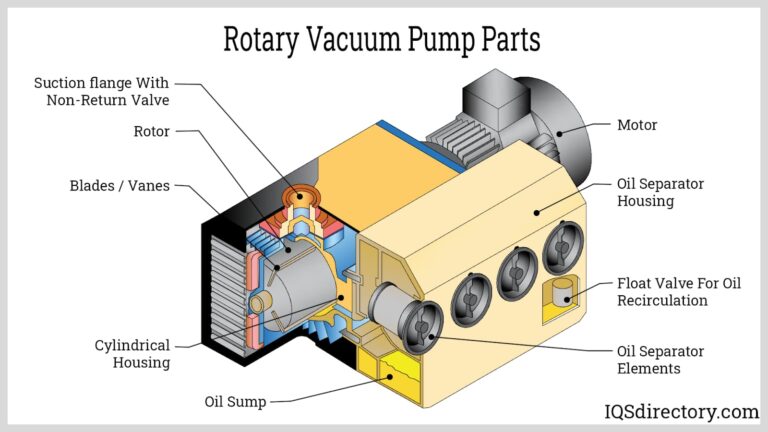

What Are the Key Stages in the Manufacturing Process of Aluminum Channel Extrusions?

The manufacturing of aluminum channel extrusions involves several critical stages, each essential for producing high-quality products. Understanding these stages can help B2B buyers make informed decisions when selecting suppliers.

Material Preparation: What Is Involved?

The first step in the manufacturing process is material preparation, which begins with sourcing high-quality aluminum alloys. The most common alloys used for channel extrusions are 6061 and 6063, known for their excellent corrosion resistance and strength-to-weight ratios. The aluminum is typically supplied in the form of billets, which are heated to a specific temperature to make them malleable for the extrusion process.

Once the billets are heated, they are cut to the required length and prepped for extrusion. This preparation is crucial, as the quality of the raw material directly impacts the final product’s durability and aesthetic appeal.

How Are Aluminum Channels Formed?

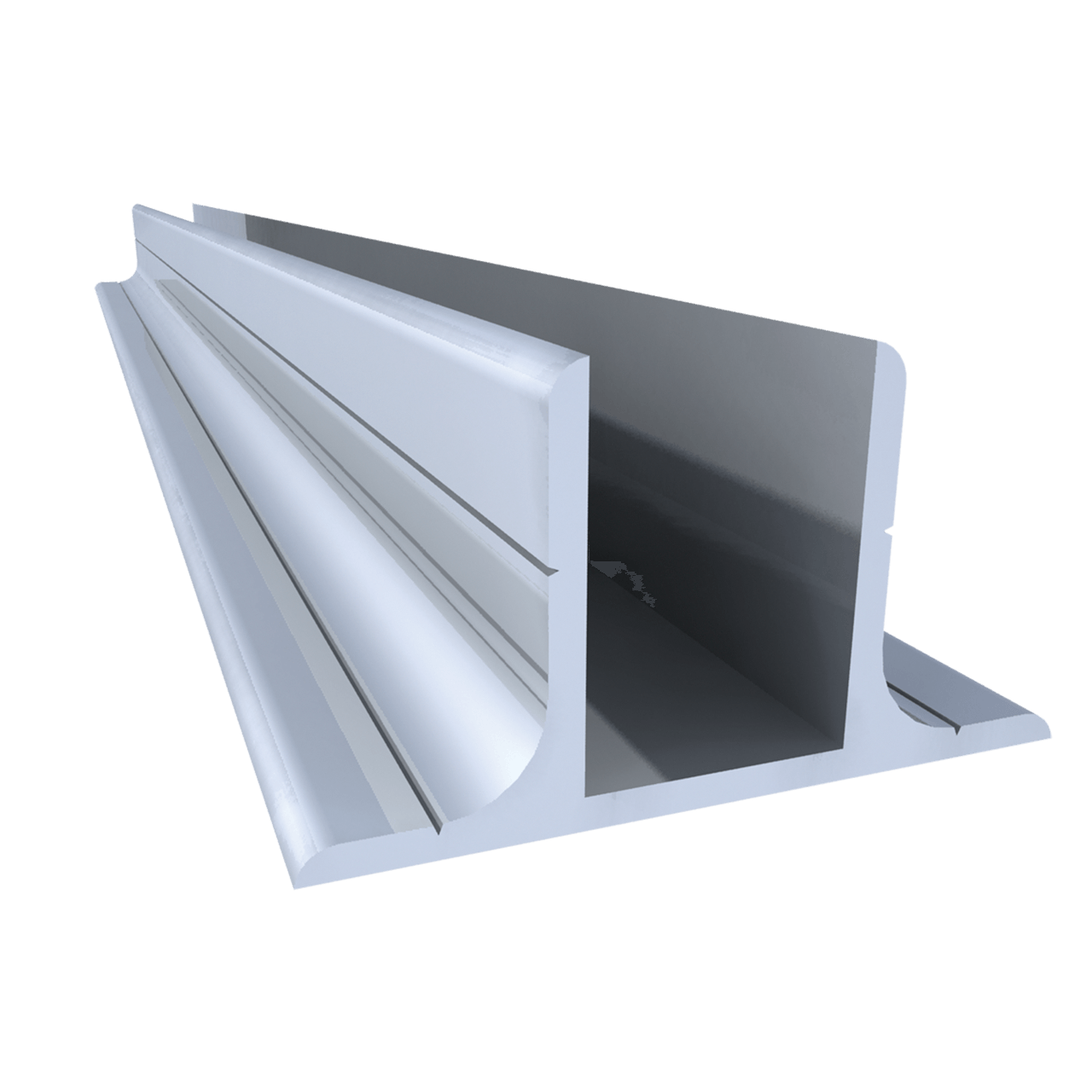

The forming stage involves pushing the heated aluminum billet through a die that shapes it into the desired channel profile. This process is called extrusion and can be performed using various techniques, including direct and indirect extrusion. Direct extrusion pushes the billet through the die, while indirect extrusion pulls it, allowing for different design capabilities and material characteristics.

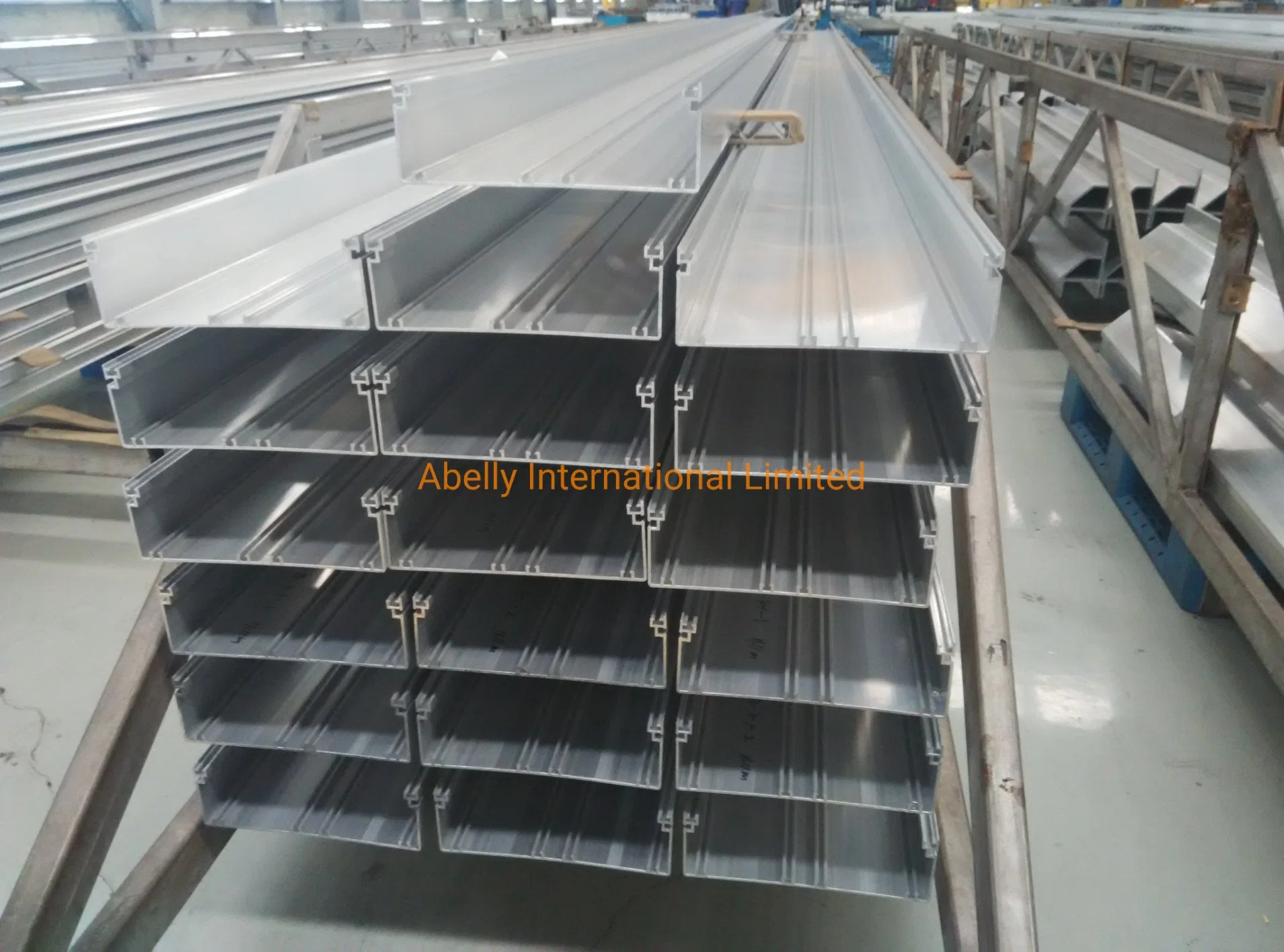

Illustrative image related to aluminum channel extrusions

After extrusion, the channels are cooled and cut to the specified lengths. This stage also includes inspection for any visible defects or irregularities that may have occurred during the extrusion process.

What Finishing Techniques Are Commonly Used?

Once the channels are formed, they undergo finishing processes to enhance their appearance and performance. Common finishing techniques include:

- Anodizing: This electrochemical process increases corrosion resistance and allows for color customization, making the channels suitable for both aesthetic and functional applications.

- Powder Coating: A dry finishing process that creates a protective layer, powder coating adds durability and can be applied in various colors.

- Machining: Some channels may require additional machining, such as drilling or milling, to meet specific application requirements.

These finishing techniques not only improve the channels’ aesthetic quality but also extend their lifespan, making them more appealing to international buyers.

What Quality Assurance Measures Are Essential for Aluminum Channel Extrusions?

Quality assurance (QA) is paramount in the manufacturing of aluminum channel extrusions, ensuring that products meet industry standards and customer expectations. For B2B buyers, understanding these QA measures can help in selecting reliable suppliers.

Which International Standards Should Be Considered?

International standards such as ISO 9001 are crucial for ensuring consistent quality across manufacturing processes. ISO 9001 focuses on quality management systems and emphasizes continuous improvement, customer satisfaction, and regulatory compliance. Additionally, industry-specific certifications, such as CE marking for products sold within the European Economic Area, are essential for confirming that the products meet safety and performance standards.

What Are the Key Quality Control Checkpoints?

Quality control checkpoints are integrated throughout the manufacturing process to maintain high standards. The primary checkpoints include:

- Incoming Quality Control (IQC): This stage involves inspecting raw materials upon arrival to ensure they meet specified requirements before processing.

- In-Process Quality Control (IPQC): Regular inspections during the manufacturing process help identify and address any deviations or defects in real time.

- Final Quality Control (FQC): After the finishing processes, a thorough inspection ensures that the final products meet all specifications and standards before shipping.

These checkpoints help maintain the integrity of the product and provide reassurance to B2B buyers regarding the quality of the aluminum channel extrusions.

What Common Testing Methods Are Utilized?

Various testing methods are employed to verify the quality of aluminum channel extrusions, including:

- Mechanical Testing: This includes tensile tests, hardness tests, and impact tests to evaluate the material’s strength and durability.

- Dimensional Inspection: Using calipers and gauges, manufacturers check that the channels adhere to specified dimensions and tolerances.

- Visual Inspection: A thorough visual inspection helps identify surface defects, such as scratches or discoloration, that could affect the product’s performance or appearance.

These testing methods provide a comprehensive quality assessment, ensuring that the products meet the required standards.

How Can B2B Buyers Verify Supplier Quality Control Practices?

For B2B buyers, particularly those in Africa, South America, the Middle East, and Europe, verifying a supplier’s quality control practices is essential for ensuring product reliability.

Illustrative image related to aluminum channel extrusions

What Steps Should Be Taken for Supplier Audits?

Conducting supplier audits is one of the most effective ways to assess a manufacturer’s quality control processes. During an audit, buyers should look for:

- Compliance with international quality standards (e.g., ISO 9001).

- Documentation of quality control procedures and testing methods.

- Evidence of regular training for employees involved in the QA process.

These audits help buyers gain insights into the supplier’s operations and commitment to quality.

How Can Buyers Use Reports and Third-Party Inspections?

Buyers should request quality assurance reports, which provide details on past performance, testing results, and compliance with standards. Third-party inspections can also offer an unbiased assessment of a supplier’s quality control practices. Engaging independent inspection agencies can help buyers ensure that they receive products that meet their specifications and quality expectations.

What Are the Quality Certification Nuances for International Markets?

When sourcing aluminum channel extrusions from international suppliers, buyers must be aware of specific quality certification nuances. Different regions may have unique requirements, such as CE marking in Europe or specific industry certifications in the Middle East. Understanding these nuances ensures that buyers select suppliers who can meet the regulatory demands of their respective markets.

In conclusion, a thorough understanding of the manufacturing processes and quality assurance measures for aluminum channel extrusions is essential for B2B buyers. By focusing on material preparation, forming techniques, finishing processes, and stringent quality control measures, buyers can confidently select suppliers that meet their needs and standards.

Practical Sourcing Guide: A Step-by-Step Checklist for ‘aluminum channel extrusions’

When sourcing aluminum channel extrusions for your business needs, a structured approach is essential. This guide outlines a step-by-step checklist to help you navigate the procurement process effectively, ensuring you select the right products and suppliers for your projects.

Illustrative image related to aluminum channel extrusions

Step 1: Define Your Technical Specifications

Start by outlining the specific requirements for your aluminum channel extrusions. Consider the dimensions, alloy grades, and any particular finishes you may need for your project.

– Key Considerations:

– Length and thickness of the channels (e.g., C-channel, U-channel).

– Required alloy, such as 6061 for structural integrity or 6063 for aesthetic applications.

Step 2: Research Potential Suppliers

Conduct thorough research to identify suppliers that specialize in aluminum extrusions. Look for suppliers with a proven track record in your industry or region.

– What to Look For:

– Customer reviews and testimonials.

– Supplier certifications and industry affiliations, which indicate reliability and quality standards.

Step 3: Evaluate Supplier Capabilities

Assess each supplier’s production capabilities to ensure they can meet your specifications. Inquire about their manufacturing processes and quality control measures.

– Important Aspects:

– The ability to produce custom sizes or shapes if standard options do not meet your needs.

– Availability of cutting services to minimize waste and save costs.

Step 4: Request Samples for Testing

Before placing a bulk order, request samples of the aluminum channels you intend to purchase. This step is crucial for evaluating the quality and suitability of the product.

– Testing Focus Areas:

– Durability, strength, and resistance to corrosion.

– Compatibility with your intended application, whether structural or aesthetic.

Step 5: Compare Pricing and Terms

Gather quotes from multiple suppliers to compare pricing structures and payment terms. This step will help you ensure you’re getting a competitive deal.

– Considerations:

– Total cost, including shipping and potential tariffs, especially for international sourcing.

– Payment terms, such as upfront payments or credit options that can affect your cash flow.

Step 6: Verify Compliance with International Standards

Ensure that the aluminum channel extrusions comply with relevant industry standards and regulations, particularly if you are importing them.

– Regulatory Compliance:

– Check for certifications like ISO or ASTM, which can assure you of the product’s quality and safety.

– Understand any import regulations specific to your region, such as those in Africa, South America, the Middle East, or Europe.

Step 7: Establish a Clear Communication Channel

Once you select a supplier, establish a clear line of communication to facilitate ongoing interactions. This helps in addressing any issues that arise during production or delivery.

– Best Practices:

– Designate a point of contact on both sides to streamline communications.

– Use project management tools to track progress and updates on your orders.

By following this checklist, you can streamline the sourcing process for aluminum channel extrusions, ensuring that you make informed decisions that support your business objectives.

Comprehensive Cost and Pricing Analysis for aluminum channel extrusions Sourcing

When sourcing aluminum channel extrusions, understanding the comprehensive cost structure is crucial for B2B buyers. This analysis will cover the key cost components, pricing influencers, and strategic tips for buyers, particularly those operating in diverse international markets such as Africa, South America, the Middle East, and Europe.

What are the Key Cost Components in Aluminum Channel Extrusions?

The cost of aluminum channel extrusions is influenced by several components:

-

Materials: The price of aluminum fluctuates based on market demand, alloy grade, and global supply chain conditions. Common grades such as 6061 and 6063 are widely used, with 6061 typically being more expensive due to its higher strength and corrosion resistance.

-

Labor: Labor costs can vary significantly based on the manufacturing location. For instance, labor costs in emerging markets may be lower, which can reduce overall production costs. However, skilled labor is often required for precision machining and custom fabrication.

-

Manufacturing Overhead: This includes costs related to the operation of machinery, utilities, and factory maintenance. Efficient production processes can mitigate these costs.

-

Tooling: Tooling costs are significant, especially for custom extrusions. The initial investment in dies can be high, but this cost is amortized over large production runs, making it more feasible for bulk orders.

-

Quality Control (QC): Ensuring product quality is essential, particularly for applications in critical industries. QC processes add to the overall cost but are necessary to meet international standards.

-

Logistics: Shipping costs can vary widely based on the destination, size of the order, and chosen transportation methods. International buyers should be aware of these costs and any potential tariffs.

-

Margin: Suppliers typically add a margin to cover their operational costs and profit. This margin can vary based on competition and market conditions.

How Do Pricing Influencers Affect the Cost of Aluminum Channel Extrusions?

Several factors can influence pricing in the aluminum extrusion market:

-

Volume and Minimum Order Quantity (MOQ): Larger orders often lead to lower per-unit costs due to economies of scale. Buyers should negotiate MOQs that align with their project needs to optimize pricing.

-

Specifications and Customization: Custom extrusions require additional tooling and labor, increasing costs. Buyers should be clear about their specifications and consider whether standard profiles could suffice for their applications.

-

Material Quality and Certifications: Higher quality materials or certifications (e.g., ISO, ASTM) can drive up costs but may be necessary for compliance in certain industries. Buyers should weigh the importance of quality against budget constraints.

-

Supplier Factors: Supplier reputation, experience, and location can all influence pricing. Established suppliers may charge a premium for reliability and service.

-

Incoterms: Understanding shipping terms (e.g., FOB, CIF) is essential for budgeting total costs, including freight and insurance. Buyers should negotiate favorable terms to minimize their financial exposure.

What Negotiation and Cost-Efficiency Strategies Should B2B Buyers Consider?

-

Leverage Relationships: Building long-term relationships with suppliers can lead to better pricing, favorable terms, and priority service during high-demand periods.

-

Total Cost of Ownership (TCO): Consider all costs associated with procurement, including logistics, tariffs, and potential quality issues. A lower upfront cost may not always result in the best value.

-

Benchmark Pricing: Regularly compare prices from multiple suppliers to ensure competitiveness. This can also provide leverage during negotiations.

-

Stay Informed on Market Trends: Awareness of aluminum market trends, such as fluctuations in raw material costs or changes in trade policies, can empower buyers to make informed purchasing decisions.

-

Explore Local Sourcing Options: For buyers in regions like Africa and South America, investigating local suppliers can reduce shipping costs and lead times, ultimately improving supply chain efficiency.

Conclusion

Navigating the cost and pricing landscape of aluminum channel extrusions requires a strategic approach. By understanding the various cost components and pricing influencers, B2B buyers can make informed decisions that align with their operational needs while optimizing their procurement budget. As always, it is advisable to obtain indicative prices and quotes from multiple suppliers to ensure competitive sourcing.

Alternatives Analysis: Comparing aluminum channel extrusions With Other Solutions

Understanding Alternative Solutions to Aluminum Channel Extrusions

In the competitive landscape of B2B manufacturing and construction, selecting the right structural components is crucial. Aluminum channel extrusions are renowned for their versatility, lightweight nature, and corrosion resistance. However, other solutions may also meet your project requirements effectively. This section will compare aluminum channel extrusions with two viable alternatives: steel channel sections and plastic extrusions.

Comparison Table

| Comparison Aspect | Aluminum Channel Extrusions | Steel Channel Sections | Plastic Extrusions |

|---|---|---|---|

| Performance | High strength-to-weight ratio; excellent corrosion resistance | Very strong; less corrosion resistant without coating | Lower strength; suitable for light-duty applications |

| Cost | Generally higher than plastic; competitive against steel | Typically lower initial cost but higher transportation costs due to weight | Lower cost; economical for large volumes |

| Ease of Implementation | Easy to cut, drill, and customize; lightweight for handling | Requires more labor for cutting and installation; heavier | Simple to fabricate; can be molded into complex shapes |

| Maintenance | Low maintenance; resistant to rust and corrosion | Requires regular maintenance to prevent rust; coatings can wear off | Minimal maintenance; UV degradation may occur over time |

| Best Use Case | Ideal for aesthetic applications and structural support in various industries | Best for heavy-duty applications like construction and infrastructure | Suitable for non-load-bearing applications, such as decorative trims and enclosures |

Pros and Cons of Alternatives

Steel Channel Sections

Steel channel sections are a robust alternative to aluminum extrusions, known for their strength and durability. They are ideal for heavy-duty applications, such as in construction and infrastructure projects. The lower initial cost of steel can be appealing, but it’s important to consider the ongoing maintenance required to prevent rust and corrosion. Steel channels are significantly heavier, which can complicate transportation and installation, particularly in remote or challenging locations.

Plastic Extrusions

Plastic extrusions offer a lightweight and economical solution, particularly for non-load-bearing applications. They can be manufactured in various colors and shapes, making them aesthetically appealing for decorative projects. Their lower strength limits their use in structural applications, and they may not withstand extreme conditions as well as aluminum or steel. However, plastic does not corrode and generally requires minimal maintenance, which can be a significant advantage in certain environments.

Conclusion: Choosing the Right Solution for Your Needs

When deciding between aluminum channel extrusions and alternative solutions, B2B buyers should carefully evaluate their specific project requirements, including load-bearing needs, environmental conditions, and budget constraints. Aluminum is often the preferred choice for its balance of strength, lightweight properties, and corrosion resistance, making it suitable for both structural and aesthetic applications. However, in instances where weight and cost are critical factors, or where the application does not require heavy-duty support, steel or plastic may be more viable alternatives. Ultimately, understanding the unique advantages and limitations of each option will empower buyers to make informed decisions that align with their operational goals.

Essential Technical Properties and Trade Terminology for aluminum channel extrusions

Aluminum channel extrusions are essential components in various industrial applications, particularly for B2B buyers looking to enhance their product offerings. Understanding the technical properties and trade terminology associated with these extrusions is crucial for making informed purchasing decisions.

What Are the Key Technical Properties of Aluminum Channel Extrusions?

1. Material Grade

Aluminum channel extrusions are typically made from specific alloy grades, with 6061 and 6063 being the most common.

– 6061 Aluminum: Known for its high strength and good corrosion resistance, this grade is often used in structural applications. It’s ideal for components requiring strength, such as truck bodies and frames.

– 6063 Aluminum: This grade is favored for architectural applications due to its excellent finish and formability. It is commonly used for creating aesthetically pleasing structures, such as furniture and decorative elements.

Illustrative image related to aluminum channel extrusions

2. Tolerance

Tolerance refers to the allowable deviation from specified dimensions. In aluminum extrusions, maintaining tight tolerances is vital for ensuring compatibility with other components.

– Importance: Precise tolerances are crucial for applications that require exact fitting, such as in modular systems or when integrating with existing structures. Buyers should specify tolerance requirements to ensure the right fit and function.

3. Wall Thickness

The wall thickness of aluminum channels influences their strength, weight, and durability.

– Importance: A thicker wall can provide greater structural support but may also increase weight. Buyers need to balance these factors based on the specific requirements of their projects, such as load-bearing capacity or aesthetic considerations.

4. Finish Type

Aluminum extrusions can be anodized, painted, or left in their natural state.

– Importance: The finish affects not only the visual appeal but also the corrosion resistance and wearability of the product. For outdoor applications in harsh environments, a robust finish is essential to prolong the life of the components.

5. Length and Customization Options

Aluminum channels can be extruded in various lengths and can be customized to meet specific project needs.

– Importance: Custom lengths reduce waste and facilitate easier installation. B2B buyers should inquire about minimum order quantities and customization capabilities to optimize their supply chain.

Which Trade Terminology Should B2B Buyers Understand?

1. OEM (Original Equipment Manufacturer)

This term refers to companies that manufacture products that are then sold under another company’s brand.

– Importance: Understanding OEM relationships can help buyers identify reliable suppliers and ensure product quality and compatibility.

2. MOQ (Minimum Order Quantity)

This is the smallest quantity of a product that a supplier is willing to sell.

– Importance: Knowing the MOQ helps buyers plan their inventory and budget, especially when dealing with custom extrusions that may require larger orders.

3. RFQ (Request for Quotation)

An RFQ is a document sent to suppliers requesting pricing for specific products or services.

– Importance: Using RFQs allows buyers to compare prices and terms from multiple suppliers, ensuring they get the best deal for their needs.

4. Incoterms (International Commercial Terms)

These are predefined commercial terms published by the International Chamber of Commerce (ICC) that clarify responsibilities between buyers and sellers in international transactions.

– Importance: Familiarity with Incoterms helps buyers understand shipping costs, risks, and responsibilities, facilitating smoother international transactions.

5. Lead Time

Lead time is the amount of time between placing an order and receiving the goods.

– Importance: Understanding lead times is crucial for project planning and inventory management. Buyers should confirm lead times with suppliers to ensure timely delivery of materials.

Incorporating this knowledge of technical properties and terminology will empower B2B buyers to make informed decisions, ultimately leading to more successful procurement processes and project outcomes.

Navigating Market Dynamics and Sourcing Trends in the aluminum channel extrusions Sector

What Are the Current Market Dynamics and Key Trends in Aluminum Channel Extrusions?

The aluminum channel extrusions market is experiencing robust growth, driven by several global factors. As industries increasingly seek lightweight, durable materials, aluminum’s inherent properties—such as corrosion resistance and high strength-to-weight ratio—make it an ideal choice for applications ranging from construction to automotive and electronics. In regions like Africa and South America, burgeoning infrastructure projects are propelling demand, while the Middle East’s construction boom, particularly in cities like Riyadh and Dubai, further fuels the market. Europe, with its stringent environmental regulations, is also leaning towards sustainable materials, including aluminum.

Illustrative image related to aluminum channel extrusions

Emerging B2B tech trends are transforming sourcing practices in this sector. Digital platforms are enabling international buyers to access a broader range of suppliers, streamlining procurement processes and facilitating just-in-time inventory management. Additionally, advancements in manufacturing technology, such as automation and 3D printing, are enhancing customization capabilities for aluminum channel extrusions, allowing businesses to tailor products to specific project requirements efficiently.

Moreover, the market dynamics are shifting towards local sourcing strategies as buyers look to mitigate risks associated with global supply chain disruptions. This trend is particularly relevant in the context of geopolitical tensions and the ongoing impacts of the COVID-19 pandemic, which have highlighted the vulnerabilities of long-distance supply chains.

How Can B2B Buyers Ensure Sustainability and Ethical Sourcing of Aluminum Channel Extrusions?

Sustainability has become a paramount concern for international buyers in the aluminum channel extrusions market. The environmental impact of aluminum production, particularly the energy-intensive smelting process, necessitates a commitment to ethical sourcing practices. B2B buyers must prioritize suppliers who adhere to sustainable practices, such as utilizing recycled aluminum and implementing energy-efficient production methods.

Certifications play a crucial role in validating the sustainability claims of suppliers. Look for ‘green’ certifications such as the Aluminium Stewardship Initiative (ASI) or ISO 14001, which signify adherence to environmental management standards. Such certifications not only ensure that the materials are sourced responsibly but also enhance the overall credibility of your supply chain.

Furthermore, buyers can leverage life cycle assessments (LCAs) to evaluate the environmental impact of aluminum channel extrusions throughout their life span—from production to disposal. By opting for suppliers committed to reducing their carbon footprint, businesses can enhance their sustainability profile while meeting the increasing demands of eco-conscious consumers and regulatory bodies.

What is the Historical Context of Aluminum Channel Extrusions in the B2B Market?

The use of aluminum in construction and manufacturing dates back to the late 19th century, but the production of aluminum channel extrusions gained momentum in the mid-20th century. Initially, aluminum was seen as a luxury material, primarily used in high-end applications. However, advancements in extraction and processing technologies have made aluminum more accessible and affordable.

The extrusion process, which allows for the mass production of complex shapes and profiles, revolutionized the aluminum industry. By the 1970s, aluminum channel extrusions began to see widespread adoption in various sectors, particularly in construction and automotive industries. Over the decades, as industries recognized the advantages of aluminum—its lightweight, corrosion resistance, and versatility—the demand for extruded products surged, leading to the establishment of specialized suppliers and a global market focused on aluminum channel extrusions.

Today, the historical evolution of aluminum channel extrusions underscores their significance in modern manufacturing and construction, making them a staple for B2B buyers looking for reliable and innovative solutions in their projects.

Frequently Asked Questions (FAQs) for B2B Buyers of aluminum channel extrusions

-

How do I choose the right aluminum channel extrusion for my project?

Selecting the appropriate aluminum channel extrusion hinges on understanding your specific application needs. Consider factors such as the load-bearing requirements, environmental conditions, and aesthetic preferences. Aluminum grades like 6061 offer strength and corrosion resistance, making them ideal for structural applications, while 6063 is suitable for architectural projects due to its formability and finish. Additionally, evaluate the channel shape (U, C, or Z) based on your installation needs, and consult with suppliers for recommendations tailored to your project. -

What customization options are available for aluminum channel extrusions?

Many suppliers offer extensive customization for aluminum channel extrusions, including cutting to specific lengths, drilling holes, and adding finishes or coatings. You can also request specific alloy grades or shapes tailored to your project’s requirements. It’s advisable to communicate your design specifications clearly and inquire about the supplier’s capabilities and lead times for custom orders to ensure they meet your expectations. -

What are the typical minimum order quantities (MOQs) for aluminum channel extrusions?

Minimum order quantities for aluminum channel extrusions can vary significantly between suppliers and regions. Typically, MOQs can range from a few hundred kilograms to several tons, depending on the supplier’s production capacity and inventory. For international buyers, it’s essential to confirm MOQs early in discussions and explore options for smaller orders or stock items to accommodate your project needs. -

What payment terms should I expect when sourcing aluminum channel extrusions?

Payment terms can vary widely based on the supplier’s policies and your relationship with them. Common arrangements include upfront deposits (often 30% to 50% of the order value) with the balance due upon shipment. For new international buyers, suppliers may require secure payment methods like letters of credit or escrow services. Always clarify payment terms before finalizing contracts to avoid misunderstandings. -

How can I ensure the quality of aluminum channel extrusions?

To guarantee the quality of aluminum channel extrusions, request certifications for material grades and quality assurance tests. Look for suppliers who adhere to international standards such as ISO 9001. Additionally, consider requesting samples before placing a bulk order to inspect the product firsthand. Establishing a quality control checklist tailored to your specifications can also help ensure that the delivered products meet your standards. -

What logistics considerations should I be aware of when importing aluminum channel extrusions?

Importing aluminum channel extrusions involves several logistics considerations, including shipping methods, customs regulations, and delivery timelines. Determine whether air freight or sea freight is more cost-effective based on your urgency and budget. Familiarize yourself with the customs documentation required for your destination country, including import duties and taxes. Working with a logistics partner experienced in international trade can streamline the process and mitigate potential delays. -

How do I vet suppliers of aluminum channel extrusions?

Vetting suppliers is crucial for ensuring reliability and quality. Start by researching their reputation through online reviews, industry ratings, and references from other customers. Evaluate their production capabilities, certifications, and experience in international trade. Conducting site visits or requesting virtual tours can provide insight into their operations. Additionally, consider engaging suppliers in discussions about their processes, quality controls, and customer support to gauge their responsiveness and reliability. -

What are the common applications for aluminum channel extrusions in various industries?

Aluminum channel extrusions are versatile and used across various industries. In construction, they serve as framing and support structures, while in automotive applications, they are utilized for lightweight components. Retail environments often use them for displays and shelving units, while electrical sectors employ them for wire management and fixtures. Understanding these applications can help you identify suitable products for your specific industry needs and enhance your procurement strategy.

Top 8 Aluminum Channel Extrusions Manufacturers & Suppliers List

1. Orange Aluminum – Extruded Aluminum Channels

Domain: orangealuminum.com

Registered: 2006 (19 years)

Introduction: Extruded aluminum channels, also known as track, U-channel or C-channel, are versatile profiles used for door framing, edge protection, and wire management. They are lightweight, corrosion-resistant, and easy to cut, drill, and customize, providing a clean, professional finish. Ideal for guiding sliding panels, supporting shelving, LED strip lighting, and organizing cables in residential and comme…

2. Eagle Aluminum – C Channels & Slide Track Channels

Domain: eagle-aluminum.com

Registered: 2010 (15 years)

Introduction: Aluminum C Channels and Slide Track Channels are lightweight, sturdy aluminum extrusion products that are versatile and add color and shape to projects. They can be used in various applications such as reveals in wood panel projects, reception desks, custom displays, shelf units, and framing around openings. Key attributes include:

– Lightweight and corrosion-resistant

– High strength-to-weight ra…

3. Metal Supermarkets – Aluminum Channel

Domain: metalsupermarkets.com

Registered: 1996 (29 years)

Introduction: Aluminum Channel is a non-ferrous metal product shaped for industrial and structural purposes. Available grades include 6061 and 6063. Typical applications for 6061 include screw machine parts, truck bodies, frames, running boards, steps, floors, walkways, platforms, cover plates, trench covers, and truck runways. Typical applications for 6063 include interior and exterior construction, lawn furni…

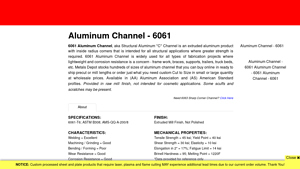

4. Metals Depot – 6061 Aluminum Channel

Domain: metalsdepot.com

Registered: 1999 (26 years)

Introduction: { “Product Name”: “6061 Aluminum Channel”, “Type”: “Structural Aluminum C Channel”, “Material”: “6061-T6”, “Finish”: “Extruded Mill Finish, Not Polished”, “Applications”: [“frame work”, “braces”, “supports”, “trailers”, “truck beds”], “Specifications”: { “Standards”: [“ASTM B308”, “AMS-QQ-A-200/8”], “Tensile Strength”: “45 ksi”, “Yield Point”: “40 ksi”, “Shear Strength”: “30 ksi”, “Elasticity”: “1…

5. SAF – Channel Aluminum Extrusions

Domain: saf.com

Registered: 1992 (33 years)

Introduction: Channel Aluminum Extrusions are available in 6063 alloy aluminum, also known as architectural aluminum channel, featuring sharp, 90-degree angle corners. They are commonly referred to as aluminum C channel, architectural channel, aluminum U channel, sharp corner channel, and aluminum trim channel. Common applications include architectural trim, framing, store fixtures, displays, glass and mirror p…

6. Eastern Metal – Aluminum Channel Extrusions

Domain: easternmetal.com

Registered: 1996 (29 years)

Introduction: Aluminum channel extrusions available in architectural, American Standard, and Aluminum Association structurals. Stock items are offered in 6061 and 6063 alloys. Channels comply with ASTM-B308/B308M and ASM-QQ-A-200/16 specifications. Custom sizes, lengths, alloys, and finishes can be requested.

7. Industrial Commercial Lighting – Aluminum Channel Extrusions

Domain: industrialcommerciallighting.com

Registered: 2024 (1 years)

Introduction: Aluminum Channel Extrusions for LED strip lights, providing protection and heat dissipation for applications like under-cabinet, staircase, cove, and bathroom lighting. Available in various widths to accommodate different strip sizes. Options include waterproof profiles, end caps, and lenses for outdoor use. Channel types include corner, surface-mounted, recessed, cove, step, and edge-lit. Lengths…

8. Wellste – Extruded Aluminum Channels

Domain: wellste.com

Registered: 2016 (9 years)

Introduction: Extruded Aluminum Channel, Manufacturer: Wellste, Material: 6000 Series, 7075, Temper: T3-T8, Shape: square, round, flat, angle, rectangular, common channel (c,u,j,f,h,t), customized; Size/Thickness: General profiles thickness from 0.3 to 5.0mm, length from 3m-6m or customized; Anodize protection film thickness from 8~25 um, powder coating from 40~120 um; MOQ: Low MOQ; Applications: protective edg…

Strategic Sourcing Conclusion and Outlook for aluminum channel extrusions

In the evolving landscape of aluminum channel extrusions, strategic sourcing is paramount for international B2B buyers seeking to optimize their supply chains. By leveraging the lightweight, corrosion-resistant, and versatile properties of aluminum channels, businesses can enhance their product offerings while ensuring structural integrity and aesthetic appeal across various applications—from construction to custom displays.

Understanding the different grades and types of aluminum channels—such as 6061 and 6063—enables buyers to make informed decisions that align with their specific project requirements. The ability to customize orders and obtain cut-to-size products further streamlines procurement processes, minimizing waste and maximizing efficiency.

As markets in Africa, South America, the Middle East, and Europe continue to expand, the demand for high-quality aluminum extrusions is projected to rise. Buyers should prioritize partnerships with reliable suppliers that can offer competitive pricing, exceptional service, and innovative solutions to meet their needs.

Looking ahead, the future of aluminum channel extrusions is bright. Embrace the opportunities for growth by exploring new applications and forging strong supplier relationships to stay ahead in a competitive market. Your next strategic move could redefine your business’s potential.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.